Low-temperature-plasma ignition power supply and ignition system

A low-temperature plasma, ignition power technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of affecting ignition reliability, shortening ignition delay time, poor ignition reliability, etc., to expand stable working range. , The effect of shortening the ignition delay time and meeting the ignition demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

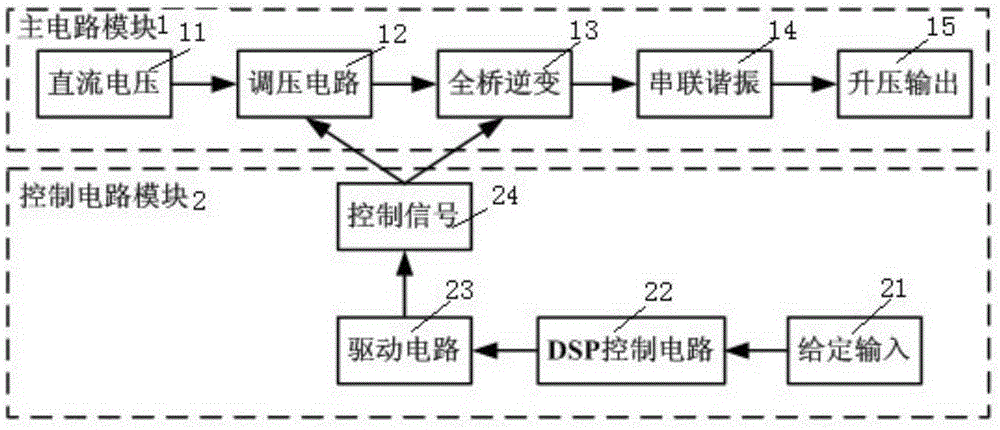

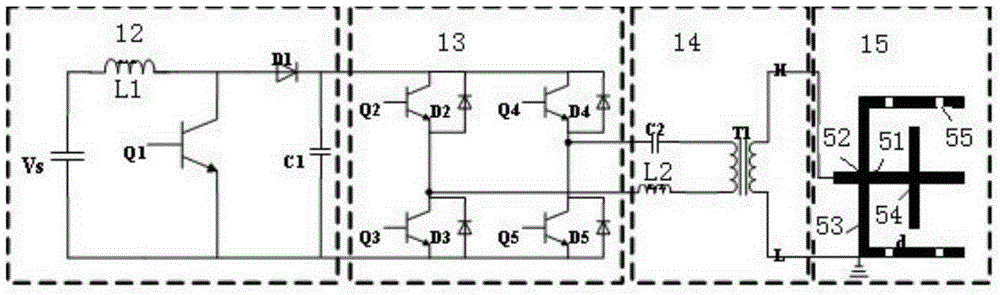

[0016] Refer to attached Figure 1-2 Examples of the present invention will be described.

[0017] In order to make the above objects, features and advantages more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The main working process of the low-temperature plasma power supply is: the AC power frequency is rectified to become a DC voltage, or Vs DC voltage, which is boosted by a voltage regulating circuit, and the voltage is converted into a high-frequency AC square wave by a full-bridge inverter circuit. The voltage is converted into a high-frequency AC sinusoidal voltage through a series resonant circuit. When the switching frequency in the full-bridge inverter circuit is close to the resonant frequency of the series resonant circuit, the voltage on the primary side of the transformer is the highest, and this AC voltage is boosted by the transformer to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com