Starting-generating device for miniature turbojet engine or turbocharger

A jet engine and turbocharger technology, applied in the field of starter power generation devices, can solve the problems of affecting turbojet combustion efficiency, requiring large power supply capacity, hindering air inhalation, etc., and achieving simple and reliable structure, long endurance, and reduced weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

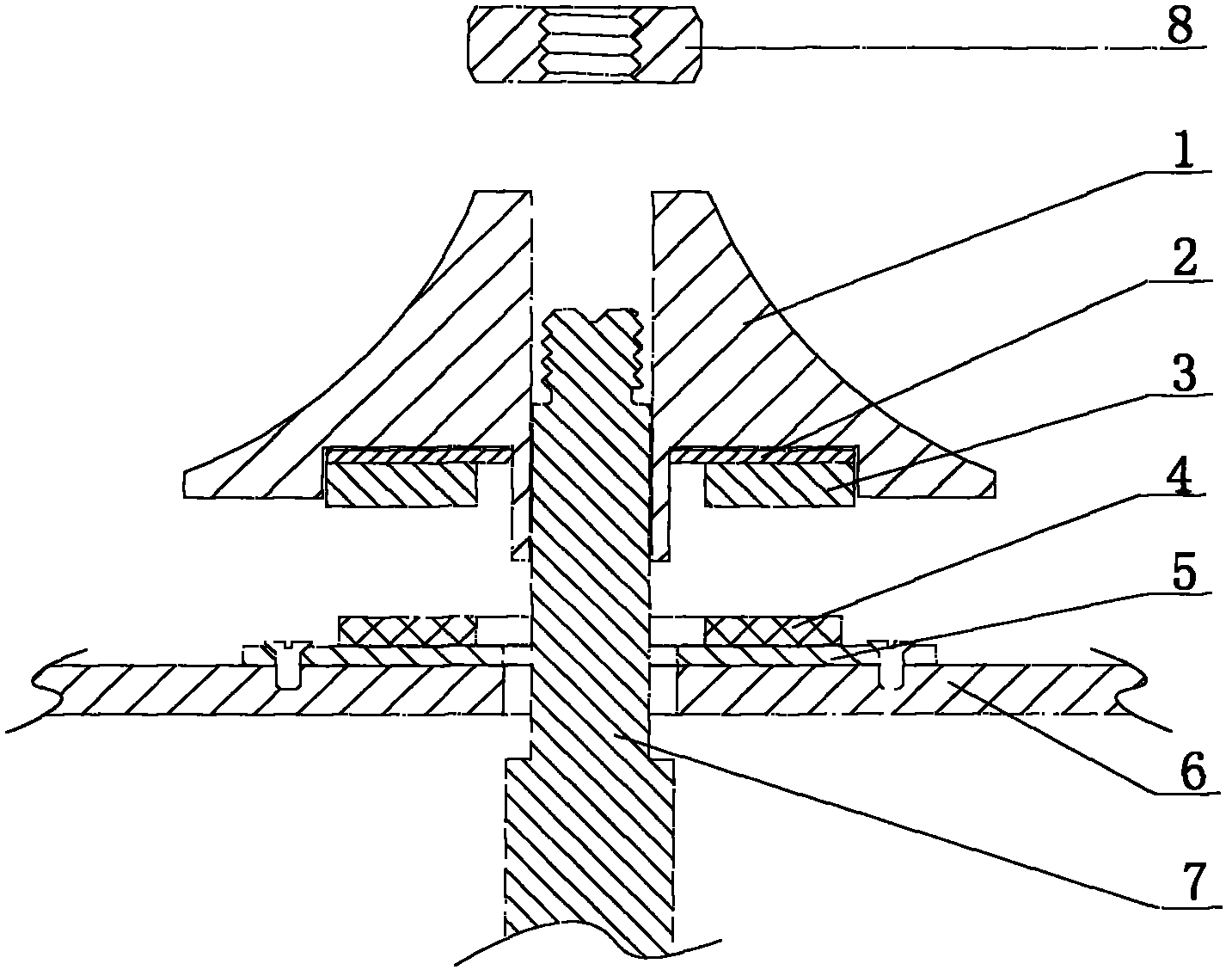

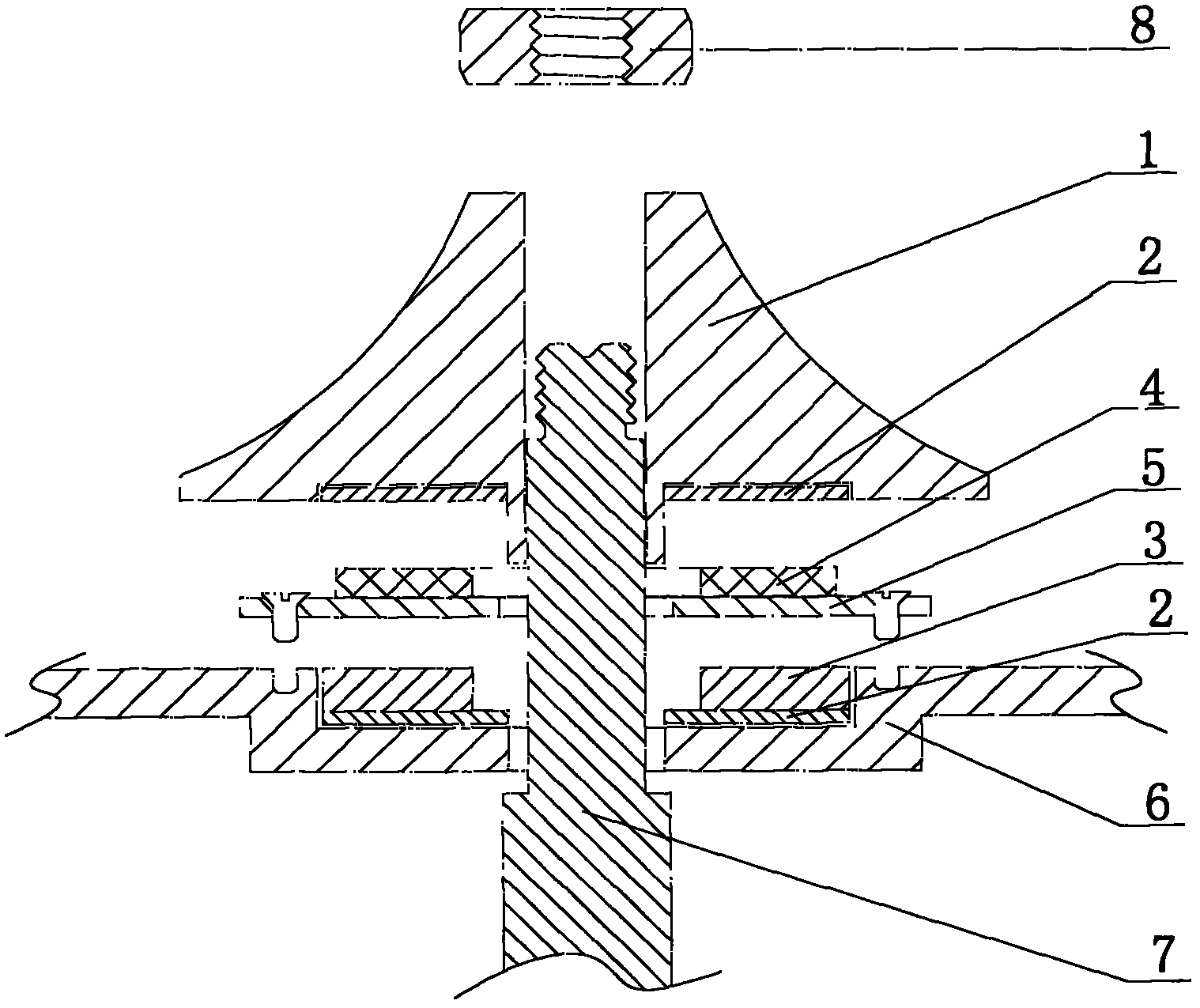

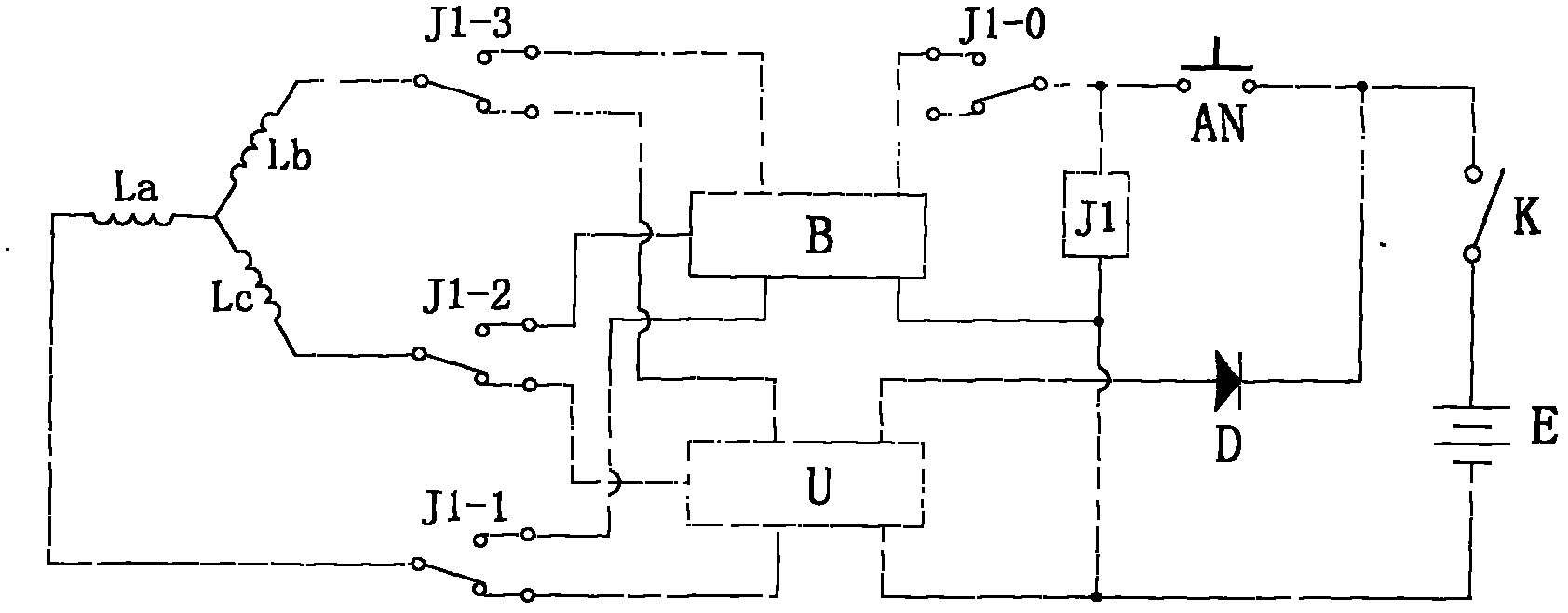

[0017] In the implementation of the present invention, as attached figure 1 As shown, the permanent magnet rotor and stator coil of the motor are installed on the inner side of the impeller 1 on the micro turbojet engine or turbocharger, and the permanent magnet rotor 3 and the magnetizer 2 are fixed on the inner side of the impeller 1 at the same time, and can also be placed on the inner side of the impeller 1 Open a groove suitable for the shape of the permanent magnet rotor 3, then place the permanent magnet rotor 3 and the magnetizer 2 in the groove and embed the impeller 1 to fix it; fix the disc stator coil 4 on the stator mounting base plate 5, and then place the The stator mounting base plate 5 is fixed on the rear cover plate 6 of the diffuser or turbocharger compressor of the turbojet engine, the disk stator coil 4 corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com