Patents

Literature

163results about How to "Improve ignition efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

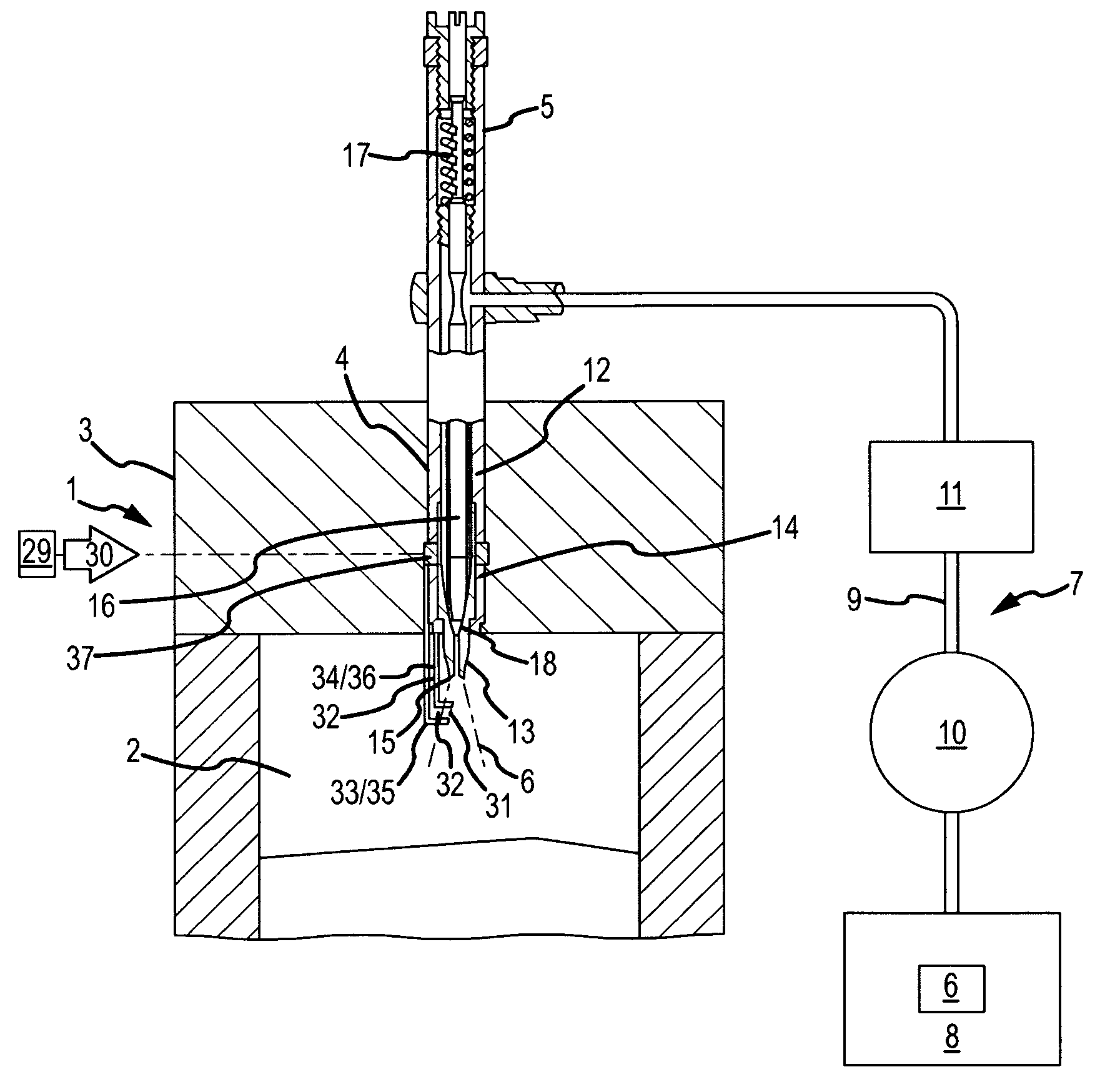

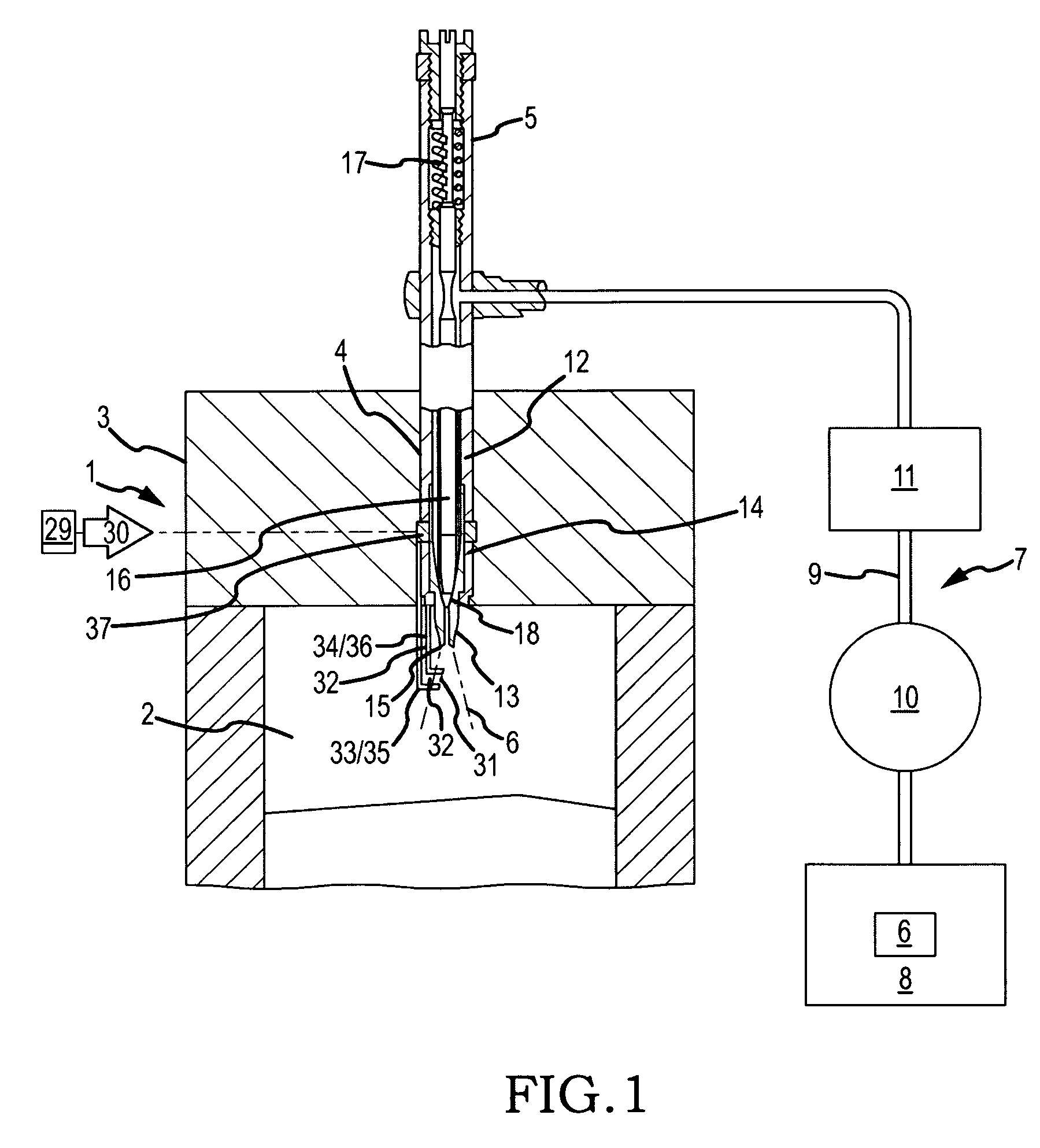

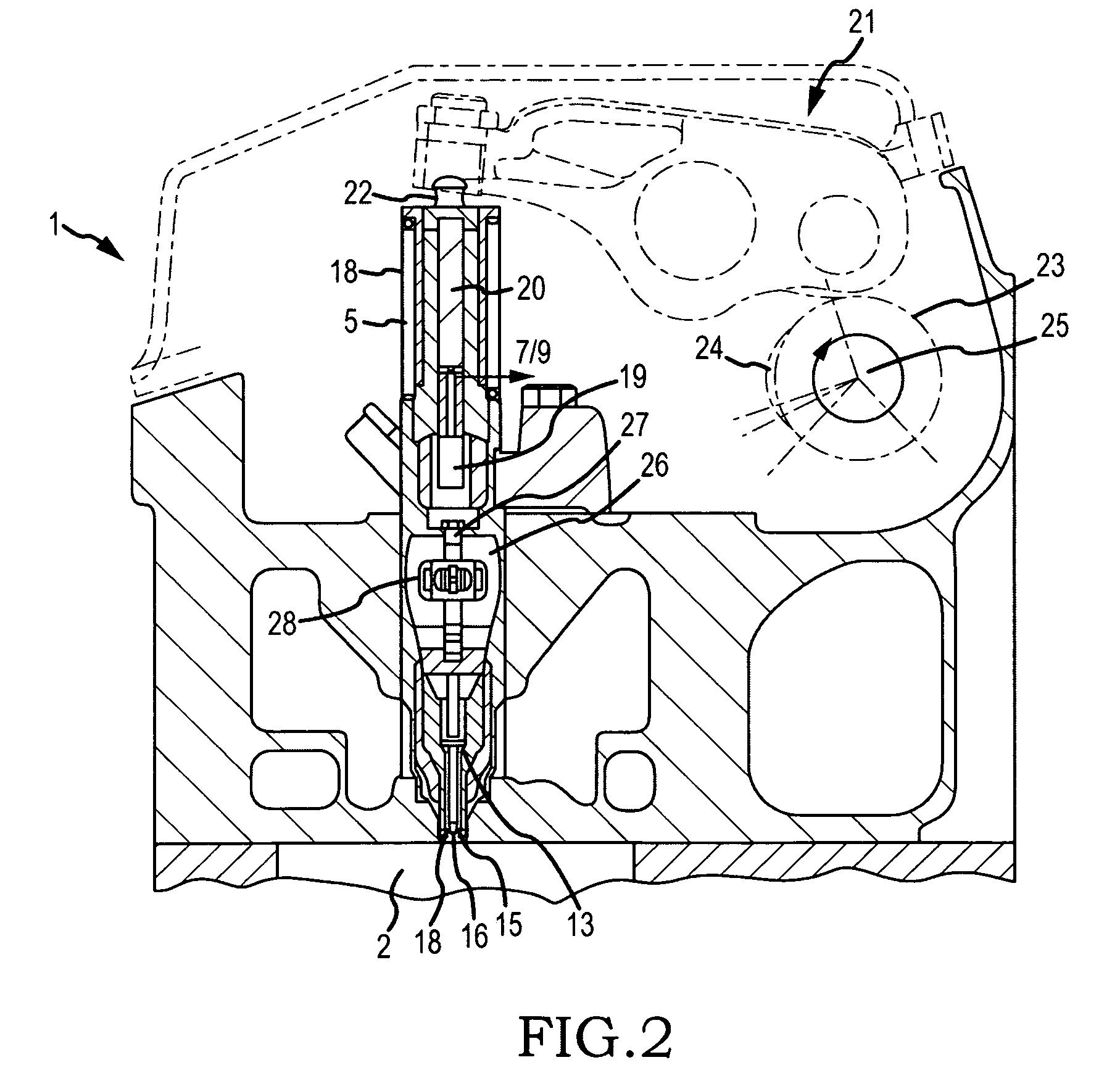

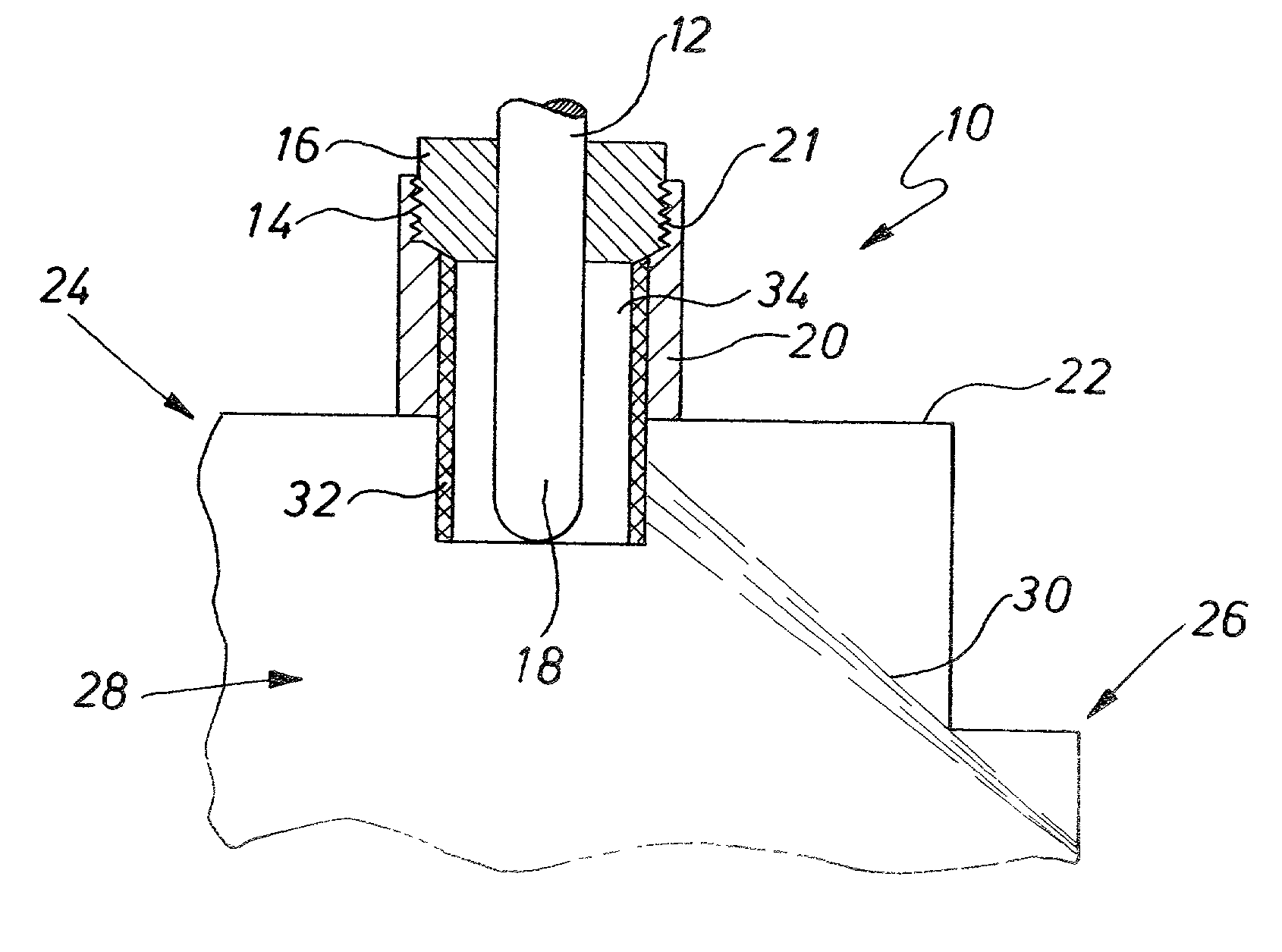

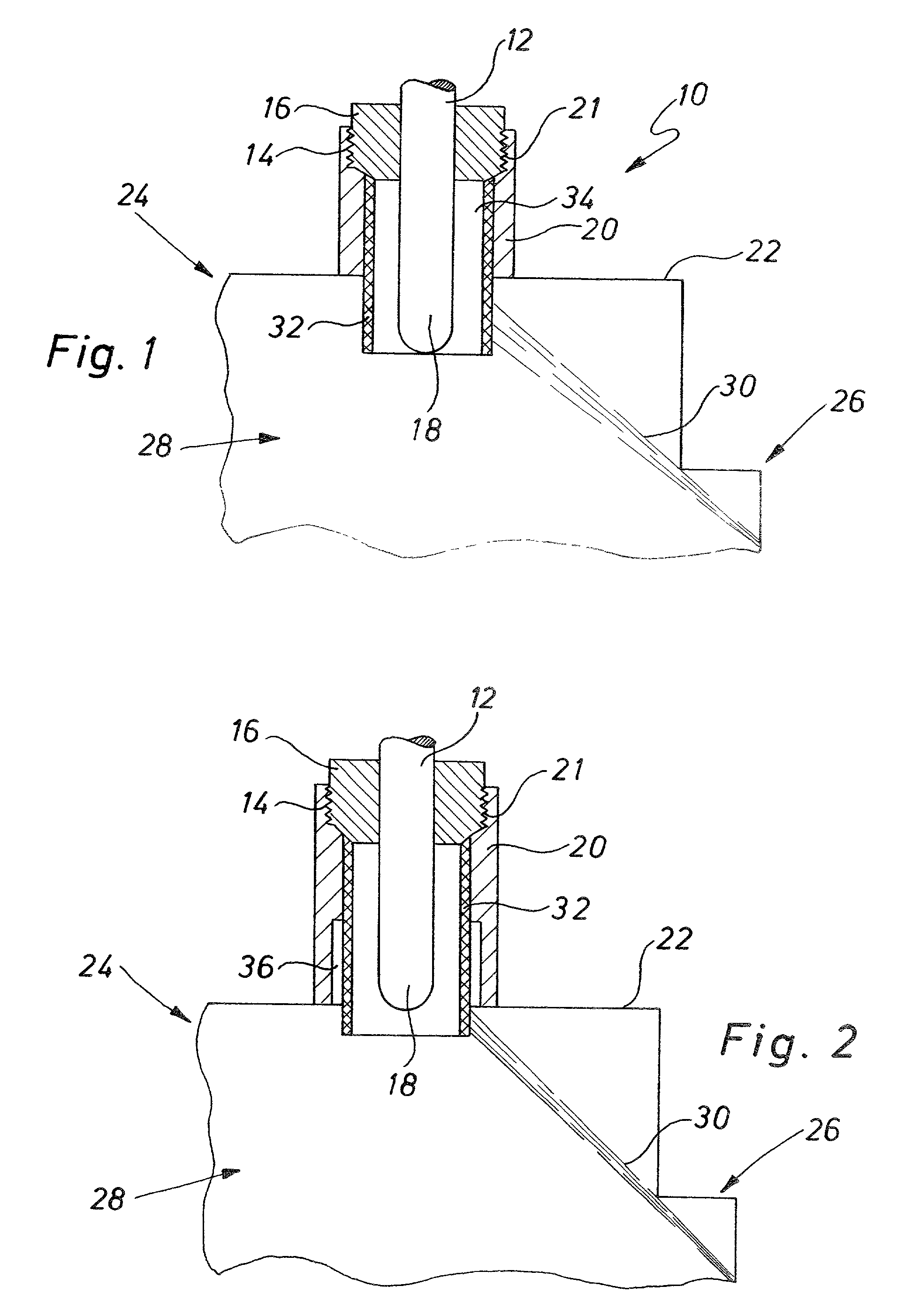

Fuel injection stream parallel opposed multiple electrode spark gap for fuel injector

ActiveUS8069836B2Improve ignition efficiencyImprove efficiencySparking plugsFuel injection apparatusElectricityCombustion

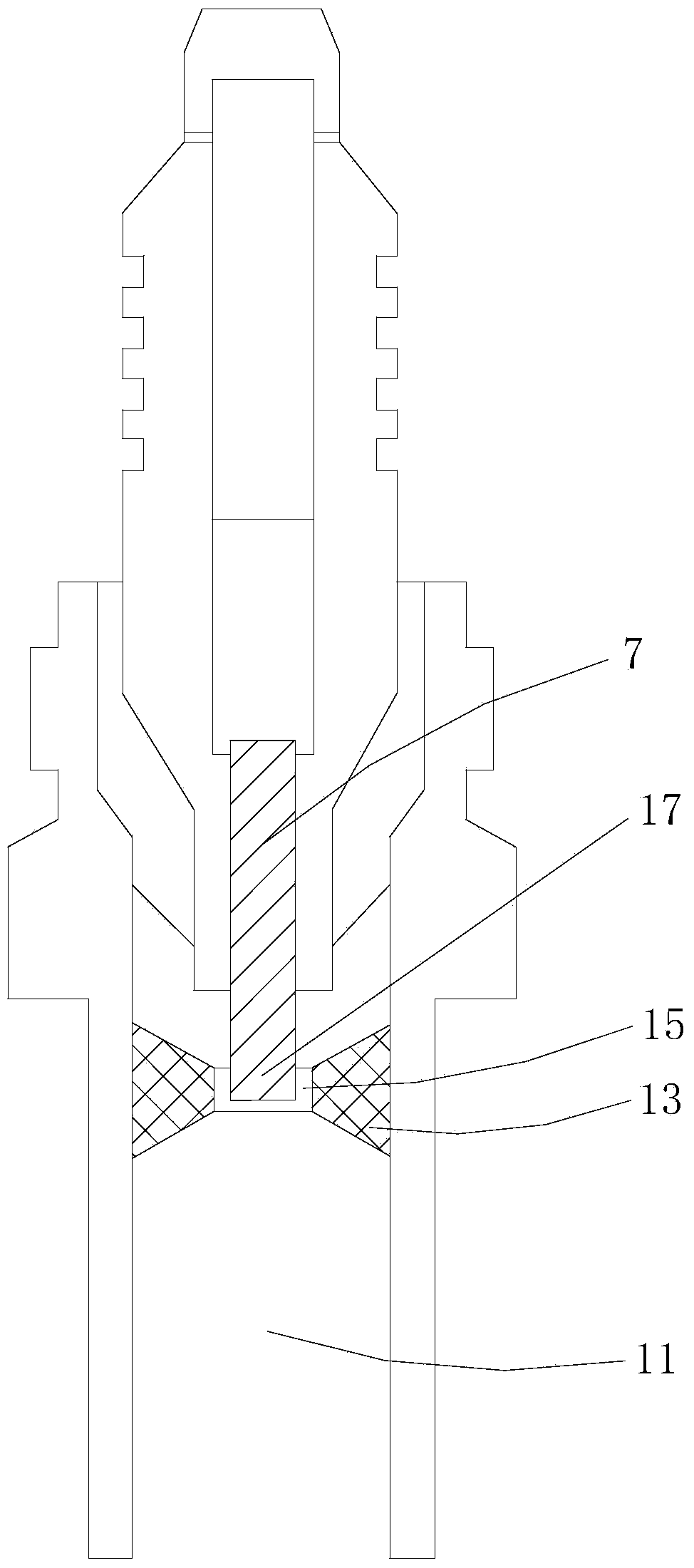

Generally, a multiple electrode spark gap fuel injector and methods of utilizing a multiple electrode spark gap fuel injector for internal combustion engines. Specifically, at least one pair of electrodes having a corresponding pair of electrode ends radially located and axially located in relation to an amount of dispersed fuel to increase efficiency of fuel combustion.

Owner:BIG CAT ENERGY CORP

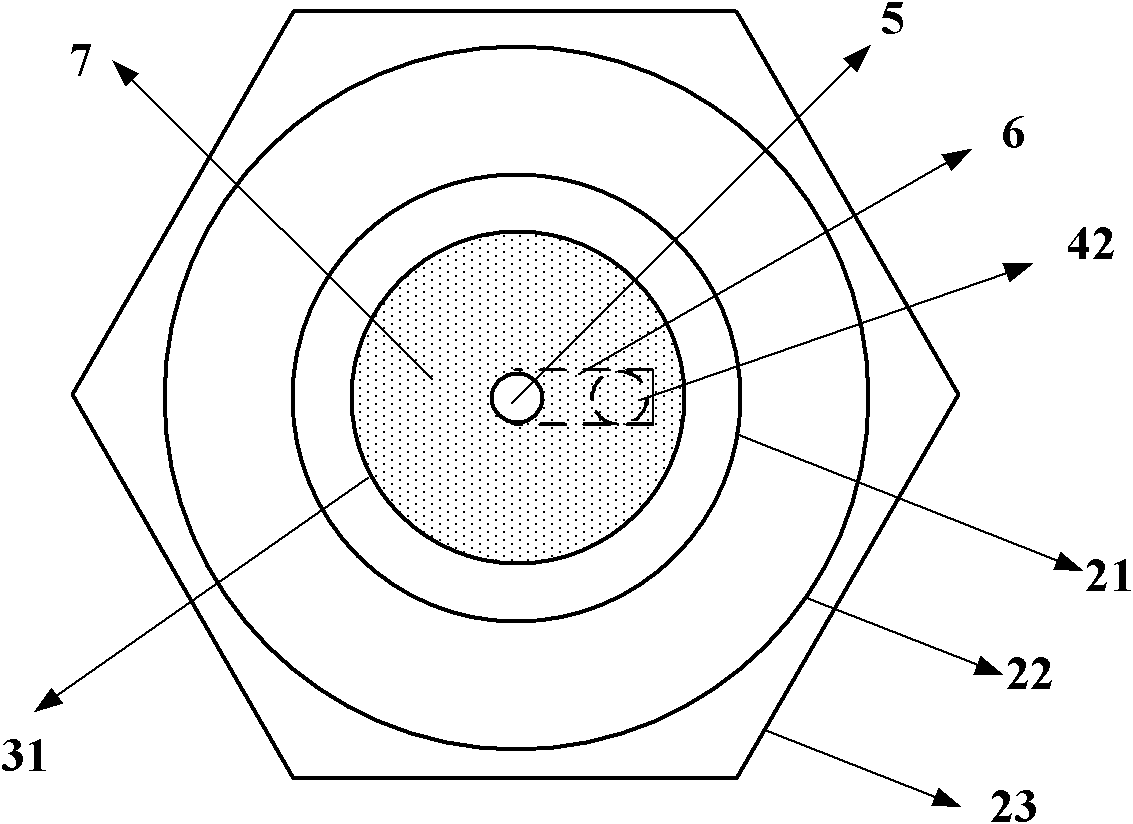

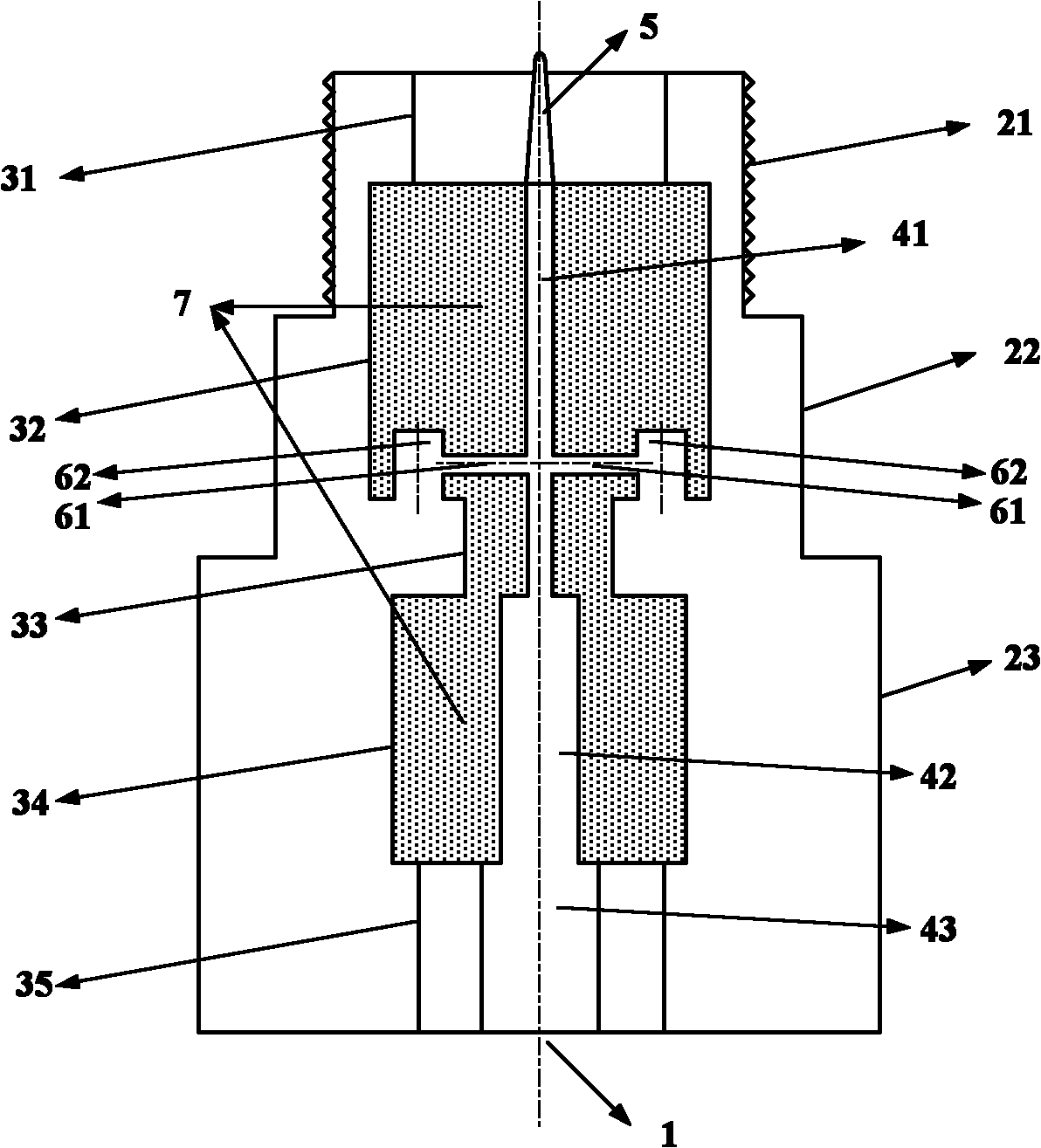

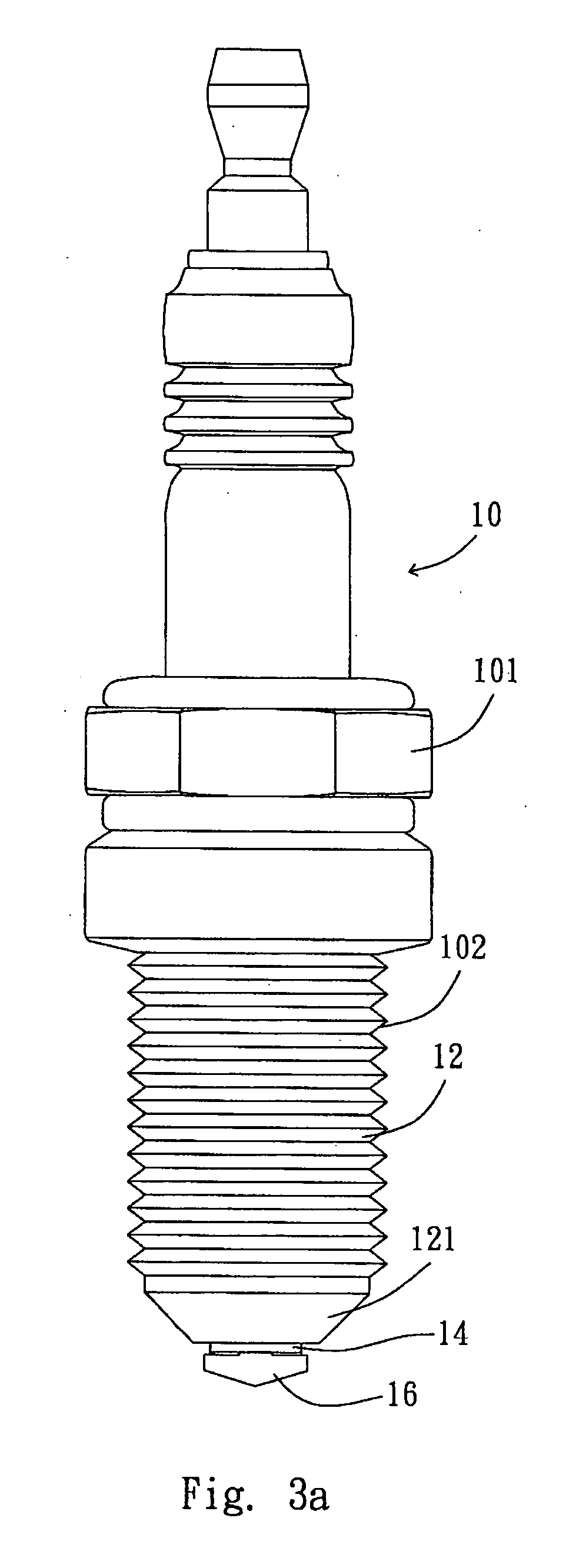

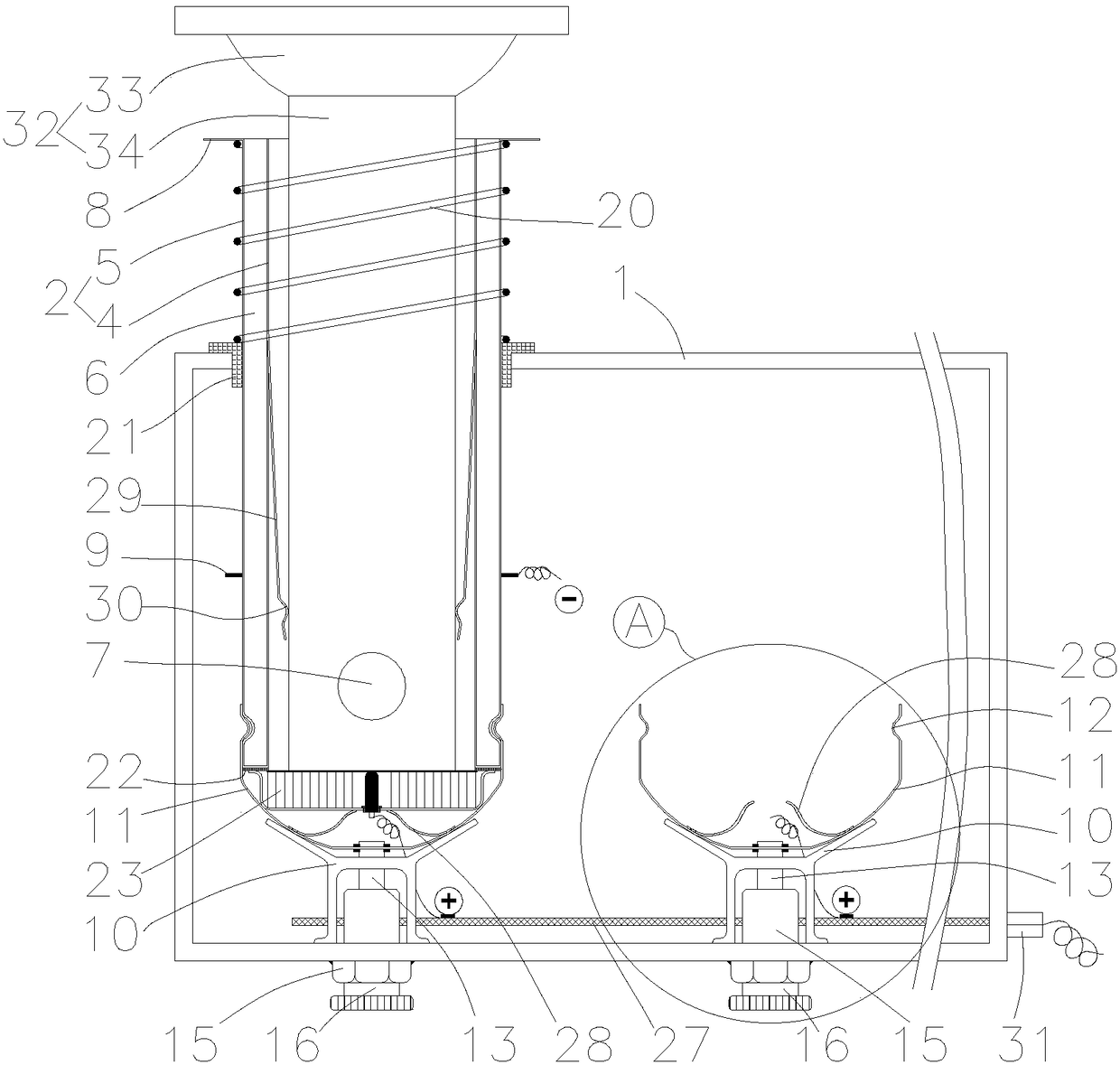

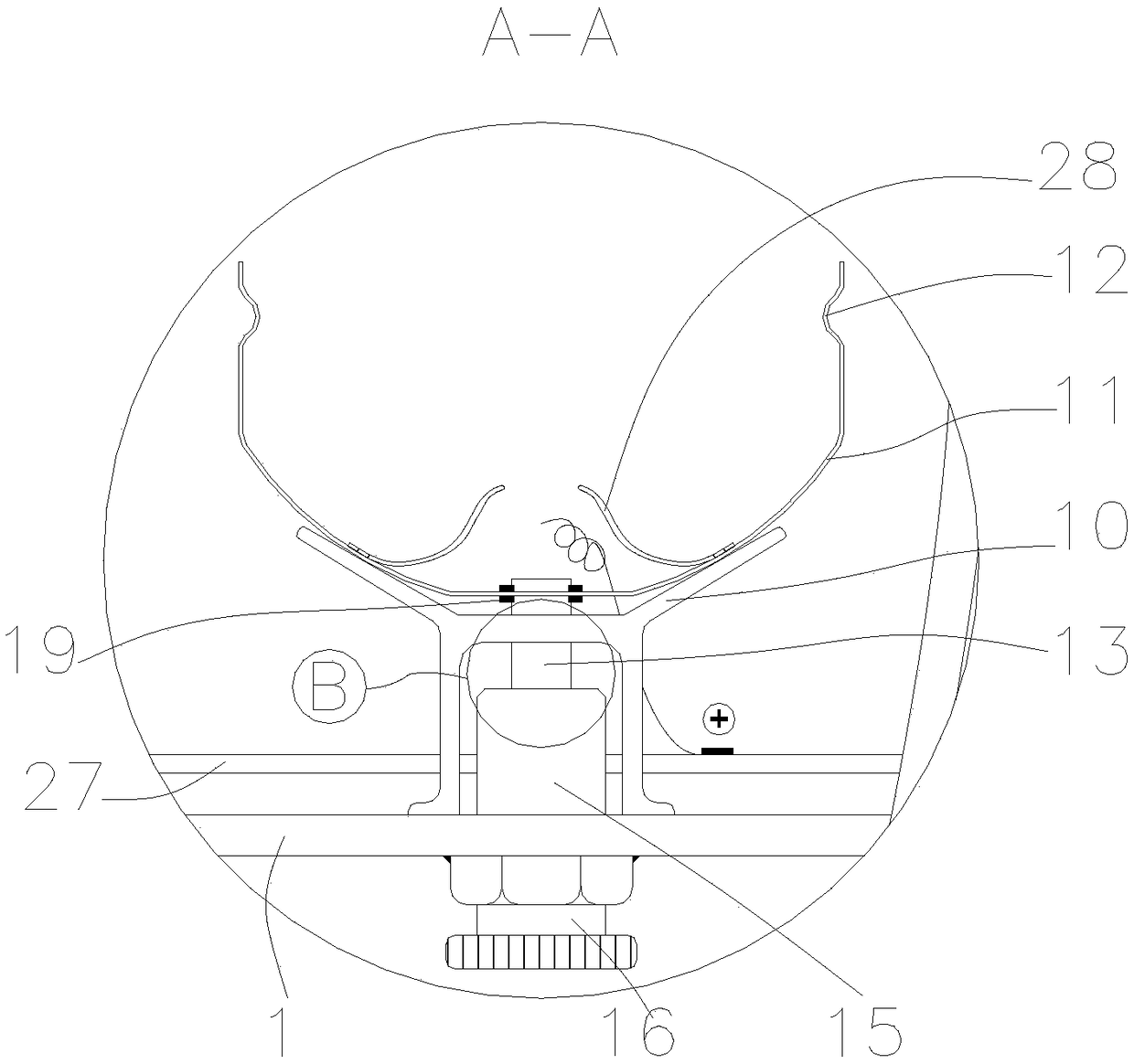

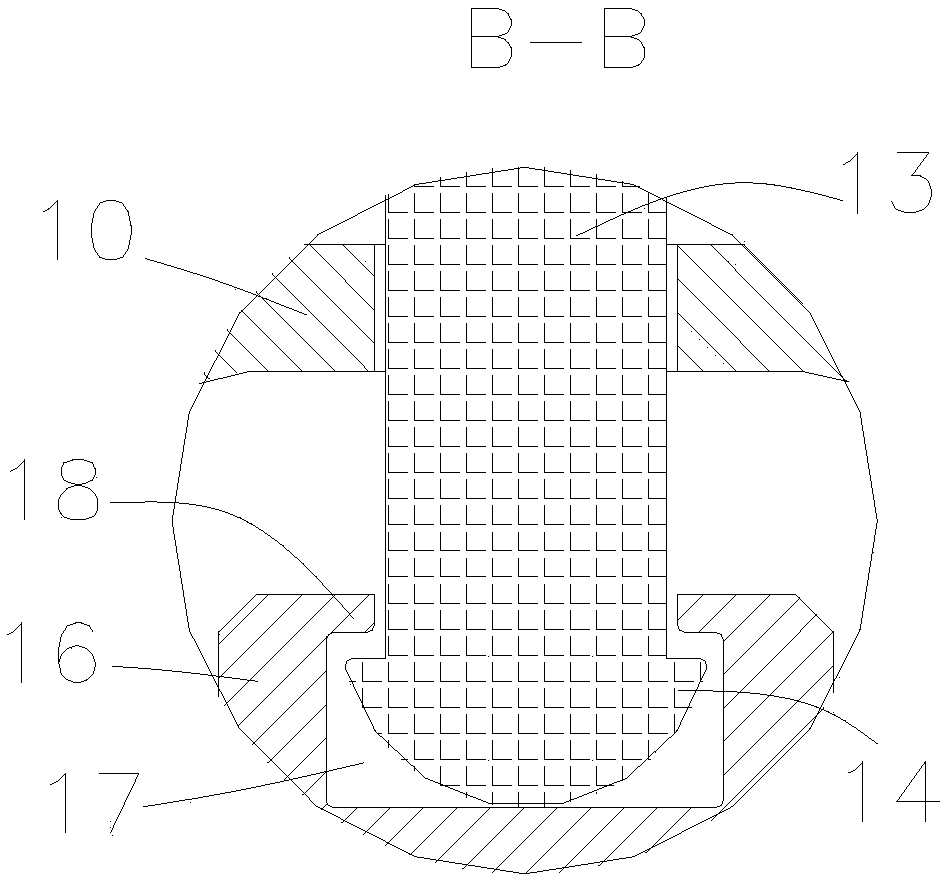

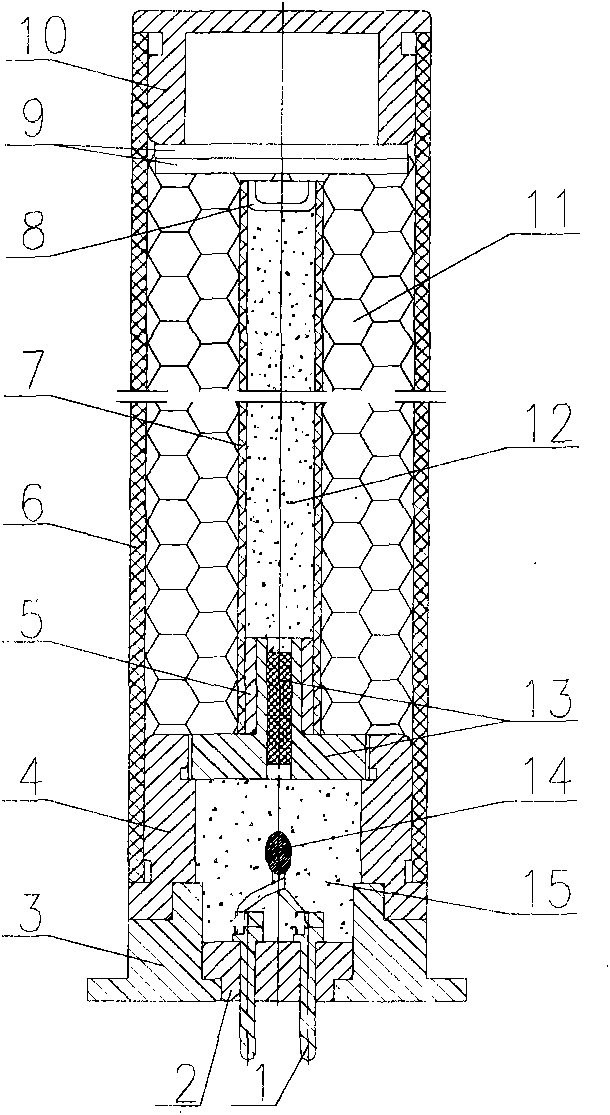

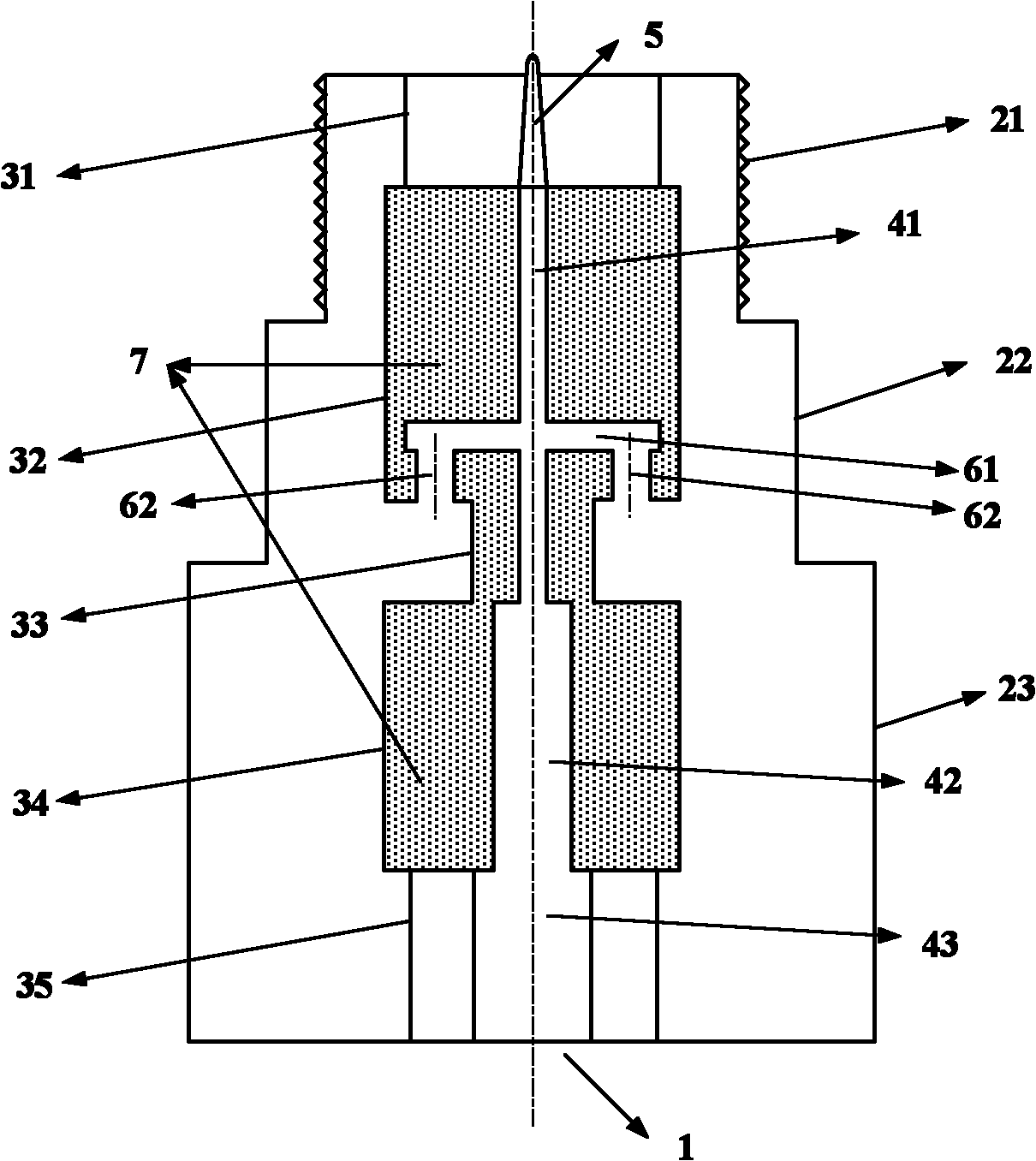

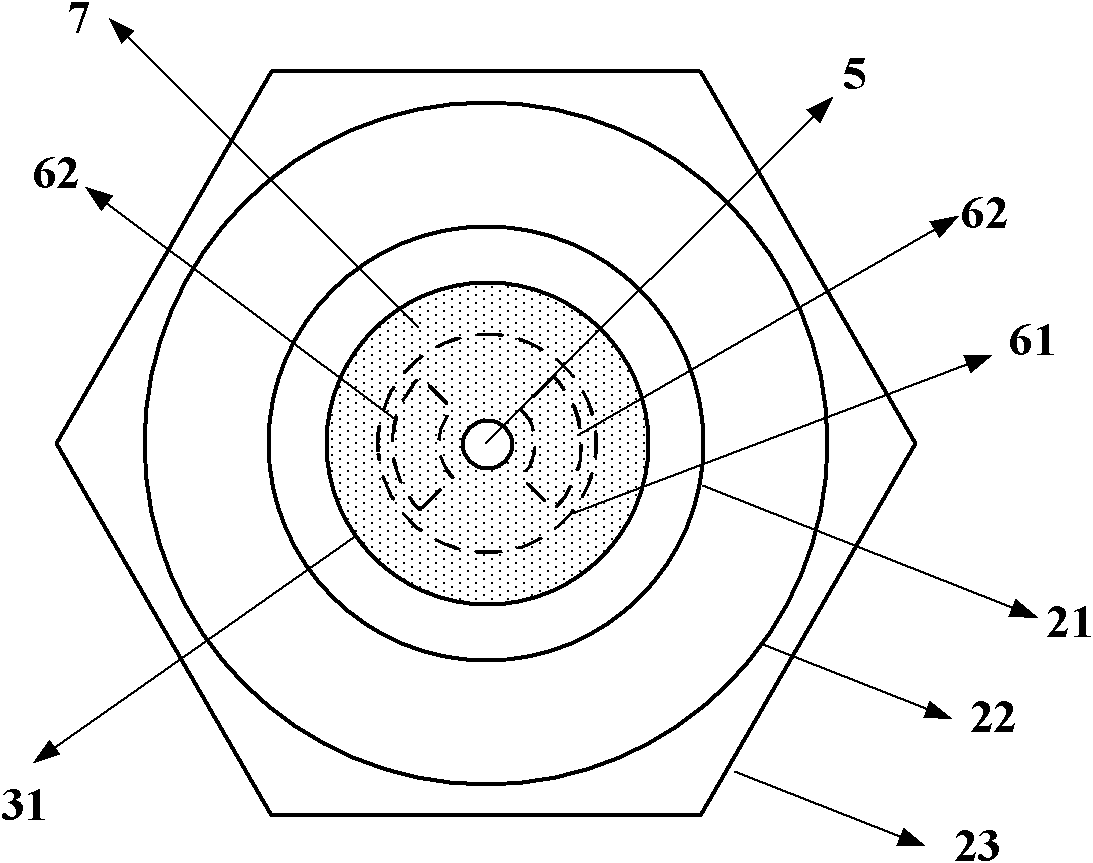

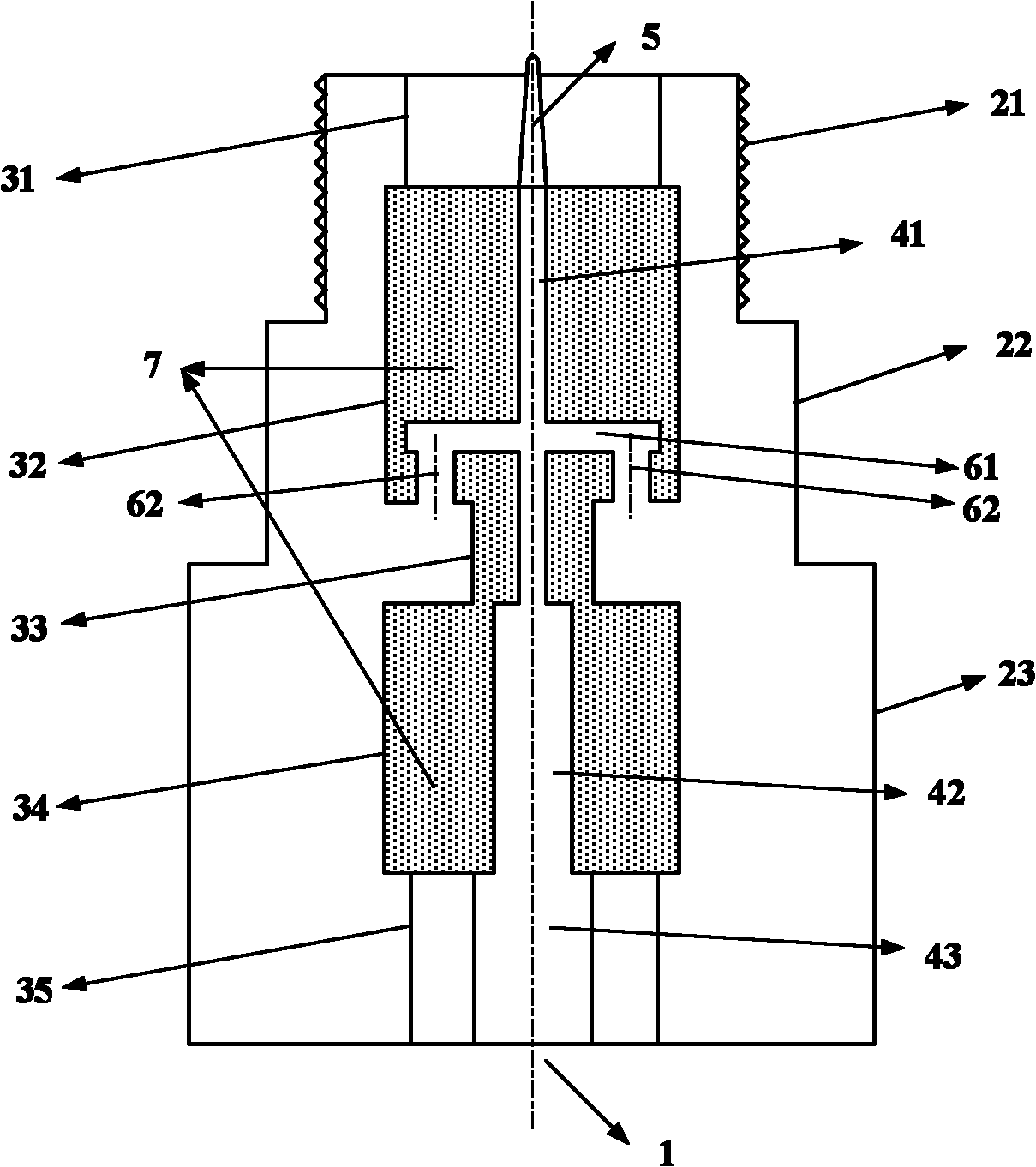

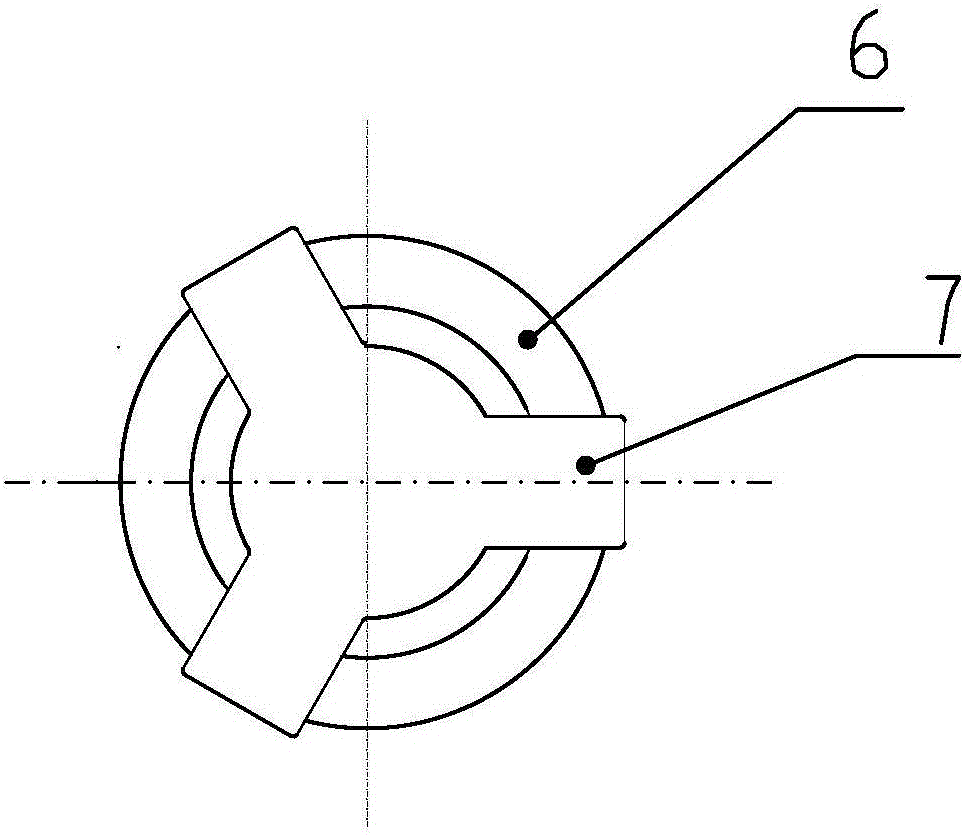

Sparking plug

ActiveCN103746291AImprove ignition efficiencyTake advantage ofSparking plugsCombustionInternal combustion engine

The invention discloses a sparking plug which comprises an insulator, a central electrode, a shell, a diversion plug-in and a grounding electrode. The insulator has a shaft hole extending in the axis direction. The central electrode is inserted in the shaft hole which penetrates through the insulator, and is exposed out of the end part. The shell is a hollow cylinder coated on the surface of the insulator. The diversion plug-in is a cylinder body; a flaming hole penetrating through the front and back end surfaces of the diversion plug-in is formed in the center of the diversion plug-in; the diversion plug-in is fixed in the shell; the front end of the diversion plug-in is aligned to the central electrode, the back end is positioned at the opening end of the shell, and the outer wall is bonded with the inner wall of the shell. The grounding electrode is arranged on the inner wall of the shell, or is arranged on the periphery of the flaming hole at the front end of the diversion plug-in; an ignition end part having a spark discharge gap is formed between the grounding electrode and the end of the central electrode. Compared with the prior art, the sparking plug avoids the generation of precipitates and the caused corrosion condition, so that the service life is prolonged. The structure of the diversion plug-in can improve the ignition efficiency and reflowing efficiency of the sparking plug so as to improve the combustion efficiency of an internal combustion engine.

Owner:张蝶儿

Ignition device, particularly for an atomizer burner of a motor vehicle heating appliance

InactiveUS20020127506A1Cost efficientEasy to igniteAir-treating devicesIncandescent ignitionMobile vehicleCombustor

Owner:EBERSPAECHER CLIMATE CONTROL SYST GMBH & CO KG

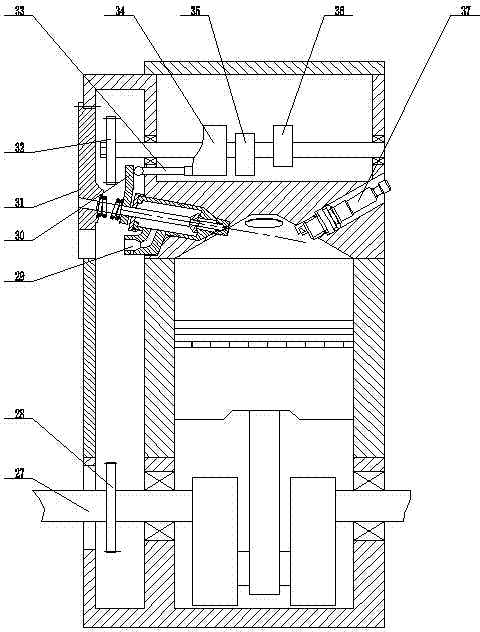

Central diffusion type tiny-oil ignition combustor

InactiveCN102537951AHeating fastExtended stayPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses a central diffusion type tiny-oil ignition combustor. An inner primary air pipe is mounted in a main primary air pipe, one section of the main primary air pipe extends into a tertiary pulverized coal combustion chamber, another section of the main primary air pipe is mounted in the inner primary air pipe, a pulverized coal concentration cone and a vortex-controllable flameexpanding blunt body are sequentially mounted in the inner primary air pipe along a flowing direction of fluid, and are coaxially installed; a small section of an L-shaped ignition oil gun in an abrasion-resistant sleeve is aligned with a cone of the vortex-controllable flame expanding blunt body, a small section of an L-shaped air inlet pipe is aligned with the bottom end of the vortex-controllable flame expanding blunt body in a hollow structure, air outlet holes are circumferentially uniformly distributed at the bottom end of the vortex-controllable flame expanding blunt body, and a plurality of circular secondary air inlet holes are equidistantly arranged on a closed end surface of the tertiary pulverized coal combustion chamber. High-temperature flame ejected by the ignition oil gun is ejected onto the flame expanding blunt body, and is obliquely diffused along the outer edge of the blunt body to a wall surface of a round pipe, ignition around a ring surface is realized, and ignition efficiency is greatly improved. In addition, the vortex-controllable flame expanding blunt body can control the size of a high-temperature backflow area formed at an outlet of a primary combustion chamber, so that fuel adaptability can be enhanced.

Owner:CHINA JILIANG UNIV

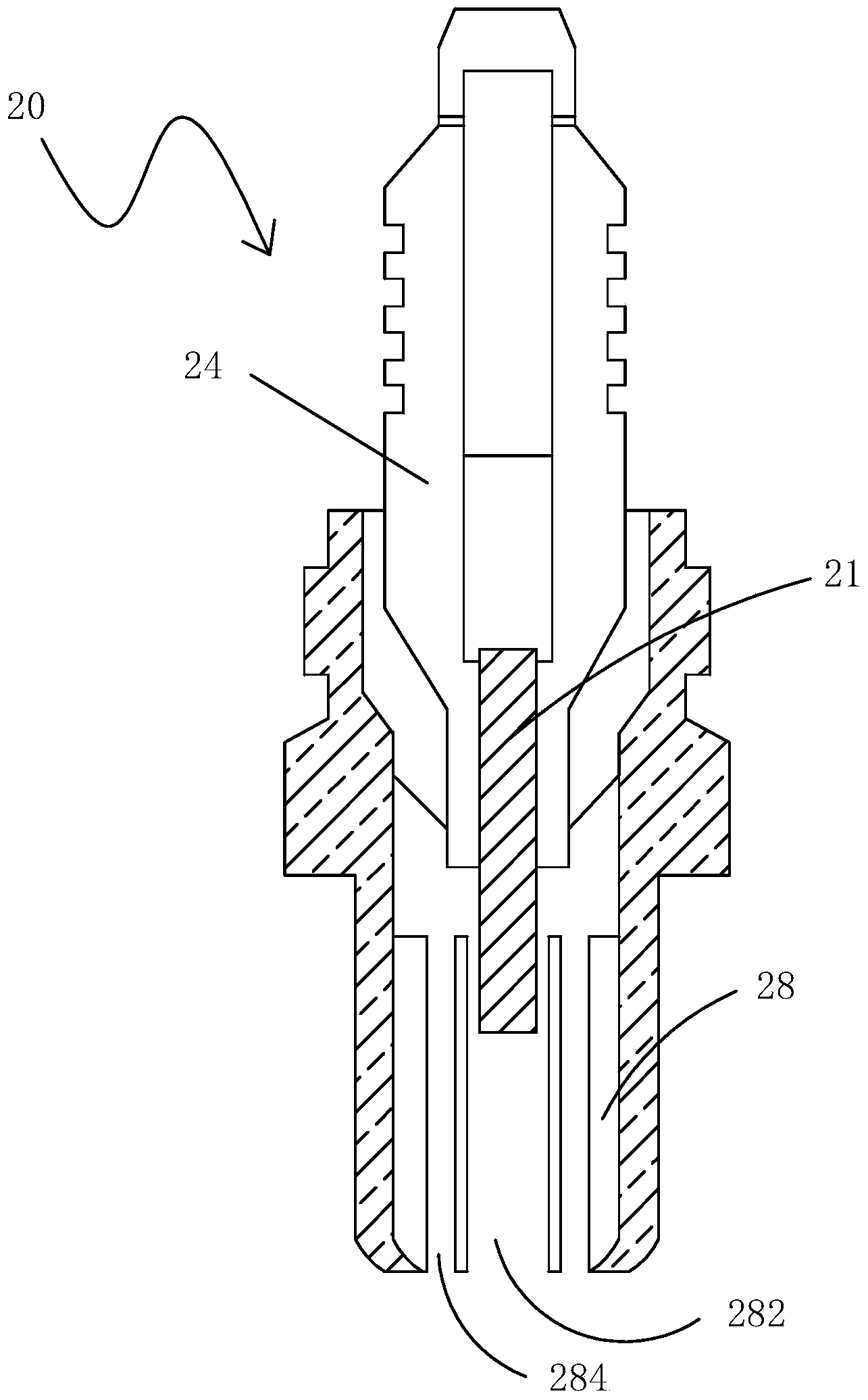

Magnetic coupling microwave plasma igniter for automobile engine

InactiveCN102121447AImprove ignition efficiencyAvoid loadEngine ignitionMachines/enginesVoltage amplitudeCombustion chamber

The invention discloses a microwave plasma igniter for an automobile engine, which belongs to the technical field of microwave application. The invention provides seven microwave plasma igniters with different structures for the automobile engine igniter, and achieves extreme field intensity at an exciter end by using an electromagnetism principle that the voltage amplitude is maximum at the end of a quarter coaxial resonator. A top structure at the end of an inner conductor can further enhance the field intensity, thereby breaking down surrounding oil gas mixture and generating the plasma and igniting. Afterwards the rapid movement of electrons of the plasma in a combustor quickly realizes the volume combustion of the whole combustor and full combustion of the oil gas mixture. The engine igniter provided by the invention has a similar external profile to the conventional spark plug, and can directly replace the conventional spark plug ignition system on the basis of not changing an engine cylinder structure. The work center frequency is 2.45GHz. The engine igniter is designed integrally, and has the characteristics of high efficiency, low cost, easy mass production and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

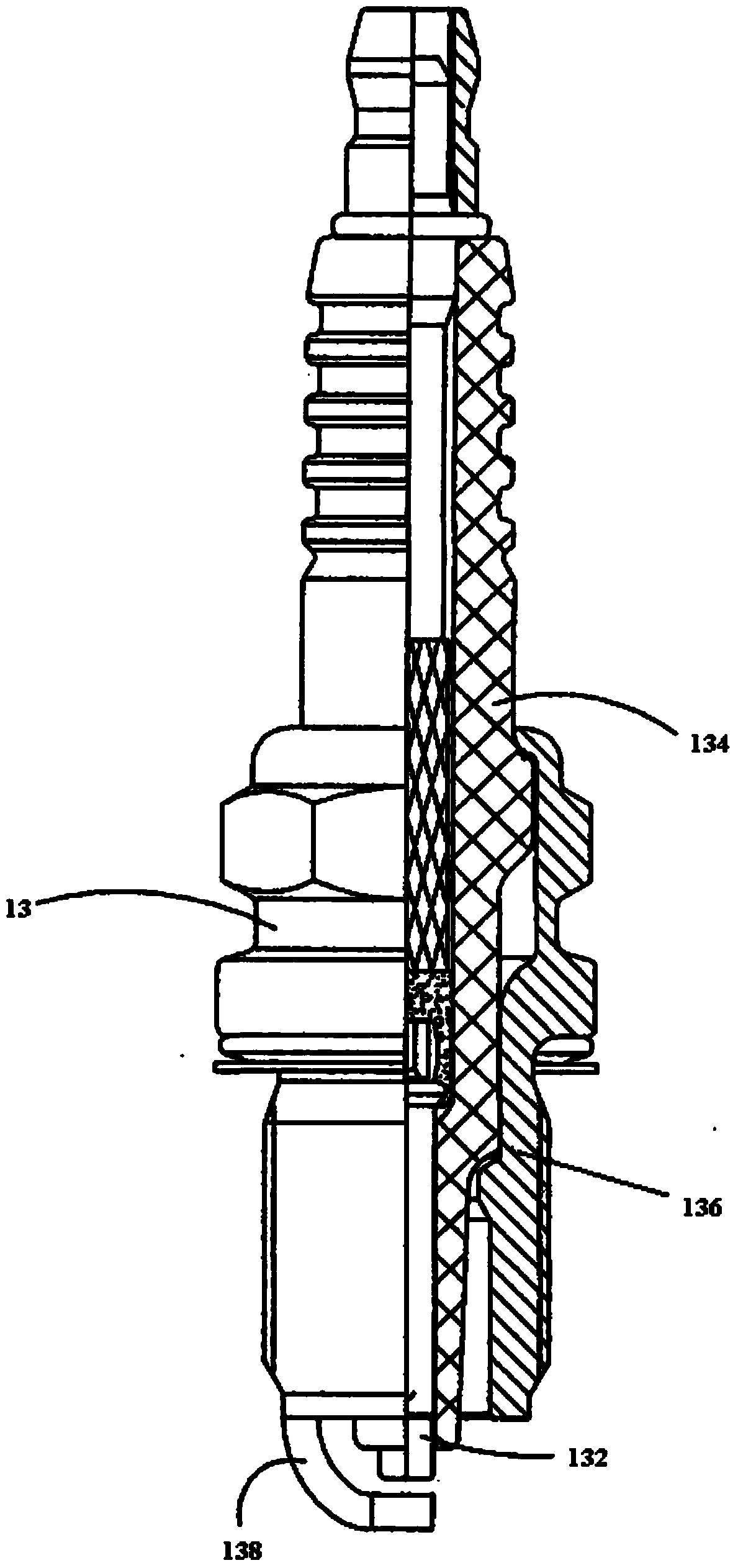

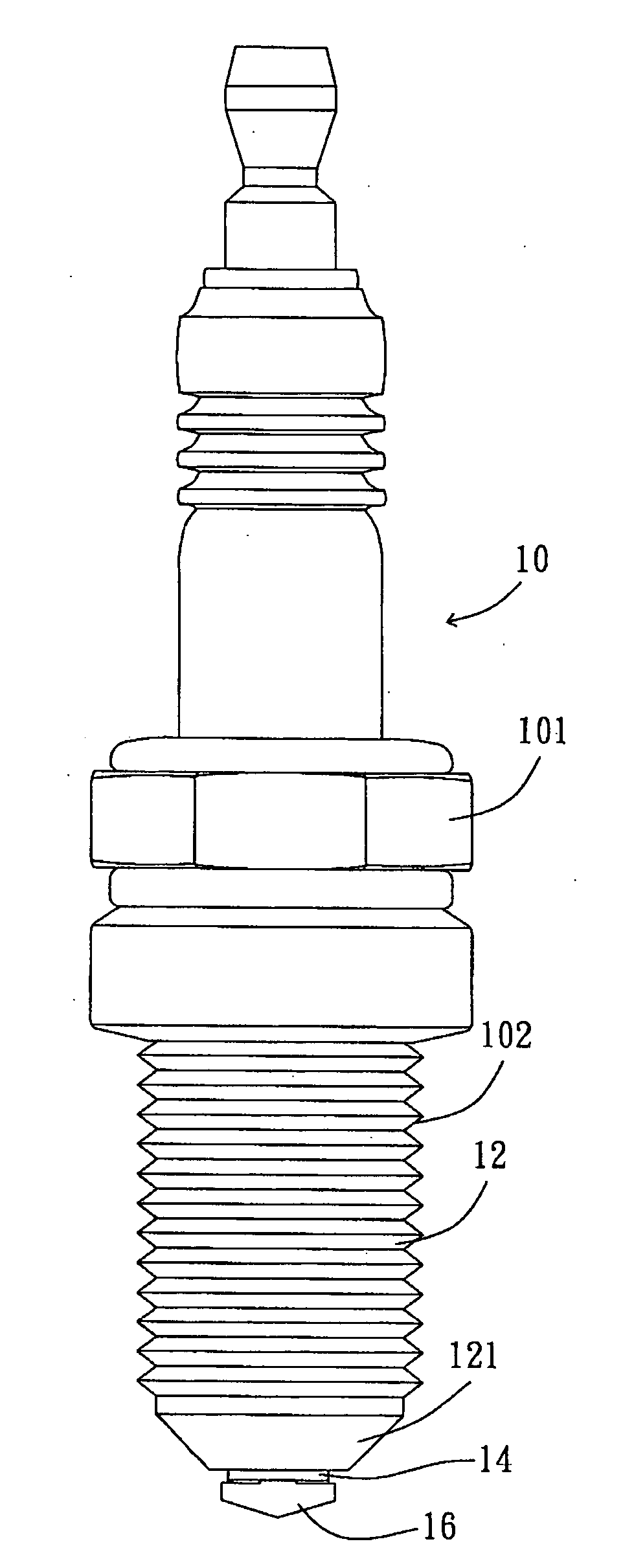

Spark plug

InactiveUS20070052336A1Extend your lifeIgniting spark discharges more efficientlySparking plugsFuel efficiencyEngineering

A spark plug provided to ignite fire and generate power for an engine, comprises an outer layer with an inner cavity and a ceramics insulator enclosing a central electrode inside the inner cavity. A gap is located between the ceramics insulator and the housing. The central electrode has a body and a head. One end of the body radically extends and forms a tip. The present invention improves ignition and fuel efficiency, thereby reducing air pollution.

Owner:VITAL TECH APPL COMPANY

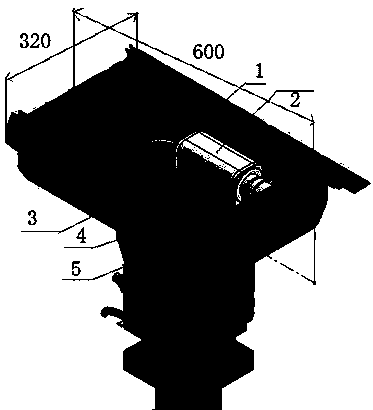

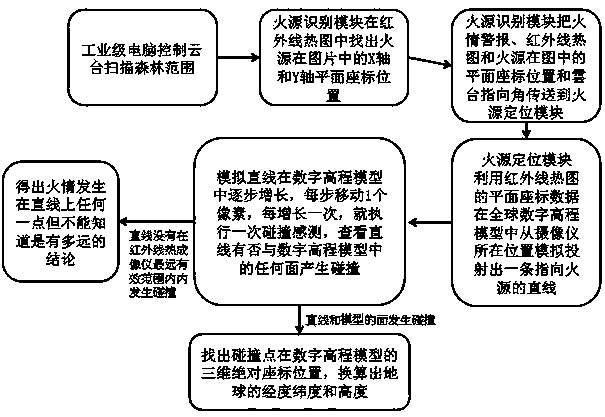

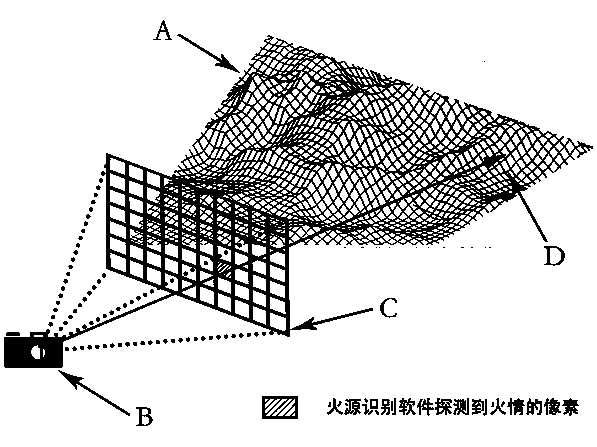

Forest fire positioning method and device based on two-dimensional images

ActiveCN103400463AImprove ignition efficiencyReduce construction costsClimate change adaptationCharacter and pattern recognitionFire hazardMeteorology

The invention relates to the fields of forest fireproof monitoring and field environment monitoring technology, in particular to a forest fire positioning method and a forest fire positioning device based on two-dimensional images. The positioning method comprises that an image collector acquires position information, a fire source identification module identifies fire behavior information from the position information and transmits the fire behavior information to a rear-end processor, and a fire behavior positioning module in the rear-end processor locates the position of the fire source. The method and device of the invention can accurately locate a forest fire hazard with the error no more than + / -50m in the range of 5km, thereby providing accurate and timely information for forest fireproof management staff, and improving fire-fighting efficiency. Compared with a parallax positioning method requiring two infrared thermal imagers, the method and device of the invention can carry out accurate positioning with only one infrared thermal imager, thereby greatly reducing construction cost of a forest fire hazard monitoring system. The positioning method runs automatically, and can accurately position a forest fire within seconds needless of human assistance.

Owner:GUANGDONG ACAD OF FORESTRY +1

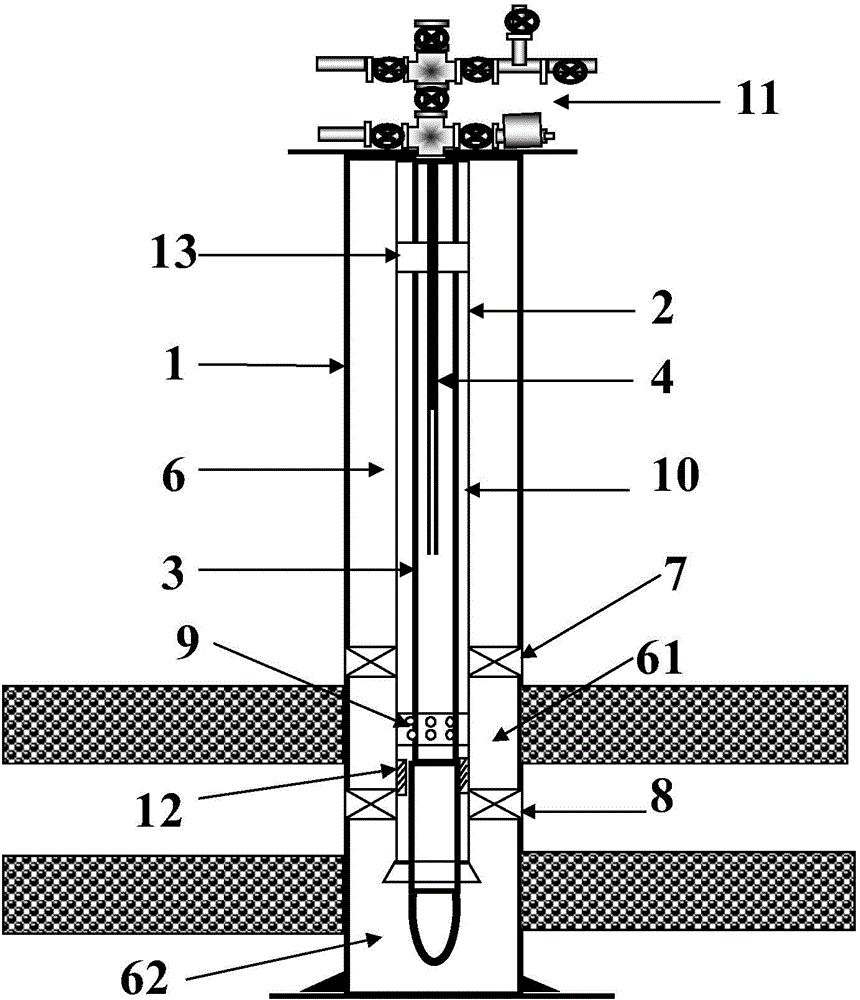

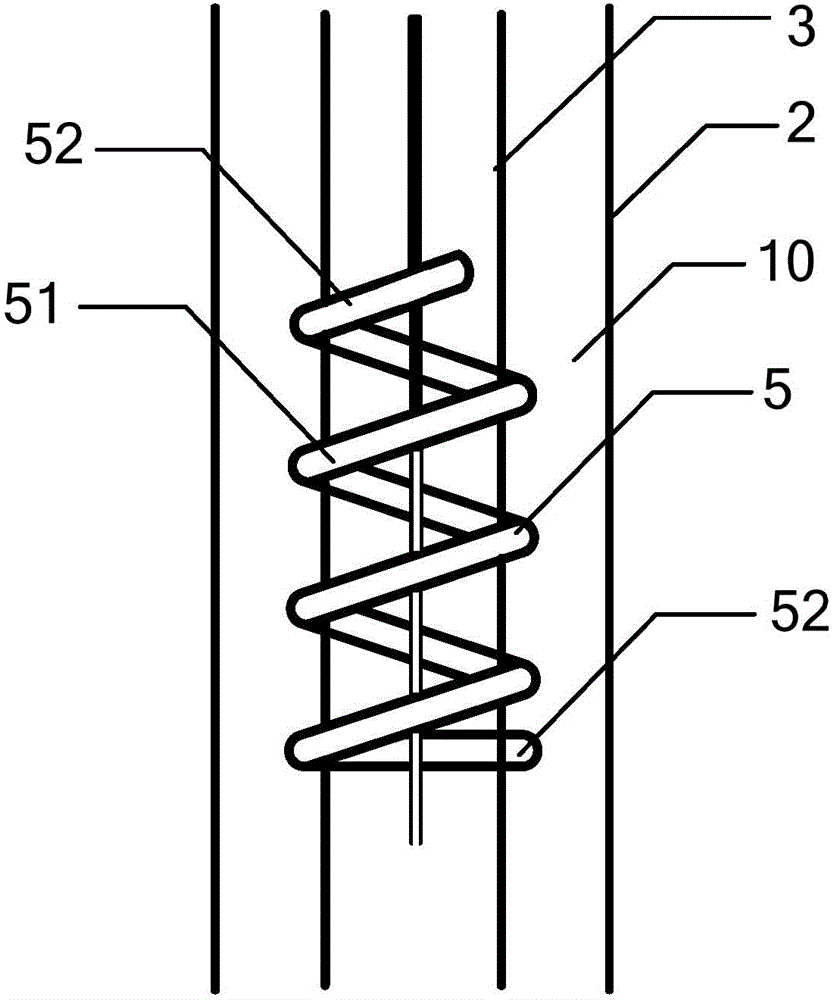

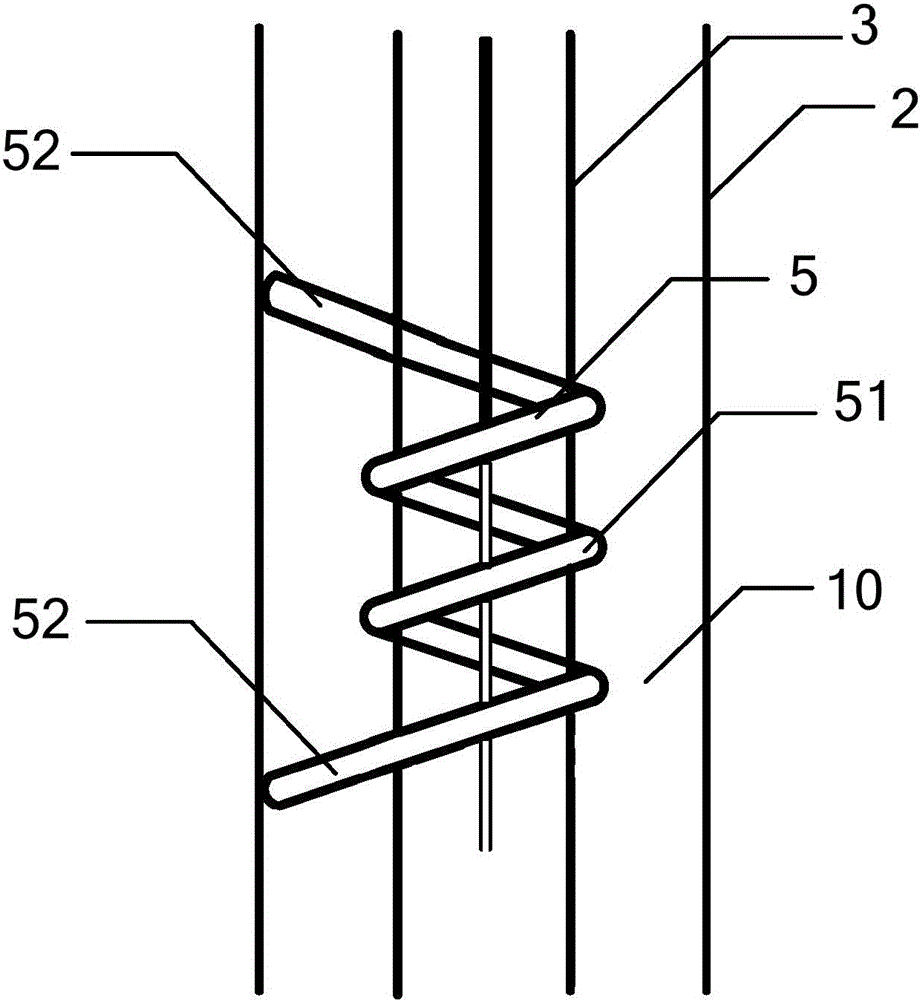

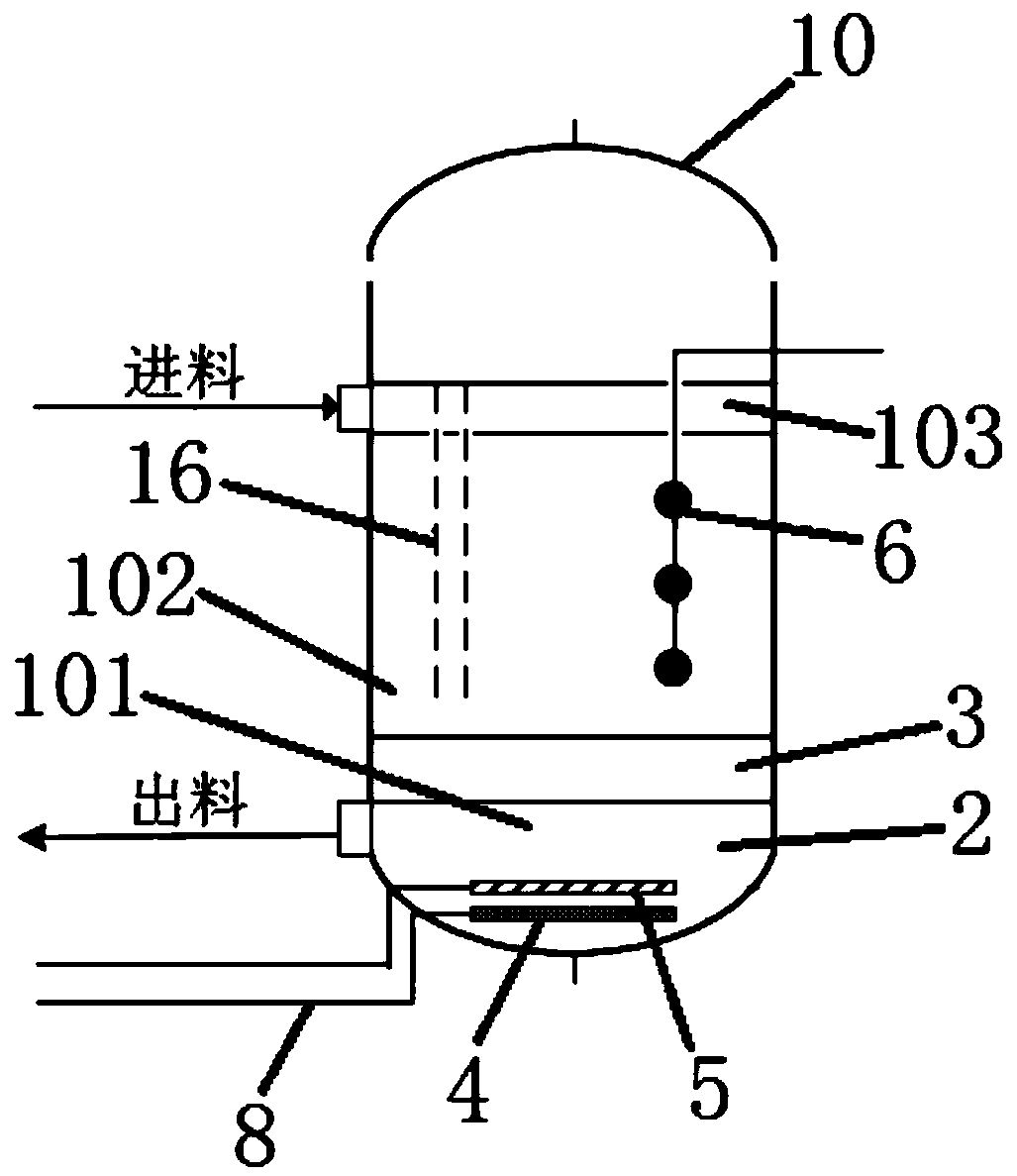

In-situ combustion layered ignition method

ActiveCN104453821AImprove power efficiencyImprove ignition efficiencyFluid removalCombustionThermal insulation

The invention provides an in-situ combustion layered ignition method. The method includes the steps that a casing pipe is landed into an oil well and extends to the well bottom; a thermal insulation pipe is landed into the casing pipe and a first annular space is formed between the thermal insulation pipe and the casing pipe; the first annular space is sealed through a first packer and a second packer, so that an upper-layer gas injection space and a lower-layer gas injection space are formed; an upper-layer gas distribution device located in the upper-layer gas injection space is arranged on the thermal insulation pipe; a Pupin oil pipe is landed into the thermal insulation pipe, a second annular space is formed between the Pupin oil pipe and the thermal insulation pipe, and an enhanced heat transfer device is arranged in the second annular space; an electric ignition device is landed in an inner cavity of the Pupin oil pipe; air is injected in the inner cavity and the second annular space and nitrogen is injected into the first annular space; the electric ignition device is started; heated gas in the thermal insulation pipe is injected into the upper-layer gas injection space through the upper-layer gas distribution device and an upper oil layer is heated and ignited; heated gas in the Pupin oil pipe is injected into the lower-layer gas injection space through the tail end of the Pupin oil pipe and a lower oil layer is heated and ignited.

Owner:PETROCHINA CO LTD

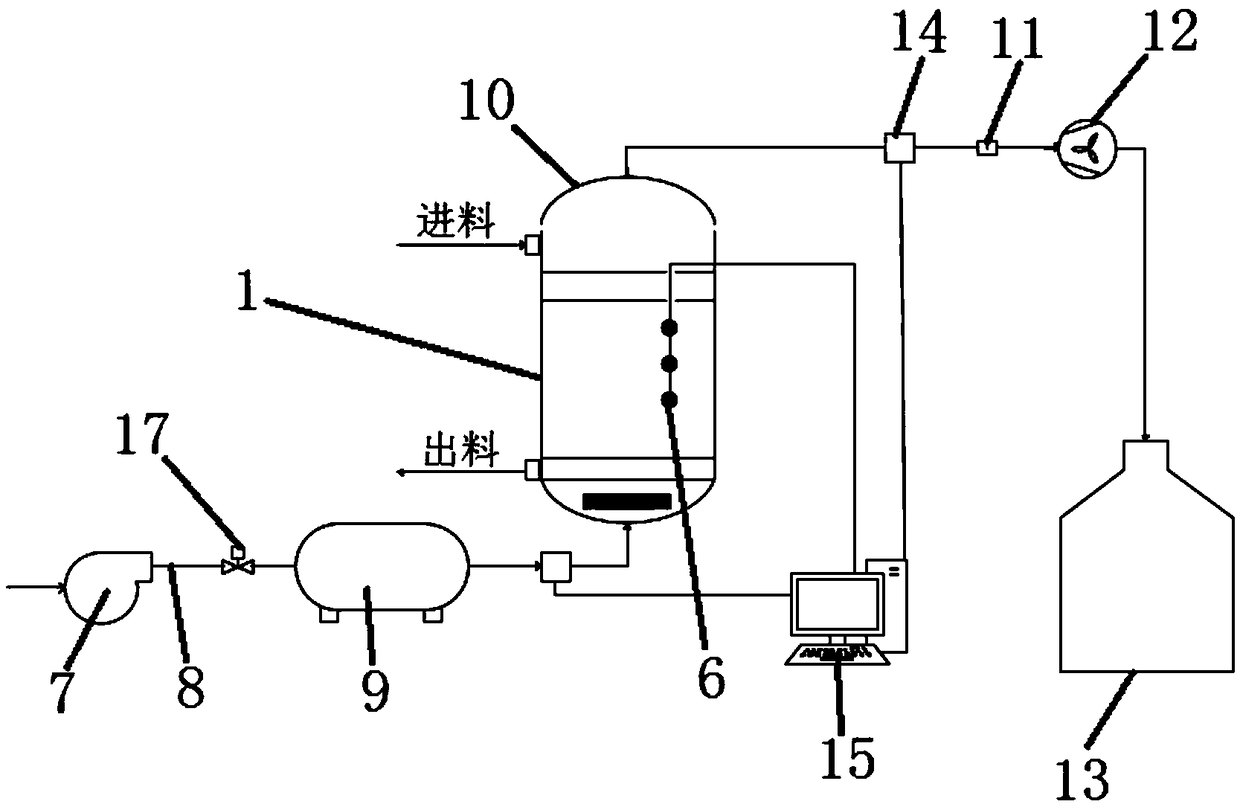

Heterotopic flameless burning treatment apparatus and method for oily sludge

InactiveCN108916889AStringent requirements for viscosity reductionAvoid direct contactIndirect carbon-dioxide mitigationIncinerator apparatusElectricityBurn treatment

The invention relates to a heterotopic flameless burning treatment apparatus and method for oily sludge. The apparatus herein comprises a reaction system, an air injection system communicated with thereaction system, a tail gas treatment system fitting the top of the reaction system, and a monitoring adjusting system electrically connected with the reaction system, the air injection system and the tail gas treatment system. In treatment, oily sludge is placed in a reaction zone; the air injection system introduces air into an ignition startup zone; an ignitor is used to ignite the oily sludge; the monitoring adjusting system adjusts air introduction into the ignition startup zone through the air injection system according to temperature data measured by a temperature monitoring mechanism;post-reaction tail gas is collected by the tail gas treatment system and discharged. Compared with the prior art, the apparatus and method have high ignition efficiency and oily sludge treating capacity, low energy consumption, good control convenience and good flexibility.

Owner:YONKER ENVIRONMENTAL PROTECTION +1

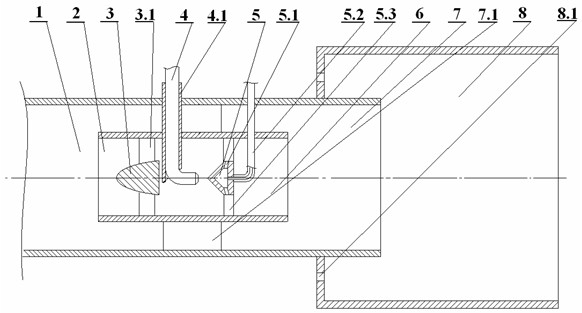

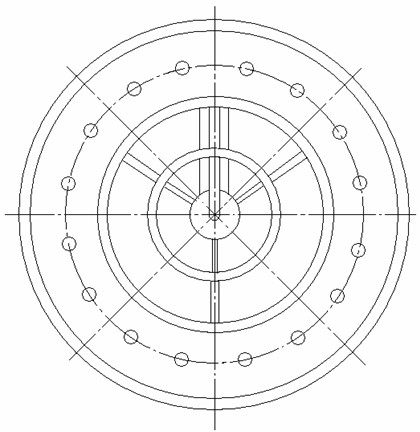

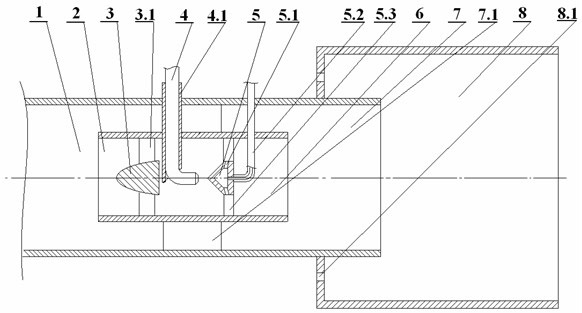

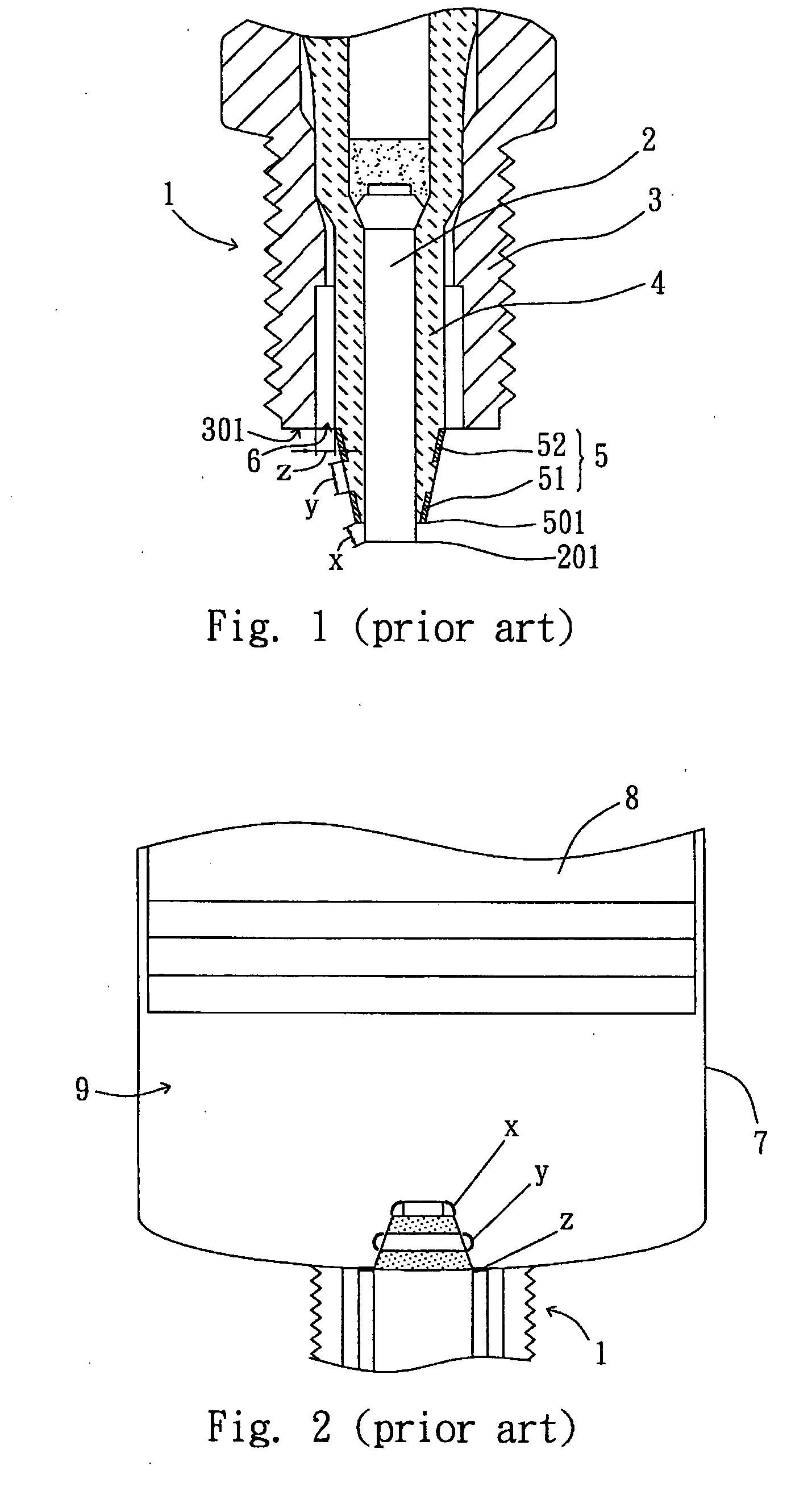

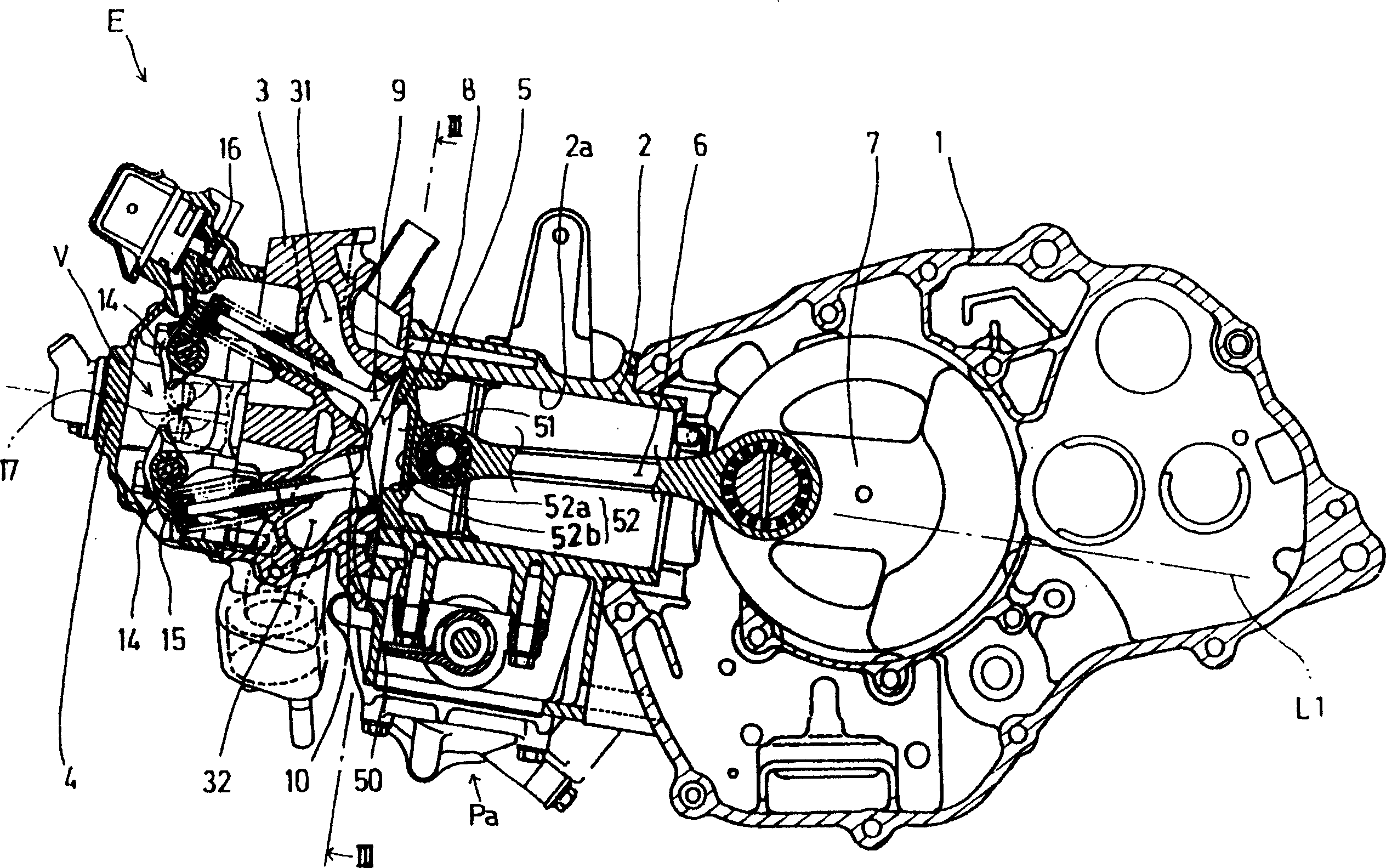

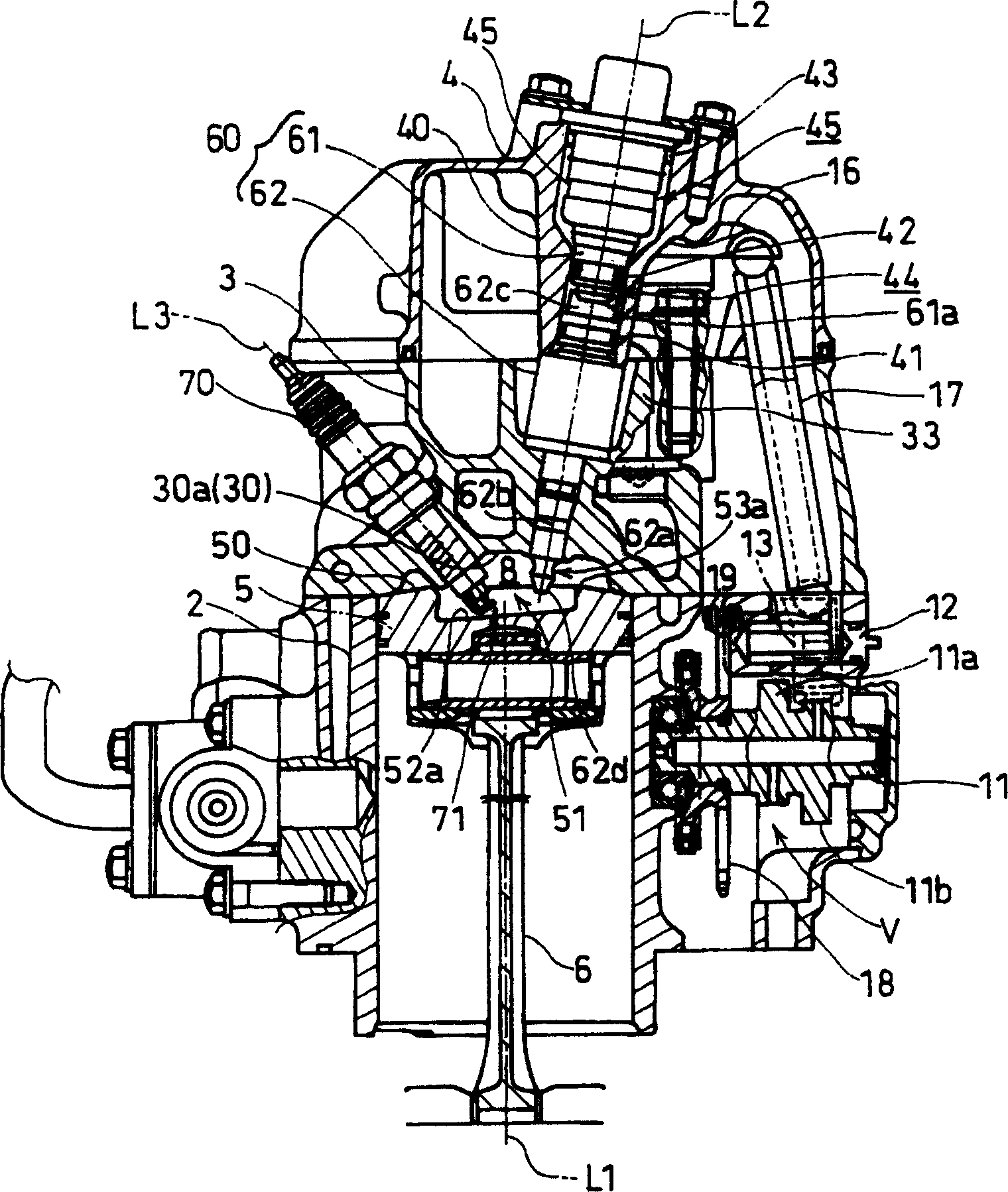

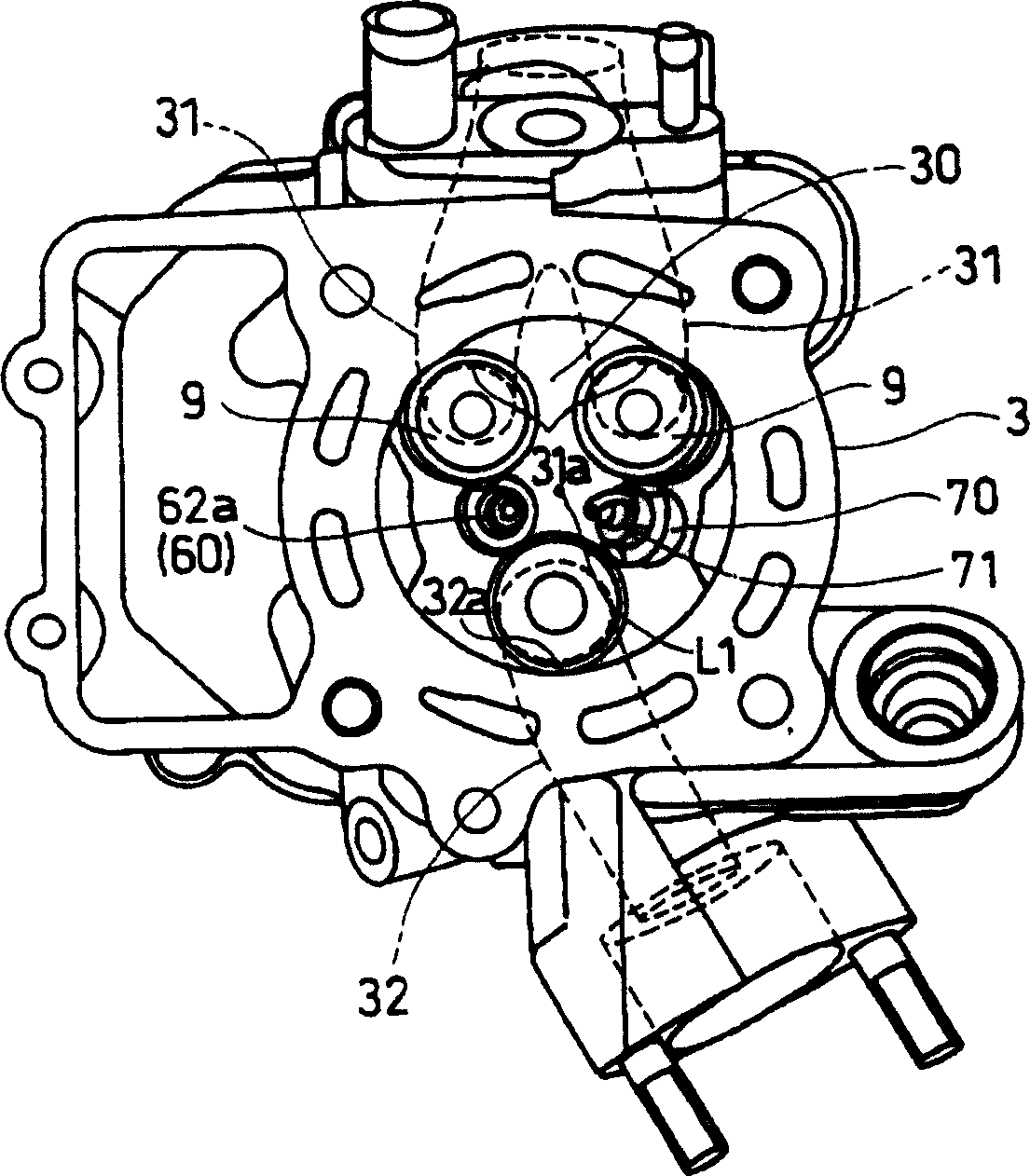

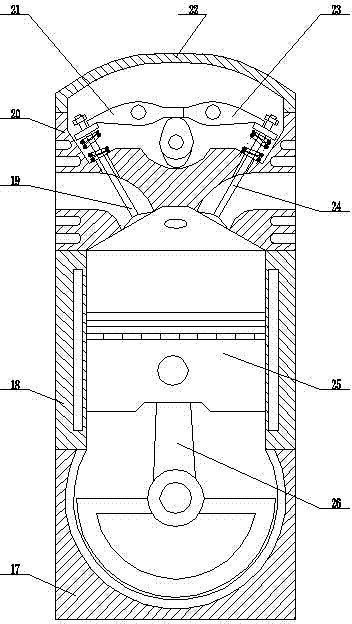

In cylinder fuel oil jet type IC engine

InactiveCN1590729AReliable ignitionImprove ignition performanceInternal combustion piston enginesHigh pressure gas fuel injectionCombustion chamberExhaust valve

PROBLEM TO BE SOLVED: To provide a cylinder injection internal combustion engine with excellent ignitability for improving combustion efficiency and improving fuel consumption without enlarging a cavity, by separating a tip firing part of an ignition plug from a jet flow of a fuel injection valve and bringing the tip firing part close to a center axis of the cavity. ŽSOLUTION: In the cylinder injection internal combustion engine, a combustion chamber 8 is formed between a piston 5 in which the cavity 51 is formed in a top surface thereof and a cylinder head 3, and a lower wall surface of the cylinder head 3 is a ceiling surface of the combustion chamber 8. A plurality of intake and exhaust valves, the fuel injection valve 60, an ignition plug 70 are disposed to face the combustion chamber 8. The ignition plug 70 is inserted from a side surface of the cylinder head 3 toward the combustion chamber 8, and the tip firing part 71 thereof is inclined with respect to the cylinder axis L1 and approximated to the center axis L1. The fuel injection valve 60 is inserted from an upper surface of the cylinder head 3 toward the combustion chamber 8 and inclined on a side approximately opposite to the ignition plug 70 with respect to the cylinder axis L1, and a tip nozzle 62a thereof is separated in an inclination direction from the center axis L1 of the cavity 51. Ž

Owner:HONDA MOTOR CO LTD +1

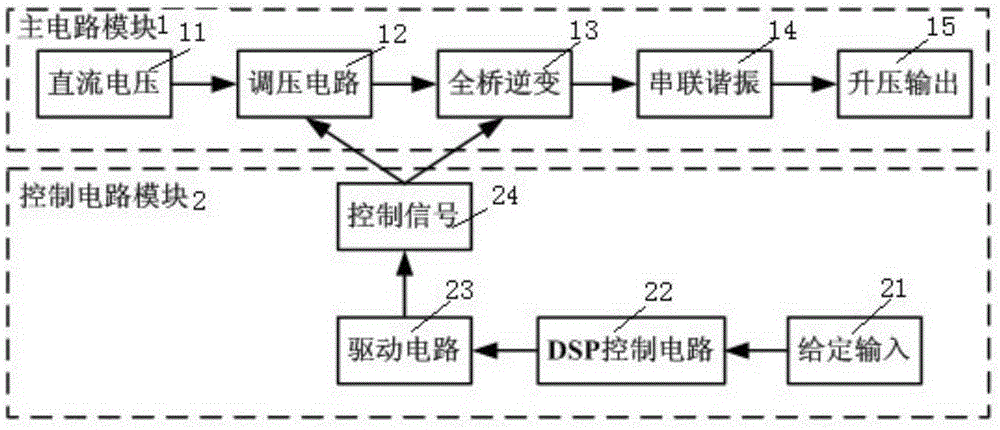

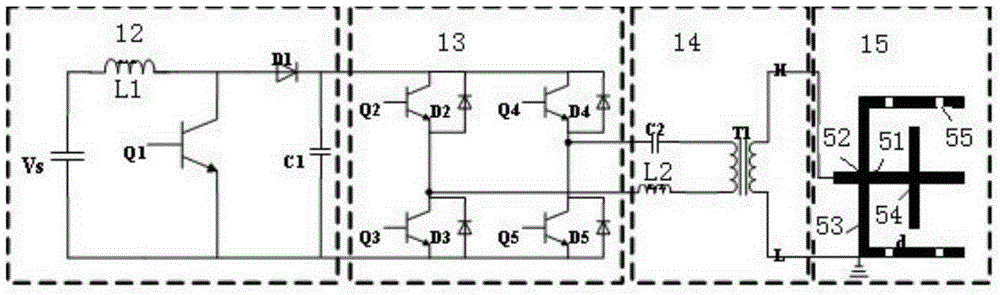

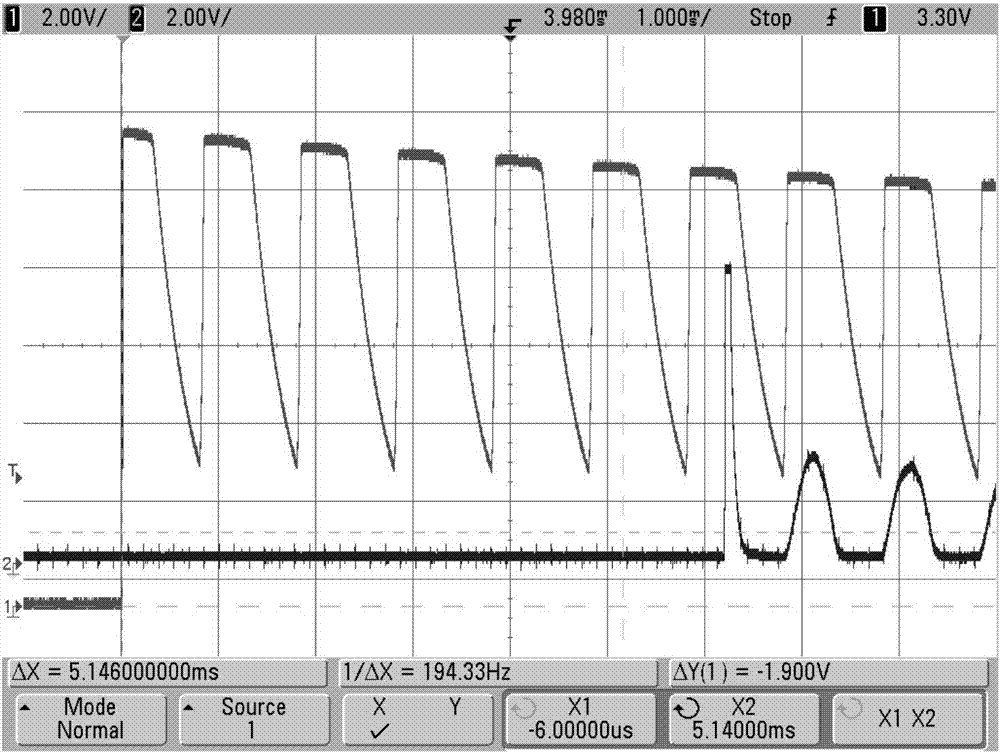

Low-temperature-plasma ignition power supply and ignition system

ActiveCN105201657AMeet ignition requirementsShorter ignition delay timeGas turbine plantsRocket engine plantsDigital signal processingOn board

The invention discloses a low-temperature-plasma ignition power supply. The low-temperature-plasma ignition power supply comprises a main circuit module and a control circuit module, wherein the main circuit module comprises a direct-current power supply, a voltage regulating circuit, a full-bridge inverter circuit, a series resonance circuit and a step-up output circuit which are sequentially connected, and the control circuit module comprises a given input control, a DSP (Digital Signal Processing) control circuit, a driving circuit and a control signal which are sequentially connected and is used for supplying control signals to a voltage regulating circuit switch and a full-bridge inversion switch in the main circuit module. A low-temperature-plasma ignition system is further disclosed and consists of the low-temperature-plasma ignition power supply and a boss discharge load. According to the power supply and the system, the low-temperature-plasma ignition power supply can generate low-temperature plasma according to certain frequency and pulse width; the energy consumption is low; the efficiency of ignition is high; laboratory power supplies are wide in parameter range and are adjustable; on-board power supplies are fixed in parameters; the size is small; the reliability is high, and thus the requirement of an engine for ignition is met.

Owner:PEKING UNIV

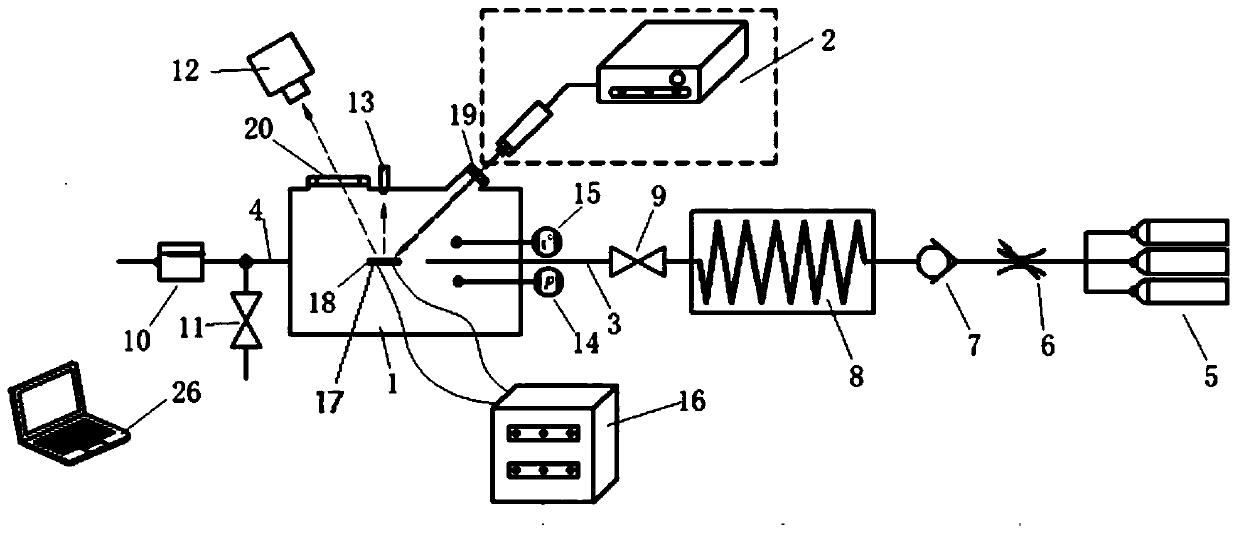

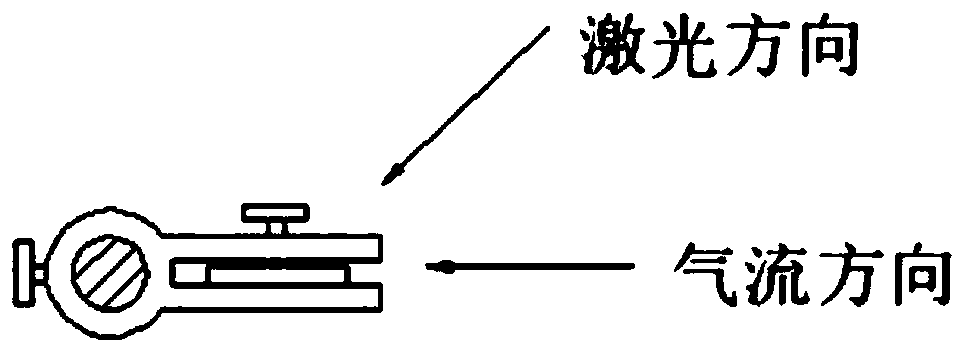

Titanium alloy combustion test device and test method thereof

InactiveCN110161175AImprove stabilityEasy to operateChemical analysis using combustionAviationCombustion chamber

The invention belongs to the technical field of aviation engines, and relates to a titanium alloy combustion test device and a test method thereof. The test device includes a combustion chamber, a fiber laser, a gas supply pipe, an exhaust pipe, a gas cylinder set, a mass flow controller, a check valve, a gas heater, an intake valve, a pressure control valve, an exhaust valve, a camera, and an infrared temperature sensor, a pressure sensor, a thermocouples, a sample heating device, a sample holder, a computer and the like. The gas cylinder set is used as a gas source, the gas heater heats thegas, the mass flow controller and the pressure control valve control the pressure in the combustion chamber, the sample heating device heats a sample, the fiber laser ignites the sample, a titanium alloy material / component combustion test with simulation conditions of a gas temperature to be 500 to 600 DEG C, the pressure to be 1.0 to 1.5 MPa and the sample temperature to be 600 to 900 DEG C can be realized, a computer program is adopted to control the test parameters such as the ignition time, and the test precision is higher. The test device has a compact structure, the mounting is convenient, the test cost is low, the urgent needs for aircraft engine titanium alloy combustion characteristic evaluation at preset and in the future can be met, and the application prospect is wide.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

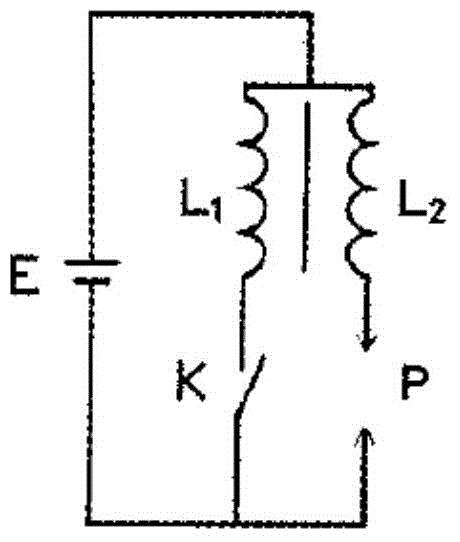

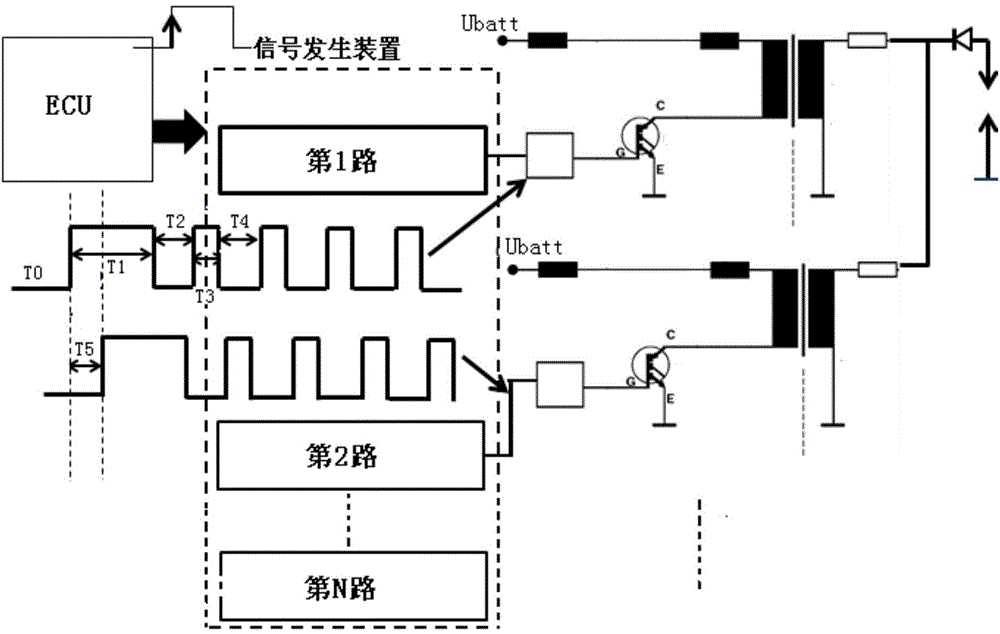

Engine ignition system and method

InactiveCN104564479AIncrease power outputBurn fullyIgnition automatic controlInstallations with induction energy storageControl signalIgnition coil

The invention discloses an engine ignition system. Multiple ignition coils are mounted in a same cylinder of an engine; a primary coil winding loop of each ignition coil is parallelly connected between a vehicular power supply and the ground, and a primary coil winding loop is parallelly connected between a high-voltage ignition end of a sparking plug of the cylinder and the ground; when receiving an ignition trigger signal, sent from an engine control unit, of the cylinder, a signal generator outputs multiple channels of ignition coil control signals for respectively controlling the ignition coils of the cylinder to start igniting successively. The invention further discloses an engine ignition method. By the engine ignition system and method, fire probability can be lowered, mixed gas in the cylinder is combusted more fully, igniting efficiency is increased, and power output of the engine is enhanced.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

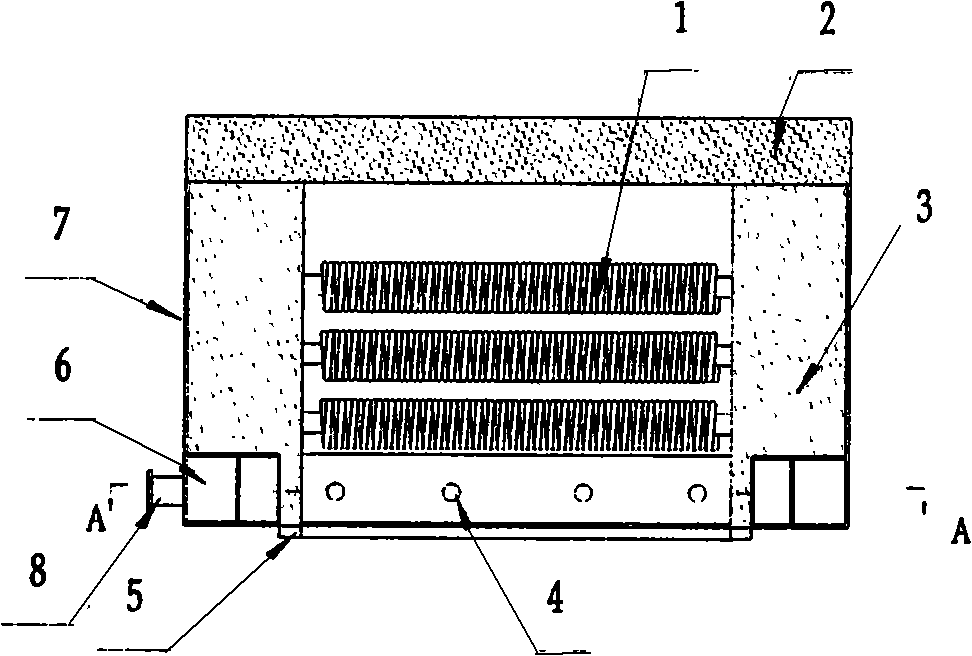

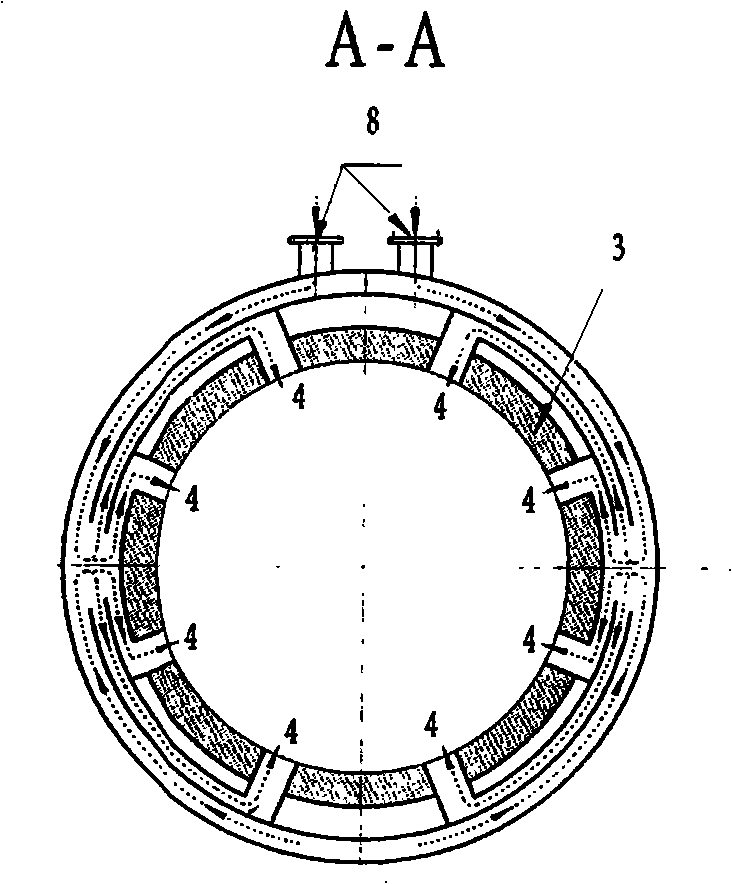

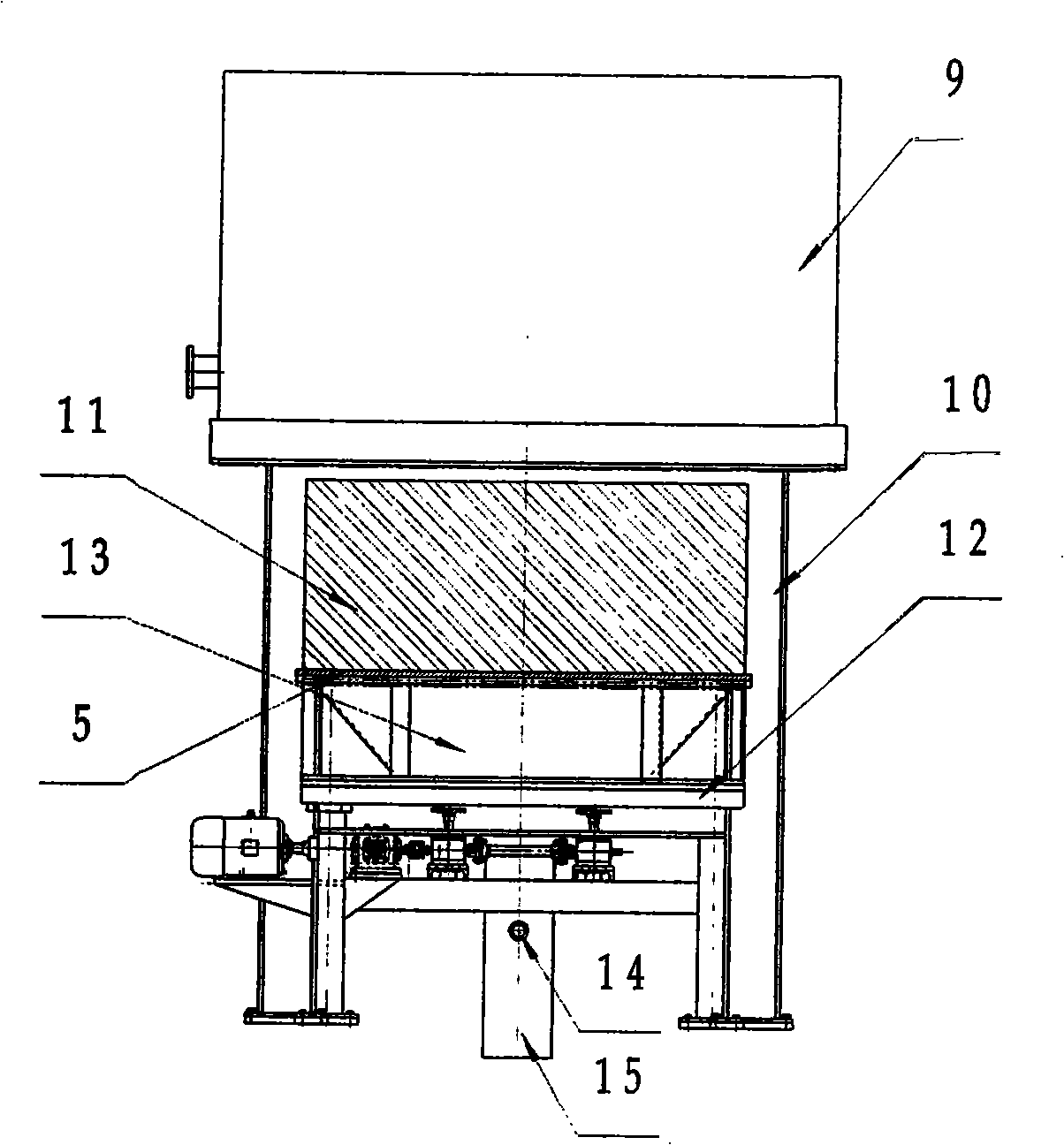

Heat-storing combustion apparatus and biomass gas heating system

ActiveCN102012029AExtended service lifeImprove ignition efficiencyIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorEngineering

The invention discloses a heat-storing combustion apparatus and a biomass gas heating system, which comprises a heat storage chamber and combustor bodies, wherein a plurality of heat storage body processing holes are arranged in the heat storage chamber; combustor nozzle holes are arranged between the plurality of heat storage body processing holes; the heat storage body processing holes and the combustor nozzle holes are radially separated rather than communicated; ceramic heat storage bodies are placed in the heat storage body processing holes; the combustor bodies are placed in the combustor nozzle holes; and external combustion-supporting medium is heated by the heat storage bodies and mixed with a biomass flammable gas entering from the combustor nozzle holes at the end of the heat-storing combustion apparatus, so that the biomass flammable gas can combust. In the invention, the high-temperature combustion product and low-temperature combustion-supporting medium perform indirect heat exchange through the heat storage bodies in turn, so the utilization rate of combustion gas heat is improved and the combustion stability of the combustion gas is ensured.

Owner:GUANGZHOU DEVOTION THERMAL TECH

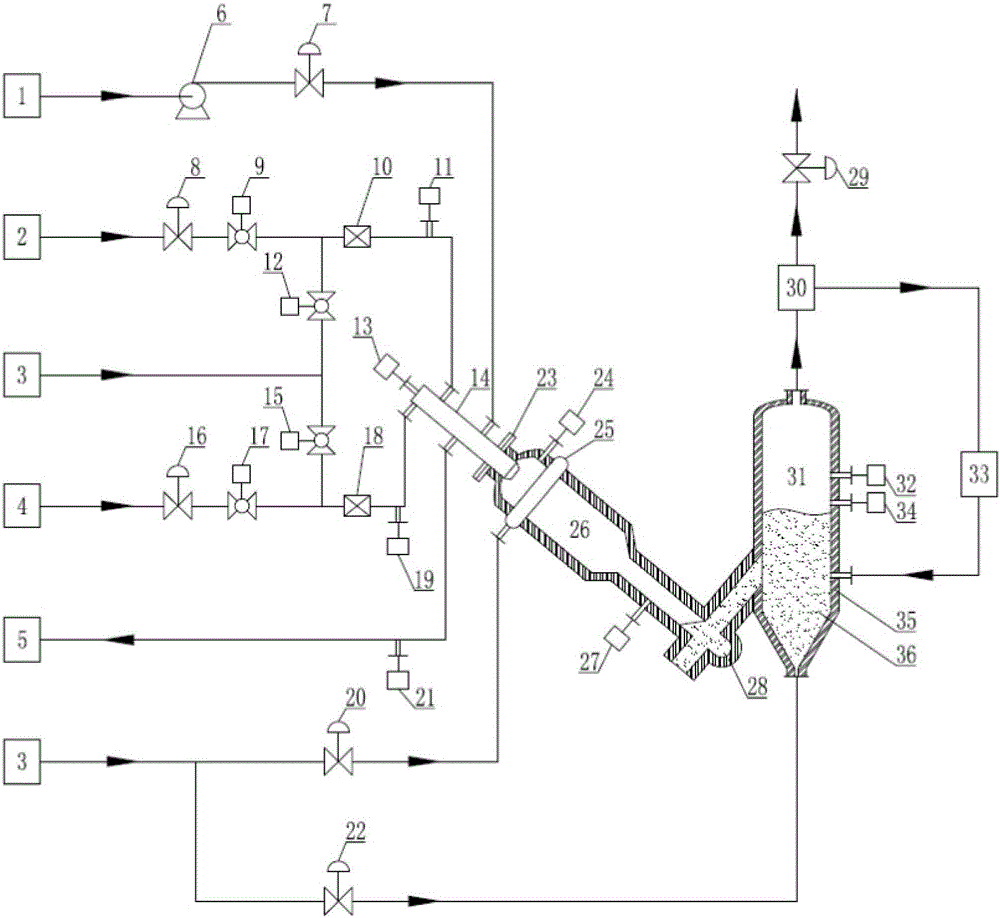

Pressurization and ignition device and method

ActiveCN106051820AMeet the process requirementsStability is not affectedCombustion ignitionGranular/pulverulent flues gasificationCombustible gasSolid particle

The invention discloses a pressurization and ignition device and method. The ignition device comprises a burner, a rectification furnace and a reaction furnace. The burner is connected with the rectification furnace through a flange. The rectification furnace is connected with the reaction furnace through a tee joint. The rectification furnace is provided with an annular air distribution pipe. The reaction furnace is internally filled with solid particles in advance. According to the pressurization and ignition device and method, on one hand, a certain pressure and solid material cycle is established for a system, and the phenomena of fluctuation of system parameters and nonuniform temperature distribution of the reaction furnace are avoided; and on the other hand, by calibrating action of an adjustment valve, the purpose of precisely controlling the mixing ratio of natural gas to air required in the ignition process is achieved, ignition efficiency is improved, and meanwhile, by means of the tee joint, excessive combustible gas can be prevented from entering the rectification furnace and the reaction furnace.

Owner:SHAANXI YANCHANG PETROLEUM GRP

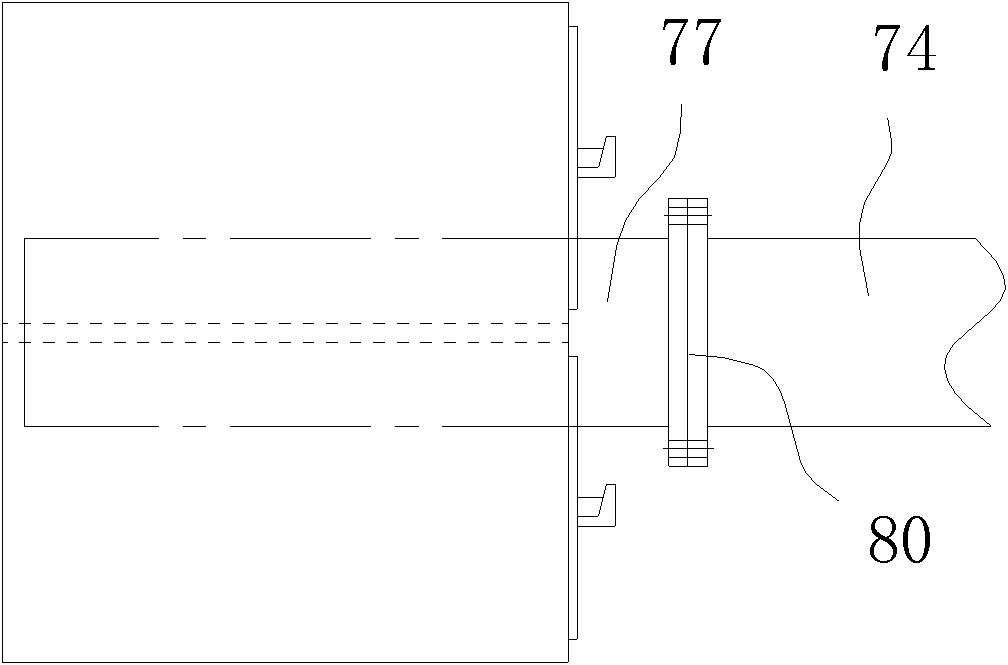

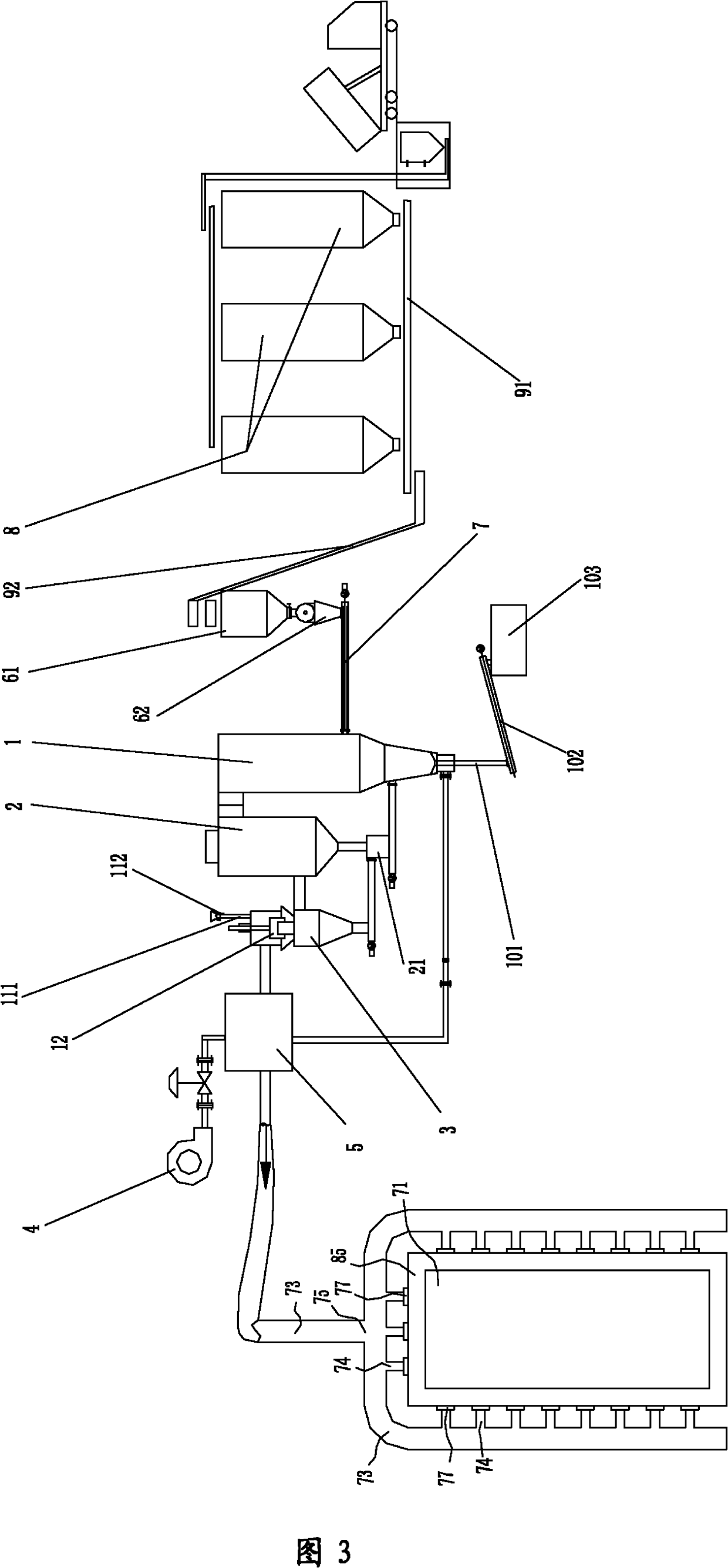

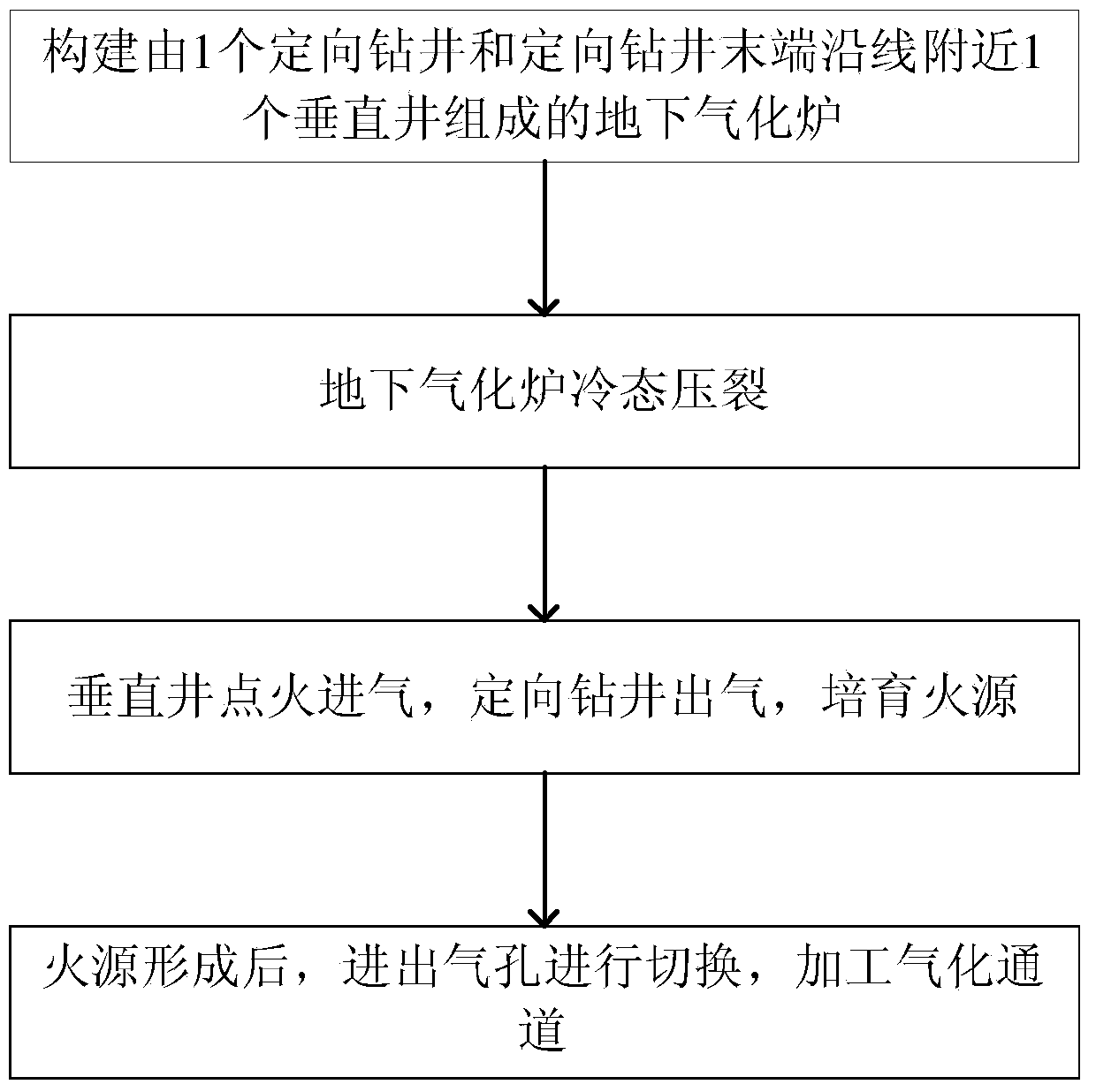

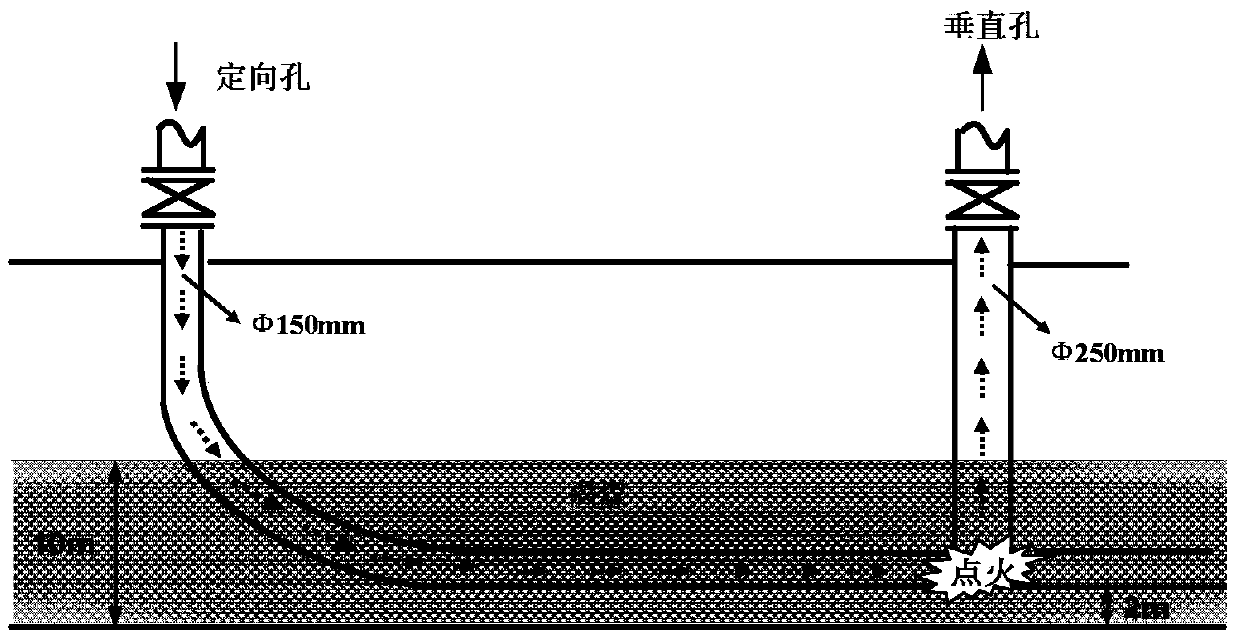

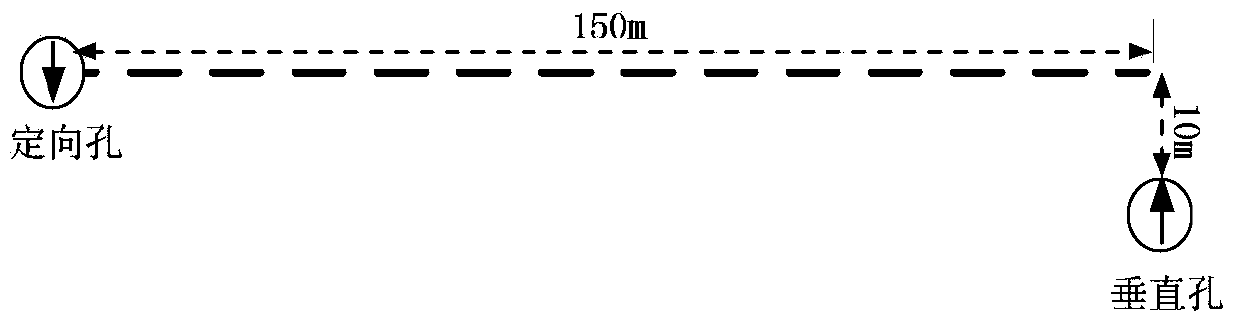

Underground gasification ignition method

InactiveCN103726818AImprove ignition efficiencyFast penetrationConstructionsFluid removalEngineeringCoal

The invention discloses an underground gasification ignition method. The method includes the steps: building a directional drilled well and a vertical well to construct an underground gasifier; pre-driving a coal seam by means of cold fracturing; igniting in the vertical well at the tail end of the directional drilled well. The method has the advantages that ignition efficiency is high and driving speed is high.

Owner:ENN SCI & TECH DEV

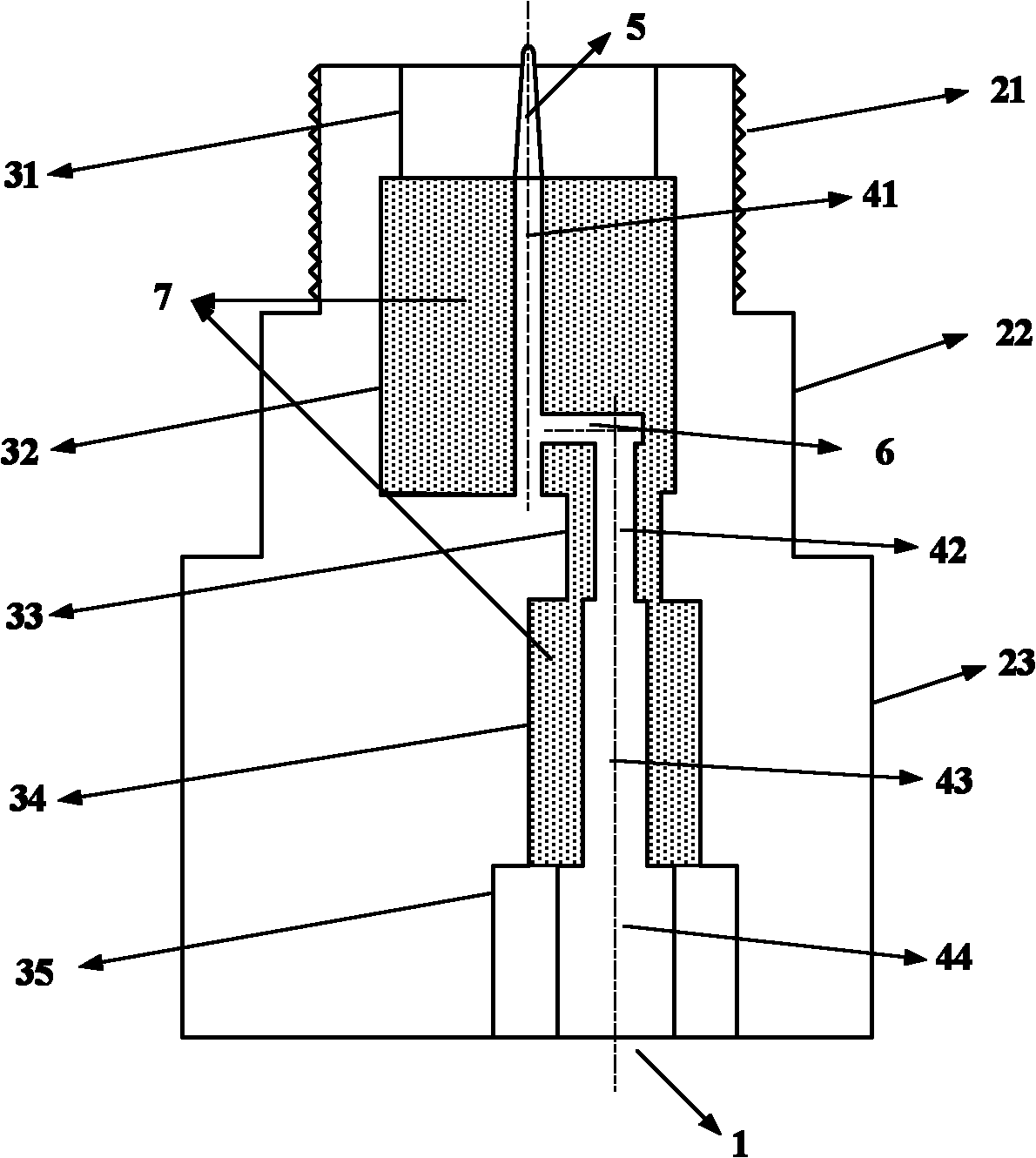

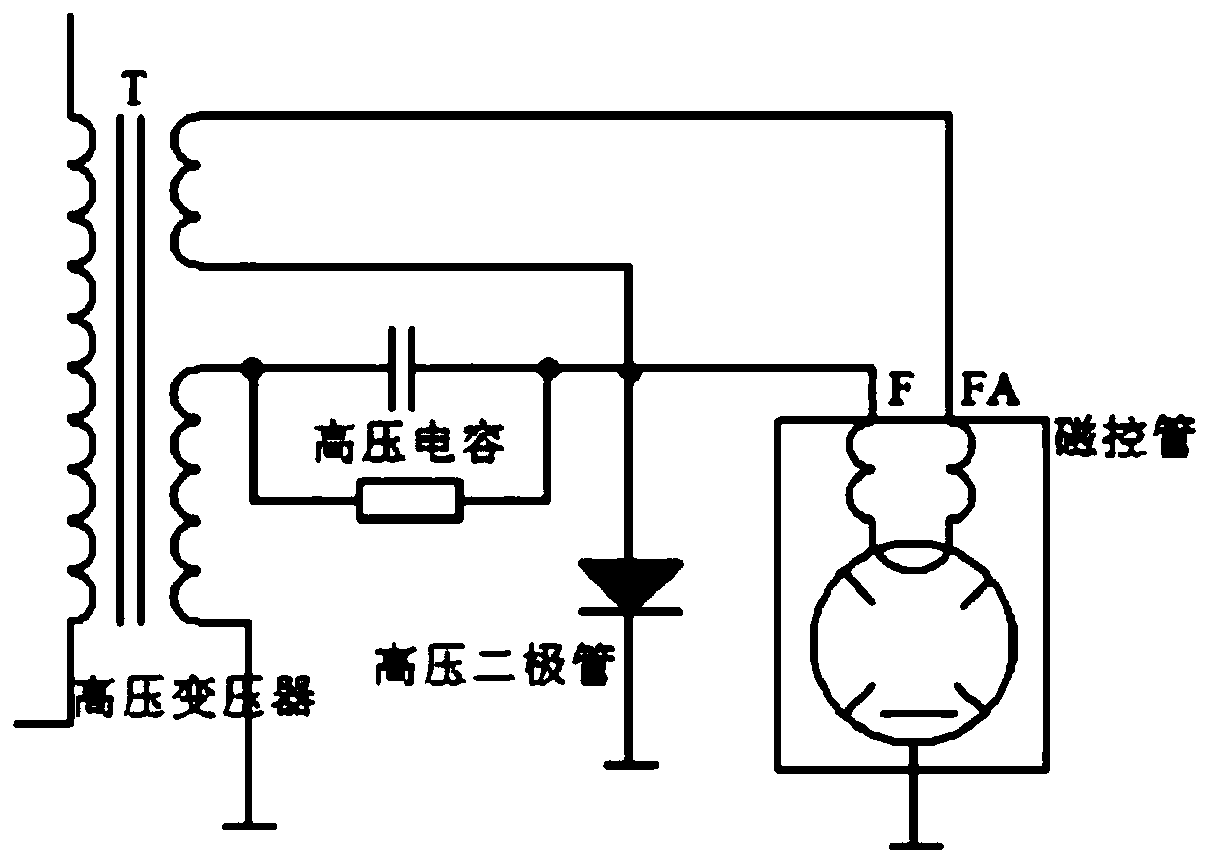

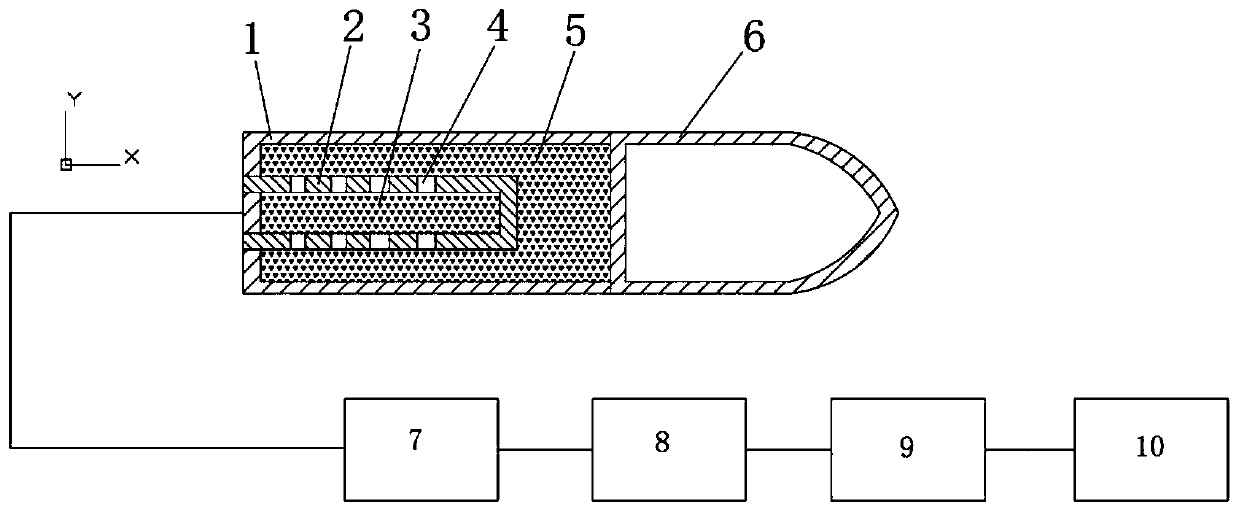

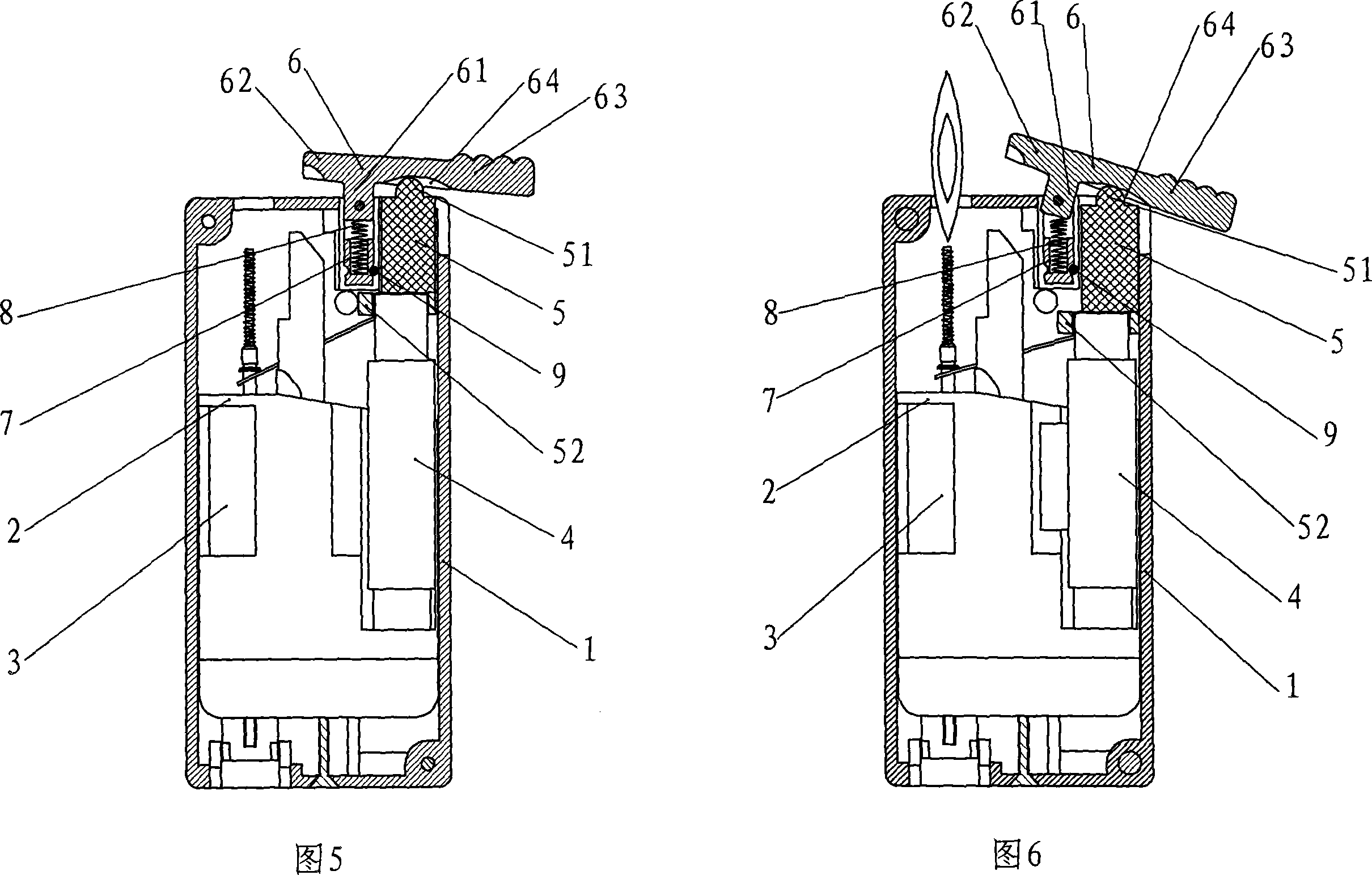

Ignition powder igniting device

ActiveCN110595304AImprove ignition efficiencyBurn fullyAmmunition fuzesPlasma techniqueResonant cavityMicrowave

The invention discloses an ignition powder igniting device. The ignition powder igniting device comprises a microwave source power supply, a magnetron, a resonant cavity, a waveguide pipe, a coaxial resonant cavity, a resonant cavity inner conductor, ignition powder and gunpowder, wherein the microwave source power supply provides a power supply for a built-in circuit of the magnetron, the resonant cavity is arranged outside the magnetron, one end of the waveguide pipe is connected with the resonant cavity, and the other end of the waveguide pipe is connected with the coaxial resonant cavity,the resonant cavity inner conductor is arranged in the coaxial resonant cavity, the resonant cavity inner conductor is filled with the ignition powder, a plurality of through holes are formed in the resonant cavity inner conductor, the arrangement of the through holes correspond to hollow points generated by microwave of the resonant cavity inner conductor, a cavity between the resonant cavity inner conductor and the coaxial resonant cavity is filled with the gunpowder, and the coaxial resonant cavity is provided with an open end for transmitting detonation waves. The ignition powder ignitingdevice can realize efficient, safe and pollution-free and reliable ignition.

Owner:NANJING UNIV OF SCI & TECH

Moxibustion patch automatically firing device

InactiveCN108309781ARealize automatic ignitionThe overall structure is simple and reliableDevices for heating/cooling reflex pointsIncandescent ignitionSupporting systemEngineering

The invention belongs to the technical field of moxibustion and particularly relates to a moxibustion patch automatically firing device. The moxibustion patch automatically firing device comprises a case, a firing tube and a support system arranged inside the case, wherein the support system comprises an adjusting seat and a U-type thermometal snap spring, the lower portion of the thermometal snapring is a fixed end, and the upper portion of the thermometal snap spring is a clamping end; one end of the firing tube is exposed out of the case, and an elastic member and a first insulating ring are arranged between the firing tube and the case; the end surface of the other end of the firing tube is sequentially fixedly provided with an insulating circle and an electric heating wire coiling; the outer wall of the firing tube is provided with a clamping slot, the clamping end of the thermometal snap spring is provided with a clamping protrusion matched with the clamping slot, when the clamping protrusion is clamped in the clamping slot, the electric heating wire coiling is in contact with the thermometal snap spring, and when the clamping protrusion is released from the clamping slot and the firing tube bounces up under the action of the elastic member, the electric heating wire coiling and the thermometal snap spring can be separated; the inside of the case is provided with a wiring board, the positive electrode of the wiring board is electrically connected with the electric heating wire coiling, and the negative electrode of the wiring board is electrically connected with thefiring tube.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

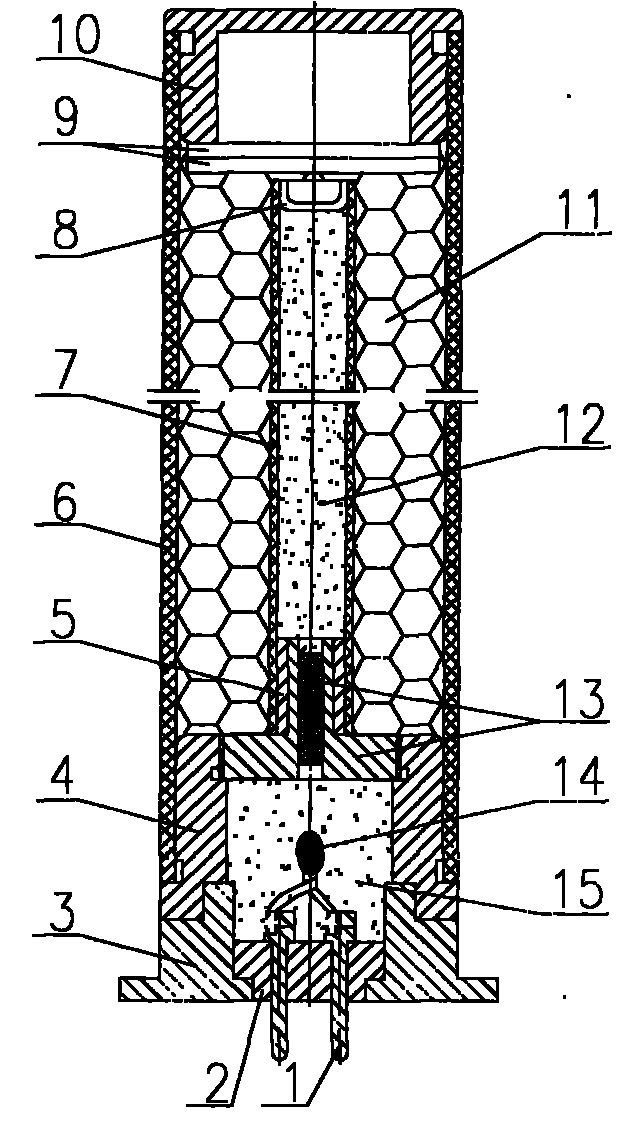

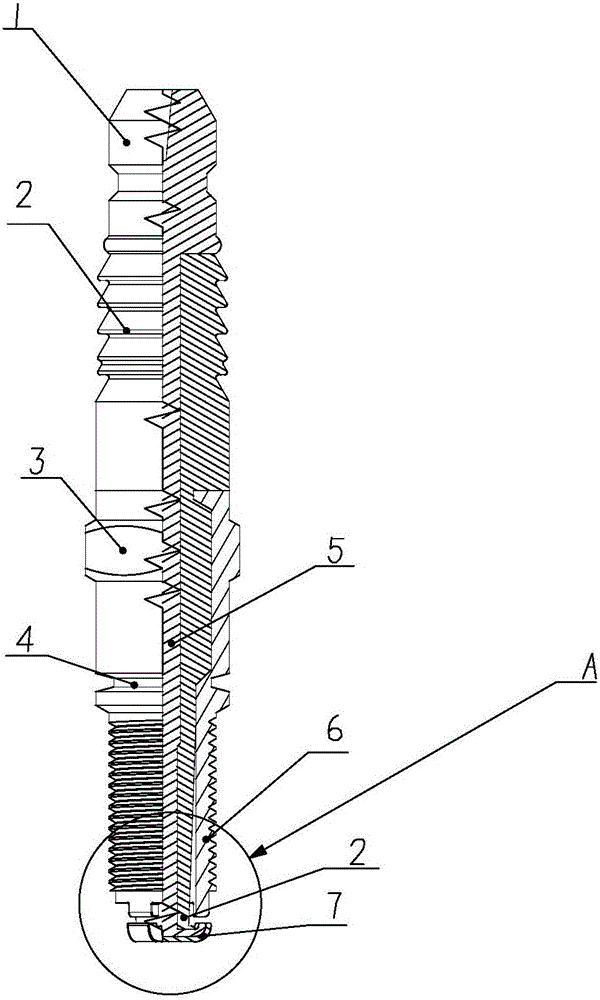

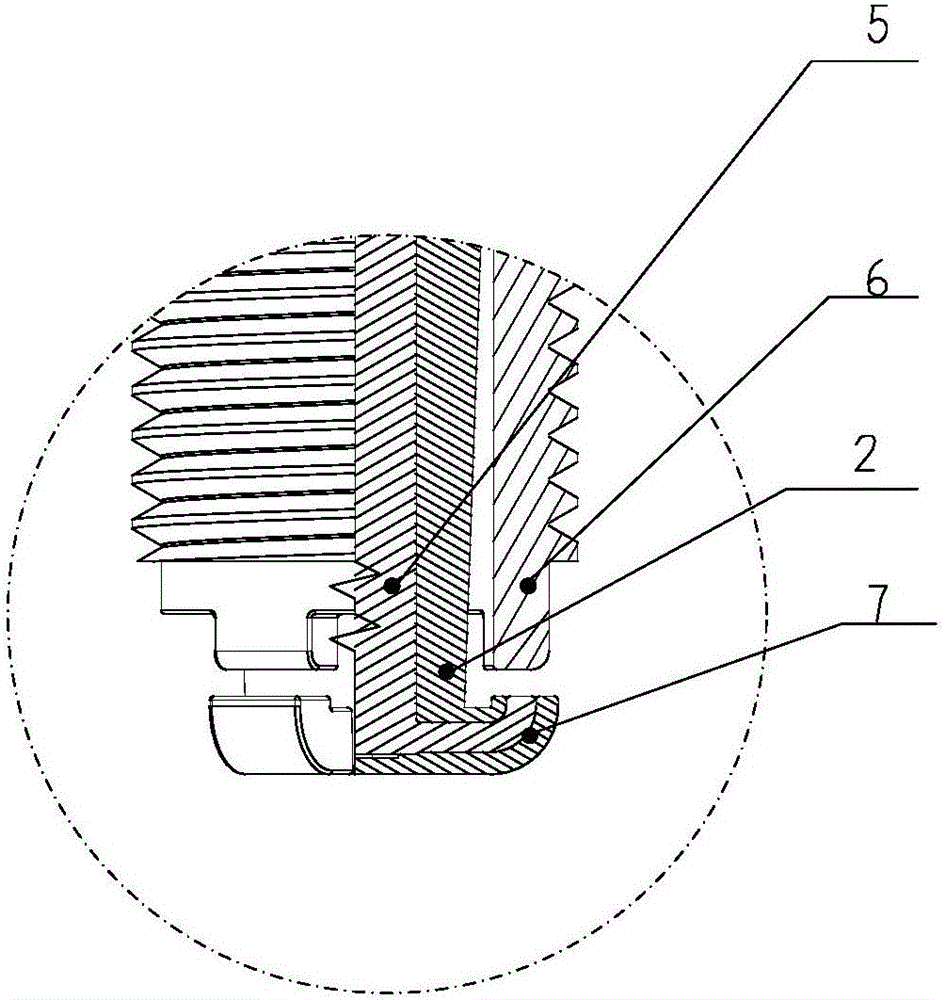

Gas well blowout prevention ignition ball

InactiveCN102003920AImprove securityImprove ignition efficiencyAmmunition projectilesProjectilesEngineeringMechanical engineering

The invention relates to a gas well blowout prevention ignition ball which comprises a plug core (1), an insulation base (2), a base (3), a connecting body (4), a lantern ring (5), a pipe casing (6), a center pipe (7), a nut cap (8), a regulating sheet (9), a plug cove (10), an ignition ball (11), propelling charge (12), a delay device (13), an ignition head (14) and propellant powder (15), wherein the plug core (1) is connected with the insulation base (2) which is connected with the base (3), one side of the plug core (1) is connected with the ignition head (14), the base (3) is provided with the connecting body (4), the outer side of the connecting body (4) is provided with the pipe casing (6), the inner side of the connecting body (4) is provided with the delay device (13) which is provided with the lantern ring (5), the center pipe (7) is arranged on the lantern ring (5) and provided with the nut cap (8), the ignition ball (11) is arranged between the center pipe (7) and the pipecasing (6), and the regulating sheet (9) and the plug cover (10) are arranged on the top of the ignition ball (11). By adopting the invention, the safety of the operator is improved; and an ignition shrapnel continuously combusts at high temperature, has the advantages of large spreading area, high ignition efficiency and better static prevention function, and is convenient and simple in operation.

Owner:山西北方晋东化工有限公司

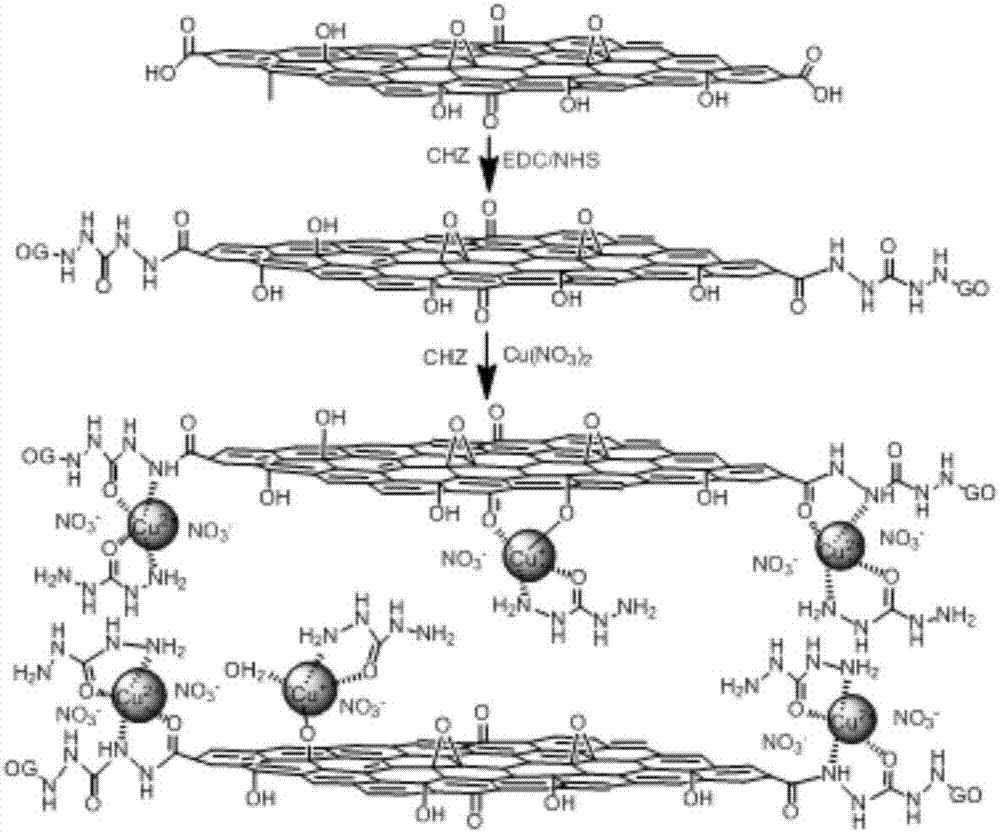

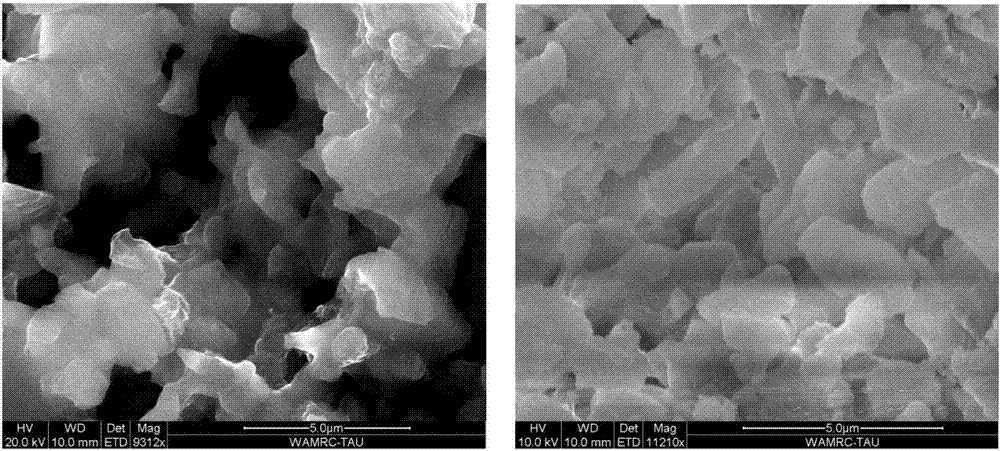

Graphene-based carbohydrazide metal complex crystal energetic material and preparation method thereof

The invention discloses a preparation method for a graphene-based carbohydrazide metal complex crystal energetic material. The preparation method comprises the following steps: S1, dispersing graphene oxide with oxygen content of no less than 45% into water or an organic solvent for 30 to 60 min so as to obtain a graphene oxide suspension; reacting the graphene oxide suspension with a coupling agent at 55 to 65 DEG C for 1.5 to 2 h so as to obtain a graphene oxide activated precursor; dispersing the graphene oxide activated precursor in a dispersing agent I for 30 to 50 min, adding carbohydrazide and carrying out a reaction at 60 to 70 DEG C for 4 h so as to obtain carbohydrazide functionalized graphene oxide; and S4, subjecting the carbohydrazide functionalized graphene oxide prepared in step 3 to cleaning and filtering, then carrying out dispersion in a dispersing agent II for 15 to 60 min, adding a carbohydrazide solution, then adding nitrate or perchlorate, carrying out a reaction at 75 to 85 DEG C for 15 to 60 min and then carrying out vacuum drying so as to obtain the graphene-based carbohydrazide metal complex crystal energetic material. The graphene-based carbohydrazide metal complex crystal energetic material prepared by the invention overcomes the problems of low laser ignition efficiency and complex preparation technology of photosensitive insensitive energetic materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

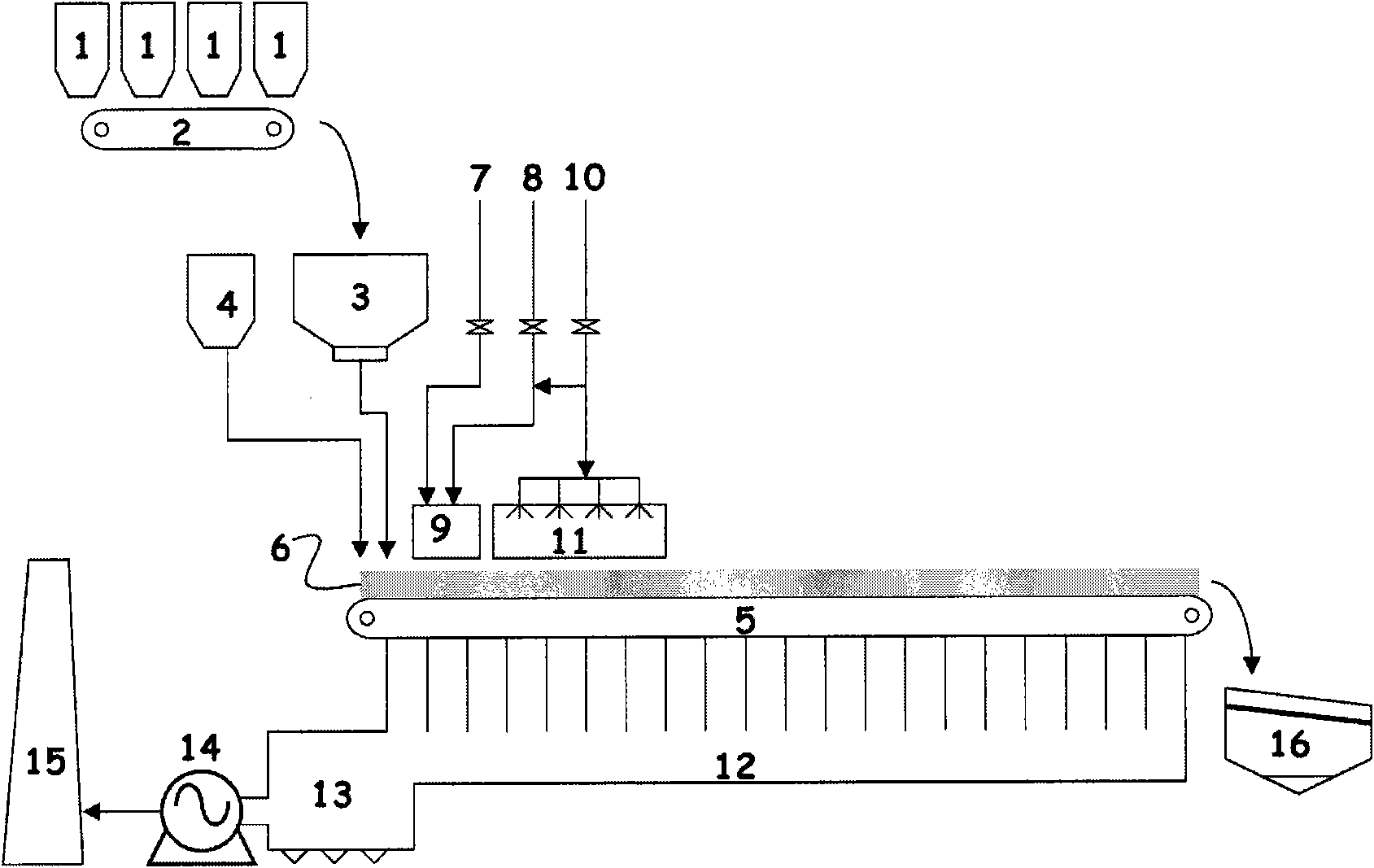

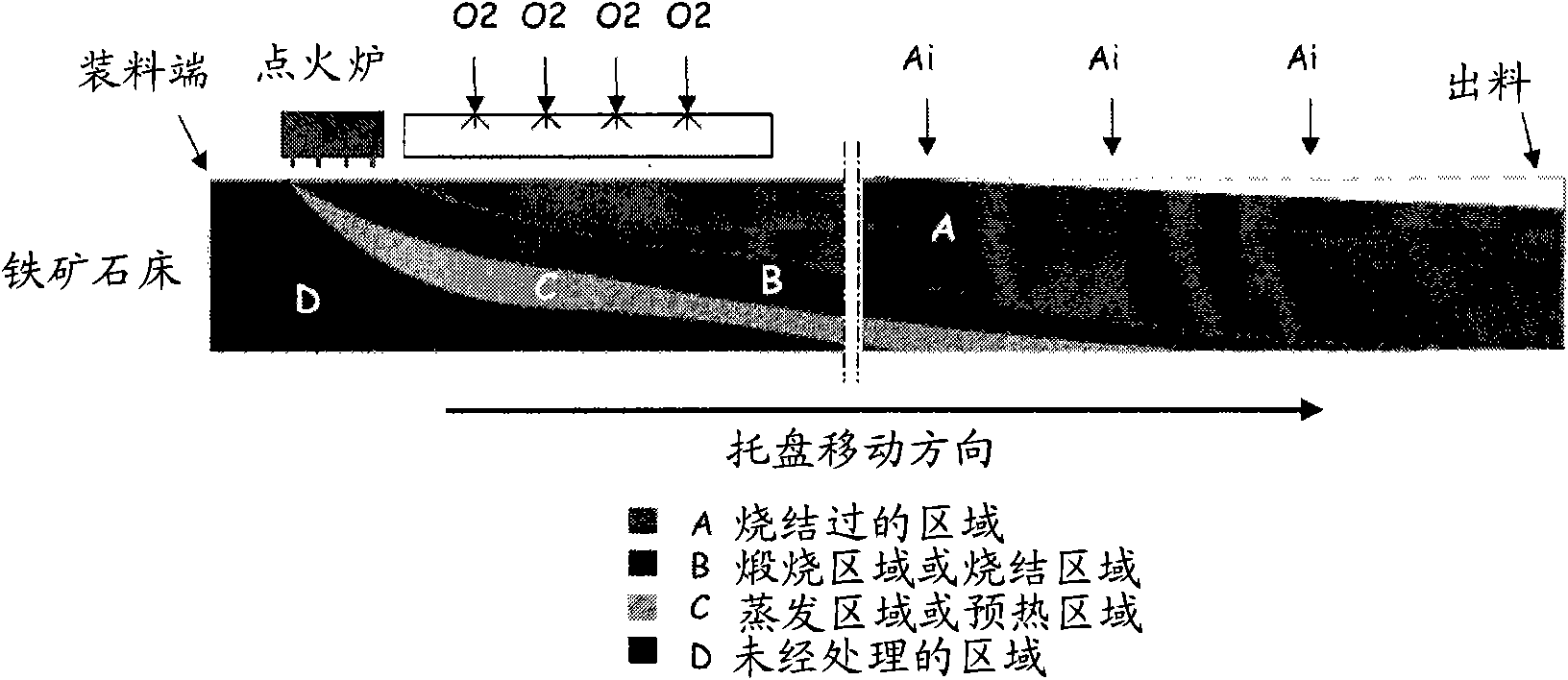

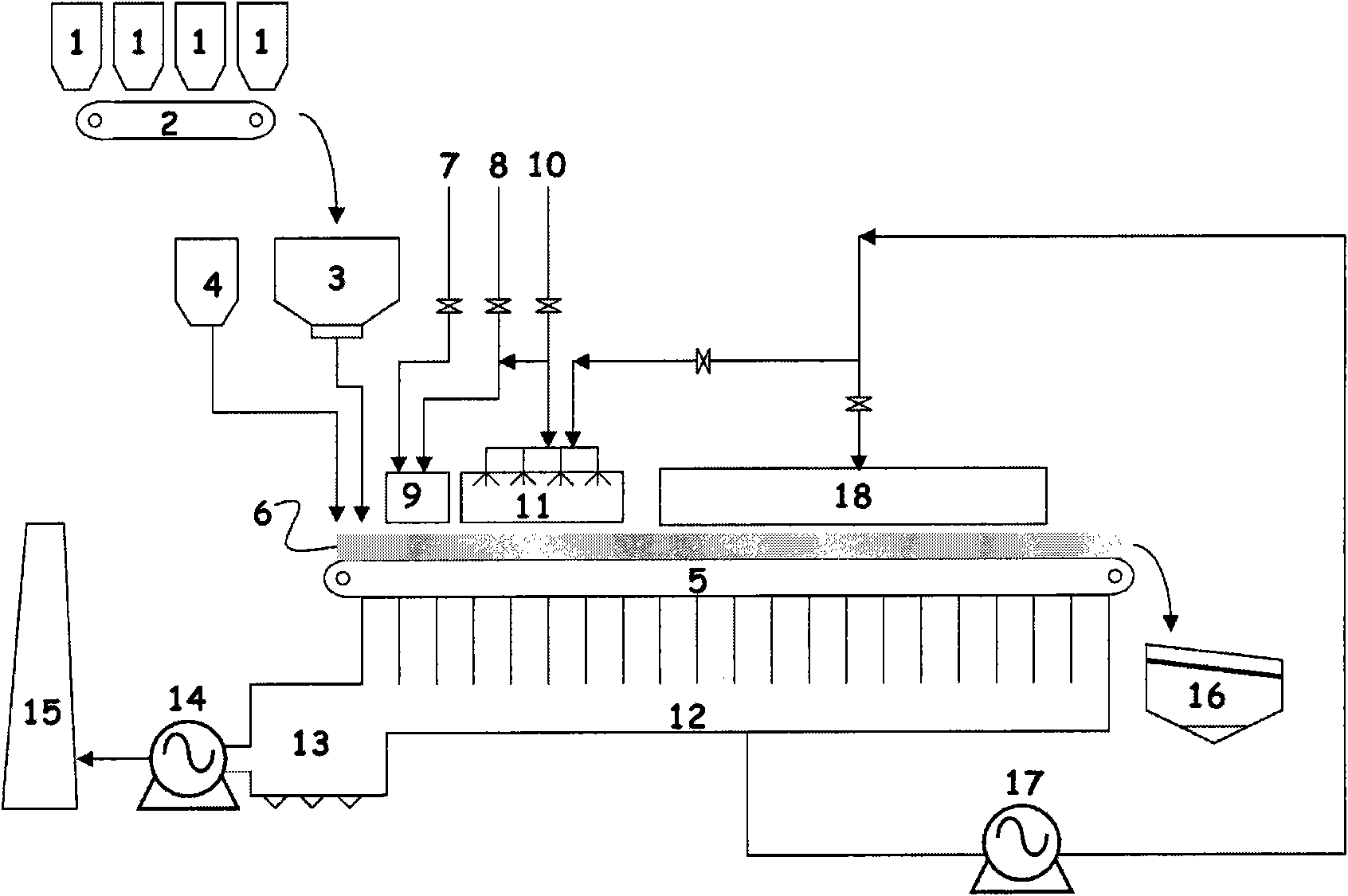

Periodic oxygen-enriched sintering of iron ore

ActiveCN101608255ALow costImprove ignition efficiencyProcess efficiency improvementAir atmosphereFlue gas

The invention relates to periodic oxygen-enriched sintering of iron ore. The iron ore is sintered by pumping an oxygen-enriched air atmosphere from previous one tenth to one third of the bed to pass through the bed and by pumping an air atmosphere or a flue gas-enriched air atmosphere to pass through the residual part of the bed, after the iron ore moving bed is ignited.

Owner:PRAXAIR TECH INC

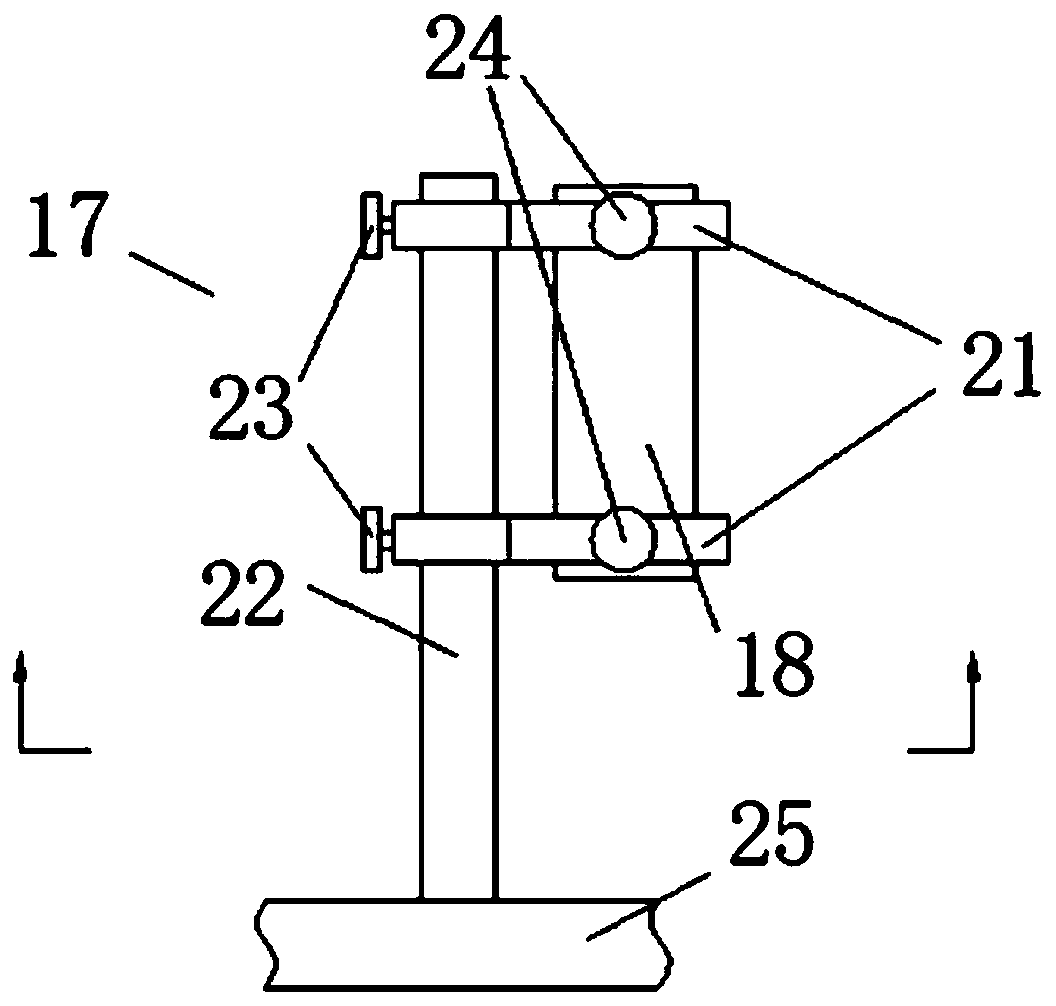

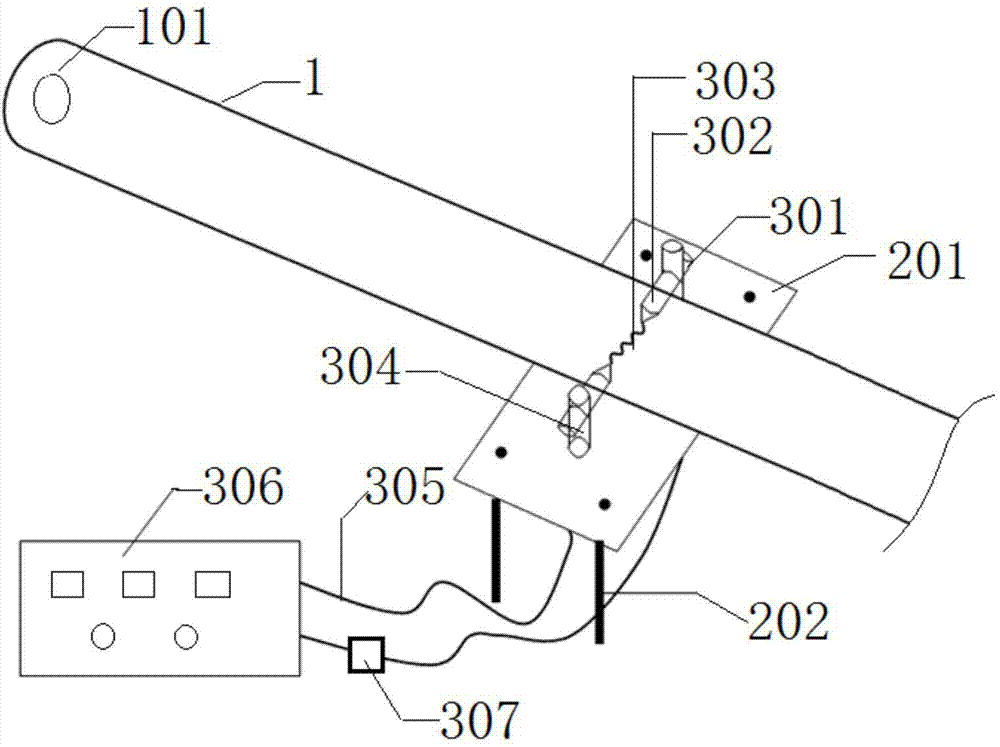

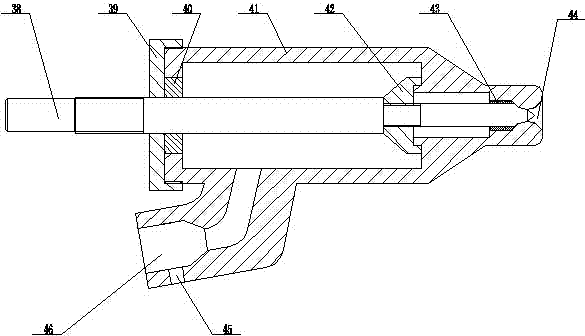

Split type high-voltage arc ignition device for experiment

InactiveCN104848255AReduce the impactImprove ignition efficiencyElectric spark ignitersCoalPowder Spray

The invention discloses a split type high-voltage arc ignition device for experiment and belongs to the field of ignition devices. The split type high-voltage arc ignition device comprises an arc generating mechanism and a support device. The support device comprises a support seat and a scale type adjusting rod, and the scale type adjusting rod is mounted on the lower surface of the support seat. The arc generating mechanism comprises a boosting device and an arcing device, wherein the arcing device is mounted on the upper surface of the support seat, a pair of discharging electrodes inserted into the side wall of a powder spraying pipeline is arranged in the arcing device and the distance between the discharging electrodes can be adjusted by a scale type adjusting disc. The boosting device is used for controlling arcing voltage of the discharging electrodes. The arc ignition mode of the split type high-voltage arc ignition device replaces a conventional platinum ignition mode, so that ignition efficiency of coal powder in a lab is improved, and cost is reduced. In addition, the split type high-voltage arc ignition device is good in flexibility, easy to adjust and convenient to use.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Ignition method and apparatus of product line for sintering porcelain granule

InactiveCN101269949AImprove ignition efficiencySimple structureClaywaresProduction lineThermal energy

The present invention relates to an ignition method and an ignition device, which are applied to the baking porcelain grain production line. The ignition method: the temperature of the ignition device is increased to pre-determined temperature, generally 800 to 1350 DEG C, a baking box that is fully provided with the baking raw materials is close to the ignition device at high temperature to reach the closed state, and then to be preheated; the baking box is ventilated with air or other combustion-assistant gas to assist the combustion, so that the surface of the raw materials can be combusted adequately; the temperature in the ignition device is introduced downwards by the guiding air so as to increase the thickness of the ignition layer; the air introduction is stopped after the ignition, and the ignited baking box is moved to a next position, and simultaneously the next baking box that is fully provided with the baked raw materials is moved to the ignition position. With the present invention, the ignition efficiency at the surface of the baking box is high, thereby greatly reducing the heat waste and shortening the ignition time; moreover, the porcelain grain that is arranged on the surface of the baking box is combusted adequately without breaking or dust; the particle is complete, thus improving the rate of the finished product of the production line. The ignition device has simple structure, not only has low production cost, but also greatly reduces the running operation compared with the traditional ignition system.

Owner:BEIJING SIDIQI SCI & TECH

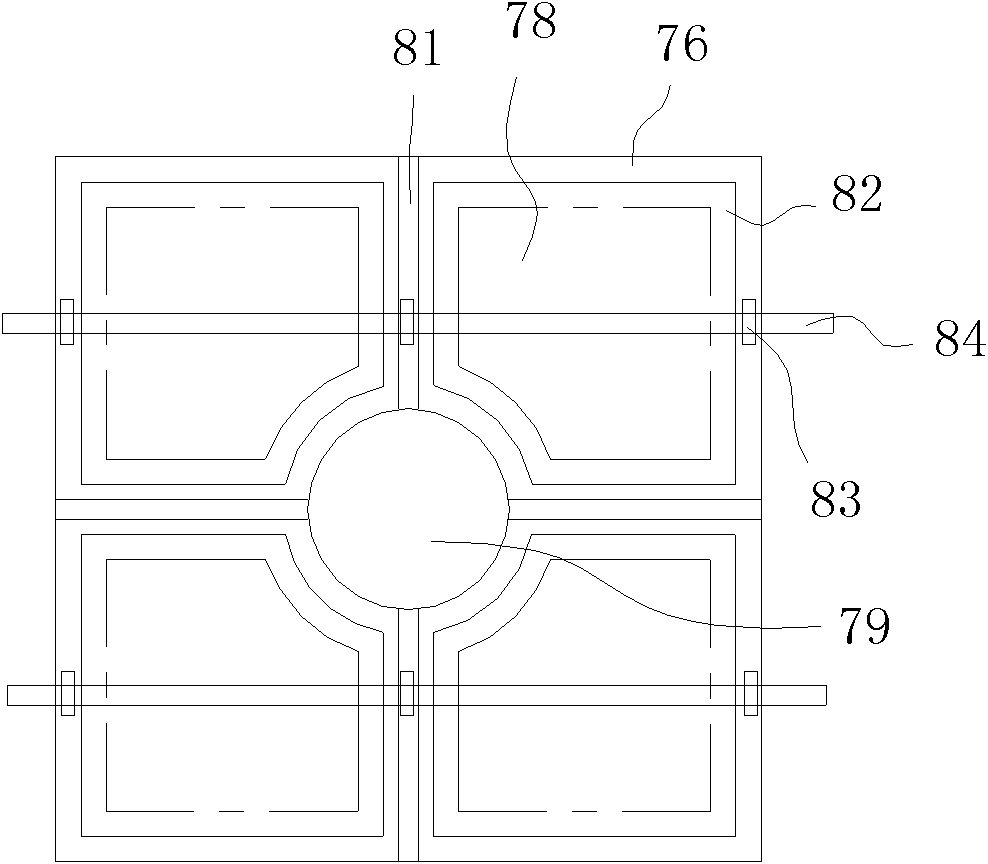

Folding coaxial cavity microwave igniter for engine of automobile

InactiveCN102121448AImprove ignition efficiencyThe degree of coupling is easy to adjustEngine ignitionMachines/enginesCombustion chamberWavelength

The invention relates to a folding coaxial cavity microwave igniter for an engine of an automobile, belonging to the technical field of microwave application. The igniter is manufactured by the integration of a one fourth wave length coaxial resonant cavity, a folding coaxial coupling structure, a step coaxial matching structure and an N type radio frequency coaxial connector; through the N type radio frequency coaxial connector and the step coaxial matching structure for hectowatt order of magnitude input power, the microwave power is coupled into the one fourth wave length coaxial resonant cavity by the folding coaxial coupling structure, then the microwave power is transmitted into an air cylinder of the engine by the coaxial resonant cavity, high electric-field strength can be realized at the tail end of the igniter to broken down the oil-gas mixture around the tail end to generate plasma, thus the gas combustion in the whole combustion chamber and the full combustion of the oil-gas mixture can be realized rapidly. The folding coaxial cavity microwave igniter for the engine of the automobile provided by the invention is similar to the existing ignition plug, and can directly replace the existing ignition plug can be replaced directly on the condition of unchanging the air cylinder structure of the engine; and the igniter is in integrated design, the degree of coupling is easy to control, the igniter has the characteristics of high ignition efficiency, low manufacturing cost, good repeatability and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Positive ceramic wrapped type multipole spark plug

ActiveCN105977790AEasy to removeReduced flame suppressionSparking plugsCeramic coatingMaterials science

Provided is a positive ceramic wrapped type multipole spark plug including a grounding nut, a ceramic insulator, a wiring screw rod, a casing, a gasket, a center electrode, and a side electrode. Threads are arranged on the wiring screw rod. The spark plug is characterized in that the center electrode is wrapped by the ceramic insulator, the side electrode is in a tubular structure and is jointed and fixed to the center electrode in the ceramic insulator coaxially, the bottom end of the center electrode is lower than the bottom end of the side electrode, the bottom end of the center electrode is welded to three L-shaped igniting electrodes at equal intervals, the front ends of the L-shaped igniting electrodes bend upwards and the end faces of the front ends are horizontal, the surfaces of the igniting electrodes except the front end faces are sprayed by ceramic coatings, the bottom end of the side electrode is provided with three protruding bosses protruding downwards in the circumferential direction at equal intervals, and the three bosses and the end faces of the three L-shaped igniting electrodes are vertically corresponding one by one and are equal in interval. The spark plug provided has the advantages of high igniting efficiency and long service life.

Owner:YANSHAN UNIV

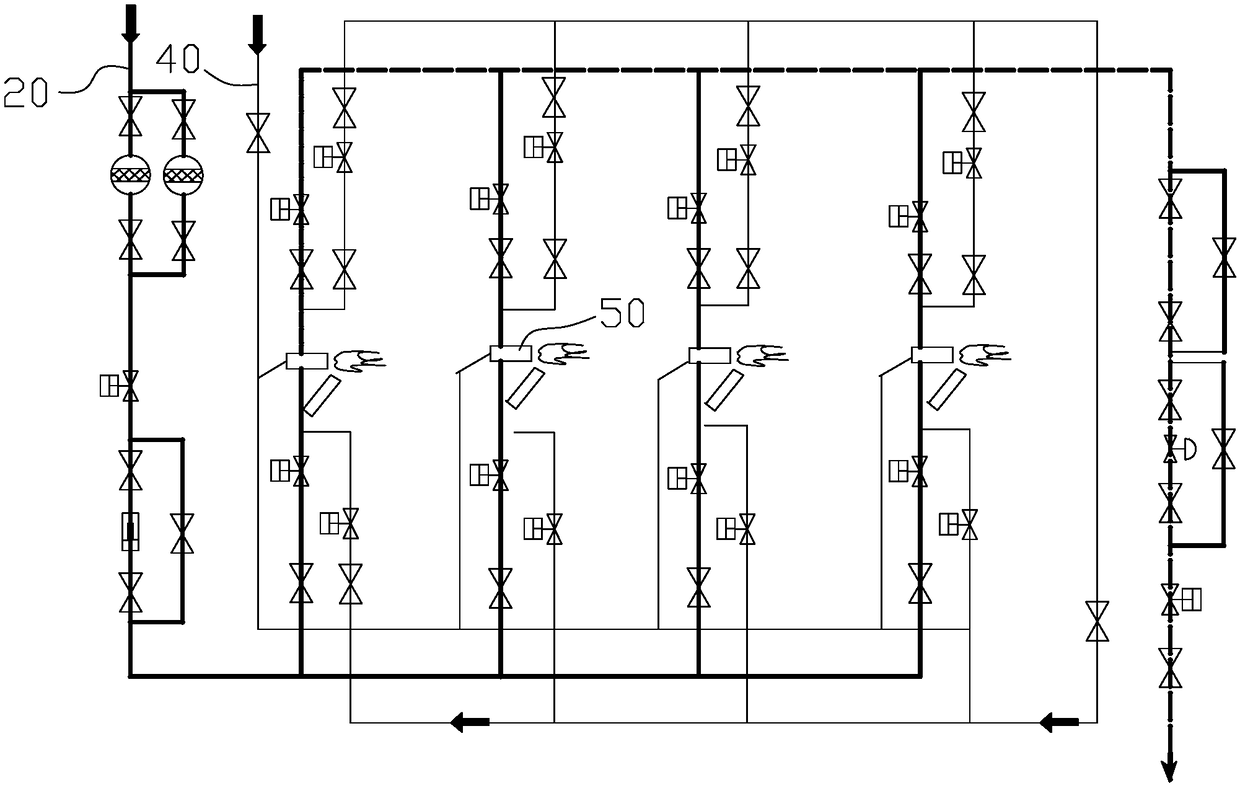

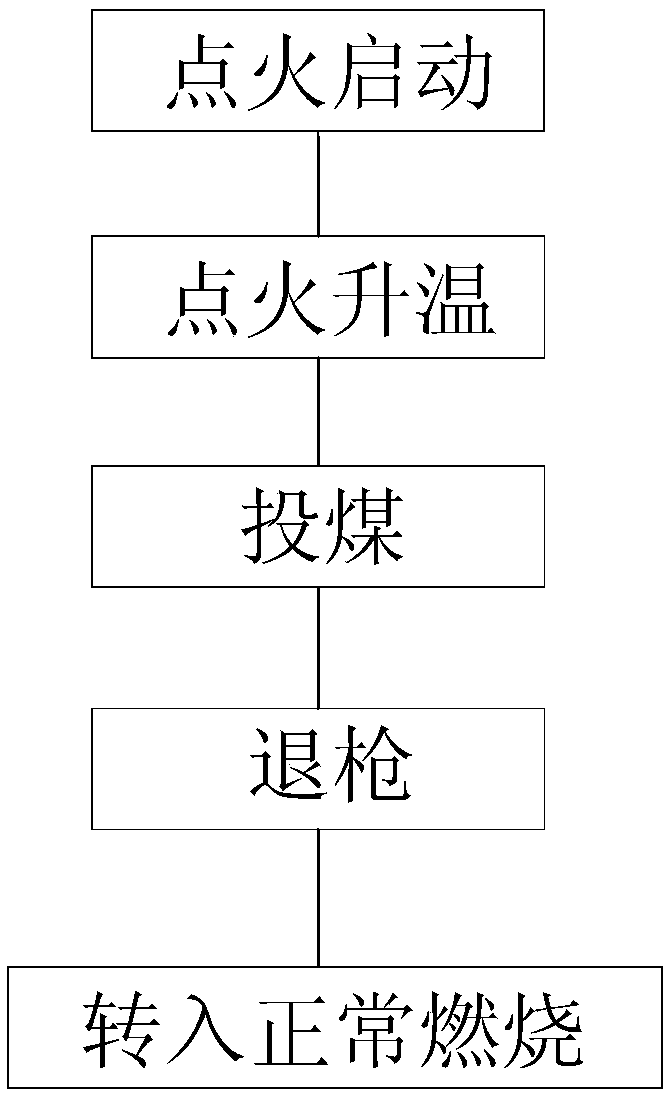

Ignition method for circulating fluidized bed boiler

ActiveCN109140431AUniform fluidizationHeating evenlyFluidized bed combustionCombustion ignitionTO-18Cold air

The invention provides an ignition method for a circulating fluidized bed boiler. In the ignition start, the thickness of a bed material is 60-80 cm, a primary air volume is adjusted to 24-260,000 Nm3 / h to ensure uniform fluidization of the bed material, after the fluidization of the bed material is uniform, the primary air volume is gradually reduced to 18,200,000 Nm3 / h, so that the bed materialis in the bubbling bed state, an ignition oil pressure is adjusted to 1.2-1.4MPa, and an ignition oil gun with a flow rate of 1200kg / h is used for igniting; during the ignition heating process, more than 90% of primary air is heated by the ignition oil gun to reduce cold air entering a furnace to not cool the bed material; when the bed temperature rises to 420-440 DEG C, pulse coal injecting is conducted; when the bed temperature rises to 620-650 DEG C, the oil gun is gradually withdrawn, and after the combustion is stabilized, the primary air volume is adjusted to be no less than 240,000 Nm3 / h to ensure normal fluidization of the bed material; when the bed temperature reaches 680-700 DEG C, coals are continuously injected, and normal combustion is entered. The ignition method can reduce the amount of fuels required for ignition.

Owner:百色百矿发电有限公司

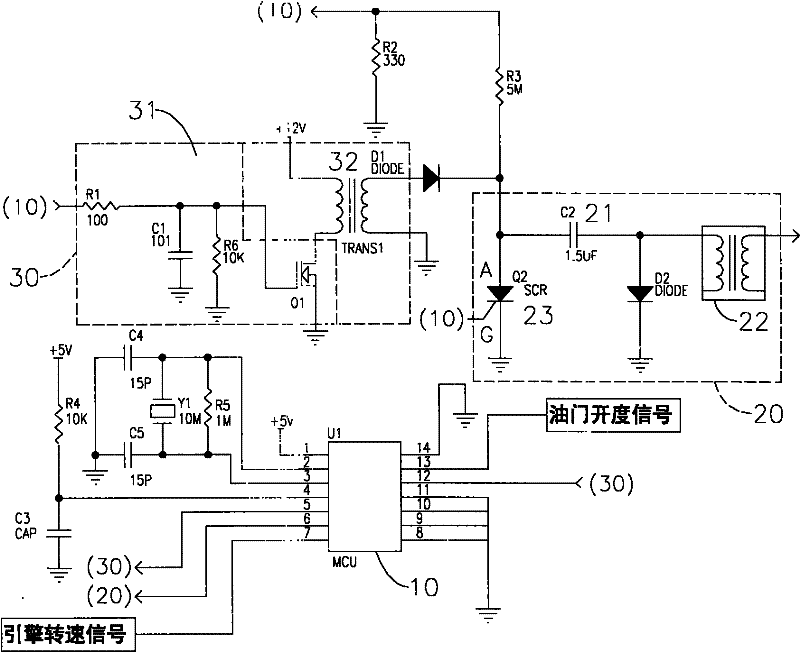

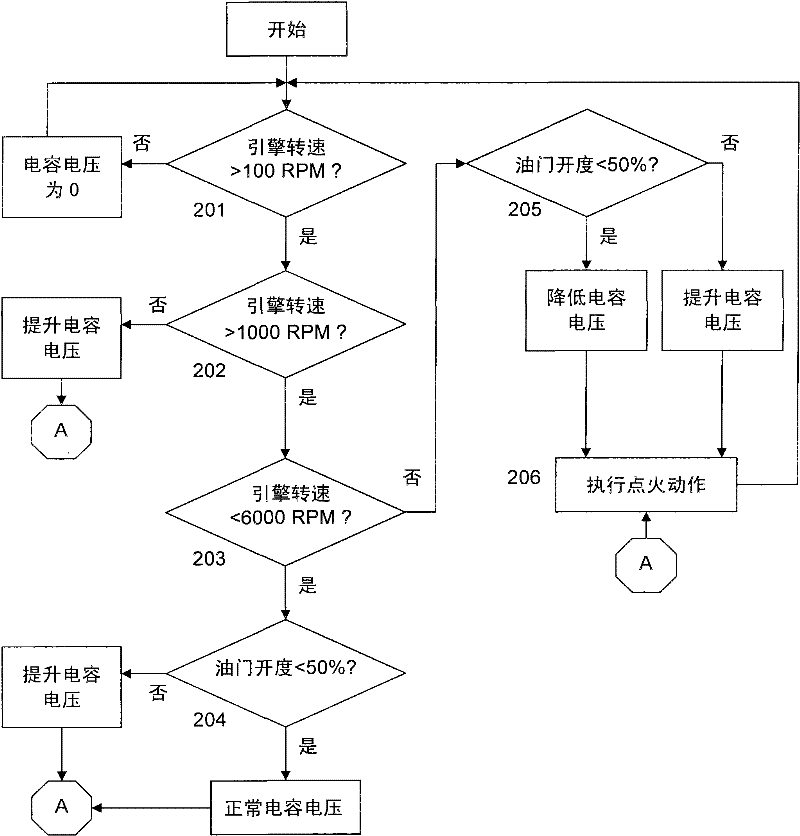

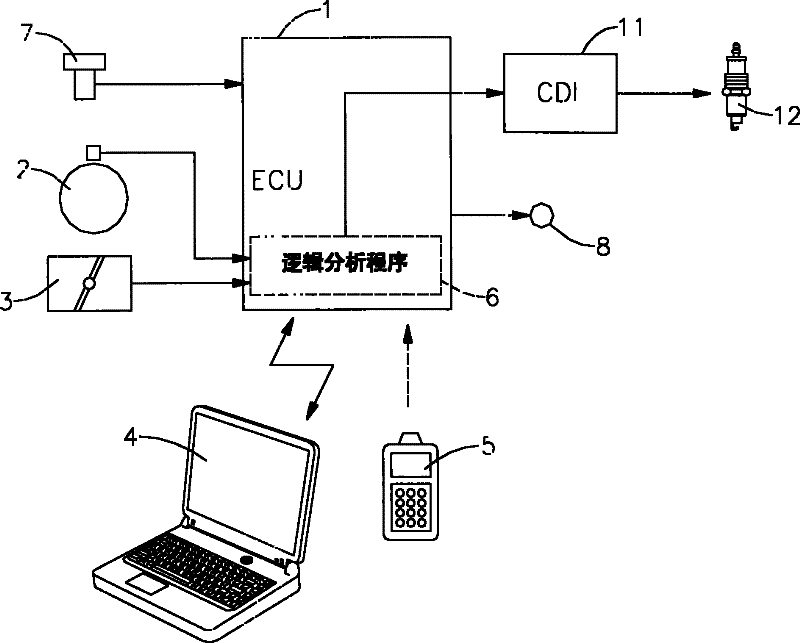

Method and device for controlling engine ignition system

InactiveCN102235290ABurn completelyEmission reductionElectrical controlMachines/enginesLow speedThrottle opening

The invention relates to a method and a device for controlling an engine ignition system. A control unit simultaneously receives an engine rotating speed signal and a throttle opening signal and crosswise judges whether the signals are higher than or lower than a set value; when different judging conditions are satisfied, ignition voltage is raised or lowered, so that voltage is increased for ignition on the conditions of low speed and high fuel quantity and voltage is lowered for ignition on the conditions of high speed and low fuel quantity. By the adoption of the adaptive control technology provided by the invention, the purposes of full burning, improvement in ignition efficiency, power saving, energy saving, carbon emission reduction and the like can be achieved.

Owner:KYMCO

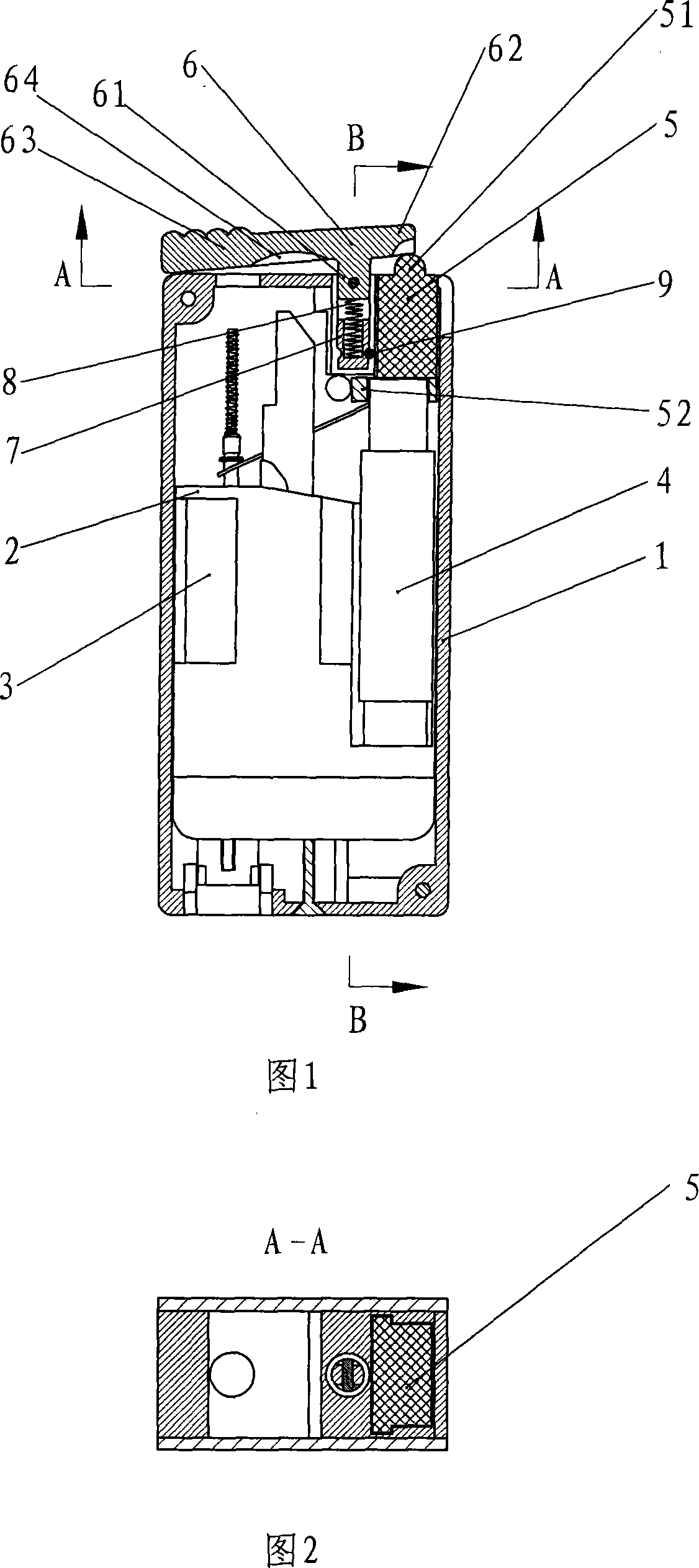

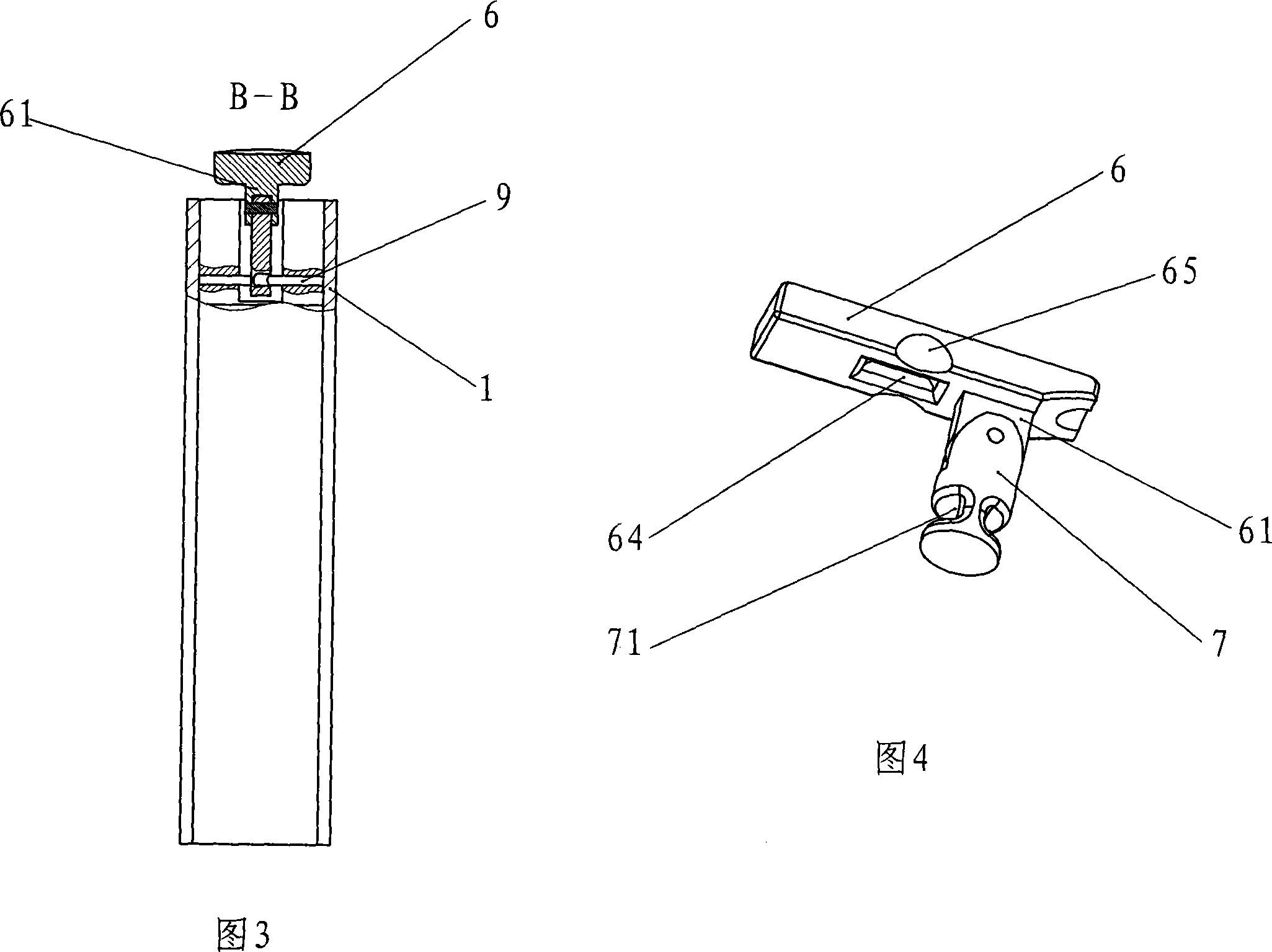

Lever-ignition lighter of keeping away children

The invention relates to a lighter especially the lever lighter which the children can not light. The character is in that: the pressing piece is set on one side of lighting button which explores of the shell; the pressing piece is set on the shell by the rotating shaft which is connected to the pressing piece by the boss which divides the pressing piece into two parts of different length. The short part is on the top of the lighting button pressing side to form the lock match and the long part is on it to form the unlock pressure match. The invention can provides a proper structure and easy to operate. Also it has the low cost and high safe efficiency.

Owner:吴铿

Oxygen-enriched combustion engine system

InactiveCN104847541AIncrease contentIncrease concentrationInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberEngineering

The invention discloses an oxygen-enriched combustion engine system and belongs to the field of energy conservation and emission reduction of engines. The system comprises an oxygen supply device, an oxygen nozzle, a cylinder head, a distribution machine and a chain wheel cover, wherein high-concentration oxygen is directly jetted into an engine combustor through the oxygen nozzle, the cylinder head contains the oxygen nozzle, and the distribution machine controls timing work of the oxygen nozzle; the oxygen supply device is driven by an engine crankshaft through a belt wheel mechanism and controlled by an electromagnetic valve to be reversed, a first adsorption tower and a second adsorption tower work alternately, and therefore low-pressure oxygen is generated continuously; the oxygen is cached in an air storage tank, pressurized through a booster pump to reach the pressure higher than the maximum pressure in an engine cylinder, and finally jetted into the combustor through the oxygen nozzle; the distribution machine controls intake and exhaust distribution of the engine and also controls timing opening and closing of the oxygen nozzle through a cylindrical cam mechanism. The oxygen-enriched combustion engine system is low in cost, and can greatly improve engine power, reduce fuel consumption, reduce emission of a part of harmful gas of the engine, improve coldstart performance of the engine and increase the response speed of the engine.

Owner:TAIYUAN UNIV OF TECH

Precise motorcycle engine ignition system and precise motorcycle engine ignition method

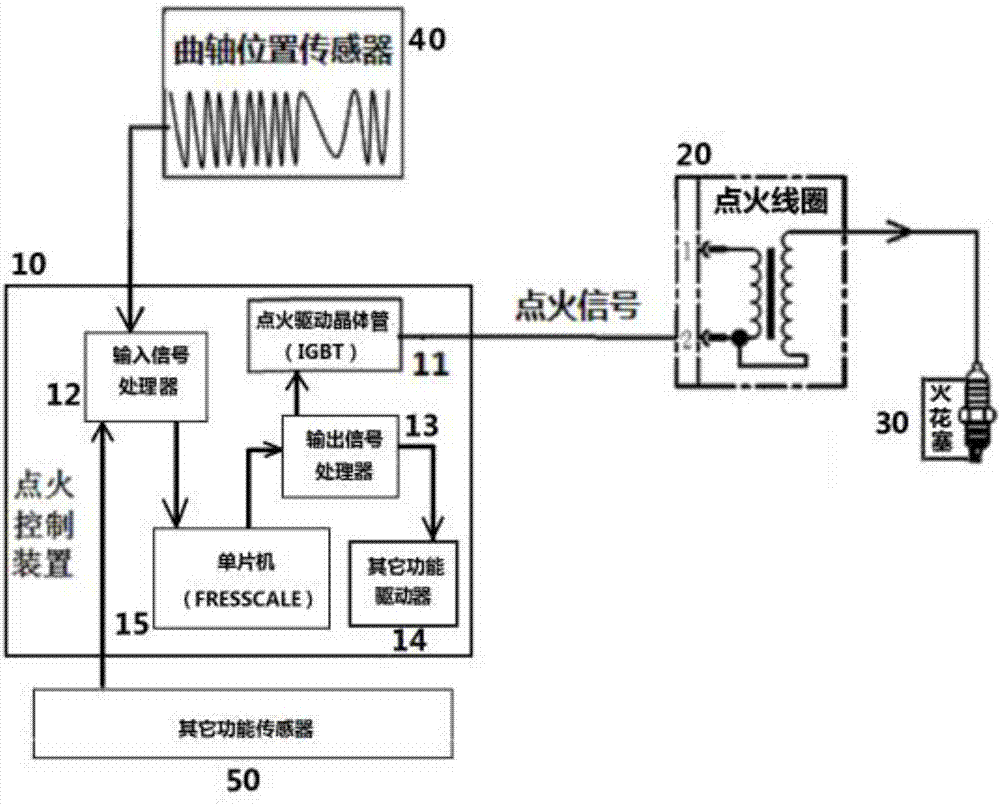

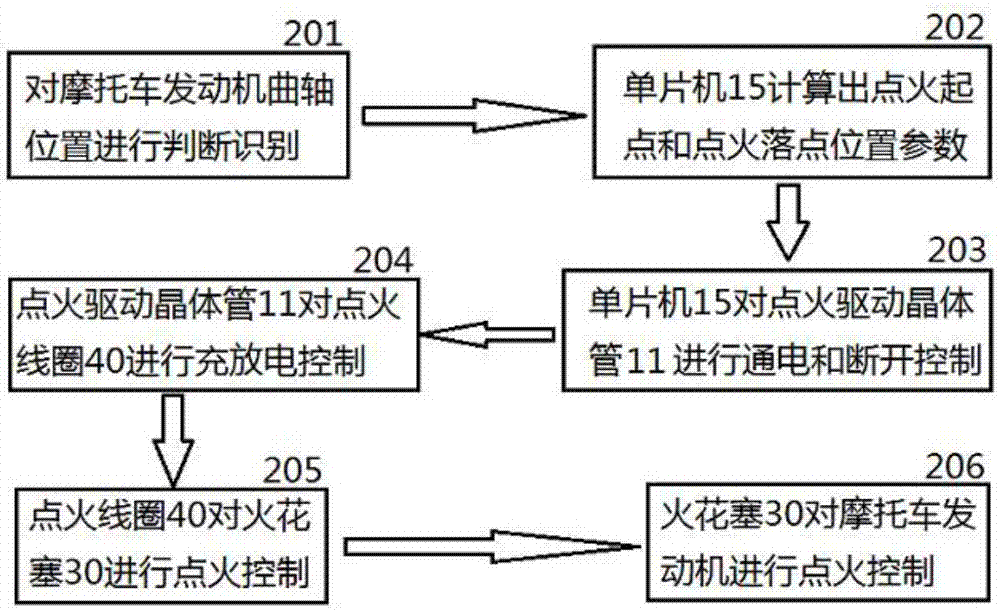

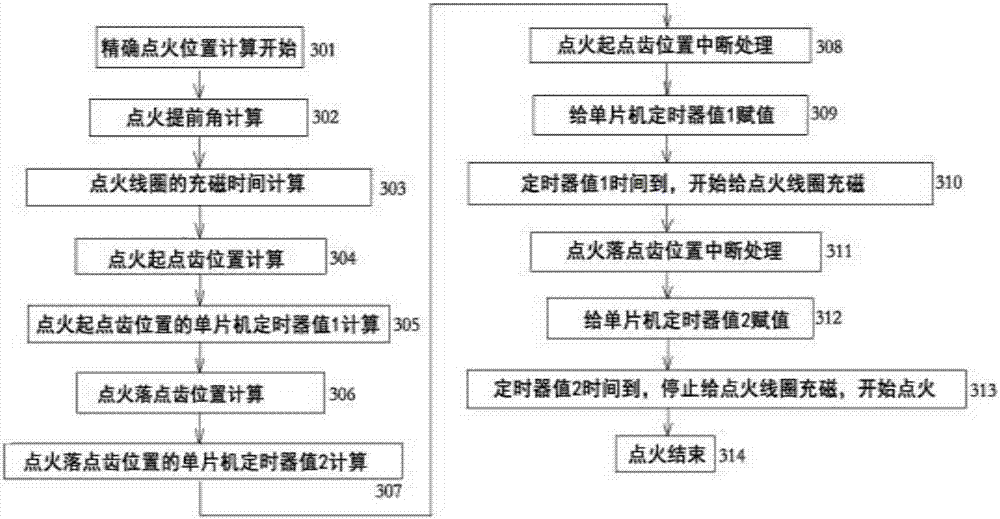

InactiveCN106996355AImprove economyImprove emission standardsIgnition automatic controlInstallations with induction energy storageIgnition coilWork cycle

The invention discloses a precise motorcycle engine ignition system and a precise motorcycle engine ignition method and relates to a motorcycle engine ignition system. The structure of the precise motorcycle engine ignition system is as follows: a crankshaft position sensor (40) and a crankshaft function sensor (50) are connected with an ignition control device (10); the ignition control device (10), an ignition coil (20) and a sparking plug (30) are sequentially connected; the structure of the ignition control device (10) is as follows: an input signal processor (12), a single-chip microcomputer (15) and an output signal processor (13) are sequentially connected; the output signal processor (13) is connected with an ignition crystal driving tube (11) and an other function actuator (14). The precise motorcycle engine ignition system can precisely control ignition of a motorcycle engine and is high in ignition efficiency and response speed; the ignition control device can carry out cylinder identification treatment by combining other sensor signals and ignites once for each working cycle namely the engine is operated by two loops; and the precise motorcycle engine ignition system can be widely applied to a motorcycle electronic fuel injection system to improve economy and discharging standard of a vehicle.

Owner:武汉菱电汽车电控系统股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com