Ultra-micro powder sewage treatment device and sewage treatment method of sewage treatment device

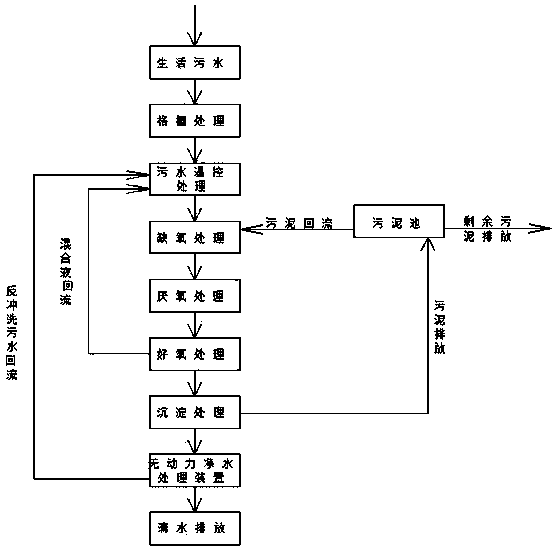

A sewage treatment method and power technology, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of improving denitrification capacity, stable operation and saving land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

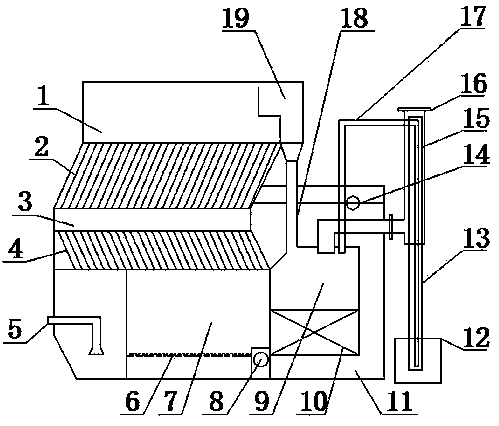

[0014] Example 1: An ultra-micro power sewage treatment device and its sewage treatment method, the process steps are: domestic sewage→grid treatment→sewage temperature adjustment treatment→anoxic treatment→anaerobic treatment→aerobic treatment→sedimentation treatment→ Unpowered water purification treatment device → clean water discharge; where: The process requirements for grid treatment are : Install artificial grille at the outlet of domestic sewage collection well, made of stainless steel square steel pipe, the specification of square steel pipe is: 500×300×40mm: grille hole 10mm: organic matter less than 10 mm enters the next process through the grille, Insoluble substances larger than 10 mm are filtered out and extracted manually with a mesh spoon; The process requirements for the temperature regulation treatment of sewage are as follows: : Adjust the temperature of the sewage treated by the grid in the temperature control pool, and use the electric heater to control t...

Embodiment 2

[0015] Example 2: An ultra-micro power sewage treatment device and its sewage treatment method, the process steps are: domestic sewage→grid treatment→sewage temperature adjustment treatment→anoxic treatment→anaerobic treatment→aerobic treatment→sedimentation treatment→ Unpowered water purification treatment device → clean water discharge; where: The process requirements for grid treatment are : An artificial grill is installed at the outlet of the domestic sewage collection well. The material is stainless steel square steel pipe. The specification of the square steel pipe is: 500×300×40mm: the grill hole is 15mm: the organic matter less than 15 mm enters the next process through the grill, Insoluble substances larger than 15 mm are filtered out and extracted manually with a mesh spoon; The process requirements for the temperature regulation treatment of sewage are as follows: : The temperature of the sewage treated by the grid is adjusted in the temperature control pool, and...

Embodiment 3

[0016] Example 3: An ultra-micro power sewage treatment device and its sewage treatment method, the process steps are: domestic sewage→grid treatment→sewage temperature adjustment treatment→anoxic treatment→anaerobic treatment→aerobic treatment→sedimentation treatment→ Unpowered water purification treatment device → clean water discharge; where: The process requirements for grid treatment are : Install artificial grille at the outlet of domestic sewage collection well, made of stainless steel square steel pipe, the specification of square steel pipe is: 500×300×40mm: grille hole 20 mm: organic matter less than 20 mm enters the next process through the grille , insoluble substances larger than 20 mm are filtered out and extracted manually with a mesh spoon; The process requirements for the temperature regulation treatment of sewage are as follows: : Adjust the temperature of the sewage treated by the grid in the temperature control pool, and use the electric heater to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com