A lignite drying method and drying equipment utilizing power plant flue gas and steam waste heat

A drying method and steam waste heat technology, applied in lighting and heating equipment, heating to dry solid materials, drying solid materials, etc., can solve problems such as poor quality, uneven drying of materials, etc., to improve service life, improve power supply efficiency, The effect of uniform moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

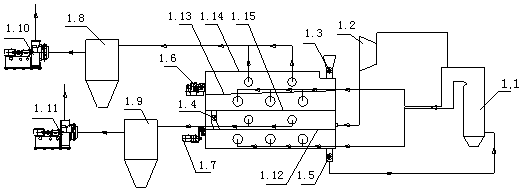

[0044] The invention provides a lignite drying method utilizing power plant flue gas and steam waste heat. The drying method includes two drying treatments (see figure 1 ):

[0045] (1) First, use the high-temperature flue gas directly discharged from the coal-fired boiler 1.1 of the power plant to perform a drying treatment on the wet material; the high-temperature flue gas directly contacts the wet material evenly to obtain the intermediate material;

[0046] (2) Then use the high-temperature flue gas and steam directly discharged from the coal-fired boiler 1.1 of the power plant to perform secondary drying treatment on the intermediate material at the same time; the high-temperature flue gas directly contacts the intermediate material evenly, and at the same time the intermediate material exchanges heat with the steam The tubes are evenly contacted for heat exchange to obtain dry materials and realize secondary drying treatment.

[0047] Among them, the primary drying proc...

Embodiment 2

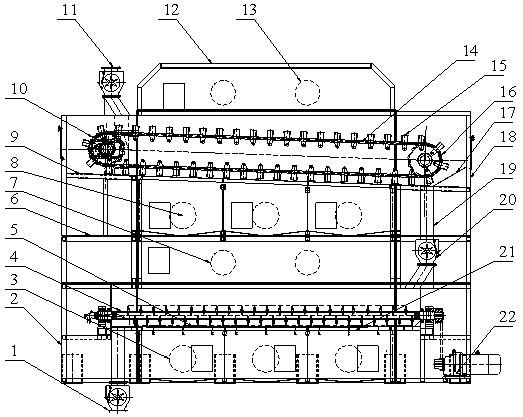

[0058] see figure 2 , the present invention is a lignite drying equipment utilizing power plant flue gas and steam waste heat, comprising a frame and a box body sealed around the frame, wherein the box body includes an upper box cover 12, an upper box body 18 and a lower box body 2. There is an intermediate partition 6 between the upper box 18 and the lower box 2; an upper hot air distribution plate 9 is installed obliquely on the frame inside the upper box 18, between the middle partition 6 and the upper hot air distribution plate 9 An air inlet 8 is arranged on the side wall of the upper box body 18, an air outlet 13 is arranged on the side wall of the upper box cover 12; An air inlet 3 is provided on the side wall of the lower box 2 below the distribution plate 5, and an air outlet 7 is provided between the lower hot air distribution plate 5 and the middle partition 6; both the air inlet 8 and the air inlet 3 are connected to the high-temperature flue gas pipeline ;

[0...

Embodiment 3

[0075] see figure 1 , the embodiment of the present invention provides an integrated system for lignite drying and power generation, including a coal-fired boiler 1.1 and lignite drying equipment (i.e. the moving fluidized bed device 1.14 in Example 1, i.e. the lignite drying equipment in Example 2 ), the high-temperature flue gas discharge pipe of the coal-fired boiler 1.1 is divided into two paths through the pipe and connected with the moving fluidized bed device 1.14, above the first-stage drying and ventilating plate 1.13, between the middle partition 1.15 and the secondary drying and ventilating plate 1.12. The tuyere and the air outlet are connected to the dust collector and the induced draft fan in turn; the steam discharge pipe of the steam turbine 1.2 of the coal-fired boiler 1.1 is connected with the screw shaft of the lignite drying equipment; Feed port connection. Wherein, the lignite drying equipment in this embodiment adopts the lignite drying equipment in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com