Small displacement engine exhaust manifold assembly structure

An exhaust manifold and assembly structure technology, which is applied to engine components, machines/engines, exhaust devices, etc., can solve the problems of low temperature and cannot meet emission standards, and achieve the effect of increasing length and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

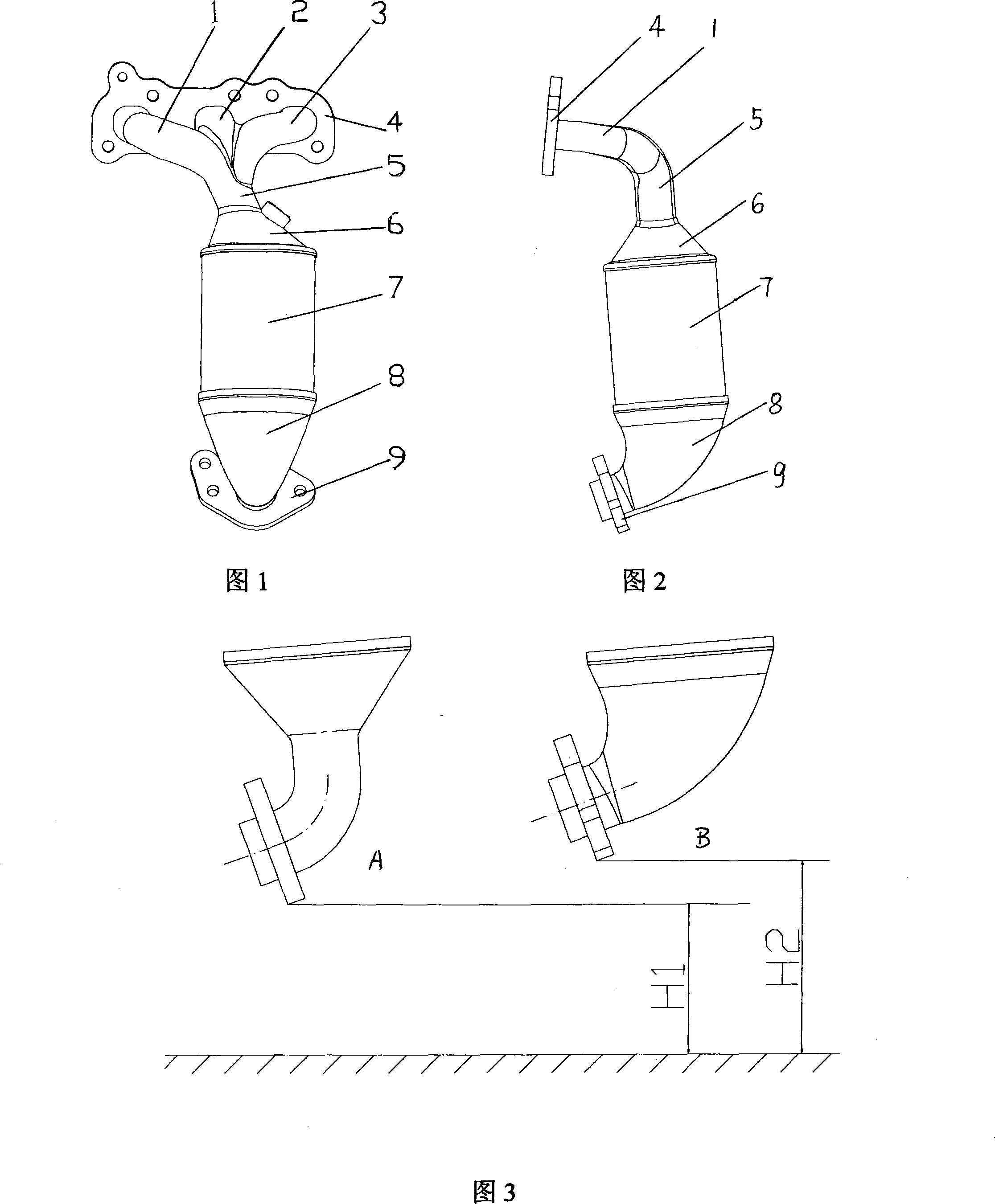

[0014] As shown in Figure 1, the exhaust manifold assembly is designed for a three-cylinder engine and is made of stainless steel. There are three exhaust manifolds for one, two and three cylinders. The blue plate 4 is welded, and the lower end is joined to the middle to form an air passage 5, which is welded to the inlet end cover 6 of the three-way catalytic converter, and the welding position deviates from the center of the inlet end cover 6 of the three-way catalytic converter by a certain angle. Each exhaust manifold air passage is welded by upper and lower half shells, and the lower half shell is integrated into one, namely air passage 5. The parting surfaces of each exhaust manifold air passage are on the same curved surface. . The outlet end cover 8 of the three-way catalytic converter adopts an angular structure and is connected to the outlet flange 9. The body of the three-way catalytic converter is a stainless steel barrel-shaped structure, and the upper and lower parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com