Antiwear dynamic self-repairing lubricant for metal and preparation method thereof

A metal anti-wear and lubricant technology, used in lubricating compositions, additives, petroleum industry, etc., can solve the problems of serious deposition, complex anti-wear treatment process, and large proportion of solid lubricants, saving fuel and reducing oil replacement. effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

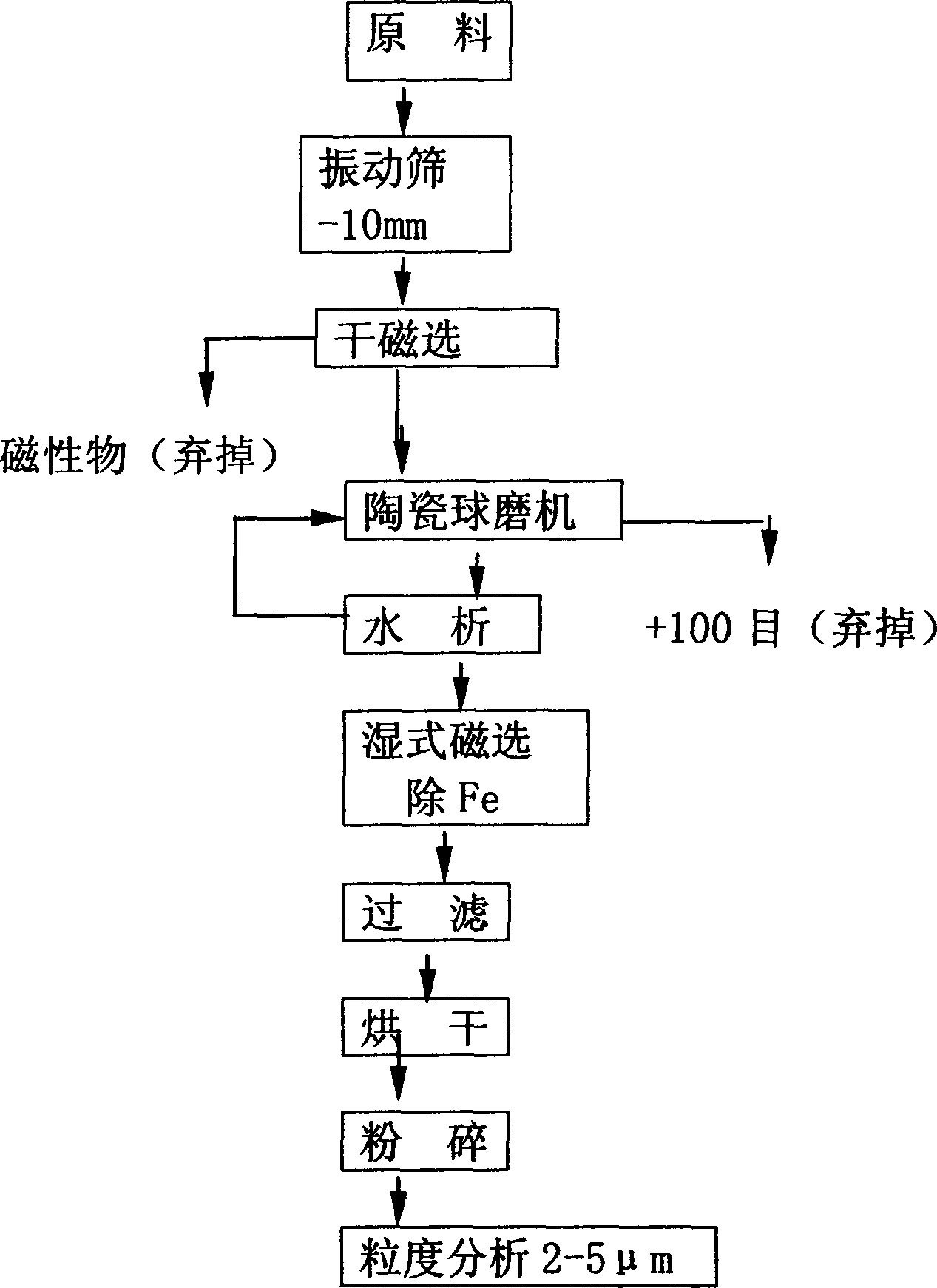

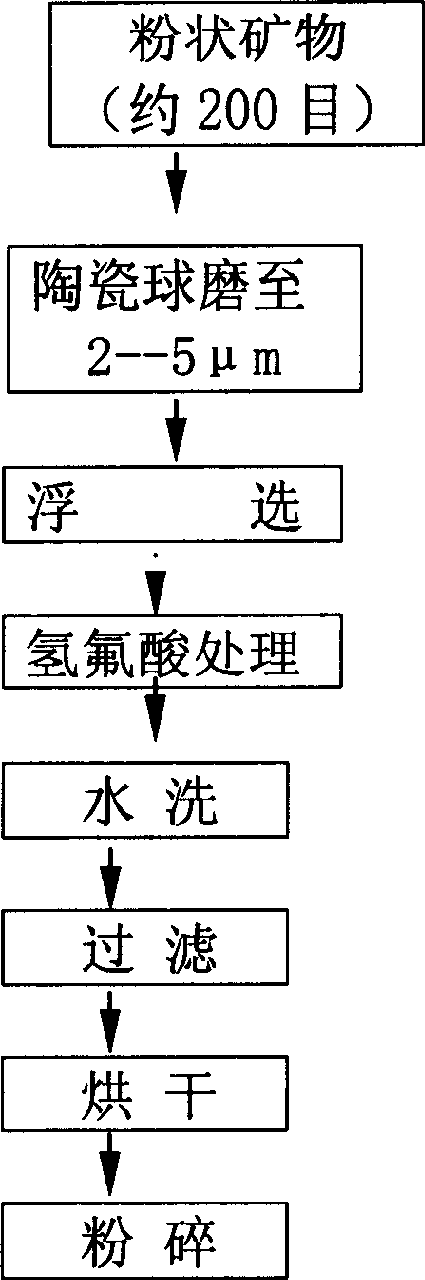

Method used

Image

Examples

Embodiment Construction

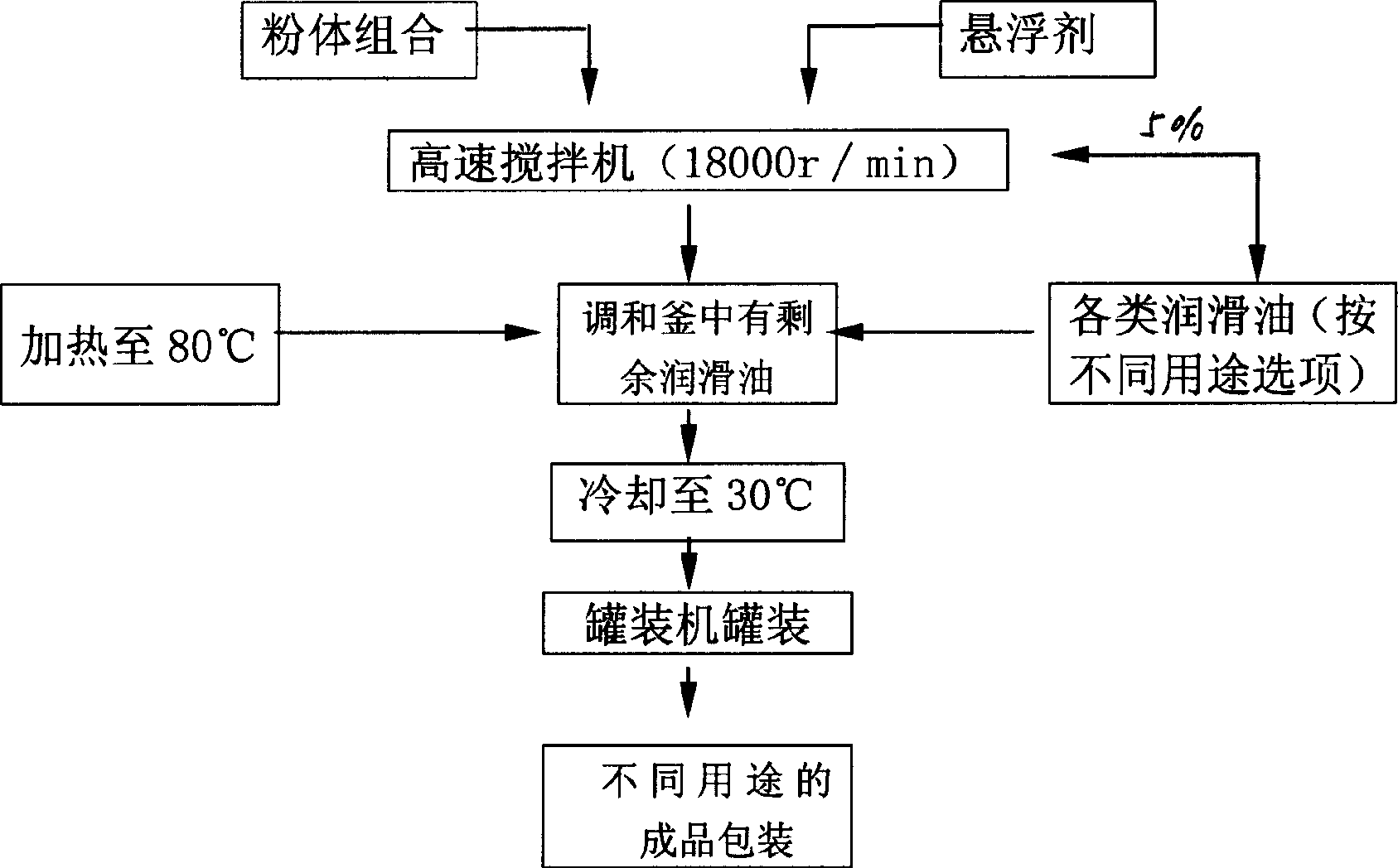

[0026] The metal anti-friction and anti-friction dynamic self-repairing lubricant of the present invention is a composition of mineral matter, suspending agent and lubricating oil, and is characterized in that the proportioning of the lubricant is by weight percentage:

[0027] Mineral powder composition 0.005-5.0: suspending agent 2.5-4.0: lubricating oil 92-97.50%;

[0028] The proportioning of the mineral powder composition is by weight percentage:

[0029] Chrysotile 57.50-64 blue asbestos 12-16 actinolite 4.5-6 aphanitic graphite 9-12 diopside 4.5-6 sericite 4.5-6.

[0030] The proportioning of the suspending agent composition is: the weight percentage is 25% polyoxyethylene ester C 17 C 35 COO(C 2 h 4O ) 6 H and heptadecylammonium ethyl ammonium ethyl imidazoline with a weight percentage of 75% are resistant to high temperature, do not change color when heated to 200° C., and do not produce bubbles.

[0031]

[0032] name

weight percentage (%)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com