Low-pollution combustor for various fuels

A burner, low-polluting technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as endangering gas turbine operation safety, ablation, burner overheating, etc., to avoid unstable combustion and simplify the blowing protection system , to avoid the effect of tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

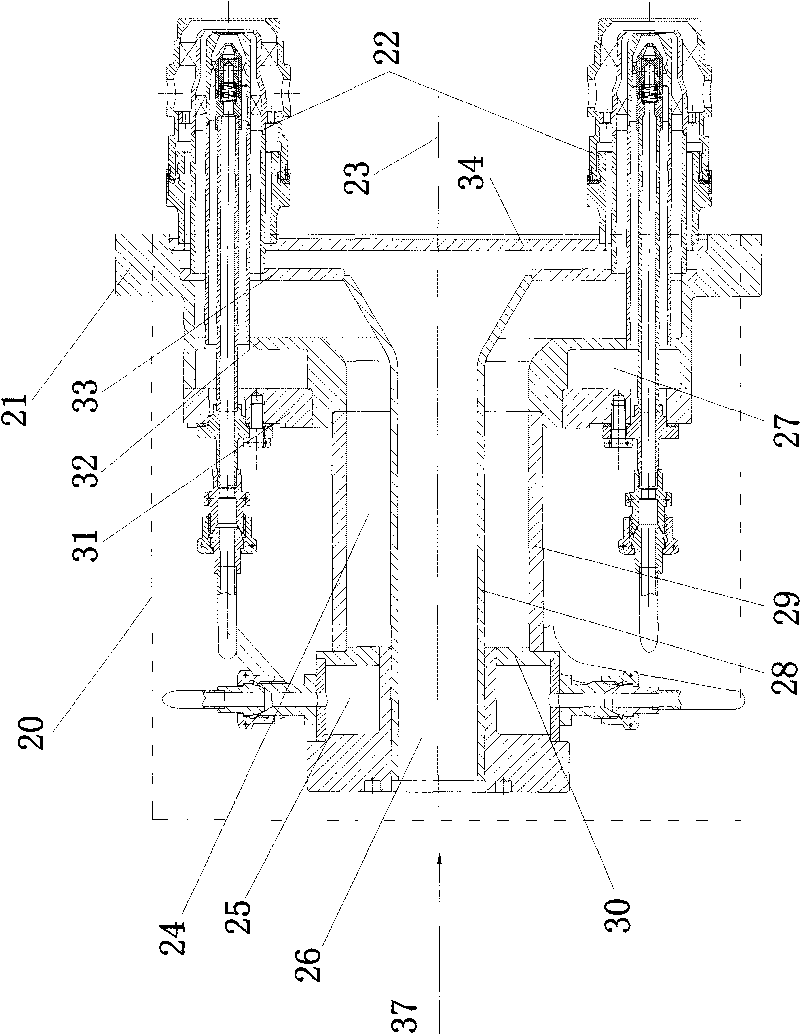

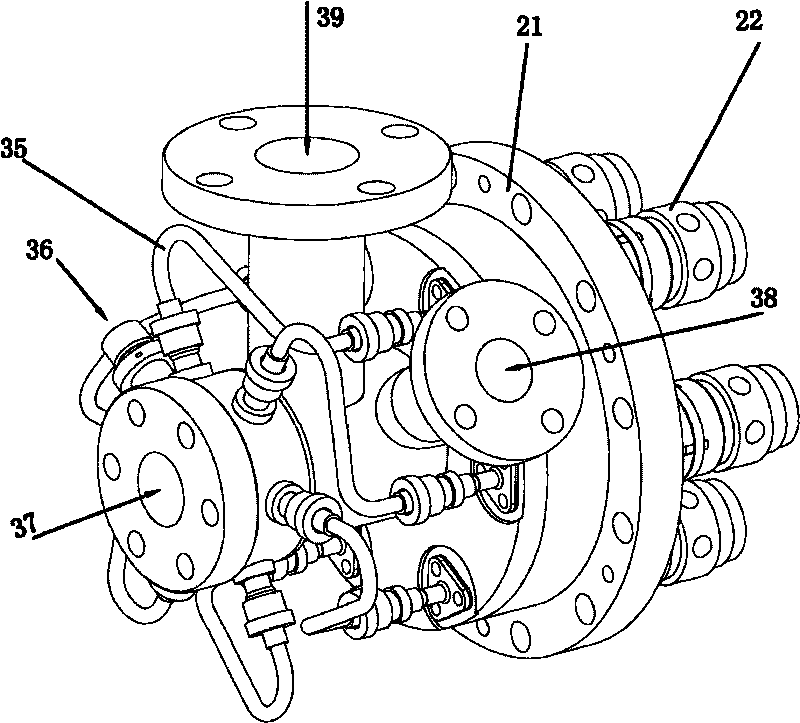

[0022] A low-pollution burner suitable for multiple fuels, including a split flow system 20, an installation edge 21, and six dual-fuel nozzles 22, wherein:

[0023] The diversion system and the six dual-fuel nozzles are connected as a whole through the installation edge; the diversion system is formed by concentric pipes 28, 29, oil supply pipeline 35, baffles 30, 31, 32, 33, 34 and processed on the installation edge The cavity is composed of four diverging channels that are opposite to each other, including the gas fuel diverting channel 24, the liquid fuel diverging channel 25, the diluent diverging channel 26, and the atomizing air diverging channel 27, which are used to realize the liquid fuel supplied from the outside, Separate flows of atomizing air, diluent and gaseous fuel within the burner and split to 6 fuel nozzles, see figure 1 , figure 2 ;

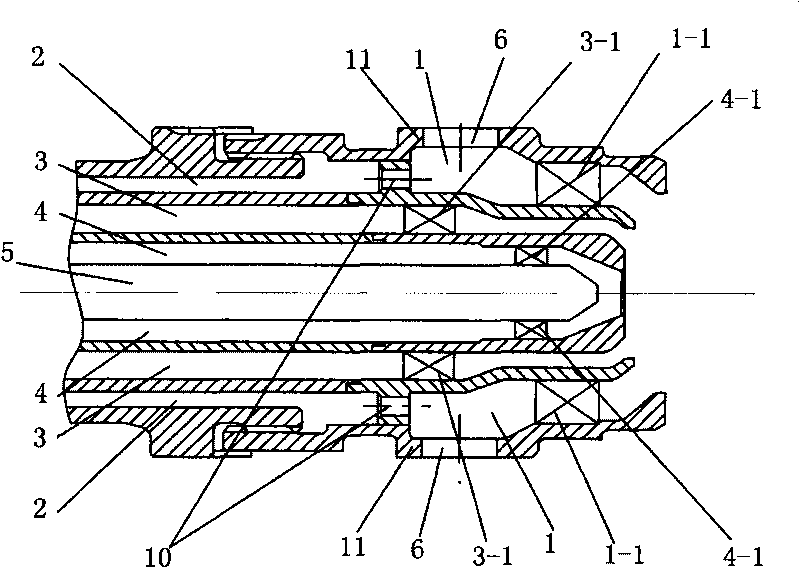

[0024] The dual-fuel nozzles consist of liquid fuel nozzles and gas fuel nozzles and are distributed along the central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com