Integrated aerobiotic advanced treatment device

A technology of advanced treatment and treatment area, which is applied in the direction of aerobic process treatment, aerobic and anaerobic process treatment, multi-stage water treatment, etc. Reduce the number of problems, to achieve the effect of preventing sludge deposition, reducing floor space, and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

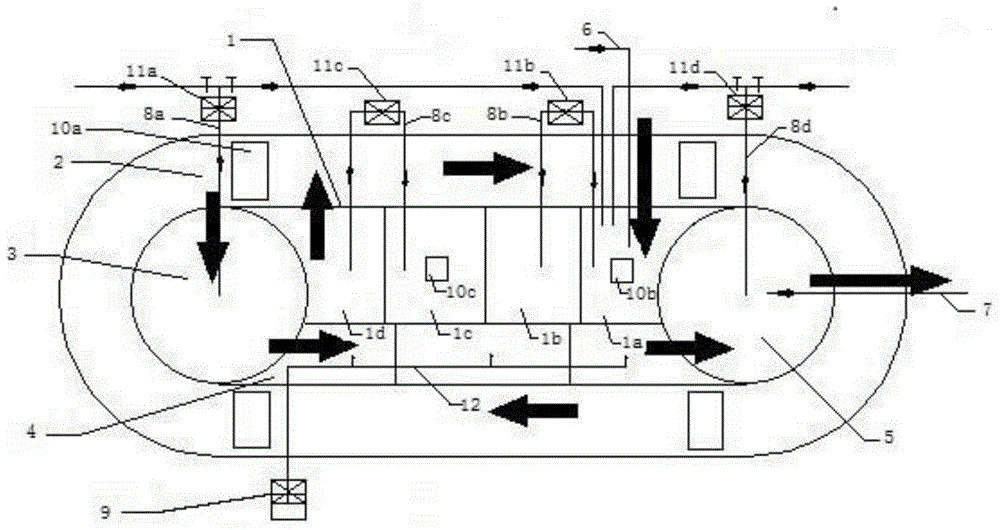

[0030] like figure 1 as shown, An integrated aerobic advanced treatment device, which includes an AB process treatment area 1, an oxidation ditch 2, a secondary settling tank 3, an advanced treatment reaction tank 4, a tertiary settling tank 5, an inlet pipe 6 and an outlet pipe 7; The ditch 2 has a ring structure; the secondary settling tank 3 and the tertiary settling tank 5 are respectively arranged at both ends of the AB process treatment area 1; In the ring of the oxidation ditch 2; the advanced treatment reaction tank 4 is arranged on one side of the AB process treatment area 1; the AB process treatment area 1 includes the A-section aeration tank 1a, the A-section sedimentation tank 1b, and the B-section aeration tank 1c and B-section sedimentation tank 1d, and are arranged in sequence; the A-section aeration tank 1a, A-section sedimentation tank 1b, B-section aeration tank 1c, B-section sedimentation tank 1d, oxidation ditch 2, secondary sedimentation tank 3, depth Th...

Embodiment 2

[0040] like figure 1 as shown, An integrated aerobic advanced treatment device, which includes an AB process treatment area 1, an oxidation ditch 2, a secondary settling tank 3, an advanced treatment reaction tank 4, a tertiary settling tank 5, an inlet pipe 6 and an outlet pipe 7; The ditch 2 has a ring structure; the secondary settling tank 3 and the tertiary settling tank 5 are respectively arranged at both ends of the AB process treatment area 1; In the ring of the oxidation ditch 2; the advanced treatment reaction tank 4 is arranged on one side of the AB process treatment area 1; the AB process treatment area 1 includes the A-section aeration tank 1a, the A-section sedimentation tank 1b, and the B-section aeration tank 1c and B-section sedimentation tank 1d, and are arranged in sequence; the A-section aeration tank 1a, A-section sedimentation tank 1b, B-section aeration tank 1c, B-section sedimentation tank 1d, oxidation ditch 2, secondary sedimentation tank 3, depth T...

Embodiment 3

[0050] like figure 1 as shown, An integrated aerobic advanced treatment device, which includes an AB process treatment area 1, an oxidation ditch 2, a secondary settling tank 3, an advanced treatment reaction tank 4, a tertiary settling tank 5, an inlet pipe 6 and an outlet pipe 7; The ditch 2 has a ring structure; the secondary settling tank 3 and the tertiary settling tank 5 are respectively arranged at both ends of the AB process treatment area 1; In the ring of the oxidation ditch 2; the advanced treatment reaction tank 4 is arranged on one side of the AB process treatment area 1; the AB process treatment area 1 includes the A-section aeration tank 1a, the A-section sedimentation tank 1b, and the B-section aeration tank 1c and B-section sedimentation tank 1d, and are arranged in sequence; the A-section aeration tank 1a, A-section sedimentation tank 1b, B-section aeration tank 1c, B-section sedimentation tank 1d, oxidation ditch 2, secondary sedimentation tank 3, depth T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com