Denitration optimization control algorithm based on intelligent model predictive control

A technology of model predictive control and optimal control, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of large consumption of ammonia water, high labor cost, control lag, etc., to achieve simple maintenance and reduce labor. Effects of interventions and reductions in ammonia use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, with reference to Figure 1 to Figure 5 shown, where:

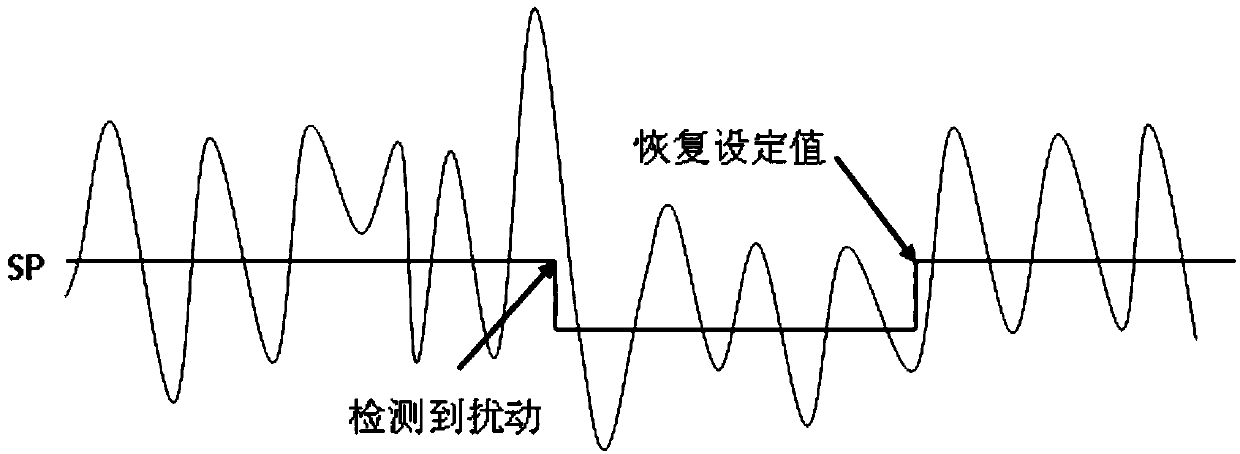

[0034] figure 1 In the Smart MPC optimal control for denitrification, the SP in the figure is the target value, and the target value of the controlled object is dynamically adjusted; it can be seen from the figure that when the working conditions are disturbed, the Smart MPC automatically readjusts the target value, so that The output can track the dynamic change of the target value. When the disturbance is removed, the target value automatically returns to the original position, and the output changes accordingly;

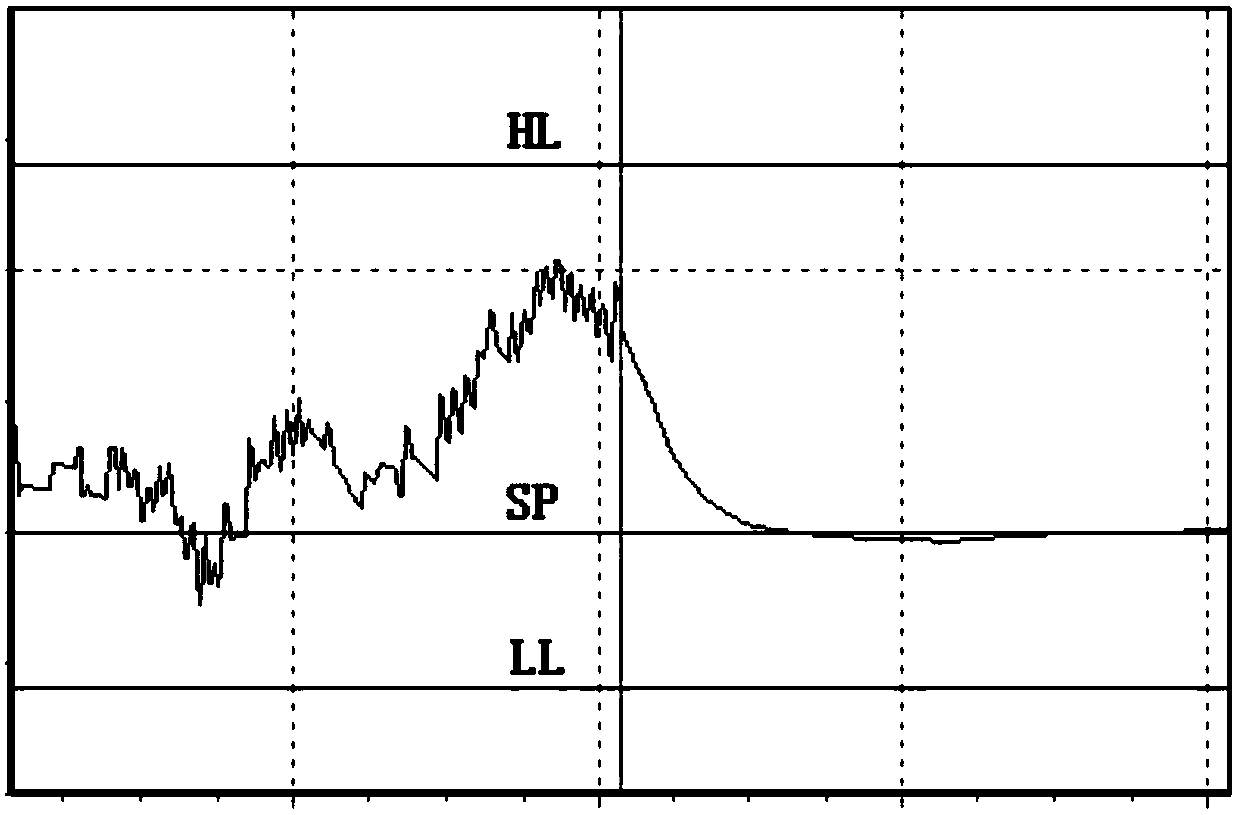

[0035] figure 2 Implementation effect diagram for Smart MPC optimization control of denitrification. SP in the figure is the target value, HL and LL are the upper limit and lower limit respectively. The black vertical line in the figure represents the current moment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com