Oxygen-enriched combustion engine system

An engine system, oxygen-enriched combustion technology, applied to combustion engines, internal combustion piston engines, engine components, etc., to achieve the effects of improving ignition efficiency, sufficient combustion, and reducing the possibility of deflagration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

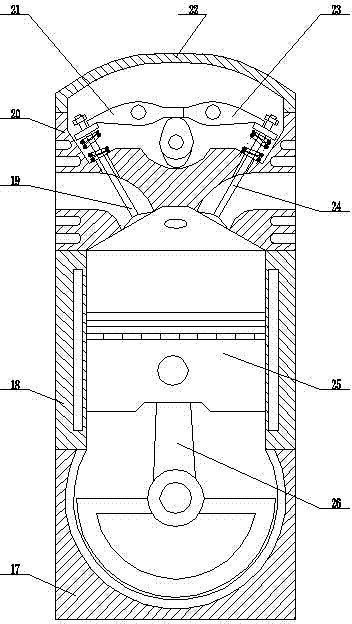

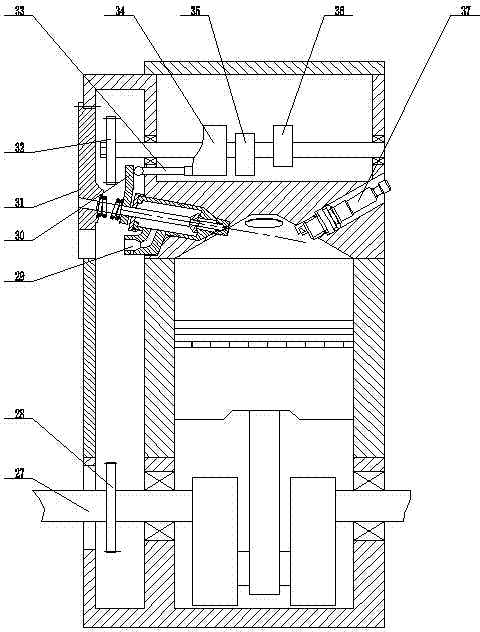

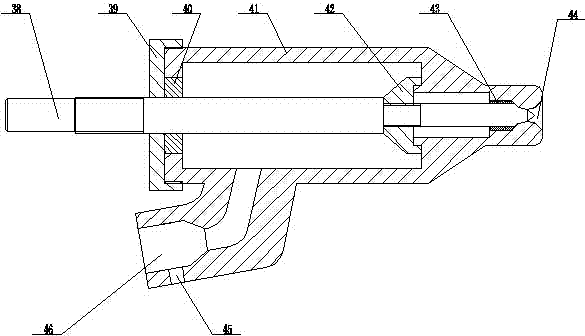

[0034] Such as Figure 1~6 as shown,

[0035] An oxygen-enriched combustion engine system, including an engine assembly and an oxygen supply device, the oxygen supply device consists of an air compressor 2, a vacuum pump 1, an air filter 3, a dryer 4, a two-position four-way solenoid valve 5, a first adsorption The tower 6, the second adsorption tower 7, the first one-way valve 8, the second one-way valve and 9, the gas storage tank 10, and the booster pump 11 are composed, and the air pressure components are connected by air pipes with joints. The air compressor is first connected in series with the air filter 3, then connected in series with the drier 4, and finally connected in series with the P port of the solenoid valve 5; the vacuum pump 1 is directly connected in series with the T port of the solenoid valve 5; Port A is firstly connected to the first adsorption tower 6 in series, and then the first one-way valve 8 is connected in series; port B is connected to the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com