Bendroflumethiazide tablet and preparation method thereof

Benfluflumethiazide tablets and Benfluflumethiazide technology, which are applied in the field of Benfluflumethiazide tablets and their preparation, can solve problems such as content differences among bendrofluthiazide tablets, and achieve easy industrialized large-scale production and preparation processes Simple, fast-dissolving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

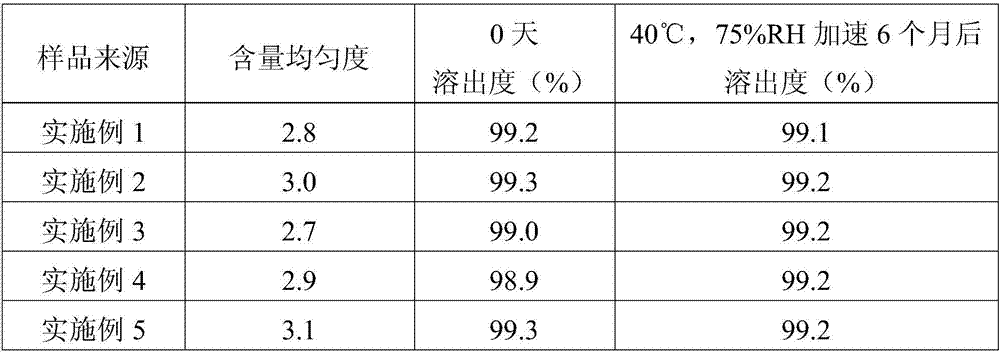

Examples

Embodiment 1

[0026] This embodiment provides a bendroflumethiazide tablet, which is made up of the following components in parts by weight: bendroflumethiazide 0.25Kg, microcrystalline cellulose PH-102 4Kg, lactose 6Kg, carboxymethyl starch sodium 0.4Kg, hard Magnesium fatty acid 0.03Kg.

[0027] The preparation method of above-mentioned bendroflumethiazide tablet, comprises the following steps:

[0028] (1) Perform jet milling of bendroflumethiazide, and the jet milling control D90=30-60 microns;

[0029] (2) get bendroflumethiazide, microcrystalline cellulose PH-102 and magnesium stearate and mix uniformly to obtain a mixed material;

[0030] (3) Add lactose and carboxymethyl starch sodium into the mixture, and mix well;

[0031] (4) Direct tablet compression by dry method, with a batch size of 100,000 tablets and a tablet specification of 2.5 mg / tablet.

Embodiment 2

[0033] This embodiment provides a bendroflumethiazide tablet, which is composed of the following components in parts by weight: bendroflumethiazide 0.25Kg, microcrystalline cellulose PH-102 6Kg, lactose 4Kg, carboxymethyl starch sodium 0.6Kg, hard Magnesium fatty acid 0.02Kg.

[0034] The preparation method of above-mentioned bendroflumethiazide tablet, comprises the following steps:

[0035] (1) Perform jet milling of bendroflumethiazide, and the jet milling control D90=30-60 microns;

[0036] (2) get bendroflumethiazide, microcrystalline cellulose PH-102 and magnesium stearate and mix uniformly to obtain a mixed material;

[0037] (3) Add lactose and carboxymethyl starch sodium into the mixture, and mix well;

[0038] (4) Direct tablet compression by dry method, with a batch size of 100,000 tablets and a tablet specification of 2.5 mg / tablet.

Embodiment 3

[0040] This embodiment provides a bendroflumethiazide tablet, which is composed of the following components in parts by weight: bendroflumethiazide 0.25Kg, microcrystalline cellulose PH-102 2Kg, lactose 8Kg, carboxymethyl starch sodium 0.2Kg, hard Magnesium fatty acid 0.04Kg.

[0041] The preparation method of above-mentioned bendroflumethiazide tablet, comprises the following steps:

[0042] (1) Perform jet milling of bendroflumethiazide, and the jet milling control D90=30-60 microns;

[0043] (2) get bendroflumethiazide, microcrystalline cellulose PH-102 and magnesium stearate and mix uniformly to obtain a mixed material;

[0044] (3) Add lactose and carboxymethyl starch sodium into the mixture, and mix well;

[0045] (4) Direct tablet compression by dry method, with a batch size of 100,000 tablets and a tablet specification of 2.5 mg / tablet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com