Treatment casing with adjustable grooving width of centrifugal air compressor

A centrifugal compressor and casing processing technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of not being able to meet the different requirements of the casing, and the effect of expanding stability, so as to improve the stable working range and improve The effect of pressure ratio and adiabatic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure, principle and working process of the present invention will be described in detail below in conjunction with the drawings and embodiments.

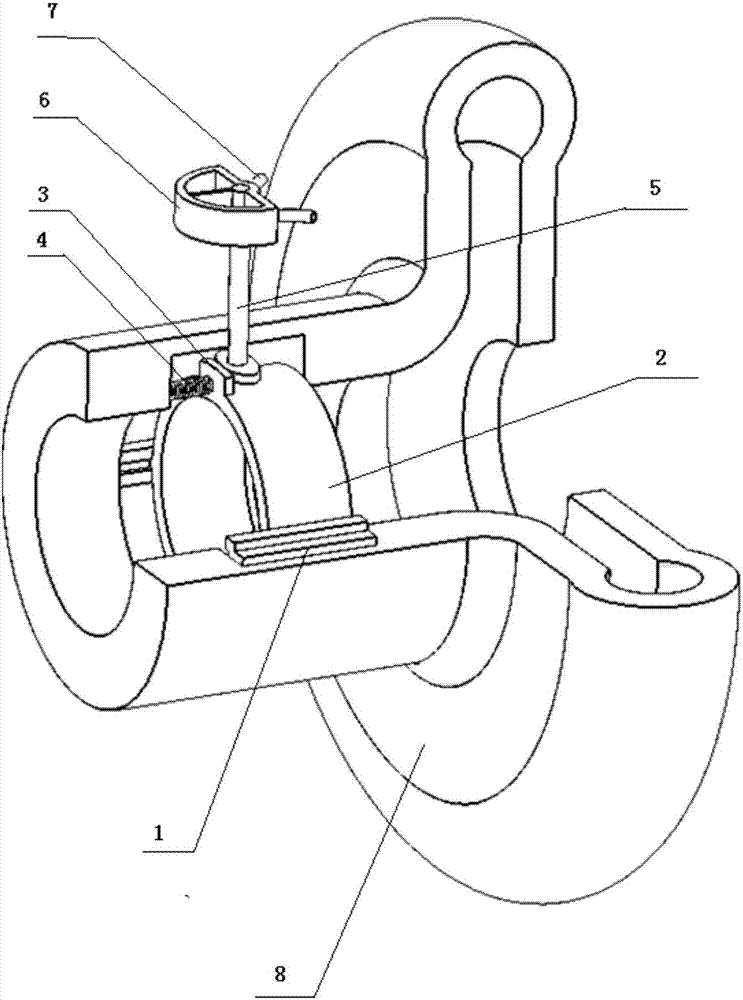

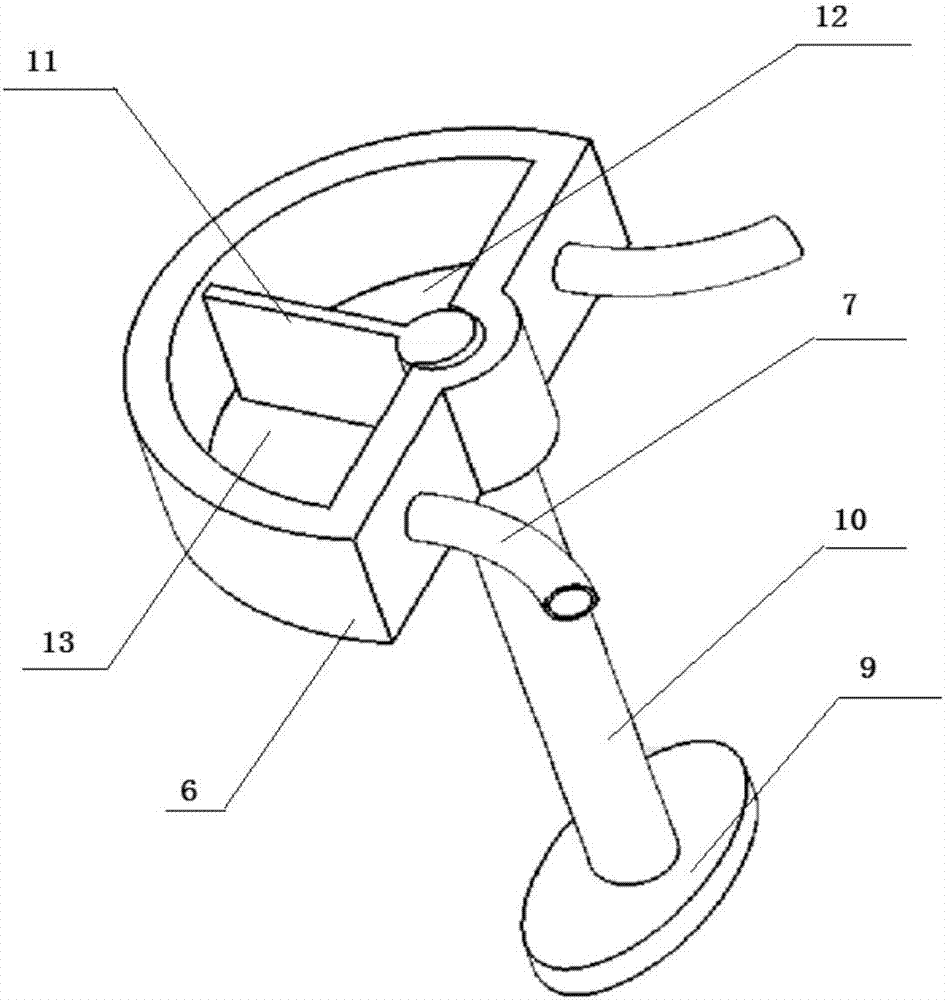

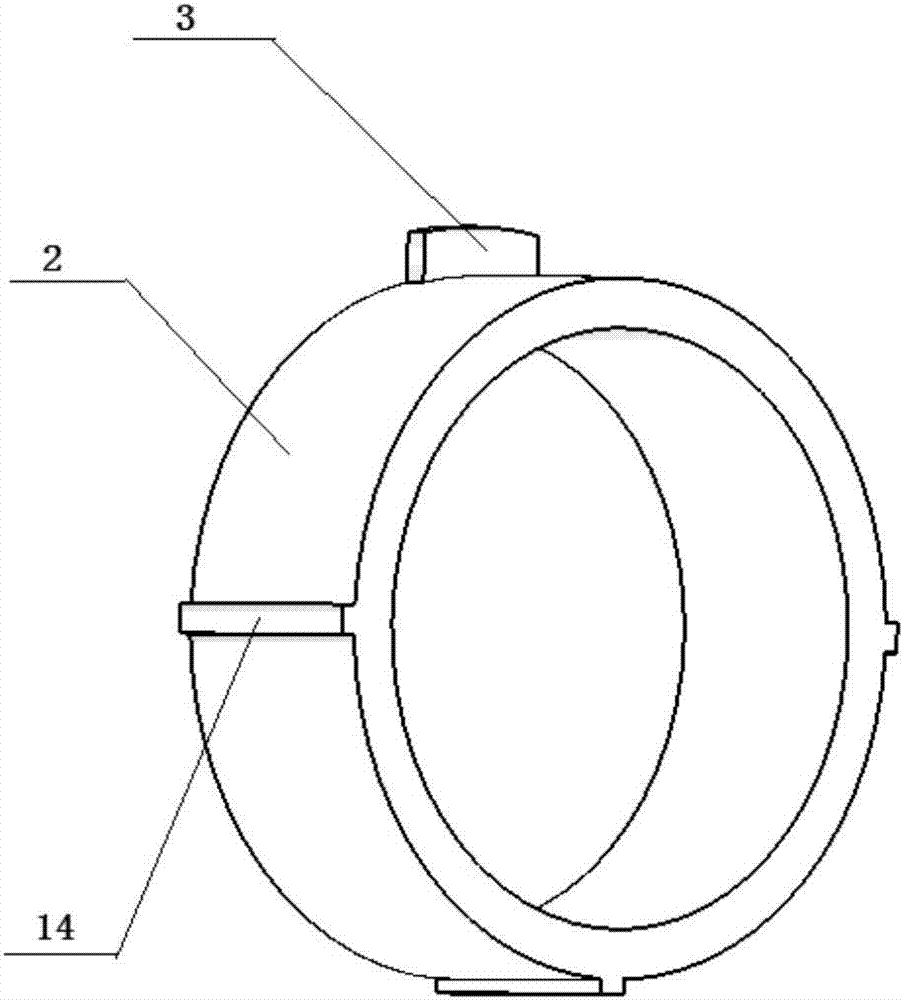

[0021] see figure 1 , figure 2 , image 3 with Figure 4 The centrifugal compressor treatment casing with adjustable slot width provided by the present invention contains a suction ring groove 15, a return ring groove 117 and a guide ring groove 16 arranged in the volute, the suction ring groove, the return ring groove The groove and the guide ring groove form a self-circulating casing channel; the centrifugal compressor processing casing also includes an adjusting device with adjustable slot width, which includes a hollow cylinder 2, a cam structure, a coil spring 4 and two guides. Trachea 7; the hollow cylinder 2 is arranged in the guide ring groove 16, and is connected with the guide ring groove through a moving pair, and the moving pair preferably adopts a slide block-rail mechanism, and the slide block 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com