Variable camber blade type tandem stator and air compressor

A blade-type, stator technology, applied in the field of aero-engines, can solve the problems such as the inability of the downstream rotor to provide the intake direction, affecting the performance of the downstream rotor, and the large deviation of the design working conditions, so as to increase the stable working range and meet the inlet airflow angle. requirements, reducing the effect of flow separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

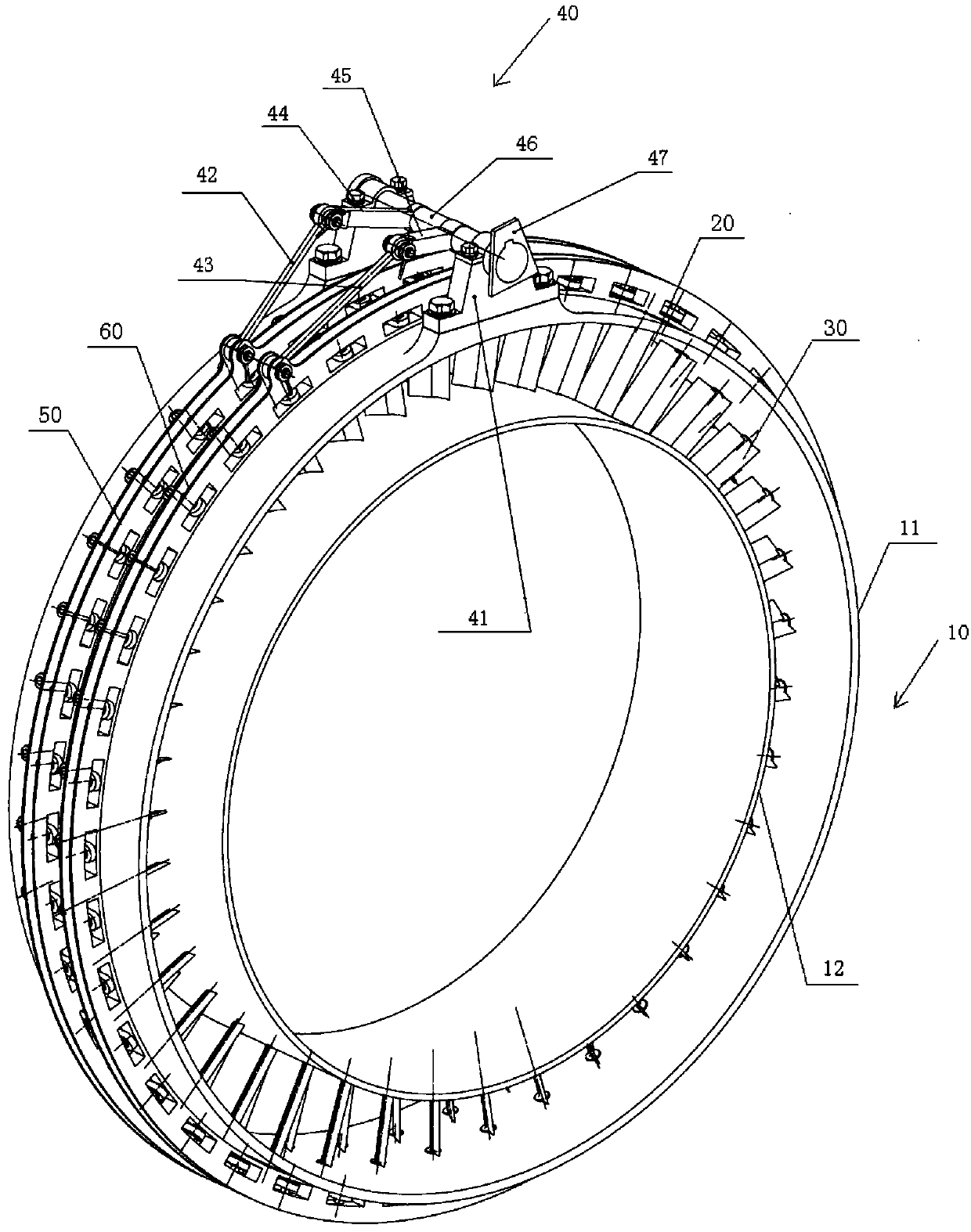

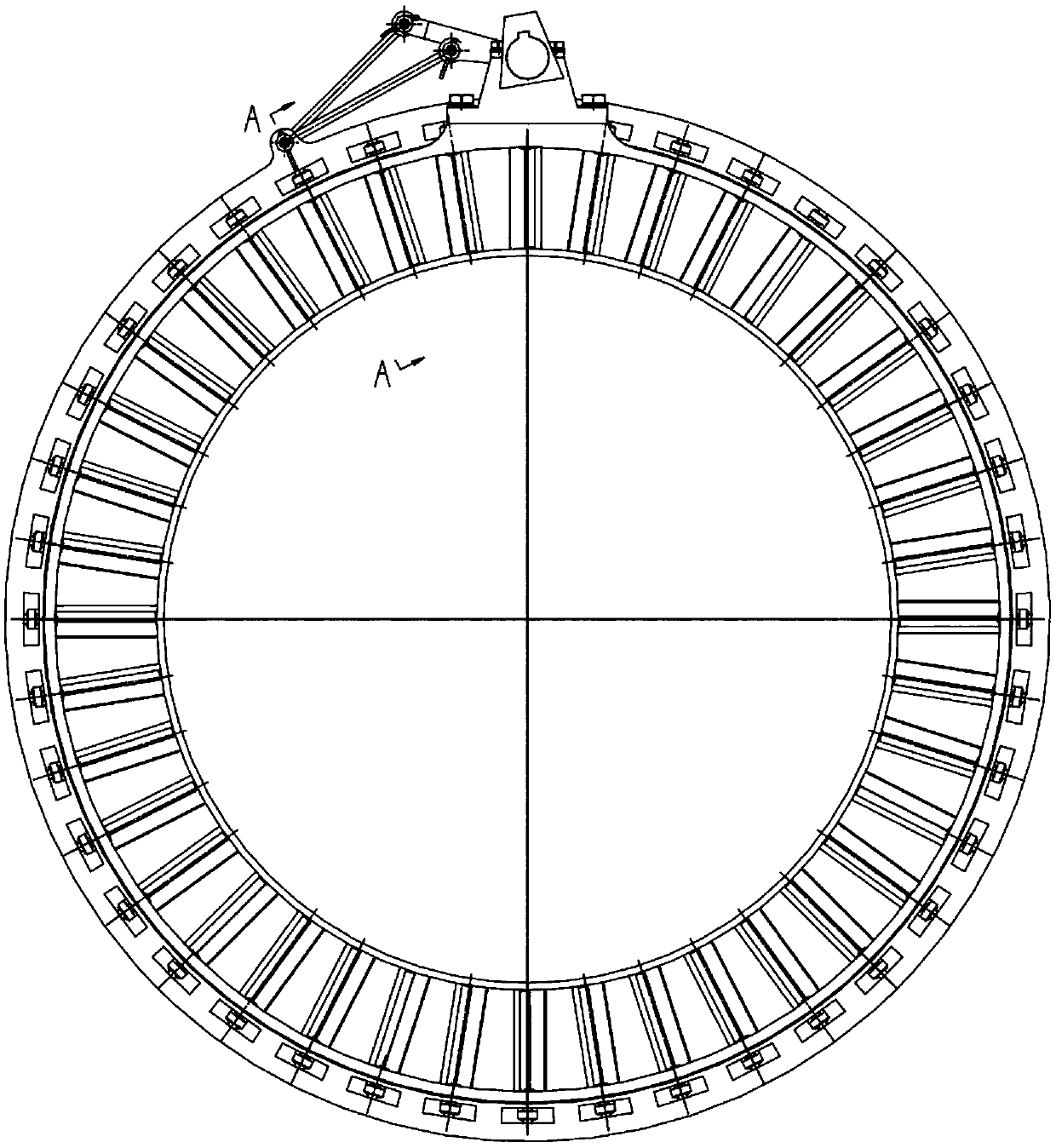

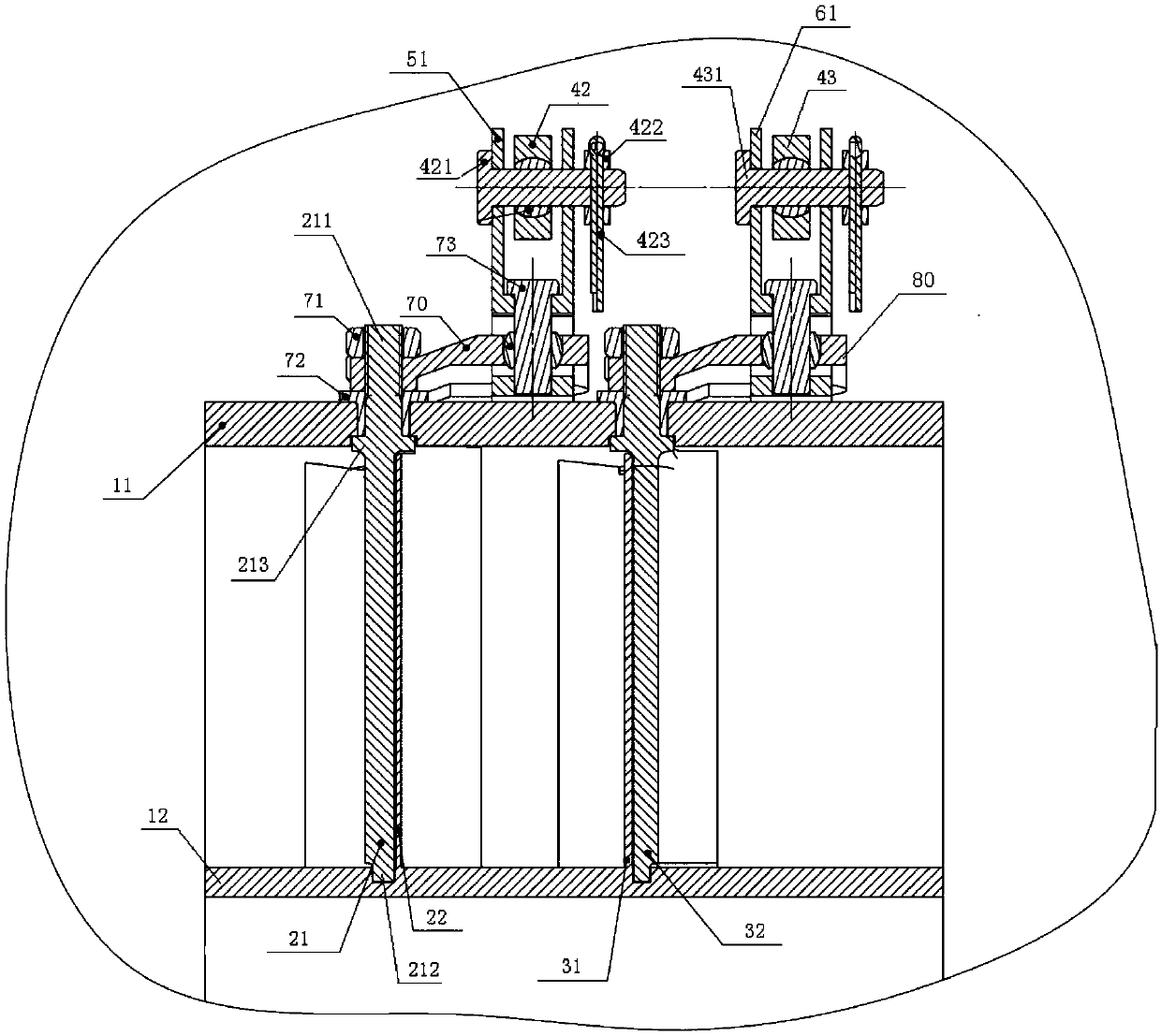

[0045] refer to figure 1 , the preferred embodiment of the present invention provides a variable curvature vane tandem stator, including a casing 10, and a front row stator 20 and a rear row stator that are installed in the casing 10 and are composed of a plurality of variable curvature blades 30. The first linkage ring 50 arranged on the periphery of the casing 10 for connecting the front row stator 20, the second linkage ring 60 arranged side by side with the first linkage ring 50 to connect the rear row stator 30; and the first linkage ring 50 The driving mechanism 40 is connected with the second linkage ring 60 and is used to drive the rotation of the first linkage ring 50 and the second l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com