Processing casing and air compressor

A technology for processing casings and slots, which is applied in the directions of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of delaying the blockage of the rotor blade tip airflow separation blade channel, inappropriate installation angle of the front section, and differences, etc. To achieve the best effect of expanding the stable working range and smooth airflow structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a processing casing and a compressor. The upper slot of the processing casing is non-linear and adopts a banana-shaped structure.

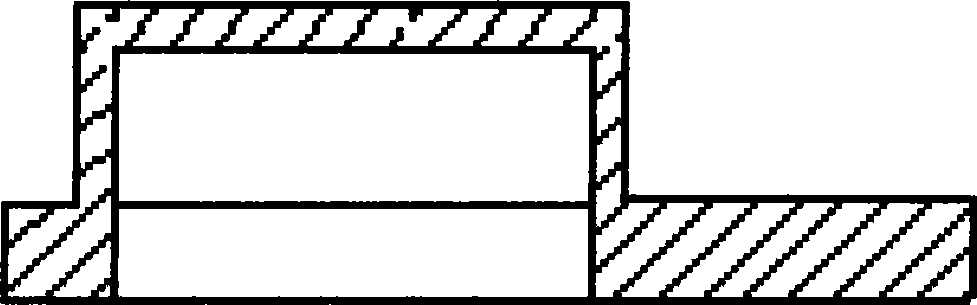

[0025] In the processing casing, the width of the upper slot of the processing casing is narrow at the front and wide at the rear or wide at the front and narrow at the rear.

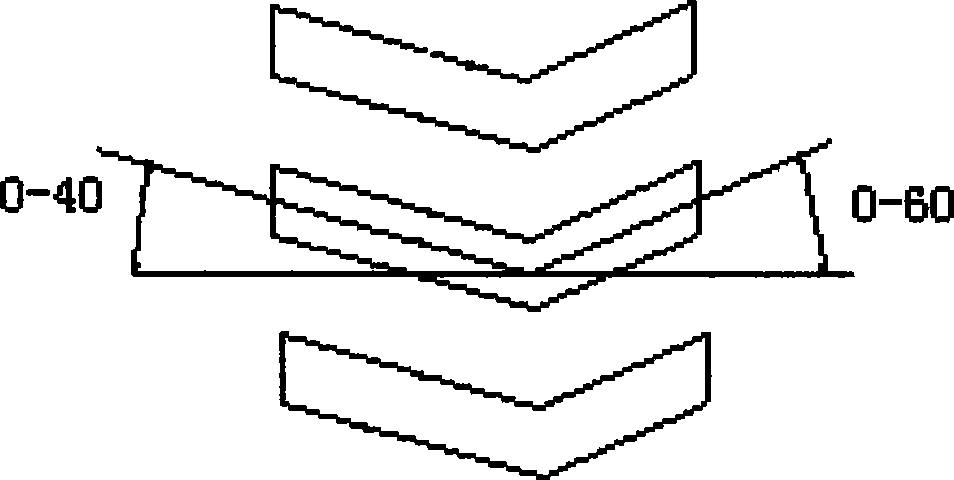

[0026] The range of the installation angle of the processing casing and the groove is: the installation angle is the inclination angle between the tangent line at the end of the arc center line and the horizontal line; the installation angle range of the front section is: 0-40 degrees; the installation angle range of the rear section is: 0-60 degrees.

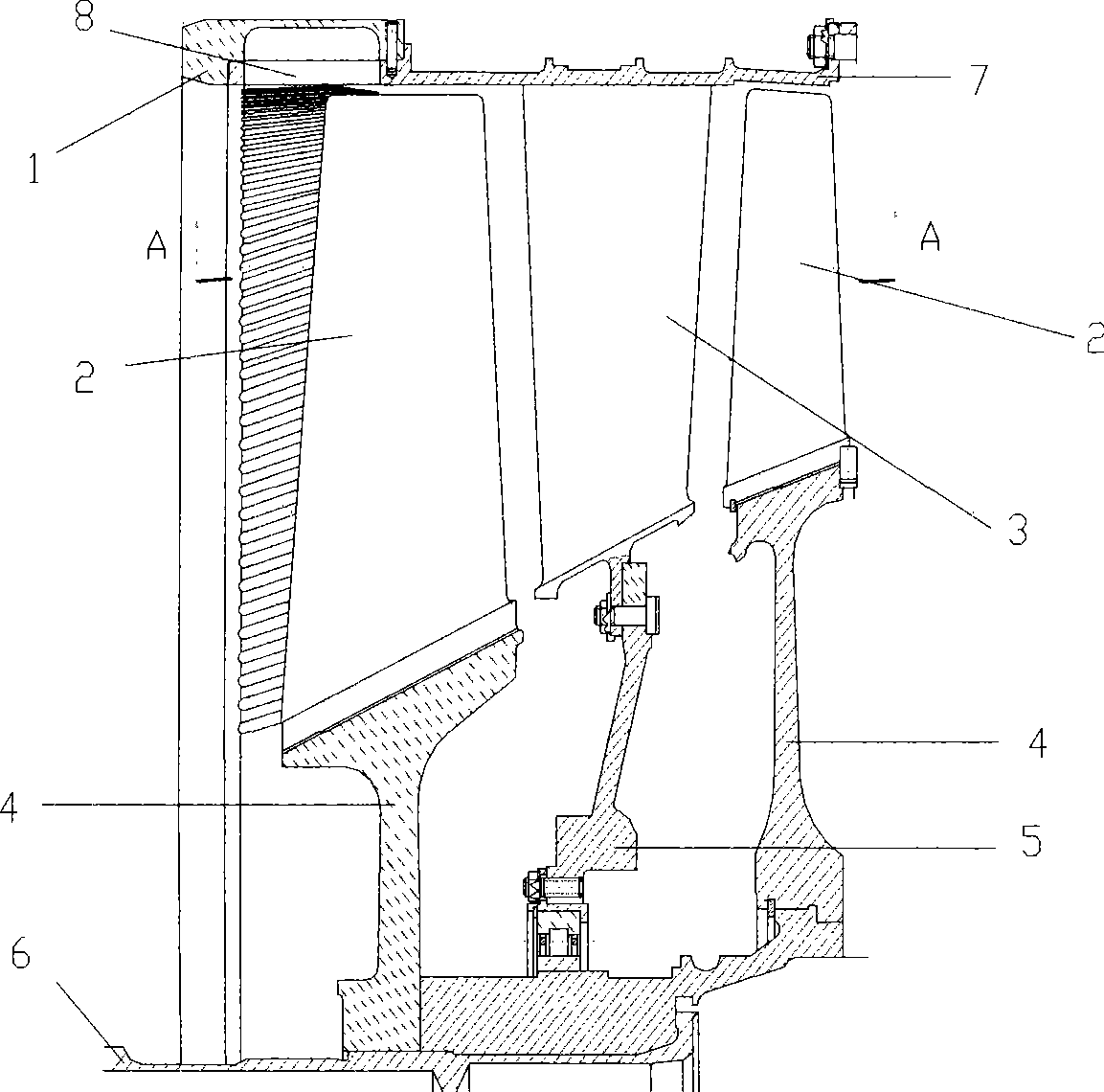

[0027] A compressor comprising a processing casing (1), rotor blades (2), stator blades (3), a wheel disc (4), a stator inner ring (5), and a shaft (6); the processing casing (1) It includes a casing (7) and a processing ring (8); one end of the stator blade (3) is connected to the stator inne...

Embodiment 2

[0029] This embodiment provides a processing casing and a compressor. The front and rear sections of the slots on the processing casing are linear, and the middle is connected by an arc section.

[0030] In the processing casing, the width of the upper slot of the processing casing is narrow at the front and wide at the rear or wide at the front and narrow at the rear.

[0031] The installation angle range of the processing casing and the groove is: the installation angle is a straight line horizontal inclination angle; the installation angle range of the front section is: 0-40 degrees; the installation angle range of the rear section is: 0-60 degrees.

[0032] A compressor comprising a processing casing (1), rotor blades (2), stator blades (3), a wheel disc (4), a stator inner ring (5), and a shaft (6); the processing casing (1) It includes a casing (7) and a processing ring (8); one end of the stator blade (3) is connected to the stator inner ring (5), the other end is conne...

Embodiment 3

[0034] This embodiment provides a processing casing and a compressor. The front section of the slot on the processing casing is linear, and the rear section is arc-shaped.

[0035] In the processing casing, the width of the upper slot of the processing casing is narrow at the front and wide at the rear or wide at the front and narrow at the rear.

[0036] The range of the installation angle of the processing casing and the slot is: when the front and rear sections are linear, the installation angle is the straight horizontal inclination angle; when it is non-linear, the installation angle is the inclination angle between the tangent line at the end of the arc center line and the horizontal line; The installation angle range of the front section is: 0-40 degrees; the installation angle range of the rear section is: 0-60 degrees.

[0037]A compressor comprising a processing casing (1), rotor blades (2), stator blades (3), a wheel disc (4), a stator inner ring (5), and a shaft (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com