Reverse flow combustor allowing wider range of stable running

A backflow combustor and stable working technology, which is applied in the direction of combustors, continuous combustors, combustion methods, etc., can solve problems such as the deterioration of the temperature distribution at the outlet of the combustor, and the narrow stable working range, so as to broaden the stable working range and widen the fuel Effect of flow rate range and widening working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

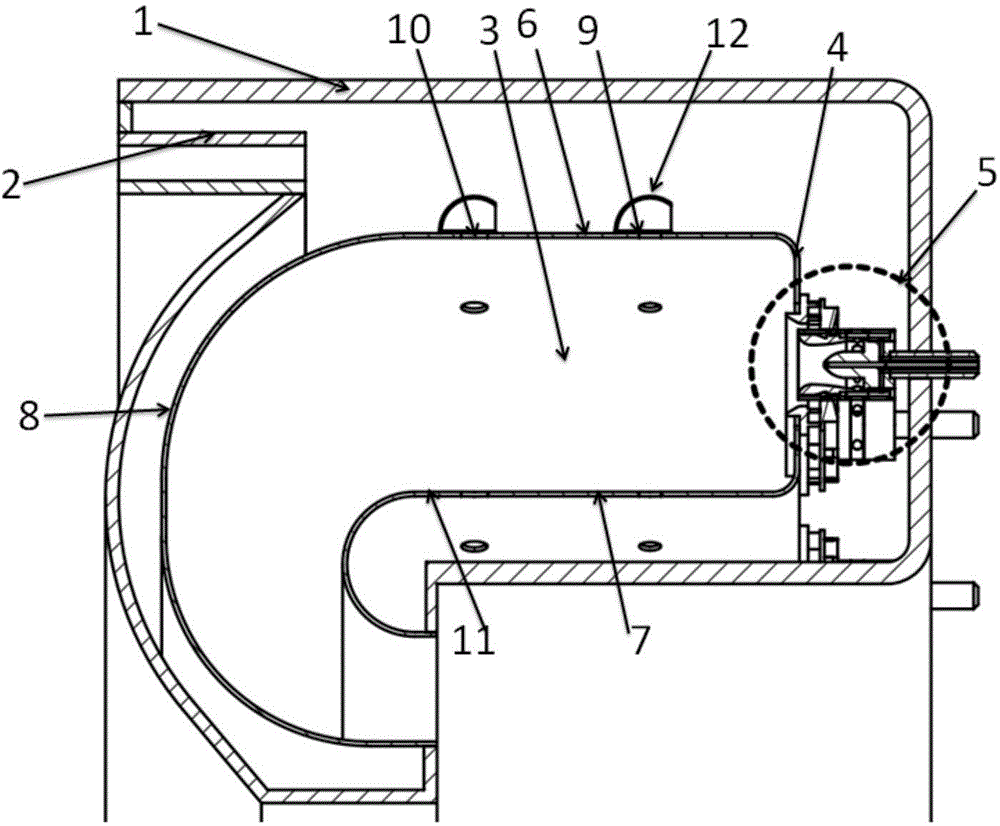

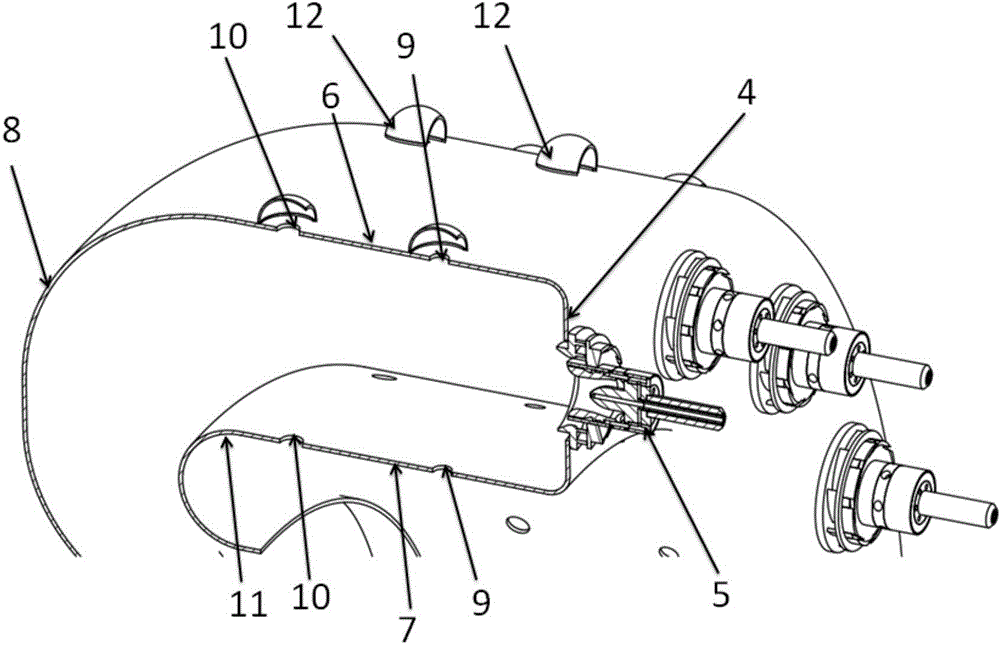

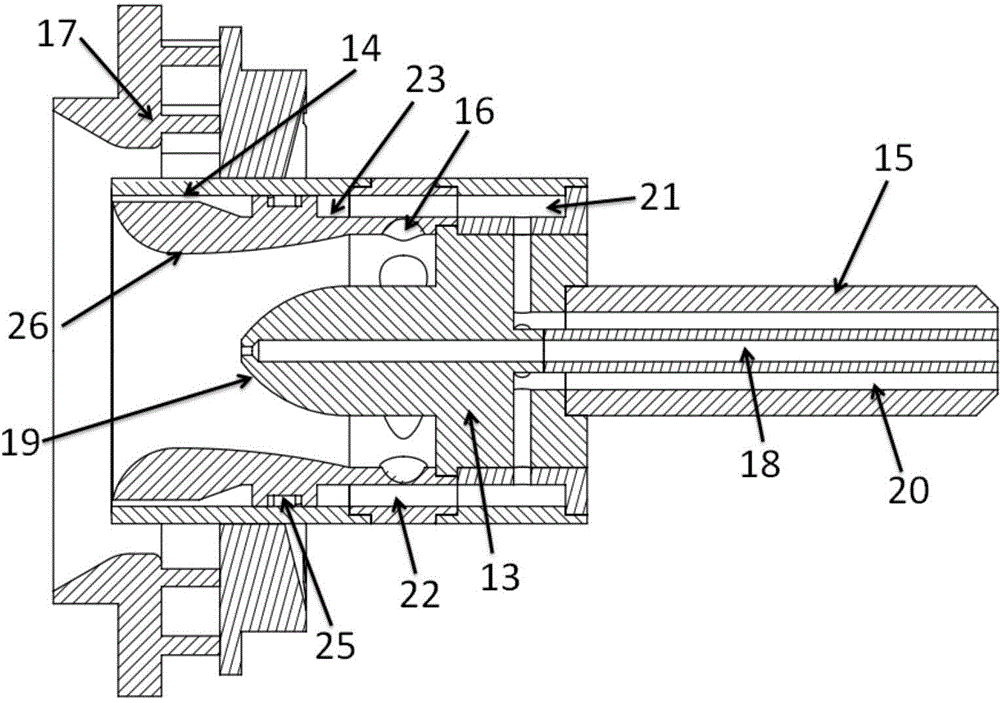

[0035] figure 1 It is a detailed structural diagram of a recirculation combustion chamber that can expand the stable working range involved in the present invention. Combustion chamber casing 1 includes flame tube 3 to form a single-ring cavity structure. The flame tube 3 is composed of a head end wall 4 , a head atomizing device 5 , a flame tube outer wall 6 , a flame tube inner wall 7 and a large elbow wall 8 . The air enters into the annular chamber of the combustion chamber through the diffuser 2 and then enters the interior of the flame tube 3 through the head atomizing device 5 , the main combustion hole 9 , the mixing hole 10 and the cooling structure 11 . The fuel is atomized through the head atomizing device 5, fully mixed with the swirling air, and then enters the inside of the flame tube 3 for combustion, and then passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com