Axial forward-moving and radial slanting reverse-vane angle-direction seam processing box

A technology for processing casings and anti-blades, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as reducing compressor pressure ratio and efficiency, and compressor blade breakage, so as to reduce efficiency loss and stabilize margins. The effect of increasing the speed and improving the stability expansion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

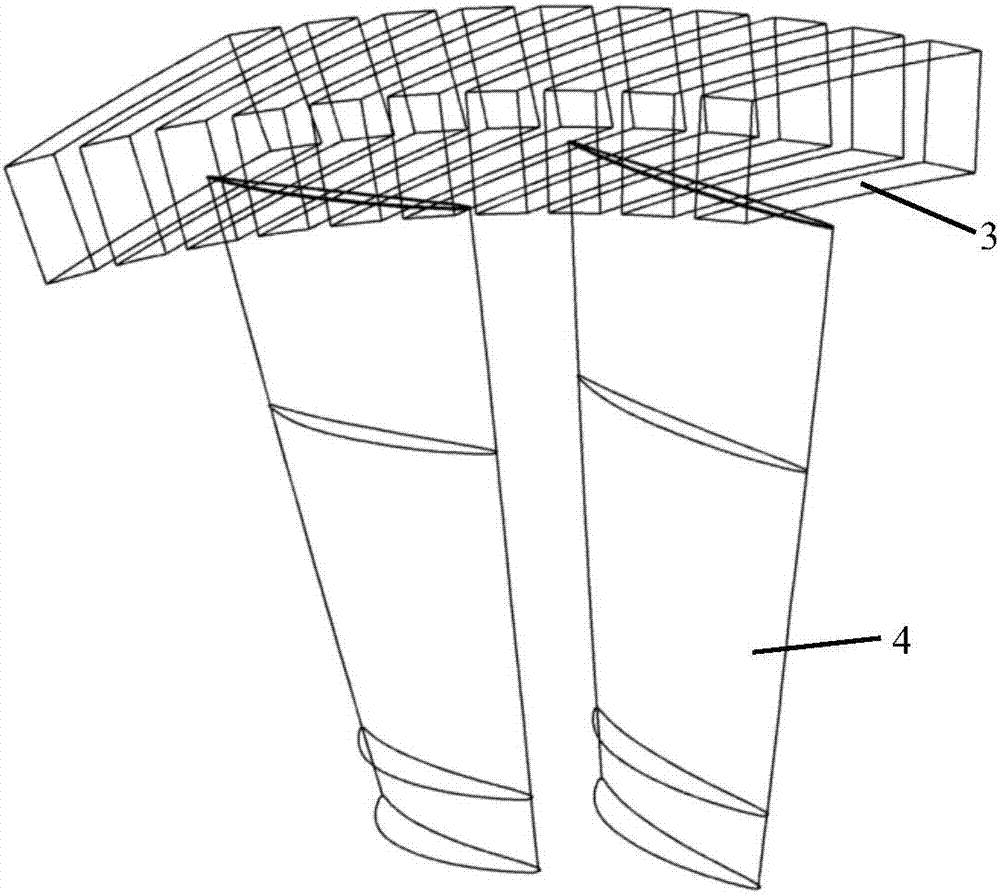

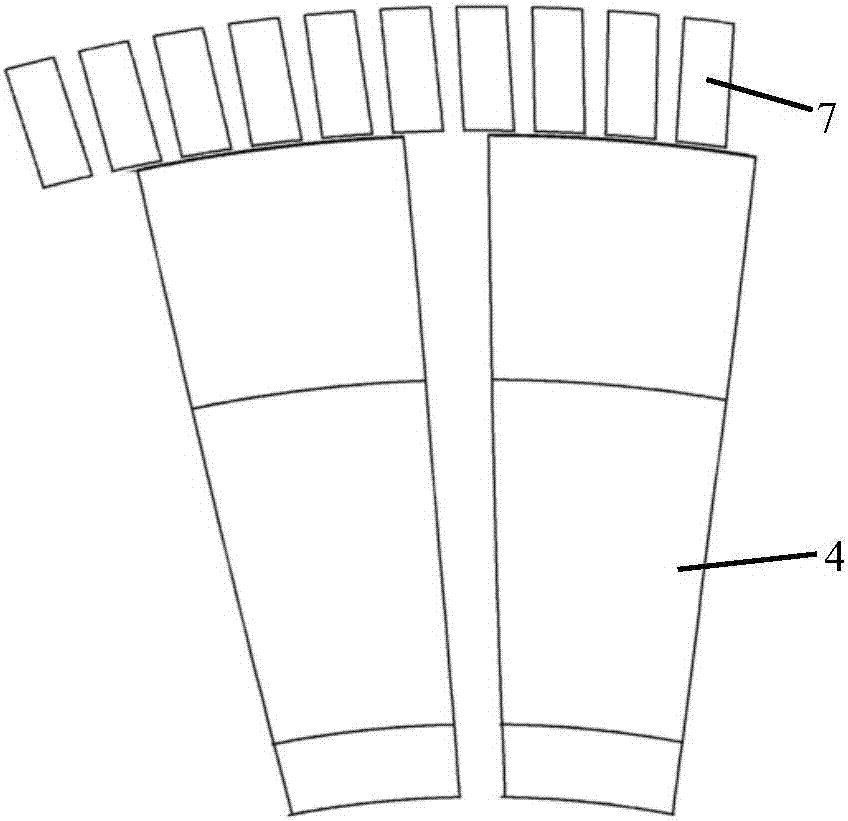

[0017] see Figure 1-Figure 6 , a subsonic axial flow compressor based on radially inclined anti-blade angular slot processing casing, which is characterized in that it includes the following steps:

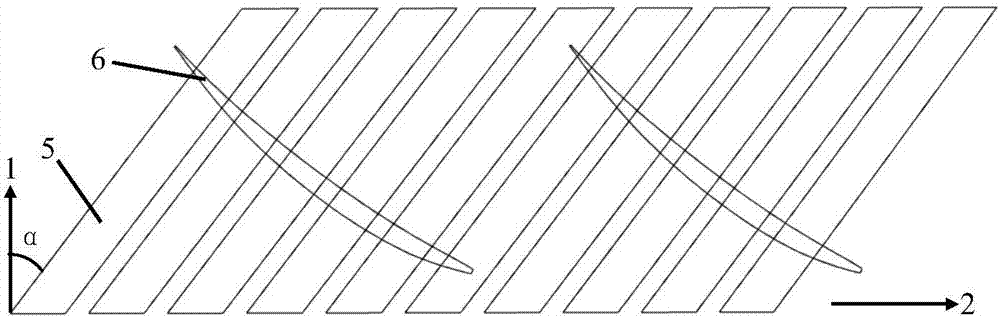

[0018] Step 1: Open a certain number of seams on the compressor casing along the angle α with the axial direction 1 and arrange them evenly along the circumferential direction 2 to form the anti-blade angular seam processing casing 3, and the anti-blade angular seam processing casing 3 The processing width covers the axial chord length of the entire blade tip 6;

[0019] Step 2: Move the anti-blade angular seam processing casing 3 forward by a certain distance along the axial direction 1. The forward movement here is the choice made by comparison after numerical simulation. At the same time, it is inclined at a certain angle β along the radial direction to form a new handle casing 8;

[0020] Step 3: The slit width is 3.5mm, the ratio of the slit width to the slit width is 0.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com