Underground gasification ignition method

An underground gasification and fire source technology, applied in coal gasification, underground mining, earth drilling and mining, etc., can solve the problems of low ignition efficiency, slow flame moving speed, long channel processing time, etc., and achieve high ignition efficiency and penetration speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

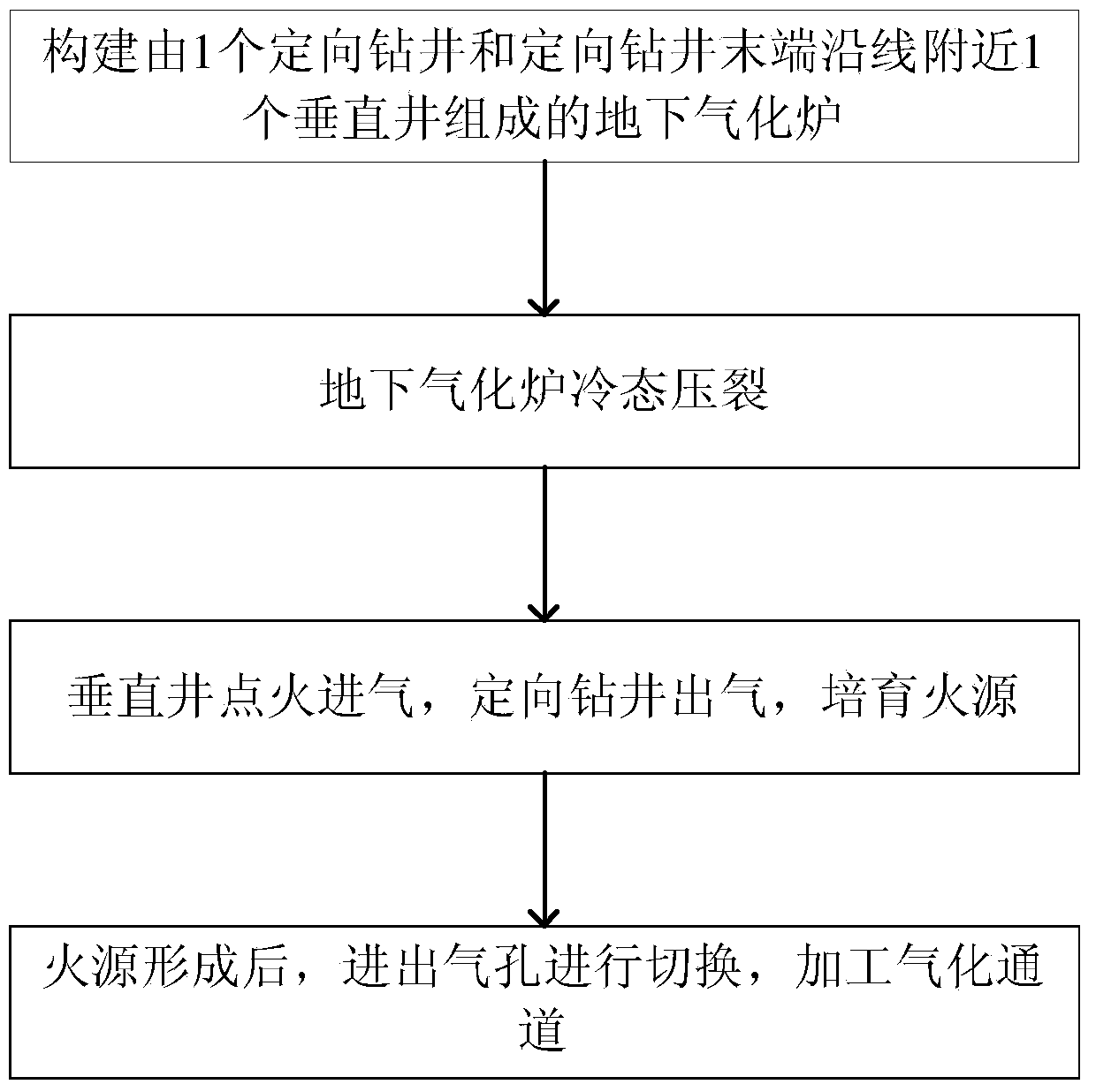

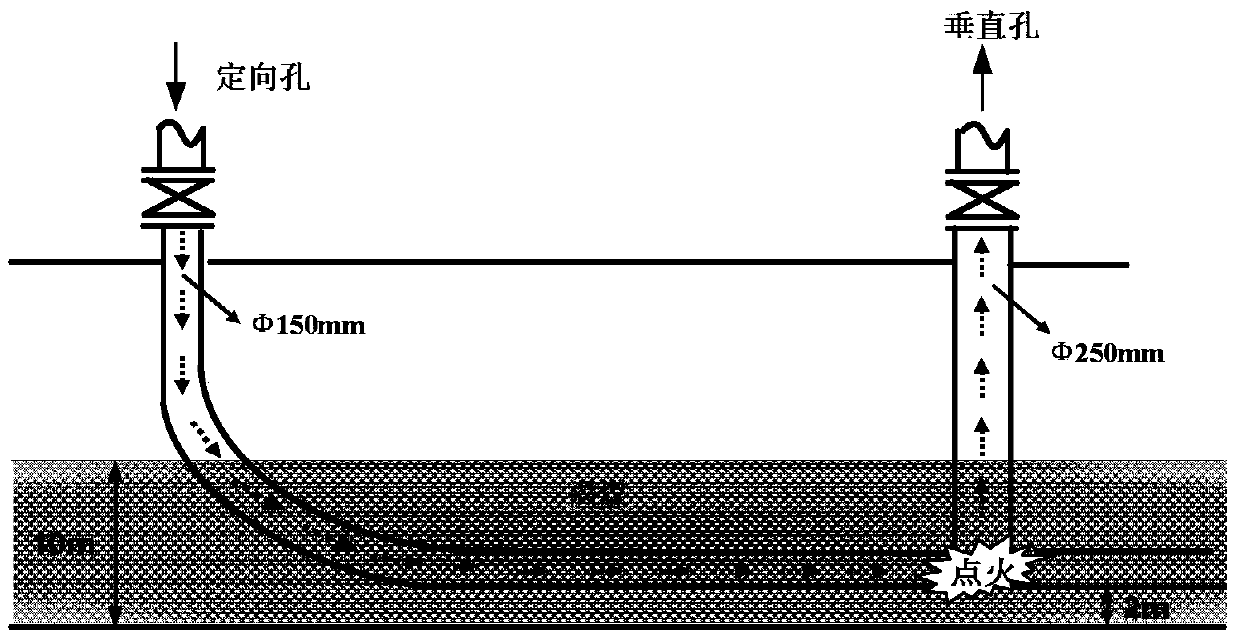

[0063] An underground gasification ignition method, comprising the steps of:

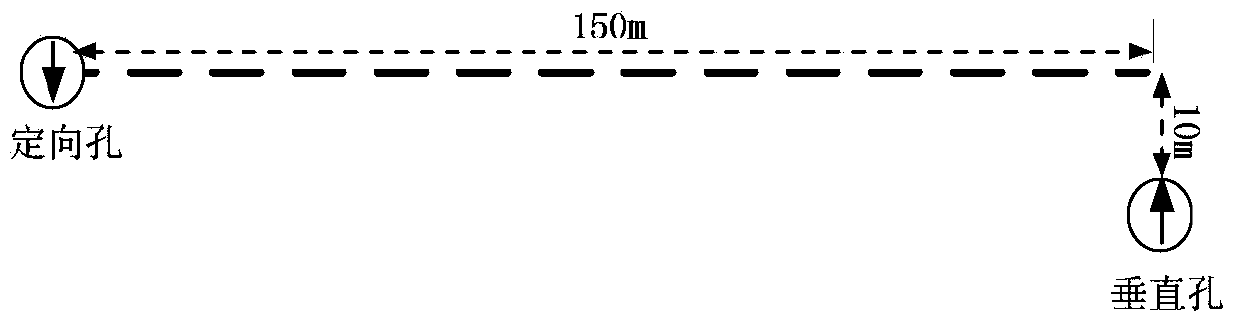

[0064] (1’) Create directional drilling and vertical wells to build underground gasifiers, and the number of vertical wells is 1;

[0065] (2’) Pre-penetrate the coal seam by cold fracturing;

[0066] (3’) fire in the vertical well at the end of the directional drilling,

[0067] (4’) When the volume of coal burning is ≥0.5 cubic meters, it is considered that the fire source is formed, and the directional drilling is switched to enter the air, the vertical well is to output the gas, and the gasification channel is processed by thermal power.

specific Embodiment approach 2

[0068] An underground gasification ignition method, comprising the steps of:

[0069] (1’) Build directional drilling and vertical wells to build underground gasifiers, and the number of vertical wells is 2;

[0070] (2') Use cold fracturing method to pre-perforate the coal seam; (3') One of the vertical wells at the end of the directional drilling is ignited, and the other vertical well outputs gas, and the directional drilling is carried out during the ignition and penetration of the vertical well. hold pressure;

[0071] (4’) When the volume of coal burning is ≥0.5 cubic meters, it is considered that the fire source is formed. According to the position of the ignition hole, it is switched to directional drilling for air intake, igniting the vertical well for gas output, and thermal processing for gasification channels.

specific Embodiment approach 3

[0072] An underground gasification ignition method, comprising the steps of:

[0073] (1’) Build directional drilling and vertical wells to build underground gasifiers, and the number of vertical wells is 2;

[0074] (2’) Pre-penetrate the coal seam by cold fracturing;

[0075] (3’) One of the vertical wells at the end of the directional drilling is ignited, and the other vertical well outputs gas, and the pressure of the directional drilling is maintained during the ignition and penetration of the vertical well;

[0076] (4’) When the volume of coal burning is ≥0.5 cubic meters, it is considered that the fire source is formed. According to the position of the ignition hole, it is switched to the original gas outlet vertical well for intake, the ignition vertical well for gas outlet, and the gasification channel for thermal processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com