Axial flow compressor blowing-type circumferential groove casing treatment method

An axial flow compressor and casing processing technology, which is applied in the directions of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as poor compressor stability margin, increase flow capacity, improve blockage conditions, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

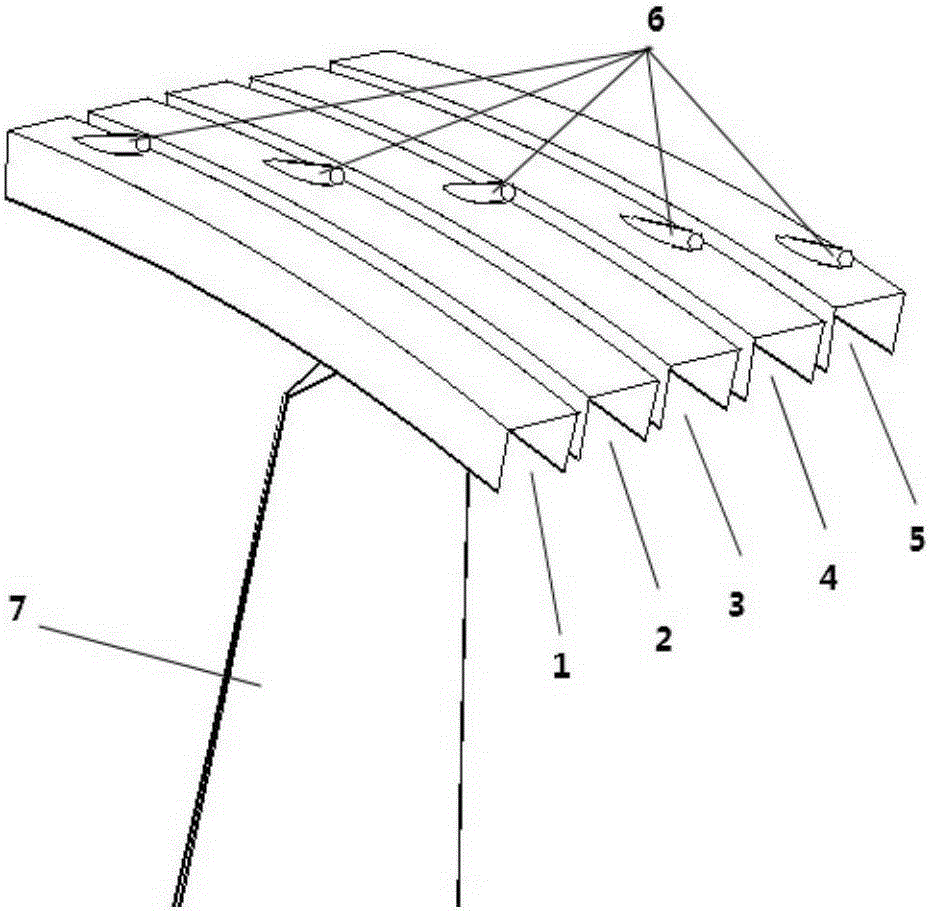

[0015] refer to figure 1 . The specific steps of the treatment method for the blowing type circumferential groove casing of the axial flow compressor of the present invention are as follows:

[0016] 1. The present invention is applied to the isolated rotor of the axial flow compressor laboratory, and its main design parameters are shown in Table 1.

[0017] Table 1 Main design parameters of isolated rotor

[0018] number of blades

30

Design speed (rpm)

15200

Design isentropic adiabatic efficiency

0.905

Design flow(kg / s)

5.6

Design total pressure ratio

1.245

blade aspect ratio

1.94

Wheel ratio

0.61

Top Radial Clearance(mm)

0.35

tip consistency

0.96

[0019] 2. The test piece used in the present invention is based on a circumferential groove processing casing, and the treatment width of the test piece covers the entire axial width of the rotor blade tip. See Table 2 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com