Hydrodynamic radial bearing and centrifugal pump

A technology of radial bearings and hydrodynamic pressure, applied in the field of centrifugal pumps, can solve problems such as disappearance, high temperature dilution, and lubricant aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

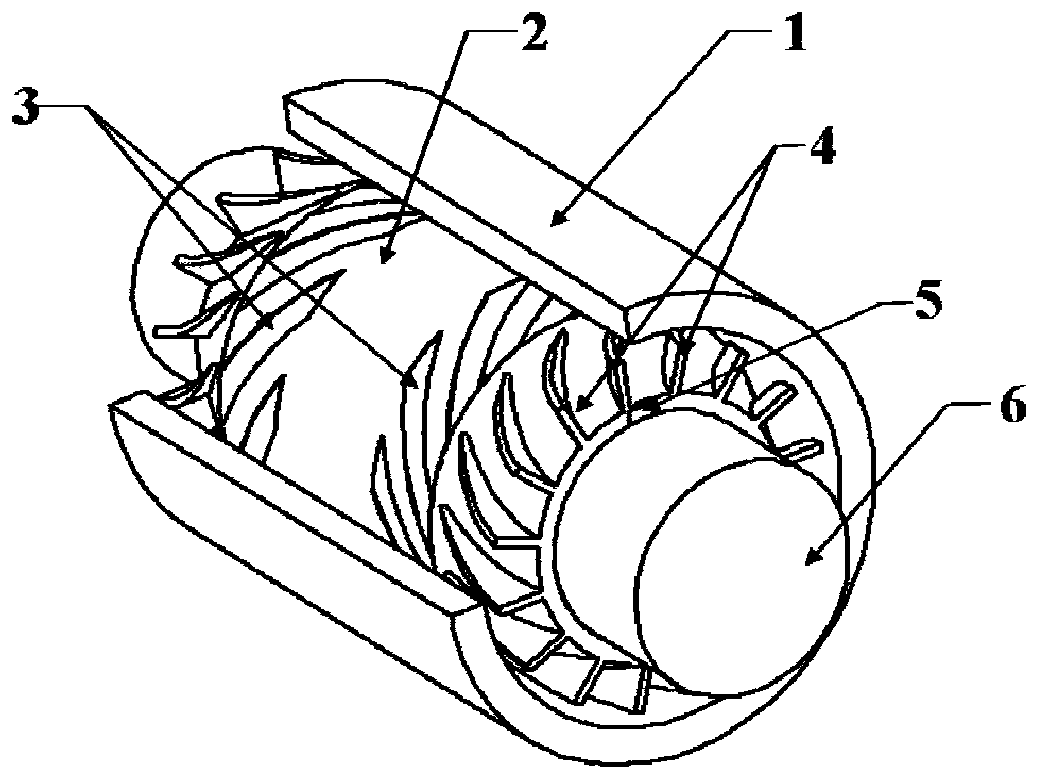

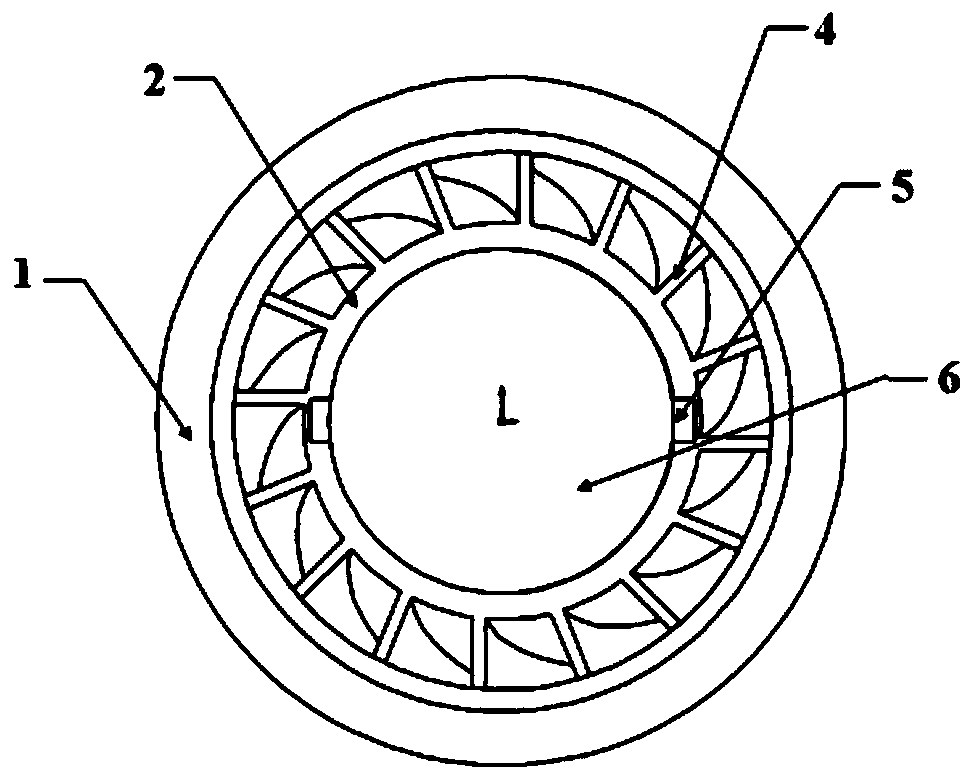

[0027] refer to figure 1 and figure 2 , the hydrodynamic radial bearing provided by the embodiment of the present invention includes a bushing 1 and a bearing body 2 inside the bushing 1, the bushing 1 and the bearing body 2 are independent of each other and a pre-gap is formed between them, so When the hydrodynamic radial bearing is in operation, a dynamic pressure liquid film is formed between the inner surface of the shaft sleeve 1 and the outer surface of the bearing body 2 . For ease of description, a rotating shaft 6 is also provided in the bearing body 2 , and a keyway 5 is provided on the inner side of the bearing body 2 , and the keyway 5 cooperates with a key provided on the rotating shaft 6 .

[0028] exist figure 1In the orientation shown, the bearing body 2 includes two front and rear end surfaces and a side surface located between the front and rear two end surfaces. Two symmetrical conical mesa surfaces are formed on the side of the bearing body 2 near the f...

Embodiment 2

[0035] Some embodiments of the present invention also provide a centrifugal pump with the hydrodynamic radial bearing described in the above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com