Engine startup pressure reduction cam axle component

An engine starting and camshaft technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as the impact of exhaust emissions, and achieve the effect of reasonable position design and reliable starting and decompression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

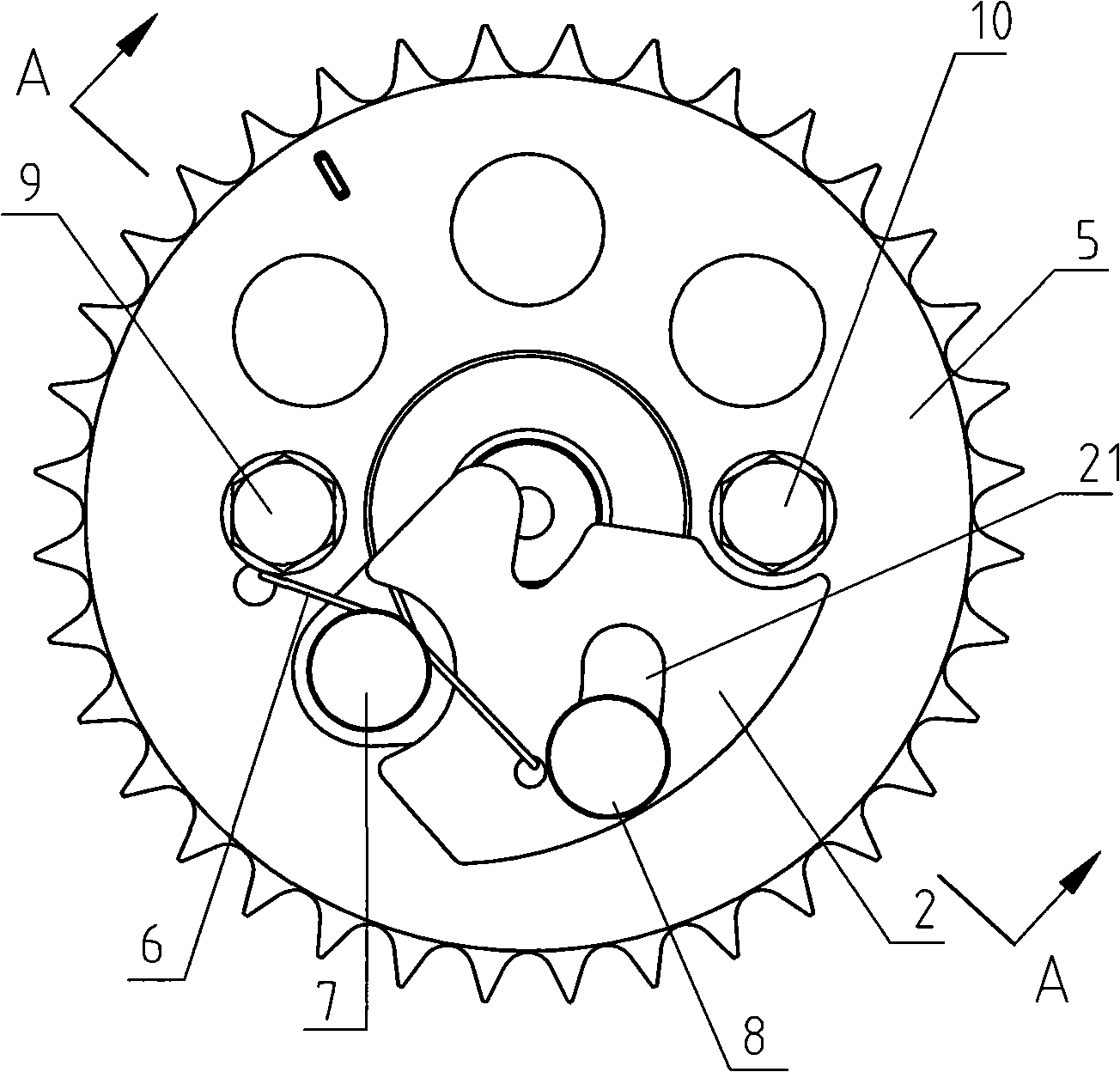

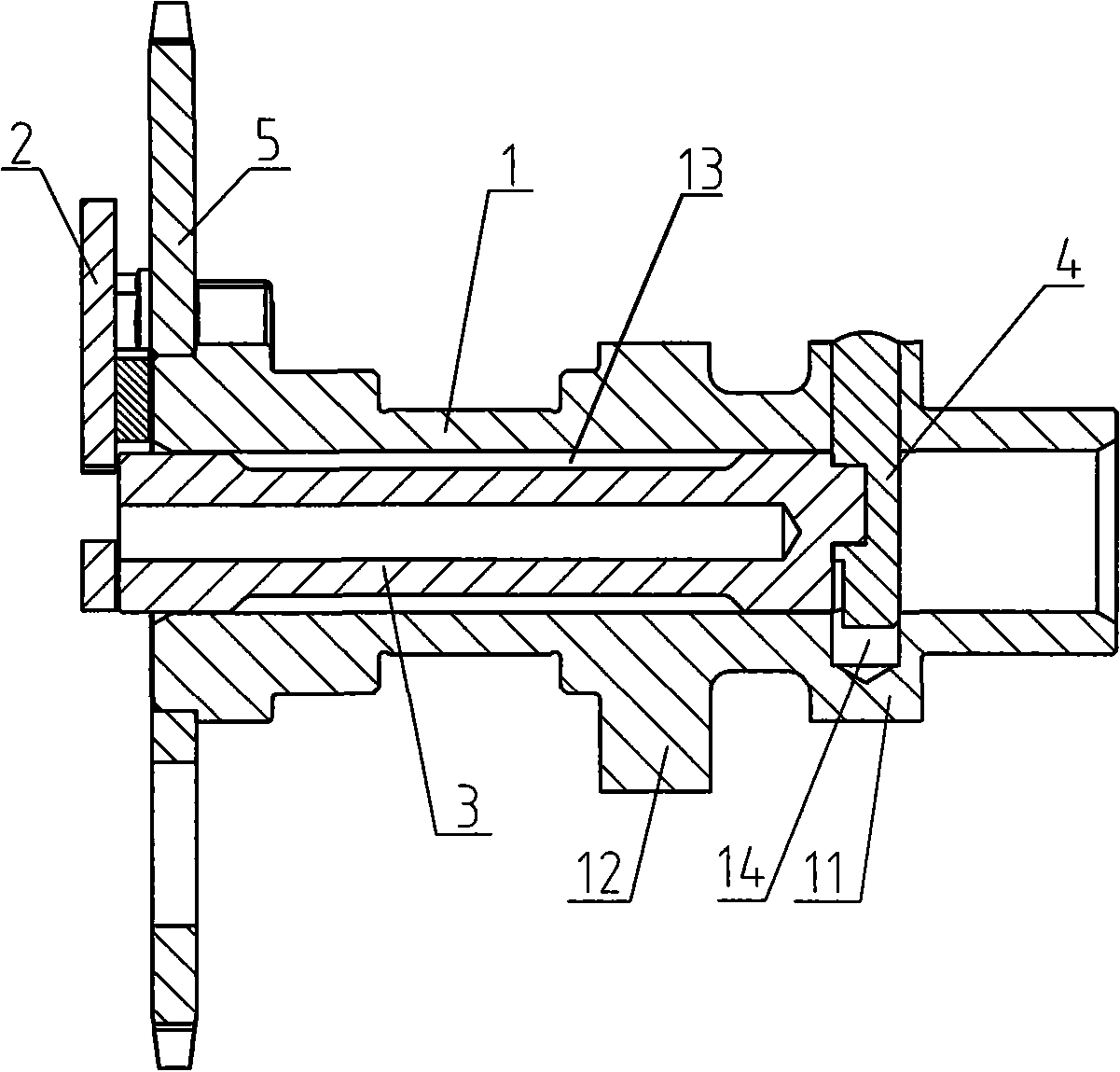

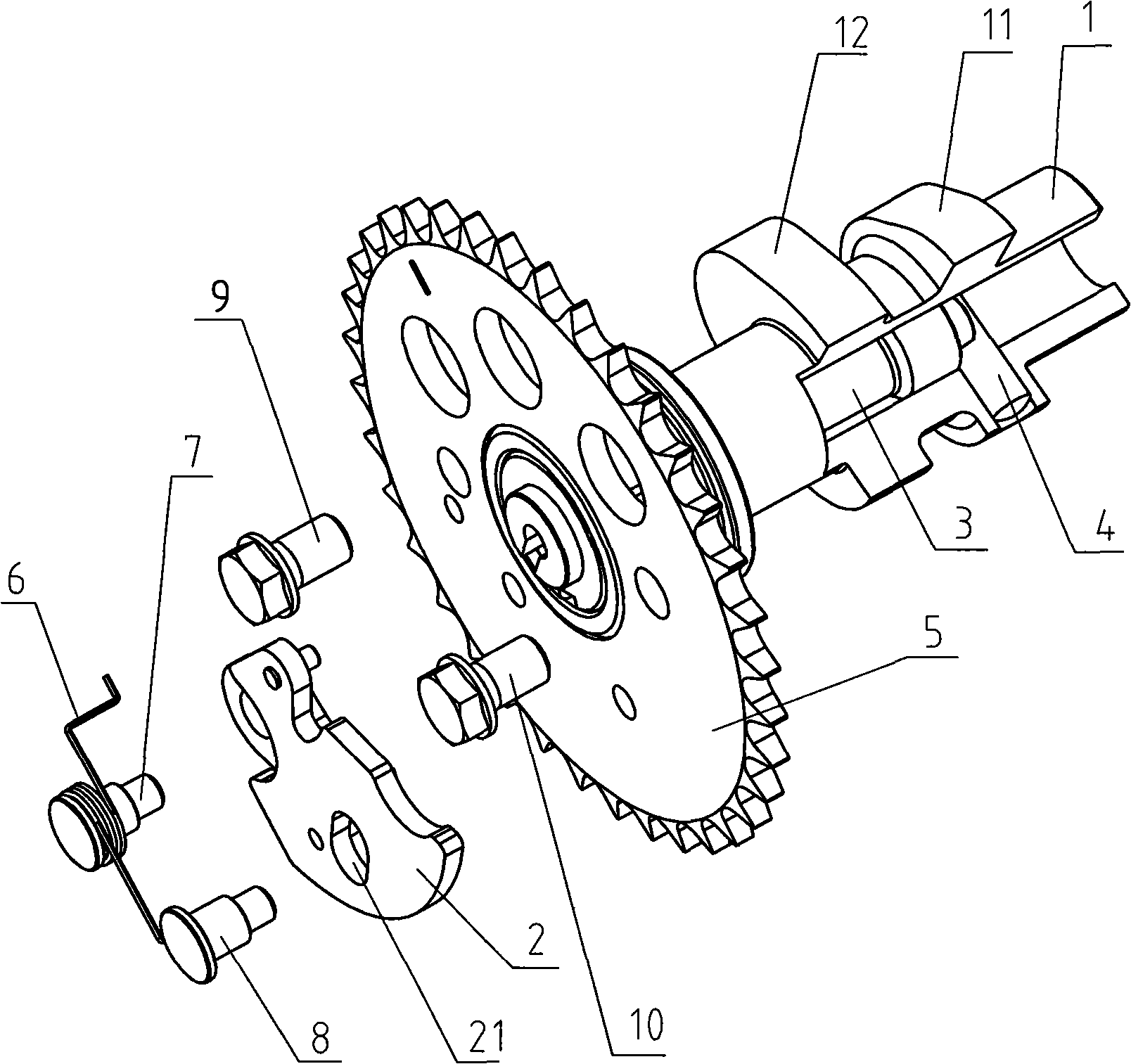

[0017] Such as figure 1 , figure 2 and image 3 Shown, a kind of engine starting decompression camshaft assembly is used on the motorcycle engine, consists of camshaft 1, centrifugal flying weight 2, flying weight shaft 3, pressure reducing valve body 4, timing driven wheel 5, spring 6, Locating pin 7, limit pin 8 and bolt 9,10 are formed. There are intake cam 11 and exhaust cam 12 on the camshaft 1, the timing driven wheel 5 is fixed on the end of the camshaft 1 with bolts 9 and 10, and the centrifugal flying weight 2 is installed on the end face of the timing driven wheel 5 with the positioning pin 7 Above, the centrifugal flying weight 2 can rotate around the positioning pin 7 under the action of centrifugal force. The spring 6 is a torsion spring and is set on the positioning pin 7. One end of the spring 6 is hung in the hole on the end face of the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com