Device for regulating and controlling actual supply amount of urea entering exhaust system and regulating and controlling method

An exhaust system and control device technology, which is applied to the electronic control of exhaust treatment devices, exhaust devices, exhaust treatment and other directions, can solve the difficulties in realization and popularization, the high cost of emission standard process, and the inability to meet the requirements of excessive urea injection. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

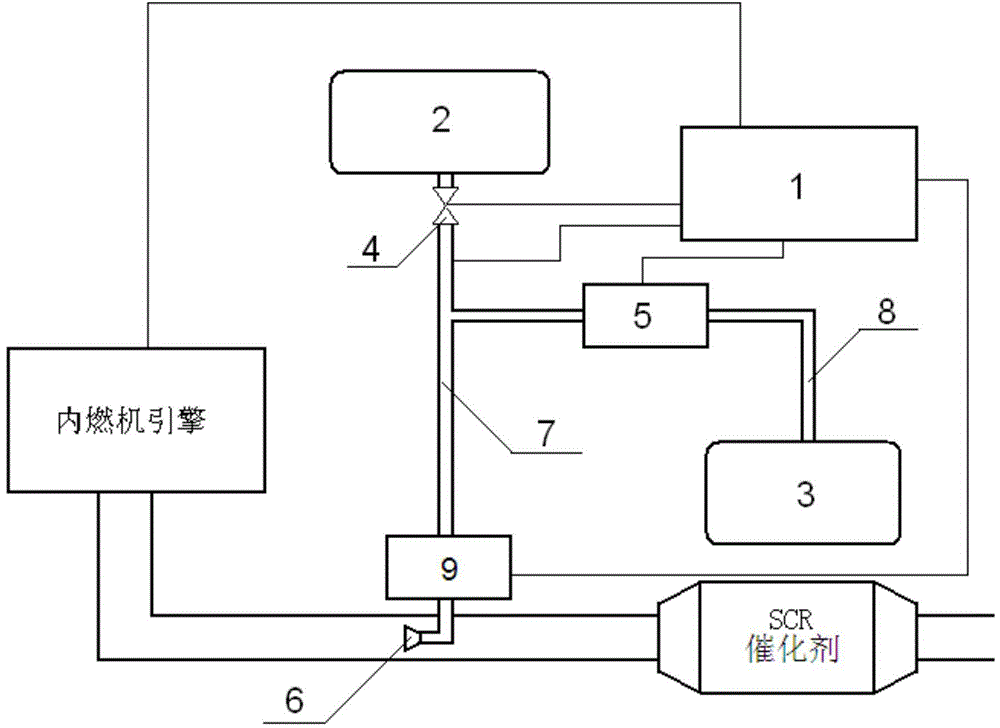

[0049] image 3 Shown is a structural diagram of the device for regulating the actual supply of urea entering the exhaust system in this embodiment. Wherein, the urea control device 9 includes a control gas valve 91 . The control air valve 91 is arranged on the main pipeline 7 and is located between the urea pipeline 8 and the nozzle device 6 . The control air valve 91 is controlled by the electronic control unit 1 , and by adjusting the opening and closing state of the control air valve 91 , the gating and closing between the main pipeline 7 and the nozzle device 6 are adjusted. When gated, compressed air is mixed with urea and fed into the nozzle assembly 6 to be sprayed into the exhaust system, while when closed, compressed air is mixed with urea in the main pipe 7 but cannot be fed into the nozzle assembly 6, thereby preventing excess urea Spray into the exhaust system.

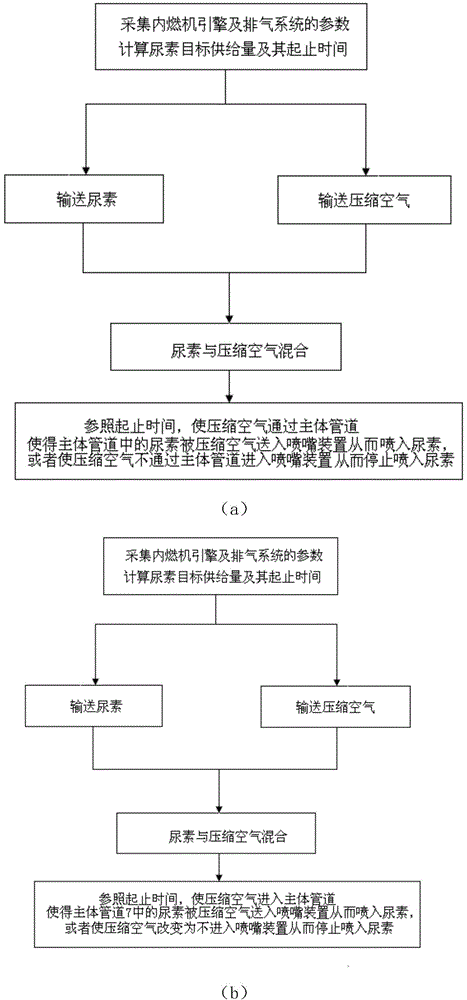

[0050] Combine the following Figure 4 The waveforms of are detailing the working flow of the devi...

Embodiment 2

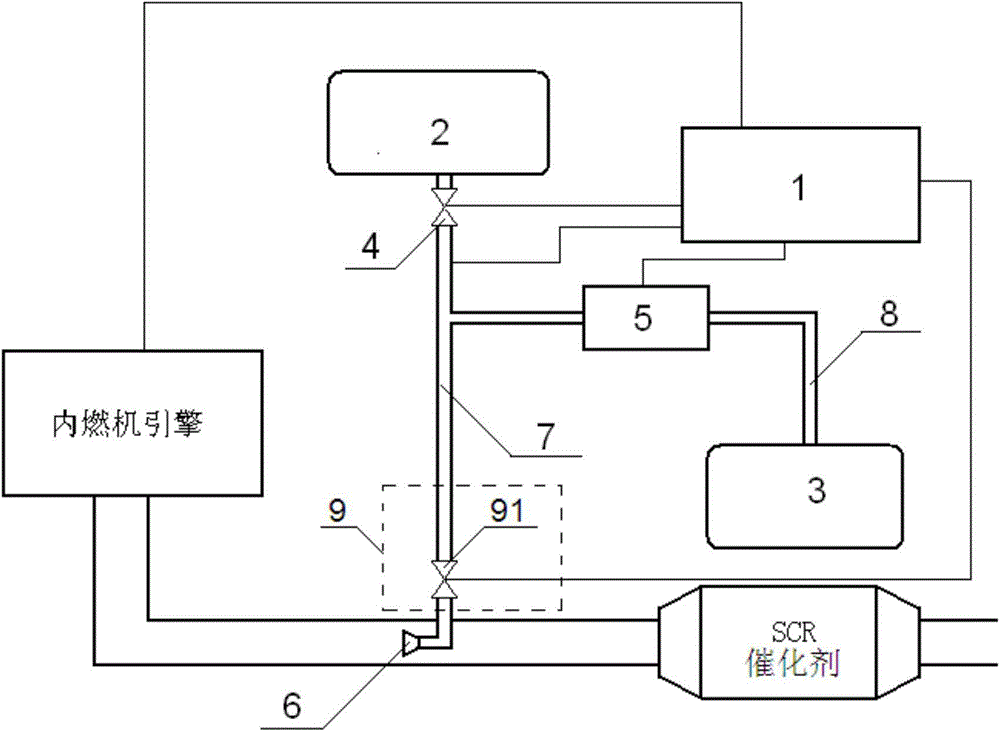

[0056] Figure 5 Shown is a structural diagram of the device for regulating the actual supply of urea entering the exhaust system in this embodiment. Wherein, the urea control device 9 includes a bypass channel 92 and a bypass control gas valve 93 . The bypass channel 92 communicates with the main pipeline 7, and the communication port is located between the urea pipeline 8 and the nozzle device 6; the bypass control air valve 93 is arranged on the bypass channel 92, and the bypass control air valve 93 communicates with the electronic control unit 1, The electronic control unit 1 can regulate the opening and closing of the bypass control air valve 93 . When the bypass control air valve 93 is closed, urea and compressed air are mixed in the main pipe 7 and sprayed into the exhaust system through the nozzle device 6 . While the bypass control air valve 93 is in the open state, since the air pressure of the bypass channel 92 is lower than the exhaust back pressure of the nozzle...

Embodiment 3

[0064] Figure 8 Shown is a structural diagram of the device for regulating the actual supply of urea entering the exhaust system in this embodiment. Wherein, the urea control device 9 includes a control gas valve 91 , a bypass channel 92 and a bypass control gas valve 93 . The control air valve 91 is arranged on the main pipeline 7 and is located between the urea pipeline 8 and the nozzle device 6 . The bypass channel 92 communicates with the main pipeline 7 , and the communication port is located between the urea pipeline 8 and the nozzle device 6 ; the bypass control air valve 93 is arranged on the bypass channel 92 . The control air valve 91 and the bypass control air valve 93 communicate with the electronic control unit 1 respectively, and the electronic control unit 1 can control the opening and closing of the control air valve 91 and the bypass control air valve 93 .

[0065] Combine the following Figure 9 The waveforms of are detailing the working flow of the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com