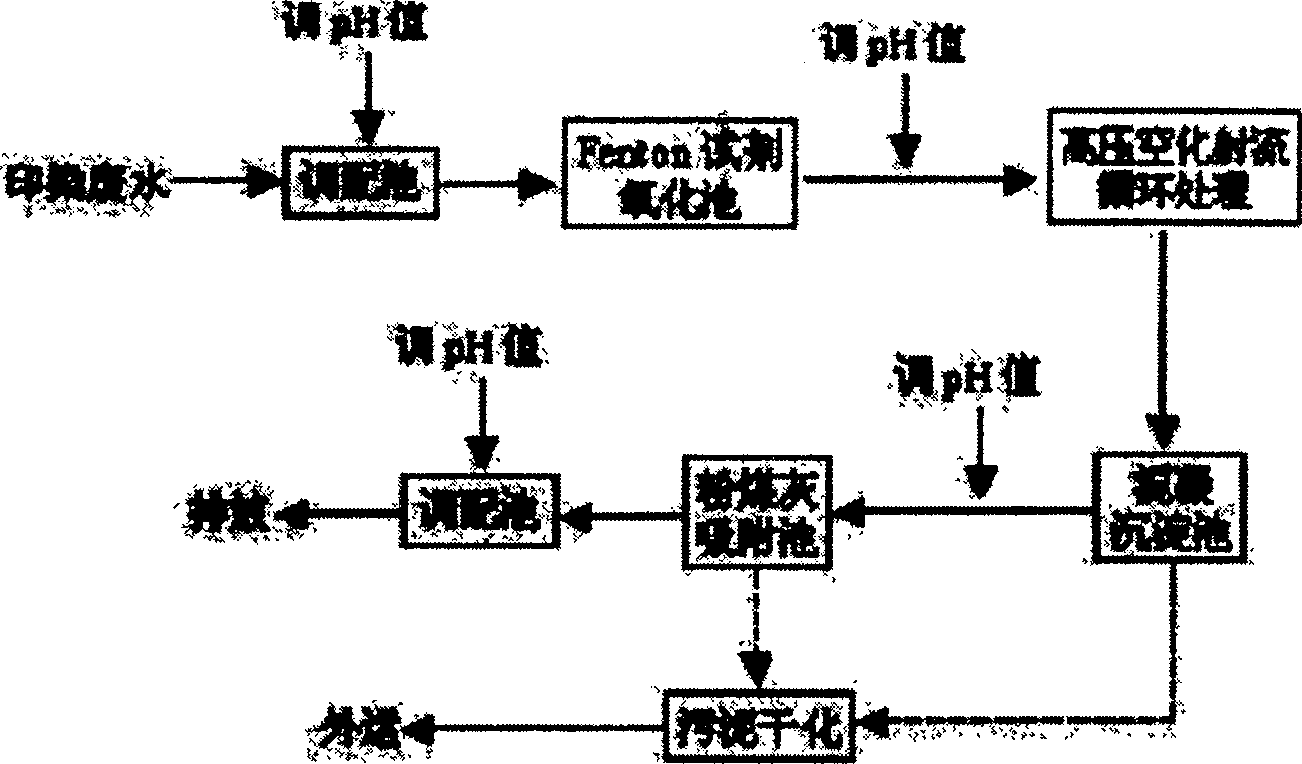

Method for treating printing and dyeing waste water by high pressure cavitation jet combined with fenton reagent

A technology of printing and dyeing wastewater and Fenton's reagent, which is applied in chemical instruments and methods, oxidized water/sewage treatment, animal husbandry wastewater treatment, etc., can solve the problems of low removal rate, incomplete treatment of COD and chroma of printing and dyeing wastewater, and achieve Good effect, complete degradation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Example 1, when processing COD is 1385mg / L, chromaticity is 658 times, pH value is 6.0 when printing and dyeing waste water, carry out according to the following specific steps:

[0020] 1. Use hydrochloric acid to adjust the pH value of printing and dyeing wastewater to 2.0;

[0021] 2. Perform Fenton reagent oxidation treatment on the printing and dyeing wastewater after pH adjustment: add ferrous sulfate at a stirring speed of 200r / min to make the concentration of ferrous sulfate ion 0.009mol / L, then add hydrogen peroxide to make hydrogen peroxide The concentration in the printing and dyeing wastewater is 0.1mol / L, and the printing and dyeing wastewater after adding hydrogen peroxide continues to stir for 30 minutes

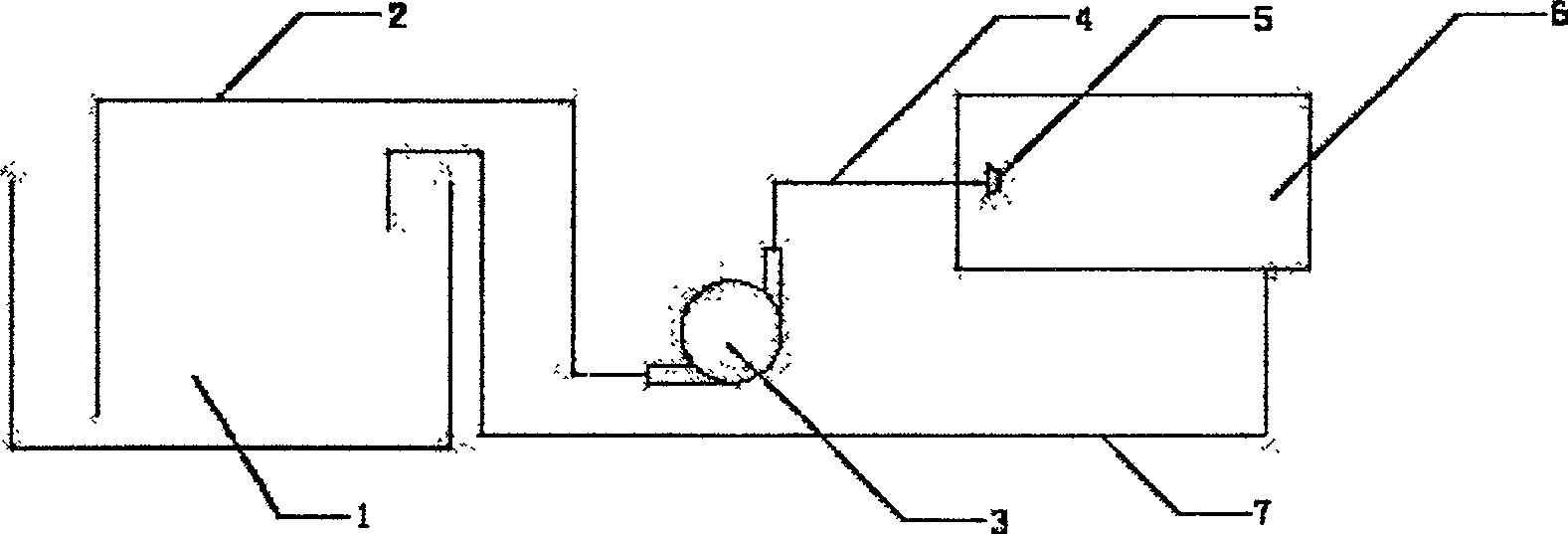

[0022] 3. Use sodium hydroxide to adjust the pH value of the printing and dyeing wastewater after the oxidation treatment to 8.0, add hydrogen peroxide to it so that the concentration of hydrogen peroxide in it is 0.01mol / L, stop stirring, and then use ...

example 2

[0027] Example 2, when processing the printing and dyeing wastewater whose COD is 1586mg / L, chroma is 722 times, and pH value is 6.4, carry out according to the following specific steps:

[0028] 1. Use sulfuric acid to adjust the pH value of printing and dyeing wastewater to 2.8;

[0029]2. Perform Fenton reagent oxidation treatment on the printing and dyeing wastewater after pH adjustment: add ferrous sulfate at a stirring speed of 230r / min to make the concentration of ferrous sulfate ion 0.012mol / L, then add hydrogen peroxide to make hydrogen peroxide The concentration in the printing and dyeing wastewater is 0.13mol / L, and the printing and dyeing wastewater after adding hydrogen peroxide is continuously stirred for 35 minutes;

[0030] 3. Use sodium hydroxide to adjust the pH value of the printing and dyeing wastewater after the oxidation treatment to 9.0, add hydrogen peroxide to it so that the concentration of hydrogen peroxide in it is 0.03mol / L, stop stirring, and then...

example 3

[0035] Example 3, when processing the printing and dyeing wastewater whose COD is 1733mg / L, chroma is 844 times, and pH value is 6.6, carry out according to the following specific steps:

[0036] 1. Use sulfuric acid to adjust the pH value of printing and dyeing wastewater to 3.5;

[0037] 2. Perform Fenton reagent oxidation treatment on the printing and dyeing wastewater after pH adjustment: add ferrous sulfate at a stirring speed of 250r / min to make the concentration of ferrous sulfate ion 0.015mol / L, then add hydrogen peroxide to make hydrogen peroxide The concentration in the printing and dyeing wastewater is 0.15mol / L, and the printing and dyeing wastewater after adding hydrogen peroxide is continuously stirred for 40 minutes;

[0038] 3. Use sodium hydroxide to adjust the pH value of the printing and dyeing wastewater after the oxidation treatment to 10.0, add hydrogen peroxide to it so that the concentration of hydrogen peroxide in it is 0.05mol / L, stop stirring, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com