Patents

Literature

112results about How to "Improve emission standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

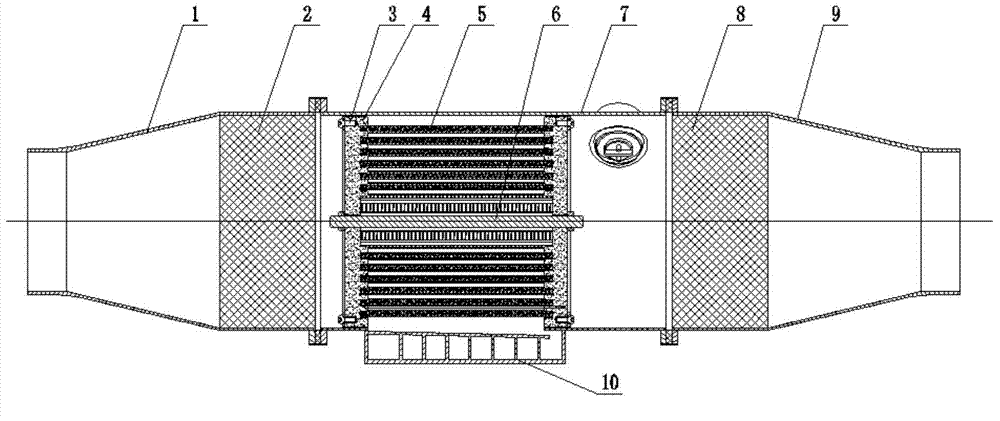

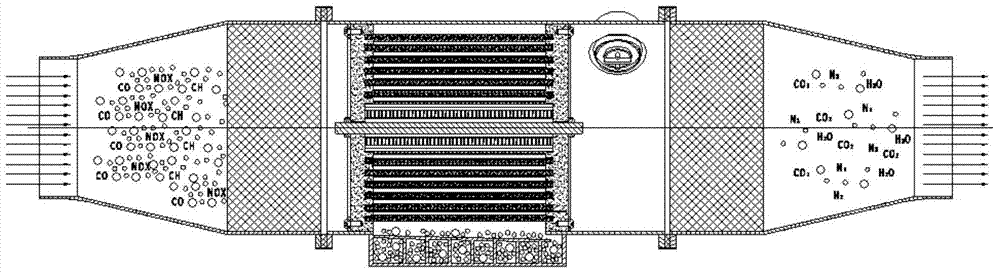

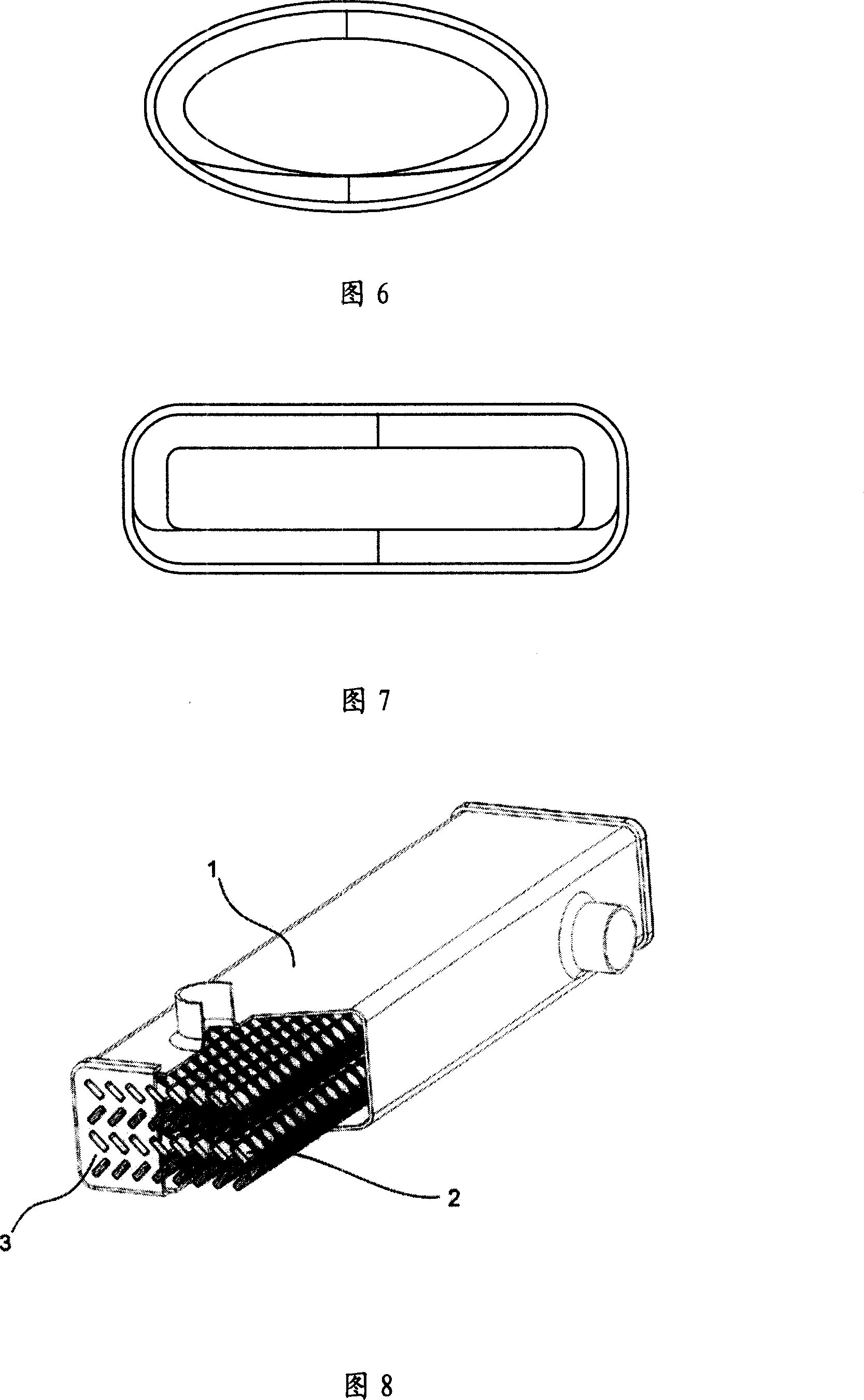

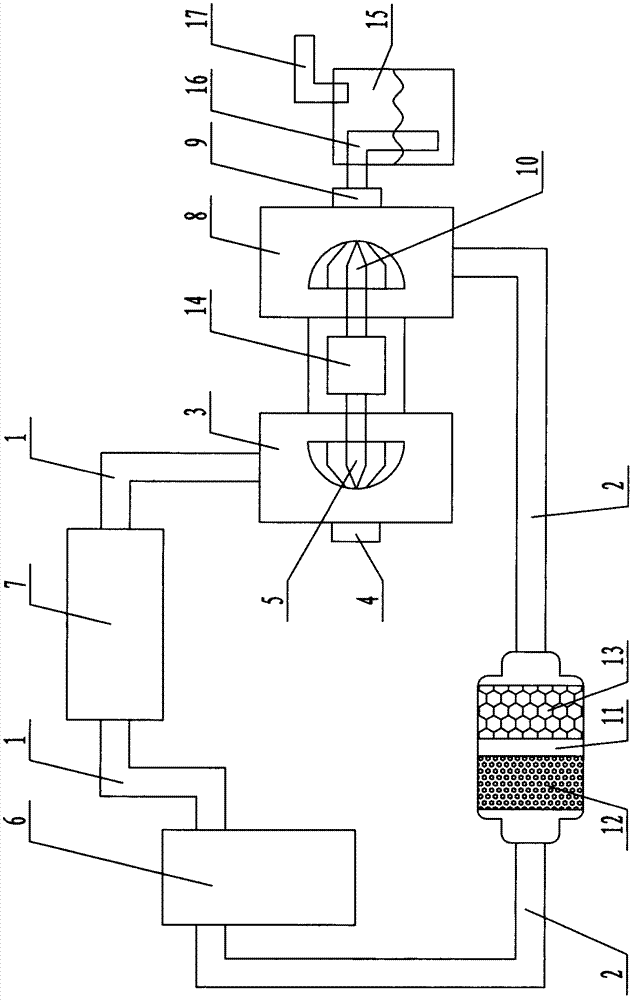

Dielectrophoresis automobile exhaust dust remover

InactiveCN103485864AReduce contentReduce pollutionExhaust apparatusSilencing apparatusEngineeringSolid particle

The invention relates to a dielectrophoresis automobile exhaust dust remover which comprises an air inlet cylinder, an air outlet cylinder, a front-end three-way catalytic converter and a rear-end three-way catalytic converter. The front-end three-way catalytic converter and the rear-end three-way catalytic converter are fixedly arranged in the air inlet cylinder and the air outlet cylinder respectively in a coaxial mode, a processing cylinder is fixedly installed between the air inlet cylinder and the air outlet cylinder in a coaxial and communicated mode, ceramic flange plates are fixedly installed at the two sides inside the processing cylinder in mirror symmetry in a coaxial mode respectively, electrode couples are fixedly distributed between the two ceramic flange plates in the radial direction at intervals, the electrode couple between the lower portion of the processing cylinder and the two ceramic flange plates is fixedly provided with a dust collecting box in a communicated mode, a gap is formed between one ceramic flange plate and the air inlet cylinder arranged at one side, and a gap is formed between the other ceramic flange plate and the air outlet cylinder at the other side. According to the dielectrophoresis automobile exhaust dust remover, the dielectrophoresis technology is adopted and due to the fact that the dielectric polarization capacity of solid particles, the dielectric polarization capacity of heavy metal and the dielectric polarization capacity of suspended gas are different, the solid particles and the heavy metal are pushed out of an electrode or the solid particles are attracted to the electrode through the dielectrophoresis force, so that the content of the solid particles and the content of the heavy metal in automobile exhaust are reduced, and therefore pollution to the atmosphere by the solid particles and the heavy metal is reduced.

Owner:BEIJING SHANGPAI ENVIRONMENTAL TECH CO LTD

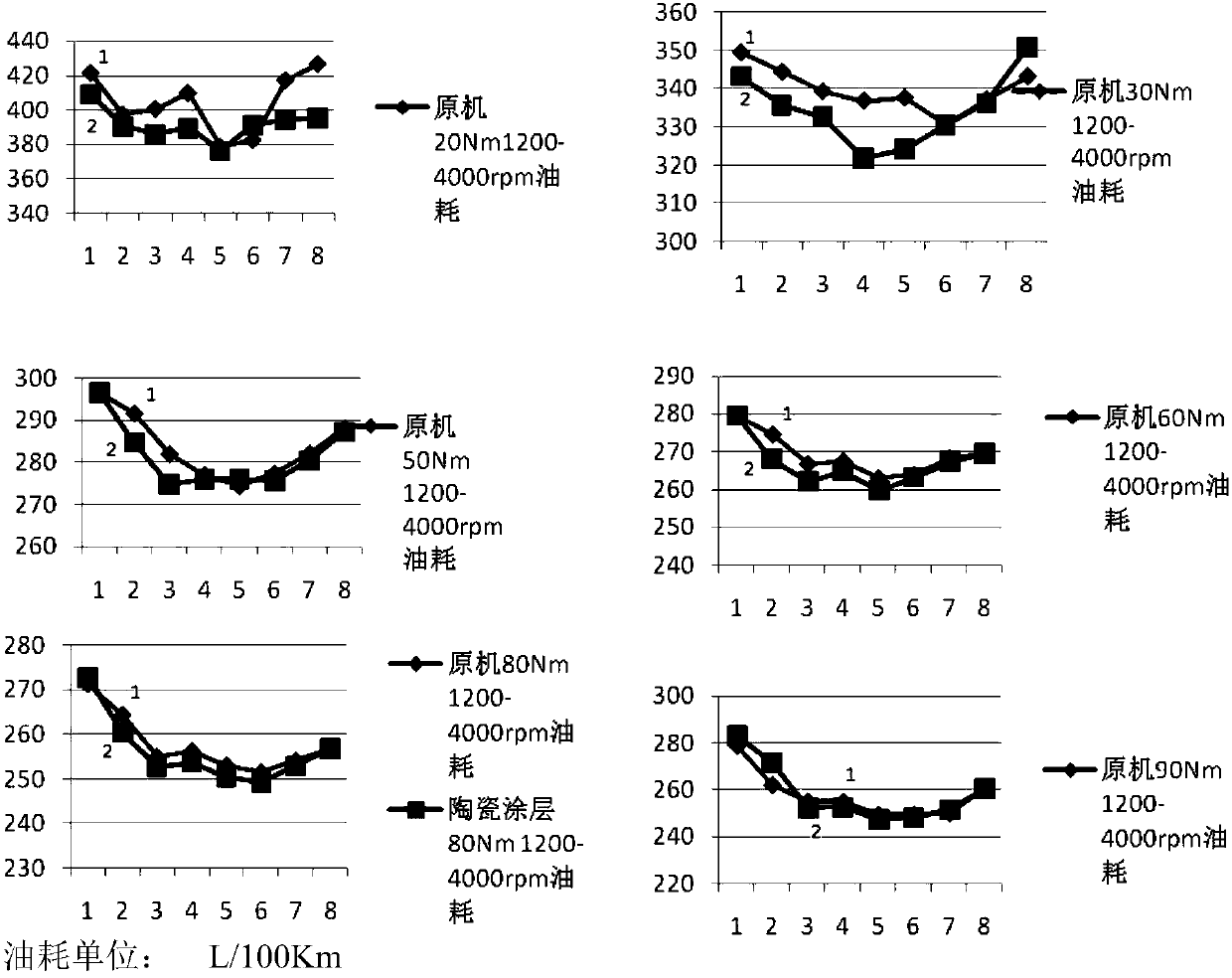

Nanometer graphene reflection thermal insulation composite multifunctional ceramic coating layer and preparation method thereof

ActiveCN105951151AOutstanding heat insulationOutstanding FeaturesAnodisationCombustion chamberPlasma electrolytic oxidation

The invention discloses a reinforced alloy material; and a surface layer of the alloy material contains such elements as aluminum oxide, silicon dioxide and nanometer graphene. The alloy material is deeply extended on the basis of anodic oxidation, microarc oxidation and multi-component composite oxidation, and is a result under a complex effect of instant high temperature, multi-component composite oxidation liquid and nanometer penetrant through applying positive and negative high voltage, high current and positive and negative pulses by using unique structures, physical and chemical characteristics as ultrahigh hardness and high-temperature resistance, small size effects and surface and interface effects of such nanometer materials as nanometer graphene and nanometer silicon dioxide. The method comprises the steps of: (1) surface cleaning; (2) oxidation; and (3) penetration. The light alloy material after surface reinforcement by the method, in particular a combustion chamber of an internal combustion engine with fuel combustion consumption and generating a pollution source is prominent in reflection thermal insulation anti-carbon self catalysis function, and is higher in high-temperature erosion resistance and wear resistance.

Owner:四川鸿森达铝业科技有限公司

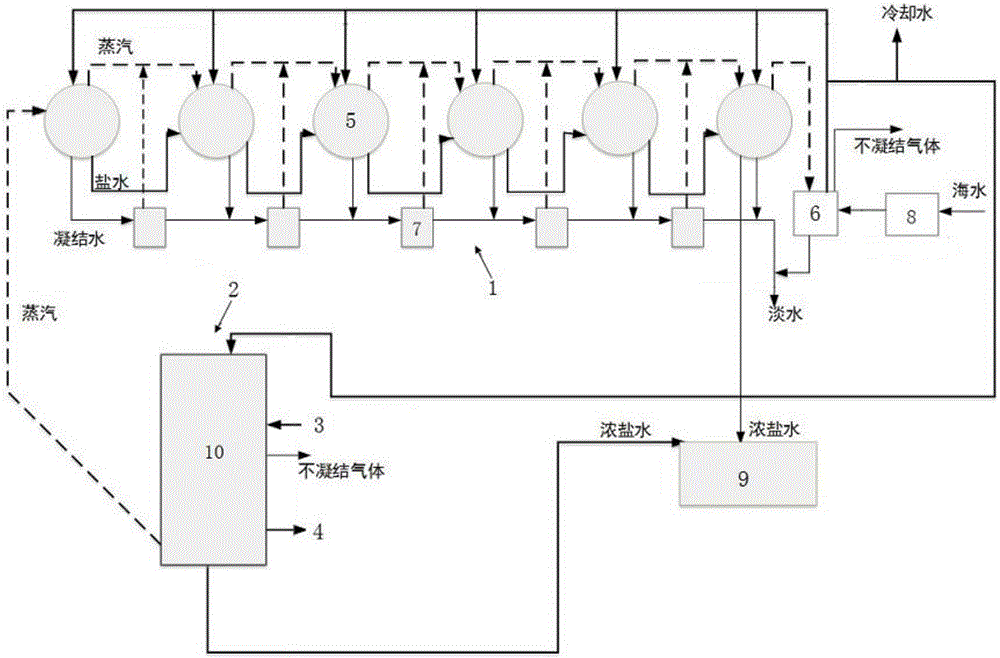

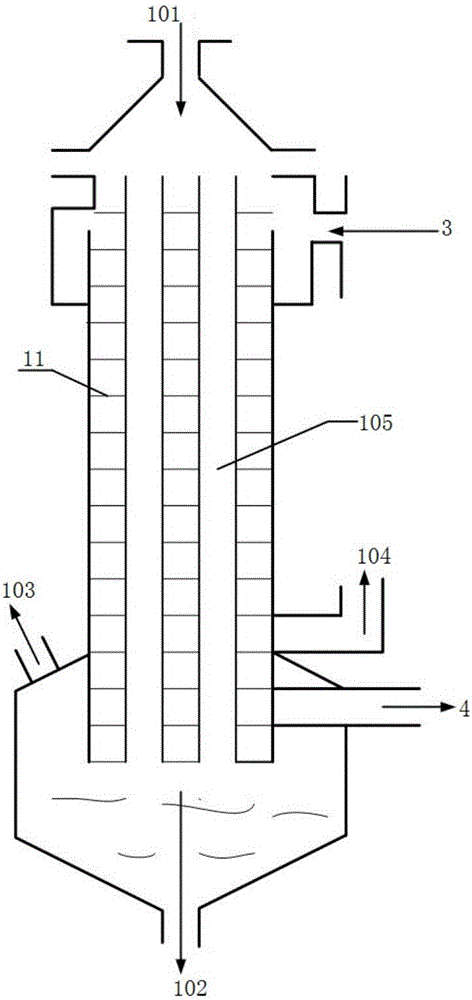

MED-TVC seawater desalination combination system by means of power station waste heat

InactiveCN105712423AIncrease productionReduce consumptionGeneral water supply conservationSeawater treatmentDistillationEngineering

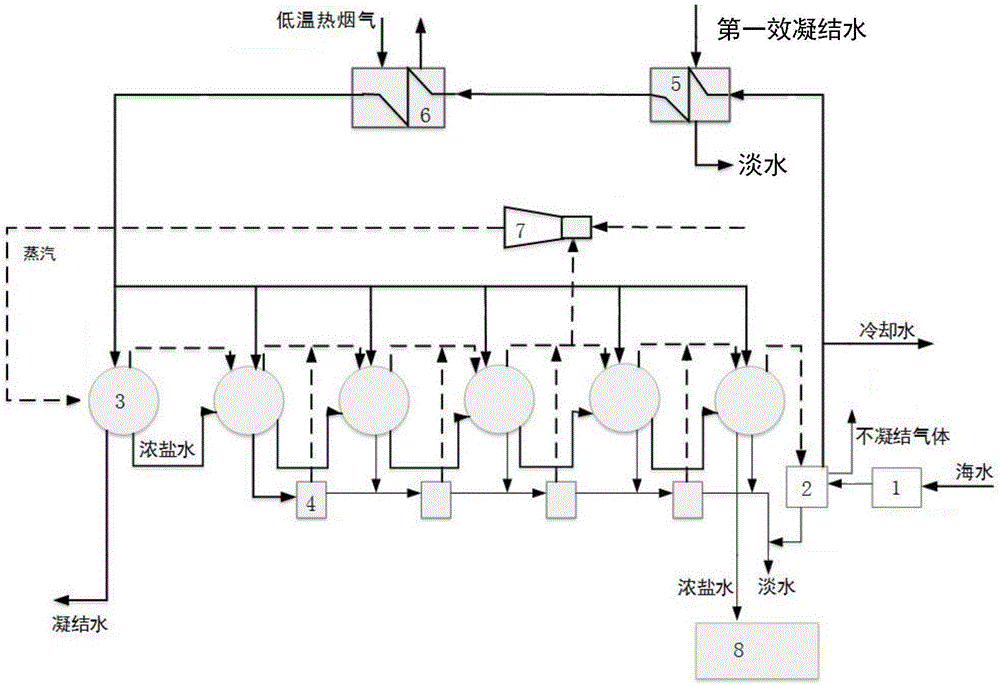

The invention relates to an MED-TVC seawater desalination combination system by means of power station waste heat. Seawater is preprocessed, conveyed to a condenser to be preheated and then further preheated through a first heat exchanger and a second heat exchanger in sequence, and enters N-effect evaporators through pipelines in a shunting mode, wherein a heat source of the first heat exchanger is condensation water of the first-effect evaporator, and a heat source of the second heat exchanger is low-temperature hot flue gas flowing inside the second heat exchanger; meanwhile, low-temperature steam extraction and middle-effect steam of a turbine are introduced to the first-effect evaporator through a steam ejector, a heat source of multi-effect distillation seawater desalination is provided, seawater is distillated on the basis of the MED-TVC technology to obtain desalted water, the condenser condenses steam flowing out of the last-effect evaporator and preheats seawater, and strong brine in the Nth-effect evaporator is conveyed to a salt chemical engineering technological unit. Power station low-temperature flue gas and low-pressure steam extraction waste heat of the turbine are recycled, seawater desalination production is achieved, the seawater desalination cost is effectively lowered, and no secondary pollution is generated.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Remote monitoring system for industrial exhaust gas discharging based on Internet-of-things

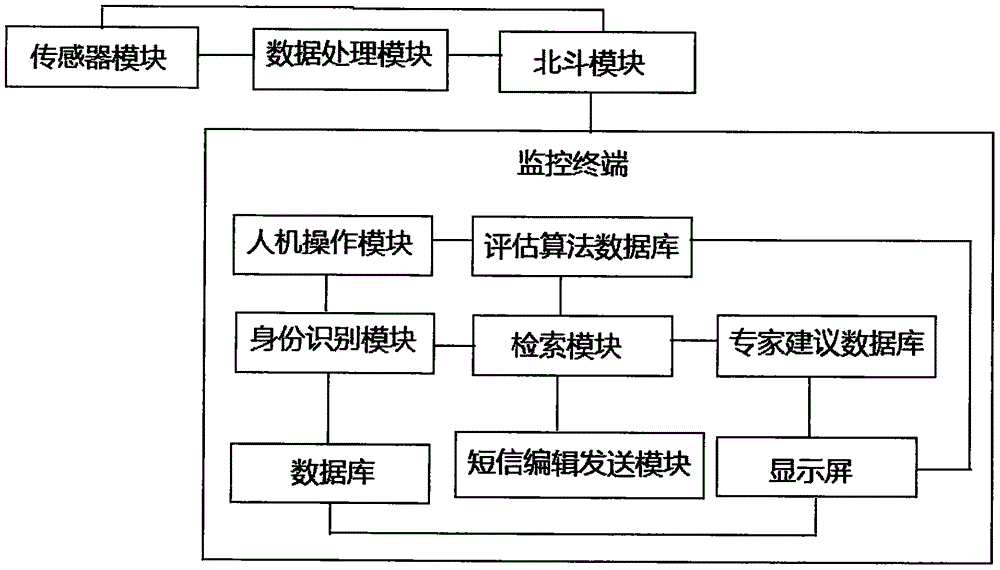

InactiveCN105867273AWide range of applicationsEasy to repair and replaceProgramme controlComputer controlCarbon disulfideExhaust gas

The invention discloses a remote monitoring system for industrial exhaust gas discharging based on Internet-of-things. The remote monitoring system comprises the components of a sensor module which is used for detecting concentrations of matters such as carbon dioxide, carbon disulfide, hydrogen sulfide and fluoride in discharged industrial exhaust gas; a data processing module which is receiving and processing detected data and transmitting the detected data to a Beidou module; Beidou modules which are mounted in the sensors and are used for receiving data transmitted from the data processing module, performing position marking on the received data by means of the corresponding sensor and transmitting the data to a monitoring terminal in a short message communication manner; and a monitoring terminal which is used for evaluating the received data through a preset evaluation algorithm, and if a standard is exceeded, performing early warning and generating a related treatment suggestion. The remote monitoring system realizes real-time monitoring on the industrial exhaust gas and has wide application range. The mounting structure of the sensors facilitates maintenance and replacement. Furthermore monitoring accuracy on the industrial exhaust gas is improved.

Owner:XINJIANG INST OF ENG

Multiple-effect distillation seawater desalination system adopting power station waste heat

InactiveCN105692750AReduce fresh water costsReduce flue gas temperatureGeneral water supply conservationSeawater treatmentSeawaterSaline water

The invention relates to a multiple-effect distillation seawater desalination system adopting power station waste heat. Seawater is pretreated through a pretreatment system and then sent to a condenser, and seawater flowing out of the condenser is divided by a pipeline to enter an N-effect evaporator and a heat exchanger; meanwhile, seawater is heated by the heat exchanger by means of low-temperature smoke, smoke waste heat is recovered to obtain steam, steam is introduced into a first-effect evaporator to provide a heat source for multiple-effect distillation seawater desalination, desalted water is obtained through desalination treatment of seawater by means of the low-temperature multiple-effect distillation technique, condensation of steam flowing out of a final-effect evaporator and seawater preheating are conducted by means of the condenser, and strong brine in the N-effect evaporator and the heat exchanger is sent to a salt chemical engineering technological unit. By recycling low-temperature smoke waste heat of coal-fired power plants, low-cost seawater desalination production is achieved, and secondary pollution is avoided in the whole process.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

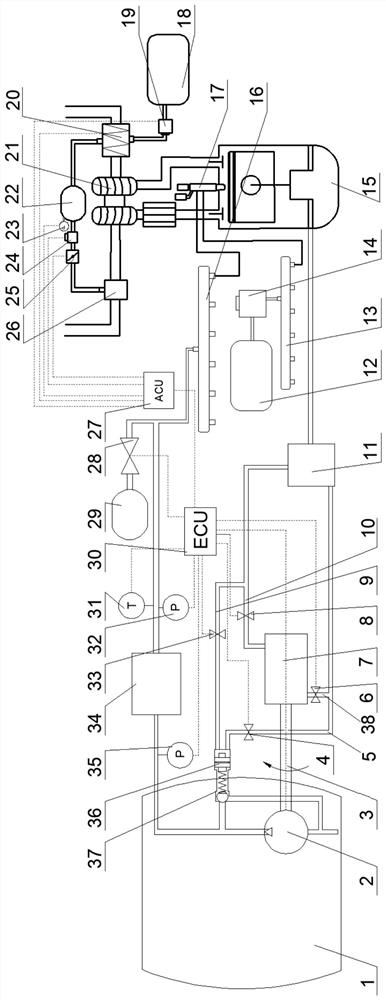

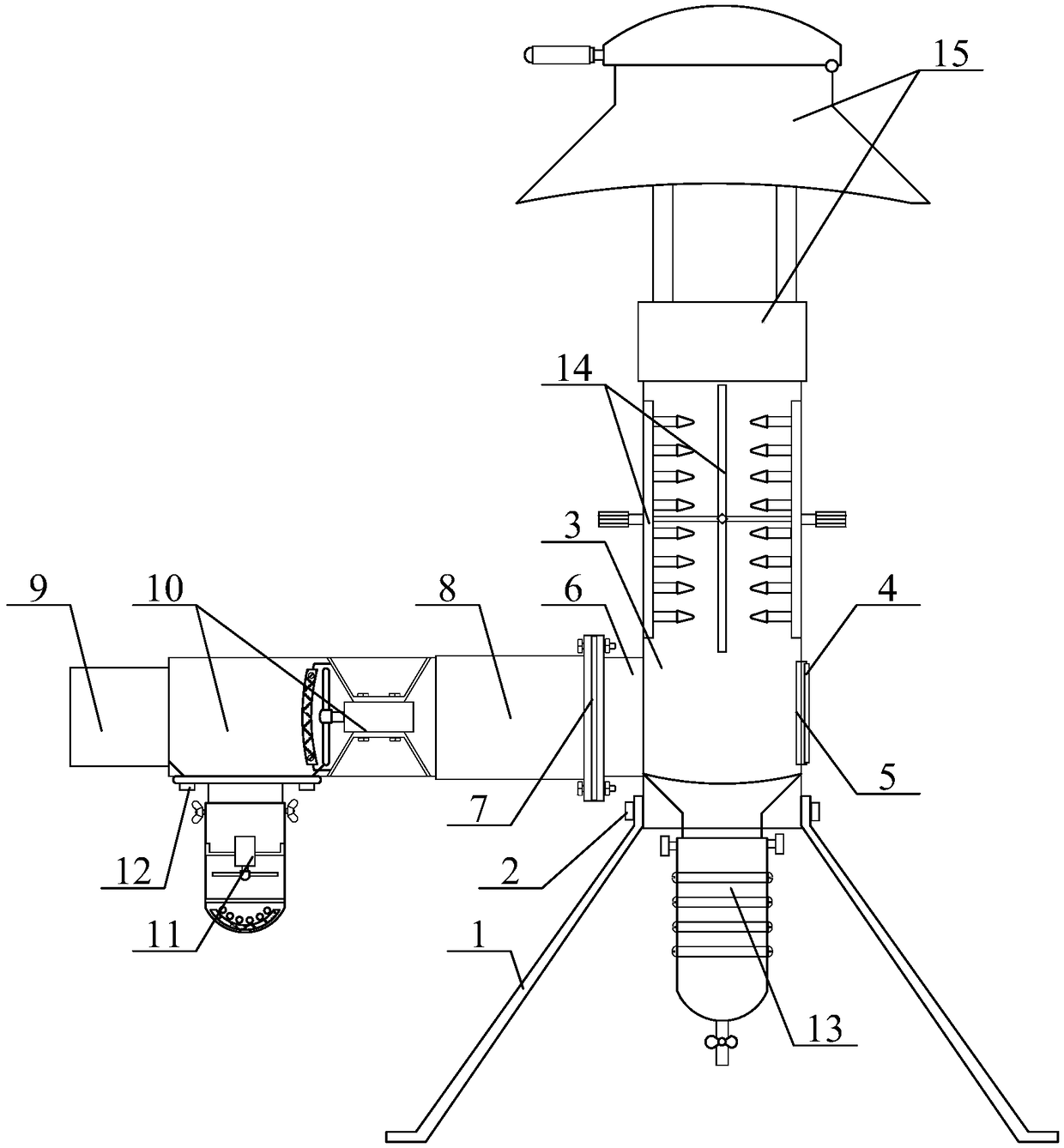

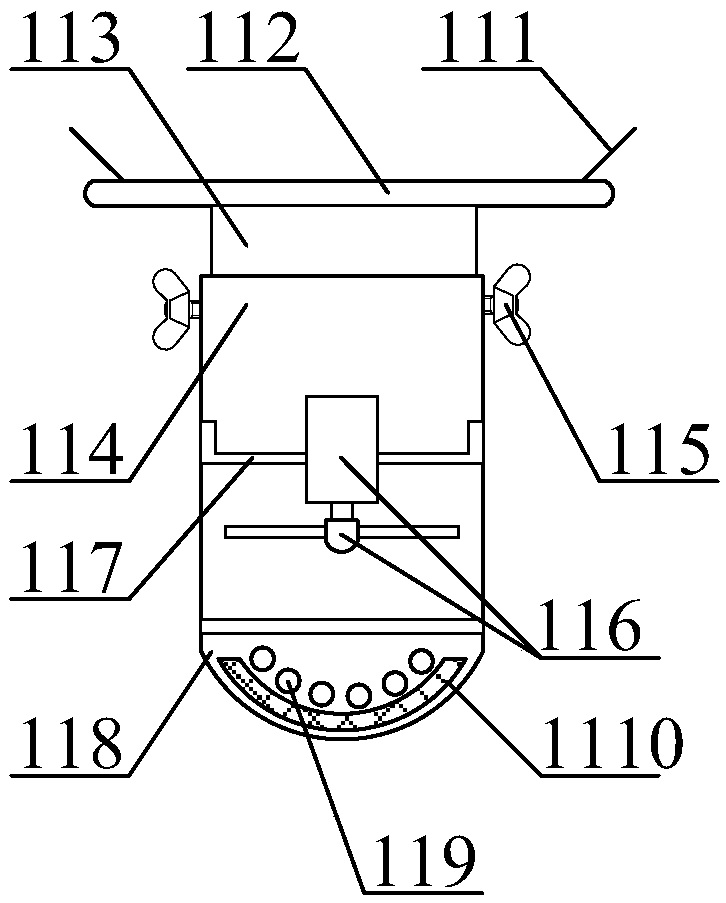

Direct injection natural gas engine system based on ammonia pyrolysis device and control method of direct injection natural gas engine system

ActiveCN112901339AReduce consumptionPromote combustionProcess control/regulationElectrical controlCatalytic pyrolysisGear pump

The invention discloses a direct injection natural gas engine system based on an ammonia pyrolysis device and a control method of the direct injection natural gas engine system. The engine system comprises an LNG boost pressure regulation and control device, an ammonia pyrolysis device and an ammonia pyrolysis device electric control unit. The control method comprises the steps of controlling the fuel gas supply process and controlling the ammonia pyrolysis device. According to the ammonia pyrolysis device, catalytic pyrolysis of ammonia is achieved, liquid ammonia is converted into ammonia pyrolysis gas, the ammonia pyrolysis gas is introduced into a gas inlet system of a high-pressure direct injection natural gas engine, a proper amount of the ammonia pyrolysis gas is supplied to an engine cylinder in the gas inlet process of the engine, the ammonia pyrolysis gas is optimized, combustion in the cylinder is improved, HC emission is reduced, and the high emission standard is met; and according to the LNG boost pressure regulation and control device, the original plunger pump boosting mode is improved into the combined application of an internal gear pump and the LNG boost pressure regulation and control device, and the high-pressure direct injection natural gas engine works under the working conditions of the optimal LNG boost pressure and the optimal LNG flow according to the pressure and the flow.

Owner:HEBEI UNIV OF TECH

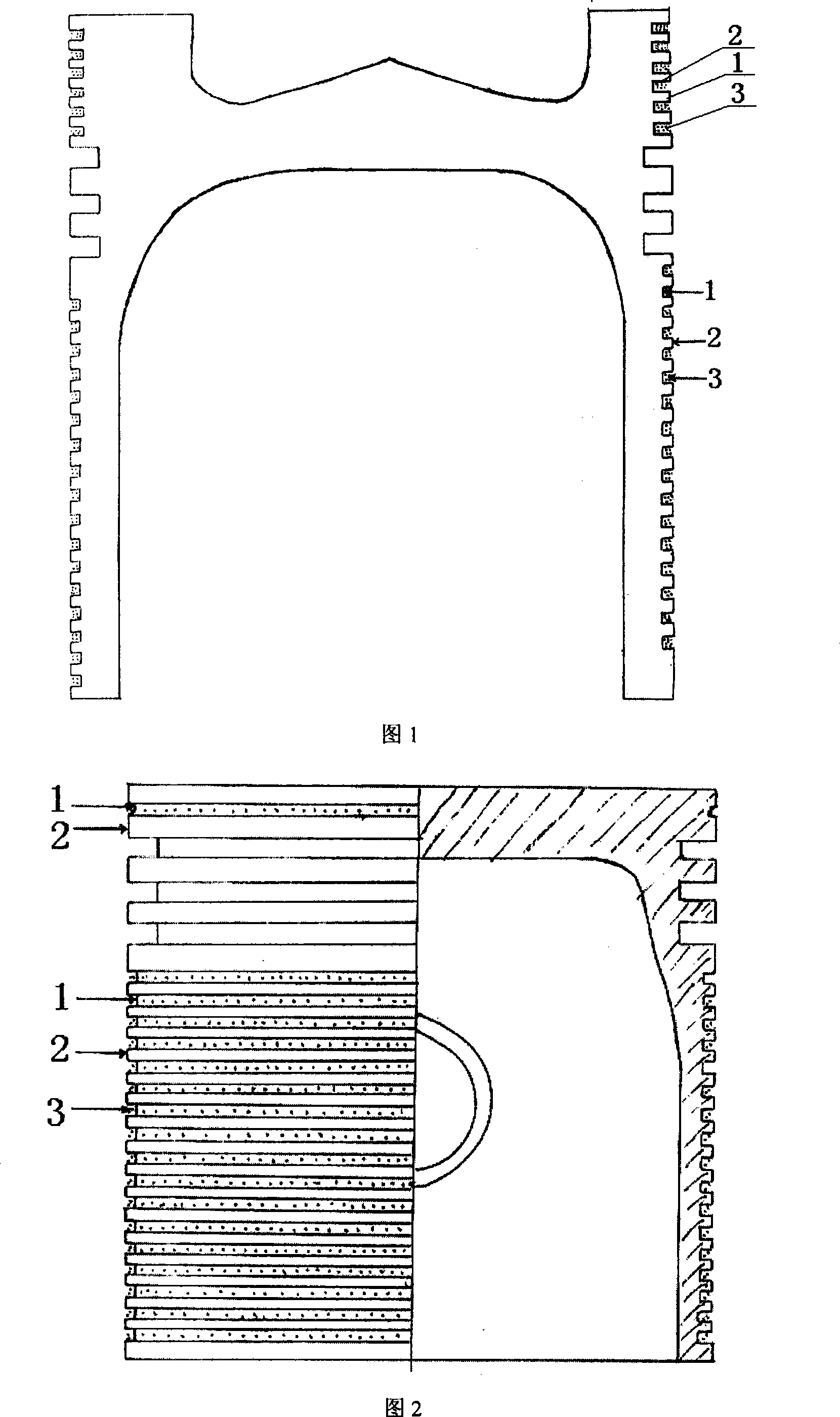

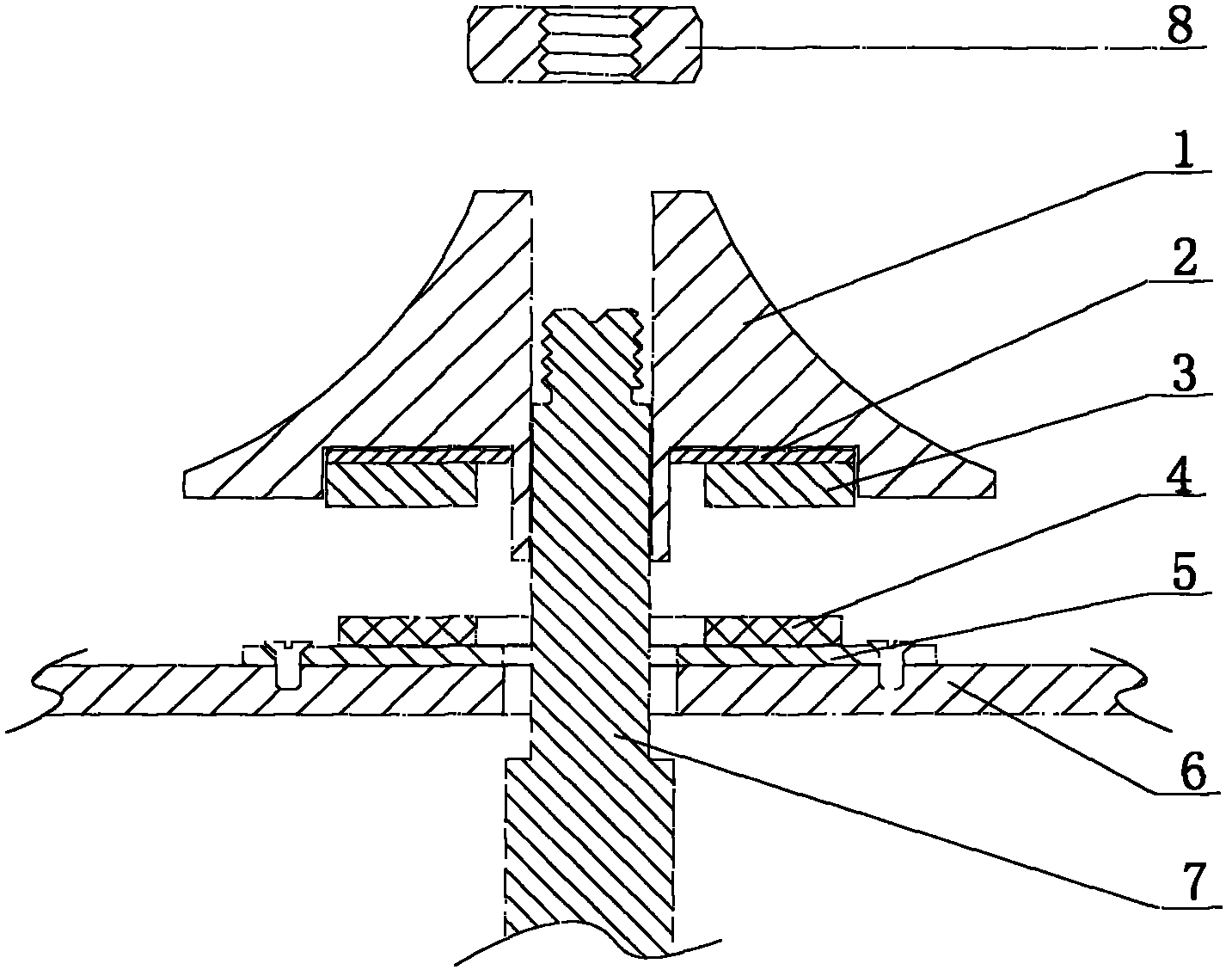

High-lubricating low-friction piston

InactiveCN101178124ARun fastGuaranteed uptimePositive displacement pump componentsPlungersPiston ringEngineering

The invention relates to a high lubrication low friction piston applied to a reciprocating piston internal combustion engine and an air compressor. The technical proposal is that the invention mainly consists of a piston head part, a piston skirt part and a piston cirque trough. The invention is characterized in that the side surface of the external wall of the piston is provided with a plurality of concave troughs which can move along the side surface radian of the external wall of the piston; an interval on the side surface of the external wall of part of the piston preserved between adjacent concave troughs forms a convex ridge; the most convex position of the convex ridge is aligned with the side surface of the external wall of the piston. The invention has the beneficial effects of reinforcing the lubrication performance, reducing the friction resistance, preventing cylinder expansion and locking, reinforcing the sealing performance, improving the exhaust standard and relieving the pollution exhaust, and prolonging the service life of the engine.

Owner:周林

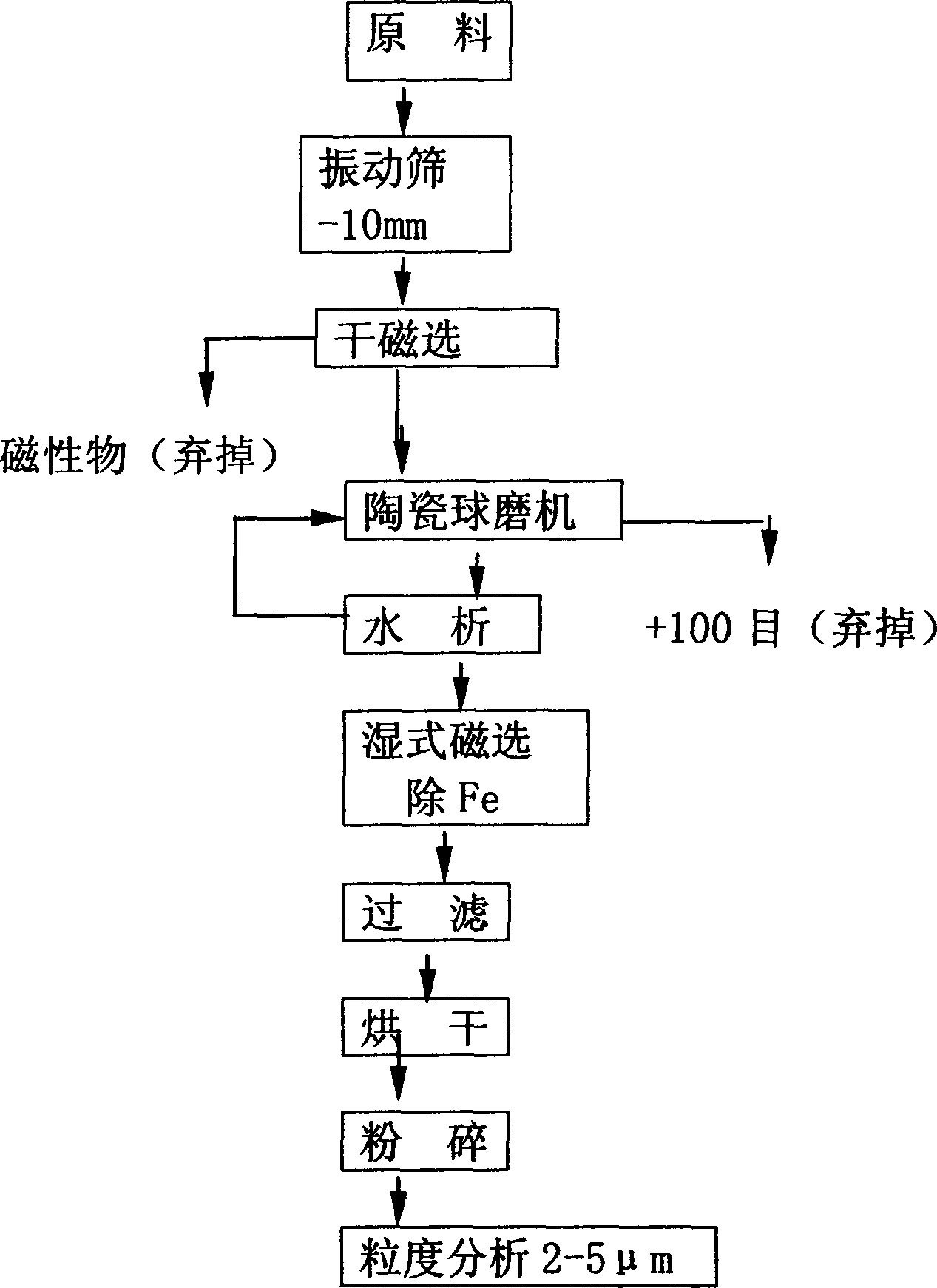

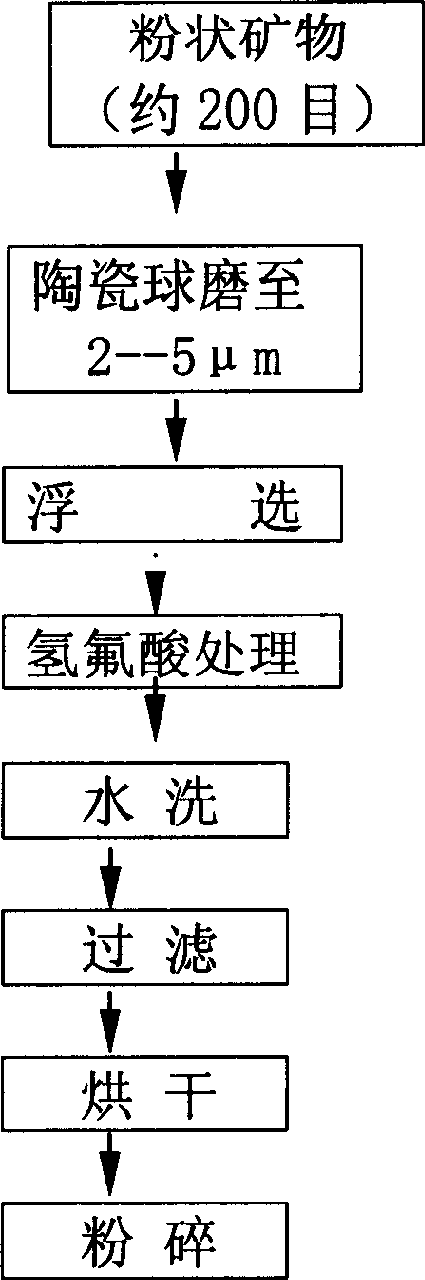

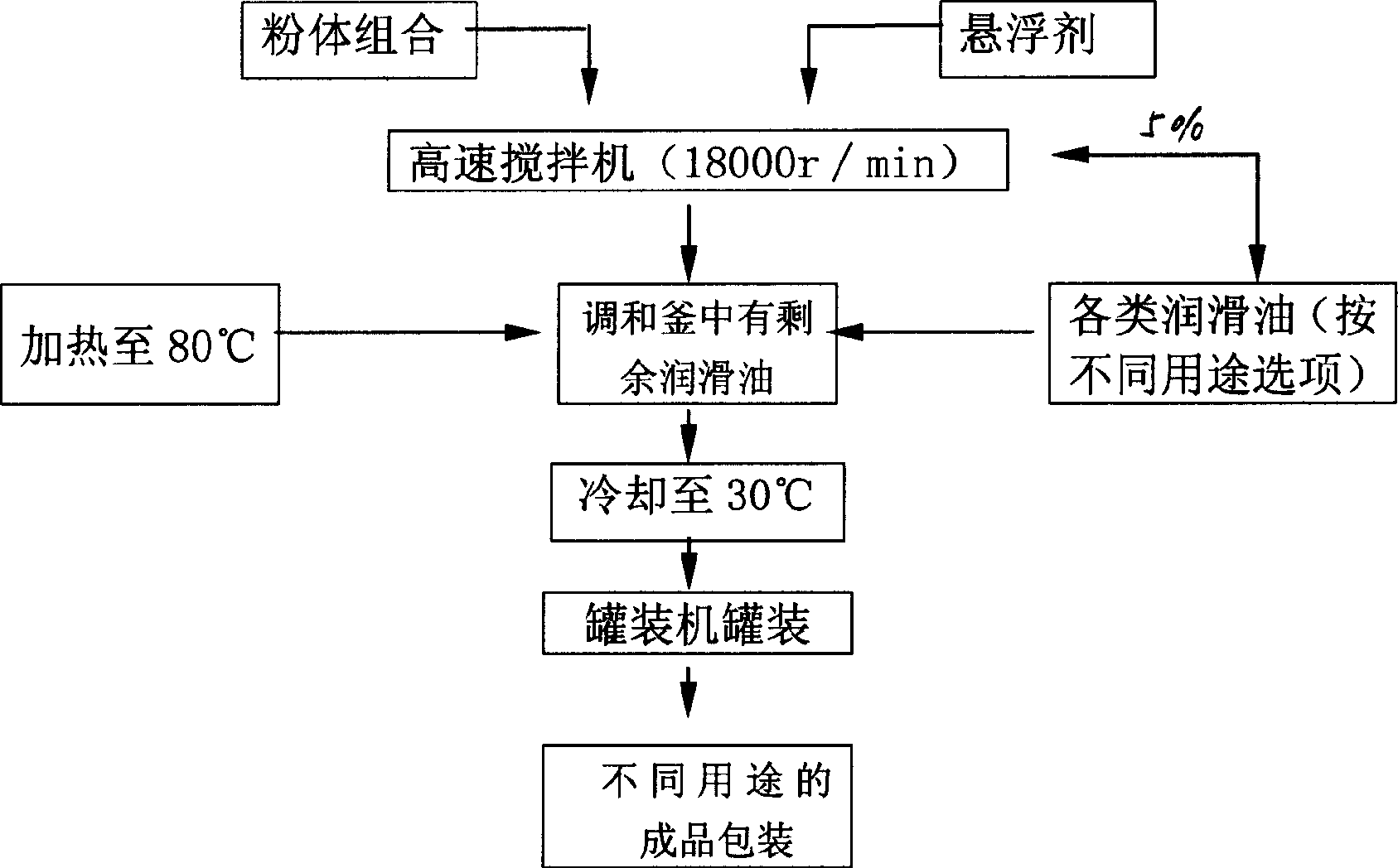

Antiwear dynamic self-repairing lubricant for metal and preparation method thereof

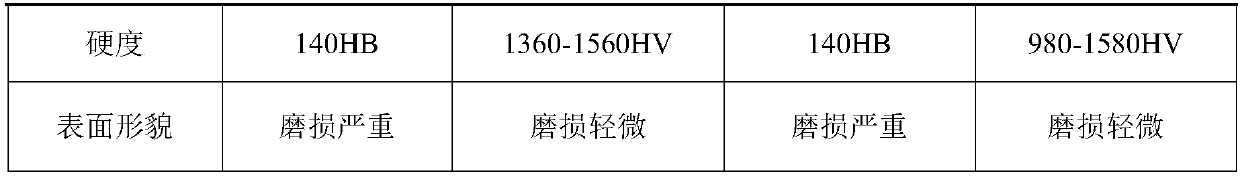

ActiveCN1654608ASave fuelReduce the number of oil changesAdditivesBase-materialsIron based alloySelf repair

The metal friction resisting and wear reducing dynamically self-repairing lubricant is composition of mineral matter, suspending agent and lubricating oil; and features that the mineral matter consists of chrysotile 57.5-64 wt%, blue asbestos 12-16 wt%, amorphous graphite 9-12 wt%, diopside 4.5-6 wt% and sericite 4.5-6 wt%. The preparation process of the metal friction resisting and wear reducing dynamically self-repairing lubricant includes the following steps: processing the mineral matter into 2-5 micron powder and mixing to form combined mineral powder; mixing the combined mineral powder with suspending agent and lubricating oil through heating and stirring; and packing. Test shows that the lubricant can form protecting layer on the friction pair surface with hardness over 2 times of iron-base alloy, and result in friction coefficient one magnitude order lowered.

Owner:张继武

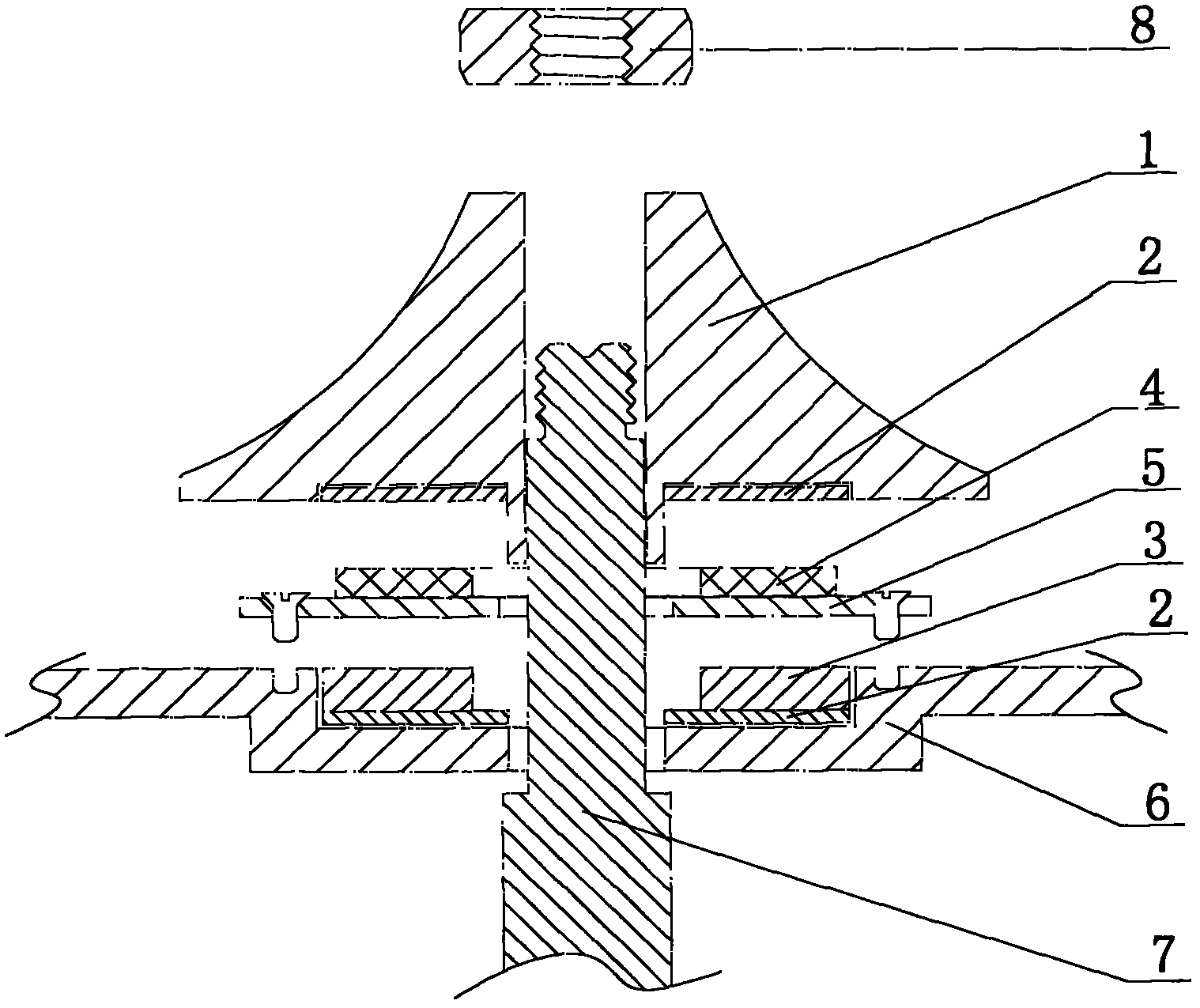

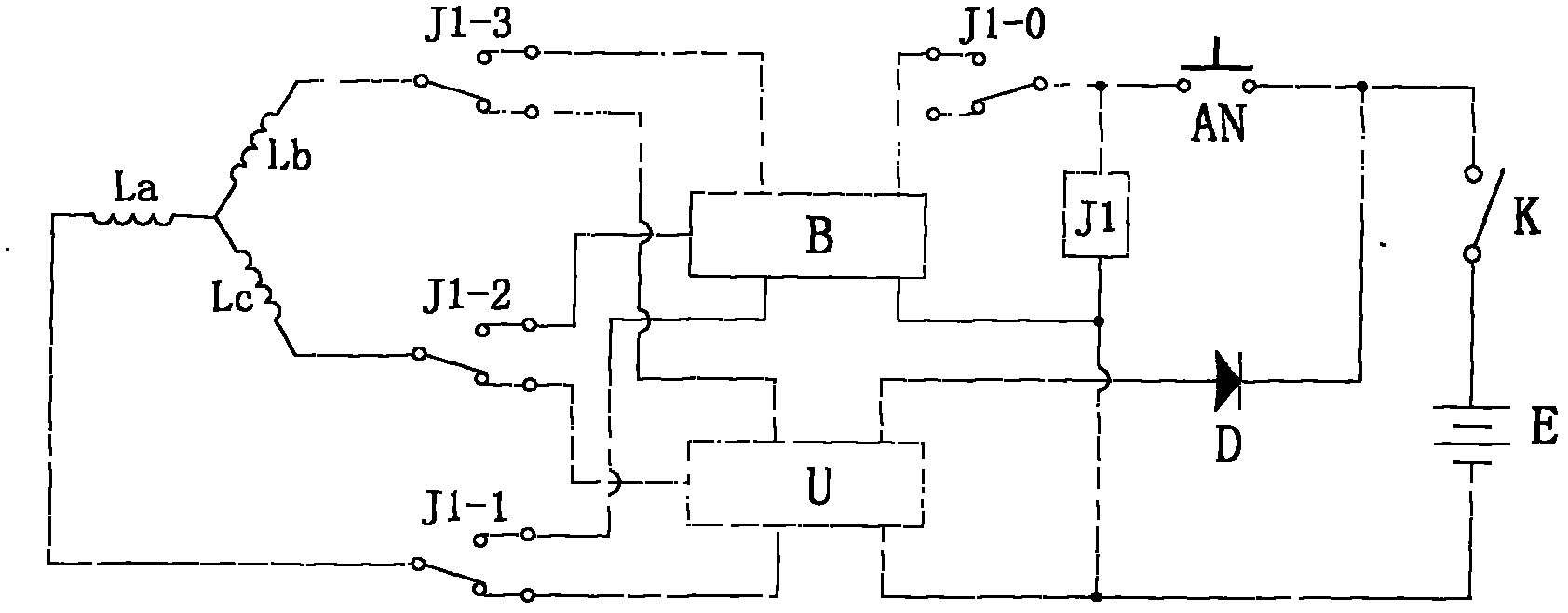

Starting-generating device for miniature turbojet engine or turbocharger

ActiveCN102691529AShorten the lengthImprove combustion efficiencyEngine manufactureEngine fuctionsImpellerPermanent magnet rotor

The invention relates to a starting-generating device, particularly relates to a starting-generating device for a miniature turbojet engine or a turbocharger and aims at providing a device which is simple in structure, improves energy efficiency and integrates starting and generating. An adopted technical scheme is as follows: a permanent magnet rotor and a stator coil are arranged at the inner side of an impeller of the miniature turbojet engine or the turbocharger, wherein the impeller rotates along with a rotating shaft; the permanent magnet rotor rotates along with the rotating shaft; the stator coil is fixed a diffuser of the miniature turbojet engine or a compressor rear cover of the turbocharger; and the permanent magnet rotor, the stator coil, the impeller and the rotating shaft are arranged coaxially. The starting-generating device is unlikely to be damaged due to the hidden installation position; the rotating shaft of an original machine is utilized and a rotor bearing is omitted, therefore the structure is simple and reliable; and the starting-generating device integrates two functions of starting and generating, therefore resources are saved and the energy efficiency is improved.

Owner:BEIJING LIANGMING TONGCHUANG WATER TREATMENT EQUIP DEV CENT

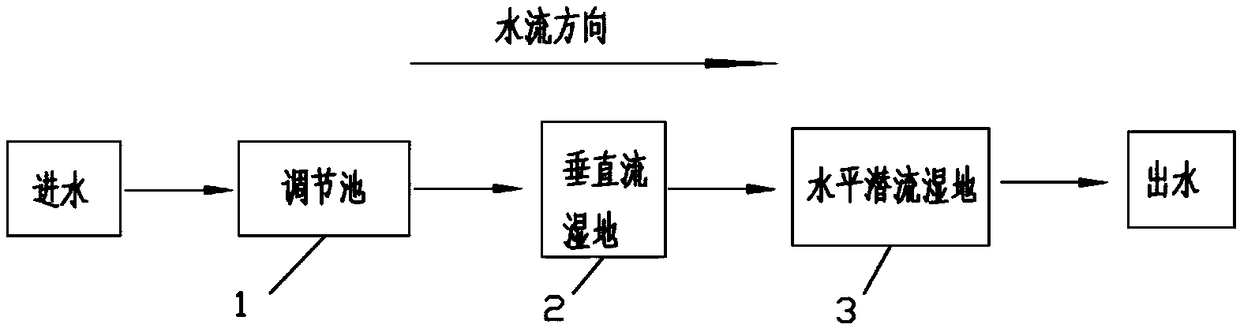

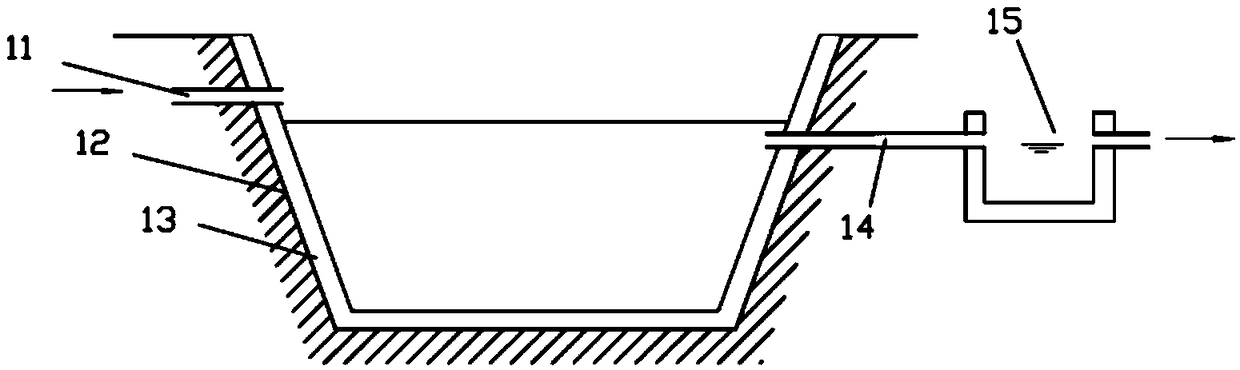

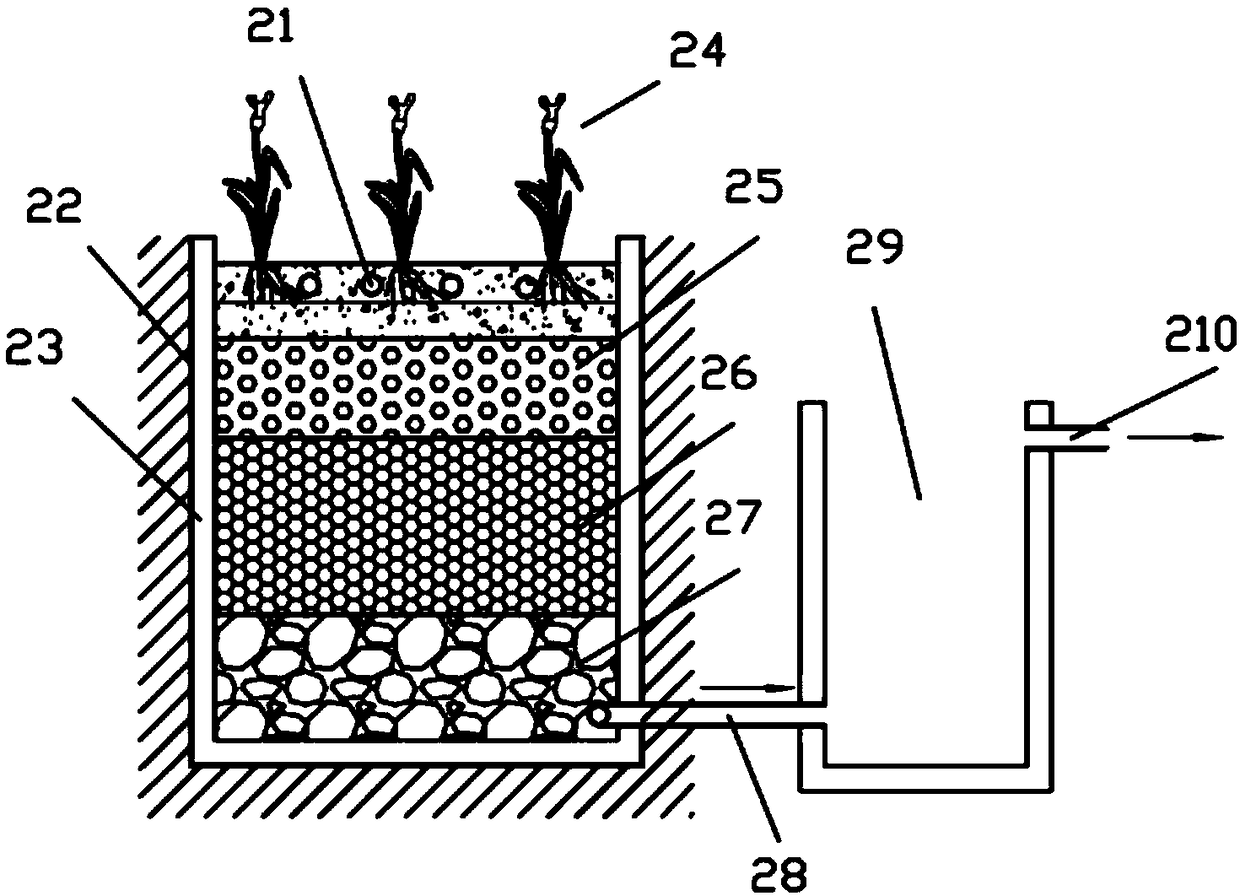

Nitrogen and phosphorus removal composite filler artificial wetland and sewage treatment method

PendingCN109081446AImprove emission standardsEfficient removalWater contaminantsBiological treatment apparatusConstructed wetlandWater storage tank

The invention relates to the technical field of sewage treatment, in particular to a nitrogen and phosphorus removal composite filler artificial wetland and a sewage treatment method. The artificial wetland comprises an adjusting tank, a vertical flow artificial wetland and a horizontal subsurface flow artificial wetland which are sequentially arranged along a water flow direction, the adjusting tank comprises a water storage tank and a water distribution tank, the water distribution tank is used for adjusting water outlet amount and flow speed of the water storage tank, the water inlet end ofthe water distribution tank is communicated with a water outlet of the water storage tank, a water inlet of the vertical flow artificial wetland is communicated with the water outlet end of the waterdistribution tank, a water outlet of the vertical flow artificial wetland is communicated with the water inlet end of a water distribution channel, the water outlet end of the water distribution channel is communicated with the water inlet end of the horizontal subsurface flow artificial wetland, the water outlet end of the water distribution channel is higher than the water inlet end of the water distribution channel, and a broken stone filler layer, a slow-release carbon source filler layer and an aluminum sludge filler layer are sequentially laid on the vertical flow artificial wetland from bottom to top. The artificial wetland effectively solves the problems of insufficient microbial denitrification process carbon source and poor phosphorus adsorption effect of a base material in theartificial wetland, the problem of blocking of the base material of the artificial wetland is relieved, and nitrogen and phosphorus removal effects are enhanced.

Owner:JIANGSU LONG LEAPING ENG DESIGN

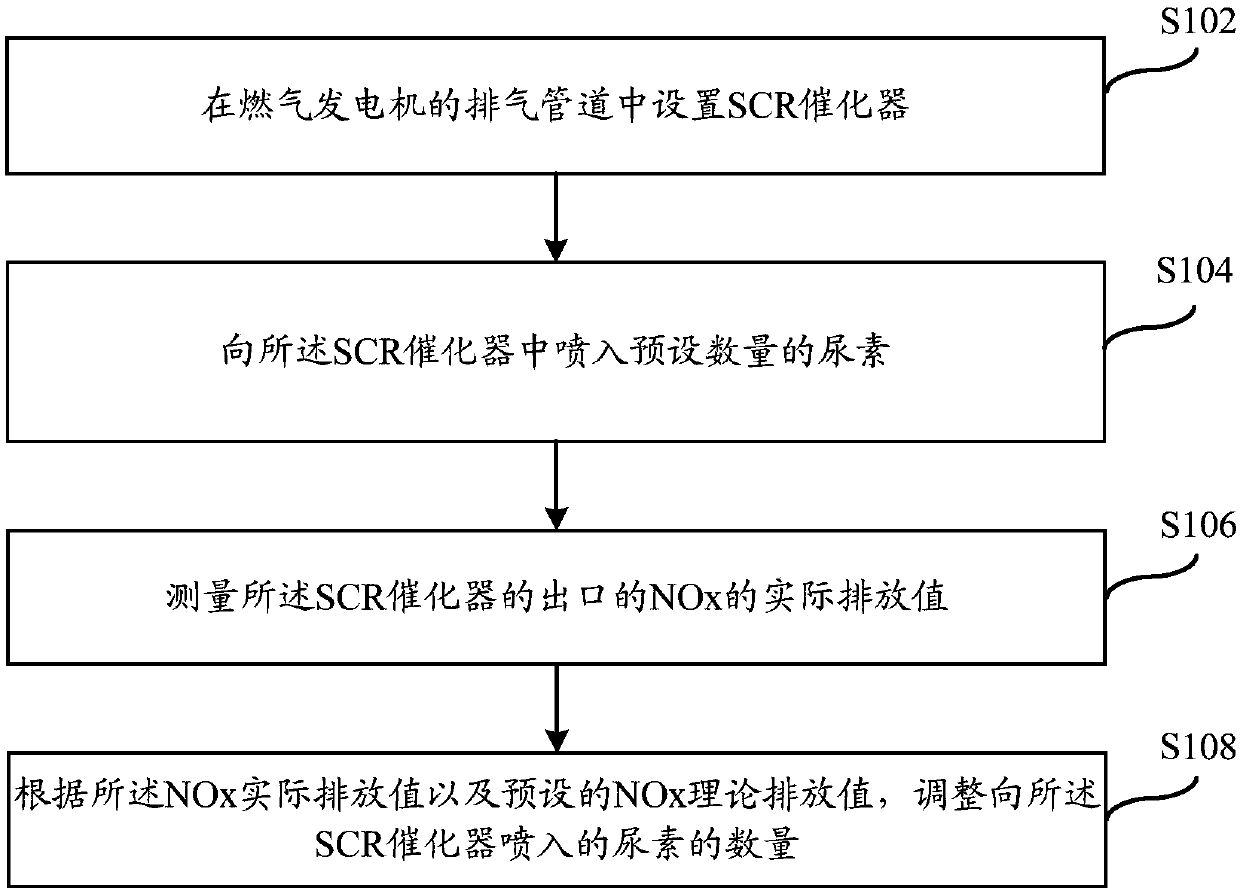

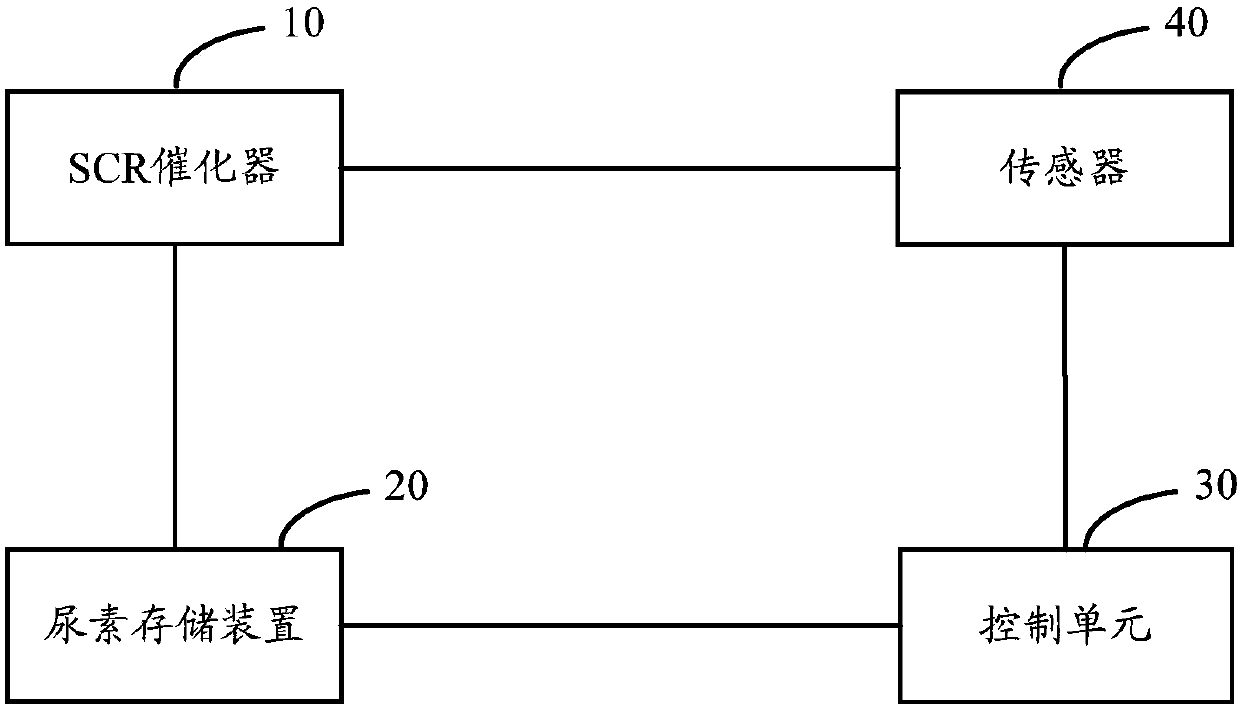

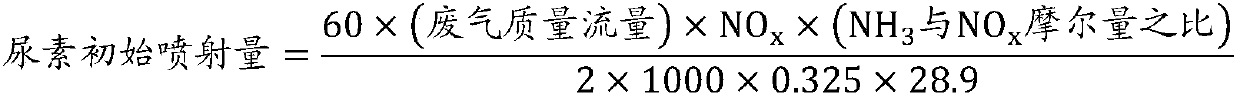

Fixed type gas turbine generators tail gas treatment method and system thereof

InactiveCN110145387AReduce mistakesReduce volatilityInternal combustion piston enginesExhaust apparatusProcess engineeringEngineering

The invention discloses a fixed type gas turbine generators tail gas treatment method and system thereof. The method comprises the following steps that an SCR catalyst is arranged in an exhaust pipeline of the gas turbine generators; a preset number of urea is sprayed into the SCR catalyst; an actual emission value of NOx of an outlet of the SCR catalyst is measured; and according to the actual NOx emission value and a preset NOx theoretical emission value, the quantity of urea injected into the SCR catalyst is adjusted. According to the method, the tail gas emission standard of the fixed typegas turbine generator can be effectively improved.

Owner:闵敏

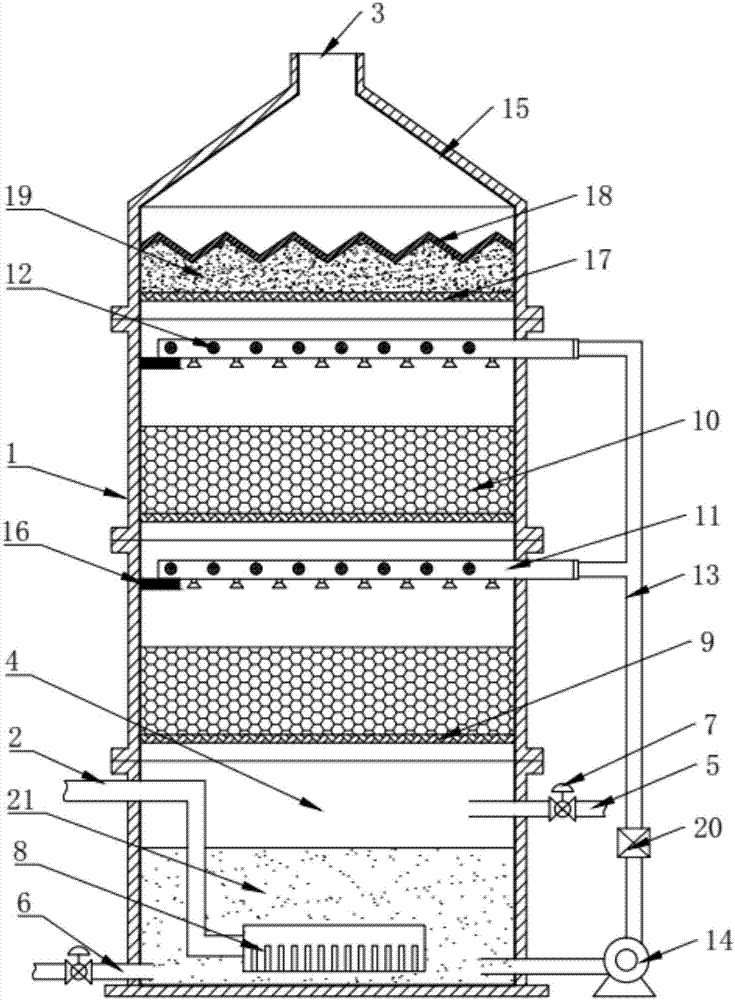

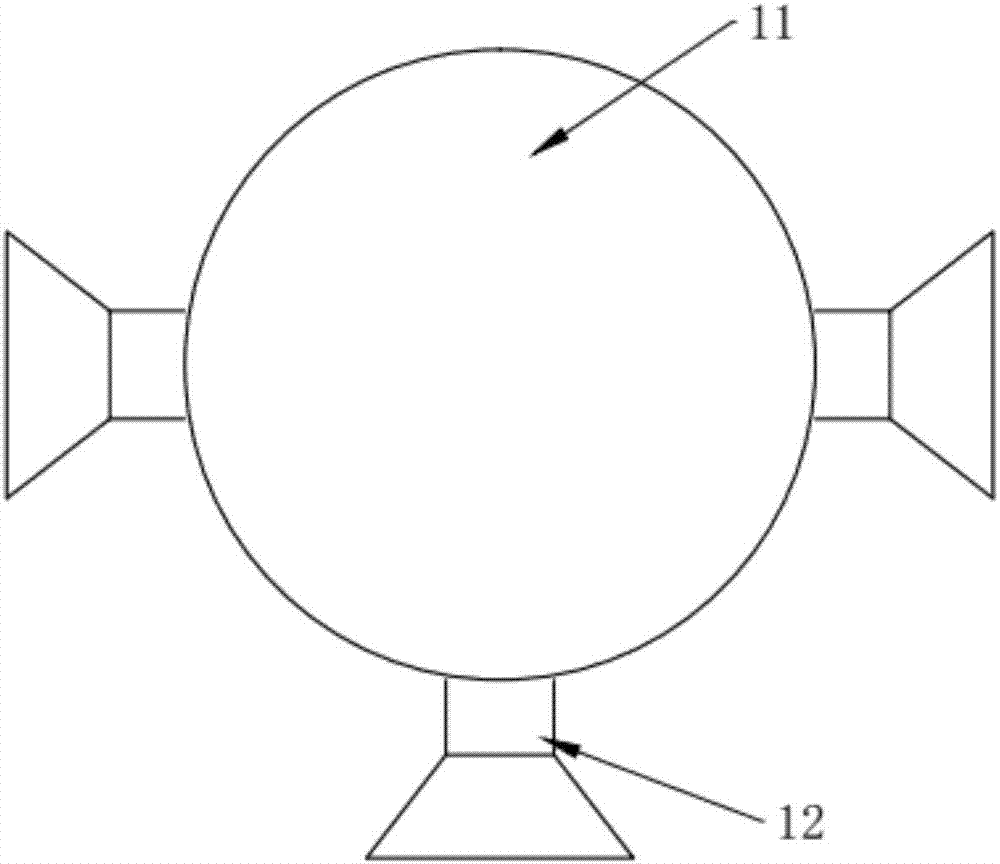

Electrolysis zinc acid mist treatment device

PendingCN107413185AIncrease contact areaImprove absorptionCombination devicesGas treatmentAfter treatmentProduct gas

The invention belongs to the technical field of acid mist treatment equipment, and provides an electrolysis zinc acid mist treatment device. The electrolysis zinc acid mist treatment device comprises a tower body provided with an acid mist inlet pipe and an exhaust pipe arranged at the top of the tower body, a liquid storage chamber for storing alkaline liquid is arranged at the bottom of the tower body, the tower body is respectively provided with a liquid inlet pipe and a liquid outlet pipe which are communicated with the liquid storage chamber, the gas outlet of the acid mist gas inlet pipe is communicated with a gas distributor located below the liquid level of the alkaline liquid; the cavity of the tower body above the liquid storage chamber is provided with at least two levels of filler absorption sections in sequence, and the upper part of each filler absorption section is correspondingly provided with a spray pipe, the periphery of the spray pipe is provided with a plurality of atomizing nozzles communicated with the spray pipes, the inner cavity of the tower body is provided with a filler demisting section near the top; the bottom of the tower body is provided with a spray liquid supplying pipe communicated with the liquid storage chamber, the spray liquid supplying pipe is respectively communicated with the spray pipes through a liquid conveying pump. The electrolysis zinc acid mist treatment device improves the purifying effect on electrolysis zinc acid mist, and the emitted gas after treatment can reach higher emission standards.

Owner:衡阳旭光锌锗科技有限公司

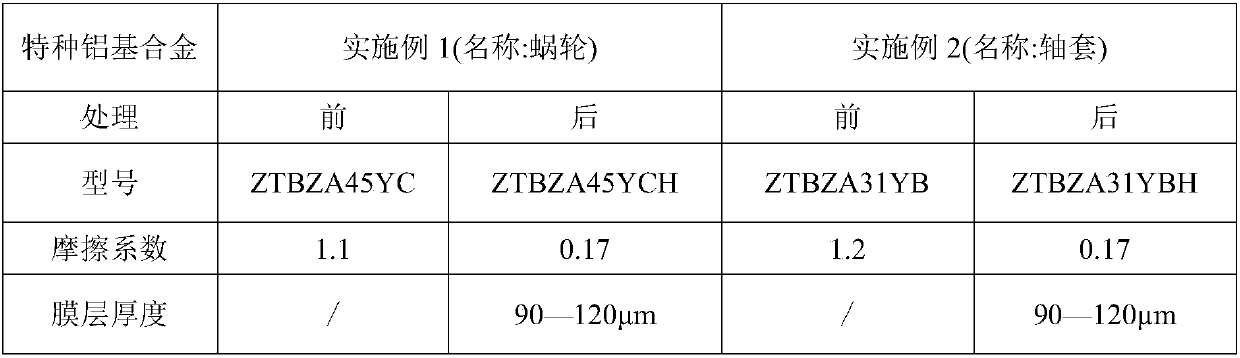

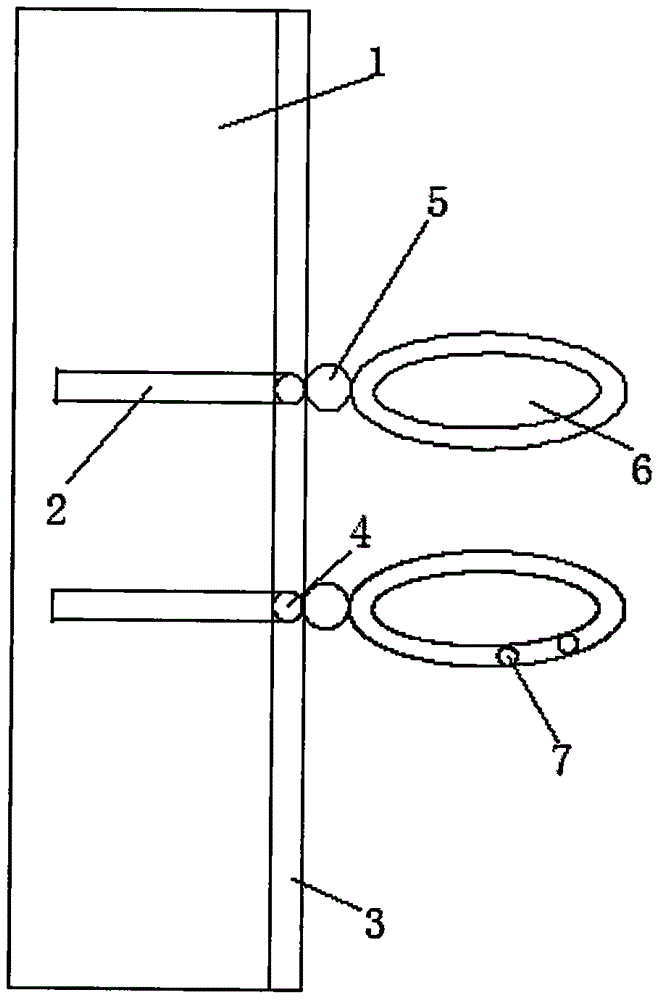

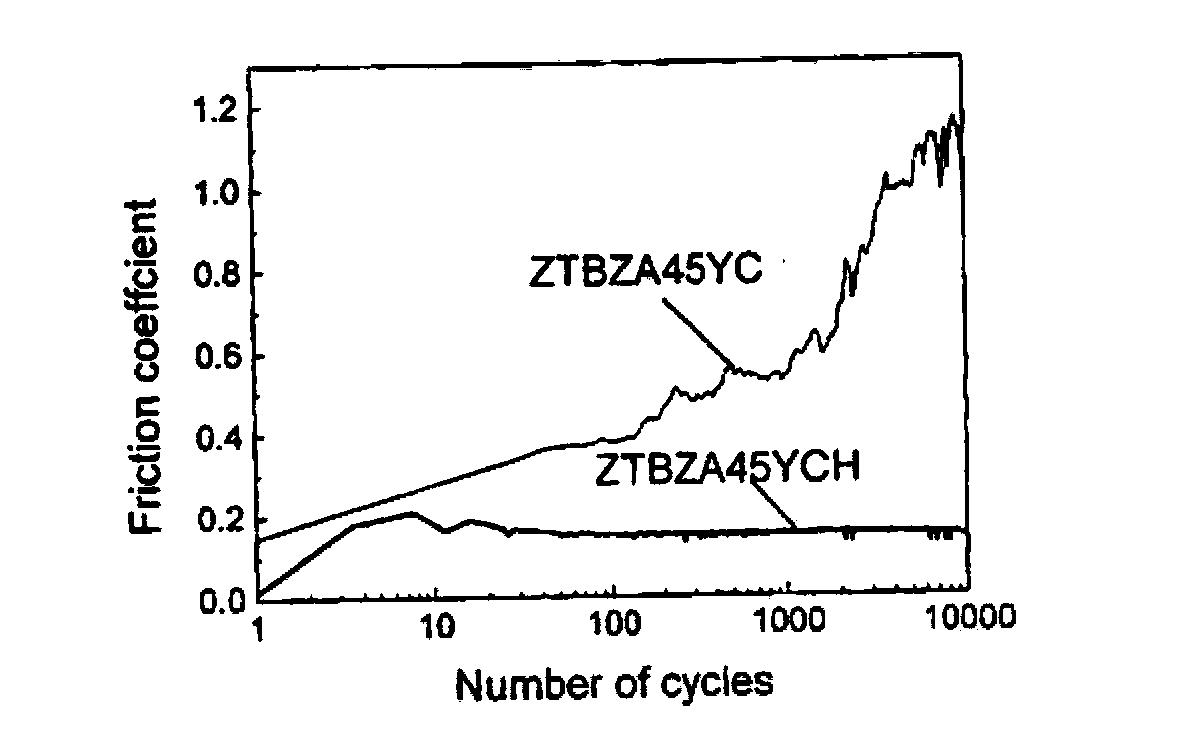

Method of processing surfaces of aluminium alloy pistons and precision friction pairs

ActiveCN103484849AHigh densityLow friction factorMaterial nanotechnologyMetallic material coating processesVolumetric Mass DensityMachining

The invention relates to a method of processing the surfaces of light alloy, in particular to a method of processing the surfaces of aluminium alloy pistons and precision friction pairs. The method comprises the steps that (1) washing is performed; (2) oxidization is performed; (3) hole plugging is performed. Nanoscale metal matrix ceramic oxidation film layers with the density up to the standard are respectively grown on the aluminium alloy pistons and precision friction pairs processed in the method, the density is increased, the diameters of blind holes are decreased obviously, nanometer penetrant blind holes are sealed, roughness is reduced, the friction coefficient is reduced, and the geometric dimensions are unchanged basically. The aluminium alloy pistons and precision friction pairs processed in the method can be installed for use in a matched mode without finish machining, industrial mass production can be achieved, and the method reduces production cost greatly compared with original technical methods.

Owner:邓才松 +1

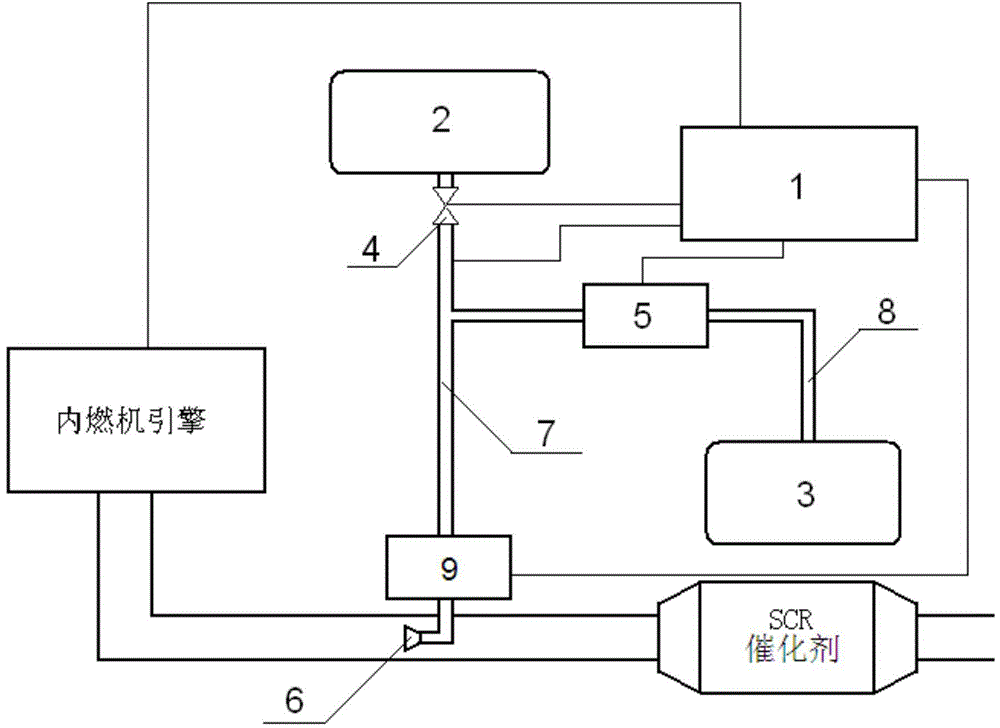

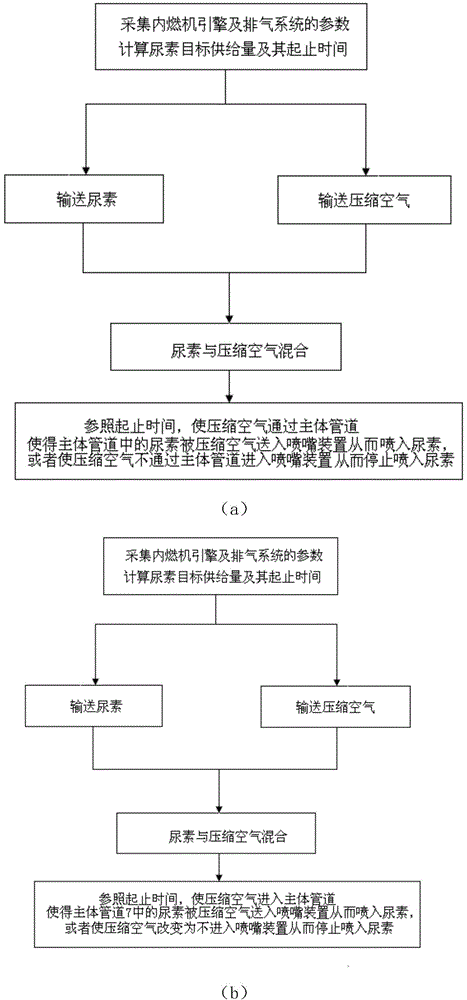

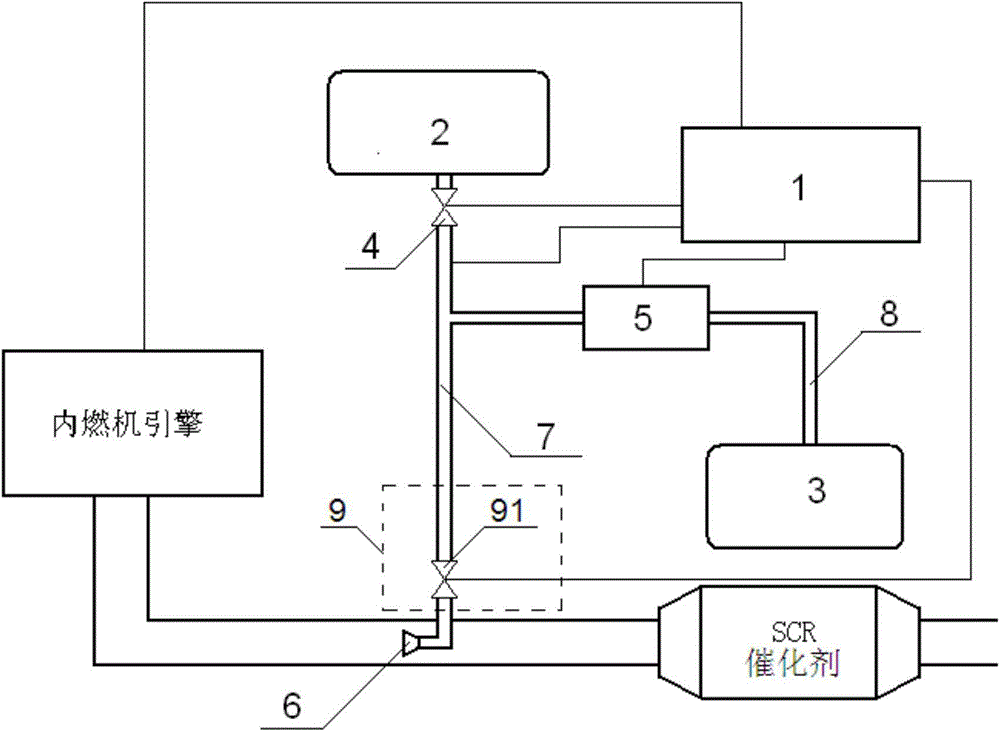

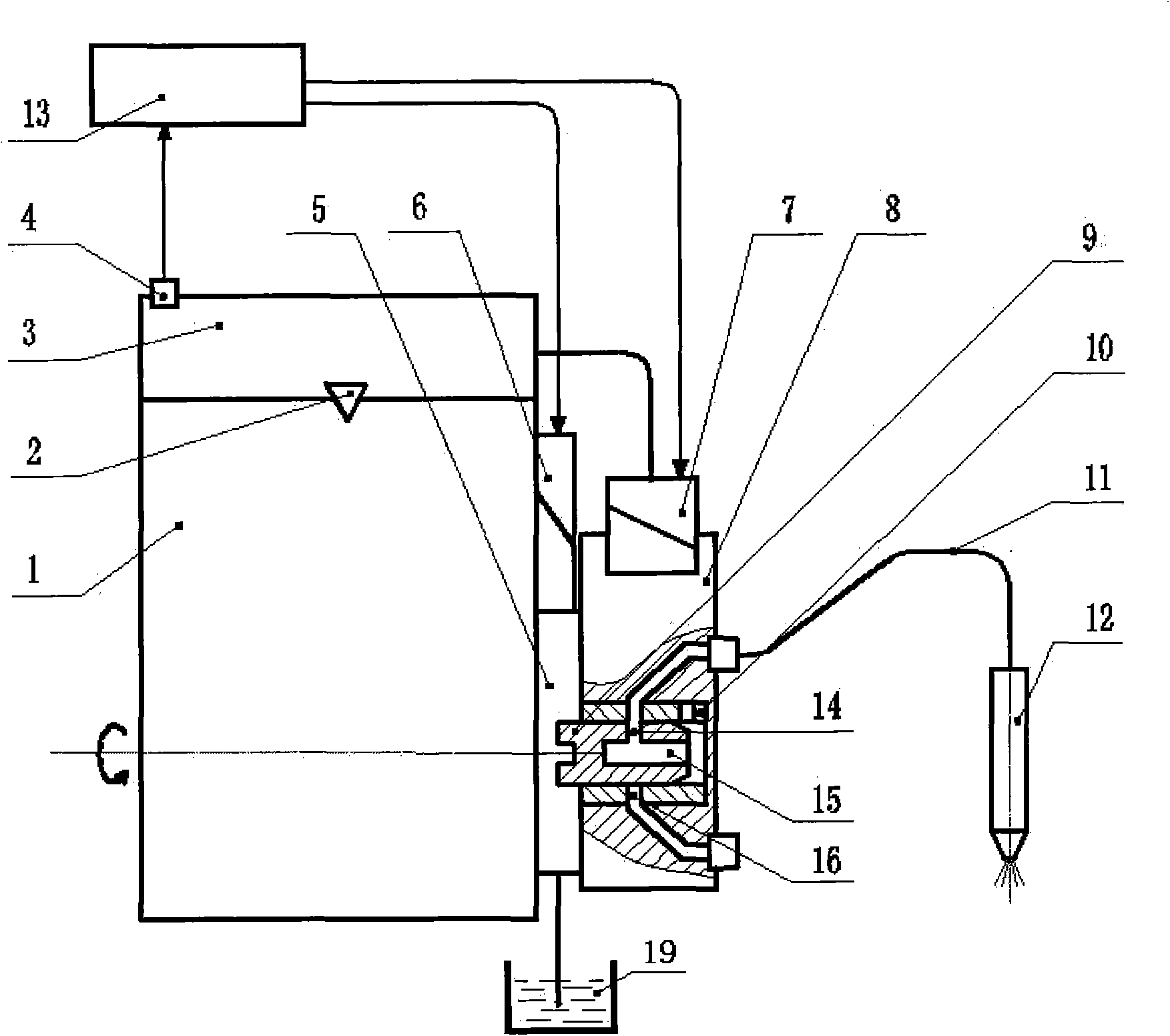

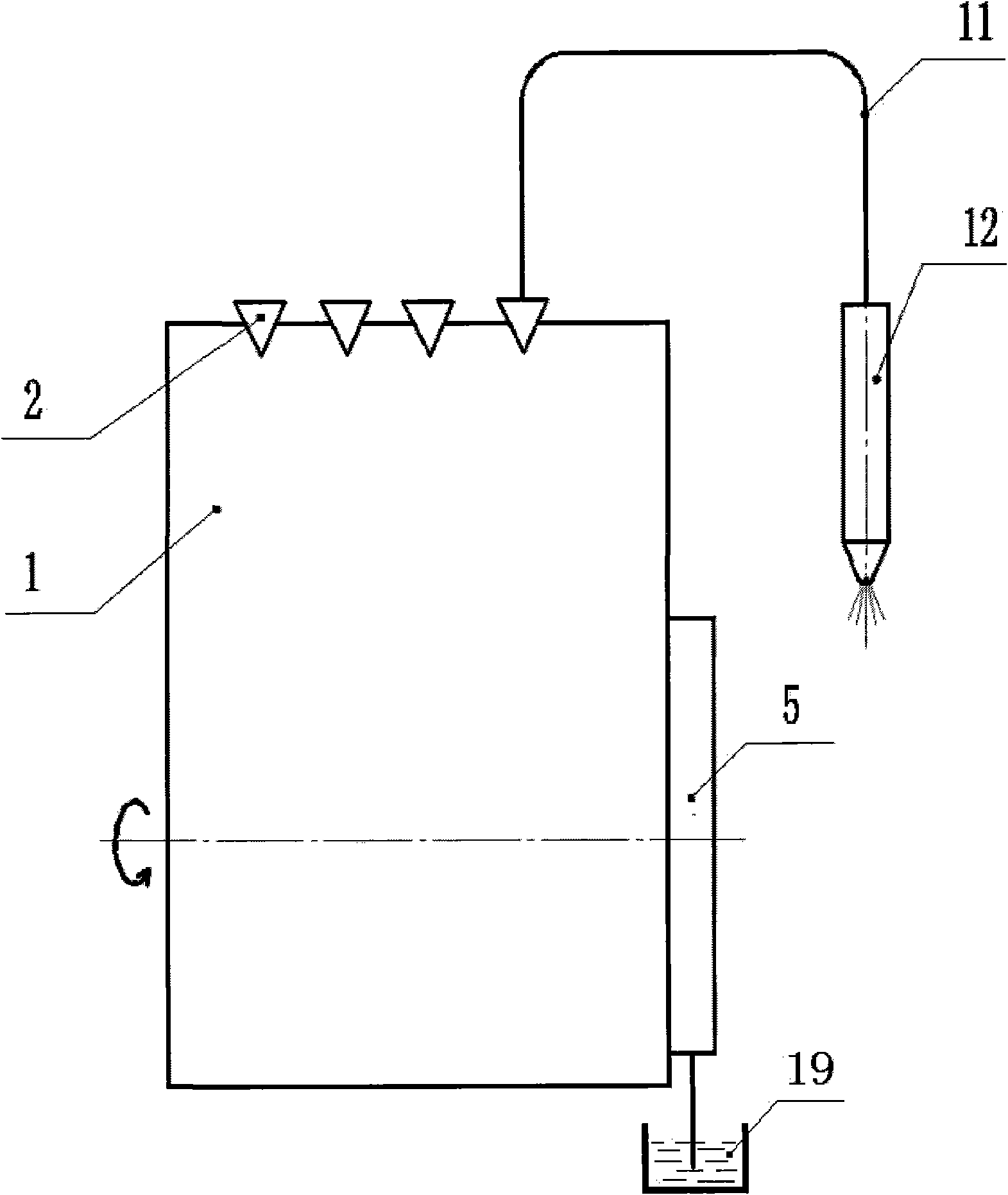

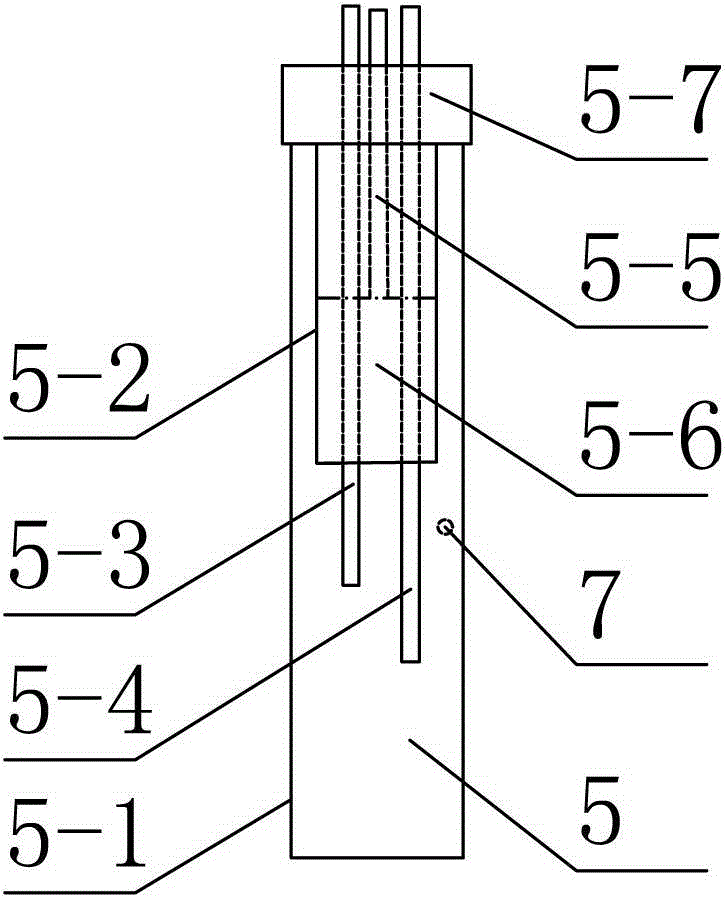

Device for regulating and controlling actual supply amount of urea entering exhaust system and regulating and controlling method

InactiveCN105626215AReduce ammonia leakageFully utilizeInternal combustion piston enginesExhaust apparatusStart timeEmission standard

The invention discloses a device for regulating and controlling the actual supply amount of urea entering an exhaust system. The device comprises an electronic control unit, a compressed air source device, a urea storing device, a compressed air controlling device, a metering pump / valve, a spray nozzle device, a main pipeline and a urea pipeline and further comprises a urea regulating and controlling device. The urea regulating and controlling device is in communication with the electronic control unit; and the actual supply amount of urea actually sprayed into the exhaust system from the spray nozzle device is controlled according to starting time and ending time. The device effectively avoids the situation that urea sprayed into the exhaust system is excessive, and by means of low-cost improvement, an original exhaust system accords with a higher emission standard. The invention further discloses a regulating and controlling method for regulating and controlling the actual supply amount of the urea entering the exhaust system.

Owner:金有纯

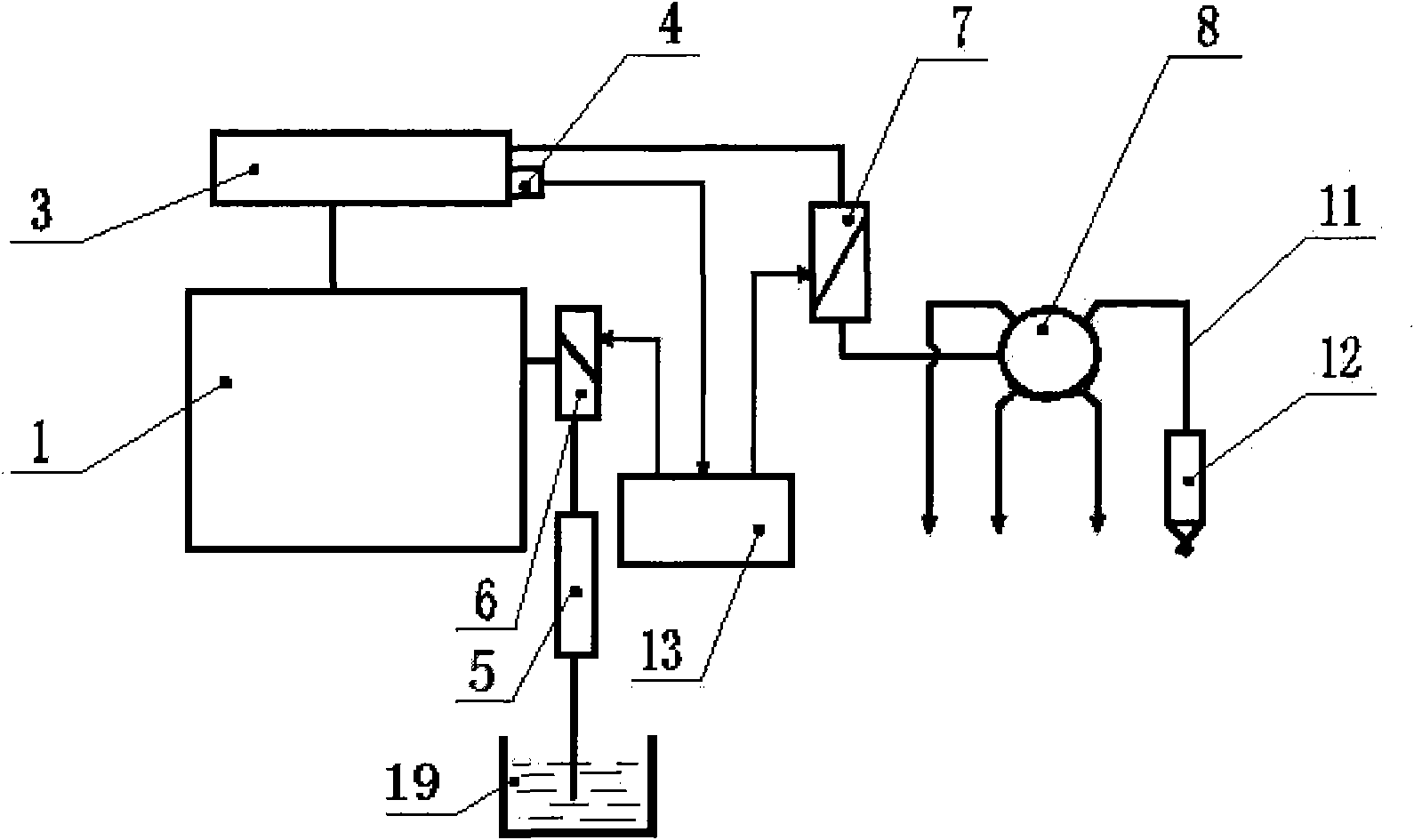

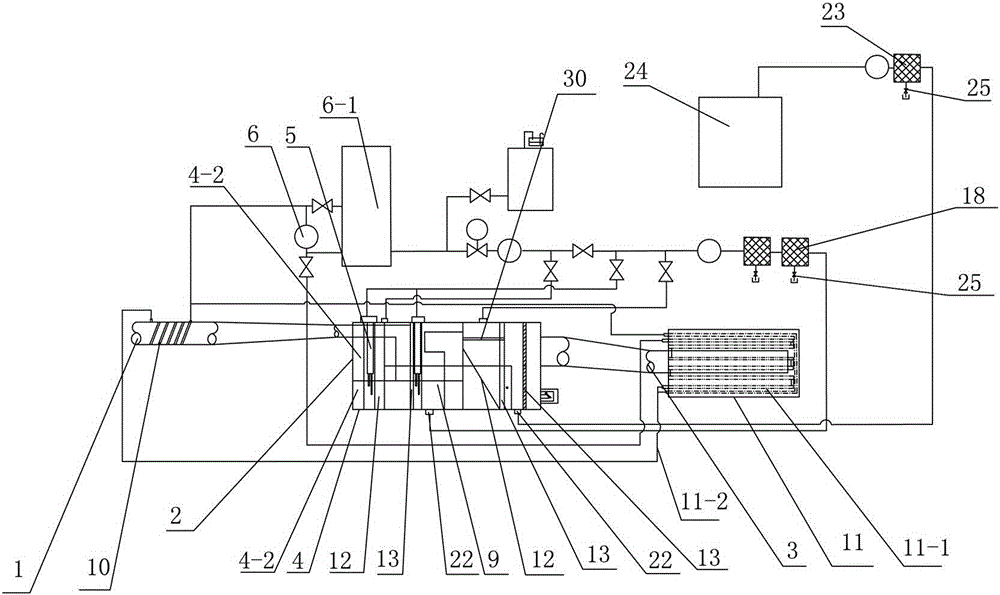

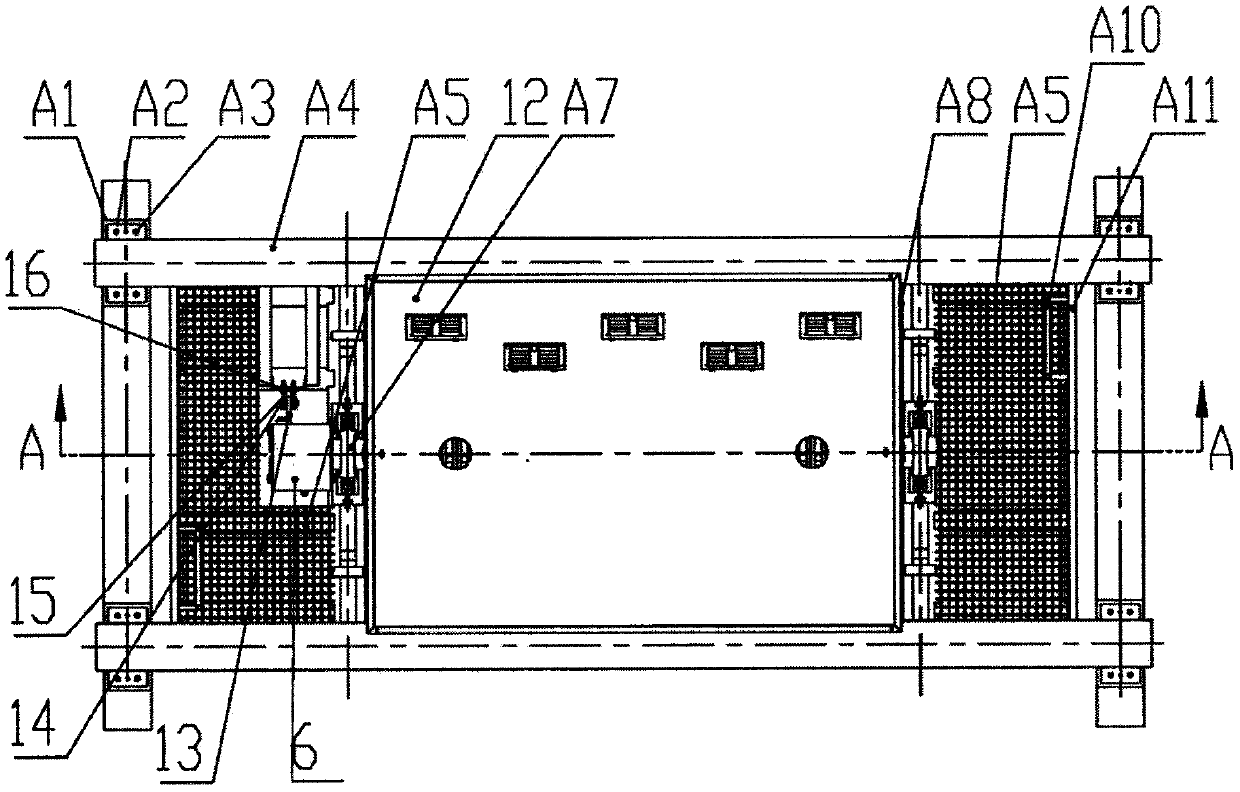

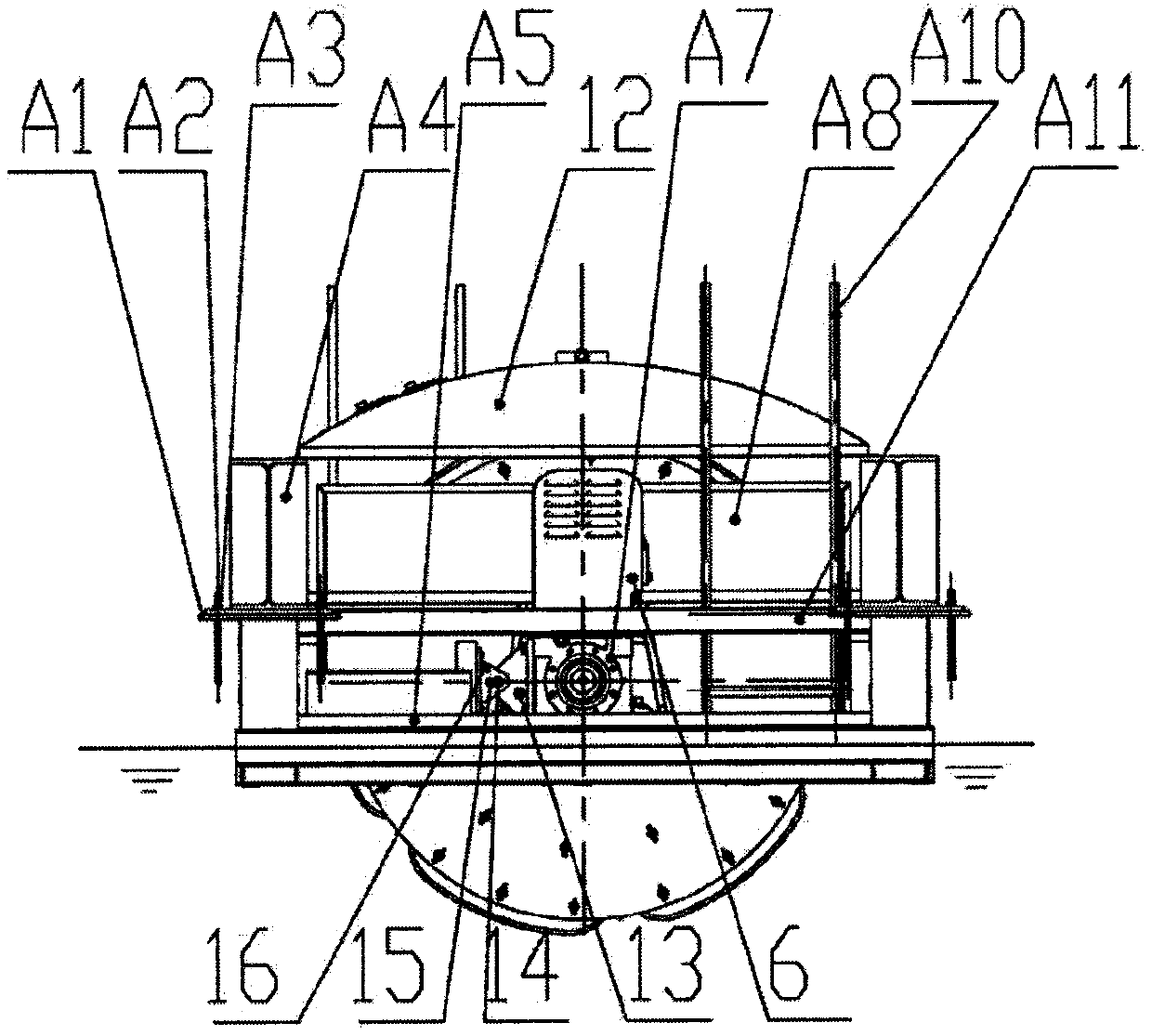

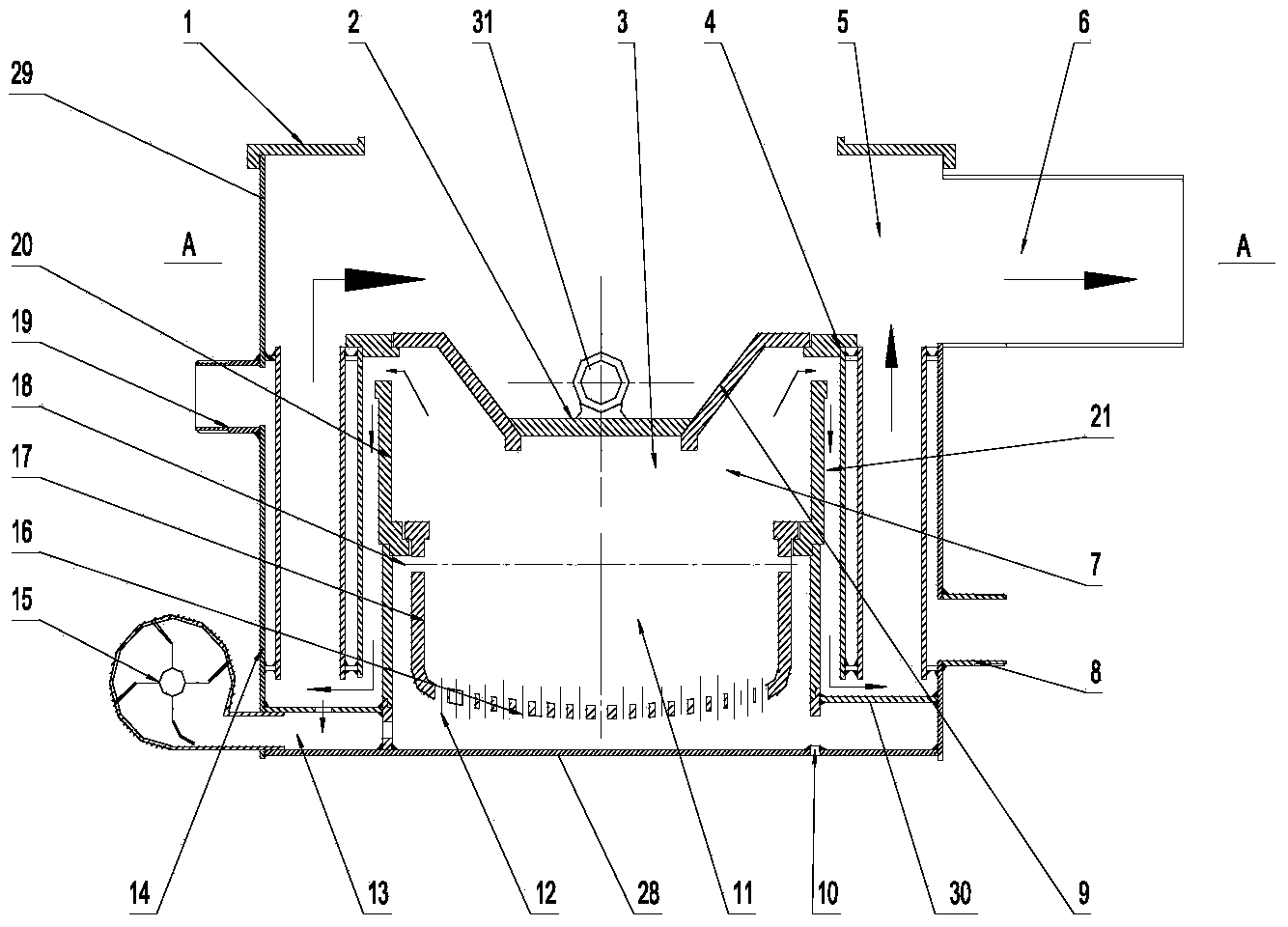

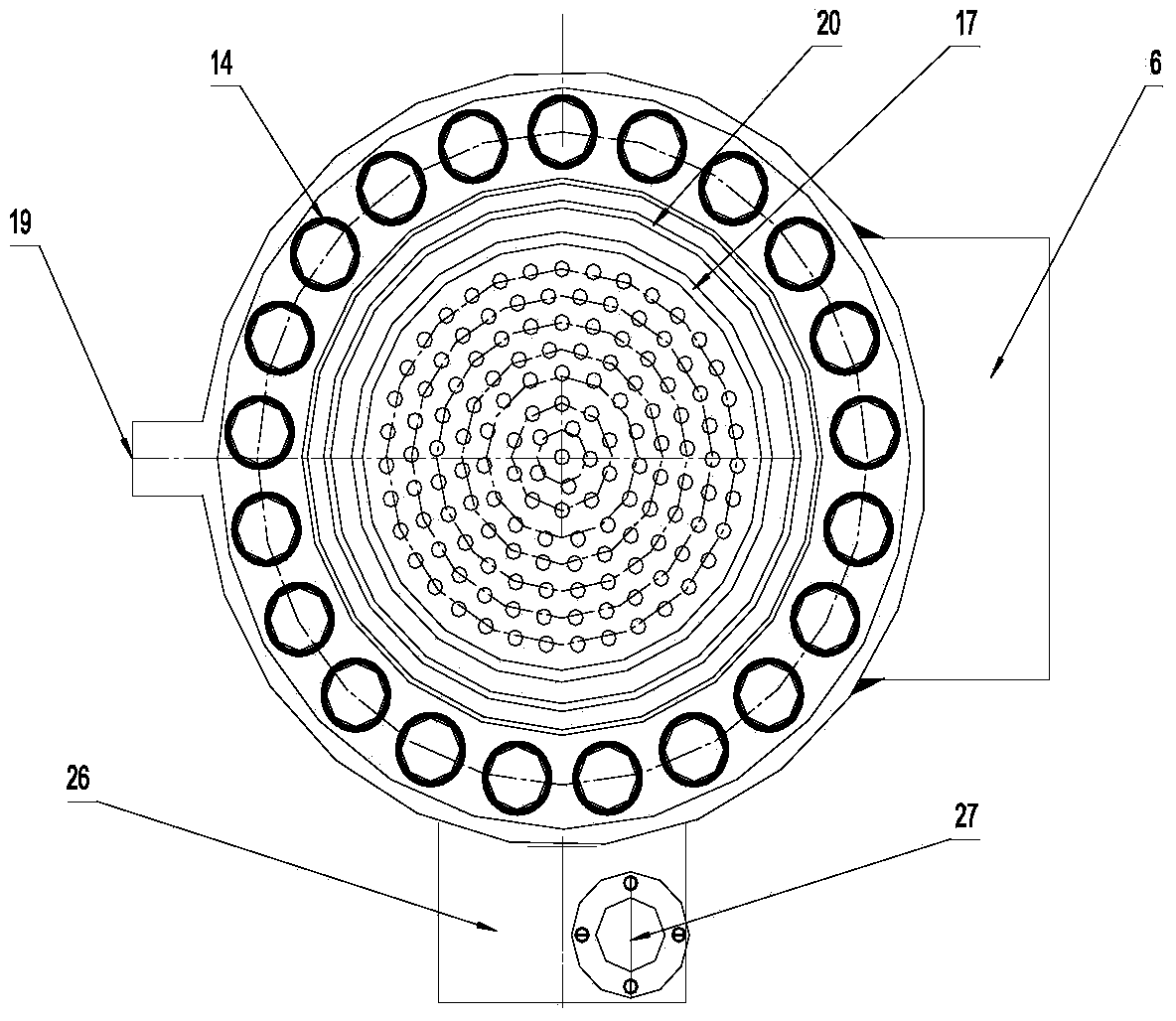

Novel high-pressure fuel oil system for internal combustion engine

InactiveCN101936244AAchieve freedom of controlImprove emission standardsMachines/enginesFuel injecting pumpsExternal combustion engineWork cycle

The invention relates to a novel high-pressure fuel oil system for an internal combustion engine, which is mainly characterized in that, a) high-pressure fuel oil in a pressure accumulator (3) is sent to a fuel oil distributor (8) in a timing and quantitative manner under the control of a high-pressure fuel oil on-off electromagnetic valve (7); b) the fuel oil distributor (8) is distributed after the high-pressure fuel oil on-off electromagnetic valve (7) and before a fuel oil injector (12); and c) an ECU (13) in the system can realize the control of fuel oil injection pressure and the fuel oil injection time, and the fuel oil injector (12) in the system adopts a traditional mechanical fuel oil injector. The high-pressure fuel oil system can realize the control of the fuel oil injection time and the fuel oil injection amount of each cylinder and lead each cylinder to realize multiple fuel oil injection in one working cycle by using the ECU (13) to control the high-pressure fuel oil on-off electromagnetic valve (7). The high-pressure fuel oil system can realize the free control of the fuel oil injection pressure and the fuel oil injection time, realize the multiple fuel oil injection in one working cycle, meet the requirements of the high emission standard of the internal combustion engine and further have the advantages of novel structure, simpleness, reliable working, convenient maintenance, low cost and the like.

Owner:中国第一汽车集团公司无锡油泵油嘴研究所

Multifunctional industrial paint spraying waste gas environment-friendly treatment equipment

InactiveCN108579254AIncrease air intakeImprove processing efficiencyCombination devicesGas treatmentFixed frameWastewater

The invention provides multifunctional industrial paint spraying waste gas environment-friendly treatment equipment, which comprises support legs, fixing bolts, a waste gas treatment eduction tube, anobservation sheet, a fixing frame, an air inlet pipe, a connection flange disc, a flow guide pipe, a waste gas guide-in pipe, a waste gas fast suction primary treatment machine structure, a peculiarsmell treatment machine structure, square-head bolts, a waste water recovery treatment barrel structure, a waste gas terminal spraying treatment head structure and an openable rain-proof air guide cover structure. Through the arrangement of air suction blades, a fast air suction motor and a trapezoidal frame, the air inflow can be favorably increased; the treatment efficiency can be improved; through the arrangement of a U-shaped hollow cover and a waste gas primary treatment screen, the entered waste gas can be favorably subjected to primary filtering treatment; through the arrangement of a guide-out hopper, a hollow plate, an air outlet guide pipe, an active carbon tube, wing bolts, an air suction fan and a U-shaped fixing frame, peculiar smell entering the waste gas can be timely treated; the influence on the discharge caused by peculiar smell spreading can be avoided, so that the better environmental friendly effect can be achieved during the discharge.

Owner:无棣浩原网具有限公司

Aqueous additive used for biological synthesizing diesel oil and its preparation method

The invention relates to biosynthesis diesel oil water craft additive belongs to diesel oil emulsification technique. Its each component is triethanolamine, monoethanolamine, cyclohexylamine, ethylene glycol monoethyl ether, isopropyl alcohol, cyclohexylamine carbonate, benzene parallel tri-nitrogen azole, methanol, ammonia water, and ethylene glycol. Its manufacturing method is that all of the operation do in proportion and mix them as the following order that one is methanol, benzene parallel tri-nitrogen azole, cyclohexylamine carbonate, ethylene glycol monoethyl ether, isopropyl alcohol; the other is triethanolamine, monoethanolamine, cyclohexylamine. Both of them are added into the ammonia water; and the ethylene glycol is added. It is used to make emulsification diesel oil. It has strong erosion and freezing resistance, and can promote oil product stable and dissolve each other.

Owner:上海新景福环保科技发展有限公司

Noise reduction and purification device for automobile exhaust gas

ActiveCN105179048ANo cavitationGuaranteed cleanlinessExhaust apparatusSilencing apparatusExhaust gasNoise reduction

The invention provides a noise reduction and purification device for automobile exhaust gas. The noise reduction and purification device is simple in structure and good in purification effect and comprises an exhaust gas inlet, a noise reduction and purification device body and an exhaust outlet. Exhaust gas enters the noise reduction and purification device body through the exhaust gas inlet and then exhausted through the exhaust outlet after noise reduction and purification are performed on the exhaust gas through the noise reduction and purification device body. The noise reduction and purification device body comprises a first-grade purification chamber. A purification pool and a gas-water purification cavity are arranged inside the first-grade purification chamber. A purification solution is contained inside the purification pool. The exhaust gas inlet is communicated with the first-grade purification chamber. The upper edge of an opening of the exhaust gas inlet is higher than the upper surface of the purification solution inside the purification pool. A water level indicator is arranged inside the purification pool of the first-grade purification chamber and induces the height of the purification solution inside the purification pool. The purification pool is connected with a purification solution adding pump. The purification solution adding pump supplements the purification solution inside the purification pool. An atomization filter net is arranged between the gas-water purification cavity and the purification pool. A gas-water separation filter net is arranged at an outlet of the gas-water purification cavity.

Owner:方冰熔

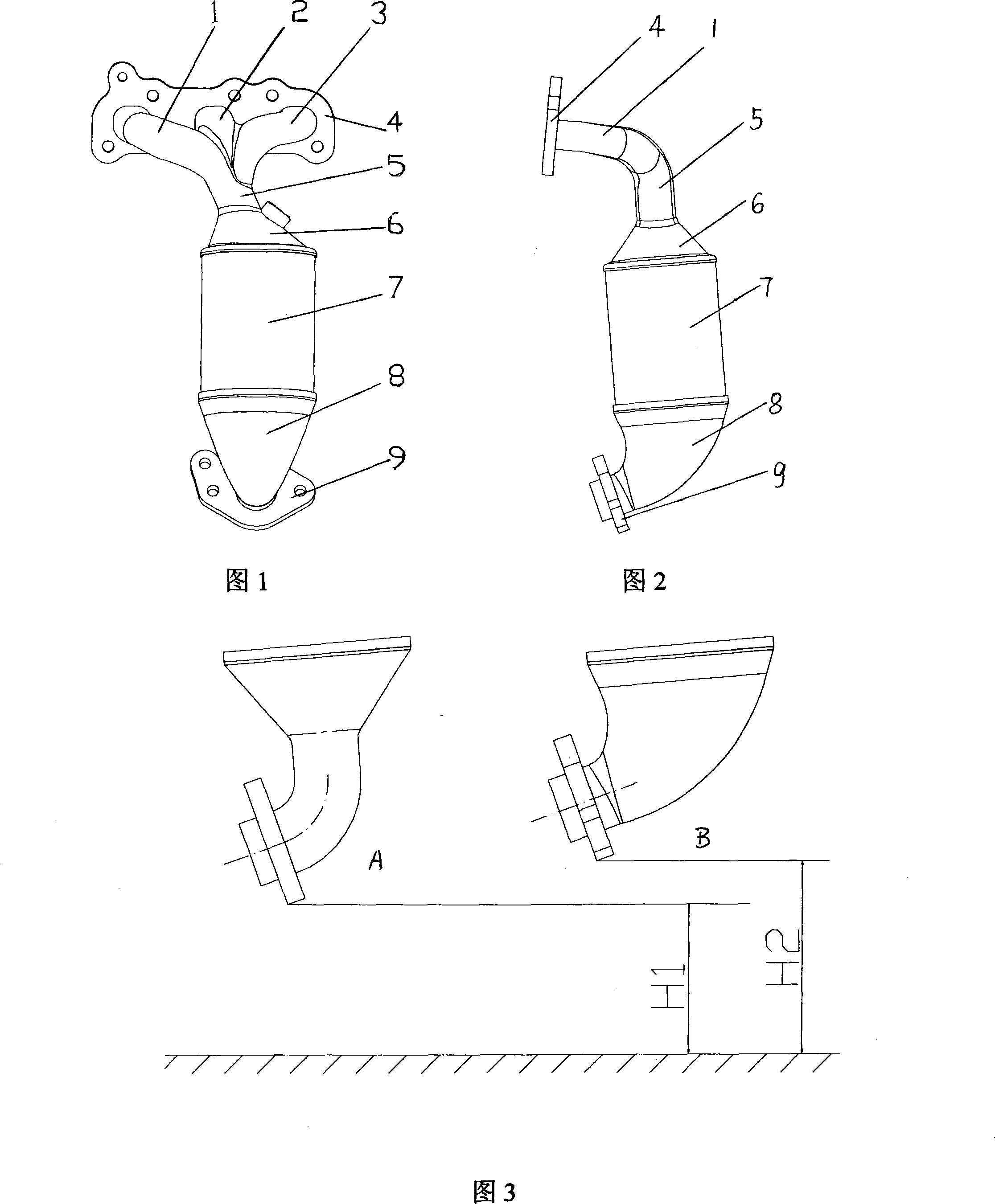

Small displacement engine exhaust manifold assembly structure

InactiveCN101161996ADoes not meet emission requirementsEmission Requirement GuaranteeExhaust apparatusSilencing apparatusPulp and paper industryAssembly structure

The invention relates to a small engine exhaust collector assembly structure, and comprises two or three exhaust collector air flues, the upper ends of the exhaust collector air flues are welded with an inlet flange, the lower ends are connected with three way catalyst assembly, the lower end of the three way catalyst is connected with an outlet flange. The lower ends of the exhaust collector air flues are formed to one flue toward the middle part. Every exhaust collector air flue is formed by welding an upper half shell and a lower half shell, the lower half shell is an integrated one, die parting face of every exhaust collector air flue is on the same curved surface. The three way catalyst assembly is formed by welding an inlet end cover of the three way catalyst, the three way catalyst body and an outlet end cover of the three way catalyst, and adopts stainless material. The welding positions of the exhaust collector air flues deviate the center of the inlet end cover of the three way catalyst, the outlet end cover of the three-way catalyst adopts steerhorn structure. The invention has compact structure and high discharge standard, and can solve the problem of arranging the long exhaust collector and the catalyst in limited space.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

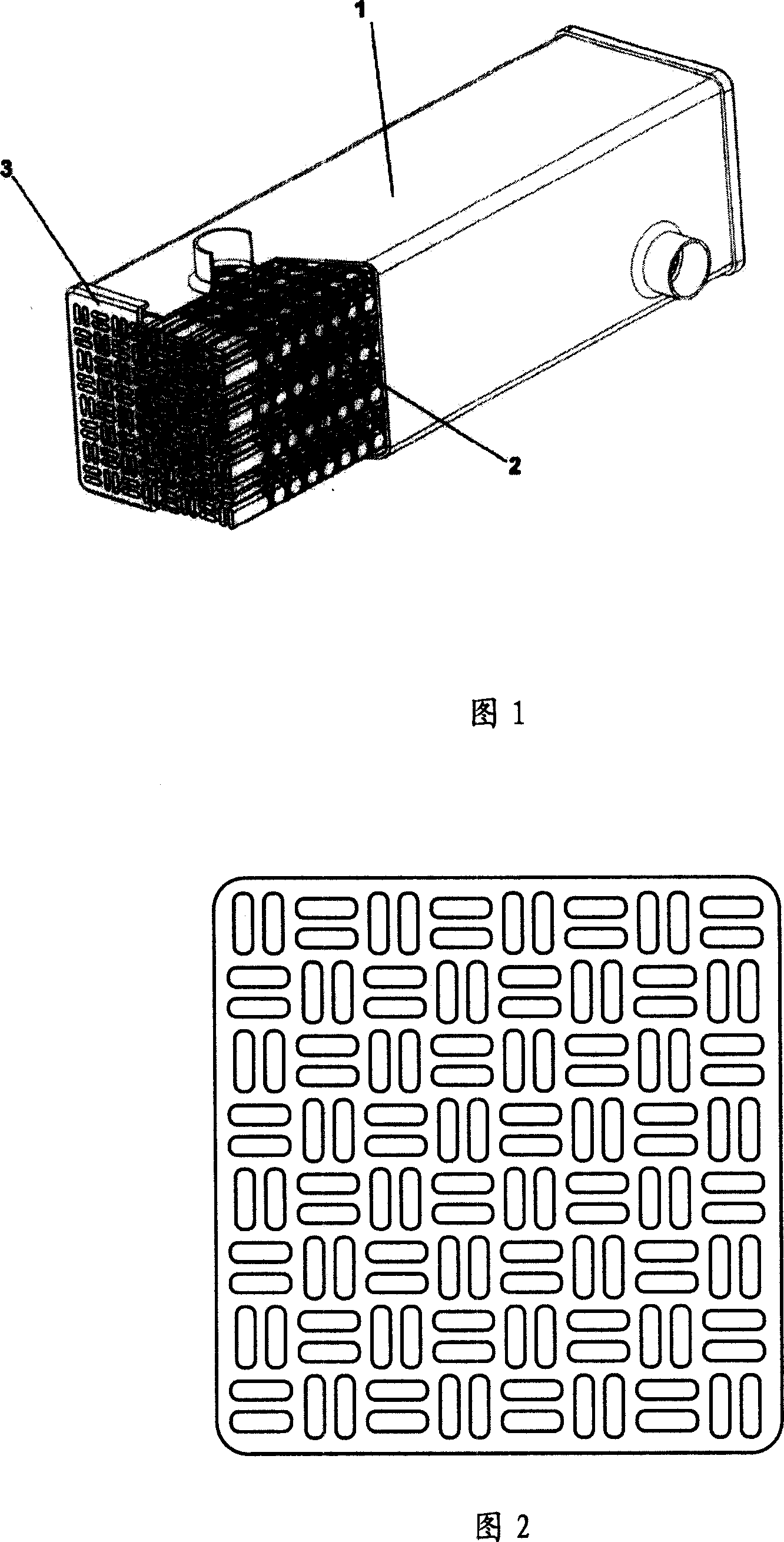

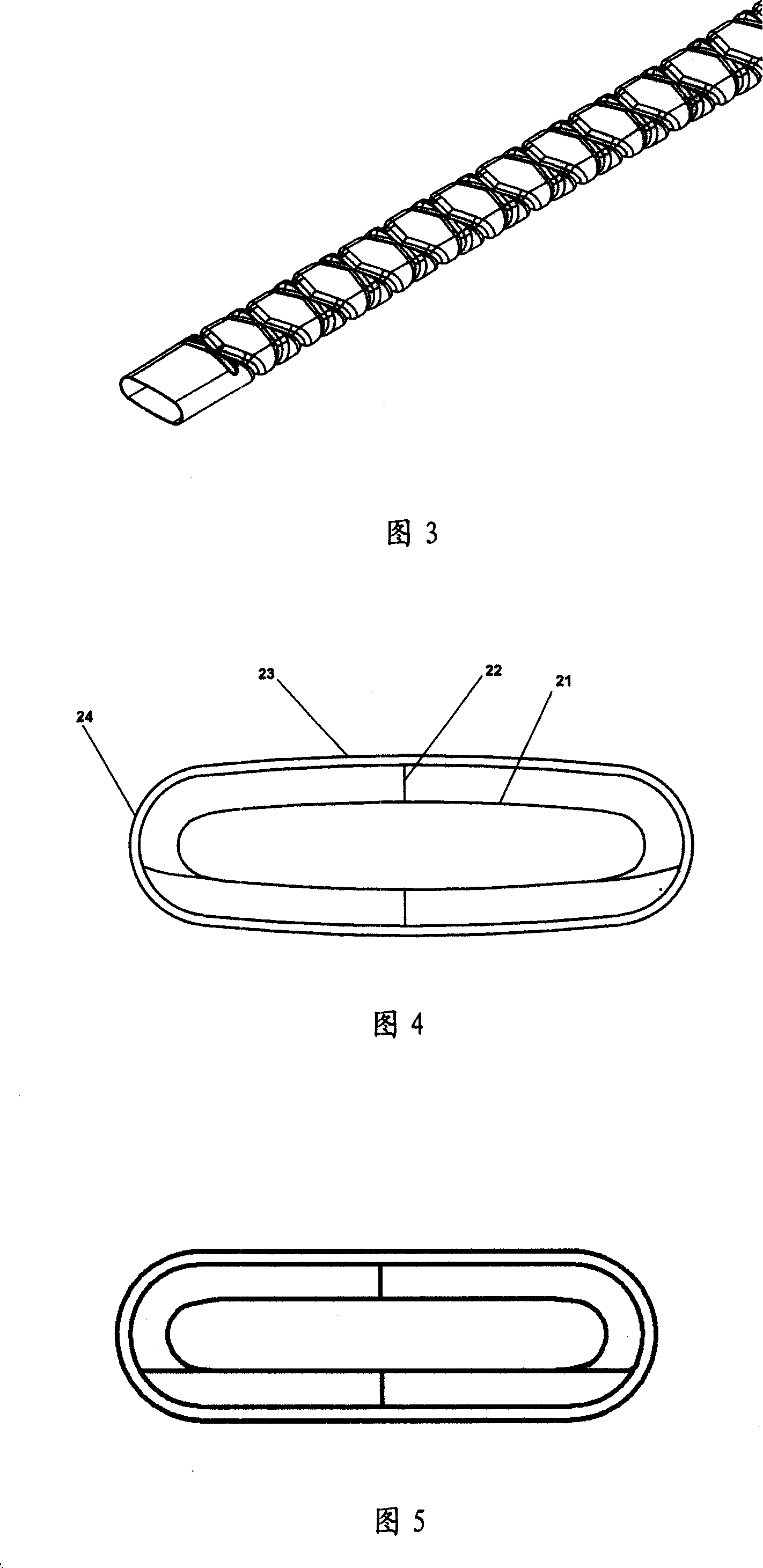

Heat exchanger employing crossed spiral tube

ActiveCN101101185ARapid coolingGood use effectStationary conduit assembliesTubular elementsPlate heat exchangerEngineering

The invention relates to a heat exchanger which used the cross-helical tube, involving an exhaust recycle heat exchanger. For improving the engine exhaust recycle heat exchanger and increasing the heat exchange efficiency. The exchanger includes the heat exchange tube, shell and the tube board. Of which the heat exchange tube is the stainless steel tube which has the entad raised cross-helical groove on the surface, and the section shape of the tube is the flat shape. The height and width of the section shape in the flat shape heat exchange tube are unlikeness, and the opposite rotating direction helix line cross on the relative long edge of the tube as the 'X' shape. Because of the application of the cross-helical heat exchange tube, the tube inside and outside is not easy to dirty and increased the heat exchange efficiency, the heat exchanger is particularly suitable for the exhaust gas recycle coolers of a vehicle engine, reduce the exhaust discharge temperature and enhance the vehicle engine discharge performance indicators to meet environmental discharge requirement. At the same time, the invention can also be used in a turbocharger system to improve the engine performance.

Owner:辽宁联友博科技有限公司

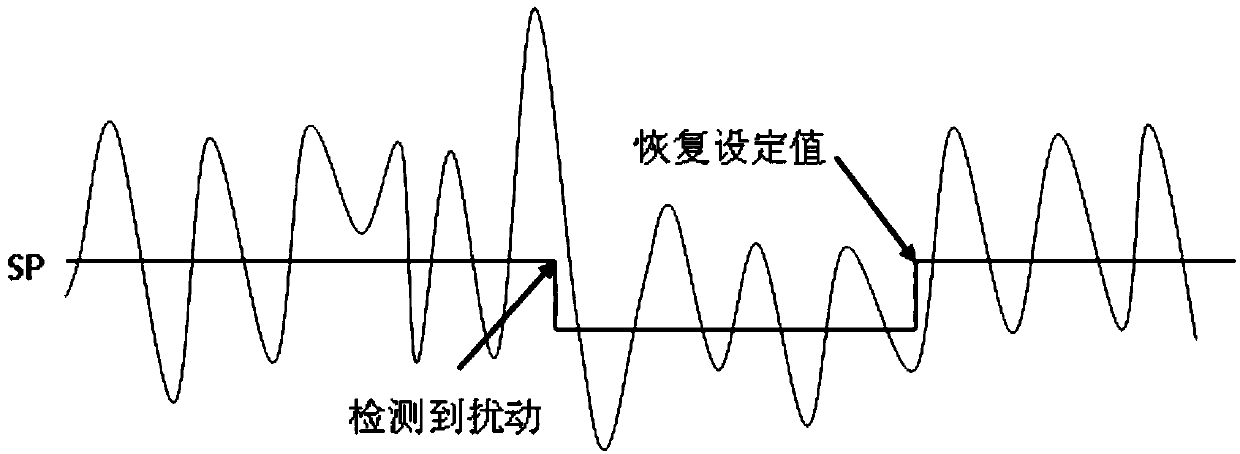

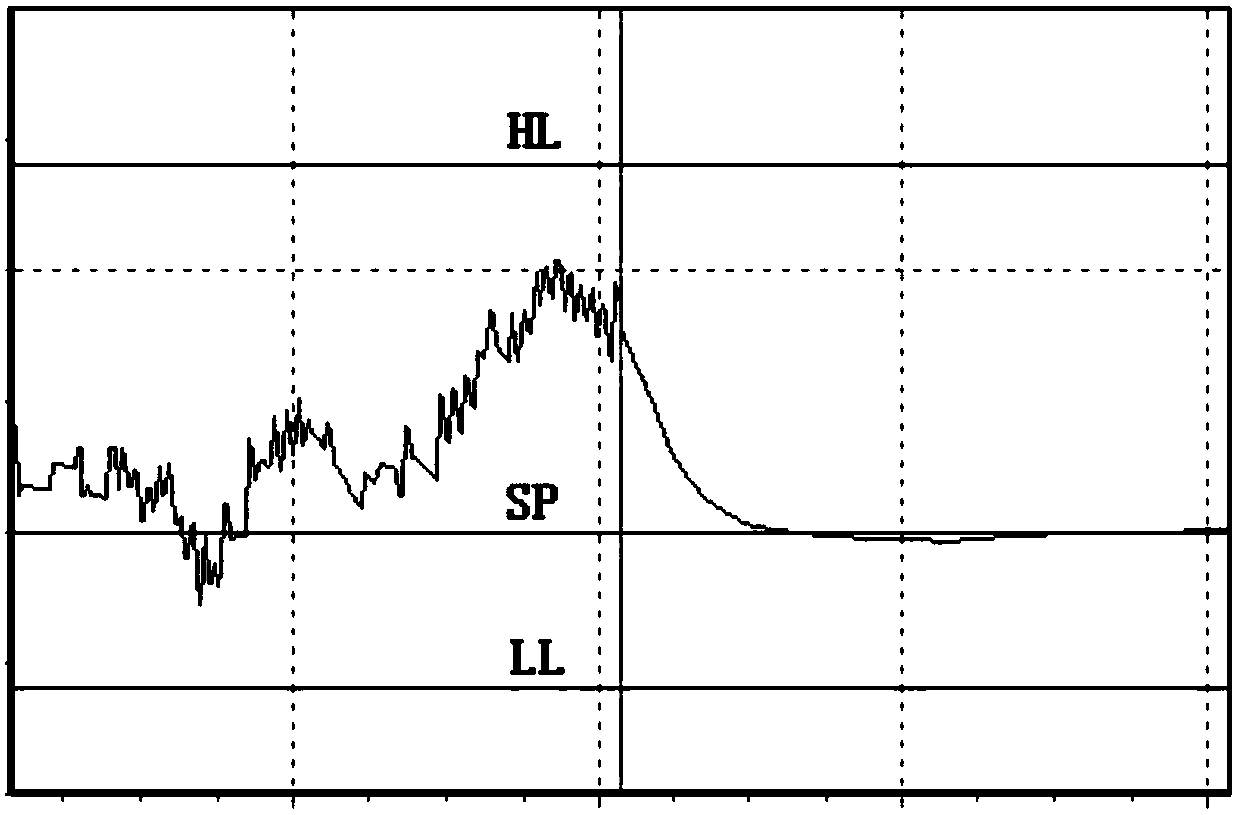

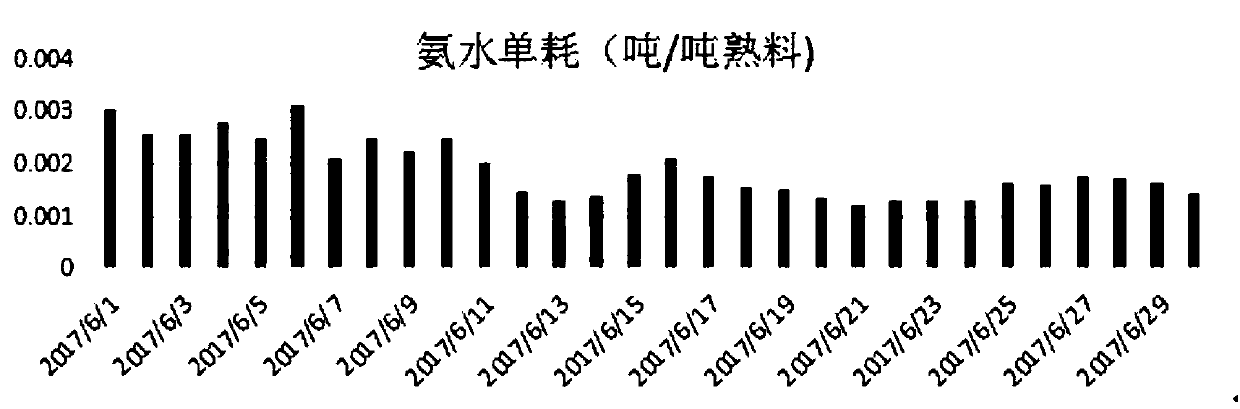

Denitration optimization control algorithm based on intelligent model predictive control

InactiveCN109917641AReduce usageImprove emission standardsAdaptive controlTime informationEmission standard

A denitration optimization control algorithm based on intelligent model predictive control is disclosed. The method comprises: collecting historical data for a controlled object and a control object,analyzing current working conditions by adopting a self-learning algorithm, and automatically calculating a target value, an upper limit value and a lower limit value of the controlled object; establishing a prediction model, and predicting the change trend of the system in a future period of time; solving the optimal control effect in a rolling mode according to constraint conditions and performance requirements obtained through learning, and implementing the current control; detecting real-time information, correcting a future predicted trend, and carrying out feedback compensation. the algorithm can visually check the prediction optimization trend, can be matched with a cloud analysis platform, can automatically configure an interface, a graph and self-defined data analysis, supports PCand mobile terminal access, obviously reduces the use amount of ammonia water, improves the NOx emission standard, and achieves the purposes of saving energy, reducing consumption and improving economic benefits; the control effect can be automatically adjusted in real time, and manual intervention is reduced; the effects of being simple to maintain and convenient to deploy are achieved, and thealgorithm opens up a new way for denitration optimization control.

Owner:NANJING KISEN INT ENG

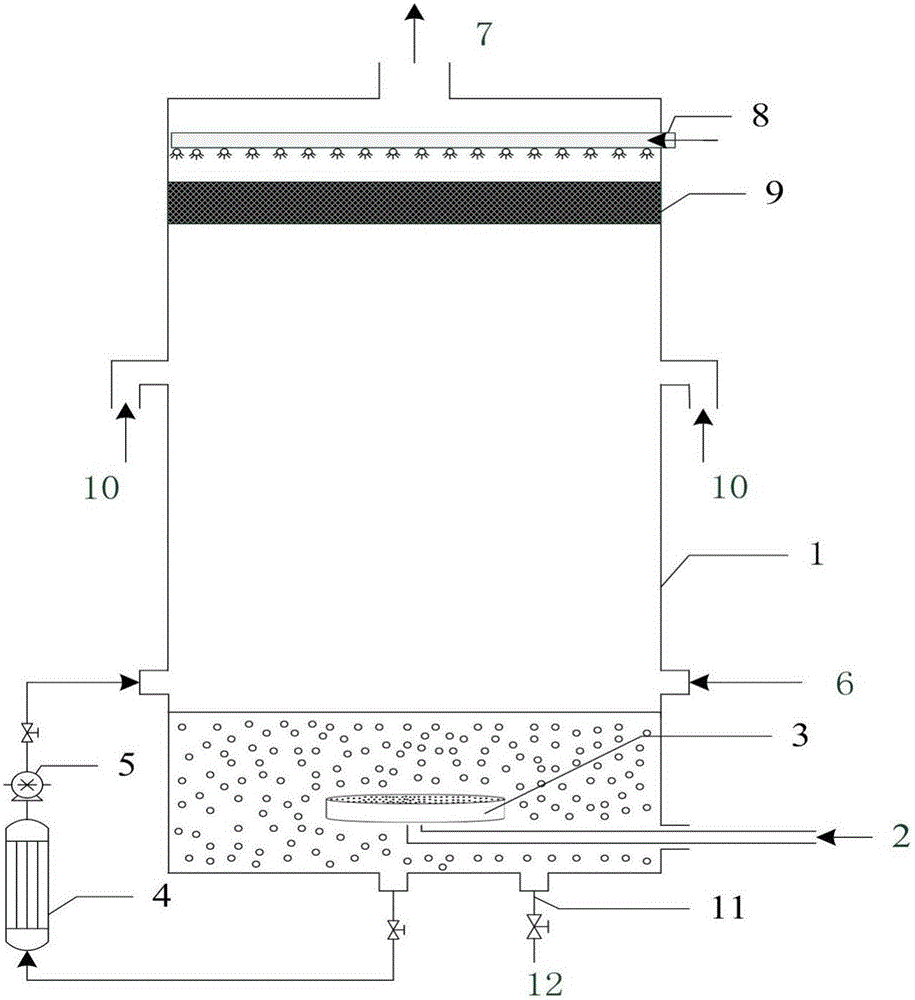

Method and device for thermal activation oxidant and steam combined synergistic flue gas purification

InactiveCN106823722ASmall footprintReduce initial investment and operating costsGas treatmentDispersed particle separationDecompositionNitric oxide

The invention provides a method and a device for thermal activation oxidant and steam combined synergistic flue gas purification. The device comprises a bubble tower, a solution heater, a solution circulating pump, a flue gas inlet, a clean flue gas outlet, a steam inlet, a flushing water system, a demister and a bubbler. Strong-oxidation hydroxyl radicals (.OH) or sulfate radicals (SO4<->.) are generated by thermal activation decomposition of hyperoxides to serve as oxidants for oxidative removal of SO2, NOx and Hg<0>; steam is sprayed through steam inlets to form a moisture oversaturated environment in the upper portion of the bubble tower, growth of fine particles carried by flue gas is promoted by heterogeneous coagulation of water drops on surfaces of the fine particles, and the large drops with the fine particles are removed through the demister. The device is simple in structure, small in floor area, low in cost, capable of realizing simultaneous removal of flue gas pollutants including sulfur oxides, nitric oxides, heavy metal element mercury and fine particles and free of secondary pollution in a removal process and has a promising market application prospect.

Owner:SOUTHEAST UNIV

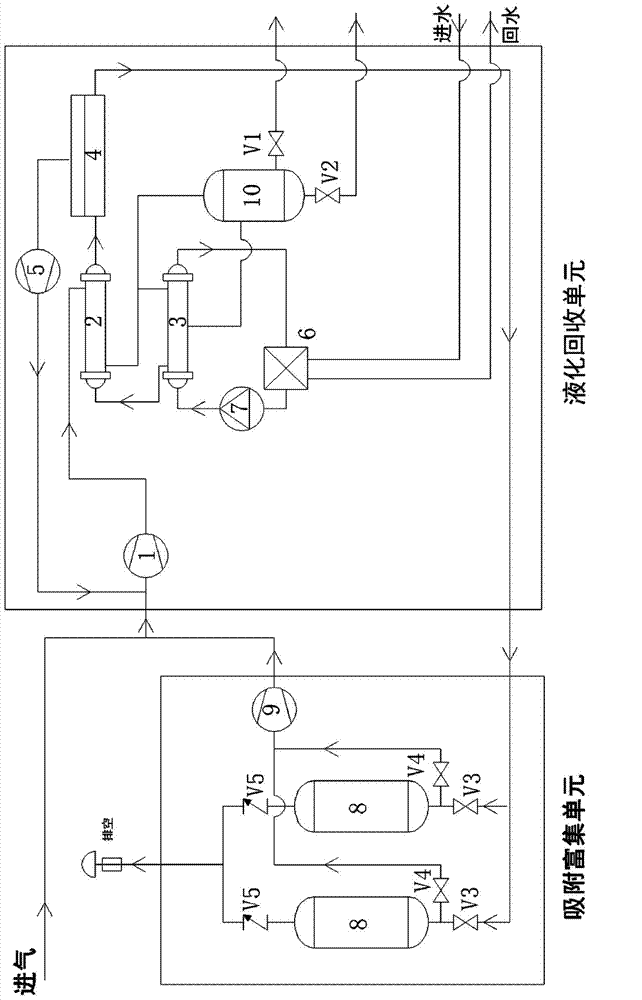

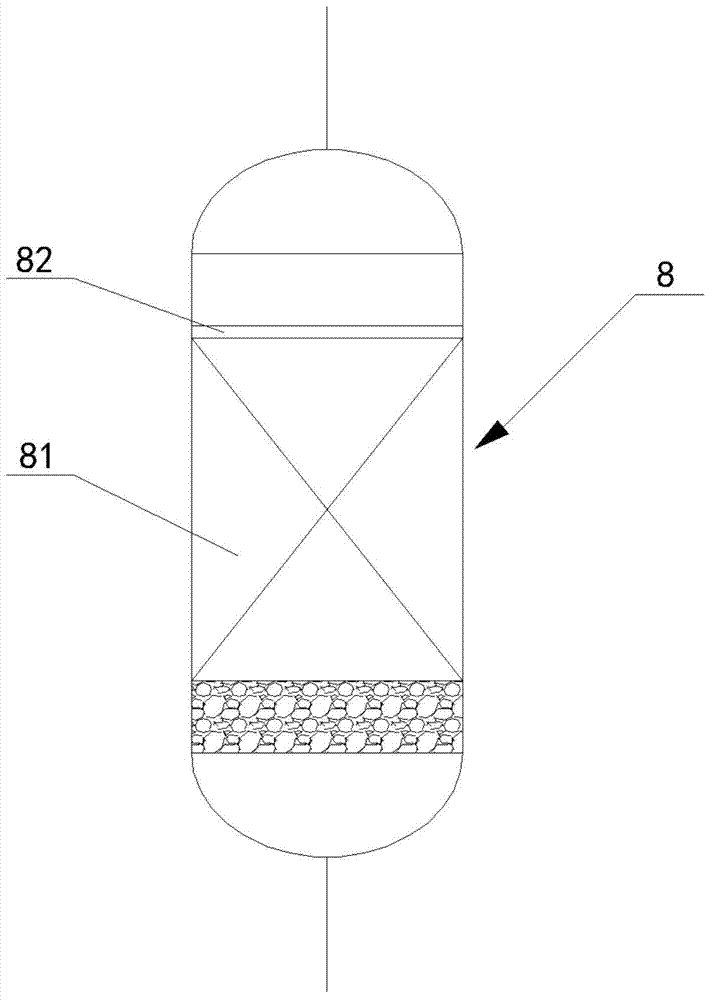

Cascade recovery apparatus and method for benzene hydrocarbon volatile gases

InactiveCN104289072AImprove emission standardsHigh standardDispersed particle separationBenzeneRecovery method

A related cascade recovery apparatus for benzene hydrocarbon volatile gases comprises a liquefaction recovery unit and an adsorption enriching unit; the liquefaction recovery unit comprises an induced draught fan, a precooler, a condenser, a membrane separator, a first vacuum pump, a refrigeration system, a refrigerant pump and a recovery tank; and the adsorption enriching unit comprises an adsorption tank, a second vacuum pump and multiple valves. The invention also provides a cascade recovery method of the volatile gases by utilizing the apparatus. By utilizing condensation, membrane and adsorption combined triple-effect normal-pressure cascade, the discharge standard-reaching problem of benzene series is effectively solved, and solvents are recoverable and reusable.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

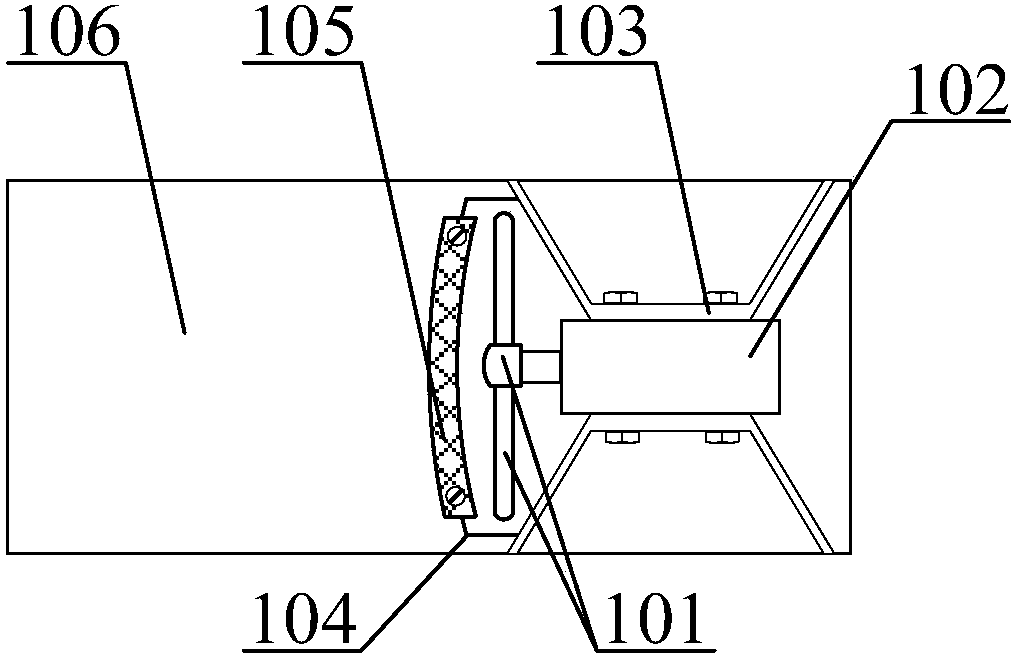

Diesel engine waste gas purification structure

InactiveCN103939198AReduce noiseImprove purification effectInternal combustion piston enginesExhaust apparatusExhaust fumesIntercooler

The invention discloses a diesel engine waste gas purification structure with a good purification effect. The diesel engine waste gas purification structure comprises a gas inlet pipeline and a waste gas pipeline. One end of the gas inlet pipeline is connected with a gas inlet device. The gas inlet device comprises a gas inlet and a gas inlet turbine. The other end of the gas inlet pipeline is connected with an engine cylinder. An intercooler is arranged in the middle of the gas inlet pipeline. One end of the waste gas pipeline is connected with a gas outlet device. The gas outlet device comprises a waste gas outlet and a waste gas turbine. The other end of the waste gas pipeline is connected with the engine cylinder. A purification device is arranged in the middle of the waste gas pipeline. Sulfide solid absorption particles and noise reduction damping blocks are sequentially arranged in the purification device. The gas inlet turbine and the waste gas turbine are both connected with a drive device. The waste gas outlet is connected with a dust removal water tank. A connecting pipe and an exhaust pipe are arranged in the dust removal water tank. One end of the connecting pipe is connected with the waste gas outlet. The other end of the connecting pipe extends to the bottom of liquid in the dust removal water tank.

Owner:JIANGSU XINHAI SCI & TECH DEV CO LTD

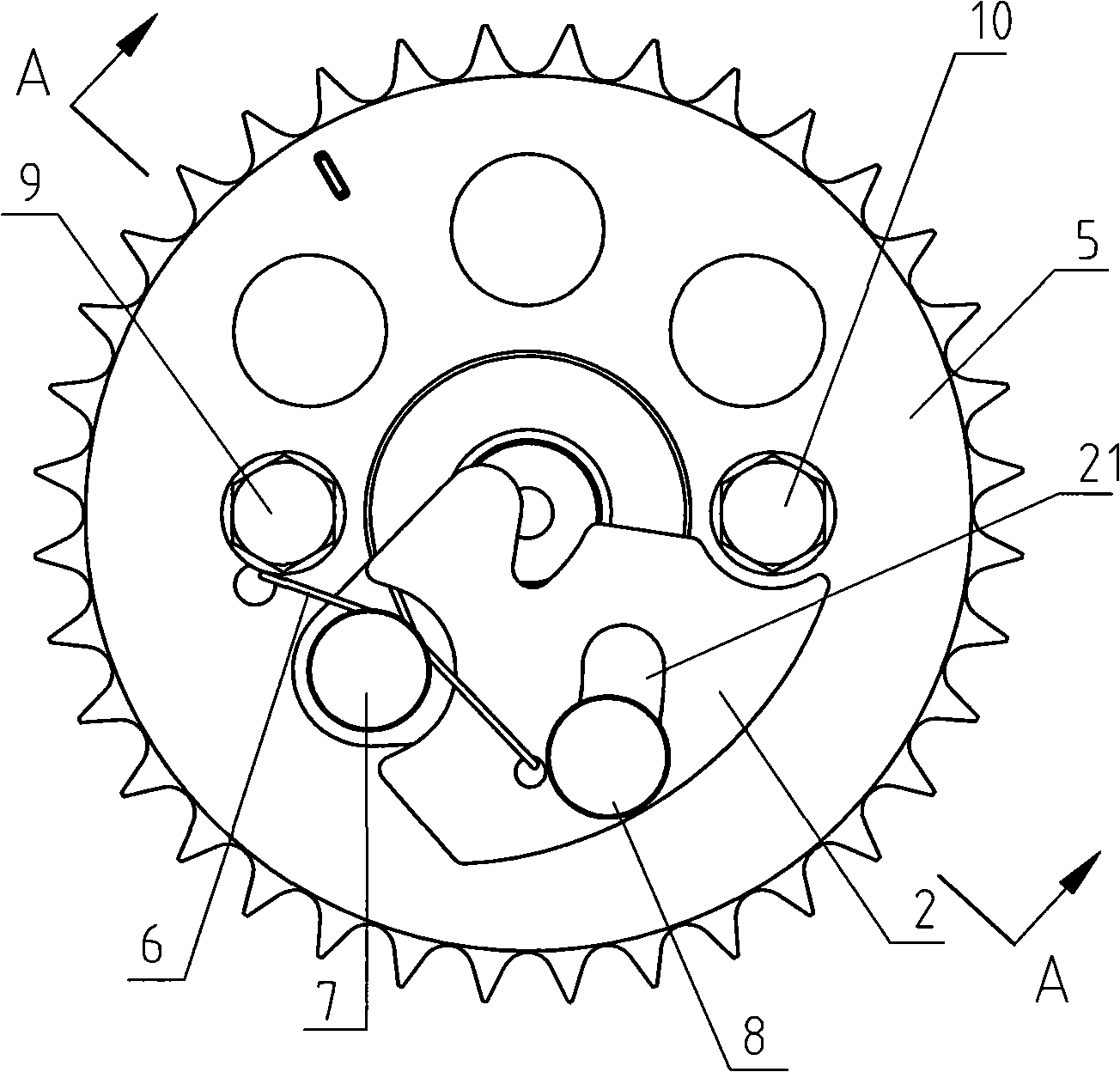

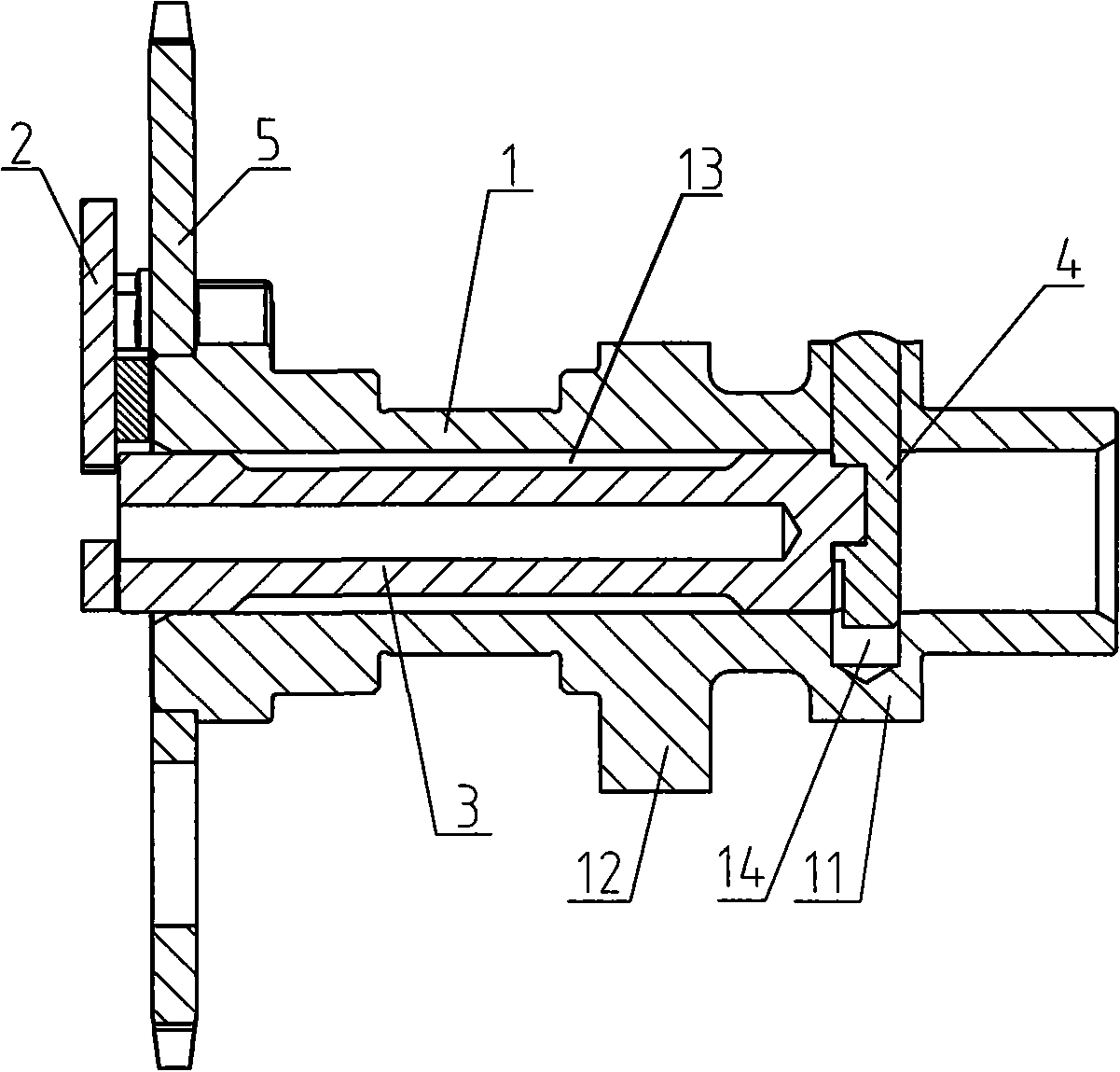

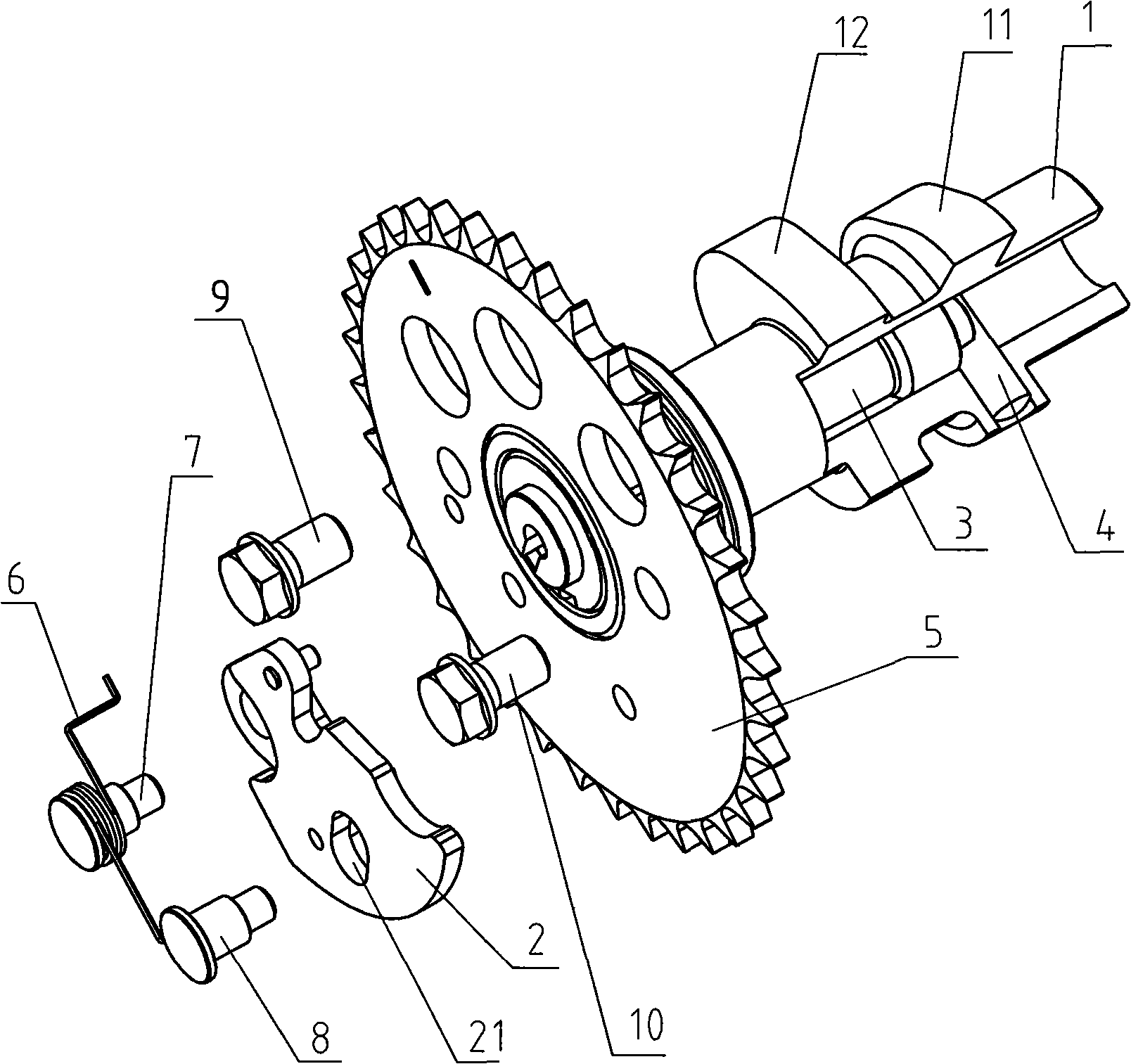

Engine startup pressure reduction cam axle component

InactiveCN101302948AReasonable location designReliable start of decompressionValve arrangementsMachines/enginesExhaust gasCam

The invention discloses a starting decompression camshaft component of an engine, which comprises a camshaft (1), a centrifugal flyweight (2), a timing driven wheel (5) and a column-shaped decompression valve (4) which is driven by the centrifugal flyweight (2). The camshaft (1) is provided with an admission cam (11) and an exhaust cam (12), the timing driven wheel (5) is fixed at the end of the camshaft, (1) and the centrifugal flyweight (2) is installed on the end face of the timing driven wheel (5). A spring (6) is arranged between the centrifugal flyweight (2) and the timing driven wheel (5). The position of the working end of the decompression valve (4) is corresponding to the base circle surface of the admission cam (11). Driven by the centrifugal flyweight (2), the working end of the decompression valve (4) can be higher than or lower than the base circle surface of the admission cam (11). In the invention, the position design of the working end of the decompression valve on the camshaft is more reasonable, therefore, not only the starting decompression can be effectively and reliably realized, but also the exhaust of unburned gas mixture into atmosphere when the engine is started can be avoided. The starting decompression camshaft component of the invention is environment protective and energy saving.

Owner:LONCIN MOTOR

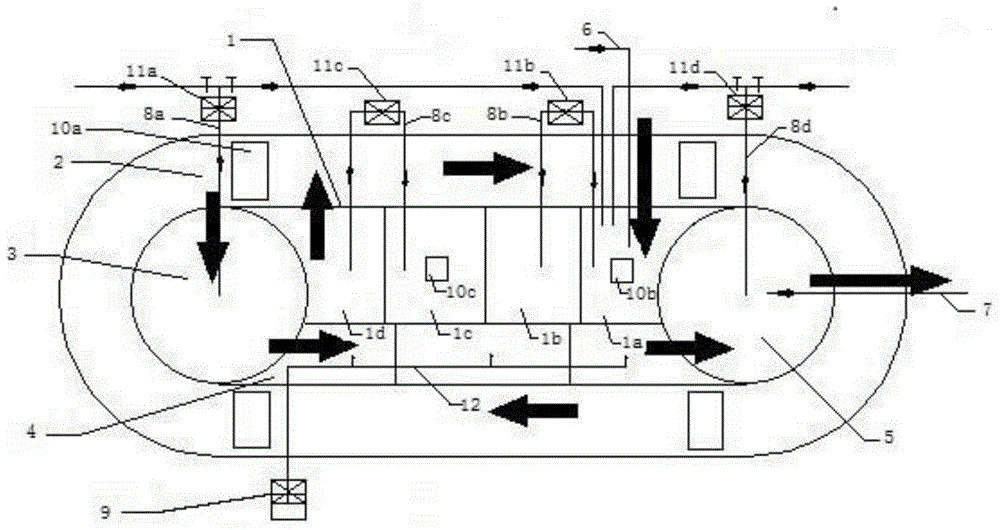

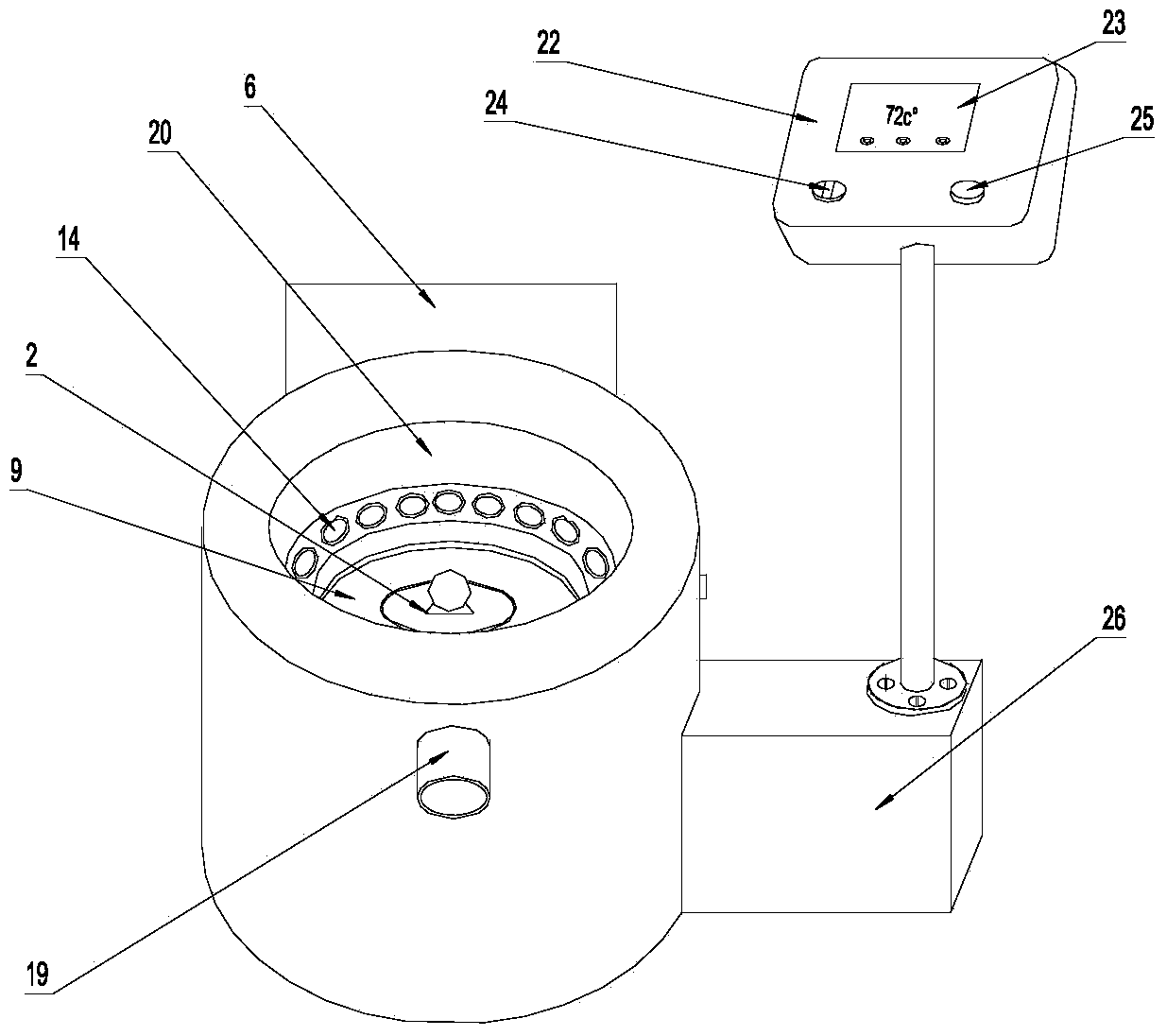

Integrated aerobiotic advanced treatment device

ActiveCN104355493ASmall footprintLow investment costTreatment using aerobic processesTreatment with aerobic and anaerobic processesSecondary treatmentOxidation ditch

The invention discloses an integrated aerobiotic advanced treatment device. The device comprises an AB process treatment region (1), an oxidation ditch (2), a secondary sedimentation tank (3), an advanced treatment reaction tank (4), a third sedimentation tank (5), a water inlet pipe (6) and a water outlet pipe (7), wherein the AB process treatment region comprises an A section aeration tank (1a), an A section sedimentation tank (1b), a B section aeration tank (1c) and a B section sedimentation tank (1d). The device disclosed by the invention has the following advantages that 1) a sewage treatment device is integrated so as to reduce the floor area, simplify the device construction and reduce the investment cost; 2) the sewage is sufficiently biochemically reacted and sedimentated through a primary treatment device, a secondary treatment device and a third treatment device so as to efficiently remove pollutants in the water body; and 3) the device automatically flows in the whole process, and is low in energy consumption and low in operation cost.

Owner:广西绿晨环境工程有限公司

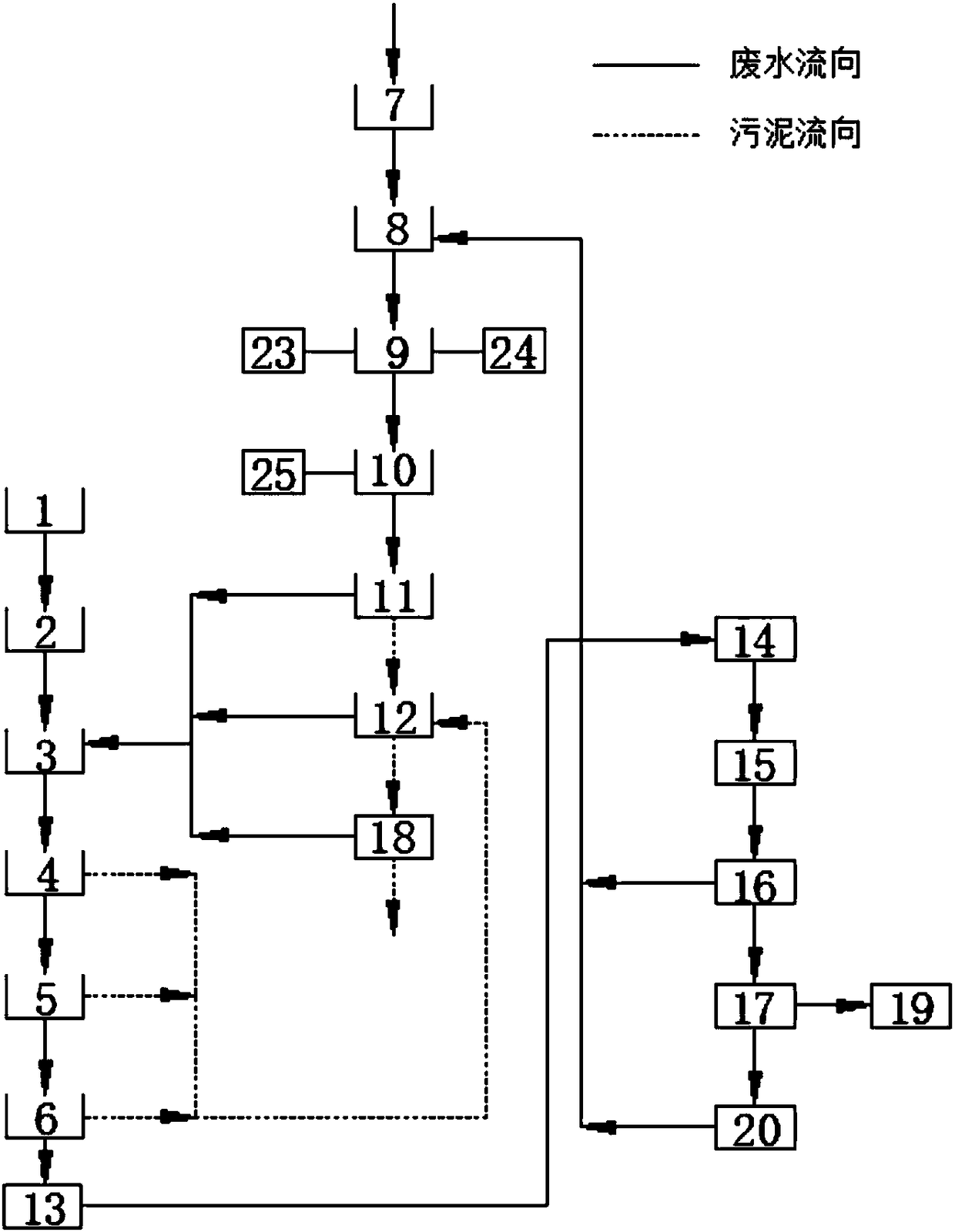

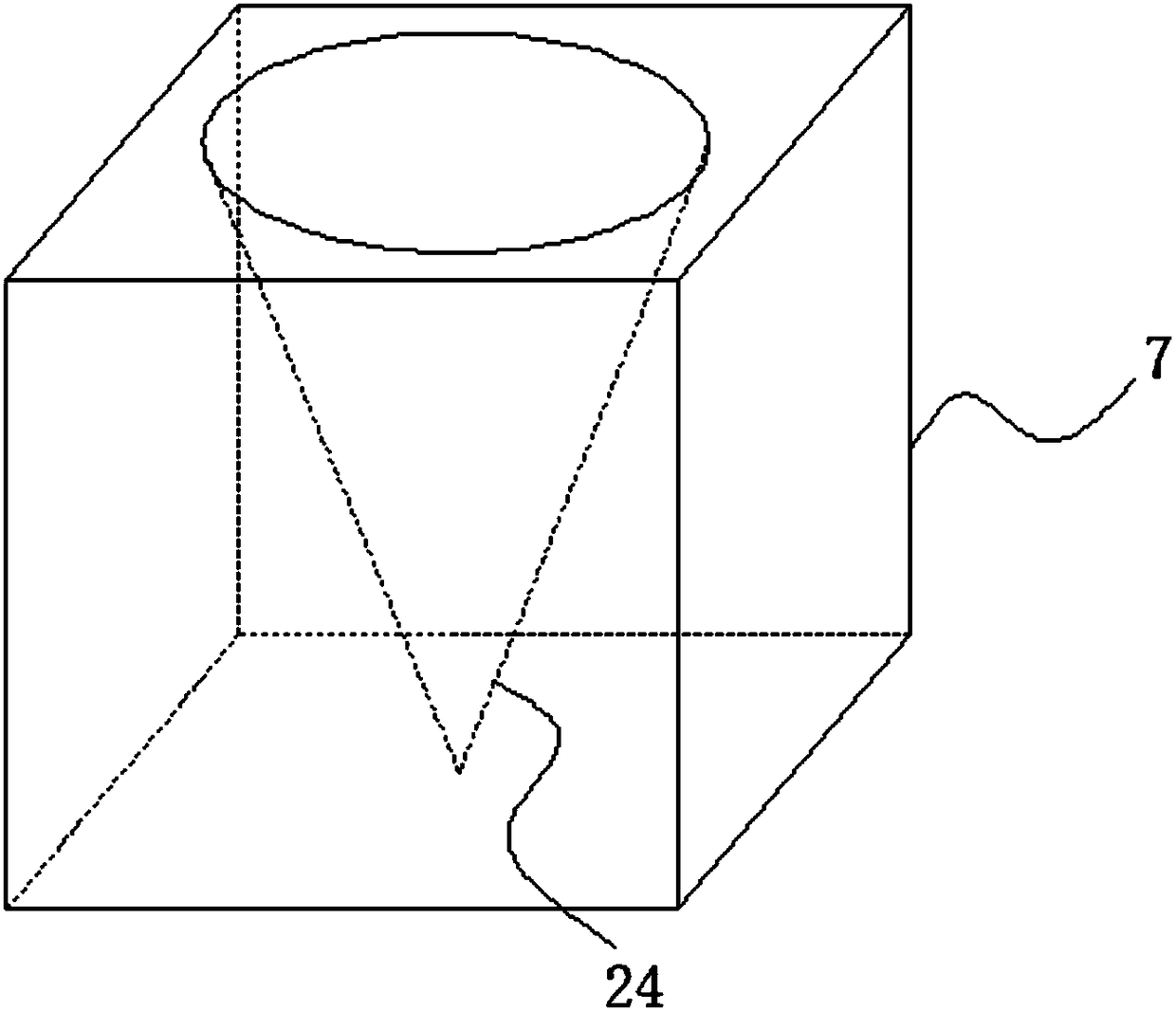

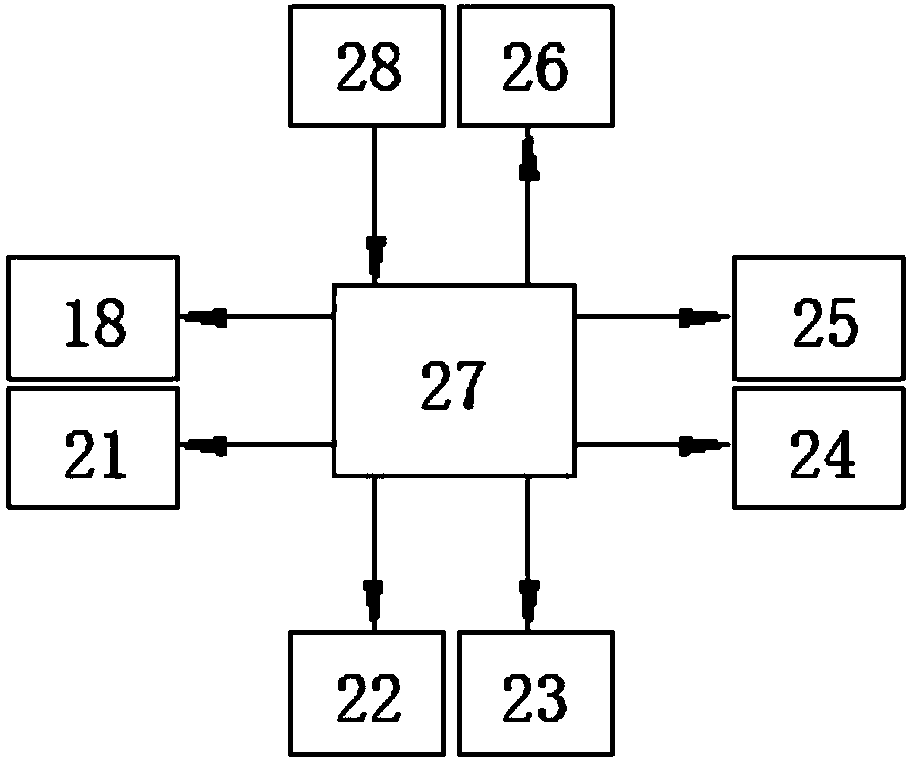

Efficient energy-saving comprehensive water treatment equipment

InactiveCN108495824AGuaranteed COD valueImprove emission standardsTreatment involving filtrationTreatment with anaerobic digestion processesWater dischargeIndustrial waste water

The invention discloses efficient energy-saving comprehensive water treatment equipment which comprises a domestic sewage pretreatment module, an industrial wastewater pretreatment module and a mixingtreatment module, wherein the domestic sewage treatment module comprises a grid well, an oil separation tank, a comprehensive regulation tank, an anaerobic tank, an oxidation tank and a sedimentationtank; the industrial wastewater pretreatment module comprises a grit chamber, an adjusting tank, a coagulation tank, a flocculation tank, an air floatation tank and a sludge concentration tank; the mixing treatment module comprises a middle water tank, a sand filtration tank, a carban filtration tank, an ultrafiltration device and a reverse osmosis device, wherein the sedimentation tank is communicated with the middle water tank; the anaerobic tank, the oxidation tank and the sedimentation tank are respectively communicated with the sludge concentration tank through a sludge pipeline; the ultrafiltration device and the concentration water tank are respectively communicated with the adjusting tank through a concentrated water return pipeline. The equipment is used for treating industrial wastewater and domestic sewage generated in the production process at the same time. The water treatment efficiency and the water discharge standard rate are improved, the enterprise water treatment cost is reduced, and the method is economical and practical.

Owner:SUZHOU RONGNENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

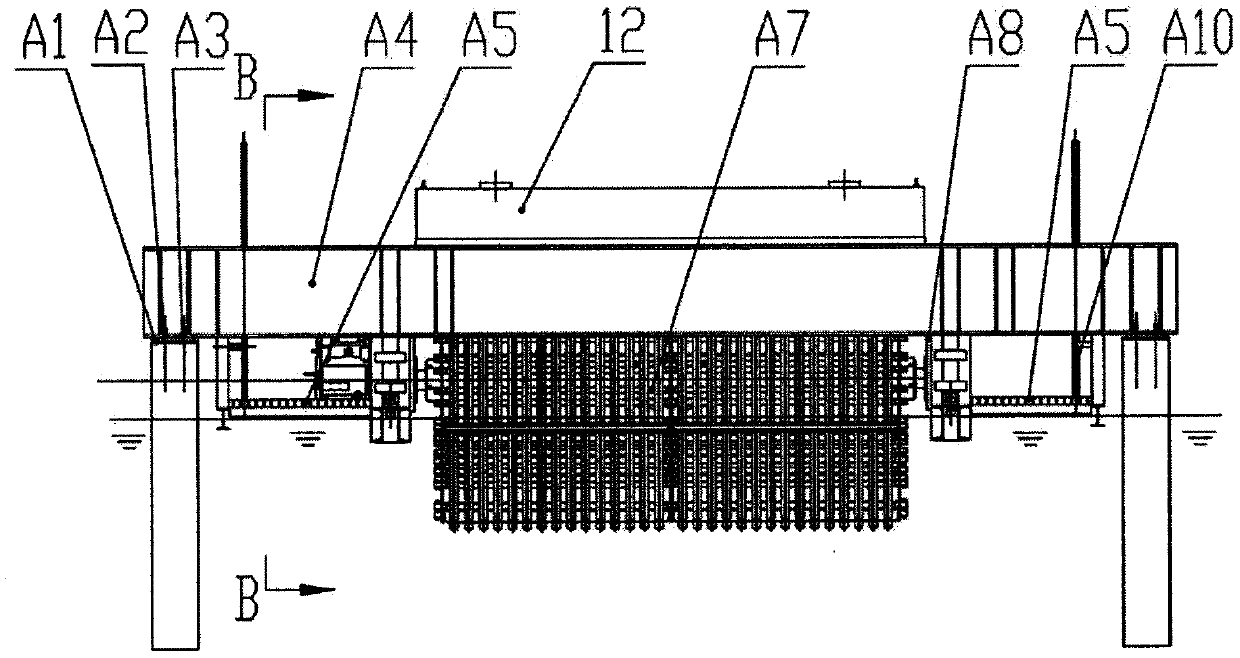

Three-dimensional rotary net-shaped contact body device, biological rotating disc tank and sewage treatment equipment

PendingCN110615528AReduce upfront investmentRealize non-stop production transformationTreatment with aerobic and anaerobic processesSustainable biological treatmentEngineeringAlloy

The invention discloses a three-dimensional rotary type net-shaped contact body device, a biological rotating disc tank and sewage treatment equipment, and relates to the technical field of environmental protection equipment. The three-dimensional rotary type net-shaped contact body device comprises a rotating disc body and a biological contact disc, wherein the biological contact disc is arrangedon the rotating disc body; the rotating disc adopts a welding structure, is made of high-strength low-alloy structural steel materials and is high in strength and long in service lifetime; a supporting shaft adopts a hollow stainless steel pipe welding structure, and is light in weight and high in strength; the biological contact body is axially fixed in a manner of compressing a connecting discwith internal and external threads, so that the biological contact body is more reliable in connection and convenient to disassemble, assemble and maintain. The biological rotating disc tank comprisesa tank body and a biological rotating disc, wherein a mixed solution is arranged in the tank body, bacillus is in the mixed solution, one part of the biological rotating disc is immersed in the mixedsolution, and the other part of the biological rotating disc is exposed in the air; the biological rotating disc comprises a main shaft and a membrane, and the membrane is of a three-dimensional netstructure and adsorbs the bacillus; a driving mechanism is connected to one end of a main shaft of the biological rotating disc and used for driving the main shaft to rotate.

Owner:青海洁神环境科技股份有限公司

Premixing secondary flaming burning civil boiler with boiler basins

InactiveCN104141967AContinuous heat transfer efficiencyPrevent ash and smokeDomestic stoves or rangesLighting and heating apparatusCombustorCombustion chamber

The invention relates to a premixing secondary flaming burning civil boiler with boiler basins. An upper boiler basin support with the periphery fixed on the boiler wall is arranged at the position, on the lower portion of a heat exchange pipe, inside a boiler body of the boiler, an upper mouth of the upper boiler basin support supports the combustor upper boiler basin, a lower basin mouth of the combustor upper boiler basin is connected with the combustor lower boiler basin in a hanging mode, the combustor lower boiler basin contains bunker coal, the wall of the combustor lower boiler basin is provided with a plurality of combustor upper air inlets distributed in the circumferential direction, and a boiler grill with a plurality of lower air inlets is arranged at the lower end of the combustor lower boiler basin; the top of the heat exchange pipe is covered with a flame nozzle edge cover, a conical reflective cover covers an inner circumferential mouth of the flame nozzle edge cover, and a flame nozzle cover covering a flame nozzle covers a lower mouth of the reflective cover; a positive pressure combustor is arranged below the reflective cover and the flame nozzle cover, the reflective cover, the flame nozzle cover and an upper boiler cover form a negative pressure combustor, and the negative pressure combustor is communicated with a smoke vent formed in the boiler body. As the boiler is structurally provided with the positive pressure combustor and the negative pressure combustor, coal can be saved by 30%; when coal ash is cleared up, environment inside a room is not polluted.

Owner:QIQIHAR XINRI MACHINERY EQUIP MFG

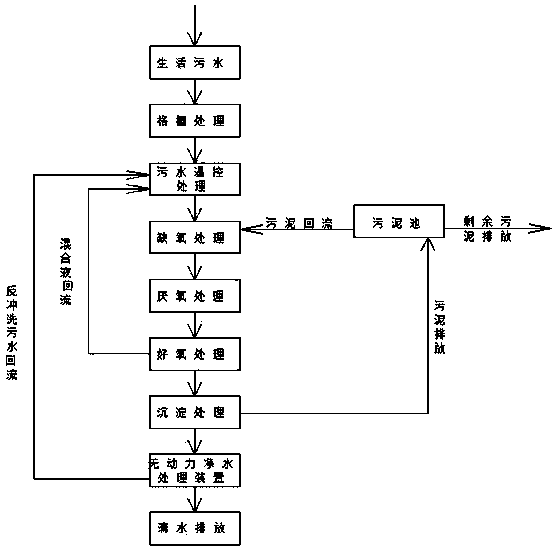

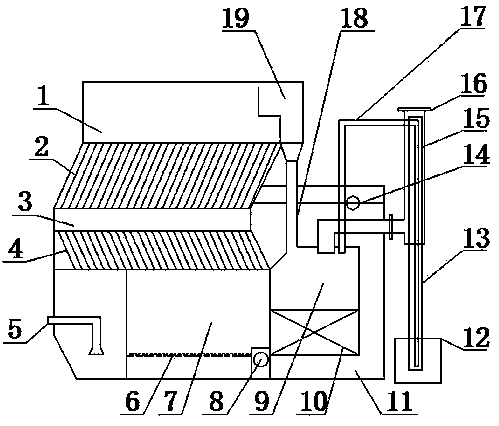

Ultra-micro powder sewage treatment device and sewage treatment method of sewage treatment device

InactiveCN104230106AImprove emission standardsImprove denitrification effectMultistage water/sewage treatmentCold seasonTemperature control

The invention discloses an ultra-micro powder sewage treatment device and a sewage treatment method of the sewage treatment device, and relates to the field of environmental protection. The ultra-micro powder sewage treatment device comprises the following processing steps: sanitary sewage taking, grid treatment, temperature adjustment of sewage, hypoxia treatment, anaerobic treatment, aerobic treatment, sedimentation treatment, treatment by an unpowered water purification treatment device, and clean water discharge. The ultra-micro powder sewage treatment device and the sewage treatment method have the beneficial effects that 1, temperature control equipment is arranged, so that the problems that the sewage is relatively low in temperature in a cold season, and is difficult to process and transport are solved; 2, a power supply adopts a convertible system of 220V / 380V, and the operation cost is also greatly reduced; 3, a denitrification process is identified; and 4, an unpowered water purification device is adopted, so that energy consumption is saved, 500-1,000t of sewage can be processed every day, an all-buried mode can be adopted in installation, a machine room can be finished into a landscape on the ground, soil resources can be saved, the environment is beautified, and the sewage treatment device is stable in operation, and low in operation and maintenance costs, has relatively efficient nitrogen and phosphorus removal ability, and is high in sewage discharge standard, which reaches the first grade A.

Owner:ZHONGGANG CONSTR GRP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com