Air distribution structure of circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, which is applied in the directions of fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc. The effect of uniform and smooth slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

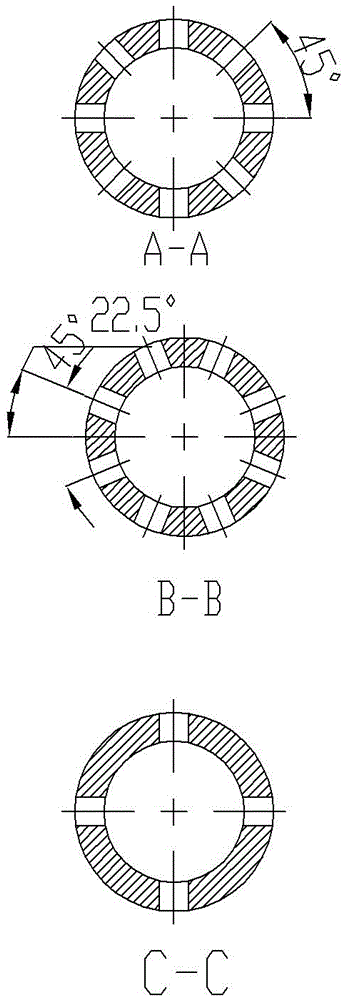

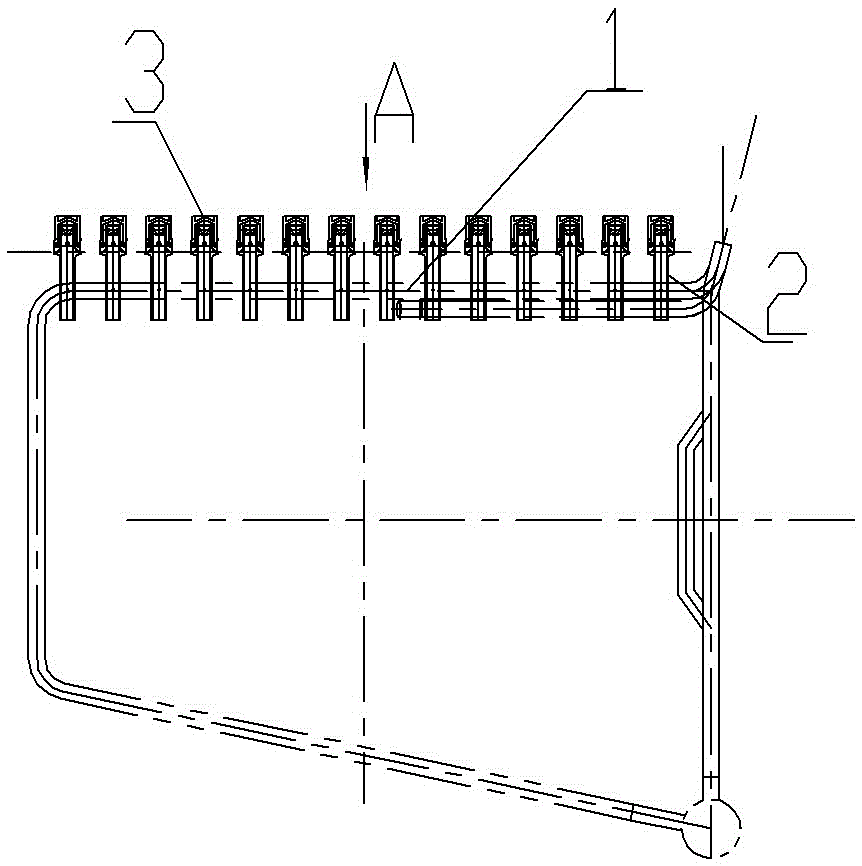

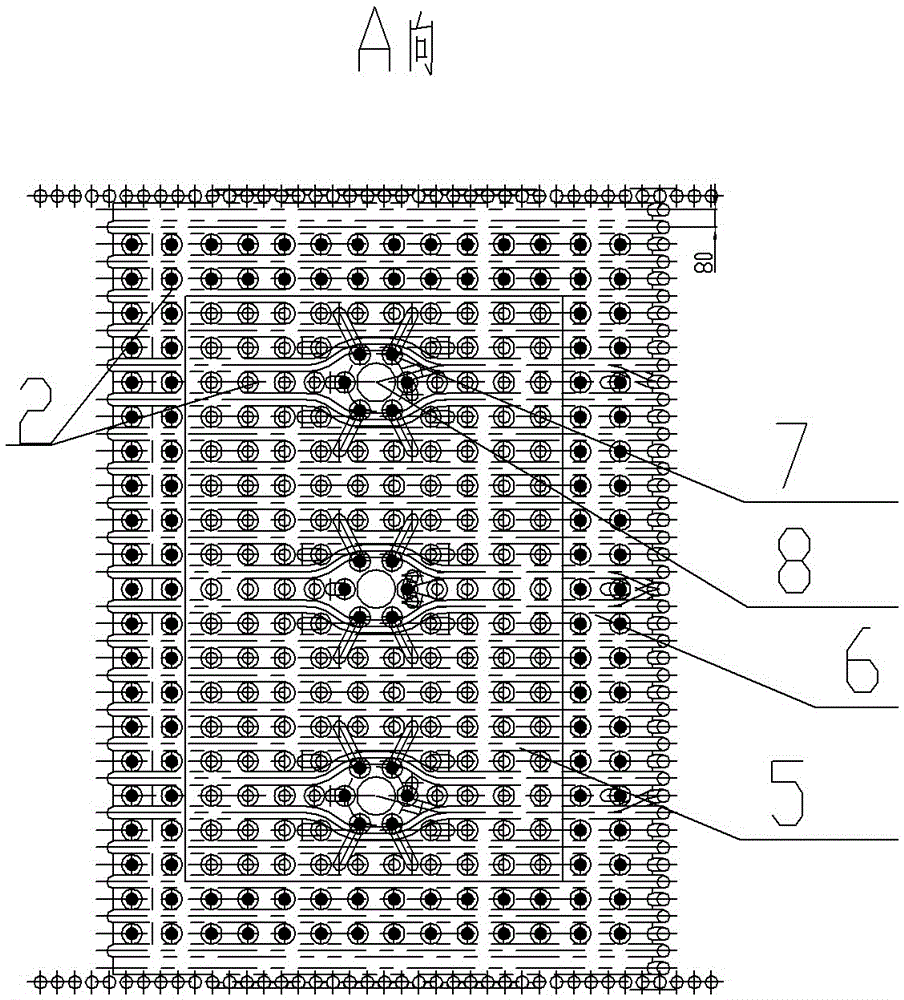

[0023] See figure 1 , figure 2 , image 3 As shown, an air distribution structure of a circulating fluidized bed boiler, which includes an air distribution plate 1, the air distribution plate 1 is installed with a connecting pipe 2 passing through the air distribution plate, the upper part of the connecting pipe 2 is equipped with a wind cap 3, and the connecting pipe 2 is provided with The opening 4 communicating with the wind cap 3, the air distribution plate 1 is divided into a central area 5 and a side wall area 6, the central area 5 is specifically a rectangular area, and the side wall area 6 is a rectangular frame area surrounding the central area 5, located on the side The opening ratio on the connecting pipe 2 of the wall area 6 is greater than the opening ratio on the connecting pipe 2 located in the central area 5; only. The connecting pipe 2 communicates with the air cap 3 through the opening 4, and the air outlet hole is arranged on the air cap 3, and the air e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com