Ignition method for circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, which is used in fluidized bed combustion equipment, combustion ignition, combustion methods, etc., can solve the problems of easy-to-condensed focus fire consumption, difficult ignition, large fuel oil, etc., to prevent the bed temperature from dropping sharply, The effect of preventing overheating and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

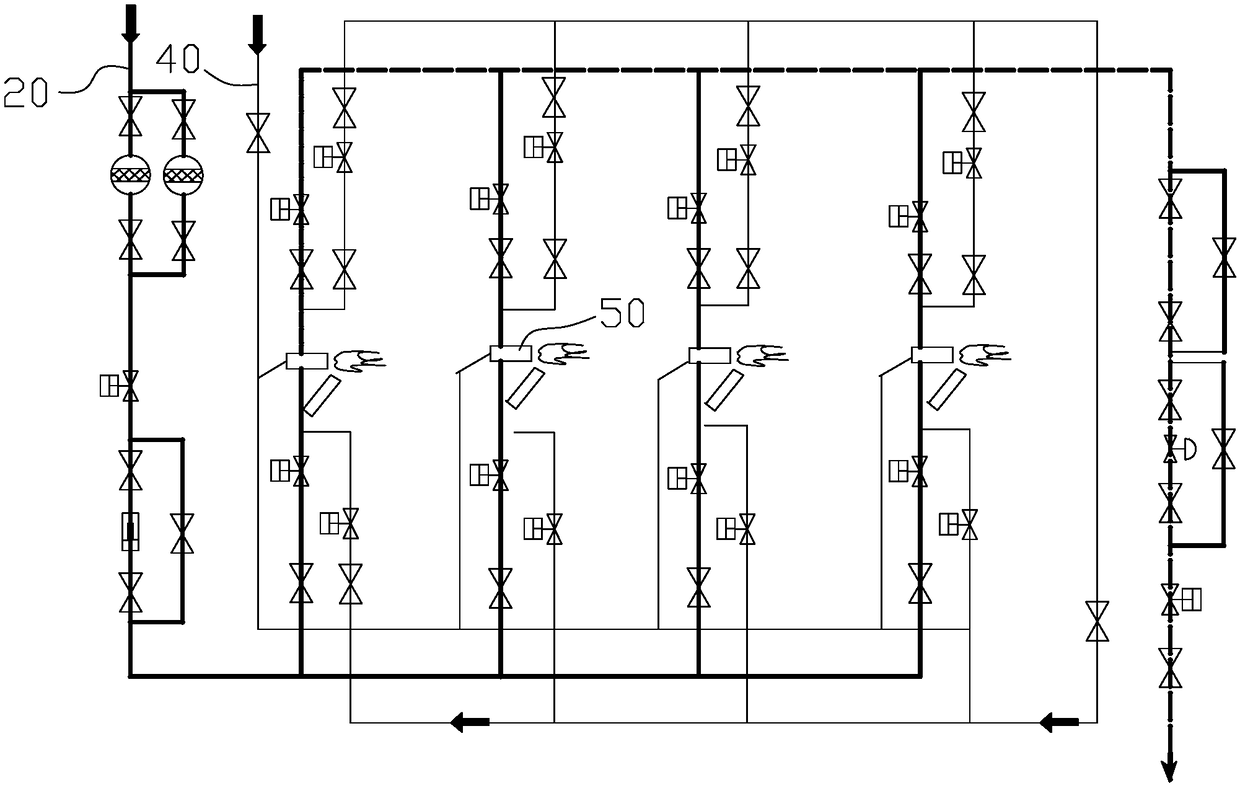

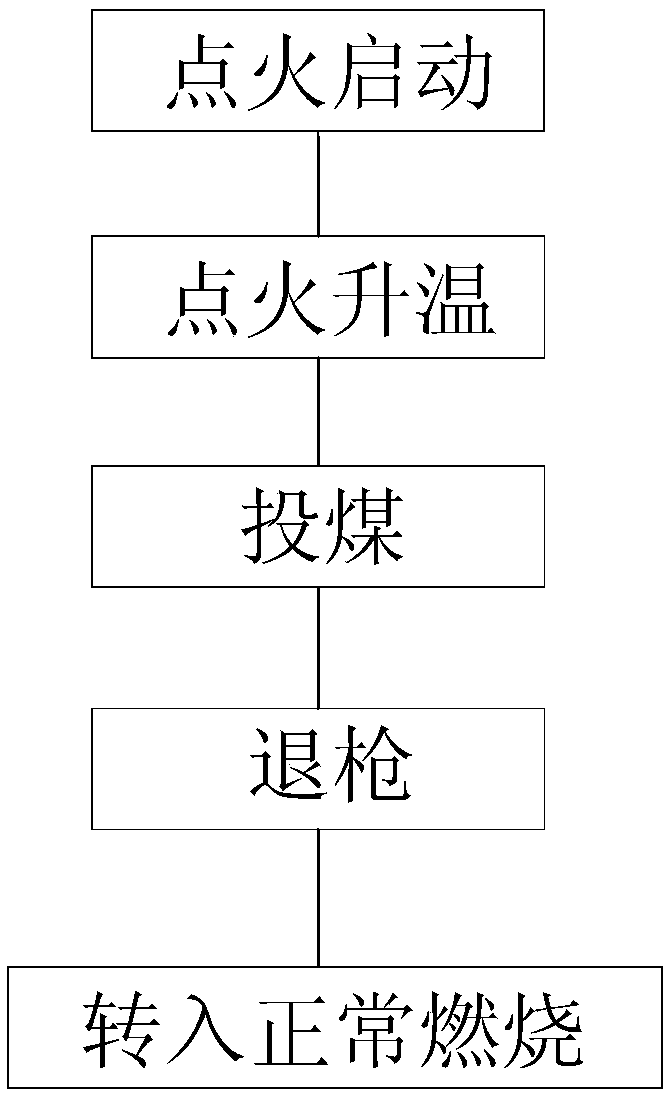

[0035] See figure 2 , based on the above situation, Embodiment 1 of the present invention provides a kind of ignition method of circulating fluidized bed boiler, and this boiler obtains directly from the market, and the model is DG-1100 / 25.4-II1 supercritical once-through furnace, adopts single hearth, M type layout, balanced ventilation, intermediate reheating, all-steel frame structure, circulating fluidized bed combustion mode, high-temperature cooling cyclone separator is used for gas-solid separation, and before the ignition method of the present invention is adopted, the flow rate of the boiler material bed The ignition oil gun with a flow rate of 1200kg / h is replaced with an ignition oil gun with a flow rate of 2150kg / h. This ignition method comprises the following steps:

[0036] Ignition start: lay bed material on the hood of the air distribution board, the thickness of the bed material is 60-80cm, and adjust the primary air volume to 240,000 Nm 3 / h, do a fluidizat...

Embodiment 2

[0043] Embodiment 2 of the present invention provides an ignition method for a circulating fluidized bed boiler. The boiler is directly purchased from the market, and the model is DG-1100 / 25.4-II1 supercritical DC furnace, which adopts a single furnace, M-shaped layout, and balanced ventilation. 1. Intermediate reheating, all-steel frame structure, circulating fluidized bed combustion mode, adopting high-temperature cooling cyclone separator for gas-solid separation, before adopting the ignition method of the present invention, the boiler material bed flow rate is 2150kg / h The ignition oil gun is replaced with an ignition oil gun with a flow rate of 1200kg / h. This ignition method comprises the following steps:

[0044] Ignition start: Spread the bed material on the hood of the air distribution plate, the thickness of the bed material is 70cm, adjust the primary air volume to 250,000 Nm3 / h, conduct a fluidization test to ensure that the bed material is evenly fluidized, and the...

Embodiment 3

[0051] Embodiment 3 of the present invention provides an ignition method for a circulating fluidized bed boiler. The boiler is purchased directly from the market, and the model is DG-1100 / 25.4-II1 supercritical direct current furnace, which adopts a single furnace, M-shaped layout, and balanced ventilation. 1. Intermediate reheating, all-steel frame structure, circulating fluidized bed combustion mode, adopting high-temperature cooling cyclone separator for gas-solid separation, before adopting the ignition method of the present invention, the boiler material bed flow rate is 2150kg / h The ignition oil gun is replaced with an ignition oil gun with a flow rate of 1200kg / h. This ignition method comprises the following steps:

[0052] Ignition start: Spread the bed material on the hood of the air distribution board, the thickness of the bed material is 80cm, adjust the primary air volume to 260,000 Nm3 / h, conduct a fluidization test to ensure that the bed material is evenly fluidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com