Patents

Literature

90results about How to "No cavitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

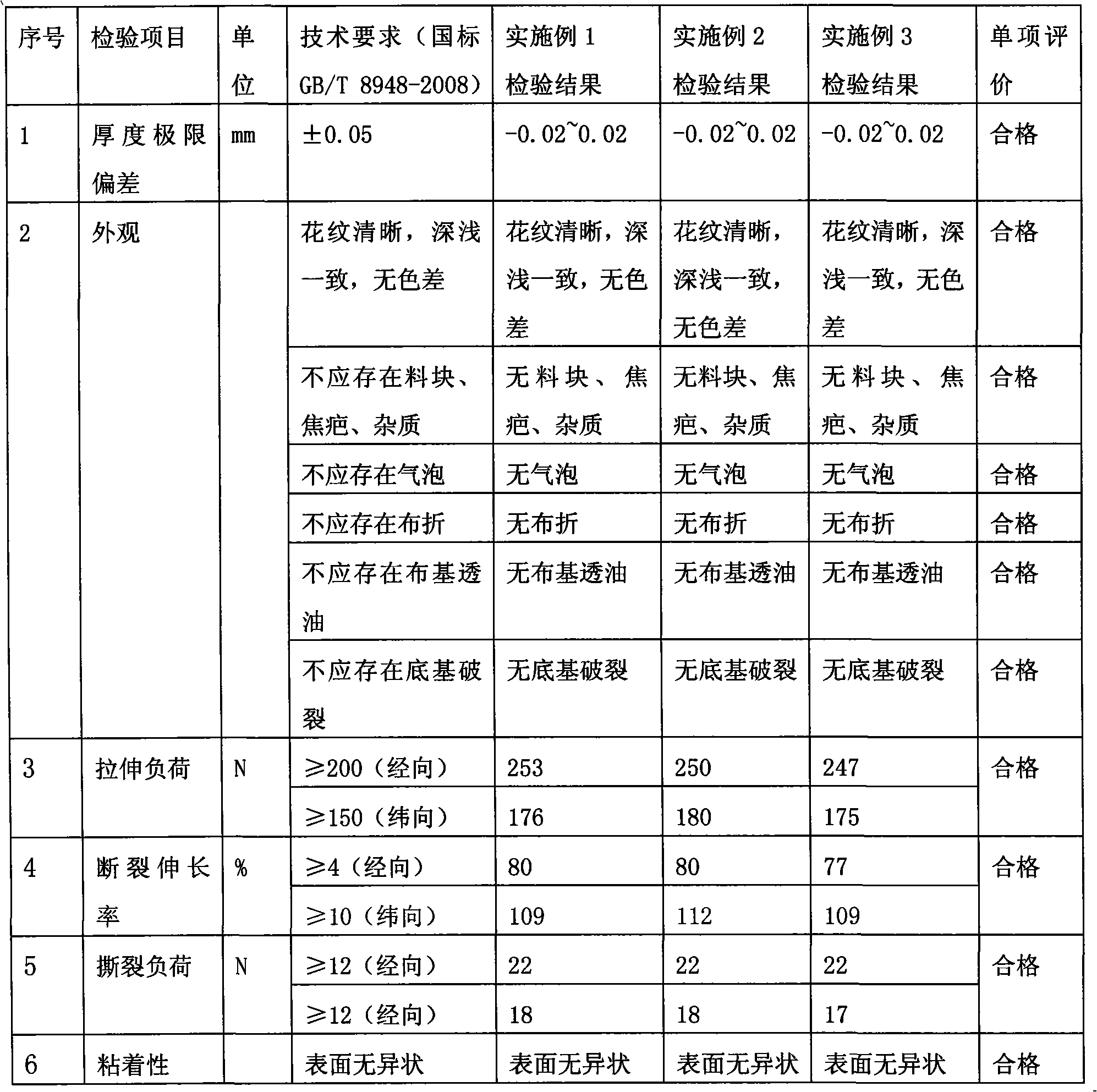

Method for manufacturing ultrasonic wave embossed release paper artificial leather

InactiveCN101570938AOvercome the problem of single leather textureNo cavitationLamination ancillary operationsPattern makingFoaming agentPotassium

The invention discloses a method for manufacturing ultrasonic wave embossed release paper artificial leather, which comprises the following steps: firstly, preparing raw materials of a bottom blank of the artificial leather, wherein a facing material comprises 100 portions of polyvinyl chloride paste resin, 60 to 70 portions of DOP, 20 to 30 portions of CaCO3 and 5 to 8 portions of potassium and zinc thermal stabilizer, a medium foaming layer comprises 100 portions of polyvinyl chloride paste resin, 65 to 80 portions of DOP, 150 to 250 portions of CaCO3, 4 to 8 portions of potassium and zinc thermal stabilizer and 8 to 16 portions of high-temperature foaming agent, and a bottom material bonding layer comprises 100 portions of polyvinyl chloride paste resin, 50 to 60 portions of DOP, 5 to 20 portions of CaCO3 and 2 to 5 portions of potassium and zinc thermal stabilizer; uniformly stirring the raw materials prepared according to the formula; making the bottom blank of the artificial leather; and obtaining a finished product by ultrasonic wave embossing. The method has the advantages of fully autonomic pattern types and cost conservation. The products of the method have high physical and chemical properties.

Owner:无锡市瑞莺合成革有限公司

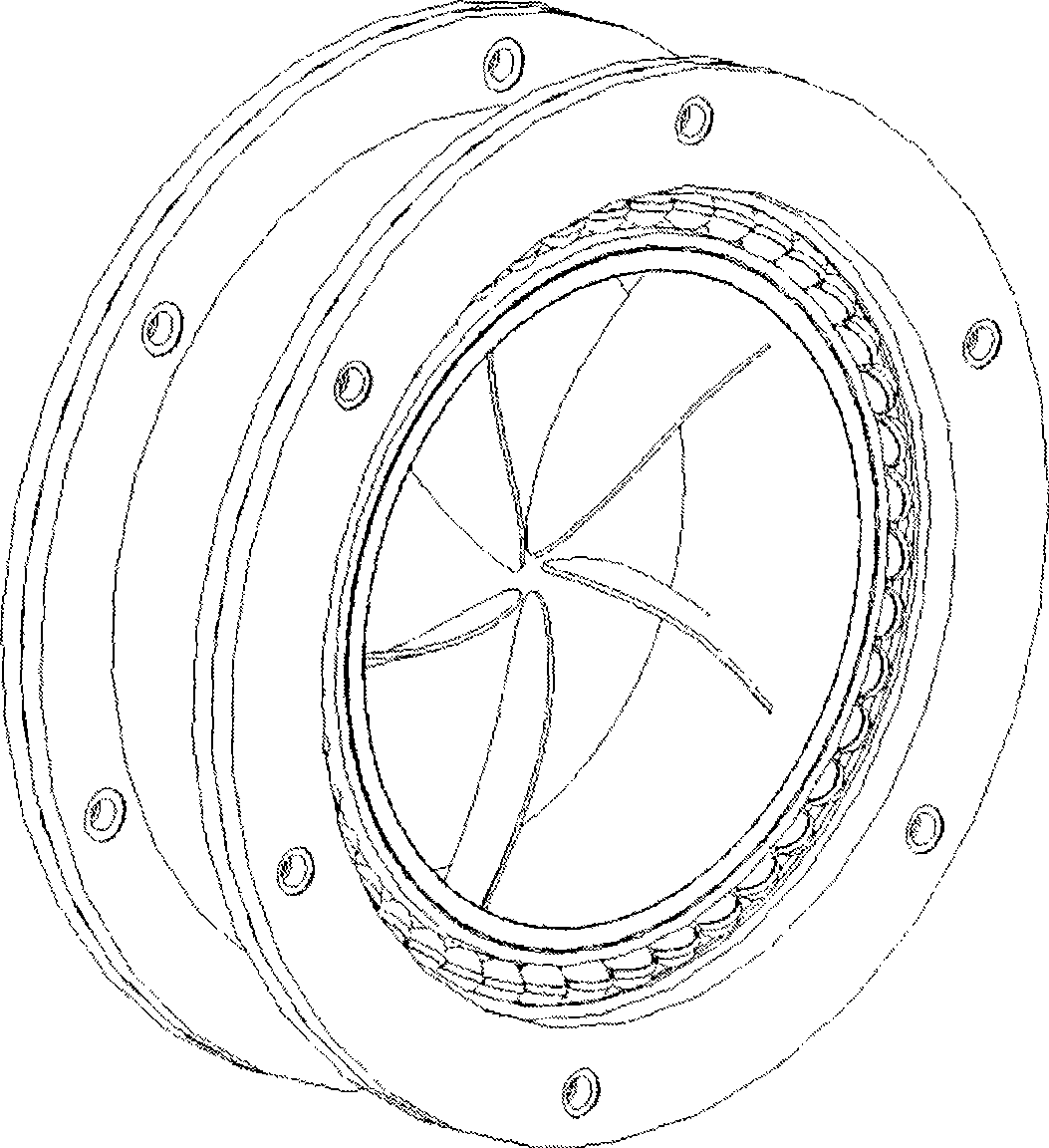

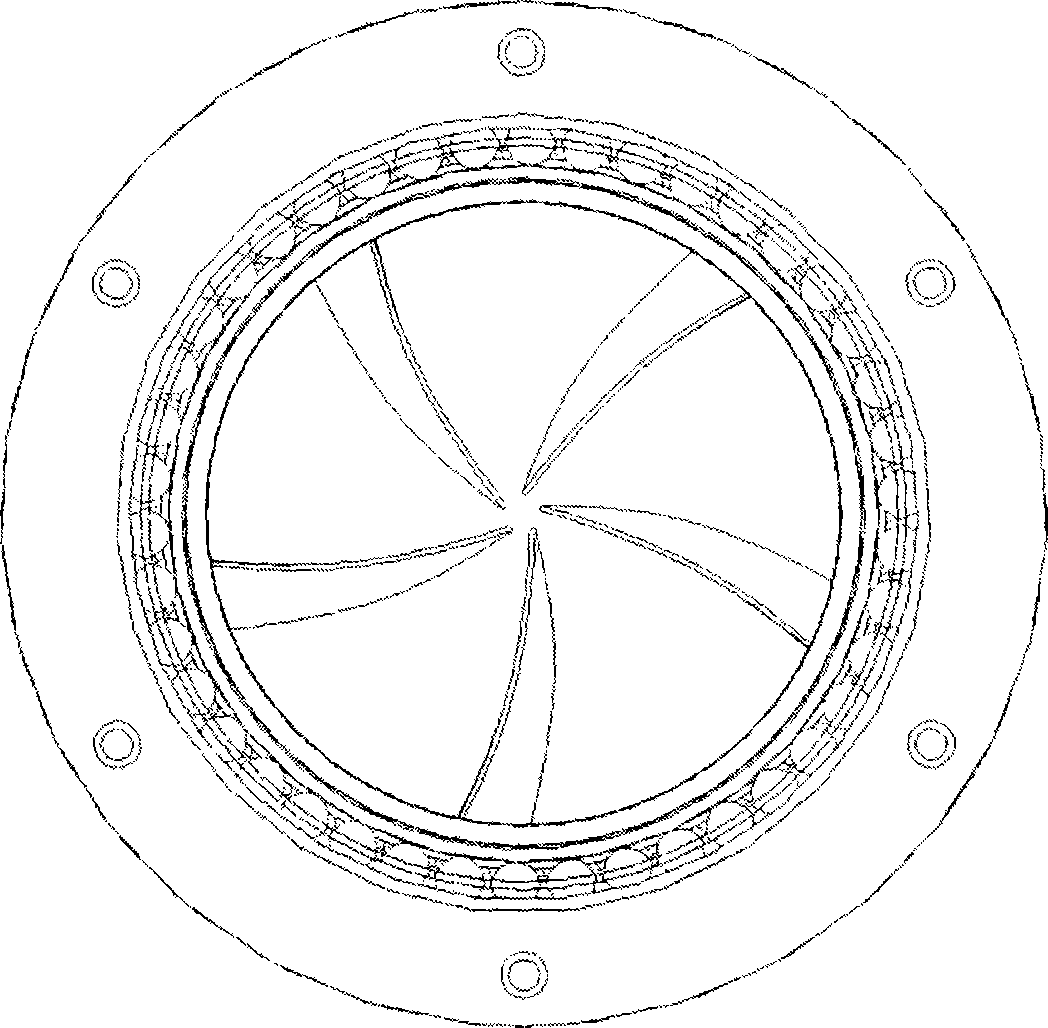

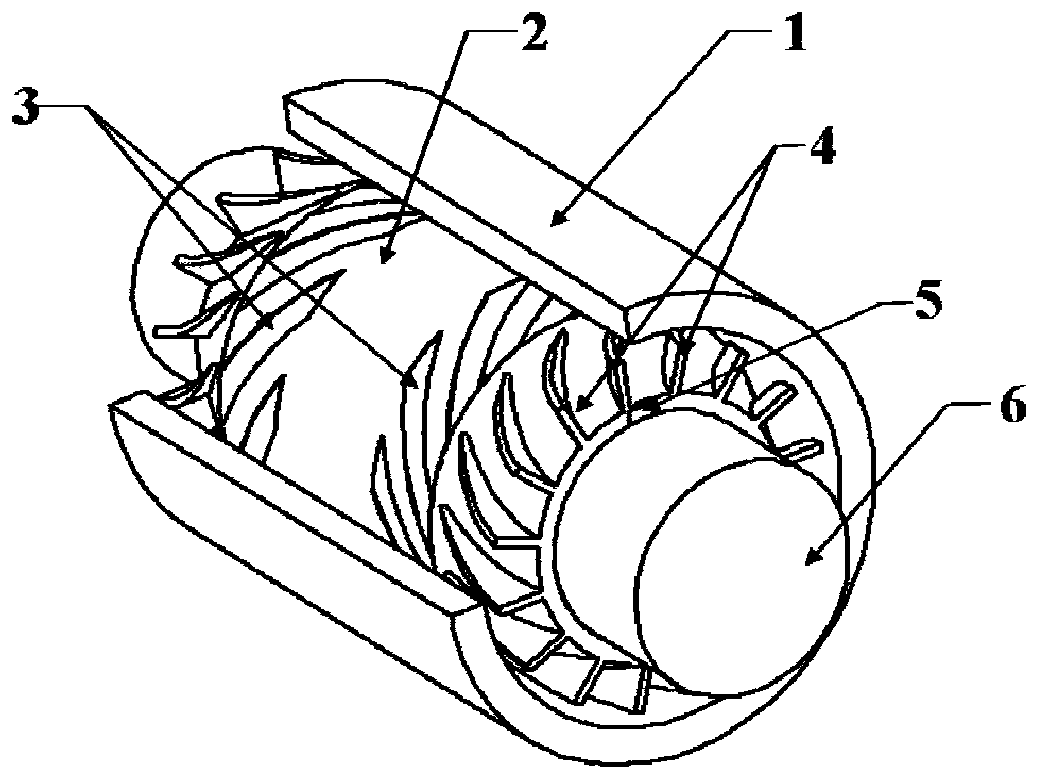

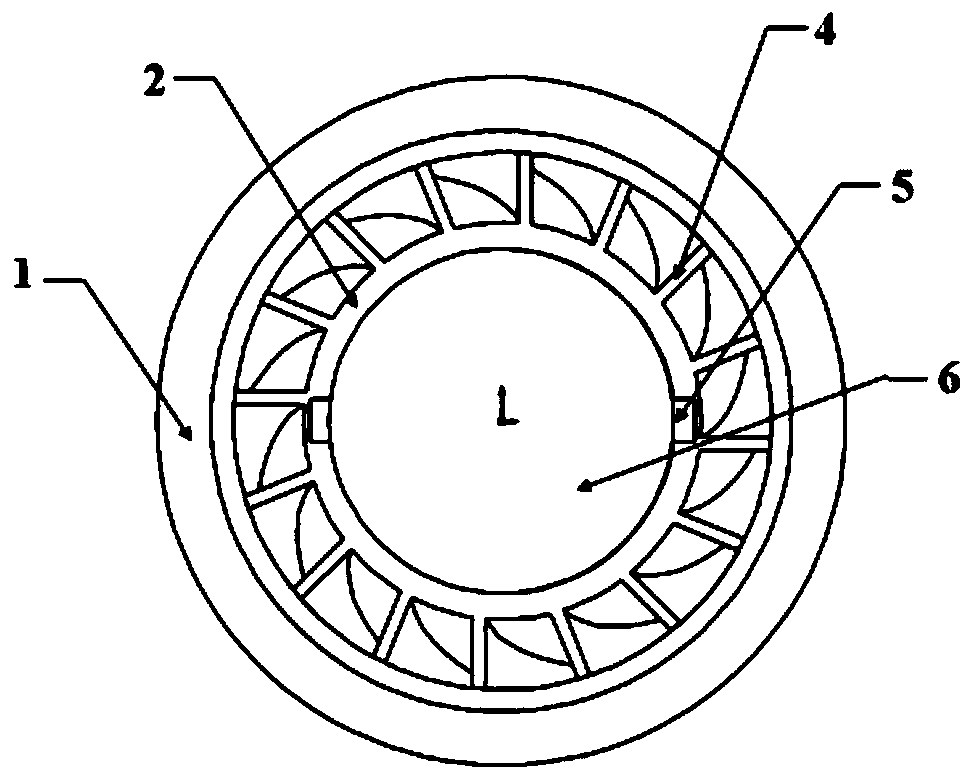

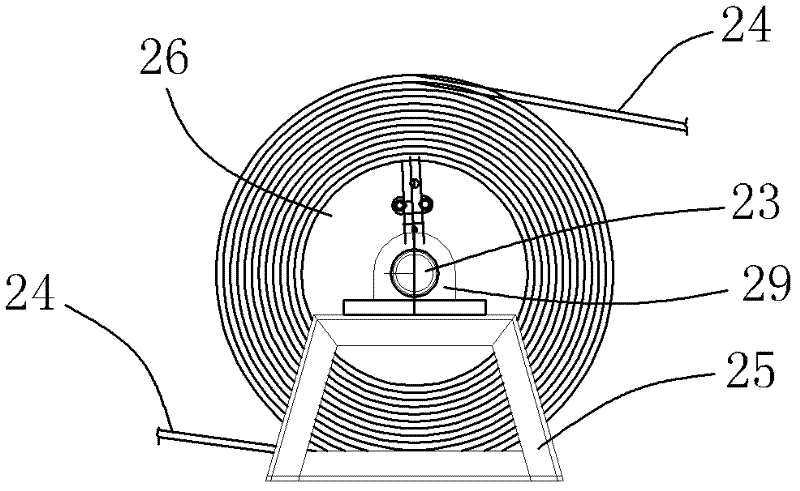

Underwater hollow hub-free propeller

InactiveCN101546939AWork lessIncrease the number of polesRotary propellersMechanical energy handlingUnderwaterPropeller

The invention provides an underwater hollow hub-free propeller, which comprises a motor shell, a stator coil, a stator silicon-steel sheet, a rotor permanent magnet, a rotor, a screw propeller and a ceramic bearing. The stator coil is wound on the stator silicon-steel sheet, the stator coil wound on the stator silicon-steel sheet is arranged at the center of the motor shell, the rotor has a hollow annular structure, split poles of the rotor permanent magnet are fixed on the rotor to form a hollow structural rotor, the screw propeller is fixed inside the hollow rotor, and the screw propeller, the rotor and the rotor permanent magnet form a whole; and the rotor is fixed in the motor shell through the ceramic bearing. When blades rotate, induced resistance and cavity bubble phenomenon are not generated so as to greatly improve the efficiency of the screw propeller. Moreover, because the diameter of a motor is enlarged, the pole number of the motor is increased and the torque of the motor is improved, the underwater hollow hub-free propeller is particularly suitable for working in an environment with large water depth and large density; and because the motor and the screw propeller of the underwater propeller have an integral hollow structure, the underwater hollow hub-free propeller can be easily arranged on a ship hull.

Owner:HARBIN ENG UNIV

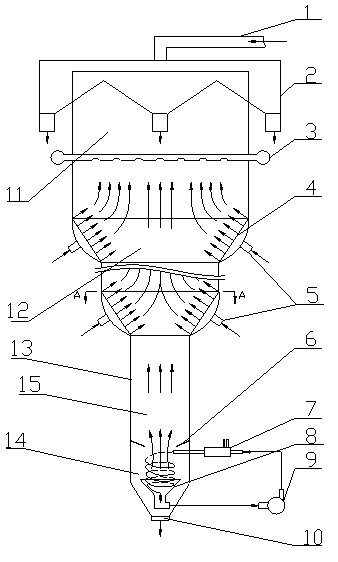

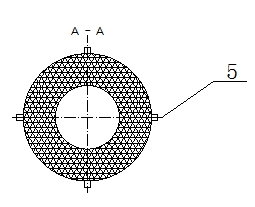

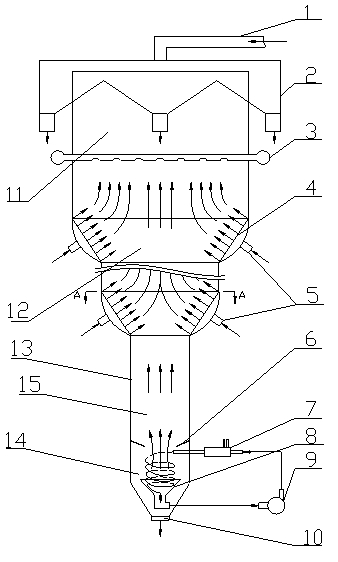

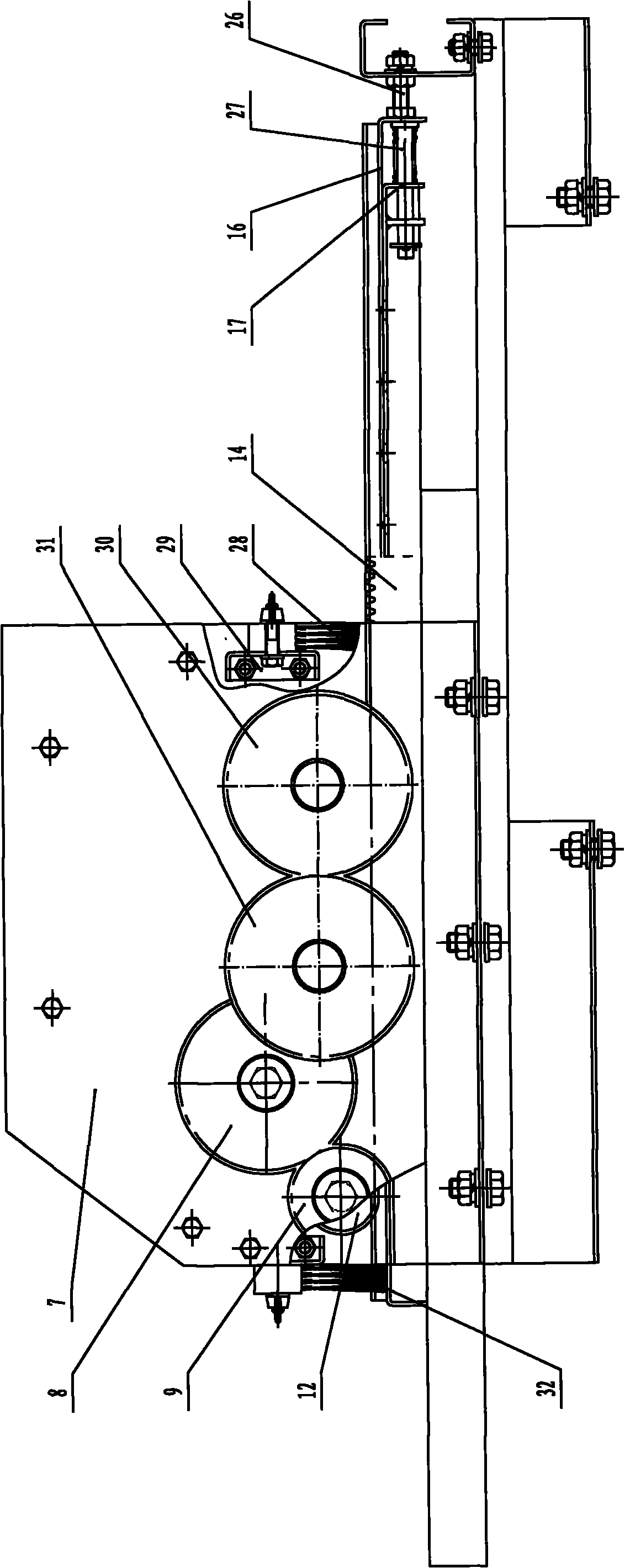

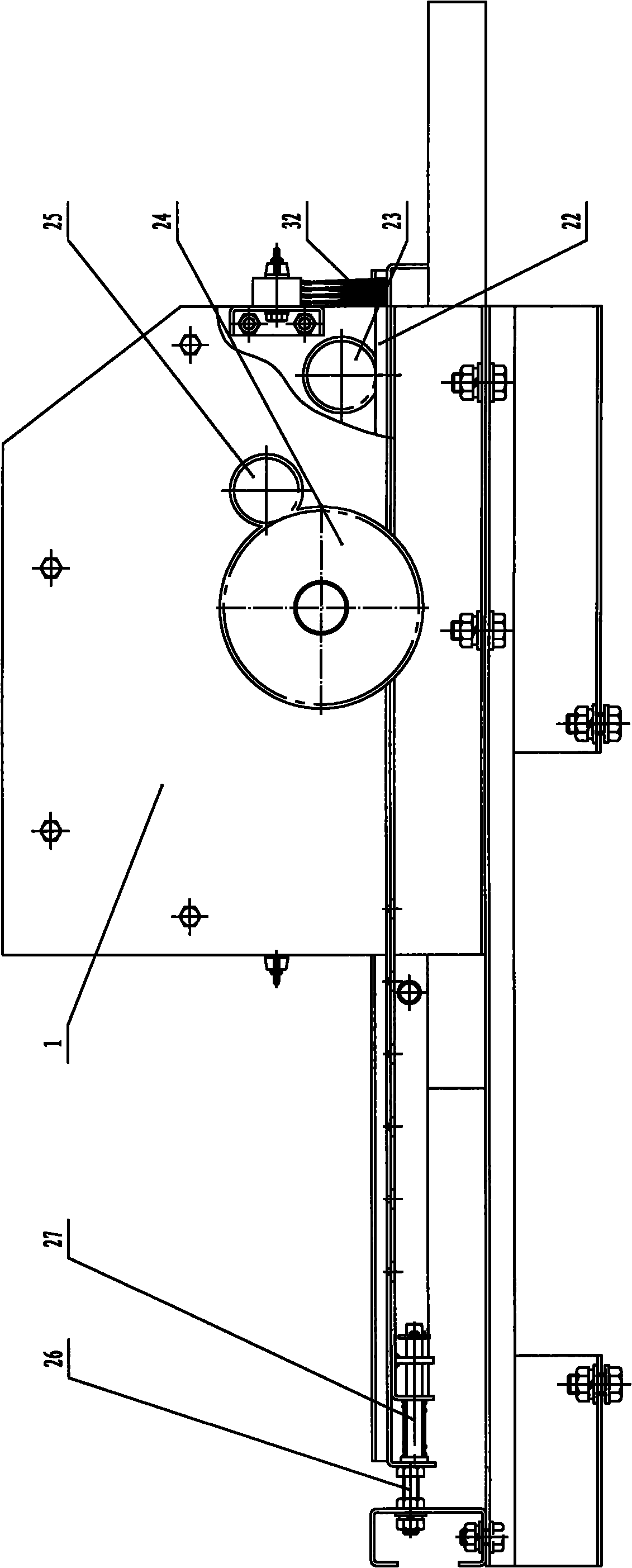

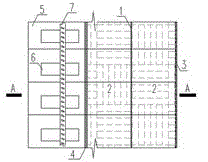

Sorting device and method for aerating cyclonic micro-bubble flotation column

The invention relates to a sorting device and method for an aerating cyclonic micro-bubble flotation column. The device comprises a foam enriching chamber, a foam ore concentrate collecting tank which is arranged on the upper part of the foam enriching chamber, and a shower pipe which is arranged on the top of the foam ore concentrate collecting tank, wherein the cyclonic micro-bubble flotation column is arranged on the lower part of the foam enriching chamber; an aerating sorting chamber is arranged between the foam enriching chamber and the cyclonic micro-bubble flotation column; a conical net is arranged in the aerating sorting chamber; and a plurality of air inlets which are vertical to the conical net side are uniformly distributed on the outer wall of the aerating sorting chamber. By arranging the aerating sorting chamber between the foam enriching chamber and column sorting chamber of the cyclonic micro-bubble flotation column, the high-concentration aerating floatation for theupper easily-floating mine, the middle-concentration column floatation for the middle floatable mine and the pipe-flow turbulence mineralization and cyclonic low-concentration flotation for the difficulty-floating mine are formed. By using the device, the gradient optimizing sorting of earlier aerating flotation for high-concentration easily-floating mine and later cyclonic flotation for difficulty-floating mine are realized, the processing capacity of the flotation column is greatly increased, the chemical consumption is reduced, and the contradiction between the sorting efficiency and the energy consumption is solved.

Owner:CHINA UNIV OF MINING & TECH

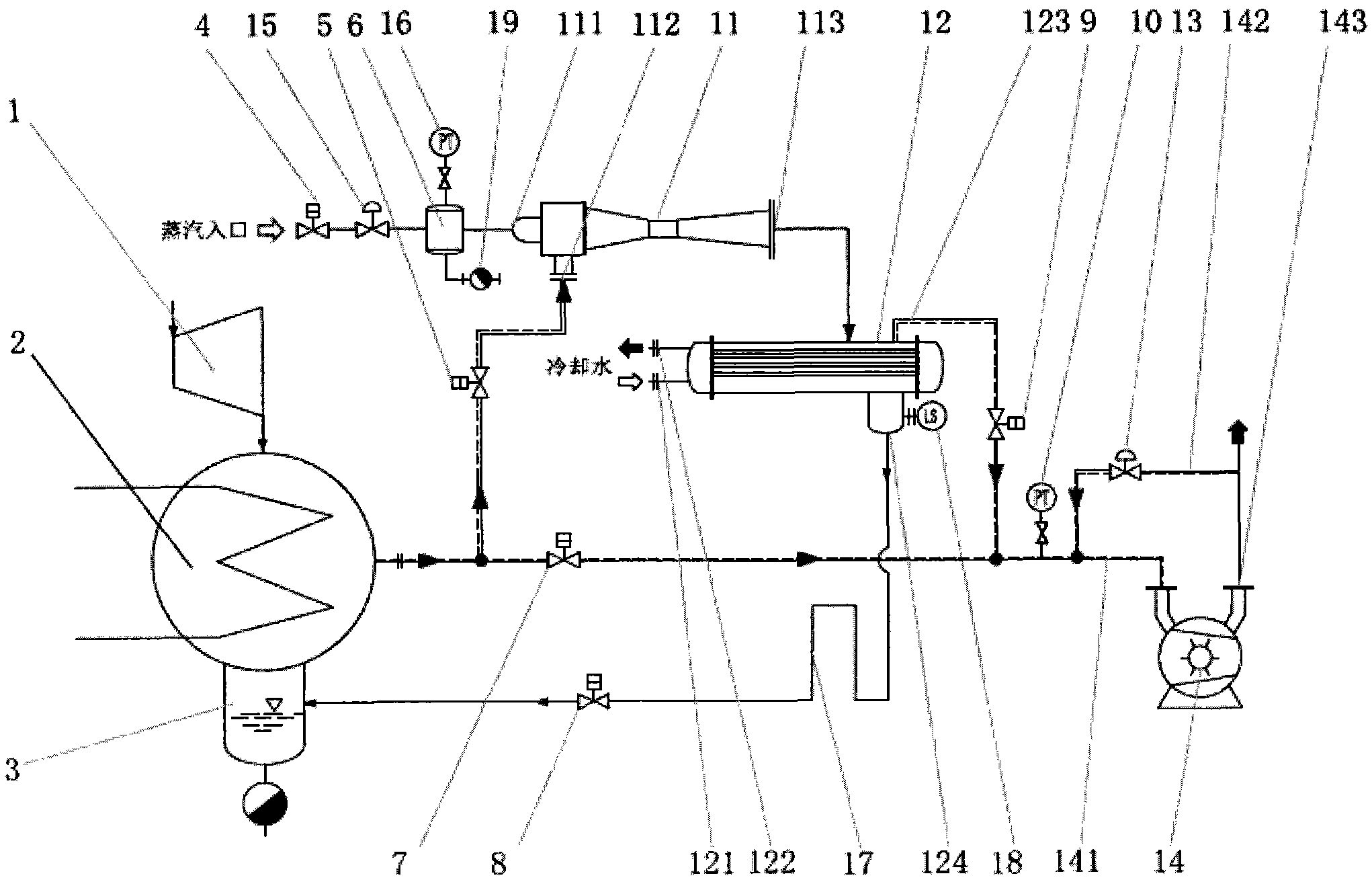

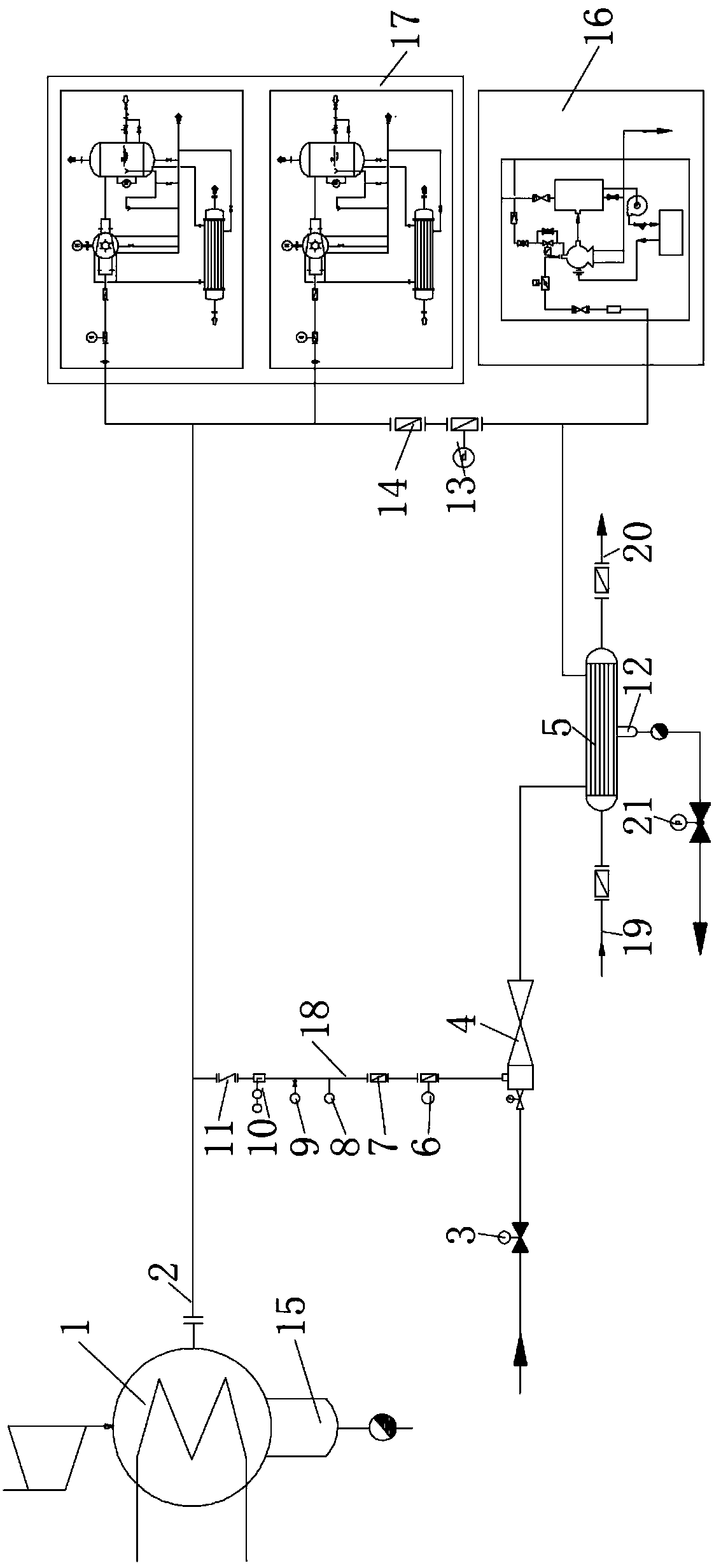

Power plant condenser steam jet and vacuumizing system with pressure control function

The invention provides a power plant condenser steam jet and vacuumizing system with a pressure control function. The system comprises a steam turbine (1), a condenser (2), a condenser hot well (3), a power steam pressurizer (6), a steam ejector (11), a steam condenser (12), a water ring vacuum pump (14), a condensate discharge valve (8) of the steam condenser, a condensate drain pipeline water seal (17), a condensate pipeline liquid level switch (18), a pressure adjusting valve (13) on the inlet of the water ring vacuum pump, multiple control valves and pipelines, wherein the control valves and the pipelines are arranged among the parts. Due to the fact that pressure control of power steam, control of the liquid level after condensates flow back to the condenser hot well and inlet pressure control of the water ring vacuum pump are adopted, the vacuumizing system can maintain the maximum vacuum degree of the condenser, force of the condenser is improved, the vacuum degree of the condenser is improved, the heat consumption rate of the steam turbine is lowered, and coal consumption for unit power generation is lowered. The system is safe and free of maintenance, guarantees 100% of force and can operate stably for a long time. A pressure backflow adjusting system is arranged on the final-stage exhaust device, namely the water ring vacuum pump, so that it is guaranteed that the cavitation phenomenon of the water ring vacuum pump does not happen.

Owner:浦江瑞尔科技有限公司

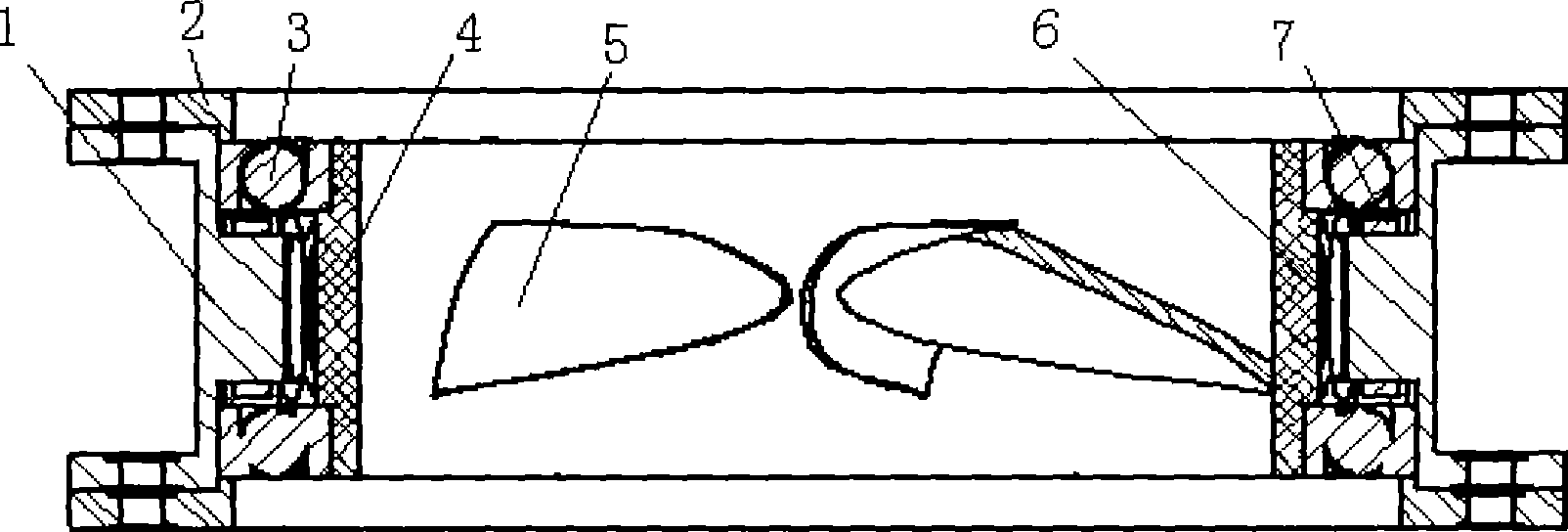

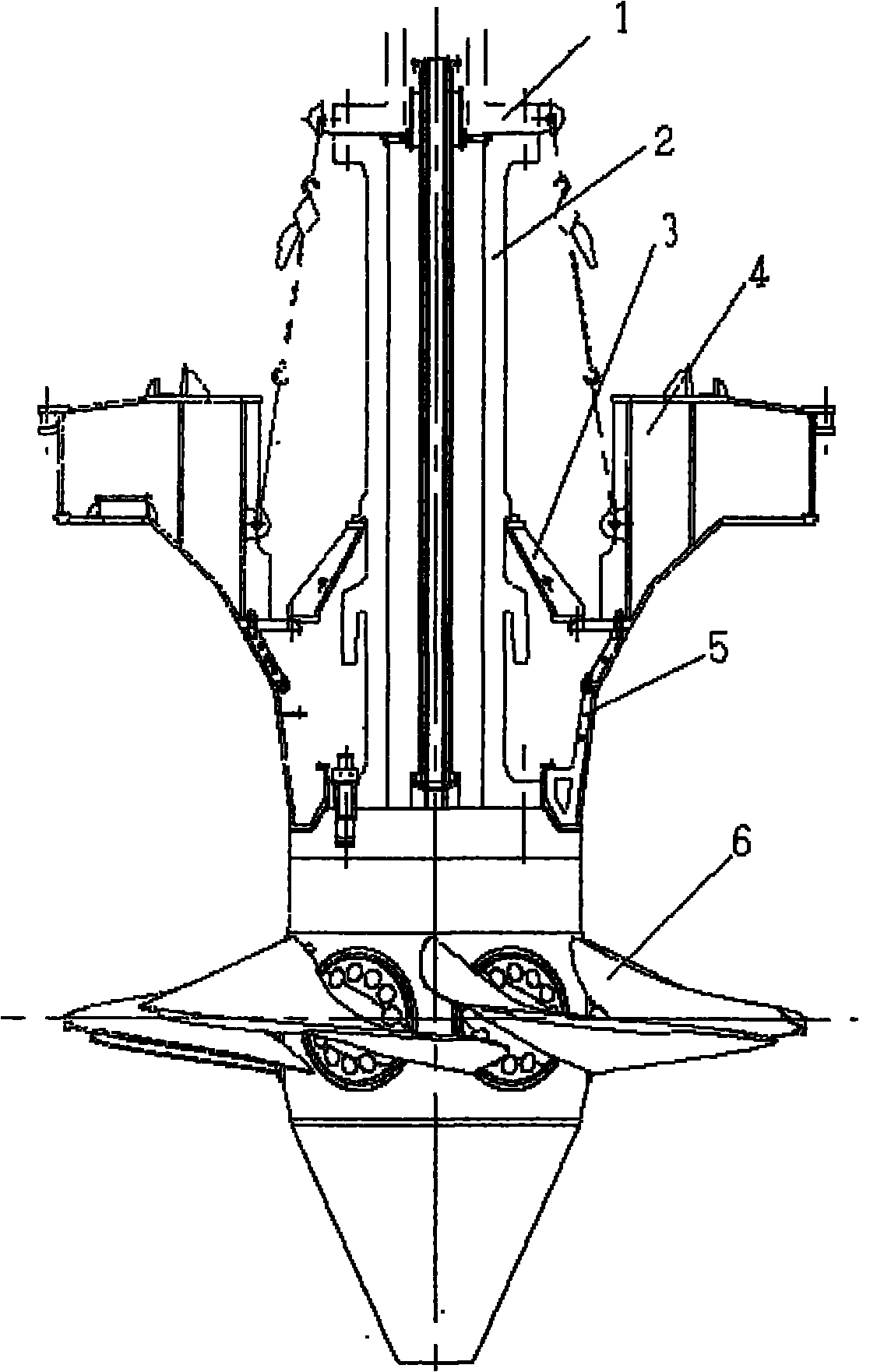

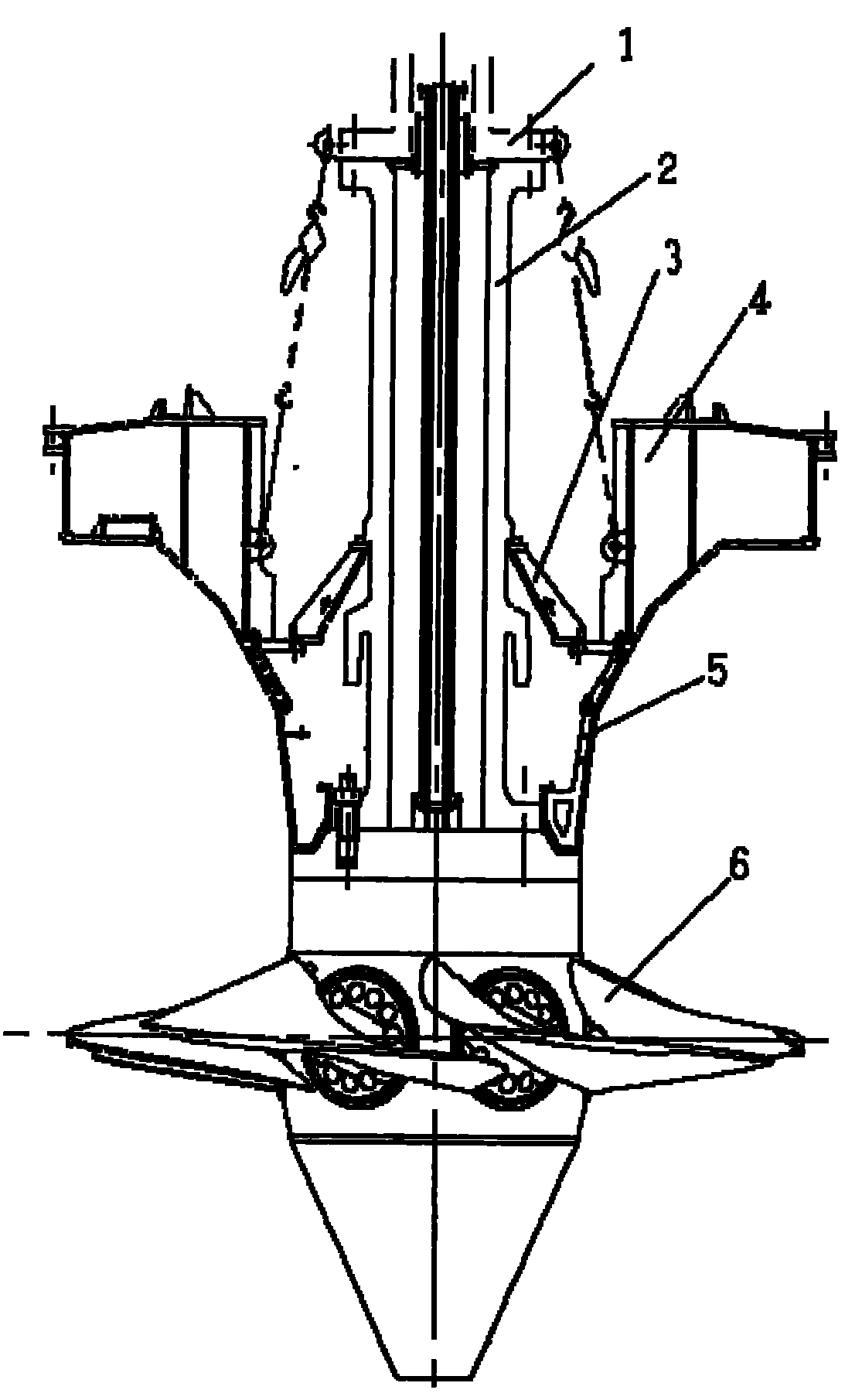

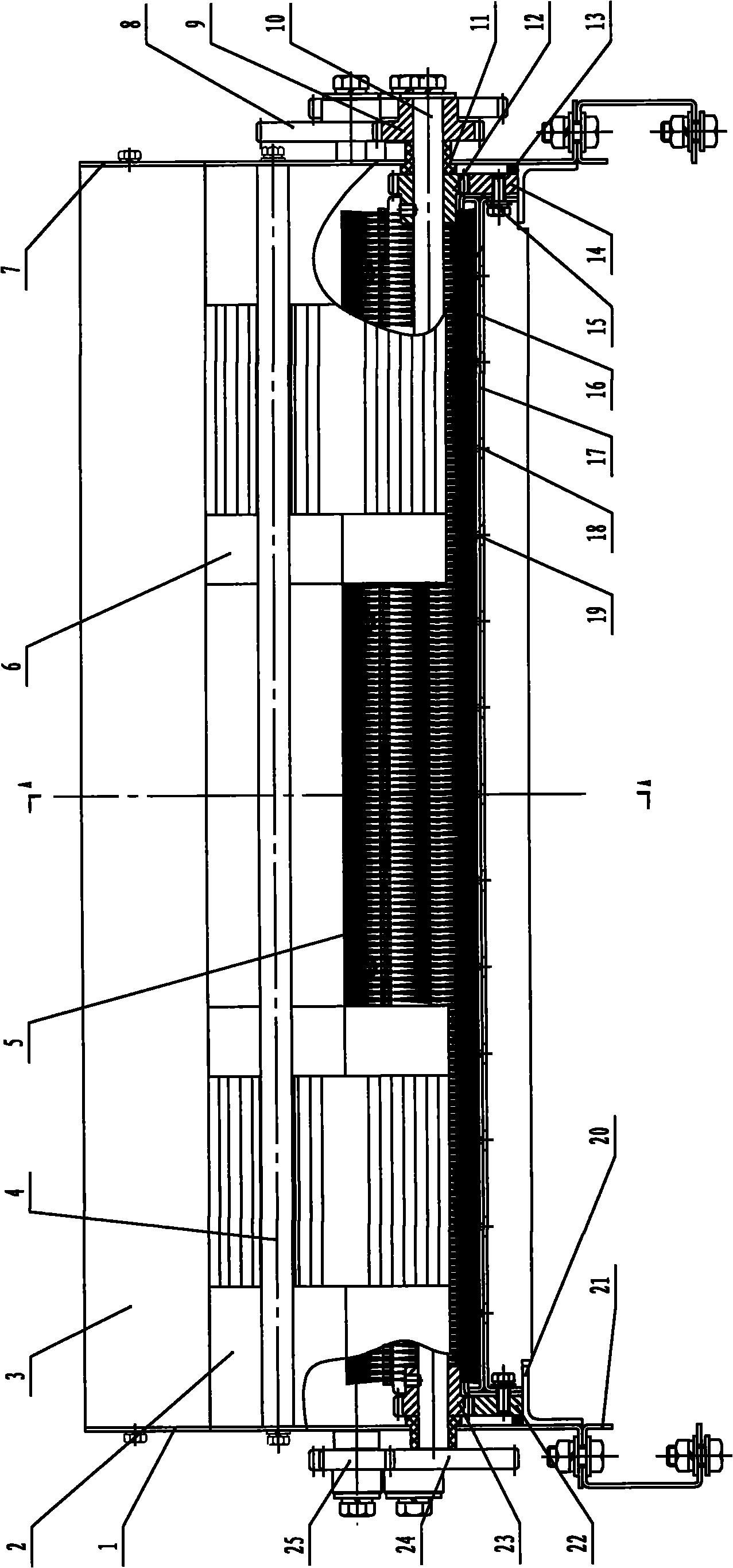

Hoisting process for rotating wheel of vertical shaft axial flow hydraulic turbine

InactiveCN102060252ASealing has no effectReduce lifting weightLifting devicesHoisting equipmentsCouplingEngineering

The invention relates to a hoisting process for a rotating wheel of a vertical shaft axial flow hydraulic turbine, which comprises the following steps of: 1, arranging a small convex plate at the appropriate position on a main shaft; 2, putting an installed rotating wheel on a platform in an installation room, allowing blades to be in the complete shut-down position, and adjusting the horizontal of an upper flange surface of the rotating wheel by 0.02mm / m; 3, hoisting a combining piece of the main shaft and an operating oil tube, connecting the operating oil tube with an operating oil tube of the rotating wheel, connecting the main shaft with the rotating wheel, and connecting the rotating wheel with a bolt and pretightening; 4, sleeving the combination body into the main shaft after combining a support cover and a flow guiding cone or combining the support cover and the flow guiding cone after sleeving the support cover and the flow guiding cone into the main shaft respectively, and putting the combination body on an upper flange or a rotating wheel cover of a rotating wheel body; 5, arranging a partitioned bearing on the support cover or the flow guiding cone, and arranging a divided clamping ring on the top of the bearing; 6, adjusting the height of combination body of the support cover and the flow guiding cone by using a hoist and conducting the safe and protective action when the combination body is hoisted in a turbine pit integrally; 7, reserving an axial gap between the convex plate on the main shaft in the installation room and the clamping ring, wherein the gap is 2 to 5 millimeters greater than the sum of a reverse machine lift value and a bayonet value of the main shaft, and the value is 2 to 5 millimeters greater than the bayonet value of the main shaft, so that the coupling is convenient; and 8, arranging a hanger, and hoisting the combination body in the turbine pit to be put in place.

Owner:浙江富春江水电设备股份有限公司

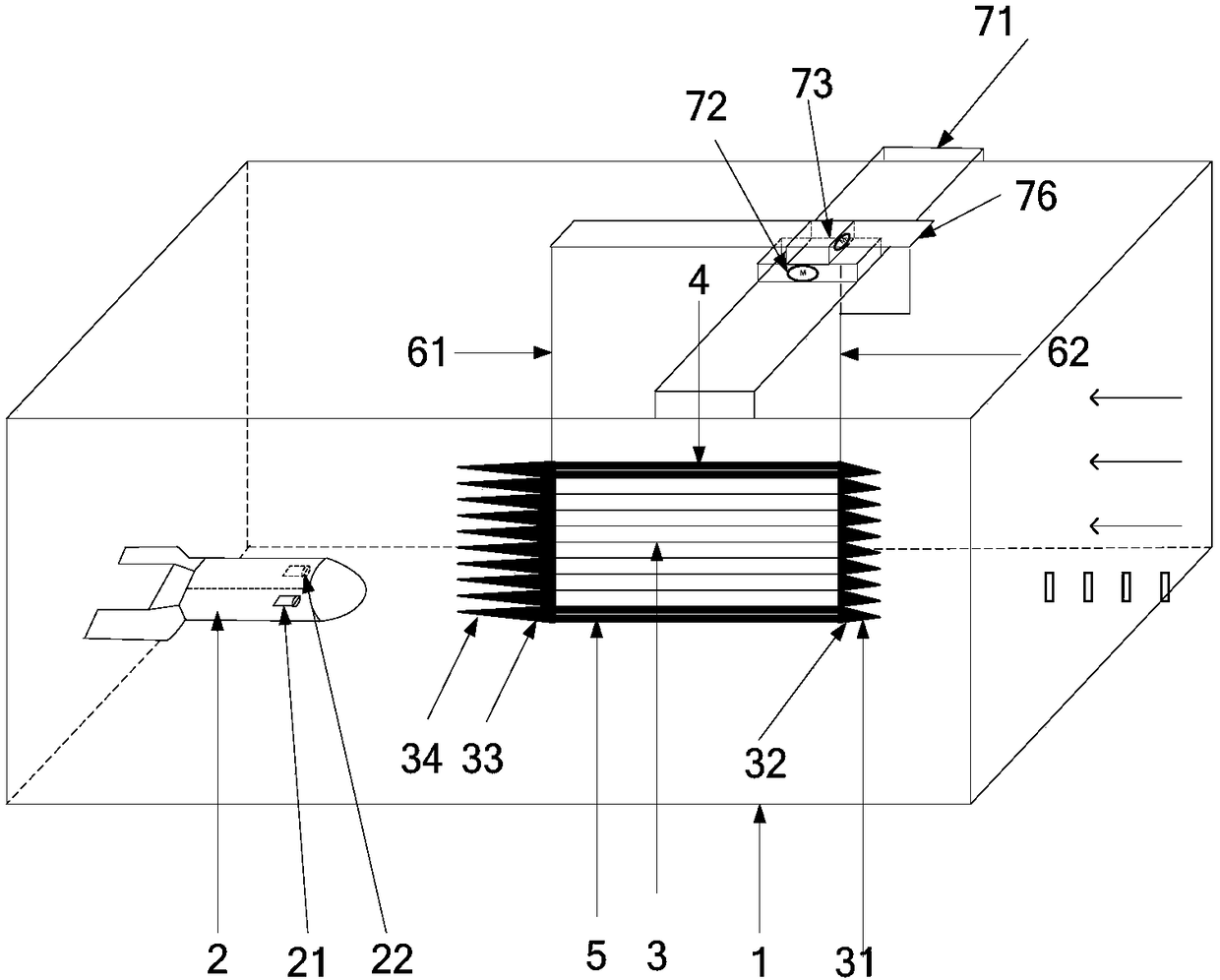

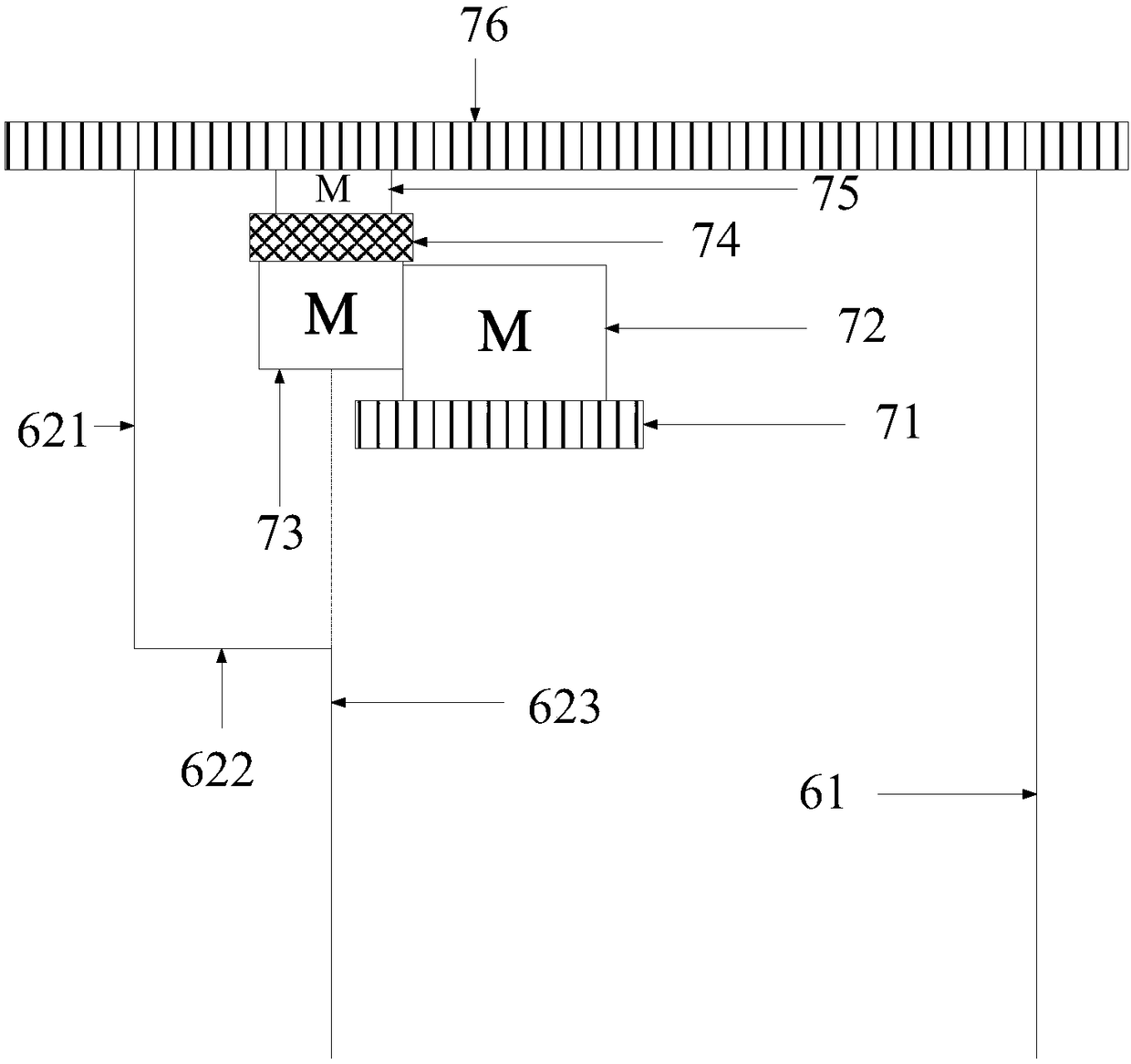

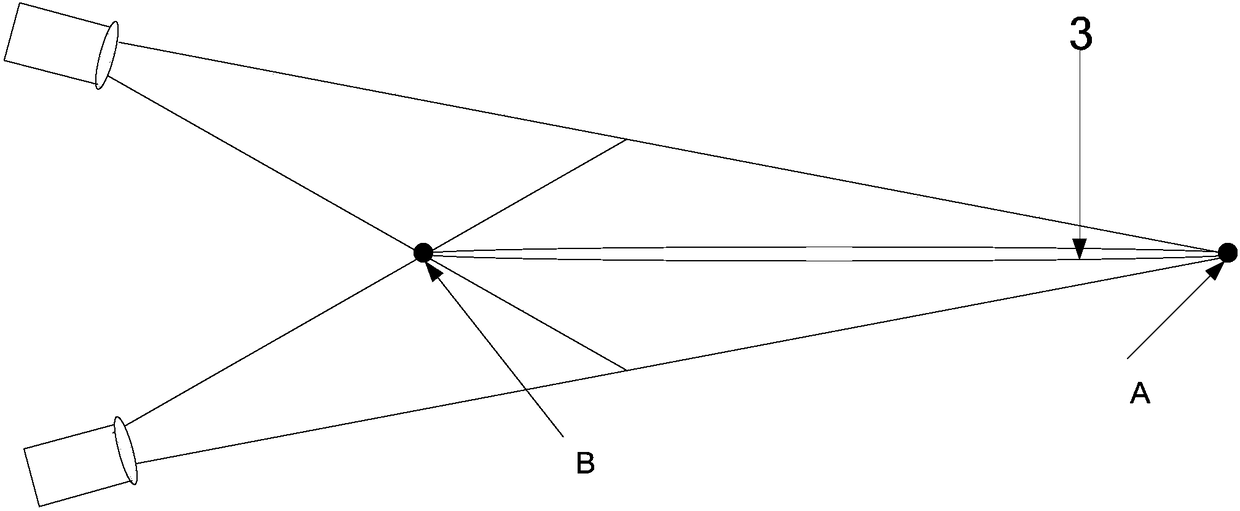

Calibration device and method for acoustic wave scattering region of Doppler current meter

ActiveCN108303570AAvoid enteringHigh precisionTesting/calibration of speed/acceleration/shock measurement devicesCurrent meterCircular cone

The invention relates to a calibration device and method for a sound wave scattering region of a Doppler current meter. The device comprises a standard plate (3), an upper damper (4), a lower damper (5), a first connecting rod (61), a second connecting rod (62) and a moving mechanism. The standard plate (3) is formed by connecting the round tubes to each other. One end of each of the round tubes is provided with a long cone (34), and the other end is provided with a short cone (31). The moving mechanism includes a first guide rail (71), a first linear stepping motor (72), a rotary stepping motor (73), a turntable (74), a second linear stepping motor (75) and a second guide rail (76). The first connecting rod (61) is a straight rod, the second connecting rod (62) includes an upper verticalrod (621), a horizontal rod (622) and a lower vertical rod (623), and the axis of the lower vertical rod (623) and the rotation axis of the rotary stepping motor (73) are in the same straight line. The effective acoustic scattering region of the Doppler current meter can be accurately calibrated.

Owner:HARBIN ENG UNIV

High-pressure water cleaning device

InactiveCN101983782BEliminate shockGuaranteed water intakeCleaning using liquidsCavitationAtmospheric air

A high-pressure water cleaning device includes a filter, a high-pressure plunger pump, a safe overflow valve, a spray gun and a connection pipeline, an overflow pipeline is connected between a water inlet of the high-pressure plunger pump and a water outlet of the safe overflow valve, the overflow pipeline is equipped with a transition water tank, a liquid level switch is installed in the transition water tank, and the liquid level switch keeps linkage with a switch of the plunger pump of the high-pressure water cleaning device. With the transition water tank installed on the overflow pipeline, the high-pressure water cleaning device has the benefits as follows: flux is directly monitored by the liquid level switch in the transition water tank, the high-pressure water cleaning device is shut down when the liquid level in the tank is lower than a predetermined value, there is no demand on a water feeding pressure is not demanded, and the cleaning device is available by ensuring the water inflow; the overflow water runs through the stainless steel transition water tank to be cool and buffered, temperature of the water rises very slowly; impact of water is eliminated by buffering of the air; a breather valve automatically opens when the water level of the water tank declines, the water tank is communicated with the atmosphere, the water inlet of the high-pressure plunger pump hasnot negative pressure, and cavitation can be avoided.

Owner:上海哈为清洗设备有限公司

Seedling-cultivation flexible seeding apparatus

ActiveCN101766077AImplement the seeding actionMeet the filling requirementsRegular seed deposition machinesReciprocating motionAssembly line

The invention provides a seedling-cultivation flexible seeding apparatus, relating to the field of agricultural machinery technology; the seedling-cultivation flexible seeding apparatus comprises a seedling storage plate and a seedling dropping plate, the seedling storage plate is arranged on the seedling dropping plate and can move relative to the seedling dropping plate, the seedling storage plate and the seedling dropping plate are provided with a seedling filling hole and a seedling dropping hole correspondingly, under a seedling filling state, the seedling filling hole and the seedling dropping hole are staggered, and under a sowing state, the seedling filling hole and the seedling dropping hole are run-through; the seedling-cultivation flexible seeding apparatus is characterized in that: two seedling filling hairbrushes are arranged on a parallel bracket above the seedling storage plate, two seedling filling hairbrushes rotate inwards by respectively revolving the seedling filling hairbrush shafts and are respectively tangent with the seedling storage plate, and a seedling containing space is left between the two seedling filling hairbrushes; the seedling storage plate and the seedling dropping plate are arranged on a transmission mechanism and do reciprocating motion vertical to the direction of the seedling filling hairbrush shafts, and a spring resetting device is arranged between the seedling storage plate and the seedling dropping plate. The seedling-cultivation flexible seeding apparatus is suitable for characteristics of different crop seedlings, meets the seedling-cultivation agricultural requirements, increases the using efficiency of an automatic system in the existing assembly line and has the advantages of flexible seedling filling and no damage to the seedlings.

Owner:JIANGSU YUNMA AGRI MACHINERY

End sealing method of tunnel dual-lining trolley air bag die containing built-in type water-stop belt

InactiveCN106150527AShorten the timeImprove ergonomicsUnderground chambersTunnel liningElectricityStandard interval

The invention provides an end sealing method of a tunnel dual-lining trolley air bag die containing a built-in type water-stop belt. The end sealing method is particularly suitable for projects of mountain tunnels, underground railroads, electric heating tunnels and other standard interval tunnels, the air bag die achieves effective fixation along the inner side and the outer side of the circular construction joint water-stop belt, installation and inflation are achieved joint by joint, close attachment is achieved between an air bag and a trolley formwork panel, between the air bag and the water-stop belt and between the air bag and a waterproof board, the size of the inflated air bag is controlled, and it is ensured that the built-in type water-stop belt is centered in the longitudinal and annular directions at a construction joint; after the air bag is installed, through long wooden boards are annularly and densely arrayed at one end of a trolley and fixed with wooden wedges. The method has the advantages of being convenient to operate, high in work efficiency, low in cost, little in pulp leakage and high in pressure bearing.

Owner:RANKEN RAILWAY CONSTR GROUP

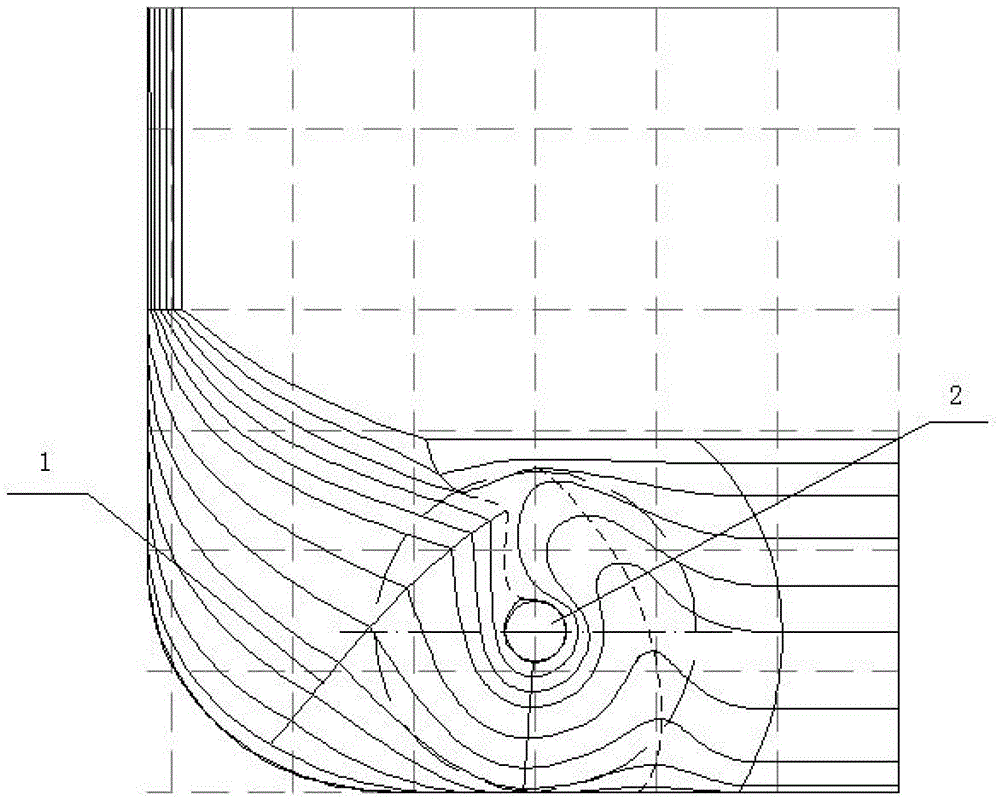

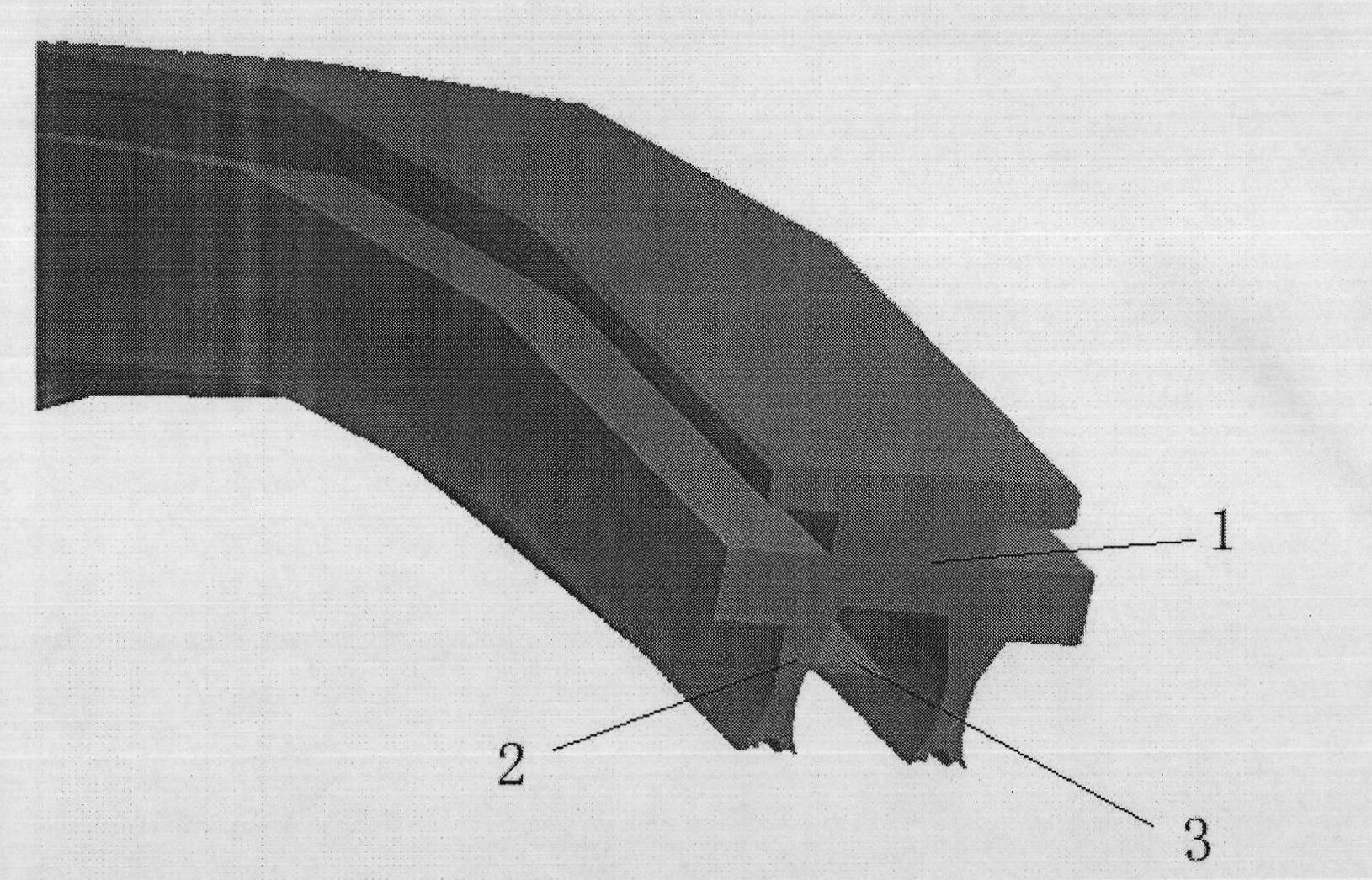

Ship with knuckle line and internal rotational fin tail

InactiveCN102745304AReduce resistanceSolve the resistanceWatercraft hull designStern postsPropellerInternal rotation

The invention discloses a ship with a knuckle line and an internal rotational fin tail, and belongs to the technical field of ships. The ship comprises a propeller, and the knuckle line is arranged on the basis of a ship with an internal rotation fin tail and positioned on the outer side of a shaft of the propeller along the length direction of the ship. The ship has the advantages that longitudinal flow and lateral flow can be guided, and a flow regulating effect can be achieved.

Owner:CSIC WUHAN SHIP & MARINE ENG EQUIP DESIGN

Layer-to-layer registration control method for inner layers of HDI (High Density Interconnector) board

InactiveCN106061139AOvercome the disadvantages of the production processNovel and reasonable designMultilayer circuit manufactureHigh densityInterconnector

The invention discloses a layer-to-layer registration control method for inner layers of an HDI (High Density Interconnector) board. The method comprises the following steps: performing earlier-stage detection on a film used for making inner layer lines and patterns, wherein the earlier-stage detection of the film includes earlier-stage compensation of the film, and detection and picking of the used film in order to ensure that the rising and shrinking of the used film are within + / -1MIL, and the rising and shrinking of a diagonal line of the used film are within + / -1MIL; setting a monitoring point on the picked and used film which is proved to be qualified by detection; and repeatedly measuring rising and shrinking numerical values of the film by 200PNL / time and recording the rising and shrinking numerical values during making of the inner layer lines and the patterns with the film, and measuring rising and shrinking data of the film and recording the rising and shrinking data after the inner layer lines and the patterns are made. The technical scheme has the advantages that the defects of a current production flow can be overcome, and the design is reasonable and novel.

Owner:奥士康精密电路(惠州)有限公司

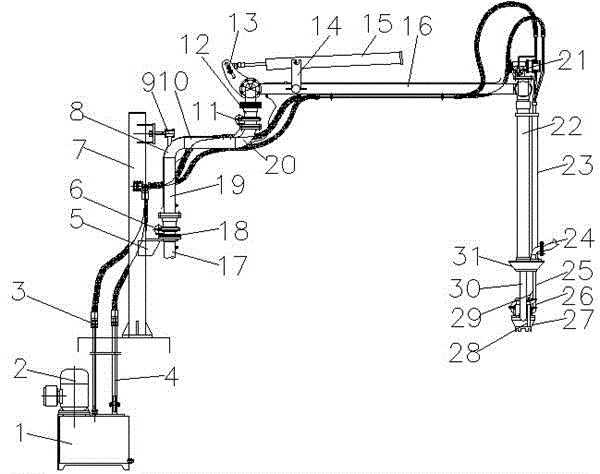

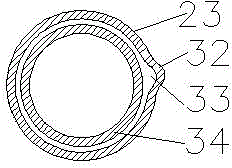

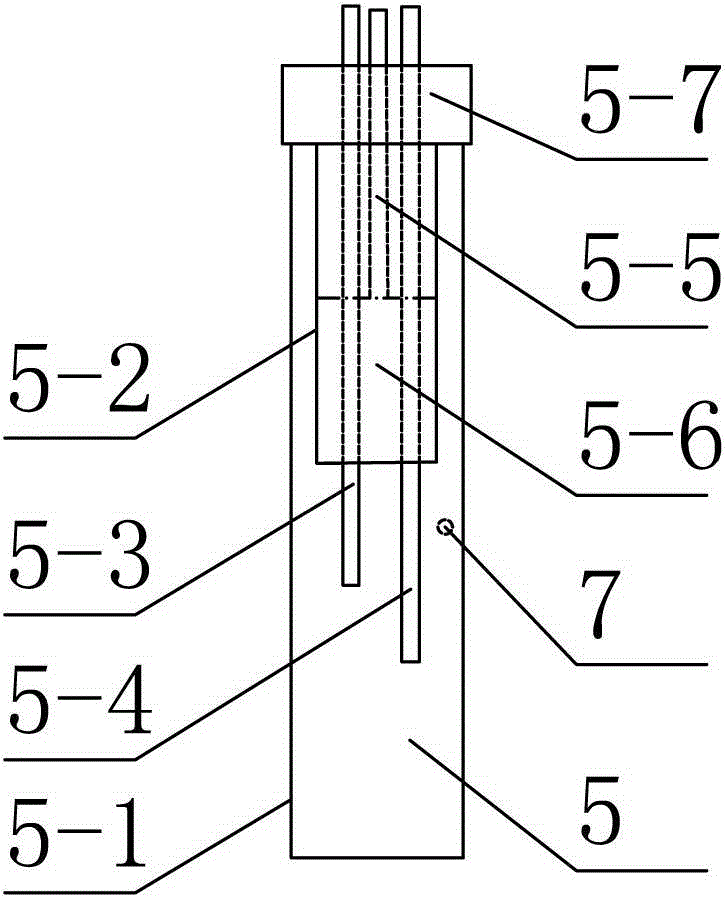

Novel unloading crane pipe with oil-immersed pump

ActiveCN104671182APhenomena that avoid the danger of acid burnsEnsure safetyAdjustable jointsLiquid transferring devicesHydraulic cylinderMarine engineering

The invention discloses a novel unloading crane pipe with an oil-immersed pump and belongs to the technical field of crane pipes. The novel unloading crane pipe comprises a hydraulic oil storage tank, a vane pump, a negative-pressure oil delivery pipe, a positive-pressure oil delivery pipe, a pneumatic hoist, a vertical pipe, the oil-immersed pump, a supporting frame module, a rotary arm module, a gaseous phase pipe, an oil outlet pipe, an oil inlet pipe, a sleeve, an oil outlet, a telescopic pipe and a seal cover, wherein the supporting frame module comprises a first bent pipe, an inner arm, a second bent pipe, a second rotary connector, a second pneumatic motor, an outer arm, a rotary frame, a rotary rod and a hydraulic cylinder. The novel unloading crane pipe has sealing effect during oil unloading, ensures the safety of volatile toxic liquid during unloading and avoids the phenomenon that an operator is possibly burned by acid. Positive-pressure oil unloading is adopted, so that air resistance and cavitation phenomena of the crane pipe do not exist, oil unloading speed is improved, and the liquid level in a tank truck can be accurately measured.

Owner:池州市星聚信息技术服务有限公司

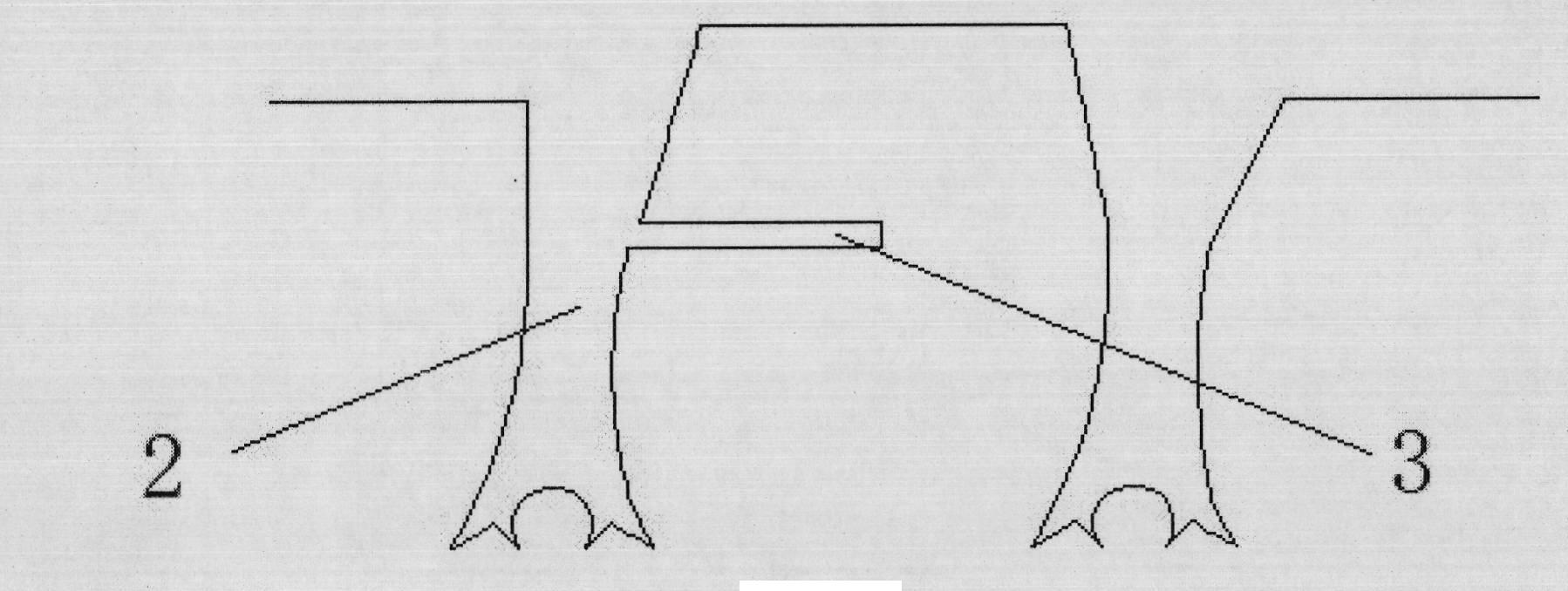

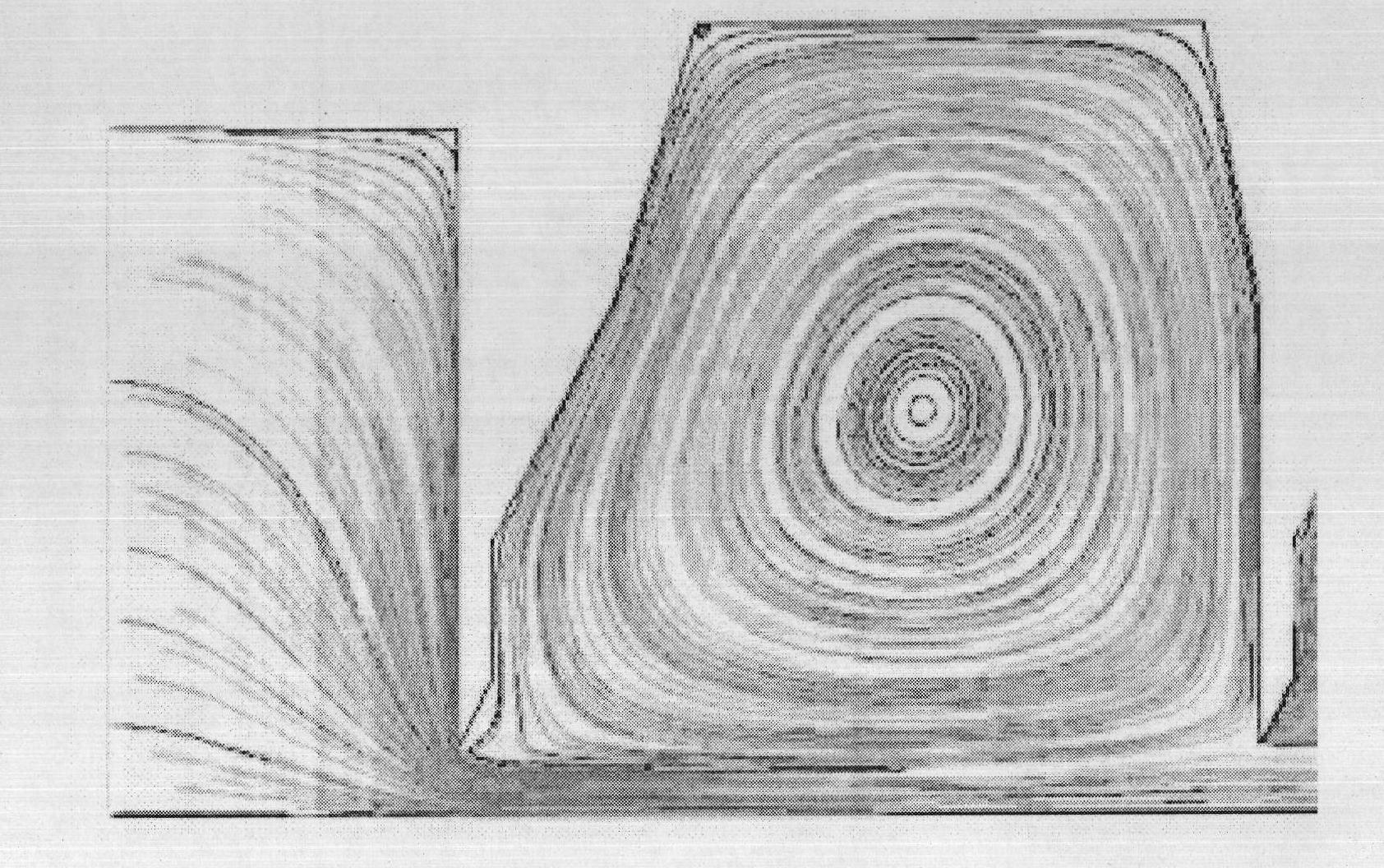

Sealing structure for dynamic and static gaps of rotating machine

ActiveCN101832392AAccelerated dissipationDissipate enoughEngine sealsPump componentsEngineeringHigh pressure

The invention relates to a sealing structure for dynamic and static gaps of a rotating machine. A transverse arm structure is arranged behind sealing tooth, and a claw-shaped structure is adopted on the top of the sealing tooth; the depth of a sealing cavity is increased, and the thicknesses of the root and the top of the sealing tooth are widened; oblique sealing tooth are applied; and both the windward side and the leeside of the sealing tooth adopt an arc surface modeling. The sealing structure is used for controlling the leakage of high-temperature and high-pressure fluid along the dynamic and static gaps and avoiding the condition that large-flow leakages influence the stable operation and the safe operation of parts of a next stage. Under the working medium conditions of high pressure, high temperature, high speed and large flow of a nuclear main pump, shown as a numerical simulation result, the sealing structure can reduce the leakage quantity by 13.8 percent compared with an ordinary straight-toothed labyrinth seal with the same gaps, can temporarily stabilize and control the leakage quantity under the extreme working condition of back flowing and has safety, durability and good throttling effect.

Owner:DALIAN UNIV OF TECH

Noise reduction and purification device for automobile exhaust gas

ActiveCN105179048ANo cavitationGuaranteed cleanlinessExhaust apparatusSilencing apparatusExhaust gasNoise reduction

The invention provides a noise reduction and purification device for automobile exhaust gas. The noise reduction and purification device is simple in structure and good in purification effect and comprises an exhaust gas inlet, a noise reduction and purification device body and an exhaust outlet. Exhaust gas enters the noise reduction and purification device body through the exhaust gas inlet and then exhausted through the exhaust outlet after noise reduction and purification are performed on the exhaust gas through the noise reduction and purification device body. The noise reduction and purification device body comprises a first-grade purification chamber. A purification pool and a gas-water purification cavity are arranged inside the first-grade purification chamber. A purification solution is contained inside the purification pool. The exhaust gas inlet is communicated with the first-grade purification chamber. The upper edge of an opening of the exhaust gas inlet is higher than the upper surface of the purification solution inside the purification pool. A water level indicator is arranged inside the purification pool of the first-grade purification chamber and induces the height of the purification solution inside the purification pool. The purification pool is connected with a purification solution adding pump. The purification solution adding pump supplements the purification solution inside the purification pool. An atomization filter net is arranged between the gas-water purification cavity and the purification pool. A gas-water separation filter net is arranged at an outlet of the gas-water purification cavity.

Owner:方冰熔

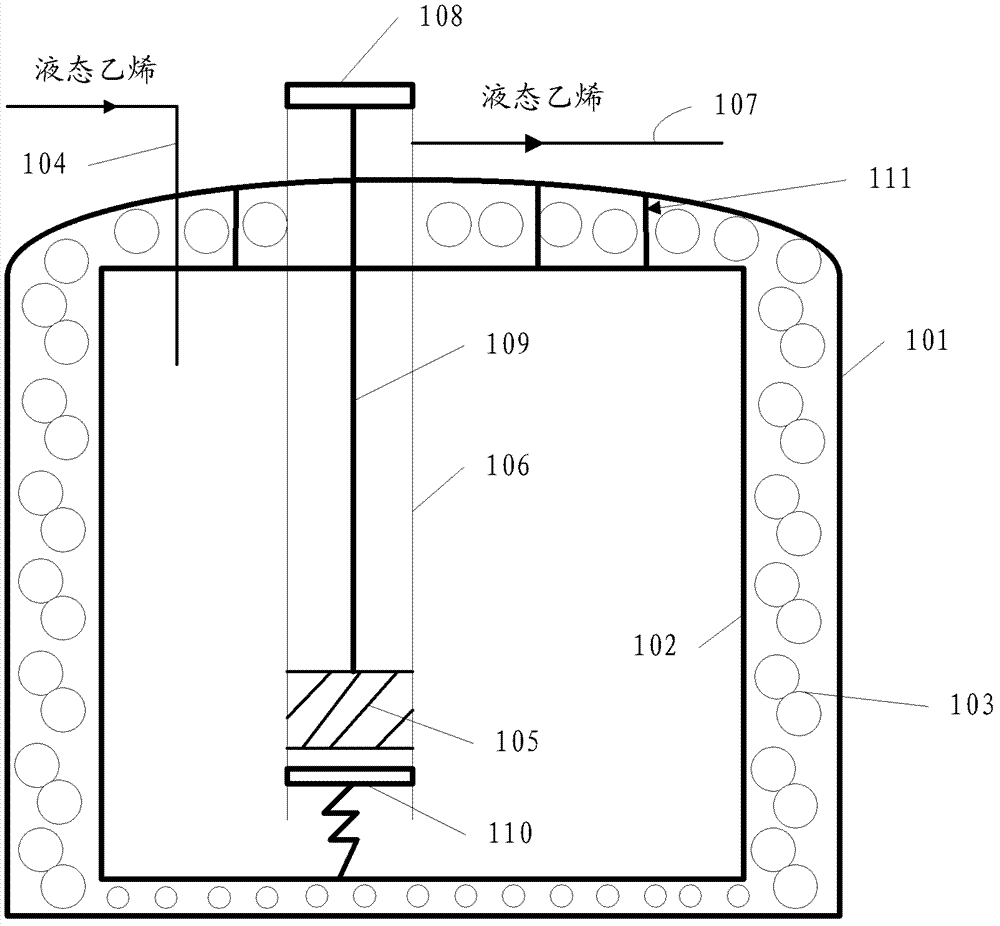

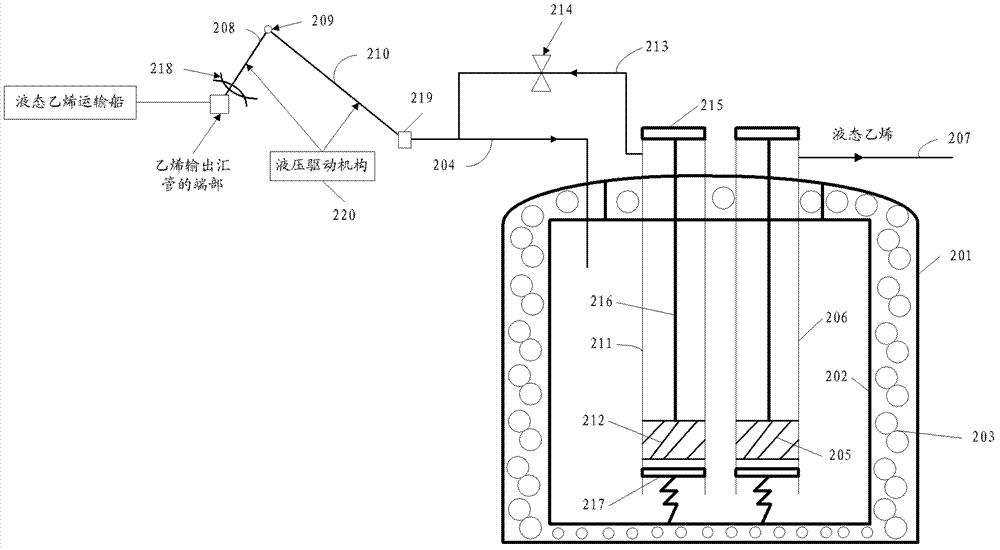

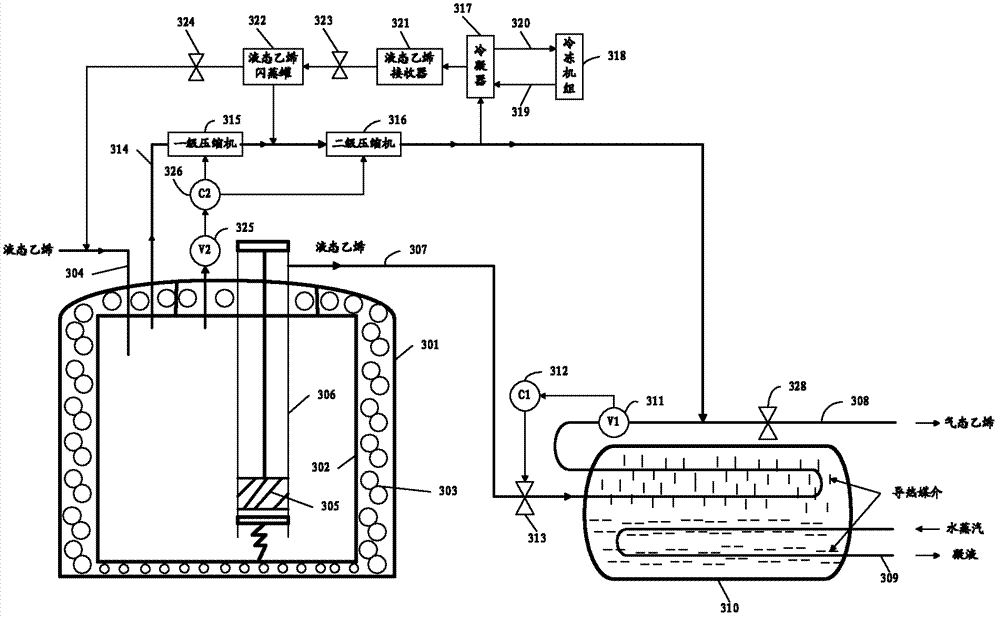

Liquid ethylene storage tank, liquid ethylene storage and gasification system and liquid ethylene gasification method

ActiveCN102213361BNo cavitationWon't breakContainer filling methodsPipeline systemsLiquid stateEngineering

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

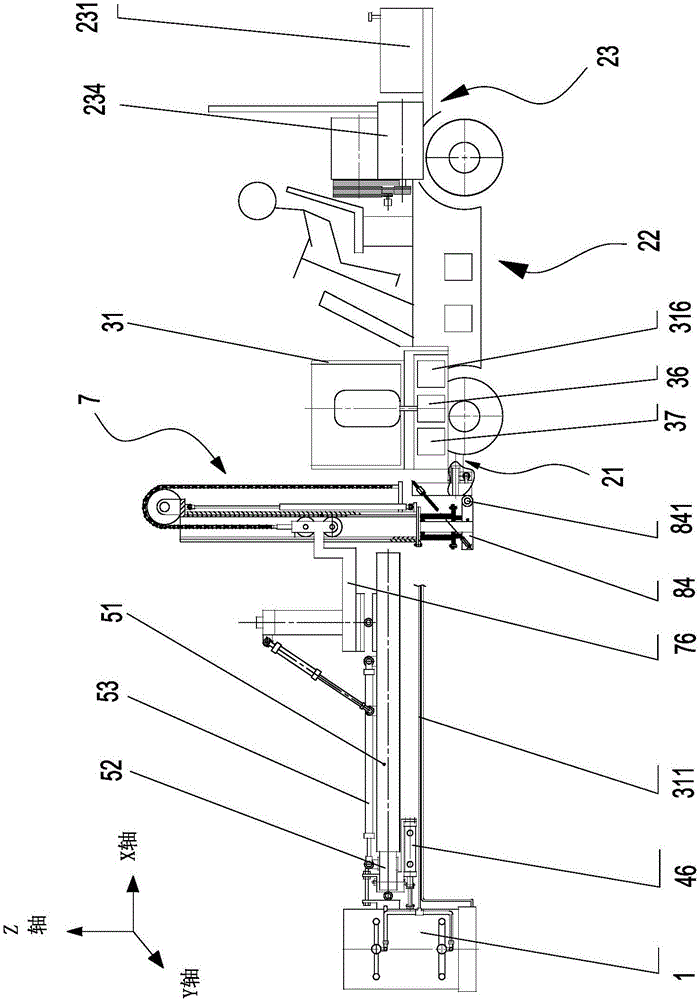

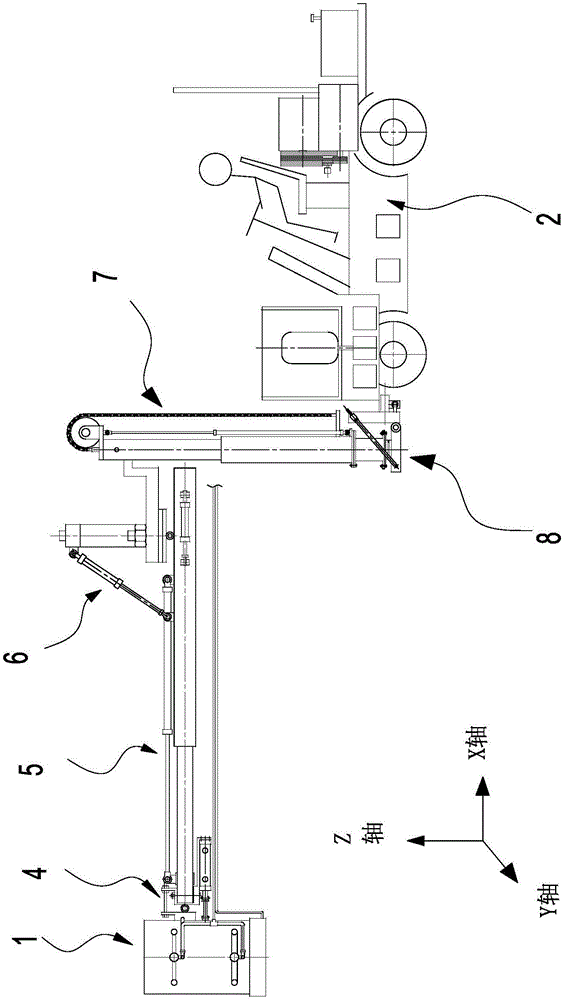

Trunk whitewashing machine

InactiveCN106670013AIncrease freedomAchieve any angleLiquid spraying apparatusPlant protectionLeft halfEngineering

The invention discloses a trunk whitewashing machine which comprises a motor vehicle. The motor vehicle is connected with a manipulator. A spray bucket assembly is connected to the front end of the manipulator. The spray bucket assembly comprises a left half bucket and a right half bucket which can be opened and closed. When the left half bucket and the right half bucket are closed, a trunk is clamped between the left half bucket and the right half bucket to be subjected to spraying. The manipulator comprises a lifting mechanism, a telescopic mechanism and a second connecting mechanism which is connected between the telescopic mechanism and the lifting mechanism. The lifting mechanism is connected with the motor vehicle through a first connecting mechanism. The telescopic mechanism is connected with the spray bucket assembly through a third connecting mechanism. The trunk whitewashing machine has the advantages that rotation in multiple directions can be achieved, the degree of freedom of rotation is high, and the application range of the trunk whitewashing machine is greatly broadened.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

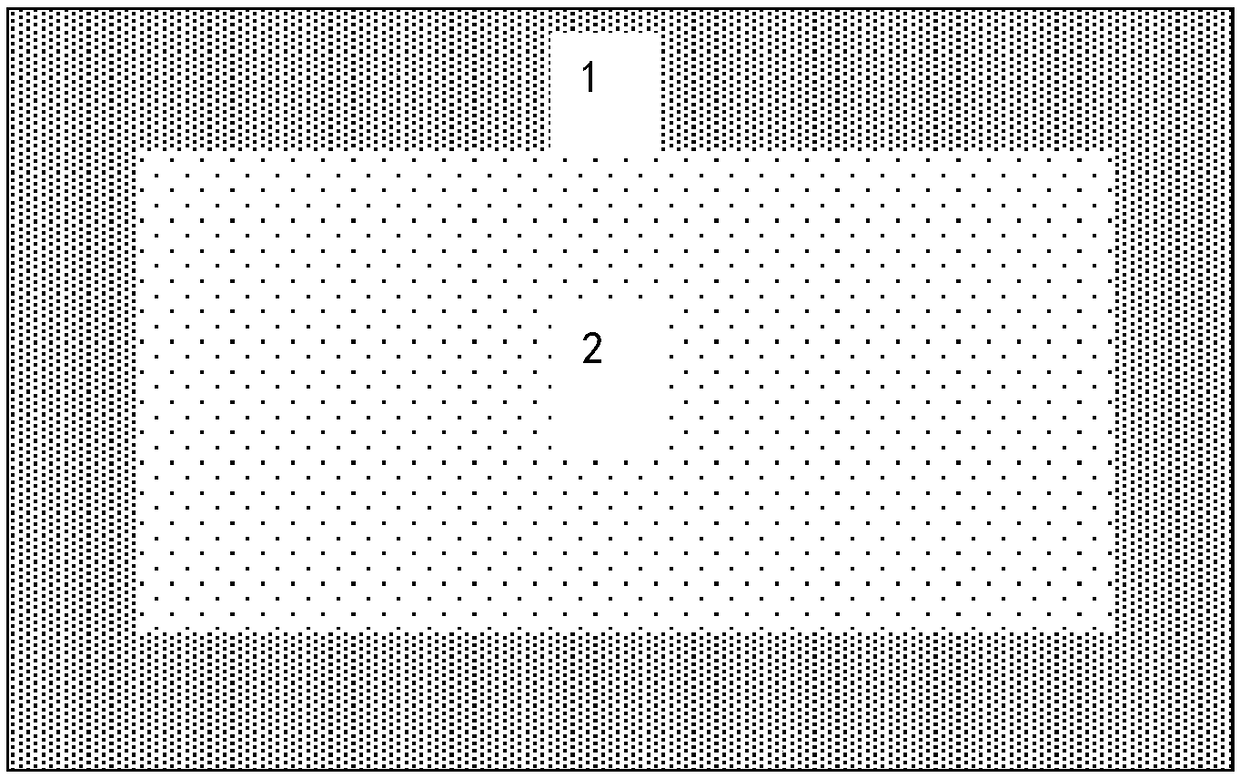

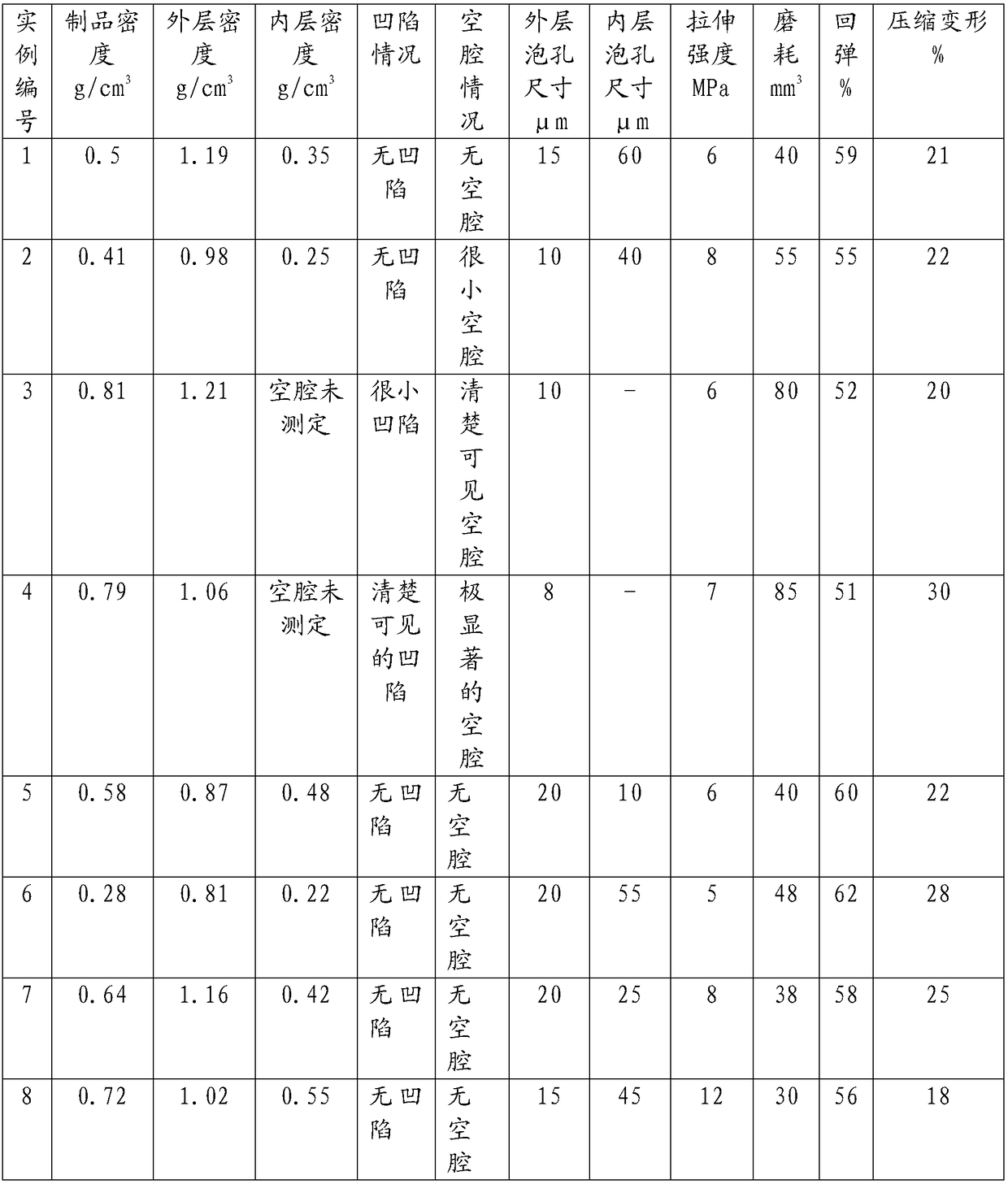

Thermoplastic polyurethane elastomer foam material having density gradient, and preparation method thereof

ActiveCN108264754ASolve the problem of easy to produce holesFine internal cell structureFoaming agentThermoplastic polyurethane

The invention belongs to the field of polymer foam materials, and particularly relates to a thermoplastic polyurethane elastomer foam material having a density gradient, and a preparation method thereof. The thermoplastic polyurethane elastomer foam material comprises an outer layer and an inner layer having no interface bonding structure, the density of the outer layer (1) is 0.8-1.3 g / cm<3>, andthe density of the inner layer (2) is 0.2-0.8 g / cm<3>, wherein the thickness of the outer layer (A) is 2-40% of the whole thickness of the cross section of the material, and the thickness of the inner layer (1) is 60-98% of the whole thickness of the cross section of the material. The thermoplastic polyurethane elastomer foam material having the density gradient is prepared through injection molding of 90-99.9 wt% of a thermoplastic polyurethane elastomer, 0.1-5 wt% of a chemical foaming agent and 0-5 wt% of a binder. The product has the advantages of light weight, high resilience, good wearresistance, excellent tensile strength, excellent compression deformation property, excellent dimensional stability to heating and good resistance to a low temperature.

Owner:MIRACLL CHEM

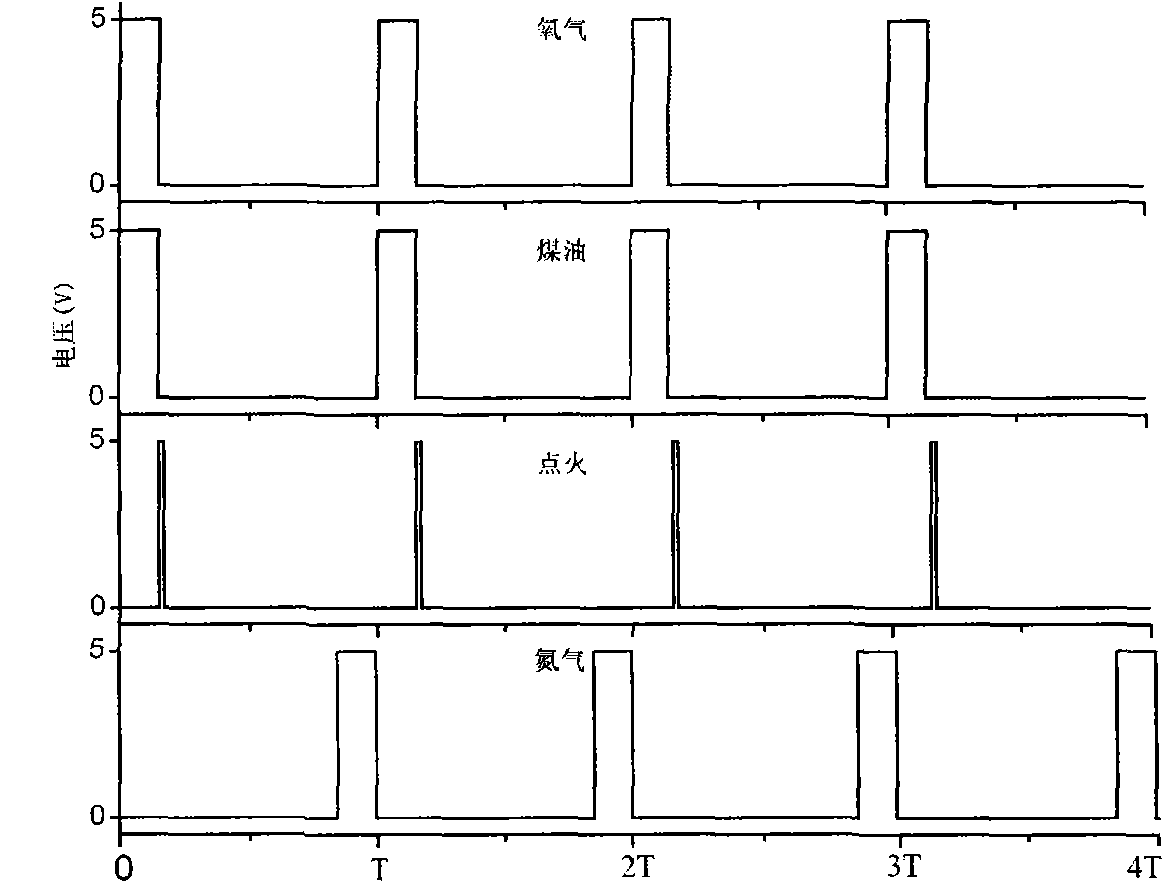

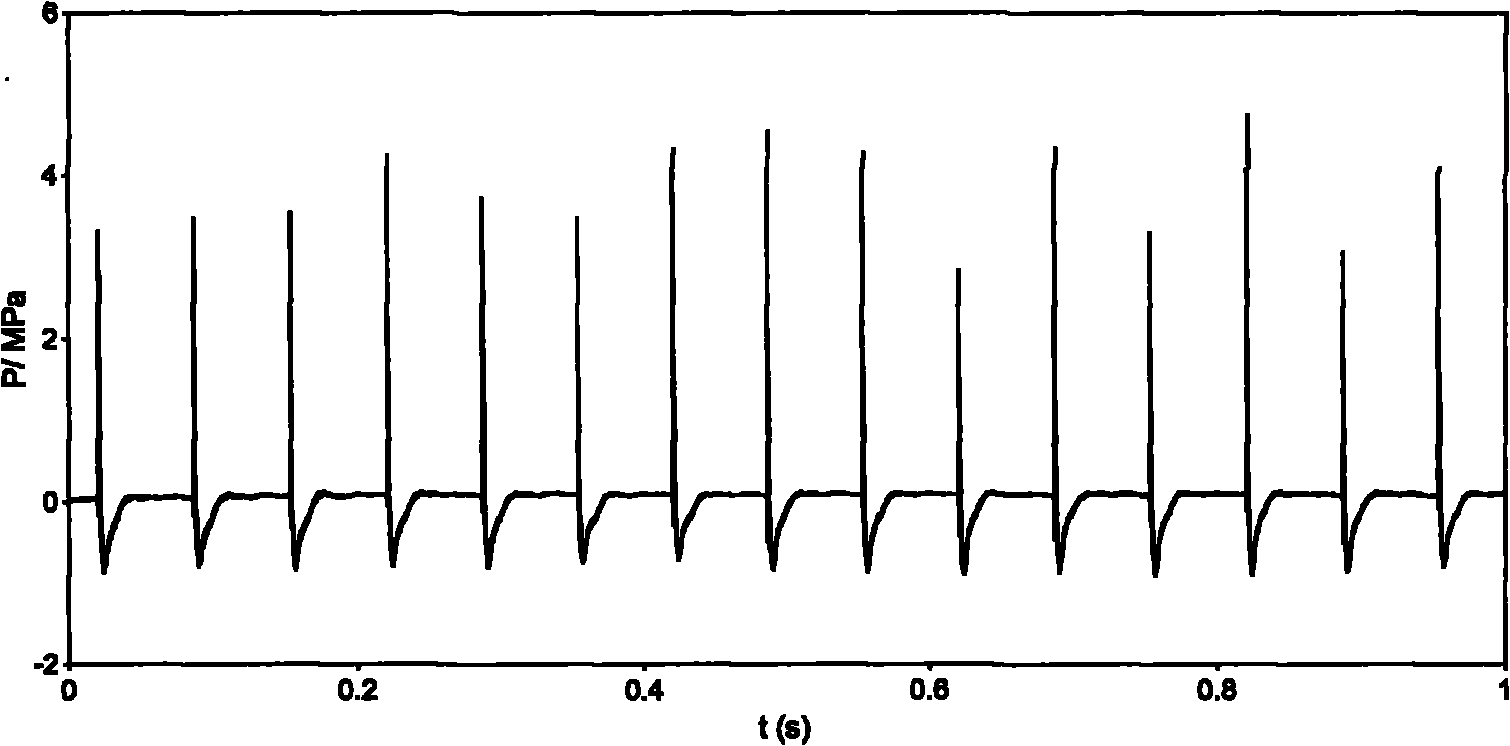

Power plant of water surface ship

InactiveCN102086822AReduce failure rateIncrease boost ratioPower plants being motor-drivenIntermittent jet plantsTrombe wallDetonation

The invention discloses a power plant of a water surface ship. The power plant comprises a pulse detonation tube and an engine inclined tube body, wherein the engine inclined tube body is divided into an inclined section and an outlet section, and a buckling is arranged between the inclined section and the outlet section; the port of the inclined section of the inclined tube body of an engine is coaxially connected with the outlet of the pulse detonation tube by virtue of a flange, and the tube wall of the inclined section is provided with a pressure probe; a controllable water inlet with a close device is arranged on the tube wall of the inclined section, and a signal processing system and a steering engine are connected between the close device and the pressure probe in series; the projected area of the outlet section of the controllable water inlet on the transverse section is at least 50% of that of the outlet section port; and when the power plant of the water surface ship works, the outlet section of the engine inclined tube body is below the water surface, and the controllable water inlet is below the water surface. According to the invention, the high temperature, high voltage, high speed fuel gas and detonation waves are generated by adopting the detonation tube to propel the fluid to be exhausted to generate push power.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

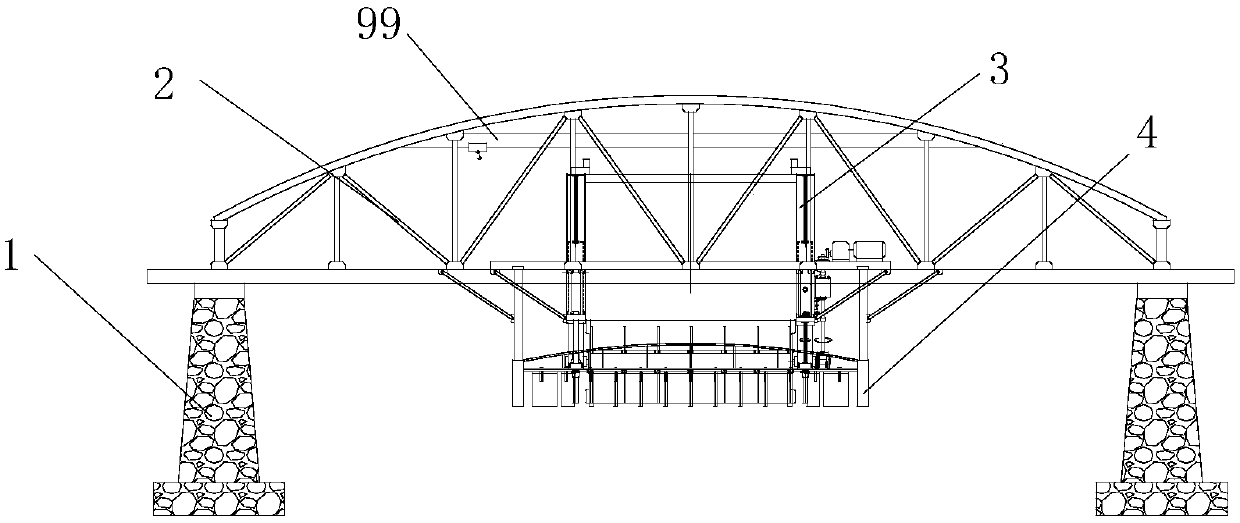

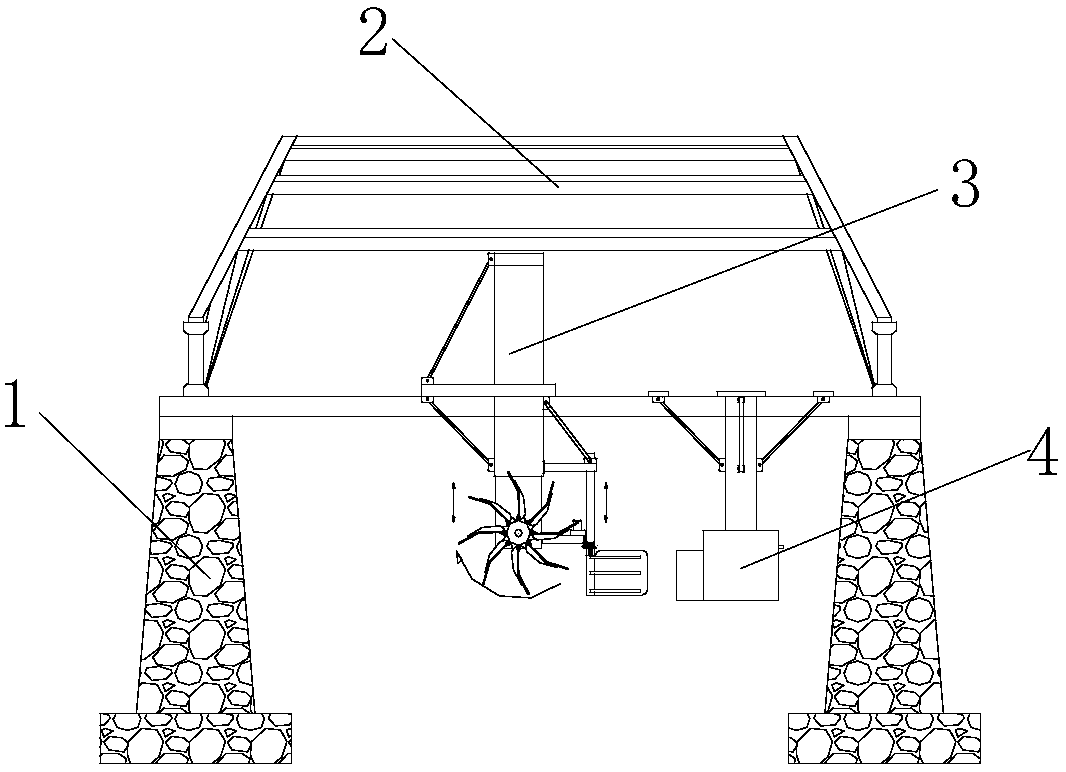

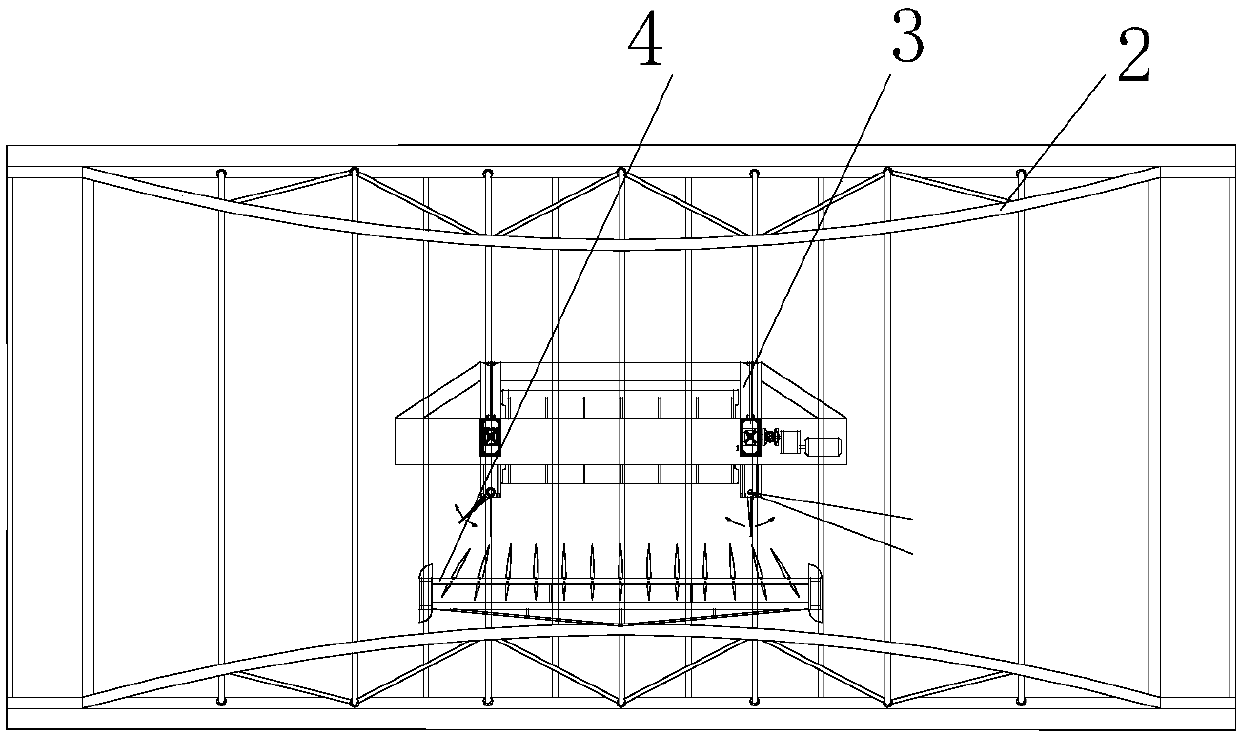

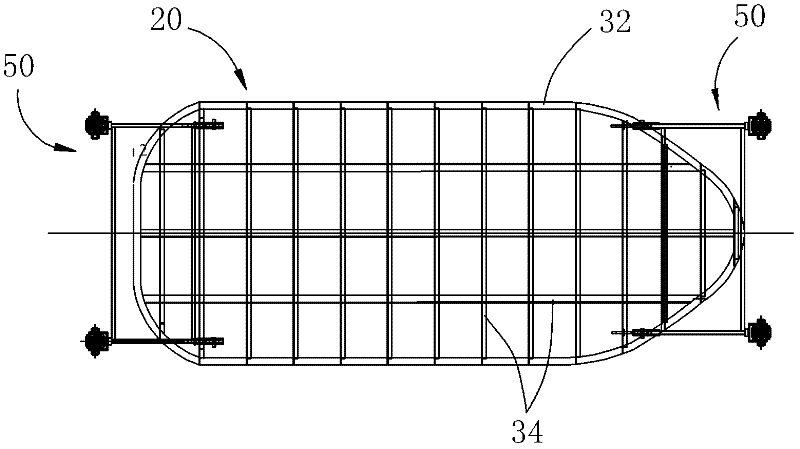

Suspension type water wheel low water head tail water power generation system

PendingCN107747526AHigh efficiency in harvesting tail water energyNo cavitationWater-power plantsHydro energy generationMechanical energyEngineering

The invention relates to a suspension type water wheel low water head tail water power generation system which comprises a supporting column. A steel truss bearing beam is installed on the top of thesupporting column, an equipment base plate is installed at the bottom of the steel truss bearing beam and provided with a power generator set, the power generator set comprises a gear box, a power generator, a fixed suspension arm, a movable suspension arm and the like. A water wheel assembly is connected to the movable suspension arm in a downward suspension mode, a floating type flow guide waterlattice is arranged in front of the upstream face of the water wheel assembly, the portion, facing water flow, of the movable suspension arm is provided with a flow adjuster, the flow adjuster comprises an upper arm, a lower arm, an up-down movement pull rod and a flow adjusting plate. The suspension type water wheel low water head tail water power generation system has the advantages that the suspension type water wheel design is adopted, and therefore the system can adapt to dam type hydropower station tail water channel environments or other complex river bed environments; by means of thespecially-designed novel water wheel assembly and water lattice, water energy can be sufficiently collected and converted into mechanical energy and electric energy; by means of the specially-designedway of combining rotating speed mechanical automatic adjustment and electric adjustment, the tail water flow speed and flow capacity can be effectively controlled, and therefore the rated rotating speed of the power generator is ensured.

Owner:顾坚毅 +1

Cold binding process of rotating target material

InactiveCN110846627AEffective squeezeConductive playVacuum evaporation coatingSputtering coatingAdhesiveEngineering

The invention discloses a cold binding process of a rotating target material, and belongs to the technical field of target materials. The cold binding process of the rotating target material comprisesthe following steps that 1, an outer tube target material sleeves a back tube; 2, an adhesive is pressed into a gap between the outer tube target material and an inner tube; and 3, after the adhesiveis solidified, the binding is connected. According to the cold binding process, air in the gap can be effectively extruded out, so that the bonding area of the outer tube target material and the backtube can reach 100%, no cavity is generated between an outer tube and the back tube, and the phenomenon of target cracking and target falling is effectively avoided in the sputtering process. Heatingis not required during binding, so that the back tube does not generate an expansion phenomenon; and a 304 stainless steel tube is adopted by the back tube, so that the back tube has the advantage ofbeing low in cost. The binding process can bind the target materials of any material, and the rotating target materials of any specification and any single section length (200mm-2000mm). The cold binding process has the advantages of being simple in operation, low in cost, energy-saving and environment-friendly and high in finished product qualification rate.

Owner:张俊杰

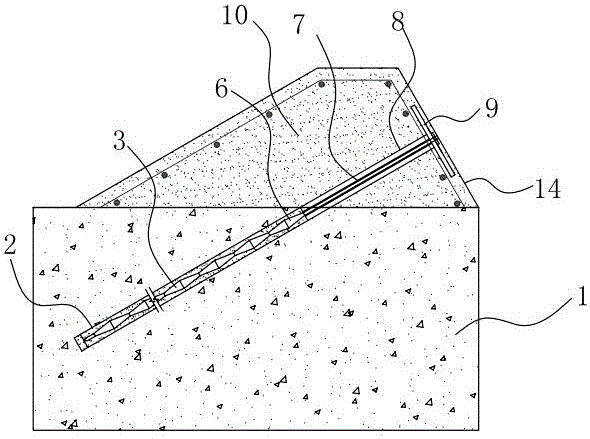

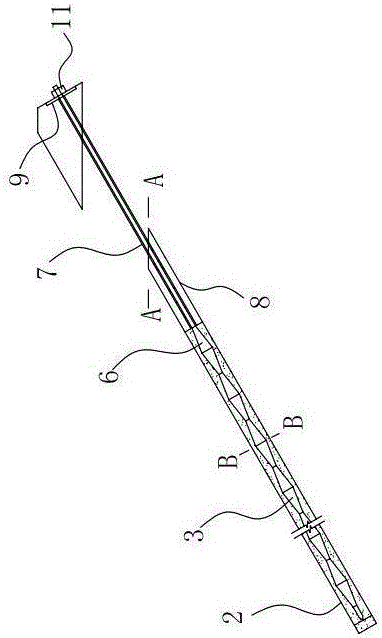

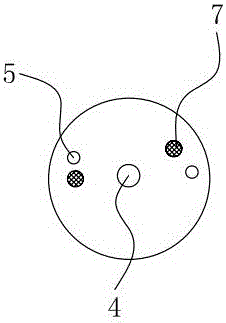

Anti-landslip construction technology for slope building concrete layer

ActiveCN106120817AGuaranteed connection strengthPrevent looseningExcavationsBulkheads/pilesBuilding construction

The invention discloses an anti-landslip construction technology for a slope building concrete layer. The anti-landslip construction technology for the slope building concrete layer includes the following construction steps of firstly, rock stratum trepanning, secondly, anchoring section arrangement, thirdly, anchoring section grouting, fourthly, anchoring section grouting compaction, fifthly, pre-tightening section arrangement, sixthly, slope face base body pouring, seventhly, pre-tightening and anchoring, and eighthly, plugging. By the adoption of the anti-landslip construction technology, a slope body and a rock body foundation can be prevented from sliding horizontally, connection is stable and firm, and construction is easy and convenient.

Owner:QINGDAO NO 1 CONSTR GRP

Hydrodynamic radial bearing and centrifugal pump

The invention provides a hydrodynamic radial bearing provided with an axial-flow pressurizing structure and a centrifugal pump. The hydrodynamic radial bearing comprises a shaft sleeve and a bearing body matched with the inside of the shaft sleeve; the bearing body comprises two opposite end surfaces and a side surface located between the two opposite end surfaces; and the axial-flow pressurizingstructure is arranged on the side surface of the bearing body, is close to at least one of the two opposite end surfaces and is far away from the central area of the side surface. Compared with the prior art, the hydrodynamic radial bearing has the advantages that a pressurizing device is added to the front part of the hydrodynamic radial bearing, the cavitation phenomenon which is caused easily in a general hydrodynamic bearing is restrained, and the reliability of the bearing is improved remarkably.

Owner:XI AN JIAOTONG UNIV

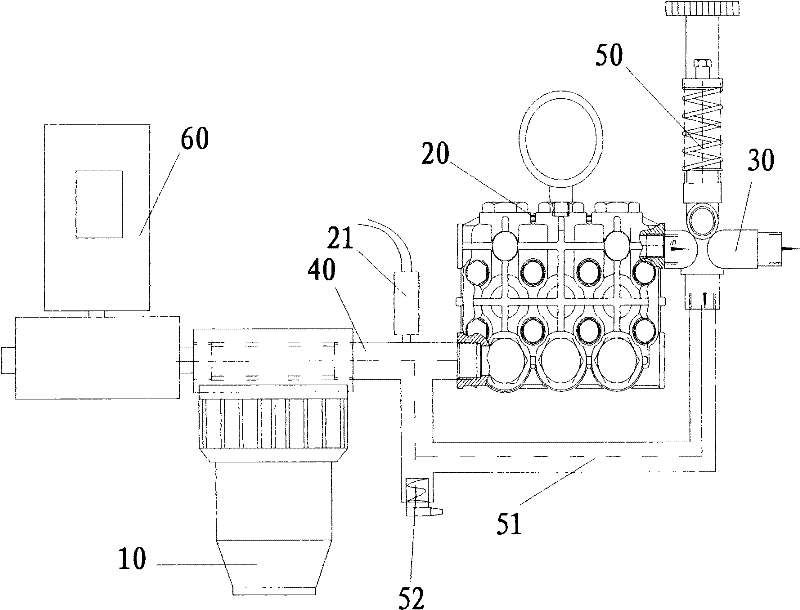

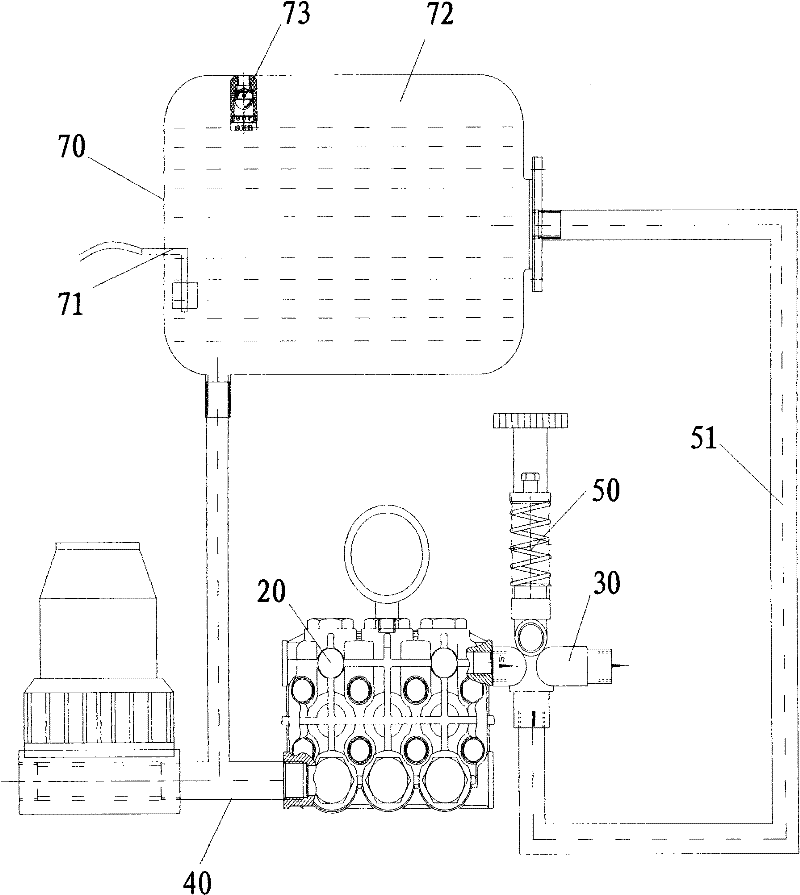

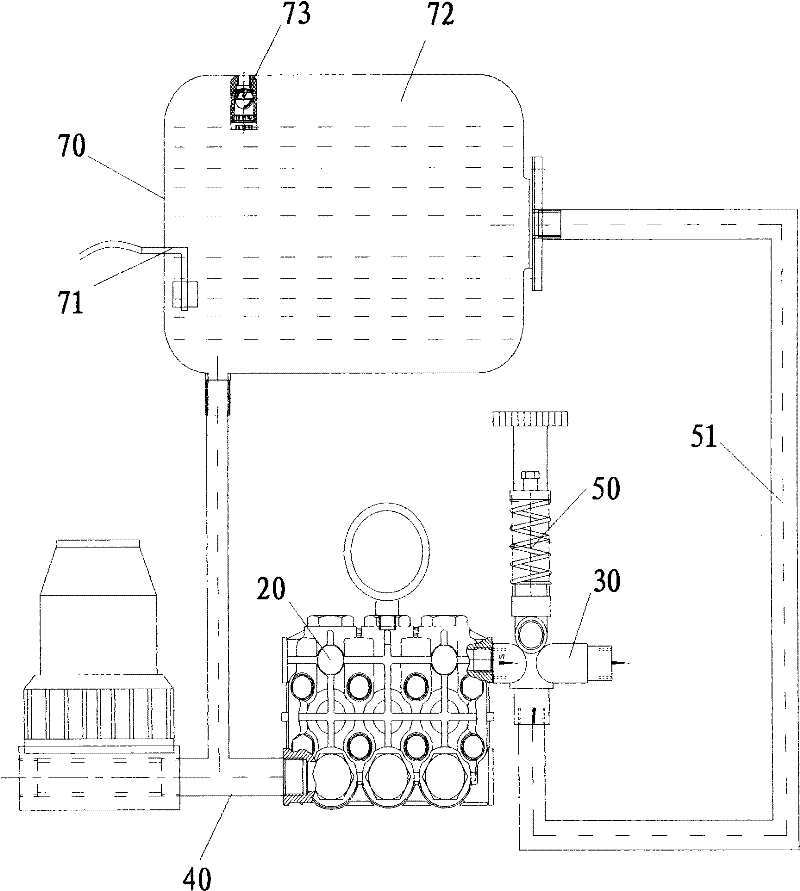

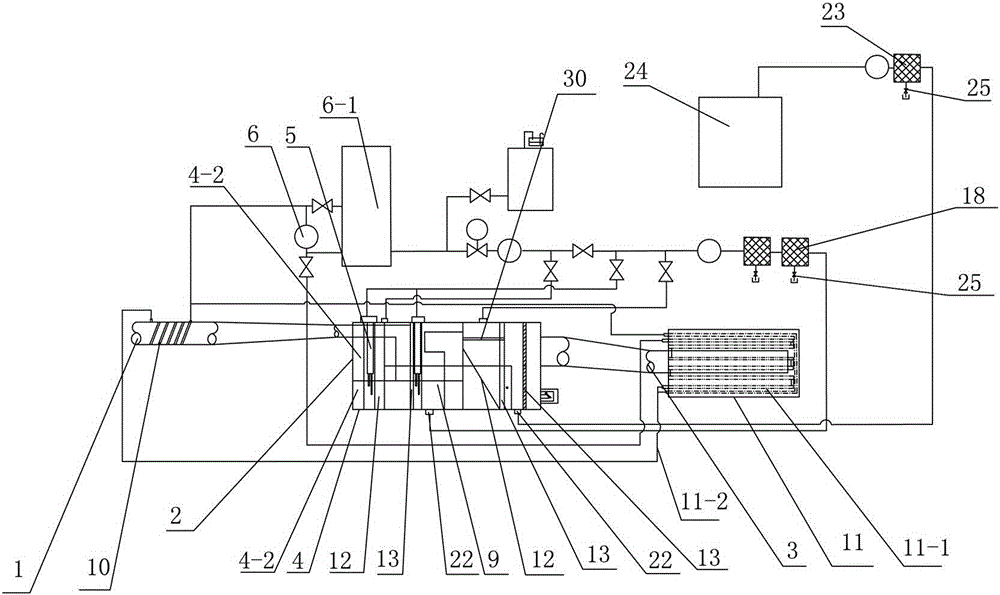

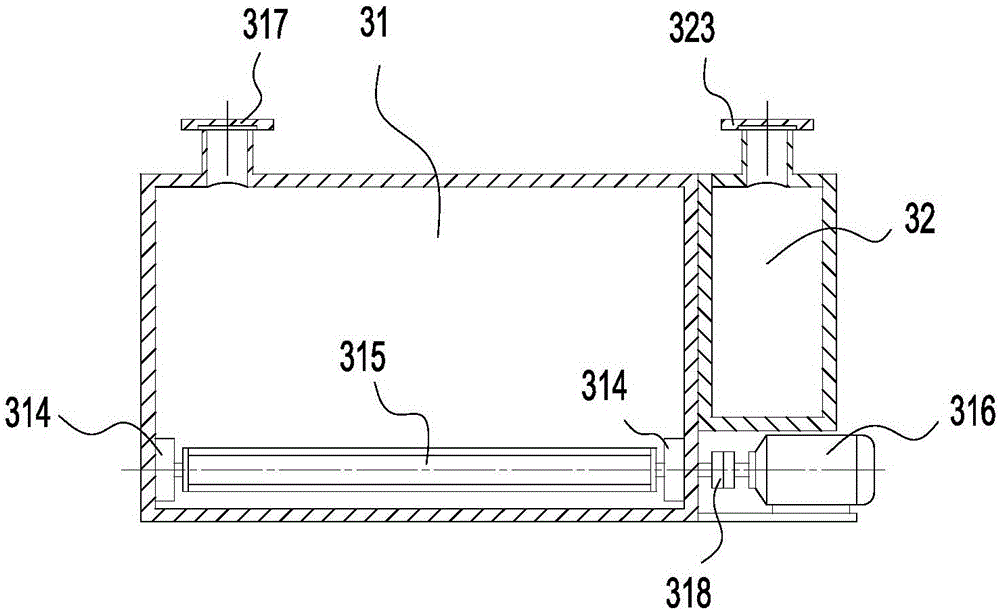

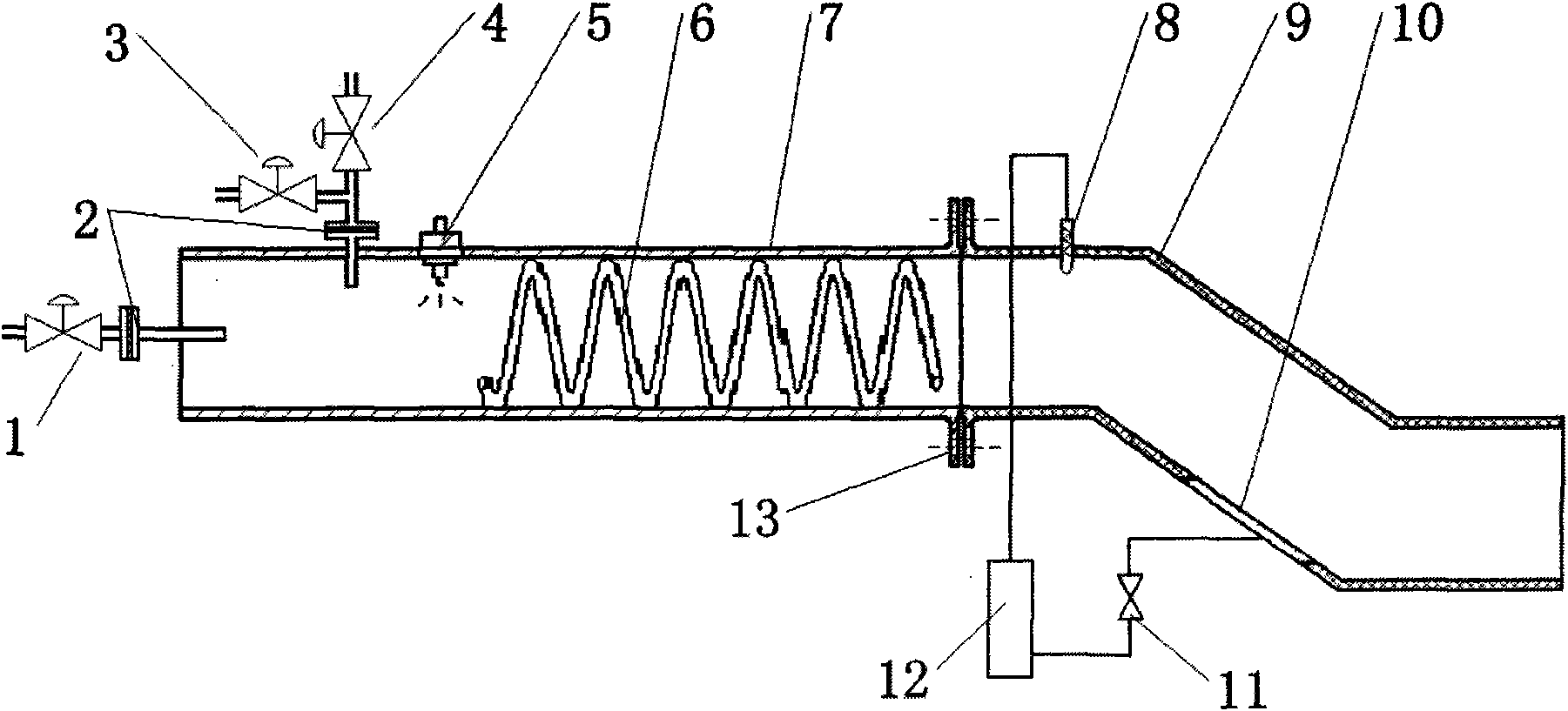

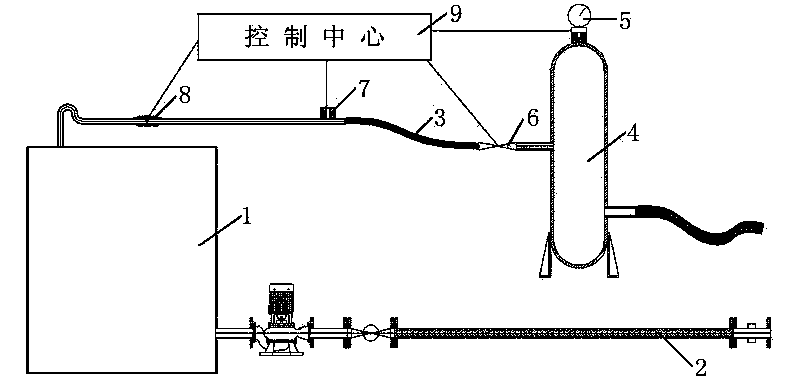

Performance test platform of high-pressure water pump

InactiveCN104100513ASolve the difficult problem of performance testingImprove test accuracyPump testingPositive-displacement liquid enginesEngineeringHigh pressure water

The invention provides a performance test platform of a high-pressure water pump. The performance test platform comprises a water storing tank, a water inlet pipeline and a water outlet pipeline. The performance test platform is characterized in that a high-pressure flow stabilizing tank is arranged on the water outlet pipeline; a pressure sensor is mounted on the top end of the high-pressure flow stabilizing tank; an electric regulating valve is connected to a water outlet of the high-pressure flow stabilizing tank; a temperature sensor and a turbine flow meter are mounted on the water outlet pipeline between the electric regulating valve and the water storing tank; the control ends of the pressure sensor, the electric regulating valve, the temperature sensor and the turbine flow meter are connected with a control center. The performance test platform of the high-pressure water pump is simple in structure and convenient to operate; testing devices work stably during testing the high-pressure water pump; the tested data are reliable; in addition, the safety coefficients are high, and any accident is avoided.

Owner:随州亿丰泵业有限公司

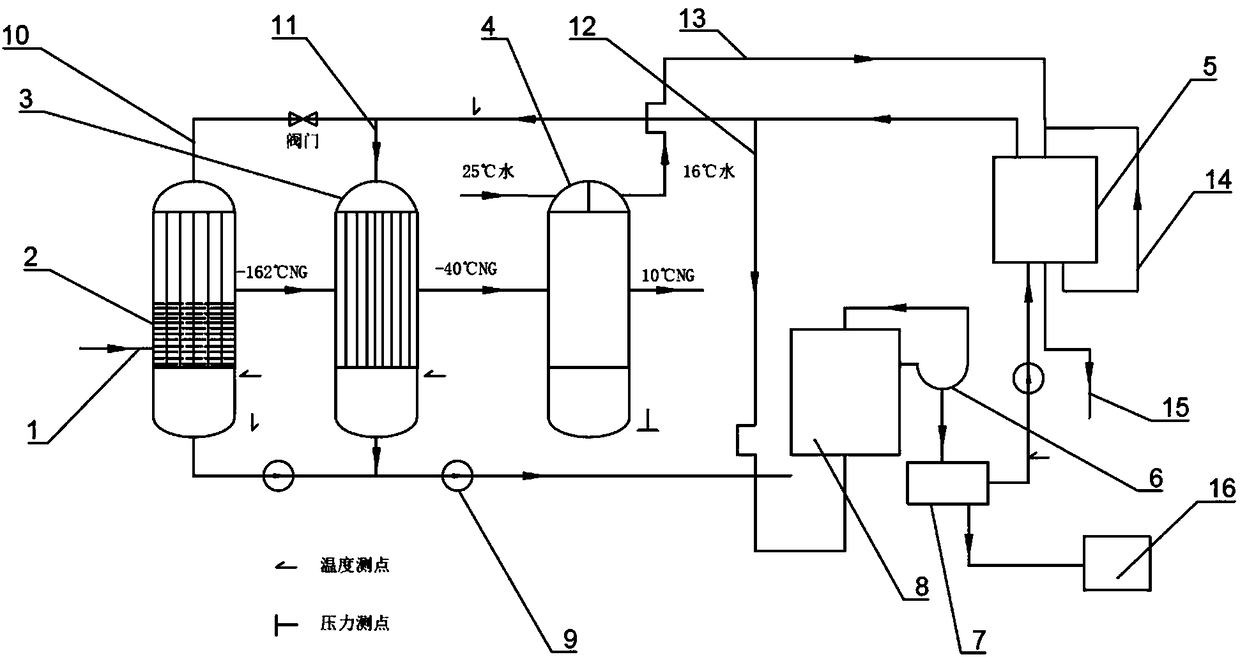

Device and method for preparing solid ice by use of cold energy released through LNG vaporization

PendingCN108518901ANo cavitationLighting and heating apparatusIce productionVapor–liquid separatorBoiling point

The invention discloses a device and a method for preparing solid ice by the use of cold energy released through LNG vaporization. The device comprises an LNG vaporizer 2, an NG superheater 3 and a water precooler 4 which are arranged side by side, a first lower-boiling-point working medium branch pipe 10, a second lower-boiling-point working medium branch pipe 11, a water precooler (4), a precooled water pipe 13 and an ice maker 5. The ice maker 5 is also connected to a low-boiling-point working medium pipe. A thermoregulator 8 is provided with a first-stage liquid-vapor separator 6, which isconnected to a second-stage liquid-vapor separator 7. The second liquid-vapor separator 7 is also connected to the ice maker 5. The method comprises seven steps. Cold energy released by LNG vaporization is fully utilized to prepare solid ice, thus reducing energy waste.

Owner:NANJING UNIV OF TECH

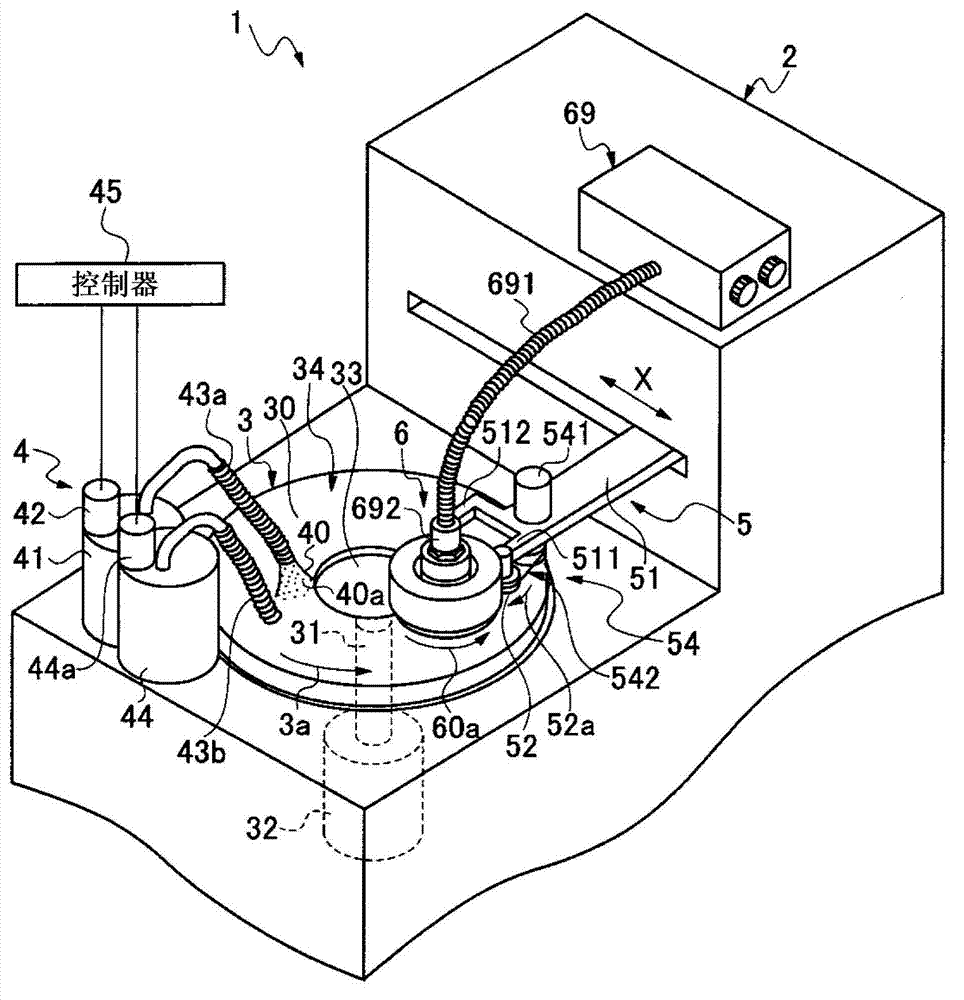

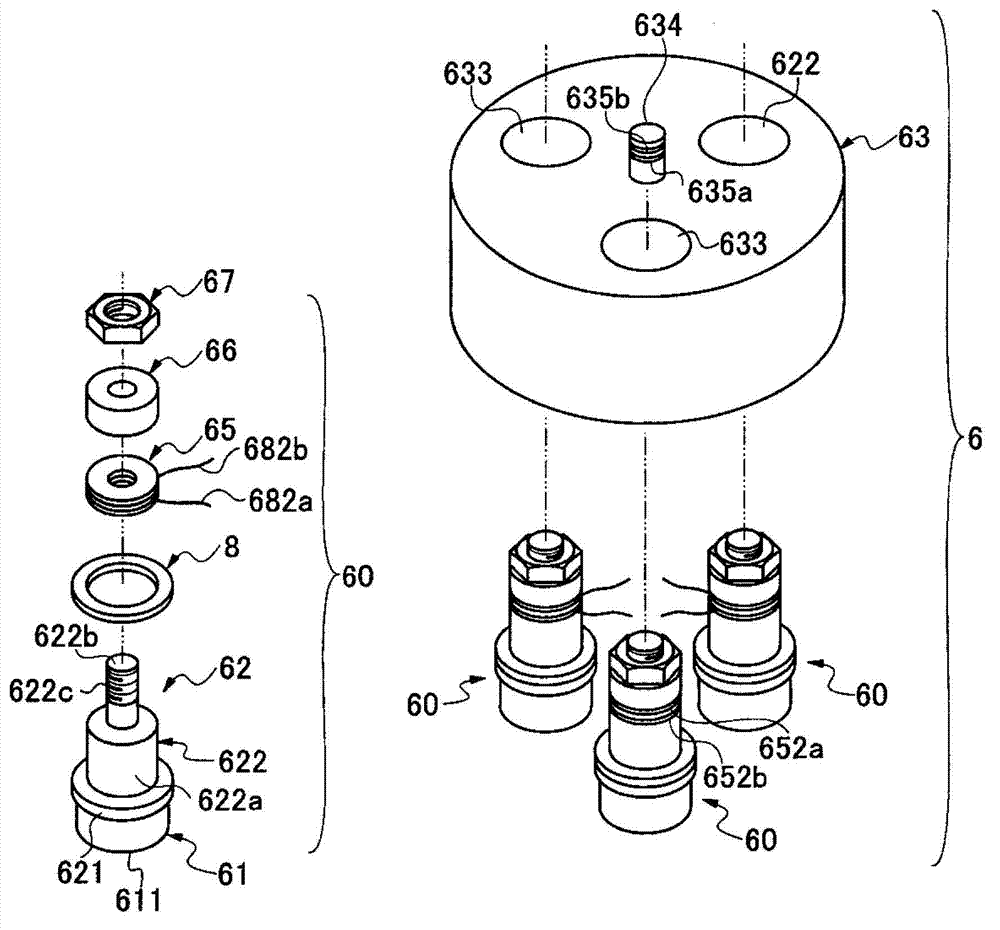

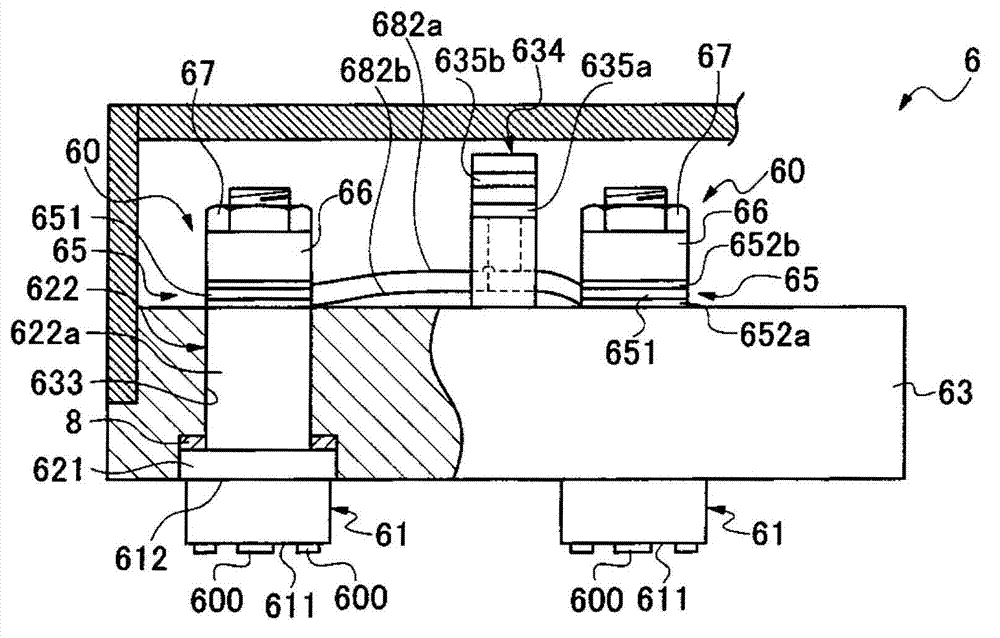

Abrasive particle burying device, polishing device and polishing method

ActiveCN102962763AEasy to embedSuppress uneven embeddingLapping machinesWork carriersWear particleSlurry

The invention provides an abrasive particle burying device, a polishing device and a polishing method. Abrasive particles are prevented from being buried unevenly and can be buried into a grinding die holder in a highly efficient manner. According to the abrasive particle burying device, slurry containing the abrasive particles is supplied to one side of a surface of the grinding die holder, and at the same time the grinding die holder is pressed by a press component through separation of the slurry, and the press component and the grinding die holder are made to slide to bury the abrasive particles contained by the slurry into the surface of the grinding die holder. The press component comprises: more than one press part; a hammer part which is arranged above the press parts and is used for pressing the press parts onto the grinding die holder; and an ultrasonic oscillator which is used for applying ultrasonic waves onto the press parts. The press parts have press surfaces equipped with a plurality of press sheets shaped like round discs, so that the press surfaces are equal in terms of length along a direction of relative sliding between the press component and the grinding die holder. Through inhibition of uneven stress of fluid, the abrasive particles are prevented from being buried unevenly into the grinding die holder.

Owner:DISCO CORP

Energy-saving type vacuum device

ActiveCN107560451AGuaranteed energy savingIncrease inlet pressureSteam/vapor condensersVacuum pumpingIsolation valve

The invention relates to an energy-saving type vacuum device. The energy-saving type vacuum device comprises a condenser, a condenser hot well, a steam condensing mother pipe, a first water ring vacuum pump system, a steam condensing branch pipe, a steam condensing pipeline check valve, a steam condensing pipeline flow meter, a steam condensing pipeline pressure transmitter, a steam condensing pipeline thermal resistor, a steam condensing pipeline isolating valve, a steam condensing pipeline pneumatic valve, a power steam adjusting valve, a steam ejector, a tubular heat exchanger, a steam trap, a hydrophobic pneumatic valve, a contact pneumatic valve, a contact isolation valve and a second water ring vacuum pump. According to the energy-saving type vacuum device, the first water ring vacuum pump system is replaced by the tubular heat exchanger and the small-power second water ring vacuum pump, thus the vacuum of the condenser can be maintained and provided, the condenser is guaranteedto be in the optimum working condition, the influence of environmental temperature changes is avoided, stable pumping capacity of the condenser is kept all the time, the vacuum degree of the condenseris improved, the power generation coal consumption of a unit is reduced, the operation power consumption of a vacuum pumping system is reduced, operation of the system equipment is reliable and safe,the maintenance workload is small, the cavitation phenomenon is avoided, and the phenomena of high noise and vibration are avoided.

Owner:WUHAN EDW PUMP & VALVE

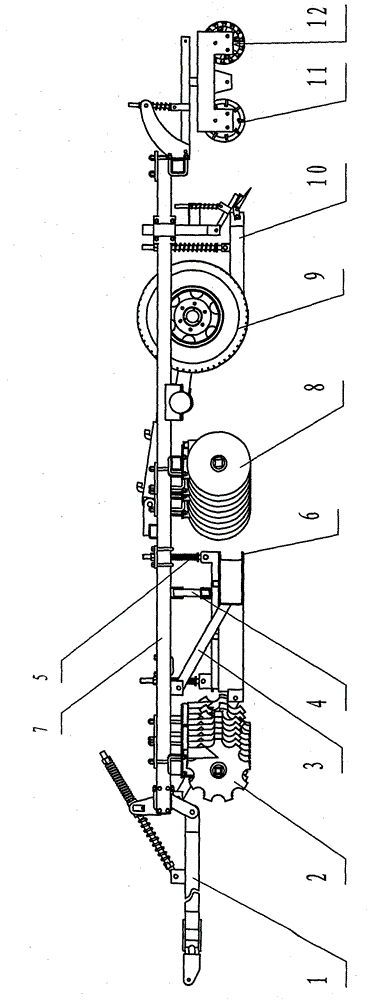

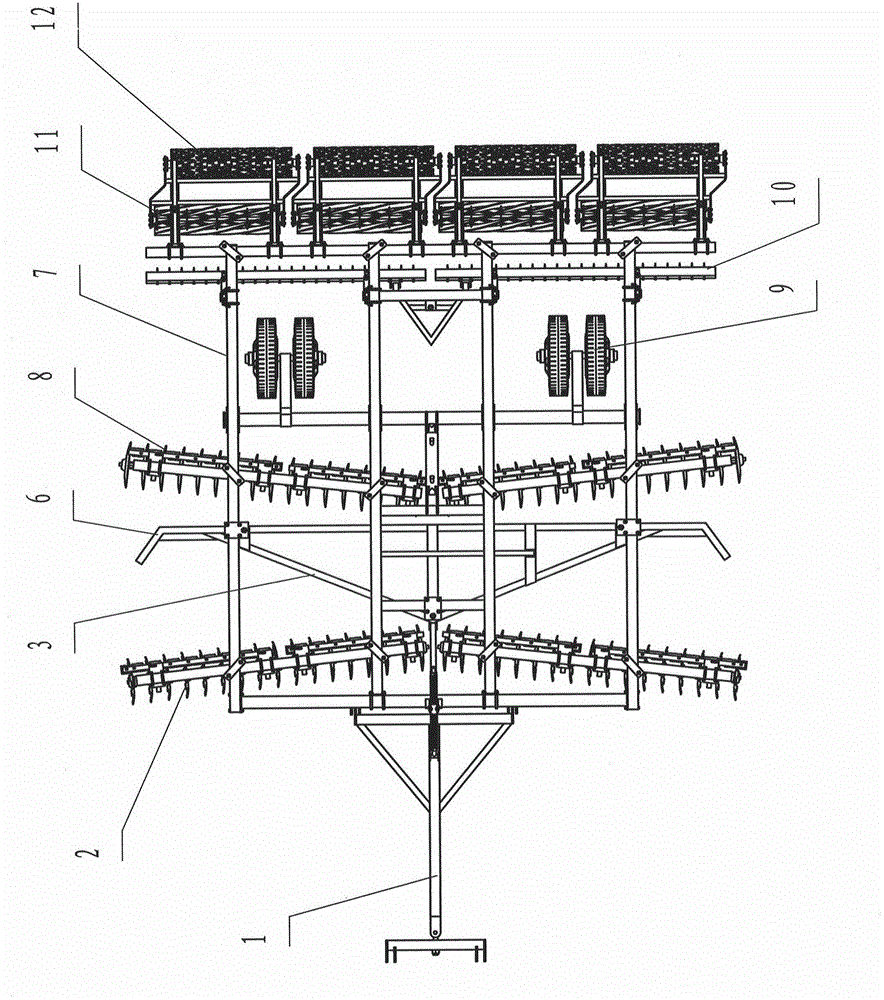

Combine seedbed preparation machine with depth-limiting function

InactiveCN104969677AReduce "white" pollutionImprove germination rateSpadesPloughsTraction framePulp and paper industry

The invention relates to a combine seedbed preparation machine with a depth-limiting function. The machine comprises a traction frame and a machine frame. A notched rake piece set, a round-disc rake piece set, a travelling ground wheel, a grading bar, a soil crushing wheel and a pressing wheel are sequentially arranged on the machine frame from front to back. A depth-limiting device is arranged under the machine frame at a place between the notched rake piece set and the round-disc rake piece set. The depth-limiting device is composed of a traction rod, a balancing bar, an adjusting rod and a trace-eliminating grading bar. The upper parts of the traction rod, the balancing bar and the adjusting rod are sequentially connected to the machine frame from front to back. The trace-eliminating grading bar is arranged on the lower ends of the traction rod, the balancing bar and the adjusting rod. One end of the traction rod is hinged on the machine frame. According to the invention, through adjusting the depth-limiting device, the requirement on land flatness when thick mulches are used can be met.

Owner:SHIHEZI GUANGDA AGRI MACHINERY

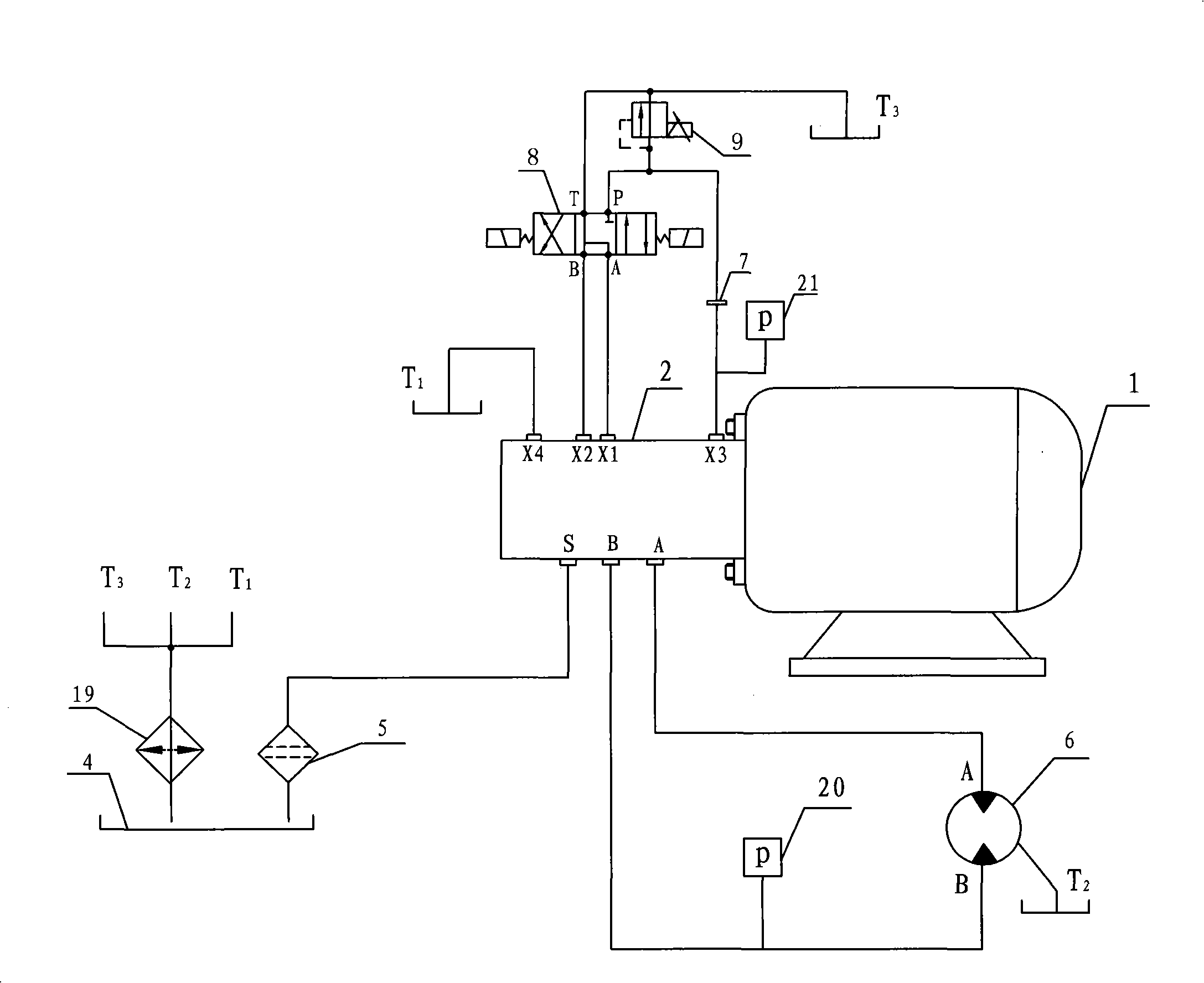

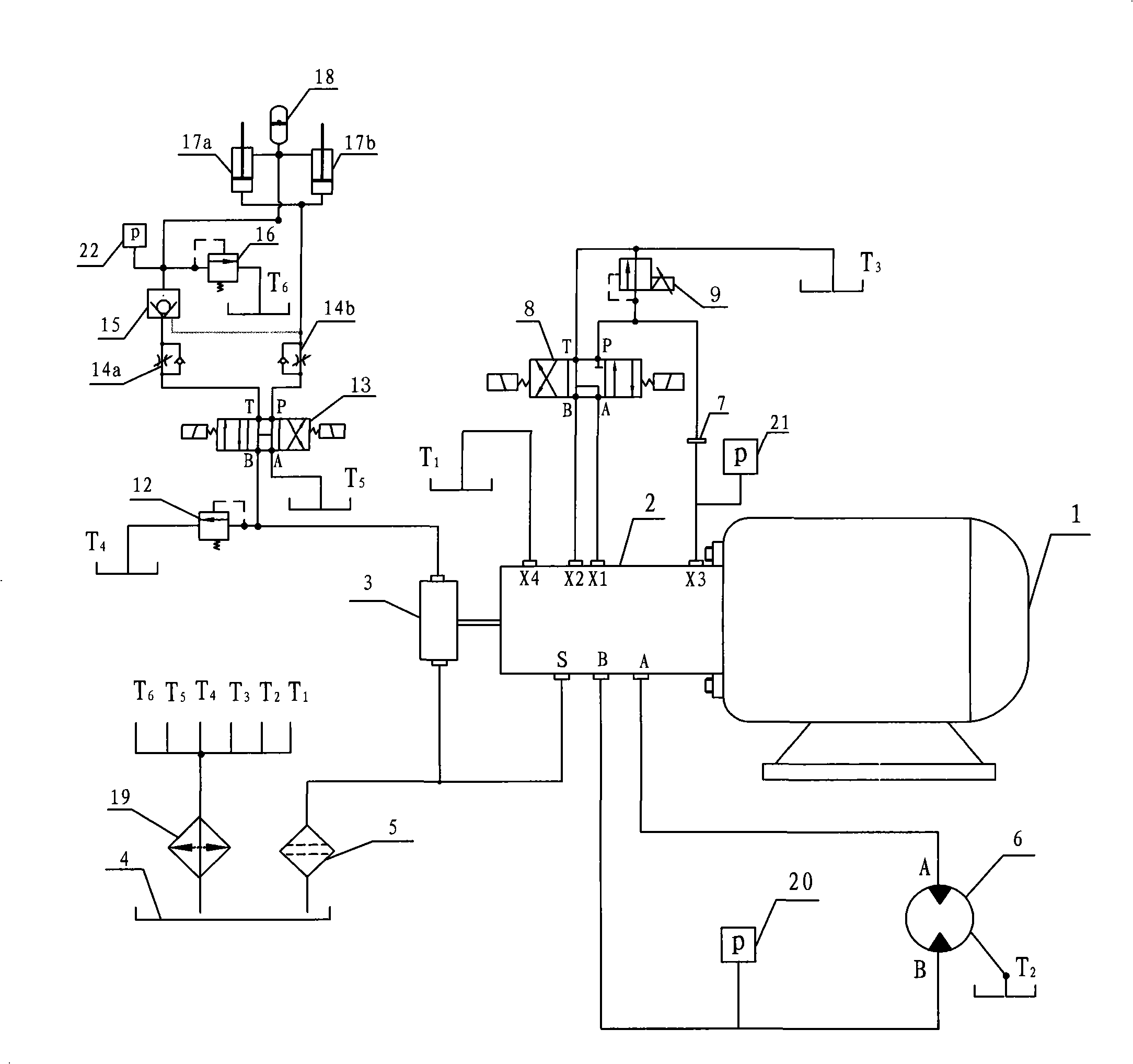

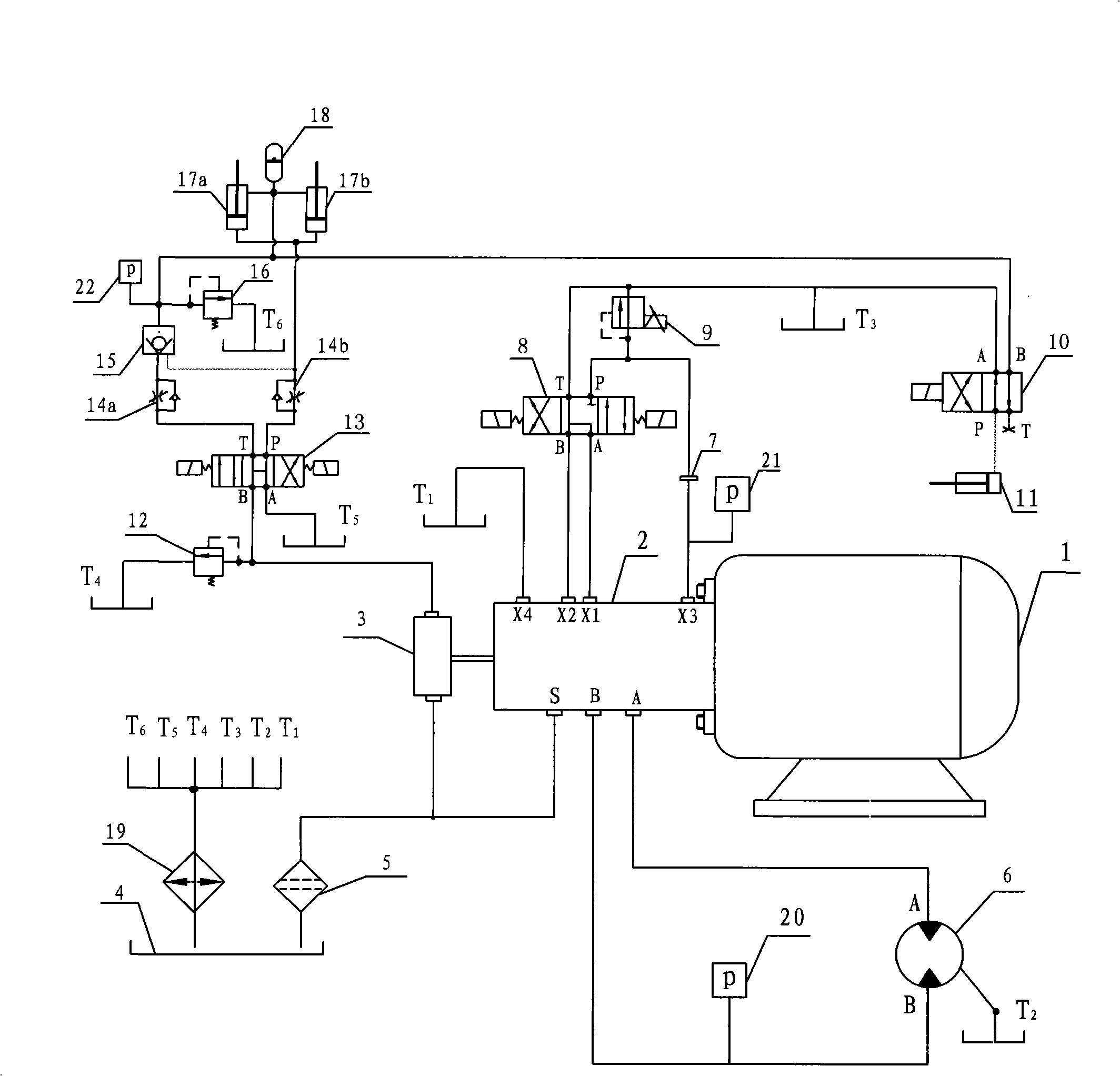

Ropeway fluid power system for mine

ActiveCN101492053BRealize no-load startExtended service lifeServomotorsRope railwaysLow speedGear pump

The invention discloses a hydraulic driving system for a ropeway for mines, which comprises a motor, a closed type pump, a gear pump, the hydraulic driving system, a hydraulic tension system and a hydraulic brake system. The hydraulic driving system for the ropeway for the mines has the following advantages: (1) the hydraulic driving system can realize stepless speed adjustment and positive and reverse rotation of the ropeway, and the ropeway can rotate positively or reversely at a low speed (which can be set freely) to check a steel wire rope; (2) no-load starting of the motor can be realized so as to prolong service life of the motor and electrical elements; (3) acceleration and deceleration properties of starting and stopping can be freely set (the time for starting acceleration and stopping deceleration can be set) so as to improve riding comfort; (4) the hydraulic tension system has the characteristics of compact volume, large tensile force and stepless adjustment, and simultaneously can display the tensile force on line to ensure realization of tension of constant tensile force under the condition of load changing; (5) the system is suitable for severe working environmental (dusty, damp and explosion-proof) conditions, hydraulic oil flow flows between the hydraulic pump and the motor circularly, and a main oil path is not contacted with air directly, so air suction cannot occur and the system is not easy to be polluted; and (6) because a flame-proof device (such as a flame-proof transducer) is not needed to adjust speed, the hydraulic system for adjusting speed is more safe in the underground gas environment due to no explosion danger factor.

Owner:XIANGTAN HENGXIN IND

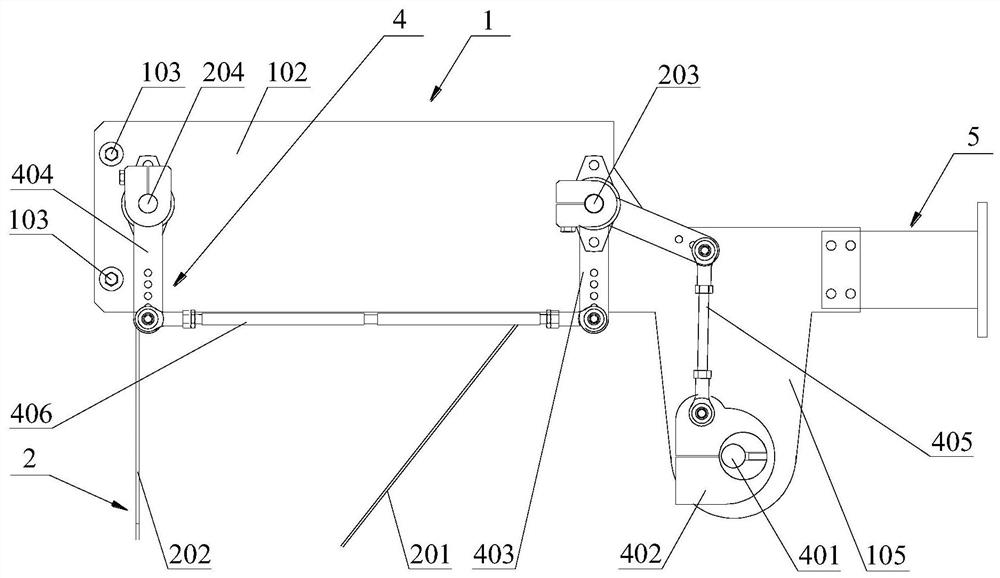

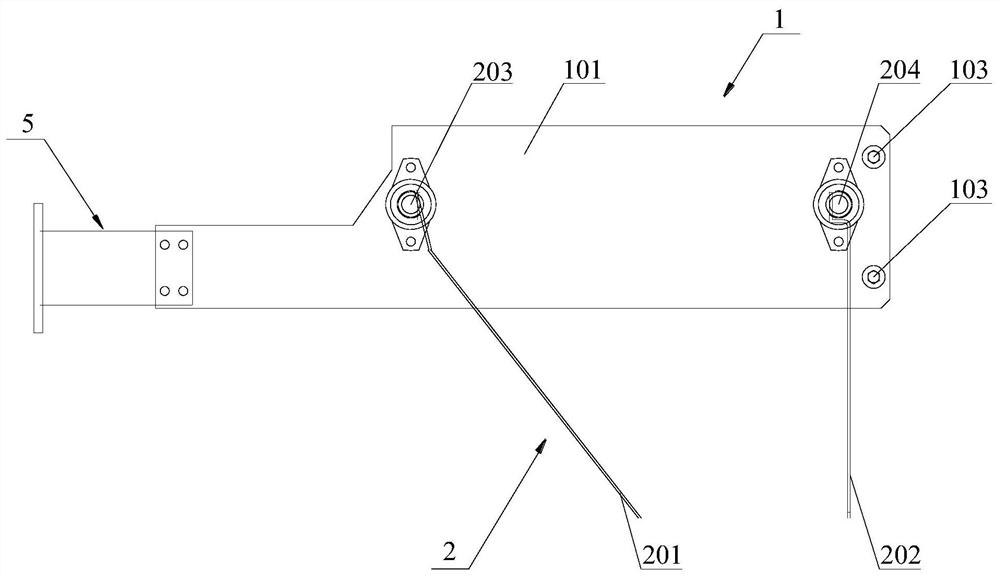

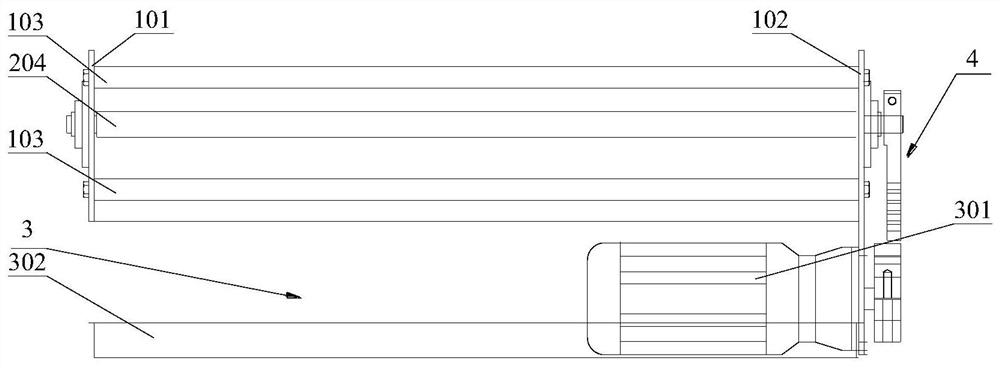

Device for distributing material uniformly

InactiveCN111717688AConsistent densityNo cavitationConveyorsTobacco treatmentStructural engineeringMechanical engineering

The invention provides a device for distributing a material uniformly. The device for distributing the material uniformly comprises a supporting portion, a material-uniform distributing portion, a driving portion and a linkage portion. The material-uniform distributing portion is hung on the supporting portion, and through reciprocating swinging on the supporting portion, tobacco in the discharging port of a tobacco cutter vibrating conveyor is stirred uniformly by the material-uniform distributing portion. The driving portion is arranged on the supporting portion and provides swinging power for the material-uniform distributing portion. The linkage portion is connected between the material-uniform distributing portion and the driving portion, and power output by the driving portion is transmitted to the material-uniform distributing portion by the linkage portion. By means of the device for distributing the material uniformly, density of middle material falling onto the feeding vibrating conveyor and density of the material on two sides can be basically consistent; the material is guaranteed to become loose and be in a short straight line shape; under the circumstance of uniform feeding, the aiding force of loose tobacco by the blade gate of the tobacco cutter is the same; no hollow-cavity phenomenon occurs; the phenomena such as slice running and stacking of the material arereduced greatly; and the shredding quality is improved.

Owner:SHANGHAI TOBACCO GRP CO LTD

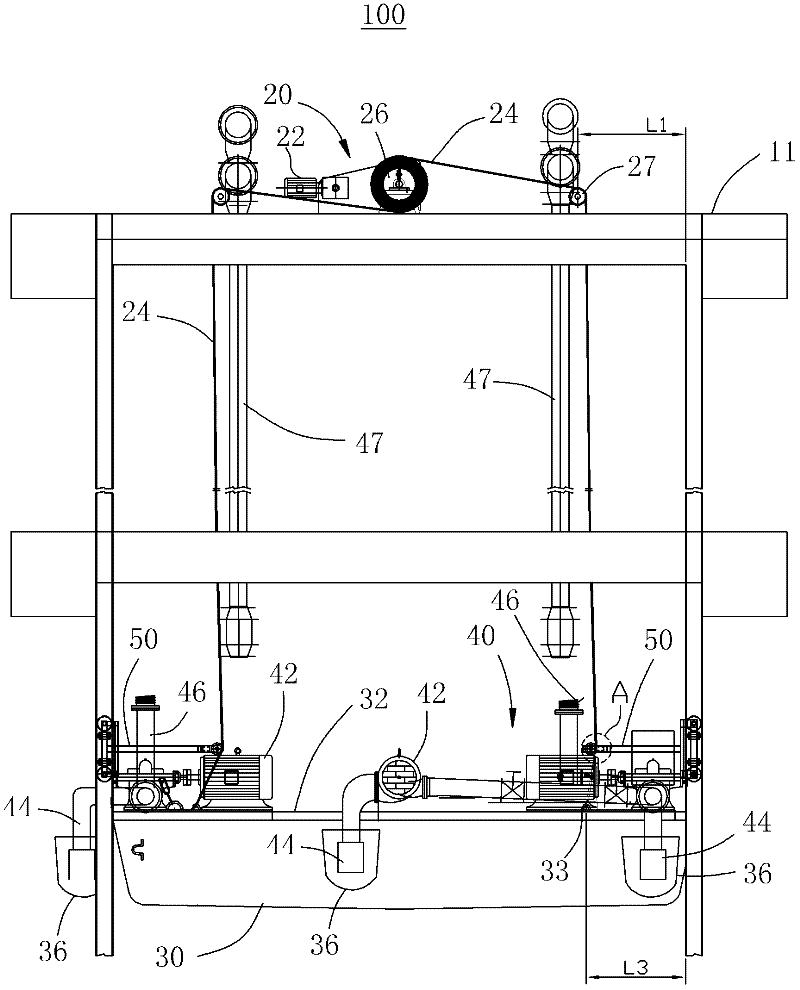

Automatic control lifting type shipyard water supply system

ActiveCN102383464ANo cavitationGuaranteed uptimePumping plantsDrinking water installationAutomatic controlAutomatic train control

The invention relates to an automatic control lifting type shipyard water supply system, which comprises a positioning system, a lifting system, a shipyard system, a centrifugal pump running system and an electrical automatic control system which controls the lifting system. The positioning system comprises a plurality of guide columns and a plurality of guide sliding devices, and each guide sliding device slides along corresponding guide columns. The shipyard system comprises a shipyard seat, and the shipyard seat is connected with the guide columns through the guide sliding devices. The lifting system is contacted with the guide sliding devices and tracts the guide sliding devices to slide along the guide columns and tracts the shipyard seat to lift and descend. The centrifugal pump running system is arranged on the shipyard seat. The automatic control lifting type shipyard water supply system is automatically controlled by the electrical automatic control system, can enable the centrifugal pump running system, the shipyard system and the lifting system to be controlled by the electrical automatic control to rise or descend along the guide columns along with the change of water level, and guarantees normal running of water supply of the automatic control lifting type shipyard water supply system.

Owner:XINYI GLASS WUHU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com