Patents

Literature

33results about How to "Large liquid flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

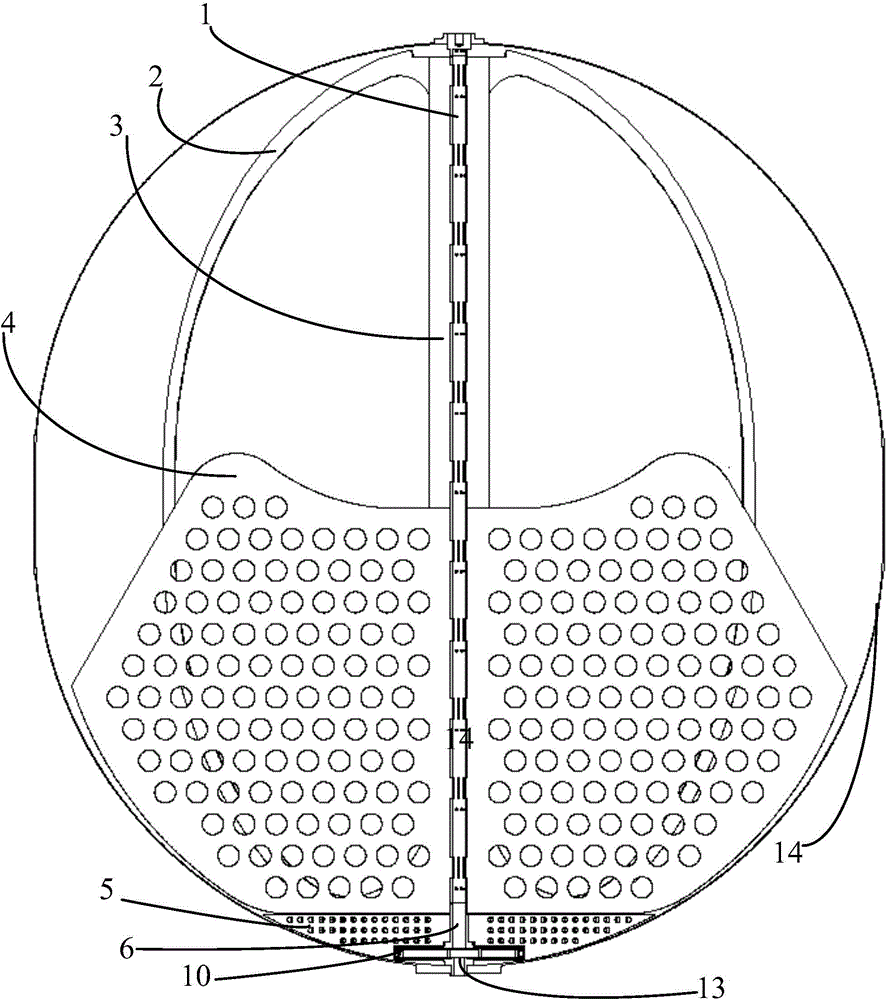

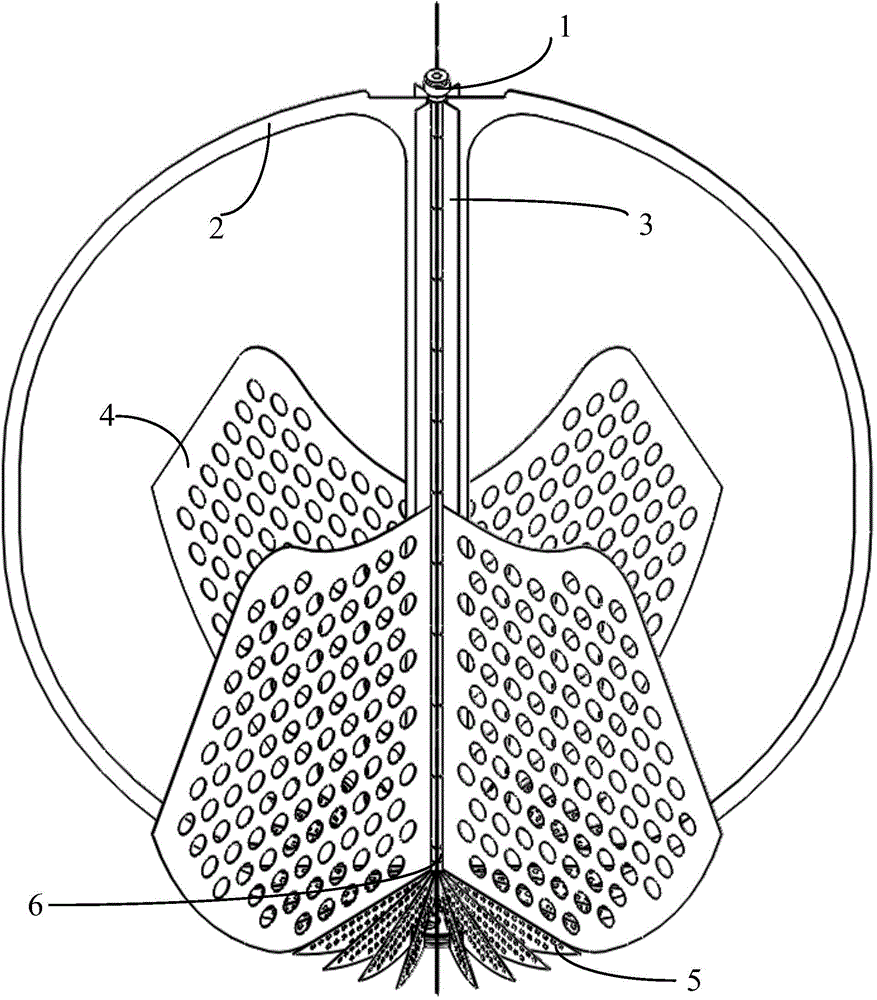

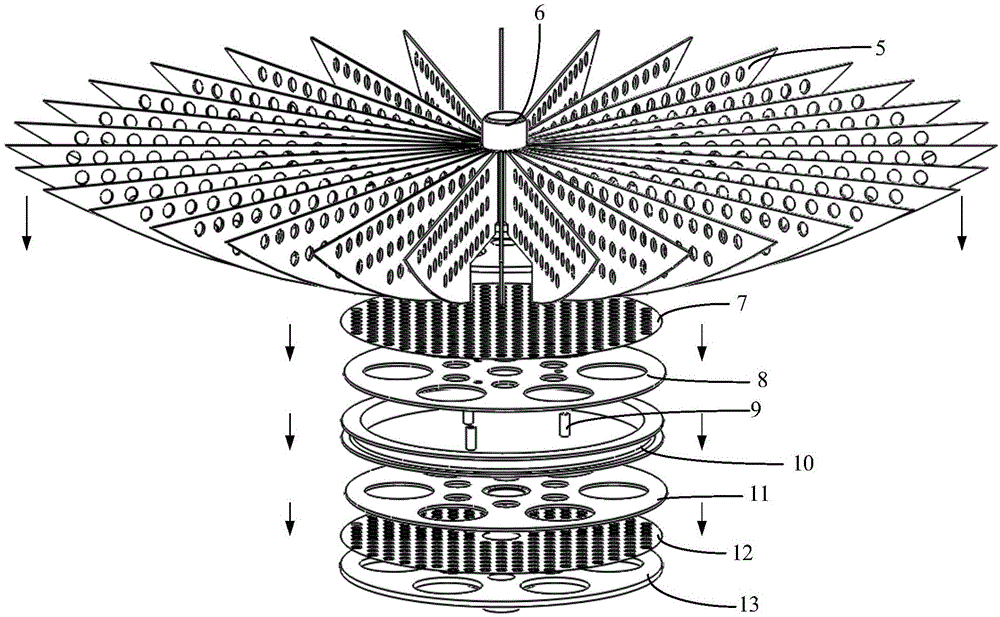

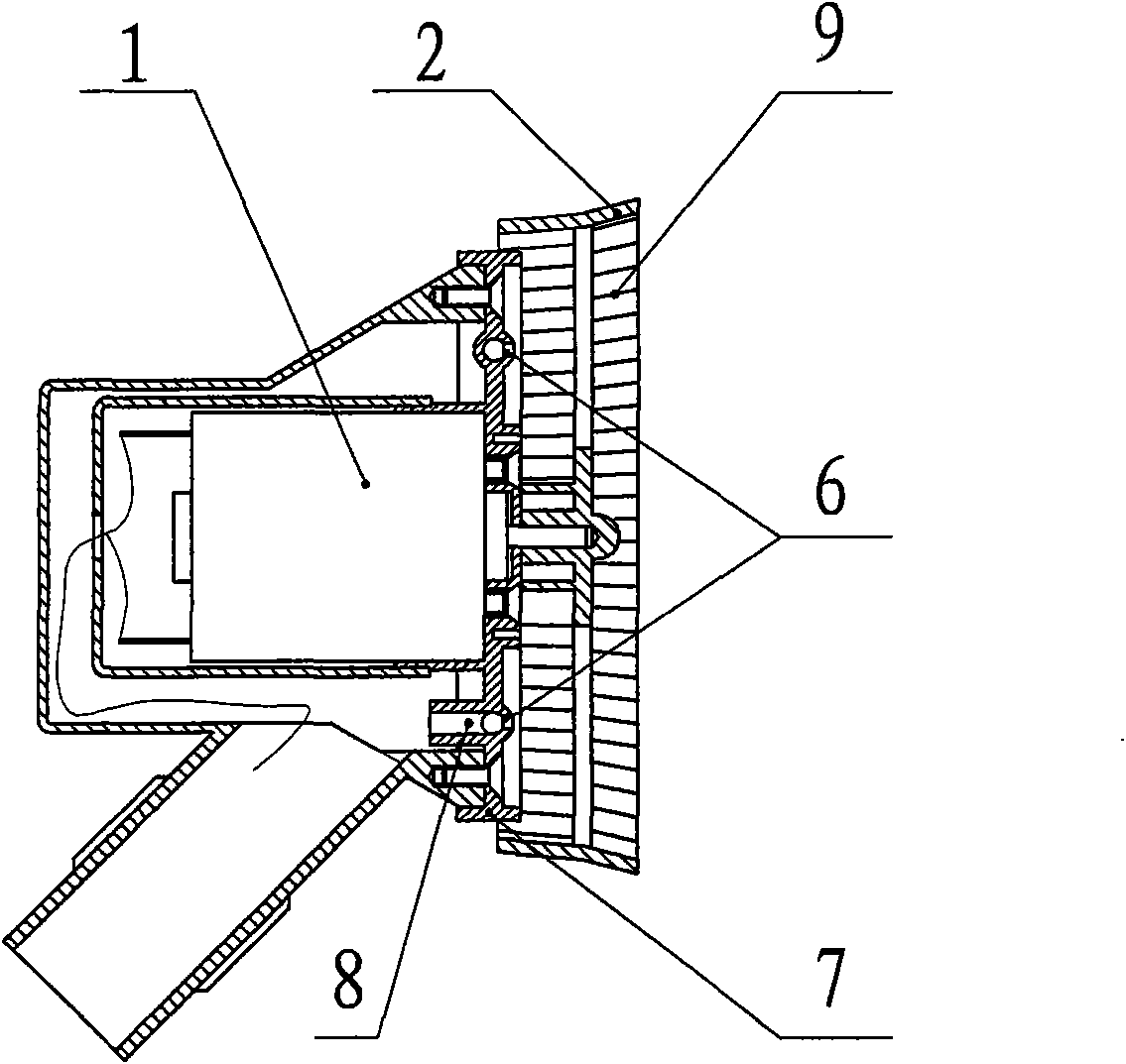

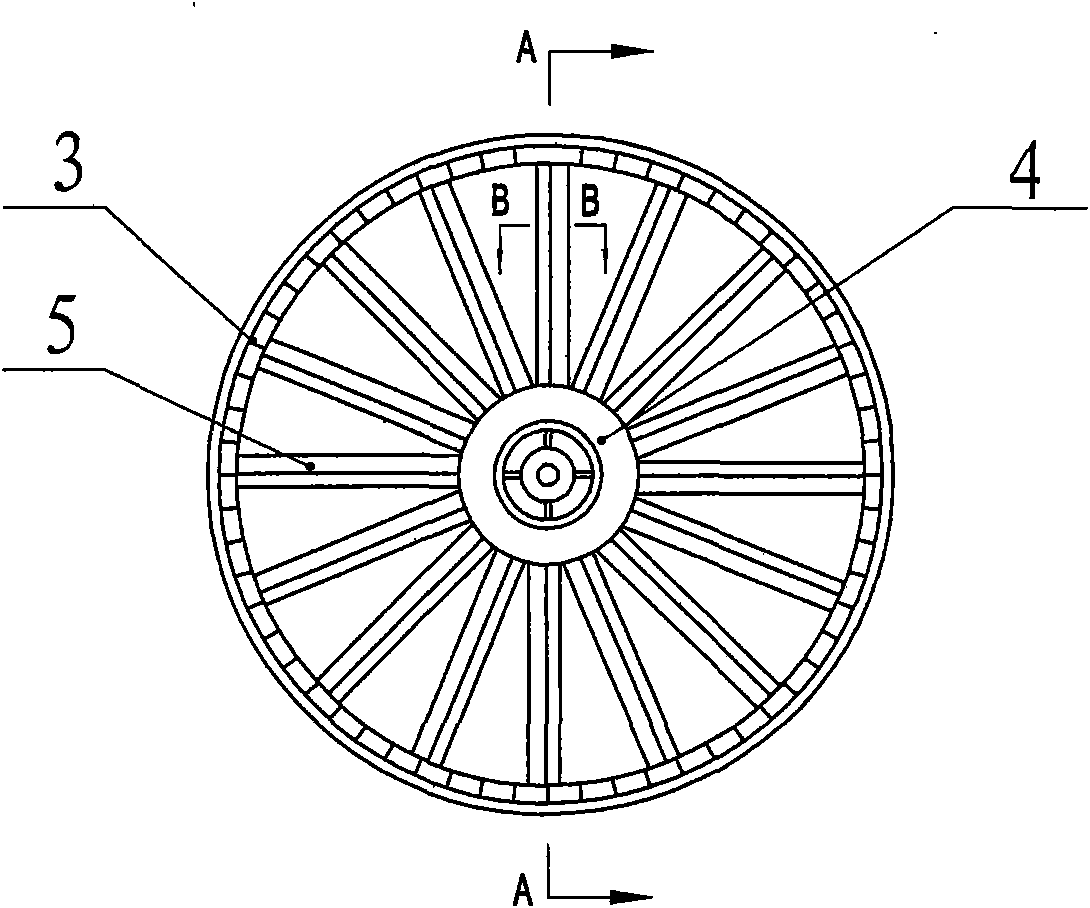

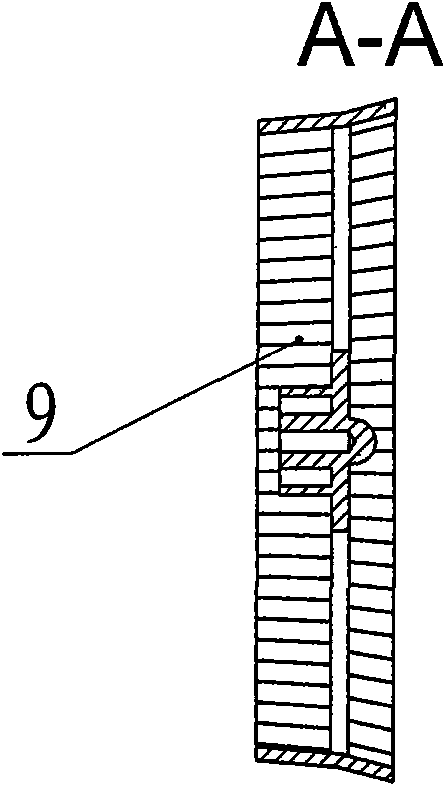

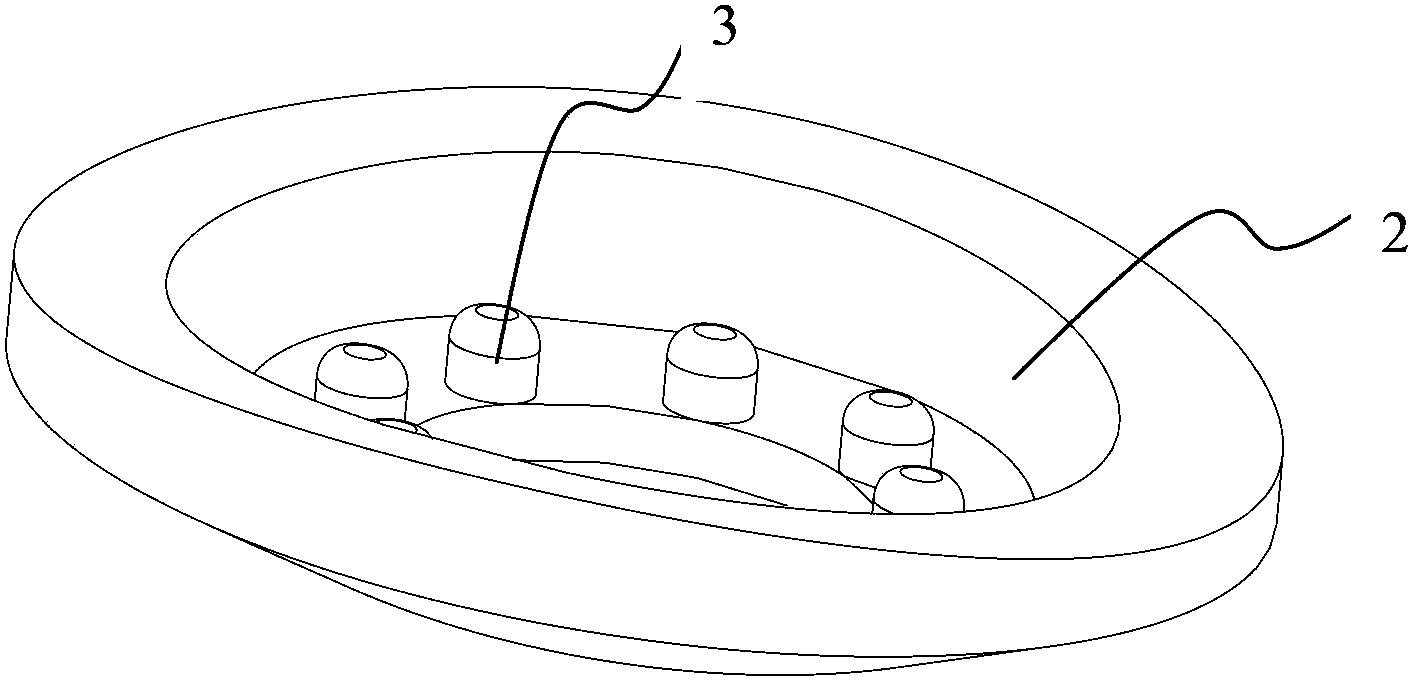

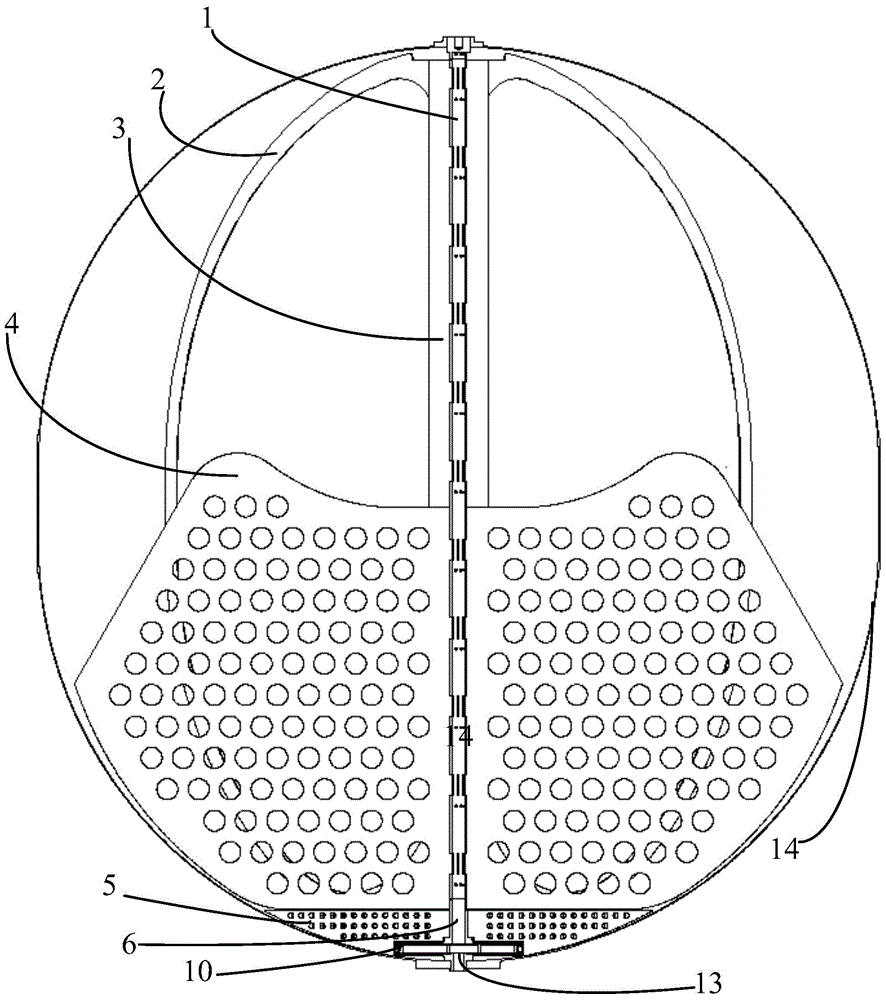

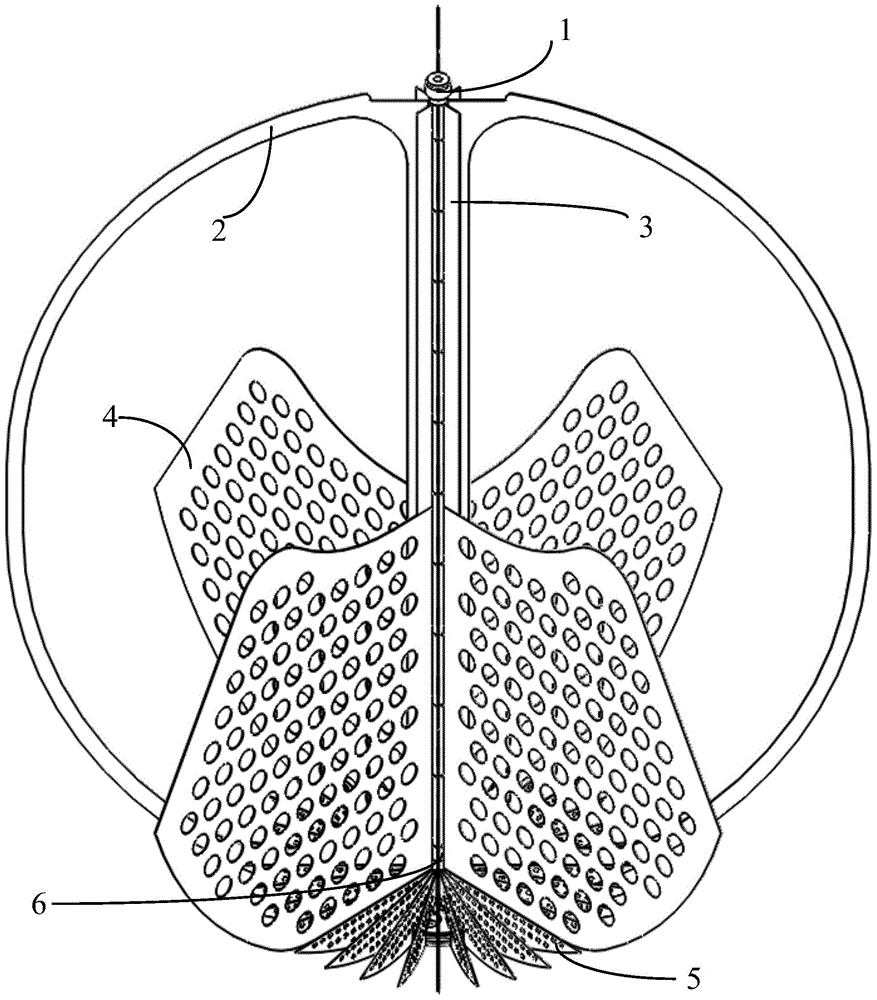

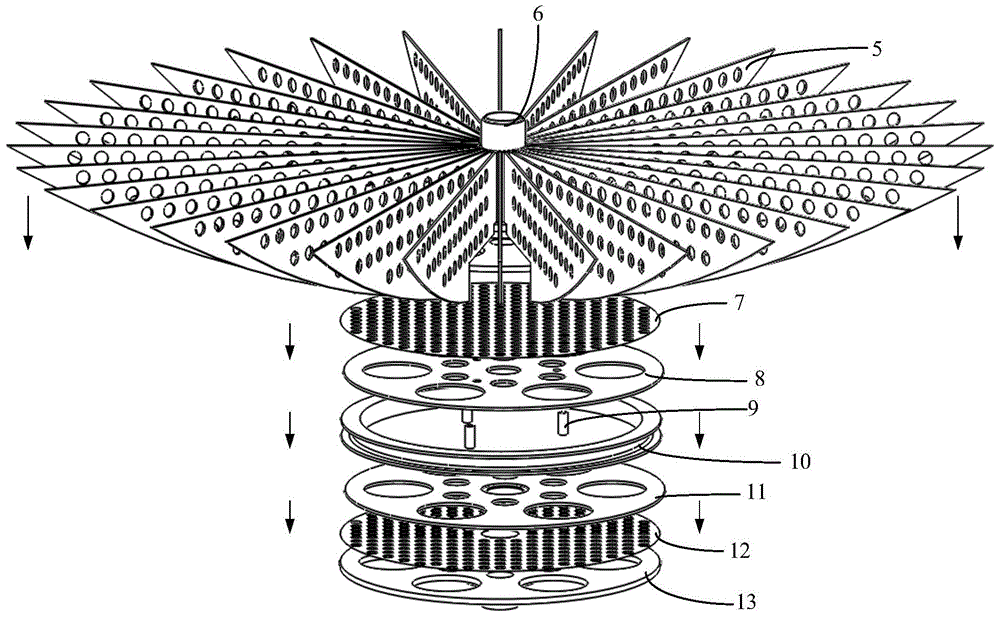

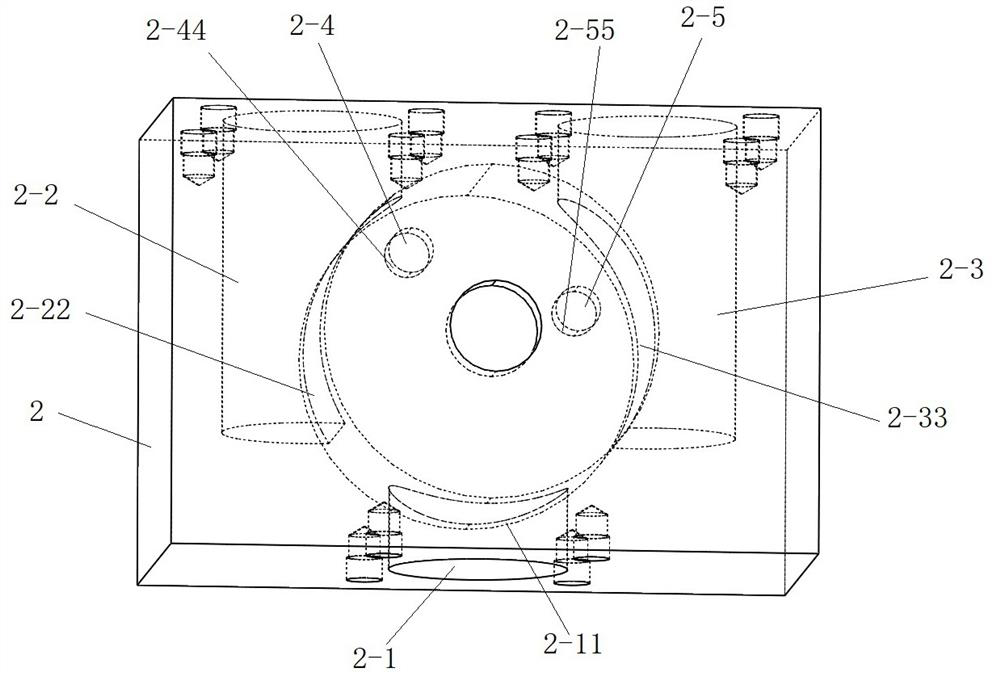

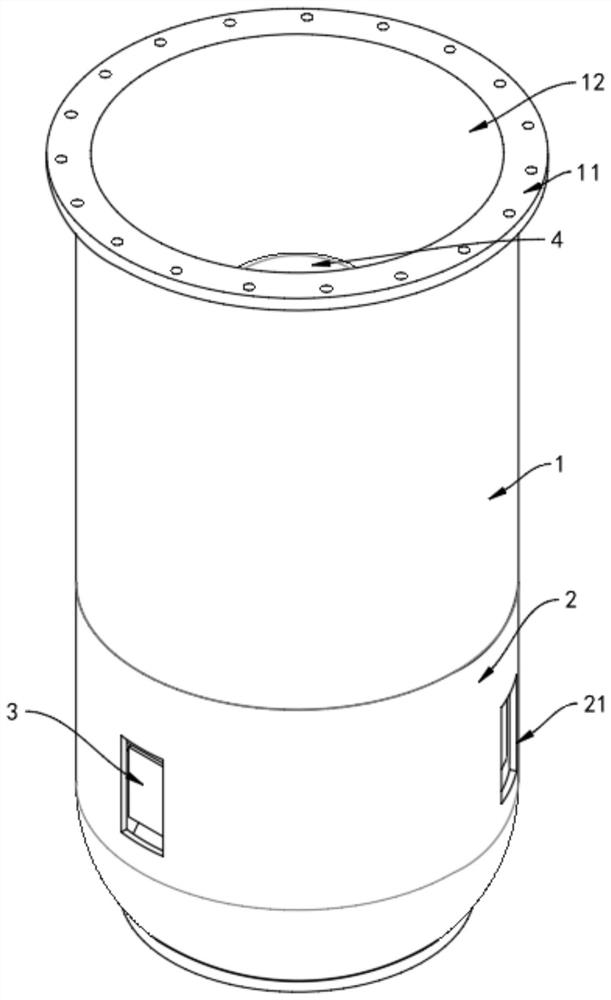

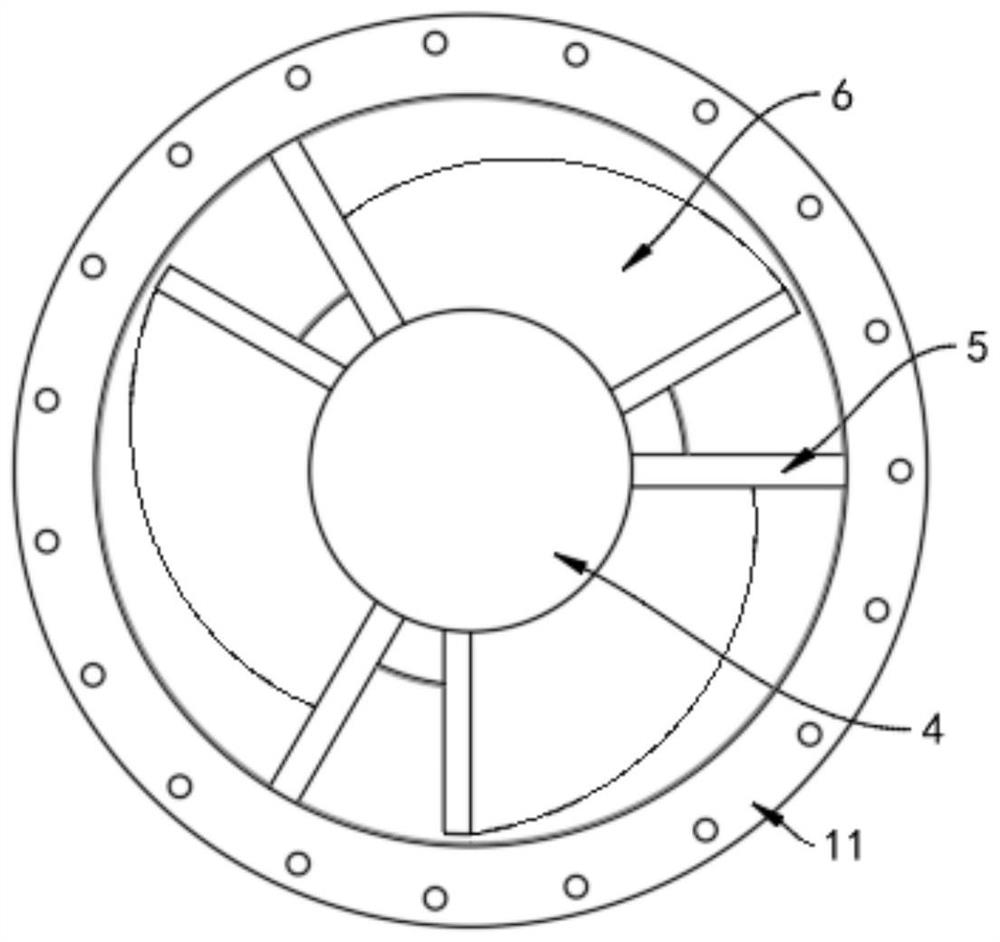

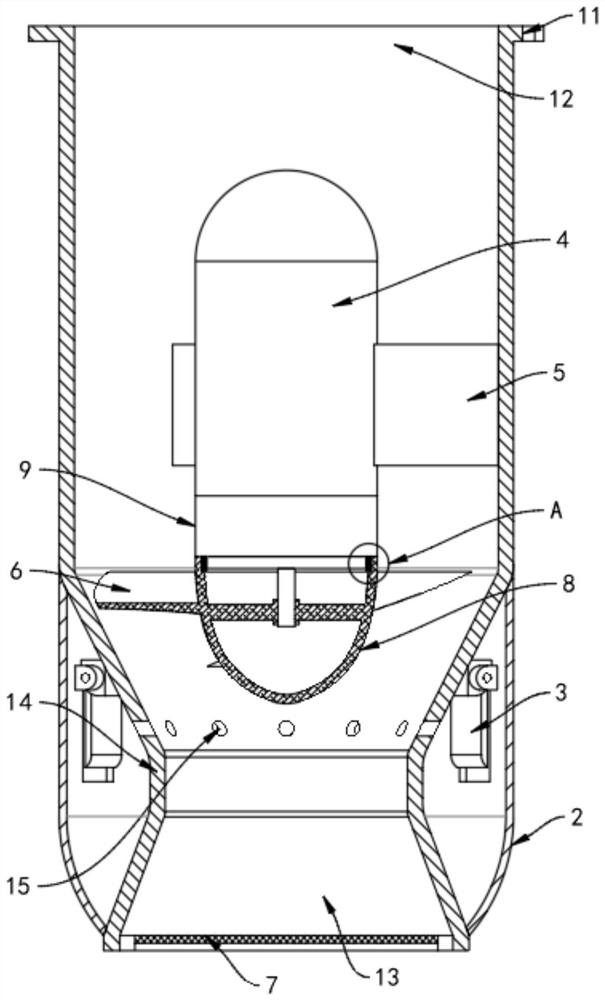

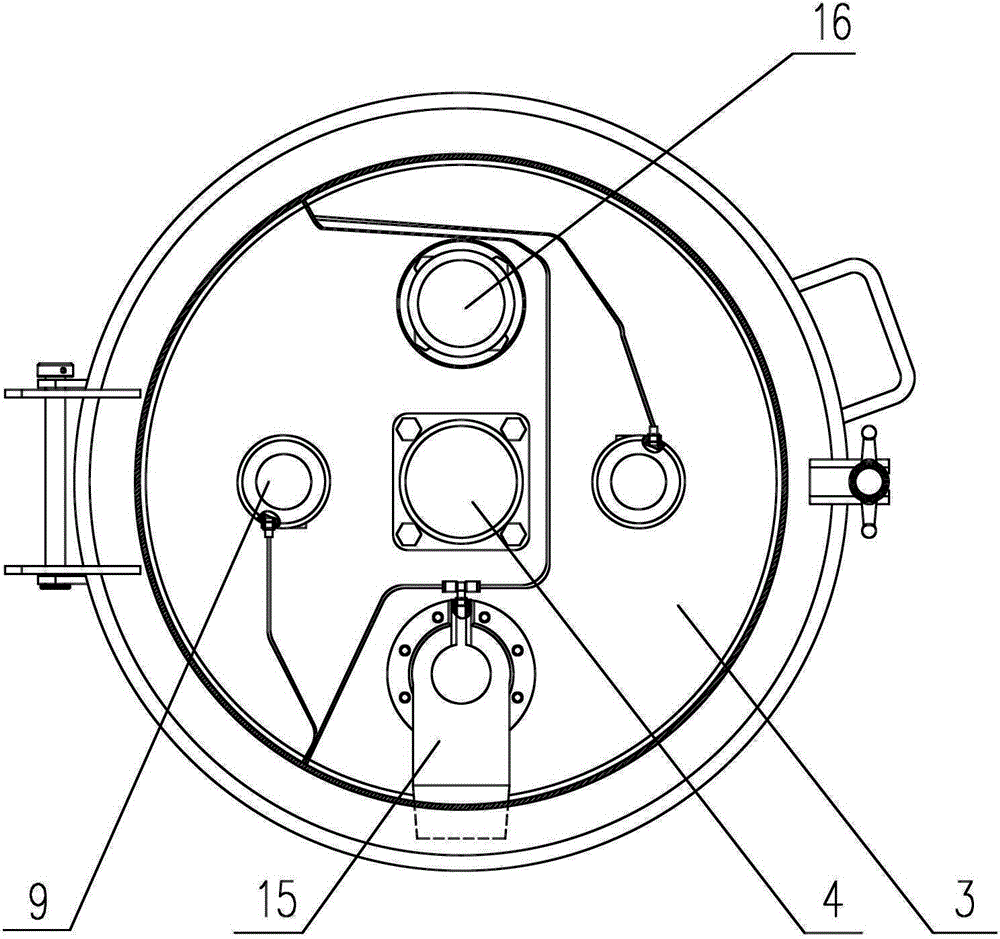

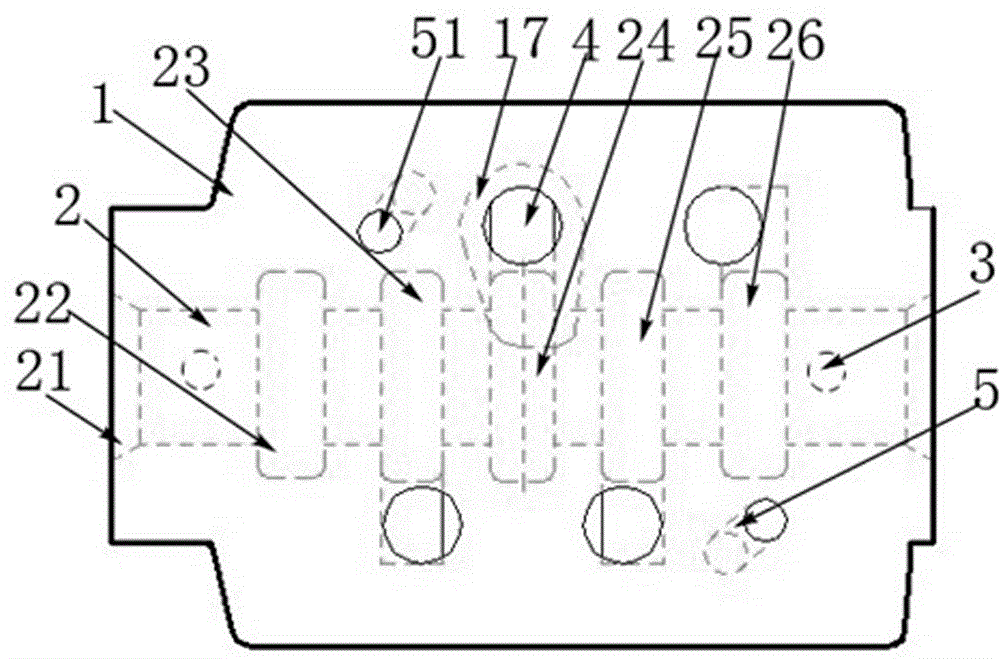

Novel propellant management device used in propellant storage box

ActiveCN104691786APromote circulationSimple structureCosmonautic propulsion system apparatusOrbitPropellant

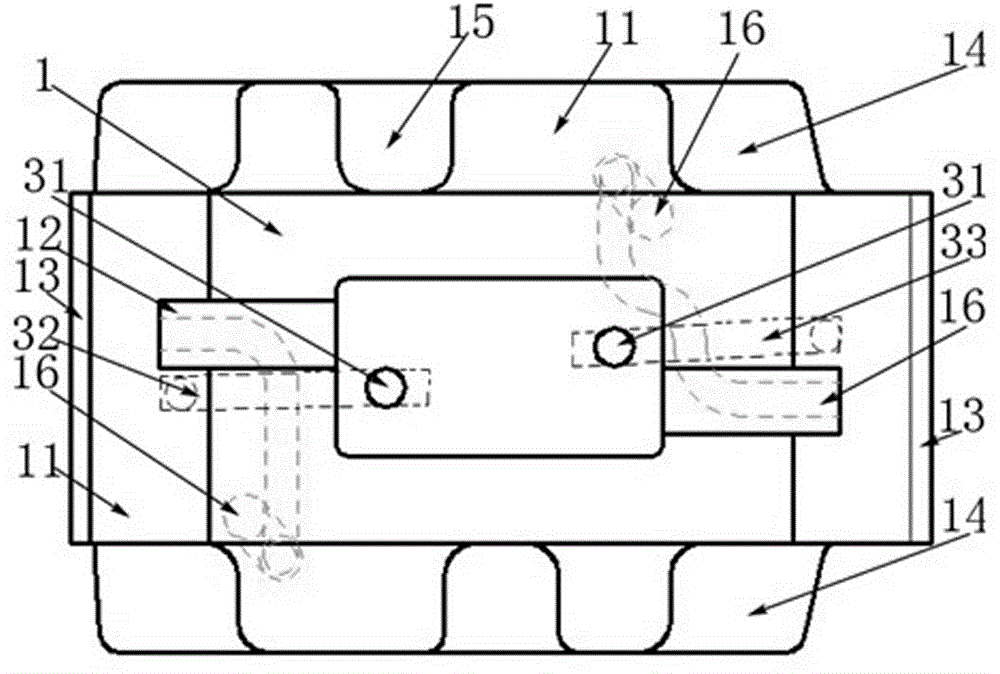

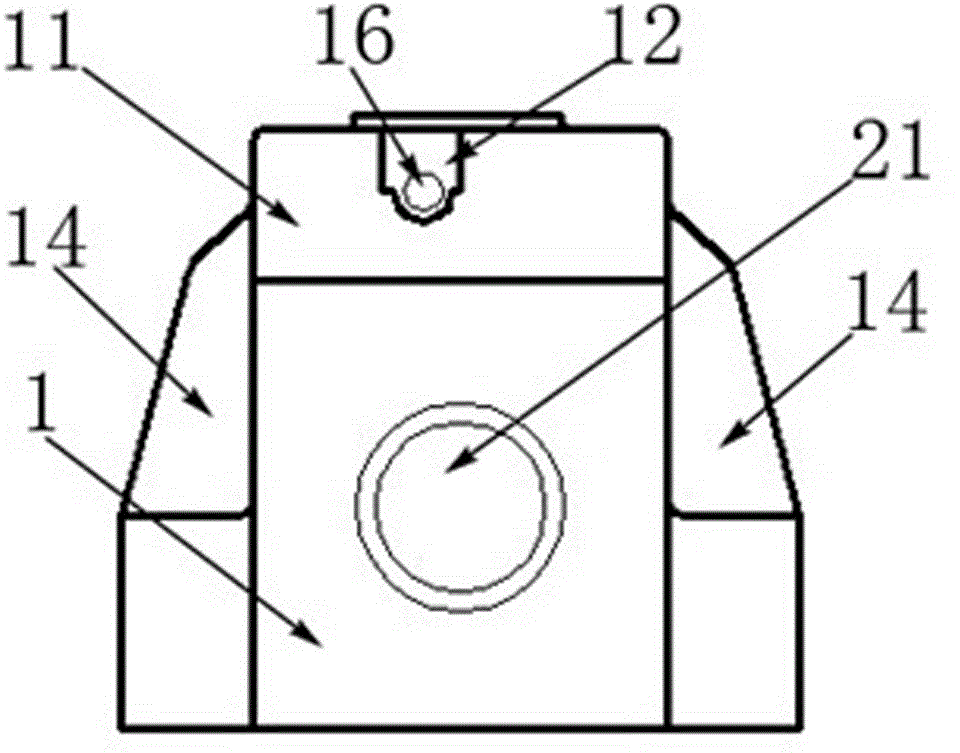

A novel propellant management device used in a propellant storage box comprises a central supporting column, flow guide blades, supporting column blades, large blades, liquid storage blades, an upper pressing plate, an upper mesh, an upper supporting plate, small cylinders, a framework, a lower pressing plate, a lower mesh and a lower supporting plate, wherein the flow guide blades, the supporting column blades and the large blades are all fixedly mounted on the central supporting column in the radial direction to form an integral structure, the integral structure is fixedly mounted on the upper pressing plate through the central supporting column, the supporting column blades and the large blades are mounted in the same plane, and a mounting plane of each flow guide blade and a mounting plane of each large blade form a certain included angle; the liquid storage blades are fixedly mounted on the upper pressing plate in the radial direction; the upper pressing plate, the upper mesh, the upper supporting plate, the small cylinders, the middle framework, the lower pressing plate, the lower mesh and the lower supporting plate are sequentially fixedly mounted from top to bottom to form the integral structure, namely, a liquid accumulation assembly. The novel propellant management device has the inhibition function on shaking of liquid, performs comprehensive management on propellants and is simple in structure, high in strength and reliability and large in liquid storage capacity, the on-orbit work application range is large, the on-orbit liquid discharge speed is high, and meanwhile, repeated large-flow filling on the ground can be realized.

Owner:BEIJING INST OF CONTROL ENG

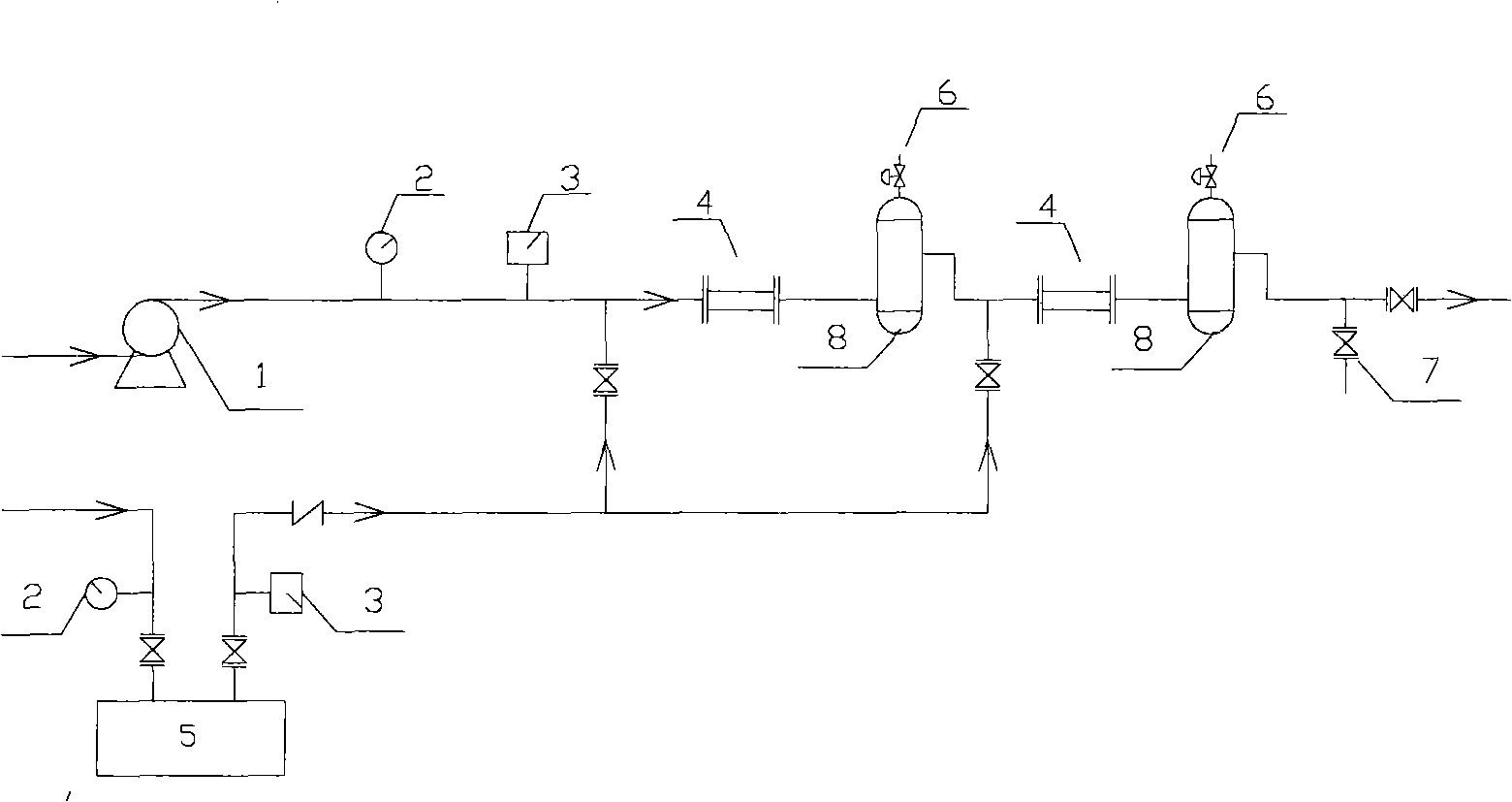

Method for coupling treatment of sewage water of waterpower cavitation and ozone

InactiveCN101343108ANo secondary pollutionImprove adaptabilityWater/sewage treatment by oxidationOzone generatorCavitation

Disclosed is a method for treating sewage by hydrodynamic cavitation and ozone coupling, which is characterized in that: the sewage treatment technique is composed of a centrifugal pump, an ozone generator and a cavitation generator and is realized by utilizing the cavitation effect produced by hydrodynamic cavitation and strong oxidation and coupling functions of ozone, the ozone produced by the ozone generator is doped into the sewage to enter the cavitation generator together and produce the cavitation effect in the cavitation generator, the contact area of ozone and sewage is increased through the micro-jet produced in a cavitation region, so as to extend the action time of ozone in sewage and change the amount of gas nucleus and distribution of gas nucleus in sewage, degrade oxygen consuming matters in the sewage, improve the coupling effect of cavitation and ozone, and achieve the purpose of reducing sewage COD, and the treated sewage can surely reach the required COD indexes by adjusting the treatment grade as required. Compared with the prior art, the technique has the advantages of simple process flow, convenient operation, high energy utilization ratio, strong adaptability, high efficiency, large treatment capacity, non secondary pollution and low cost.

Owner:SINOPEC PETROLEUM ENG DESIGN

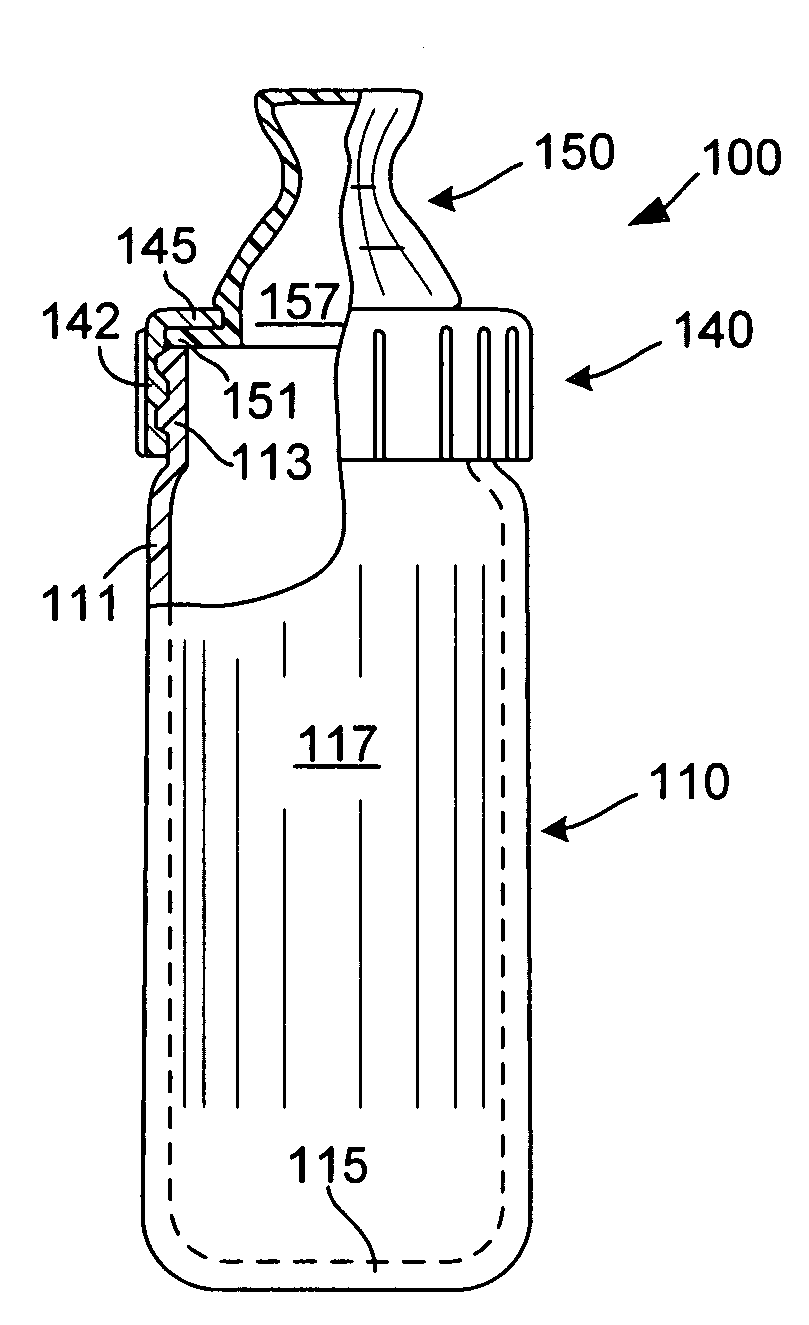

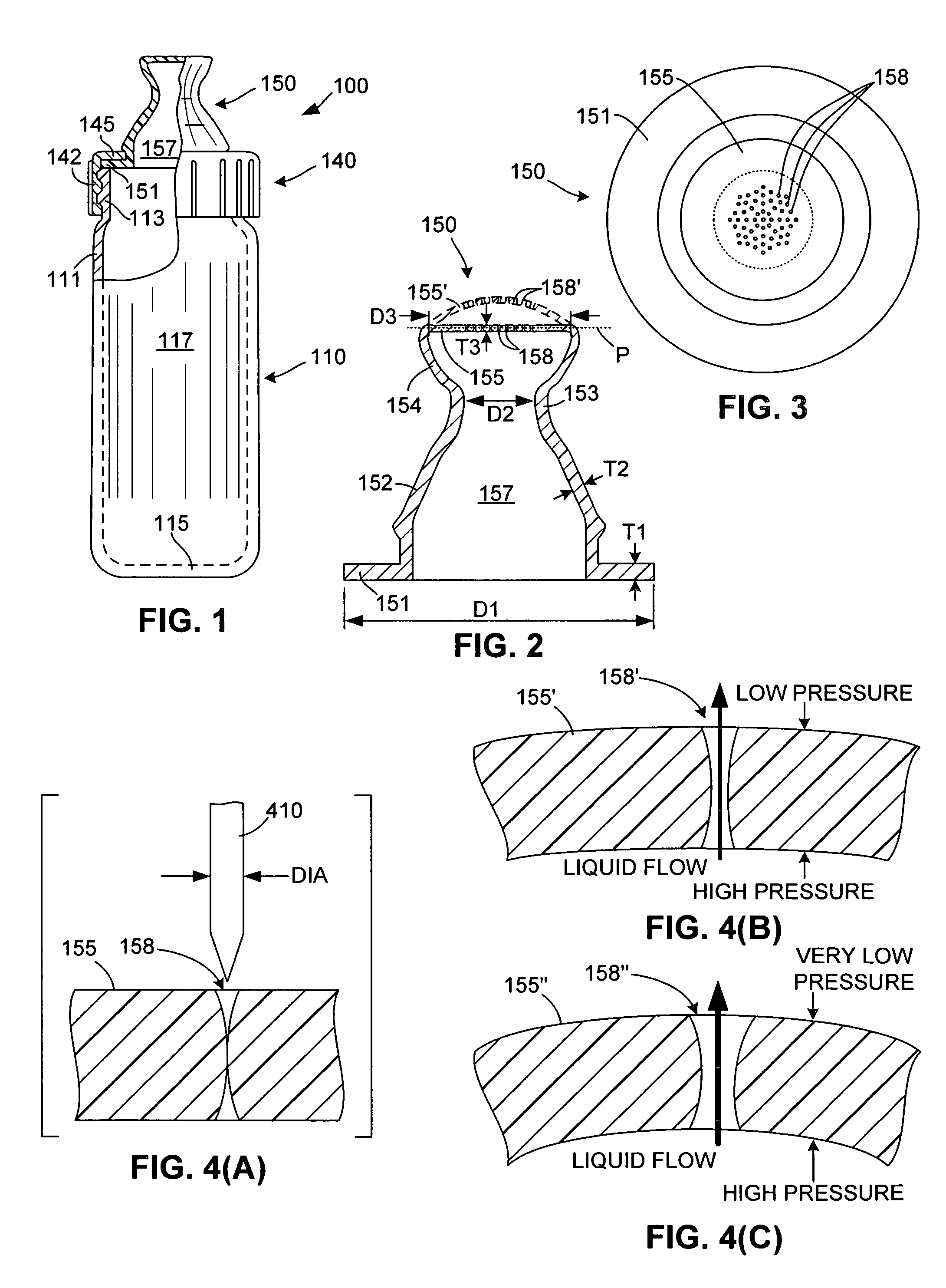

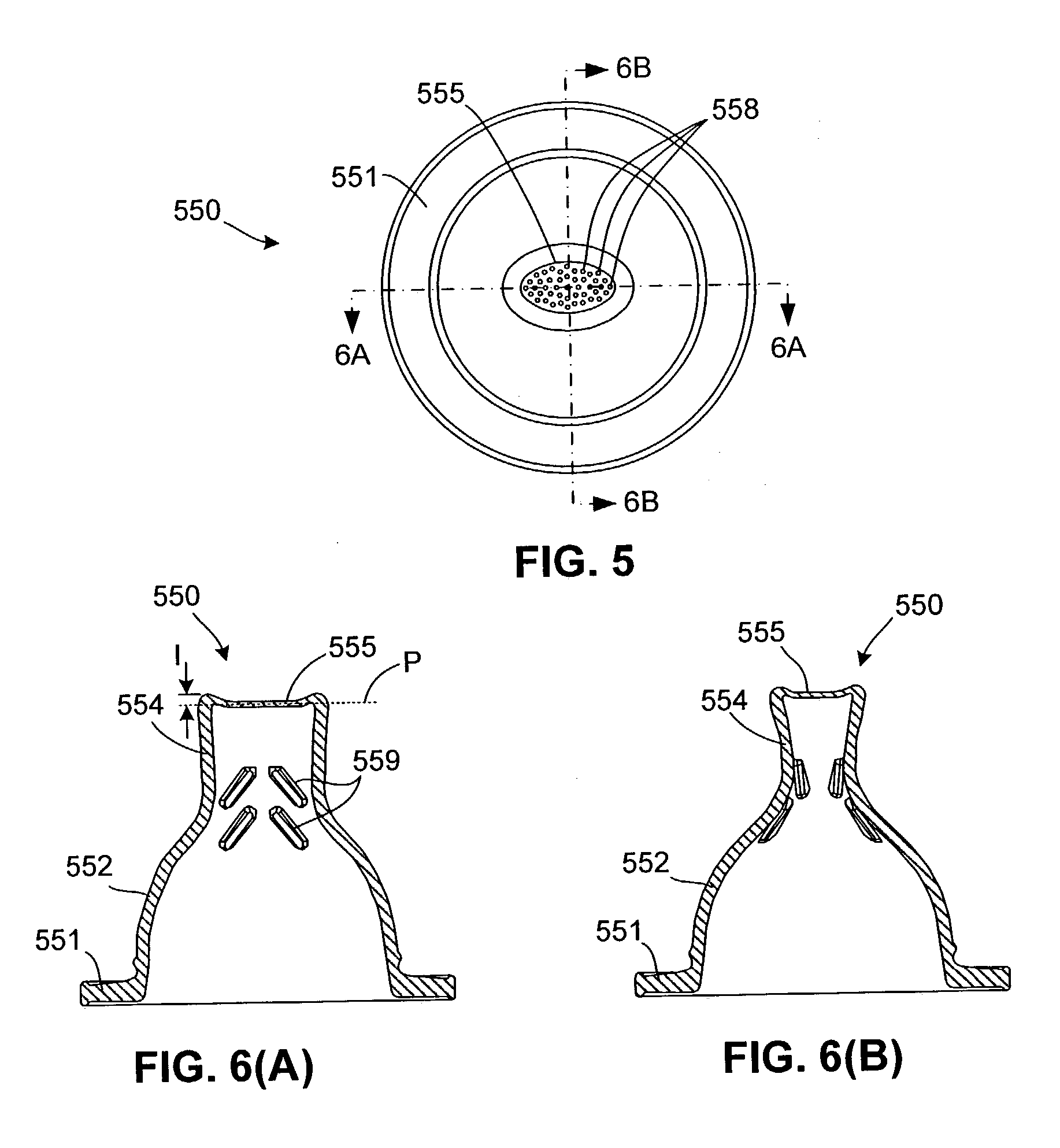

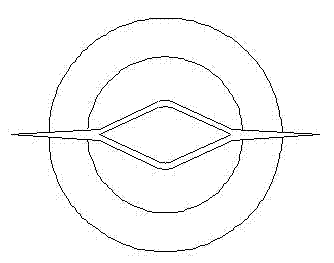

Nipple with multiple pinholes for baby bottle assembly

A baby bottle assembly including a nipple having a substantially flat membrane defining multiple pinholes for controlling the flow of liquid. The nipple is mounted on a cap that screws onto the bottle body. The nipple is formed from a suitable elastomeric material (e.g., soft rubber, thermoplastic elastomer, or silicone) such that the membrane stretches when subjected to a differential pressure. The pinholes are formed by puncturing the membrane while subjecting the membrane to radial tension, and using one or more pins having a substantially circular cross-section and sized such that each pinhole is closed by the surrounding elastomeric material when the pins are removed.

Owner:MEDELA HLDG AG

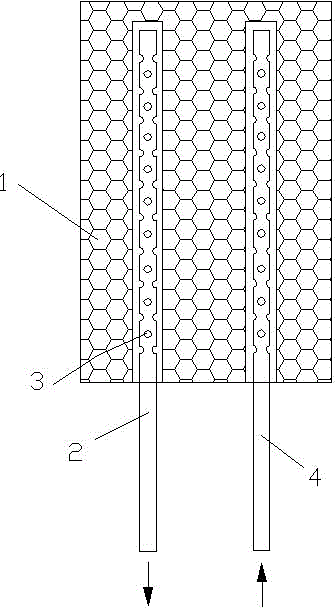

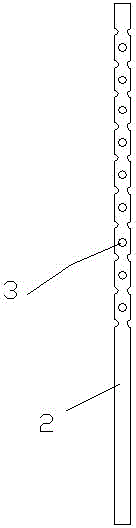

Negative pressure drainage dressing having attraction and flushing functions

InactiveCN104873332AEasy to wash awayAvoid easy cloggingCannulasEnemata/irrigatorsInhalationDrainage catheters

The present invention discloses a negative pressure drainage dressing having attraction and flushing functions. The negative pressure drainage dressing comprises a sponge body and at least one drainage conduit; one end of the drainage conduit is inserted into the sponge body; the other end of the drainage conduit is connected with a negative pressure source; and a conduit wall of the drainage conduit inserted into the sponge body is provided with a plurality of negative pressure attraction through holes. The negative pressure drainage dressing also comprises a perfusion pipeline, the perfusion pipeline is inserted into the sponge body and capable of injecting flushing liquid or soup into the sponge body to intervene in a wound, and negative pressure attraction of the wound secretion, the flushing liquid and the soup in the sponge body can be carried out by the drainage conduit. The negative pressure drainage dressing has the advantages that the liquid can be injected to the wound, the wound can be wetted and cleaned, the efficiency of attracting the secretion and edema liquid is higher, the wound can be intervened, and inhalation channels are not easy to be blocked.

Owner:傅秋良 +1

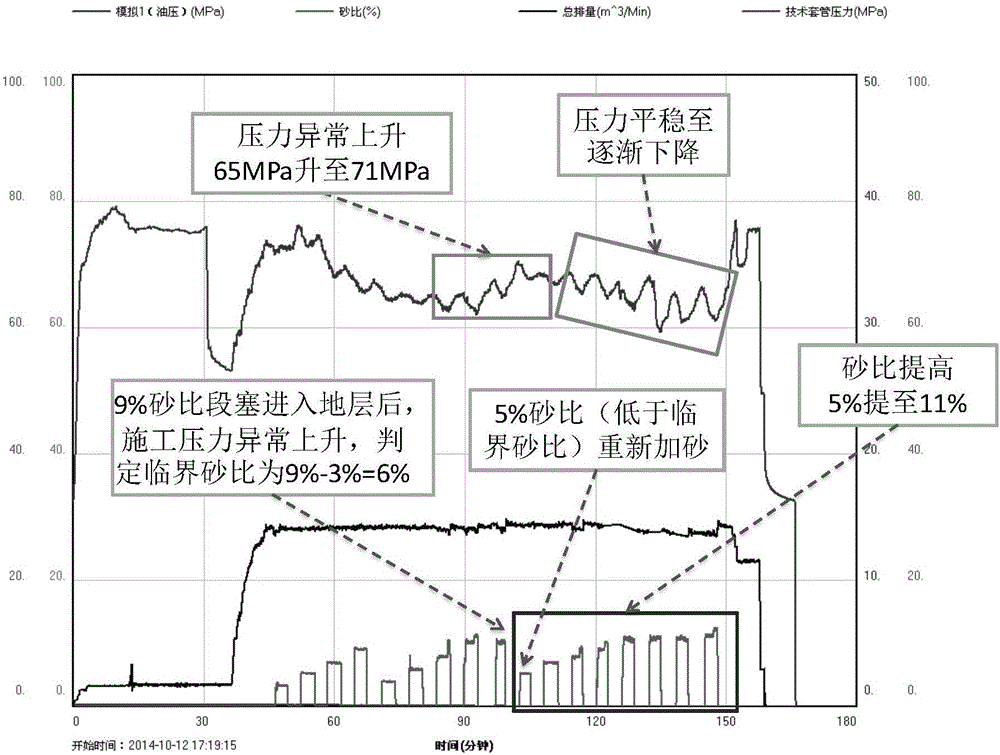

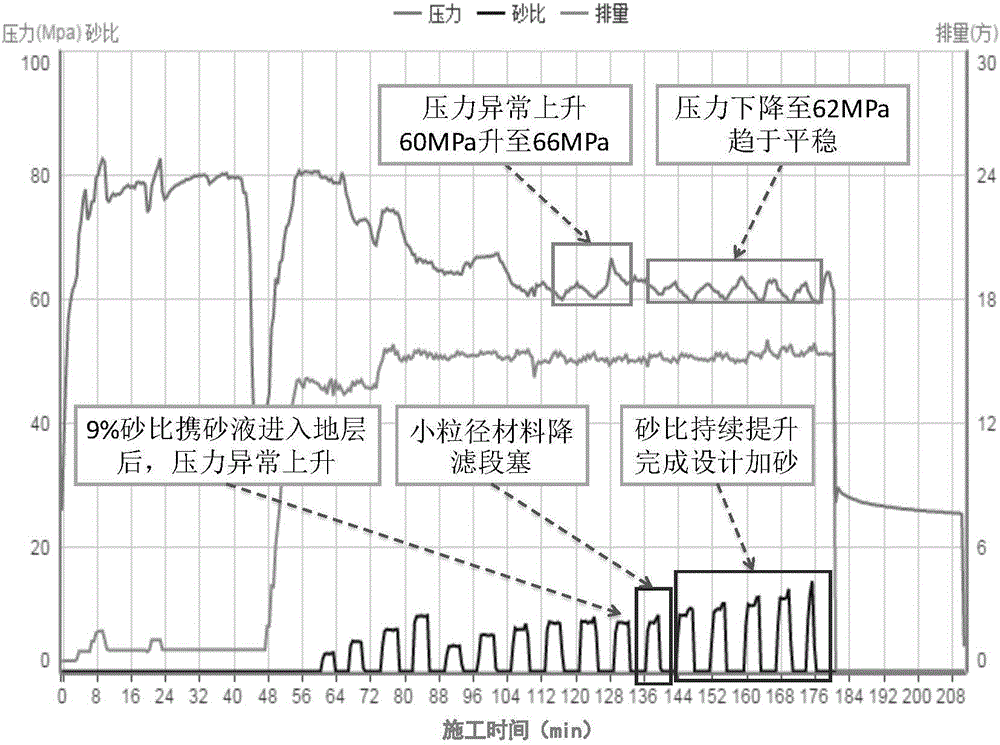

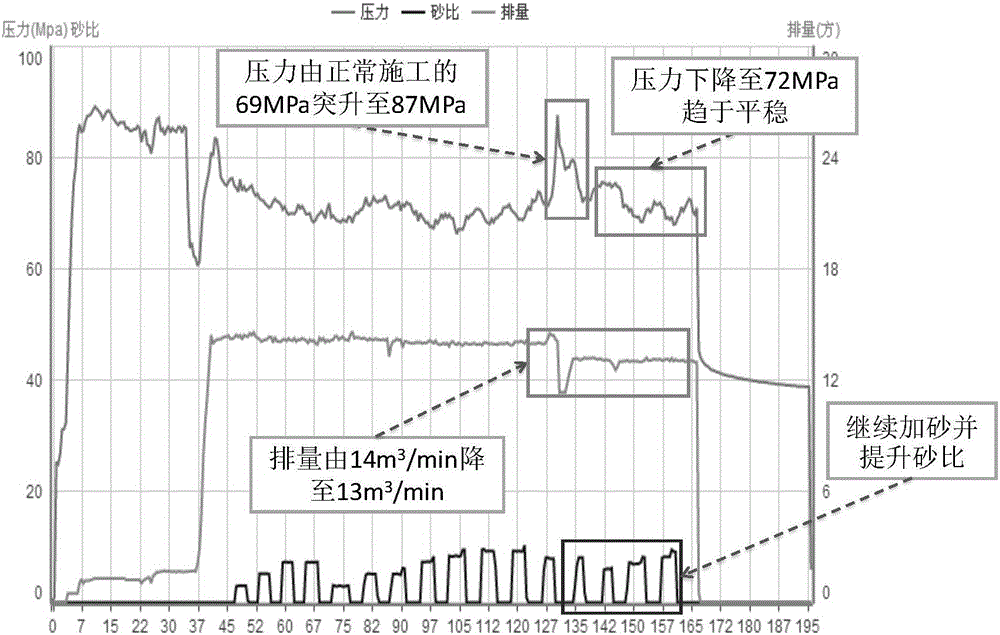

Processing method for controlling abnormal pressure rise in shale fracturing process

InactiveCN106761644ASlow down the rate of formationEfficient pluggingFluid removalPressure riseFracturing fluid

The invention discloses a processing method for controlling abnormal pressure rise in the shale fracturing process. The processing method comprises the following steps that in the middle and later periods of fracturing, a critical sand ratio method is adopted for construction when abnormal pressure rise occurs and comprises the specific steps that 1, the critical sand ratio is determined, wherein a critical sand ratio range is determined as the sand ratio subtracted by 2%-5% at the moment when pressure rises at the slope greater than 1 / 2 in the sand adding process, sand adding is stopped immediately, fracturing fluid injection continues, the injection amount is 1-1.5 times of shaft volume, sand adding is stopped but fluid injection is not stopped; 2, abnormal pressure rise is processed, wherein the point not exceeding the critical sand ratio serves as a starting point to perform pressurized fracturing again after the injection of a fracturing fluid 1-1.5 times of shaft volume is completed, and a sand ratio value in fracturing sand is gradually increased till designed sand adding amount is completed. By adopting the critical sand ratio method, a sandy dyke formation speed can be reduced, the rapid rise situation of construction pressure is effectively controlled, and the method has the advantages that operation is simple and convenient, an existing fracturing process is not changed, the fracturing construction quality can be improved, and a reconstruction effect is ensured.

Owner:PETROLEUM ENG TECH RES INST OF JIANGHAN OILFIELD BRANCH OF

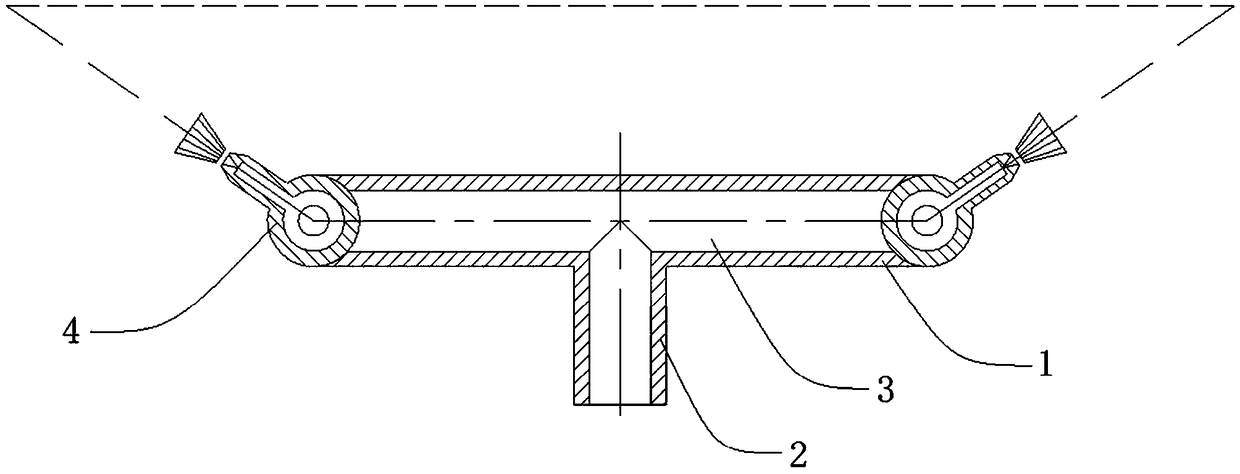

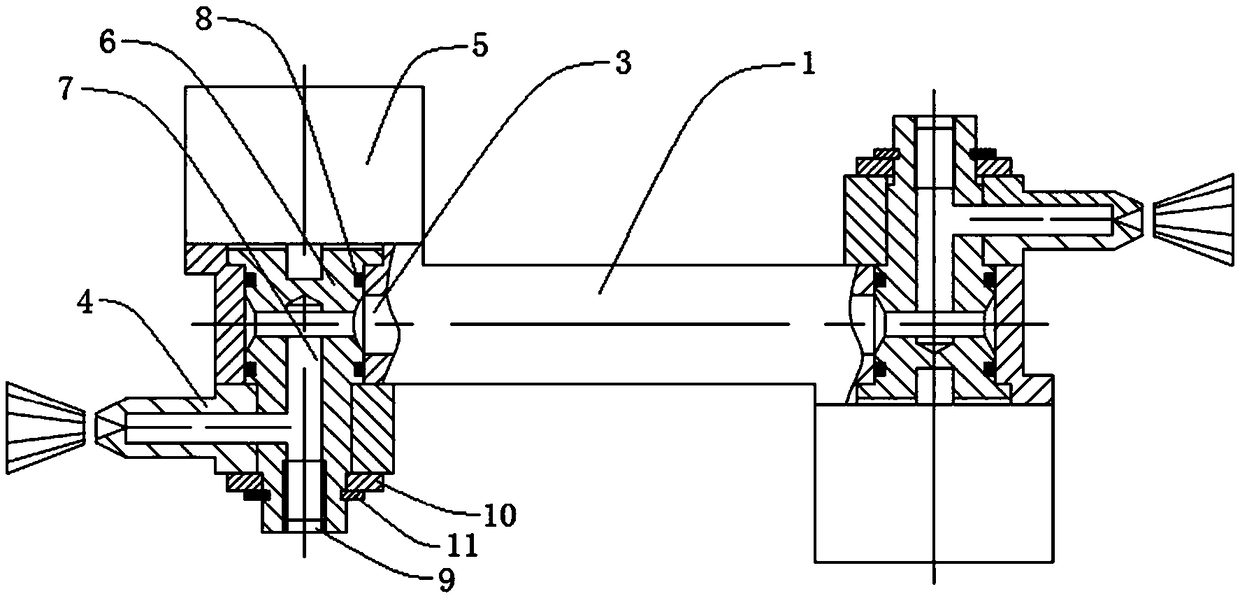

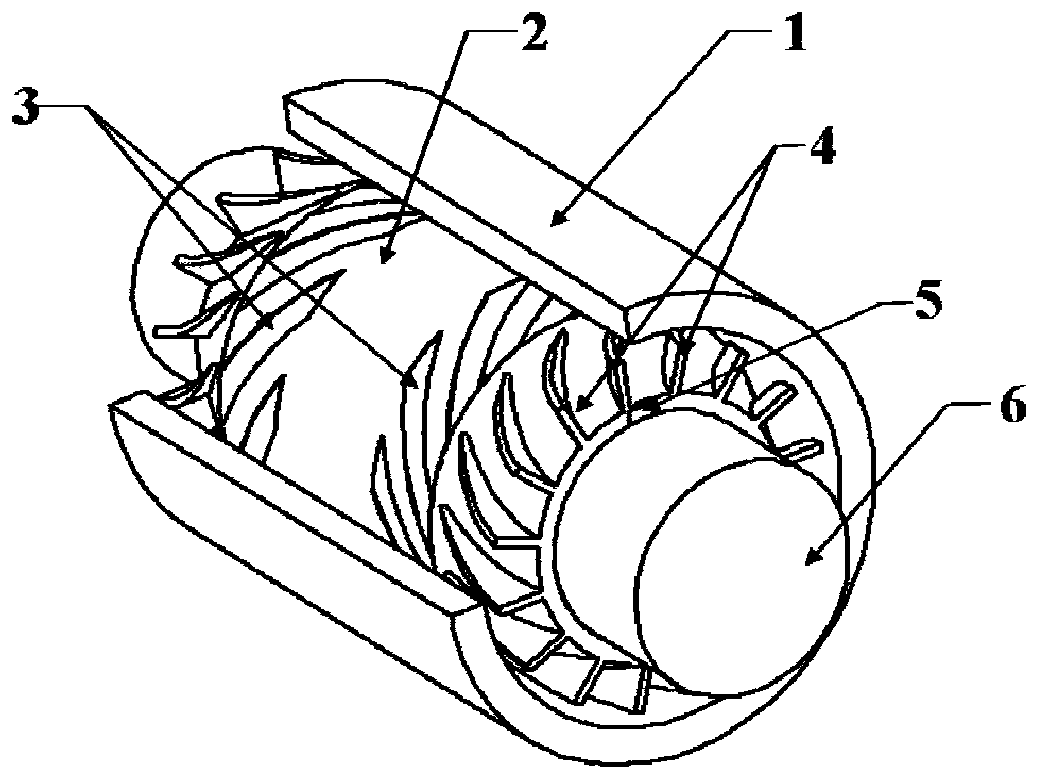

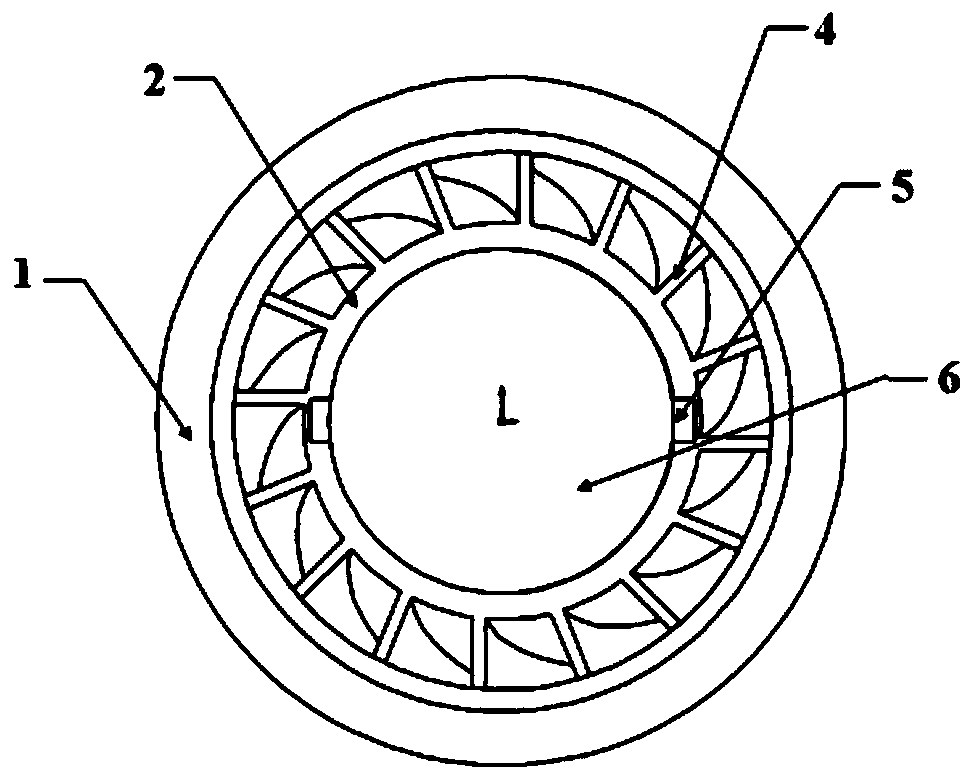

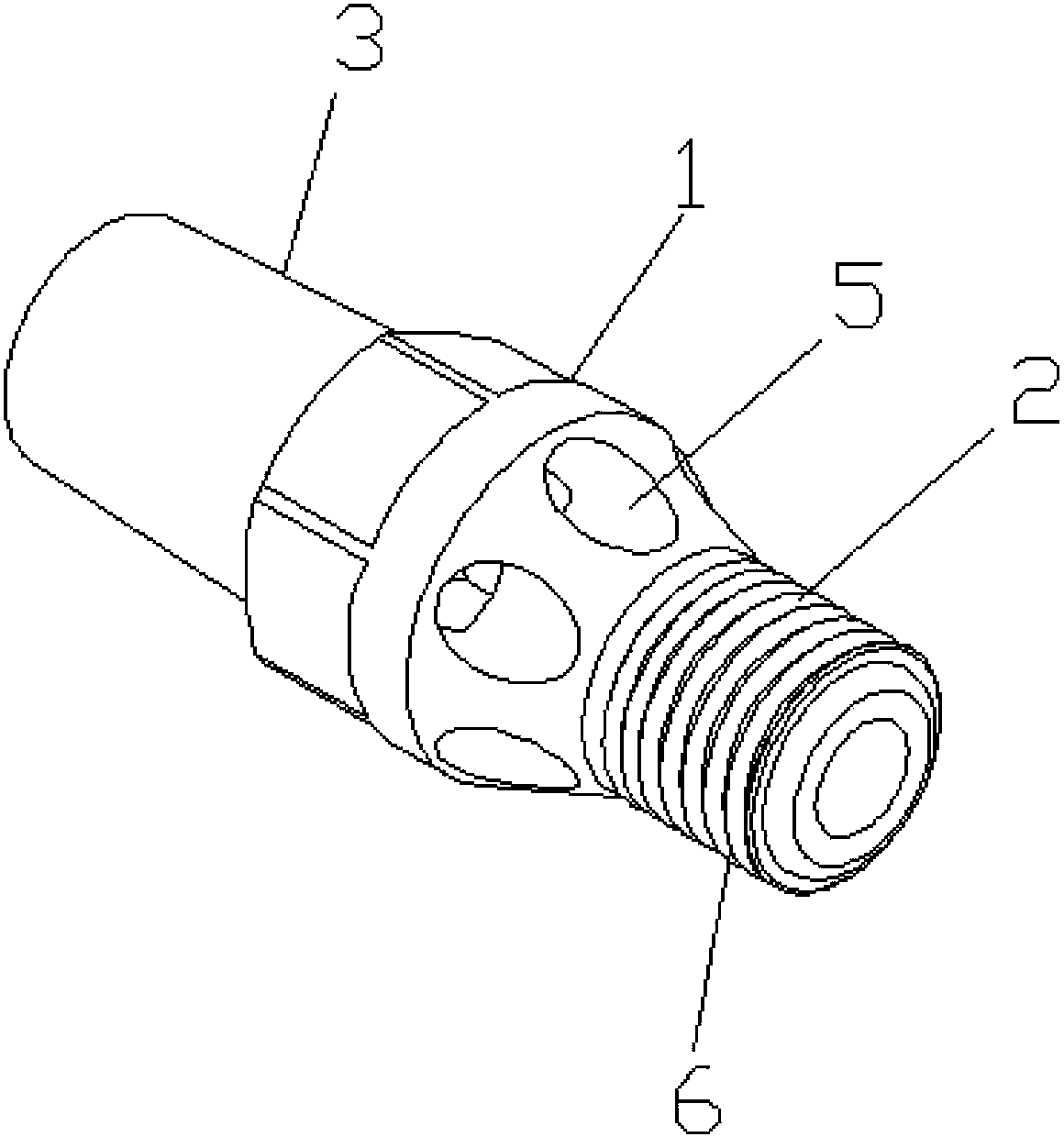

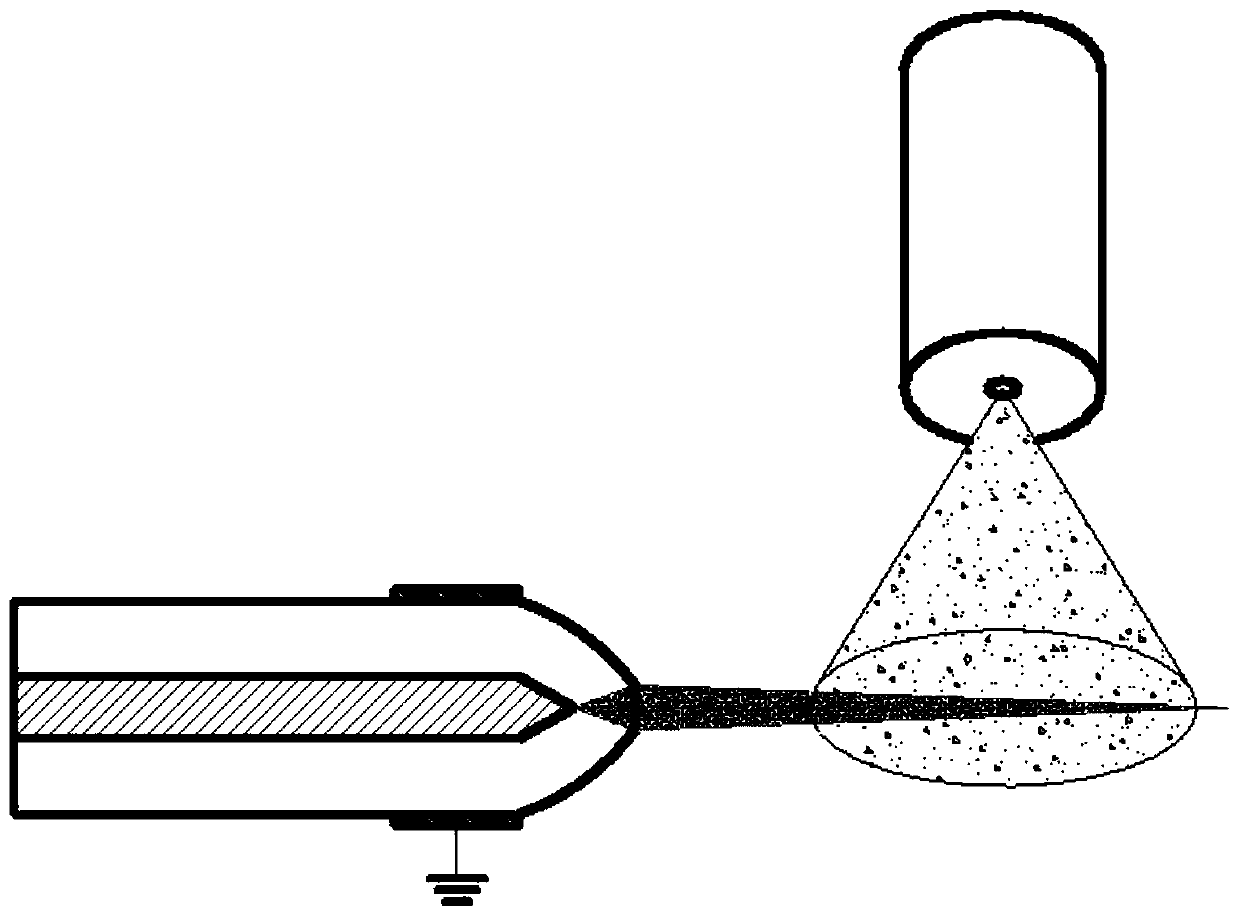

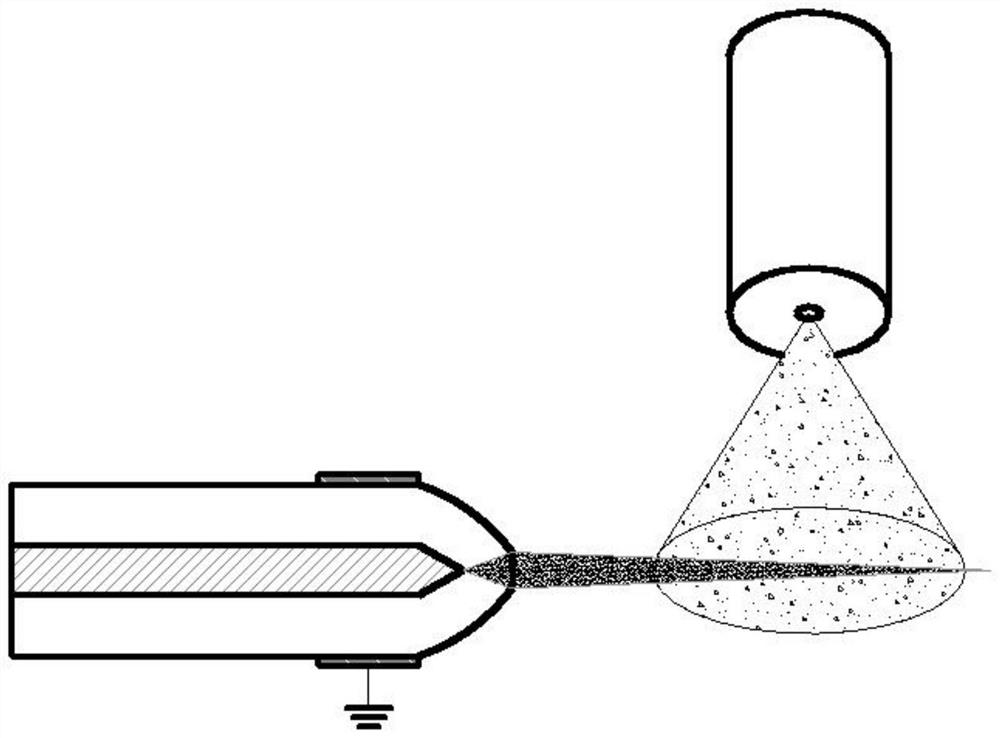

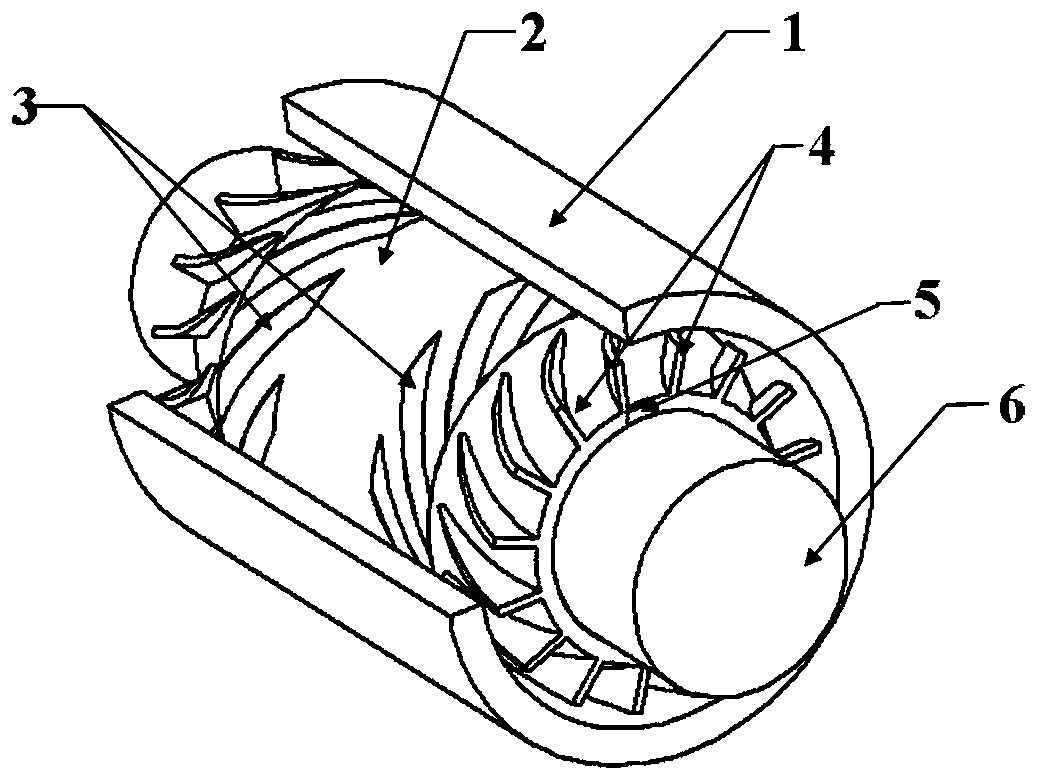

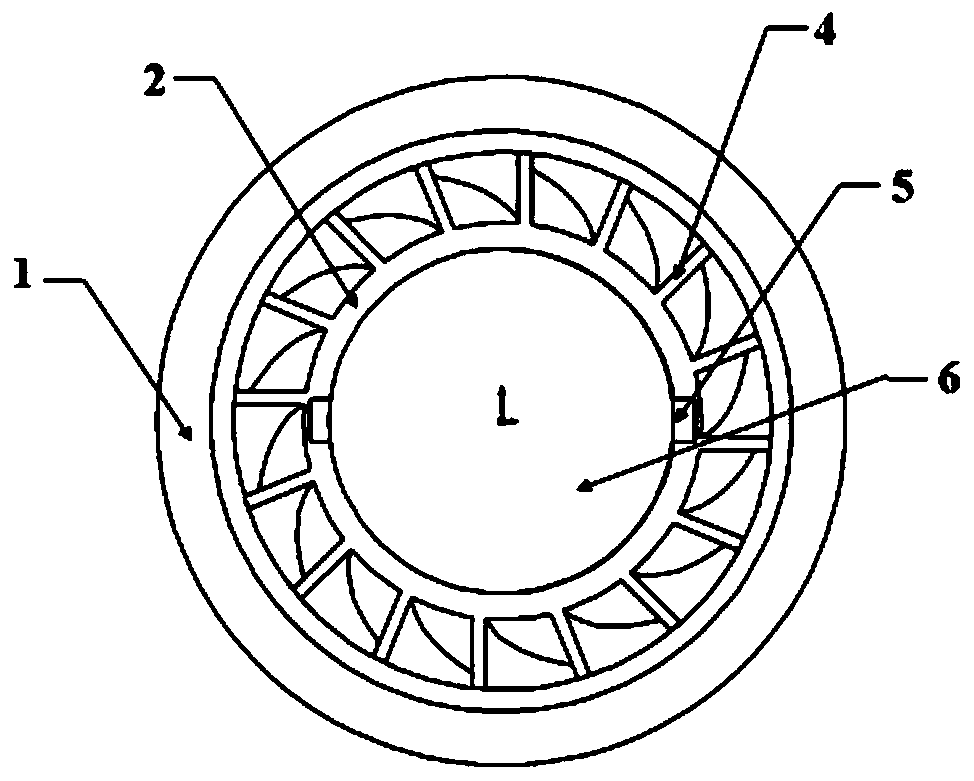

Impeller-type spray head of novel electrostatic sprayer

InactiveCN101632966ALarge liquid flowImprove atomization effectSpray discharge apparatusImpellerSprayer

The invention relates to an impeller-type spray head of a novel electrostatic sprayer, comprising a motor and an impeller rotatably connected with a rotating shaft of the motor. The impeller comprises a profile and a base which are coaxially arranged, and a plurality of fan blades evenly distributed between the profile and the base along a circumference direction; a motor base of the impeller-type spray head is provided with a liquid inlet and a liquid outlet; when the motor of the impeller-type spray head drives the impeller to rotate, liquid medicine is sprayed out of the liquid outlet through the liquid inlet by means of the spray gun from the liquid medicine tank; the highly-rotated fan blades break the liquid medicine into tiny fogdrops with charge, most of fogdrops are blown forward from clearances among the fan blades, and small part of fogdrops are thrown out along a diversion trench on the inner surface of the profile on the edge of the impeller. Compared with the rotary spray head in the prior art, the impeller-type spray head has larger amount of sprayed medicine liquid flow and favorable atomization effect, and can more deeply spray the fogdrops inside the target as force blowing forward is generated to the fogdrops.

Owner:苏州稼乐植保机械科技有限公司

Method for treating wastewater by cooperation of choking cavitation and H2O2

InactiveCN104045145AReduce energy consumptionEasy to operateWater/sewage treatment by oxidationShock waveCavitation

The invention discloses a method for treating wastewater by cooperation of choking cavitation and H2O2. The method is characterized by being realized by adopting a process of treating the wastewater by cooperation of the cavitation effect generated by a choking cavitation unit consisting of a hydrogen peroxide storage box, a centrifugal pump and a choking cavitation device and strong oxidizing property of H2O2. The method comprises the following steps: feeding a solution of H2O2 into the centrifugal pump and the choking cavitation device while pumping the solution into the wastewater, generating the cavitation effect in the choking cavitation device, and forming strong shearing disturbance through micro jet flow and shock waves generated in a cavitation region, so that the area of contact between H2O2 and the wastewater is enlarged, the action time of H2O2 in the wastewater is prolonged, the probability of collision between H2O2 and organic molecules in the wastewater is increased, the degradation of the organic molecules in the wastewater is accelerated, the cooperative treatment effect of the choking cavitation and H2O2 is improved, and the purpose of degrading difficultly degraded components in the wastewater is achieved. Compared with the prior art, the technology has the advantages of simple process, convenience in operation, high energy utilization rate, strong adaptability, high efficiency, large treatment capacity, no secondary pollution, low cost and the like.

Owner:HUNAN UNIV OF TECH

Dishwasher spray mechanism

PendingCN109106308AImprove cleaning efficiencyEasy to cleanTableware washing/rinsing machine detailsSpray nozzleAgricultural engineering

The invention relates to a dishwasher spraying mechanism in the technical field of a dishwasher, comprising a spraying arm connected with a rotating rod and provided with a water-passing mold cavity;a high-pressure spray nozzle communicating with a water-passing mold cavity; the high-pressure spray head is rotatably arranged with respect to the spray arm; the rotating lever drives the spray arm to rotate. The invention can carry out spray operation with less high-pressure spray nozzles, and has the advantages of strong cleaning ability and high cleaning efficiency.

Owner:SUZHOU CLEANTEC APPLIANCE CO LTD

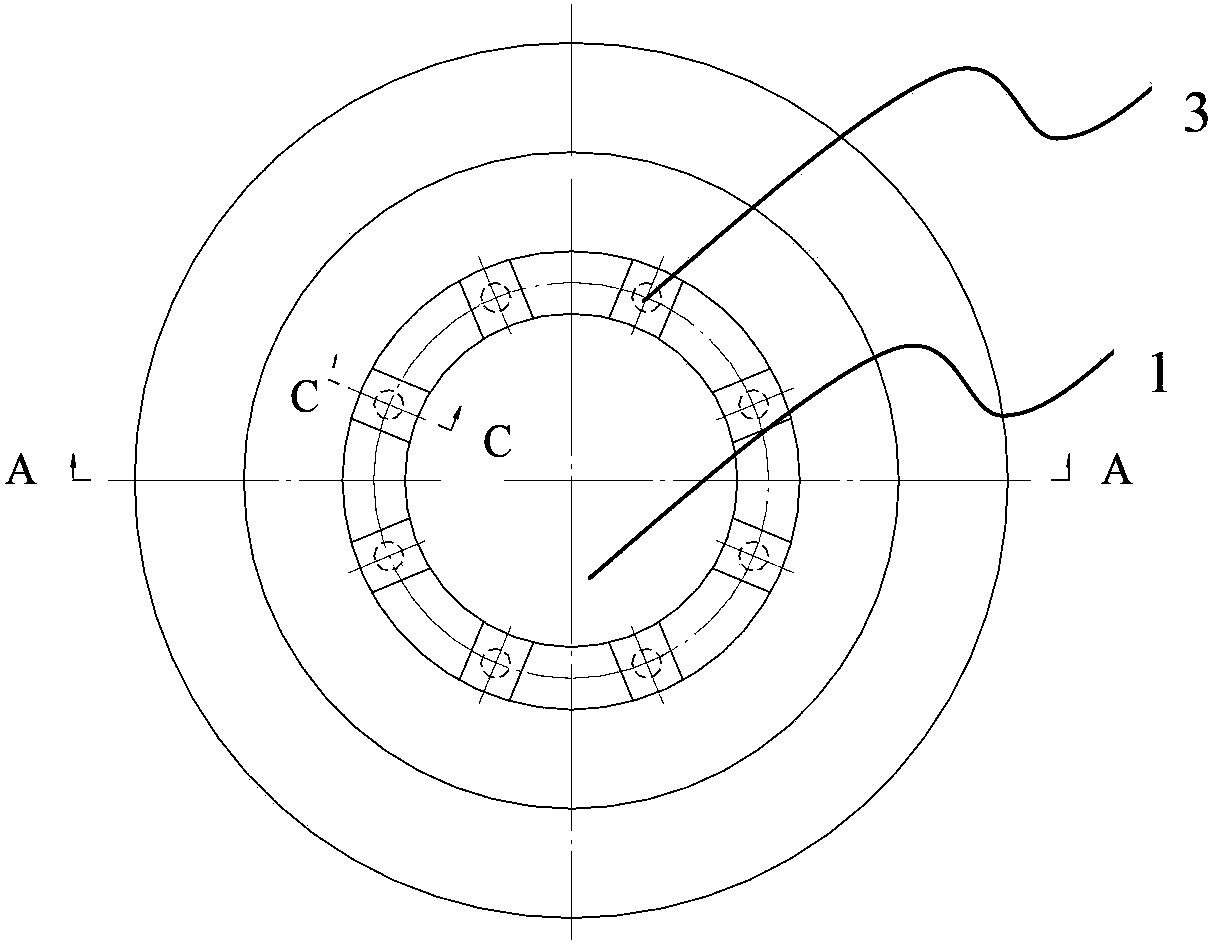

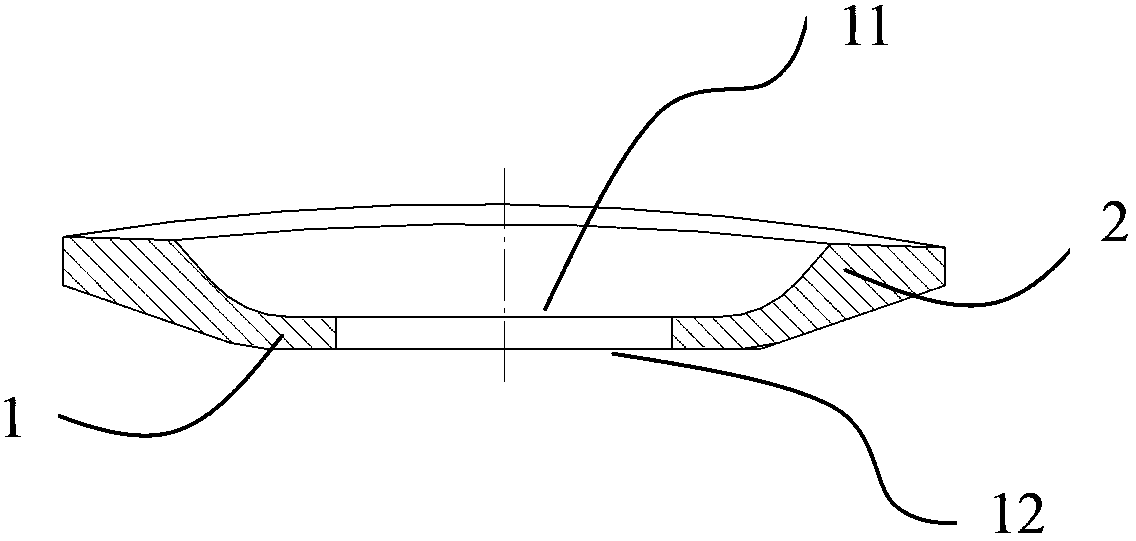

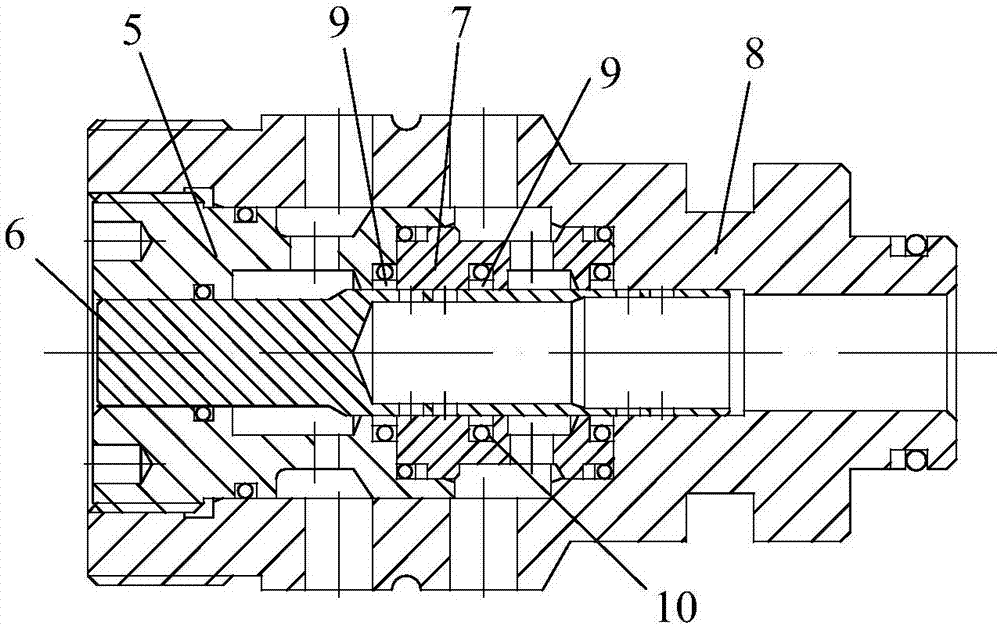

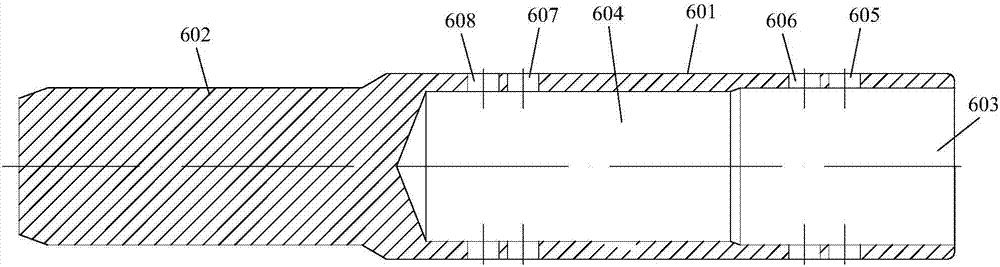

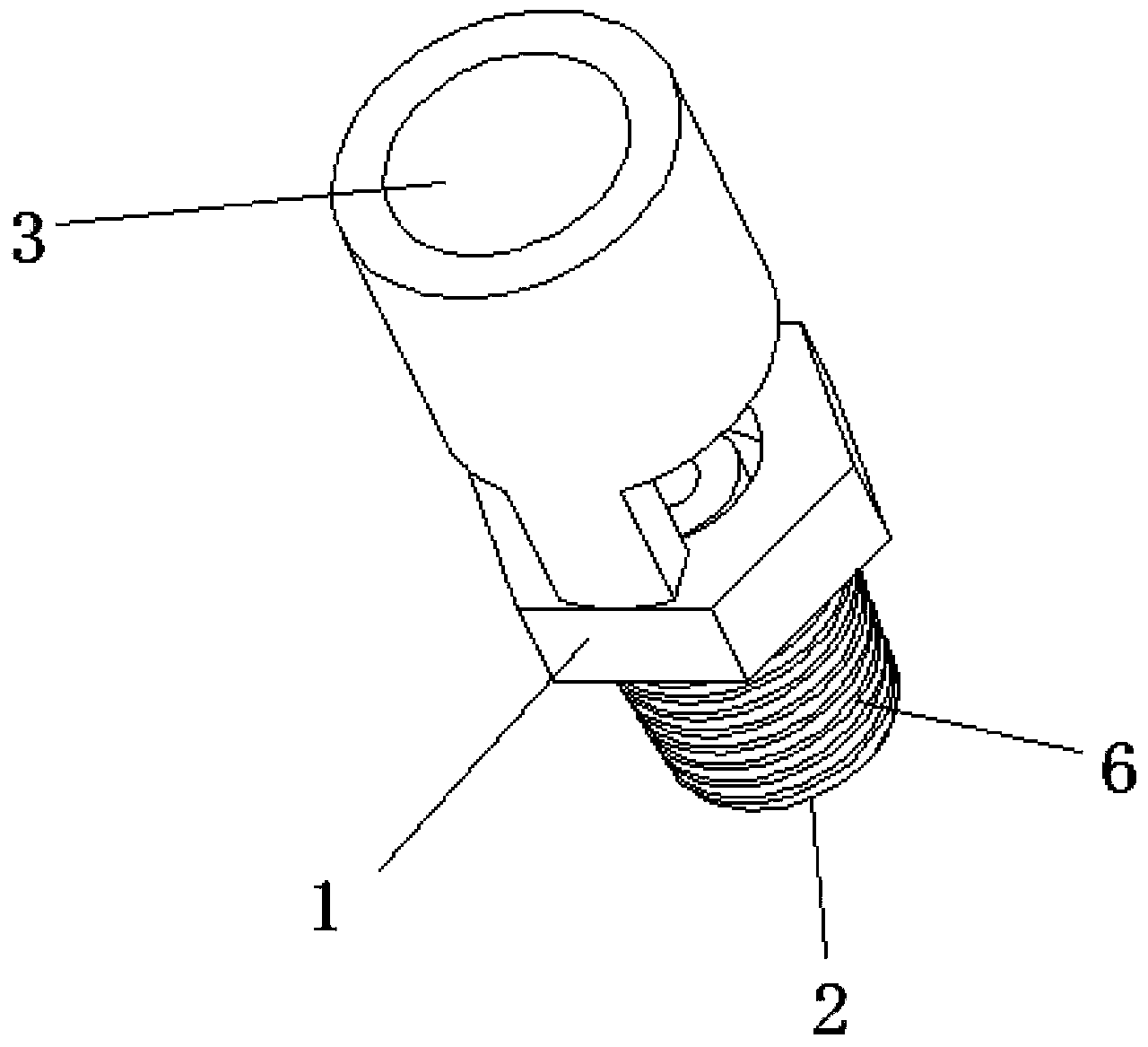

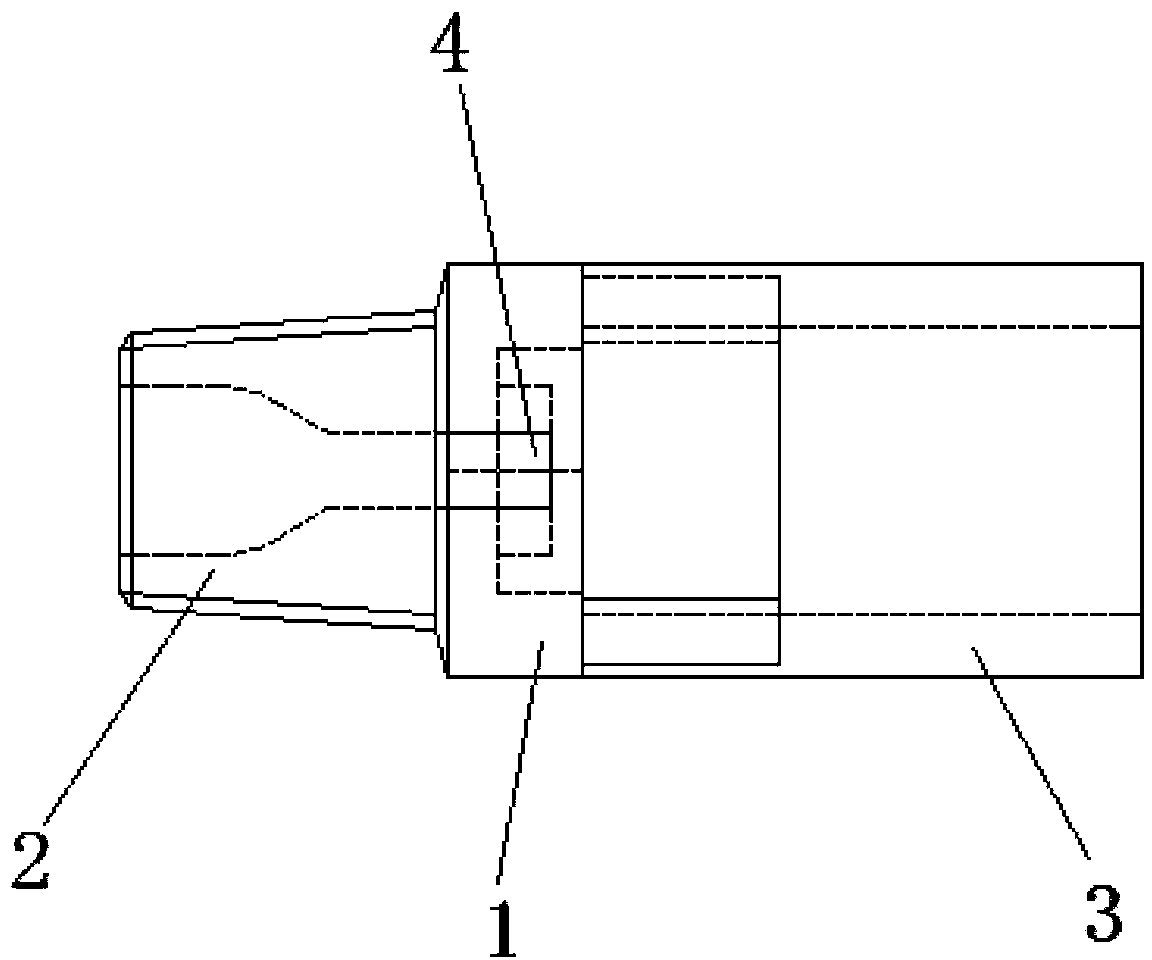

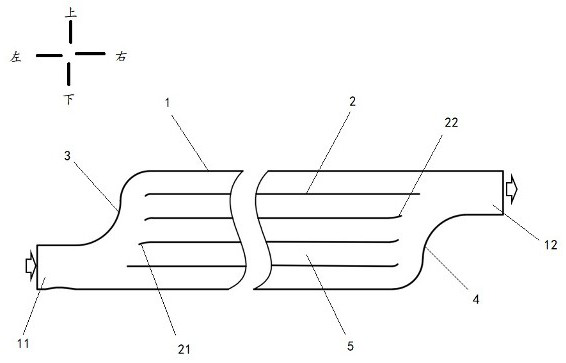

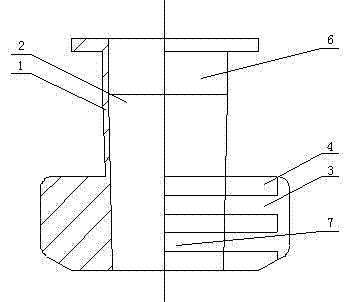

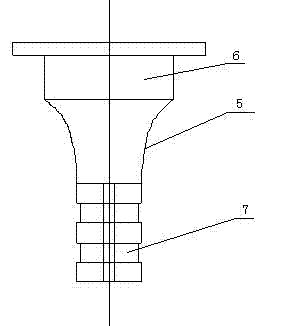

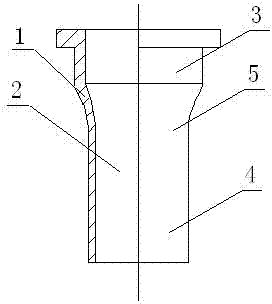

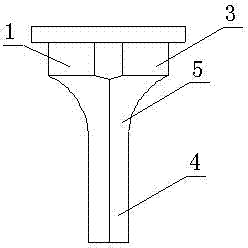

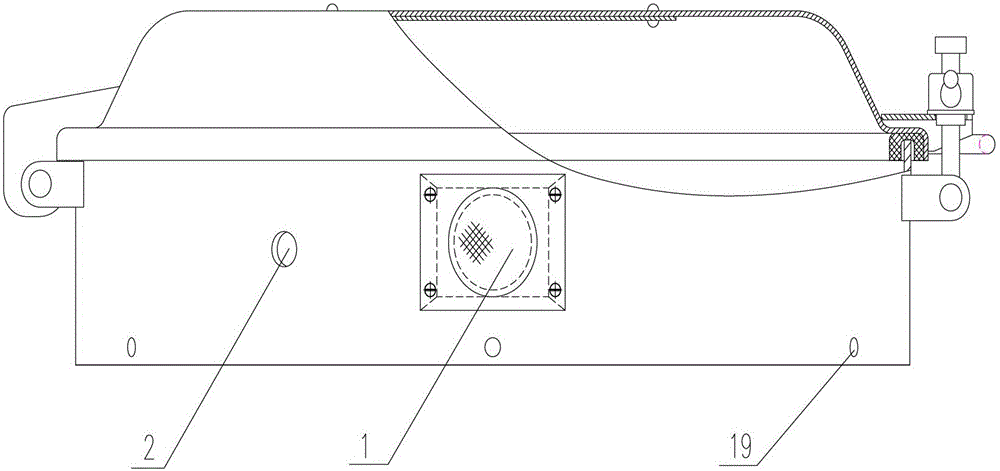

Oil filling and discharging valve seat

InactiveCN103542155AReduce sizeLarge liquid flowLarge containersLift valveCharge and dischargeEngineering

An oil charging and discharging valve seat is applied to a bottom unloading oil discharging device or a top loading bottom unloading oil discharging device, and is connected to an oil charging and discharging valve of a tank body. The oil charging and discharging valve seat comprises an oil charging and discharging valve seat bottom portion (1) and an oil charging and discharging valve seat root portion (2) that extends from the edge of the oil charging and discharging valve seat bottom portion to an upper portion. The thickness of the oil charging and discharging valve seat bottom portion is smaller than the thickness of the oil charging and discharging valve seat root portion. The oil charging and discharging valve seat is high in working efficiency and good in tightness, and is easy to form.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

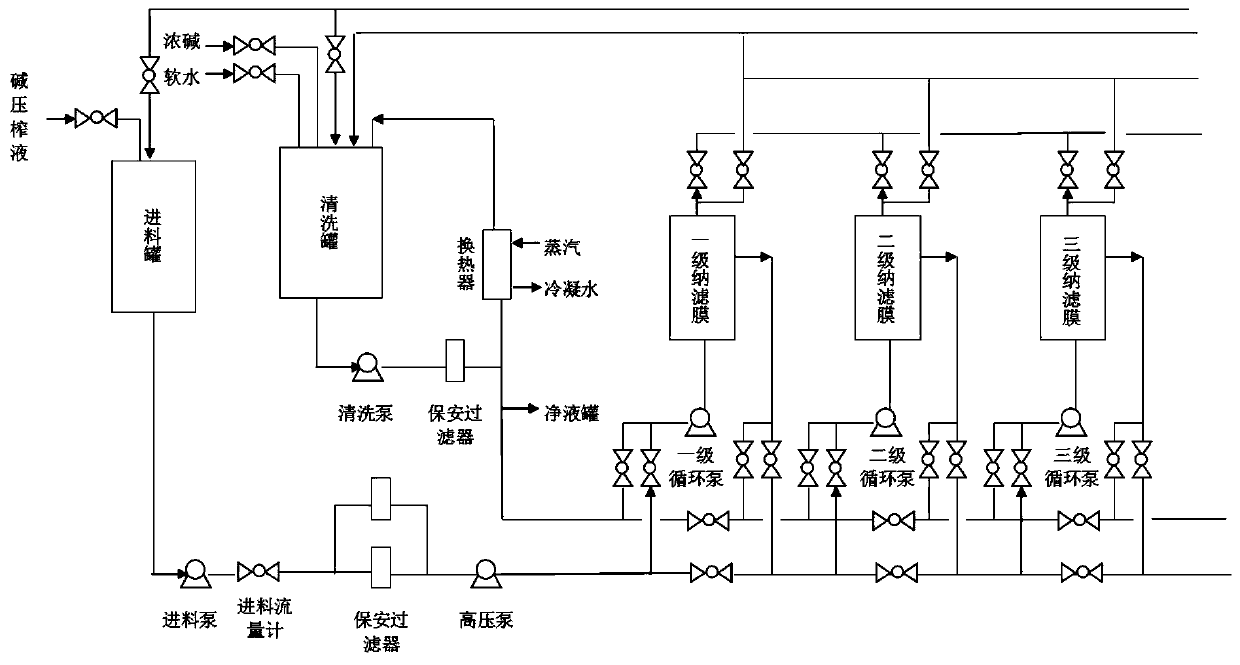

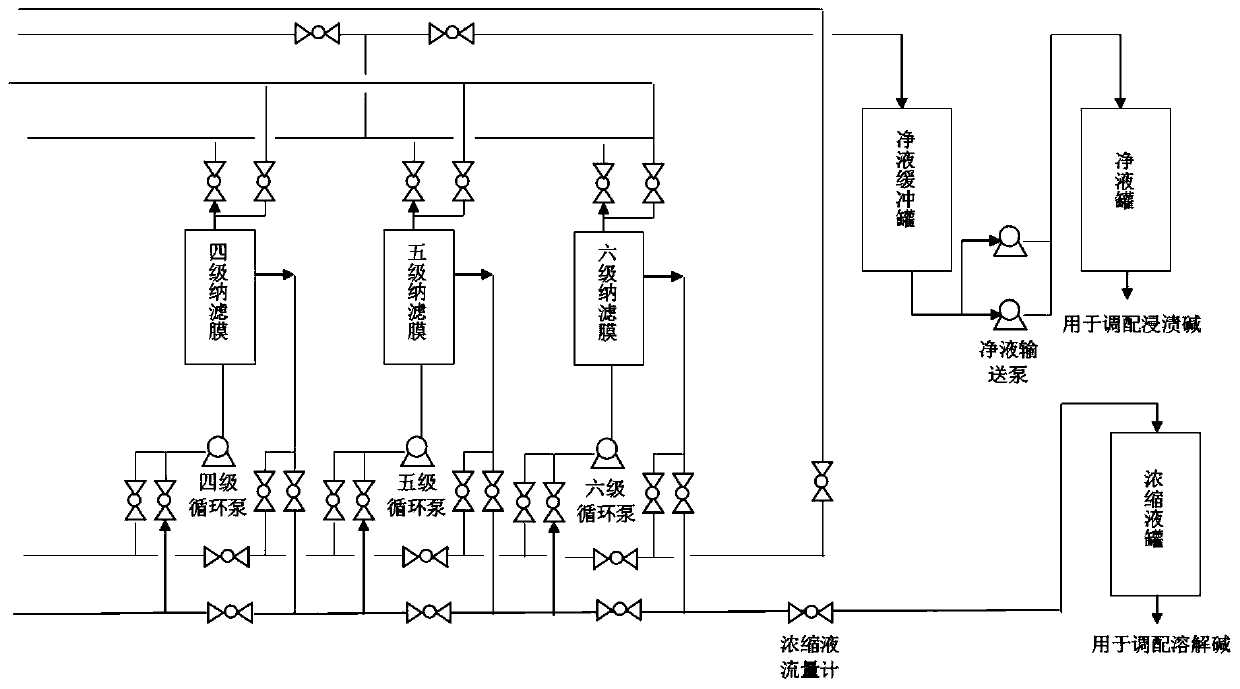

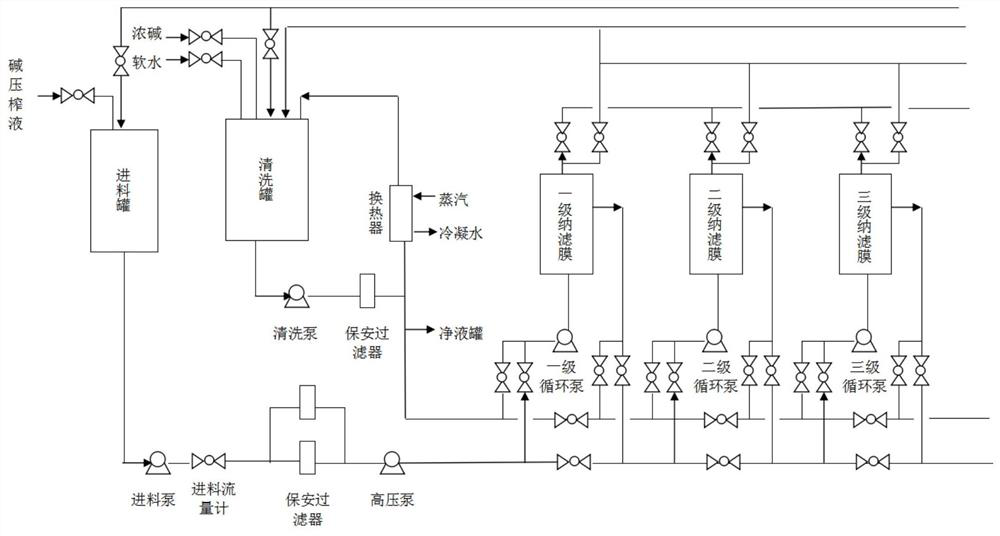

Continuous membrane treatment method for alkali pressed liquid in viscose fiber production process

ActiveCN110559861AIncrease profitReduce cleaning timesReverse osmosisMaterials preparationOperation mode

The invention relates to a continuous membrane treatment method for alkali pressed liquid in a viscose fiber production process. The method comprises the steps of material preparation, feeding and system operation. The system operation process further comprises a cleaning step: one stage of nanofiltration membrane assembly is switched out of a nanofiltration membrane system to be cleaned, and other nanofiltration membrane assemblies operate normally; alkali pressed liquid or concentrated liquid generated by the previous-stage nanofiltration membrane assembly skips the nanofiltration membrane assembly being cleaned and is introduced into the next-stage nanofiltration membrane assembly or a concentrated liquid tank; and after cleaning is finished, the nanofiltration membrane assembly is connected back to the nanofiltration membrane system in series again; and each stage of nanofiltration membrane assembly can be separately cleaned in the same manner. The treatment method is a continuousmembrane treatment process with full-automatic operation and cleaning, and a batch intermittent operation mode adopted in a conventional technology is changed, so that the utilization rate of nanofiltration membranes can be effectively improved, the cleaning times of the nanofiltration membranes can be reduced, and the service life of the nanofiltration membranes can be prolonged.

Owner:唐山三友远达纤维有限公司

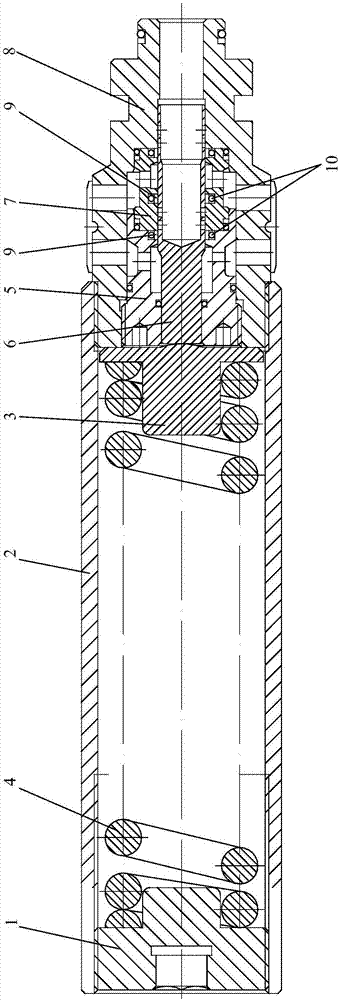

Hydrodynamic radial bearing and centrifugal pump

The invention provides a hydrodynamic radial bearing provided with an axial-flow pressurizing structure and a centrifugal pump. The hydrodynamic radial bearing comprises a shaft sleeve and a bearing body matched with the inside of the shaft sleeve; the bearing body comprises two opposite end surfaces and a side surface located between the two opposite end surfaces; and the axial-flow pressurizingstructure is arranged on the side surface of the bearing body, is close to at least one of the two opposite end surfaces and is far away from the central area of the side surface. Compared with the prior art, the hydrodynamic radial bearing has the advantages that a pressurizing device is added to the front part of the hydrodynamic radial bearing, the cavitation phenomenon which is caused easily in a general hydrodynamic bearing is restrained, and the reliability of the bearing is improved remarkably.

Owner:XI AN JIAOTONG UNIV

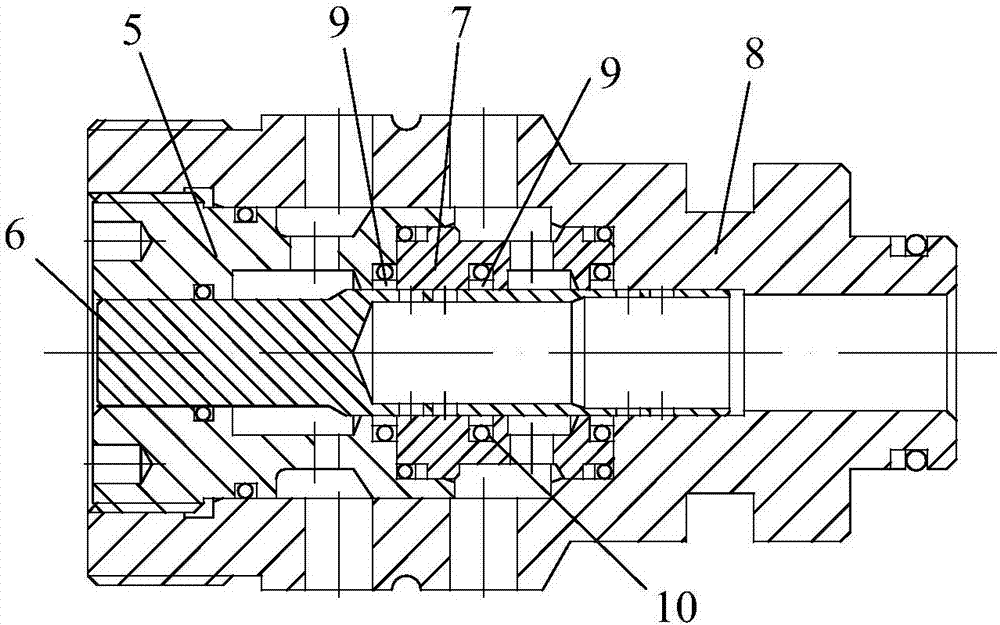

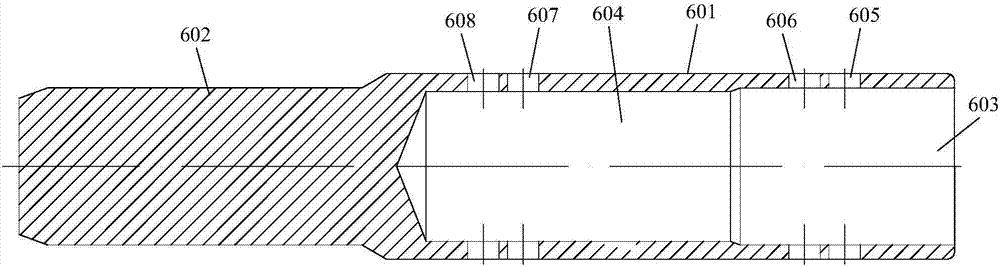

Valve element of safety valve

InactiveCN107503783AIncrease drainage flowImprove unloading capacityMine roof supportsEngineeringSafety valve

The invention discloses a valve element of a safety valve. The valve element comprises a liquid incoming section and a guide section which are axially arranged sequentially, a first liquid passing hole, a second liquid passing hole, a third liquid passing hole and a fourth liquid passing hole which are axially arranged sequentially are formed in the liquid incoming section, the first liquid passing hole and the second liquid passing hole are used for guiding liquid entering the valve element to a second liquid discharging hole of the safety valve, and the third liquid passing hole and the fourth liquid passing hole are in staggered arrangement. The first liquid passing hole, the second liquid passing hole, the third liquid passing hole and the fourth liquid passing hole are in staggered arrangement, so that liquid passing flow is increased, metal performance of the valve element is improved, rigidity of the valve element is improved, so that the valve element is less prone to breaking; the valve element is large in liquid passing flow, so that increasing of liquid discharging flow of the safety valve is facilitated, and unloading capacity of the safety valve is improved.

Owner:HONGDA INTELLIGENT MACHINERY CO LTD

Filter

InactiveCN102309884AHigh filtration precisionLarge liquid flowStationary filtering element filtersFilter elementBiochemical engineering

The invention relates to a filter, which comprises a cylindrical filter body, a filter element and a filter screen, wherein a liquid outlet is formed at one end of the filter body; an interface connected with a hydraulic system pipeline is formed on the outer side of the liquid outlet; the other end of the filter body is fixedly connected with the filter element; a filtering cavity is formed between the filter body and the filter element; a liquid inlet is formed on the filter element; the filter screen is of a cylindrical structure; and one end of the filter screen is fixedly connected with the filter element. The filter is characterized in that: the other end of the filter screen is arranged in the filtering cavity; the outer diameter of the filter screen is matched with the inner diameter of the filtering cavity; and a plurality of filtering sheets are arranged on the cylindrical filter screen. The filter has the advantages of high filtering precision, high liquid flow rate, long service life and low manufacturing cost.

Owner:施锦成

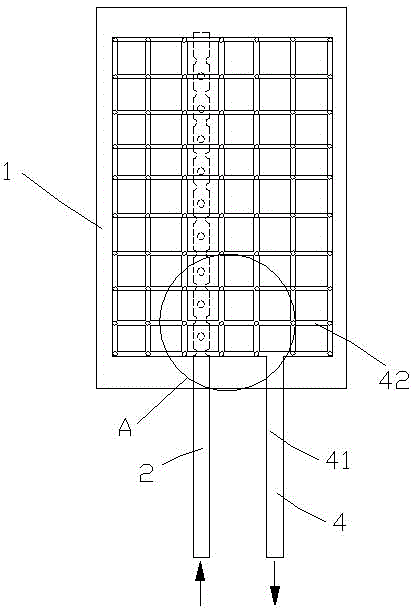

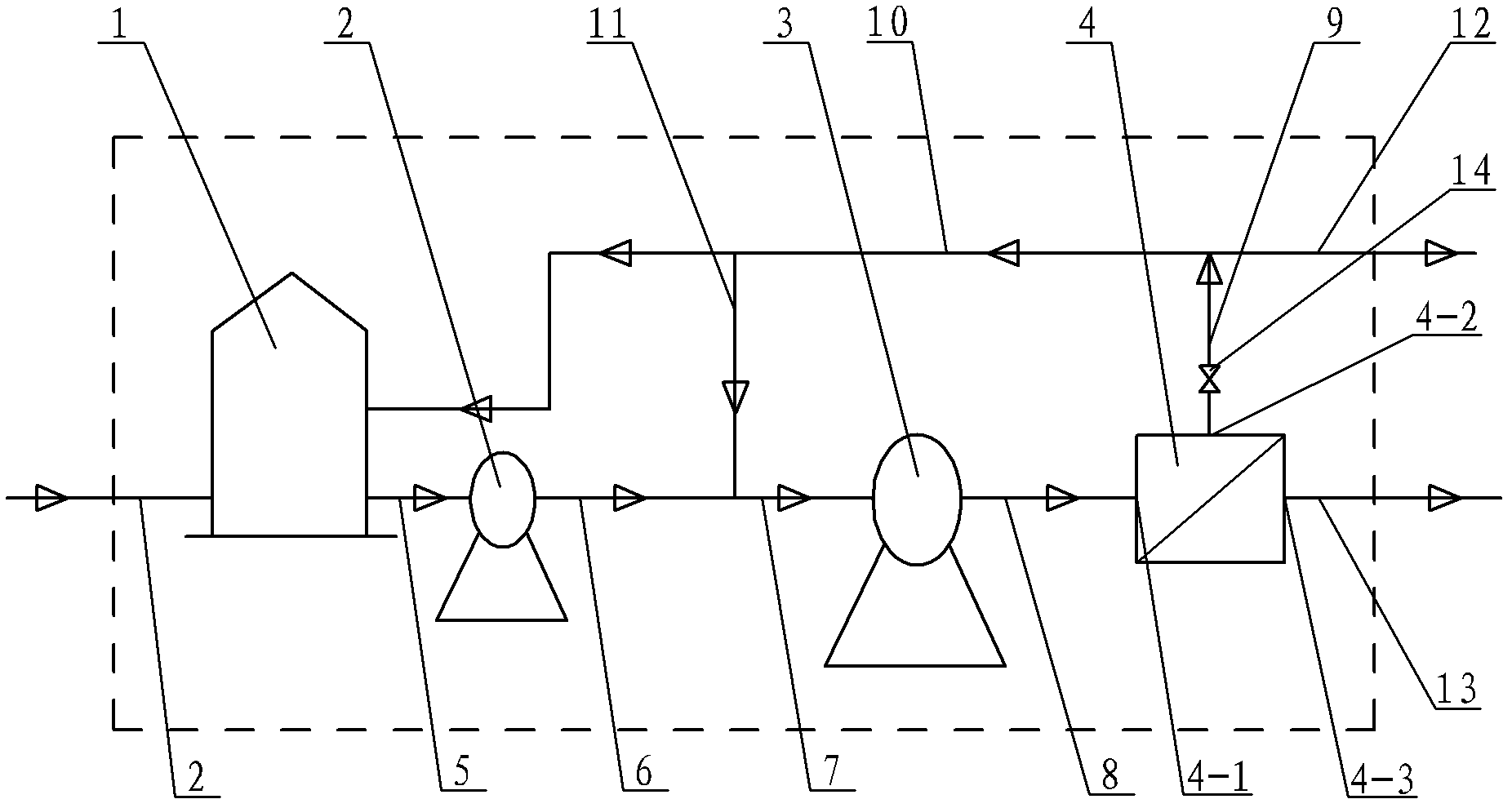

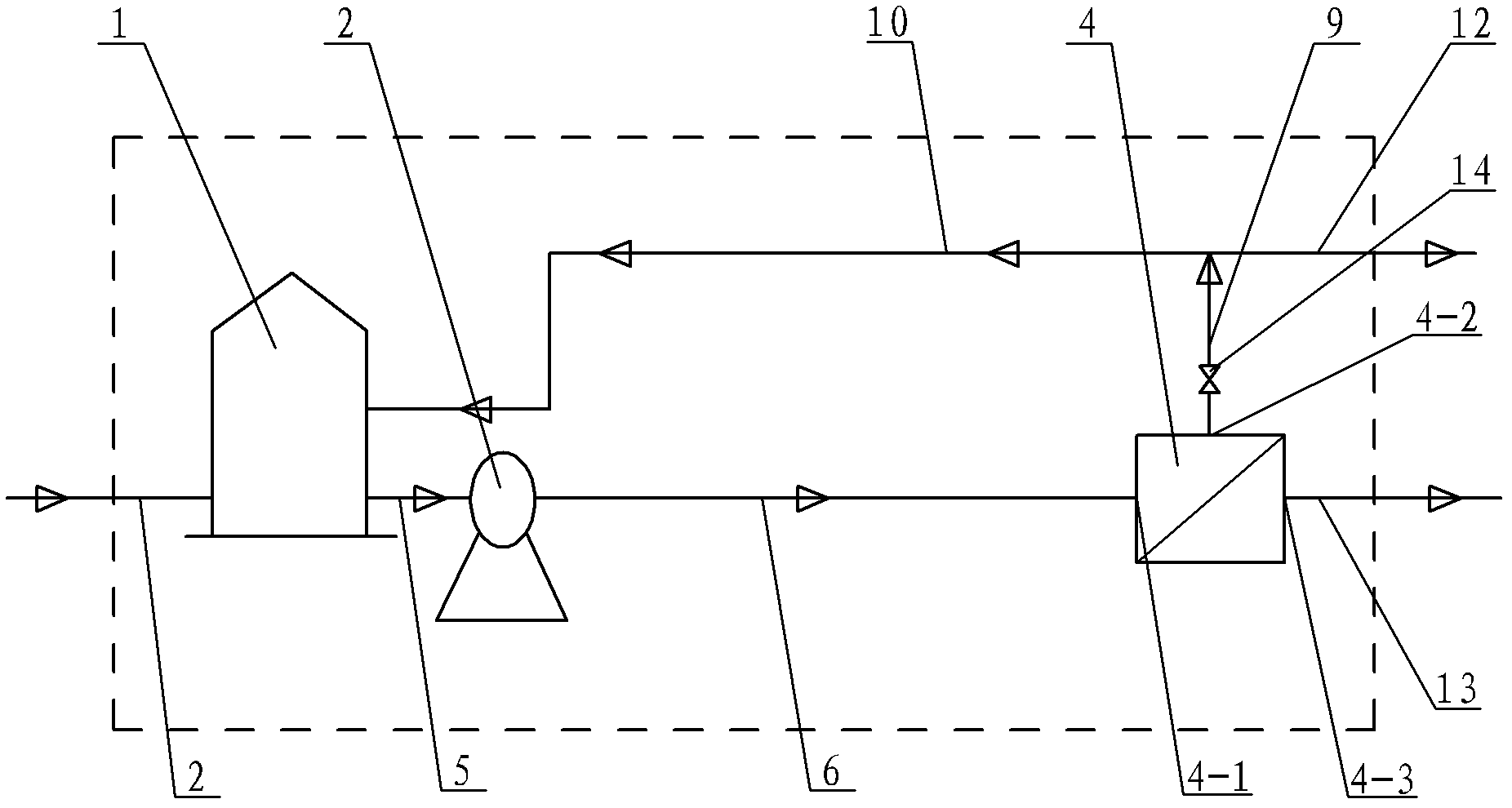

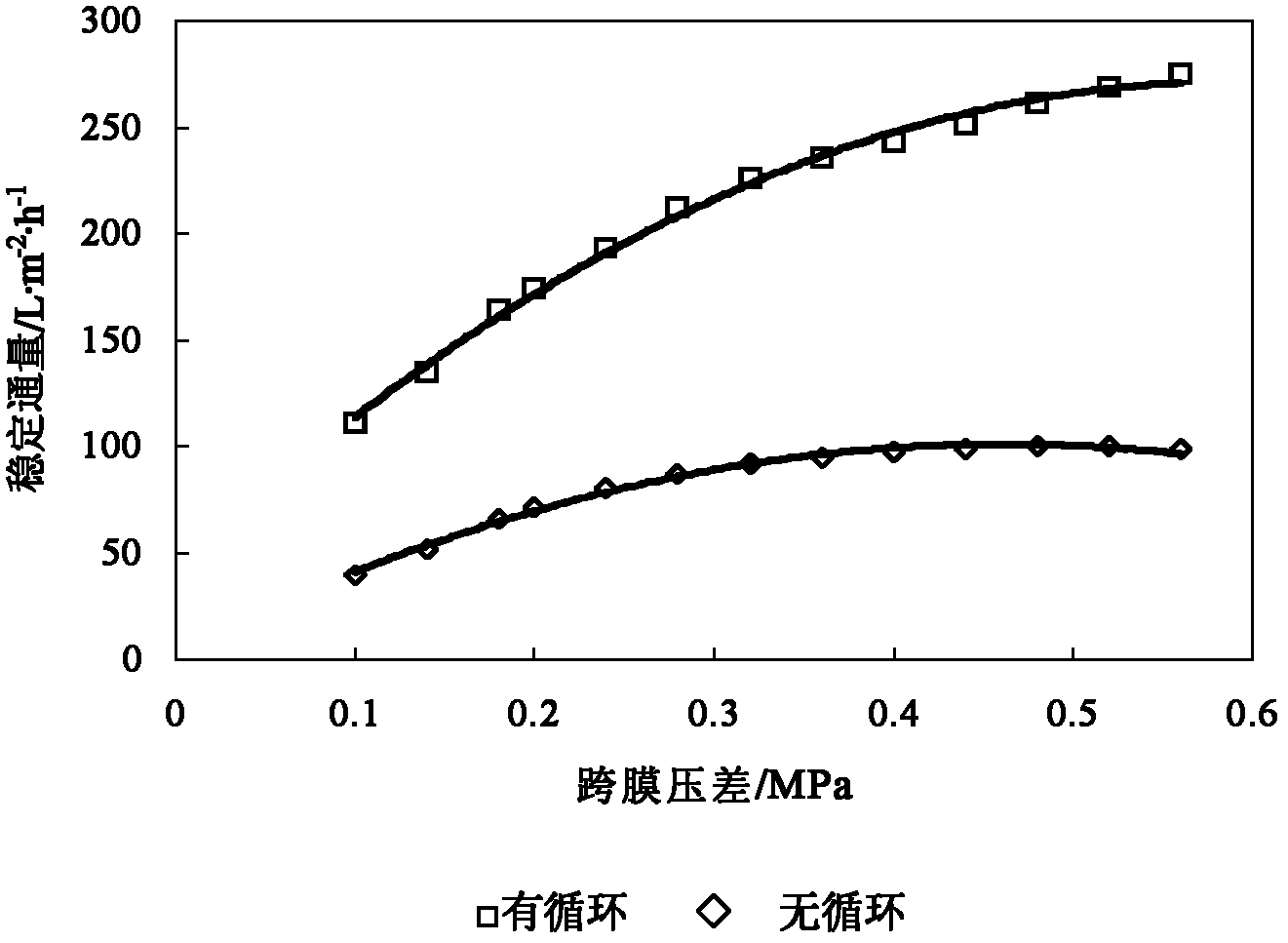

Concentrated solution backflow circulating type membrane separation equipment and method thereof

InactiveCN102580534AIncrease surface velocityReduce pollutionSemi-permeable membranesHigh concentrationCirculator pump

Concentrated solution backflow circulating type membrane separation equipment and a method thereof relate to membrane separation equipment and methods in the field of liquid material separation and aim to solve the problems of membrane pollution and low membrane flux when the conventional membrane equipment is used for separating high-concentration material. The equipment is characterized in that the two ends of a feeding pump 2 are connected with a buffering water tank and a circulating pump respectively; the circulating pump is connected with a membrane component; and the membrane component is connected with the buffering water tank, the circulating pump and a concentrated solution discharge pipe through pipelines respectively. The method comprises the following steps: 1, the feeding pump conveys feed liquid to the circulating pump from the buffering water tank; 2, the circulating pump conveys the feed liquid to the membrane component; 3, membrane separation of the feed liquid is implemented in the membrane component; 4, concentrated solution separated by the membrane component is divided into three paths after flowing to the outlet of the membrane component, wherein one path is discharged or collected and utilized by the concentrated solution discharge pipe, another path enters the membrane component through a return pipe and a circulation pipe for circulating separation, and the other path flows to the buffering water tank through the return pipe; and 5, penetrating fluid of the membrane is conveyed to a main pipeline or storage equipment through a delivery pipe.

Owner:于水利

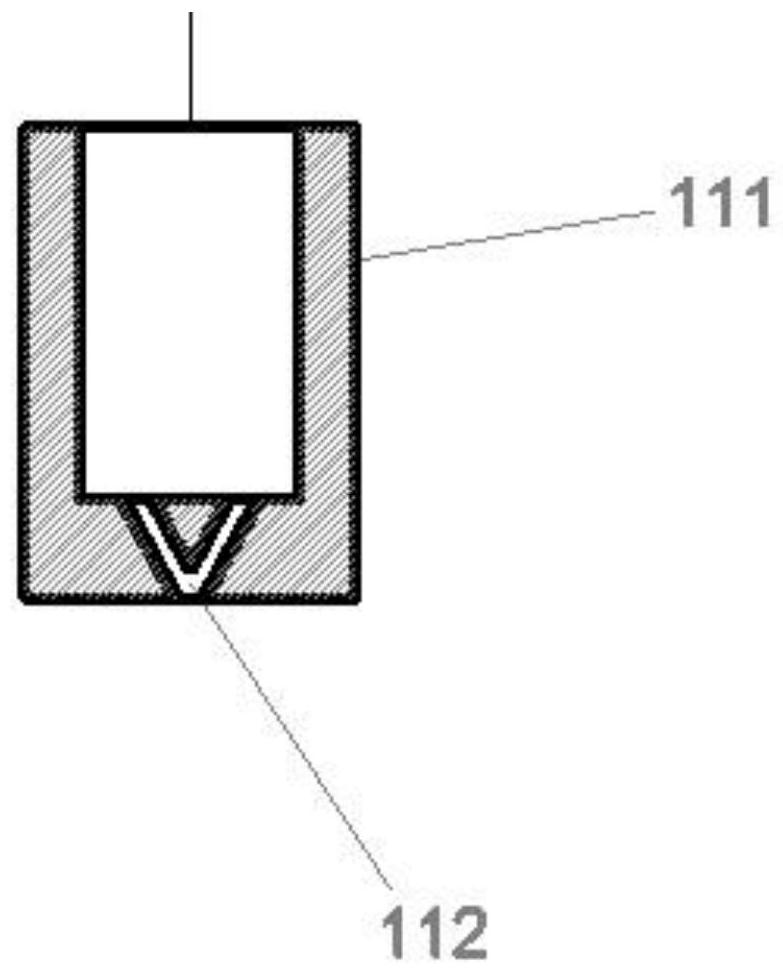

Spray nozzle

InactiveCN104338631AEnough injection pressureIncrease injection pressureSpray nozzlesAcute angleSpray nozzle

The invention discloses a spray nozzle. The spray nozzle comprises a spray nozzle body, wherein a liquid inlet end is arranged at one end of the spray nozzle body; a liquid outlet end is arranged at the opposite end of the spray nozzle body; a cavity communicated with the liquid outlet end and the liquid inlet end respectively is formed inside the spray nozzle body; an inclined plane is arranged on the outer side surface, near the liquid inlet end thereof, of the spray nozzle body; the included angle between the inclined plane and the axis of the liquid inlet end is an acute angle; a plurality of drainage holes are formed in the inclined plane and are communicated with the cavity inside the spray nozzle body respectively. Through arrangement of the inclined spray nozzle body as well as the drainage holes, forming a radial shape, arranged on the spray nozzle body at intervals, the spray nozzle can provide a high enough spraying pressure; the flow of liquid entering the spray nozzle body is enlarged through the drainage holes to enlarge the outflowing amount of the liquid at the liquid outlet end of the spray nozzle, so that the spray nozzle has a very high spraying amount and a very high spraying force, and thus the quality of an electroplated product is improved; particularly, the spray nozzle can provide great help when a workpiece hole is relatively deep.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

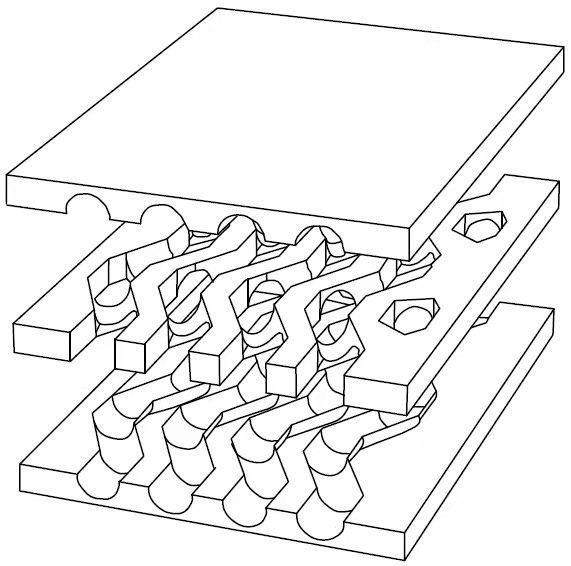

Thermoelectric conversion device and system

ActiveCN114189174AAvoid shockReduce the formation of swirl zonesThermal electric motorPhysicsHeat sink

The invention provides a thermoelectric conversion device and system, and belongs to the technical field of thermoelectric conversion. Comprising a heat exchange heat sink shell, a liquid inlet and a liquid outlet are formed in the two ends of the heat exchange heat sink shell in the length direction respectively, and a plurality of rib walls are arranged in the heat exchange heat sink shell; the end where the liquid inlet is located is provided with a first arc-shaped area, and the end where the liquid outlet is located is provided with a second arc-shaped area. The first end, close to the liquid inlet, of each rib wall is bent towards the liquid inlet, and the second end, close to the liquid outlet, of each rib wall is bent towards the liquid outlet. In the plurality of first end parts, the bending radian of the first end part far away from the liquid inlet is greater than that of the first end part close to the liquid inlet; the distance from the first end part far away from the liquid inlet to the first arc-shaped area is smaller than the distance from the first end part close to the liquid inlet to the first arc-shaped area. By using the thermoelectric conversion device and system provided by the invention, the flow resistance of the liquid can be reduced while the heat exchange uniformity and the thermoelectric conversion efficiency are improved.

Owner:SICHUAN UNIV

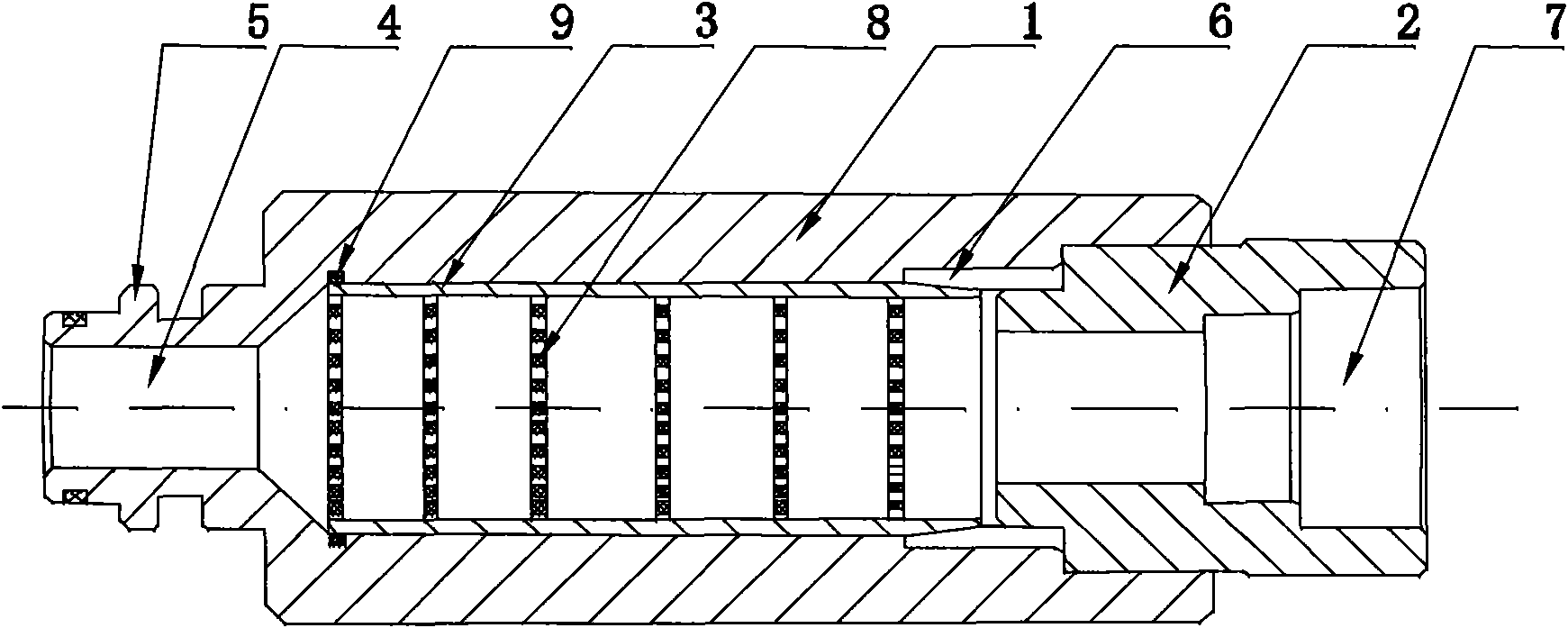

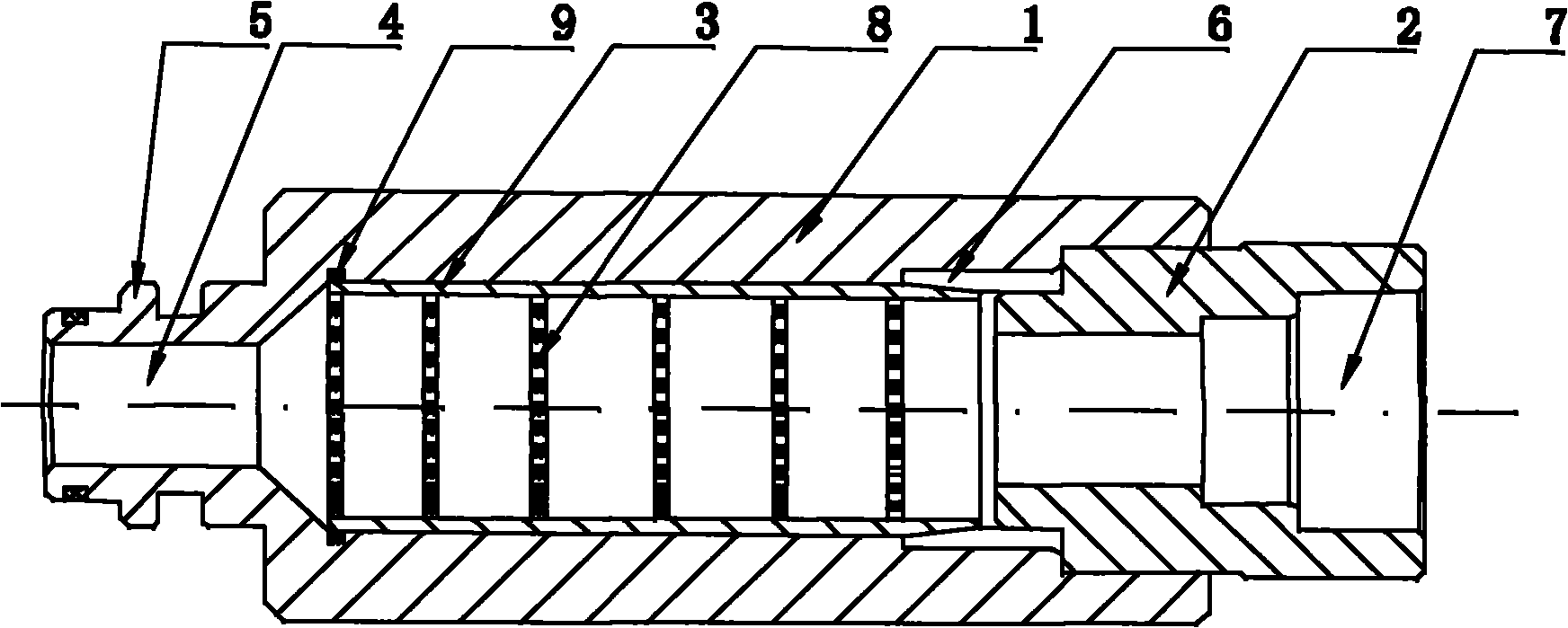

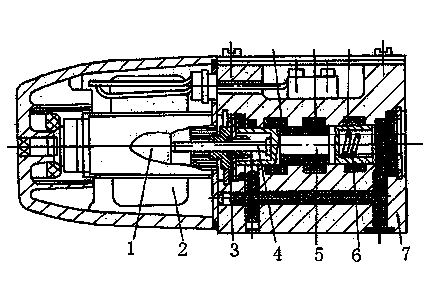

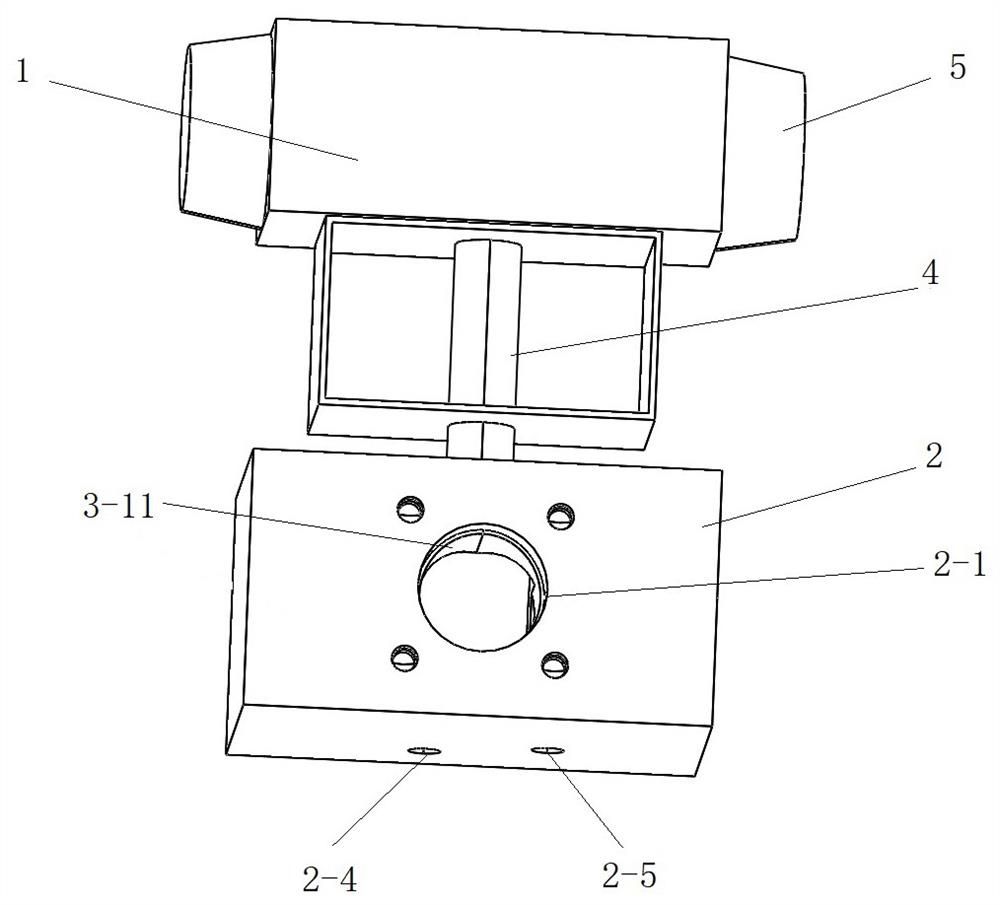

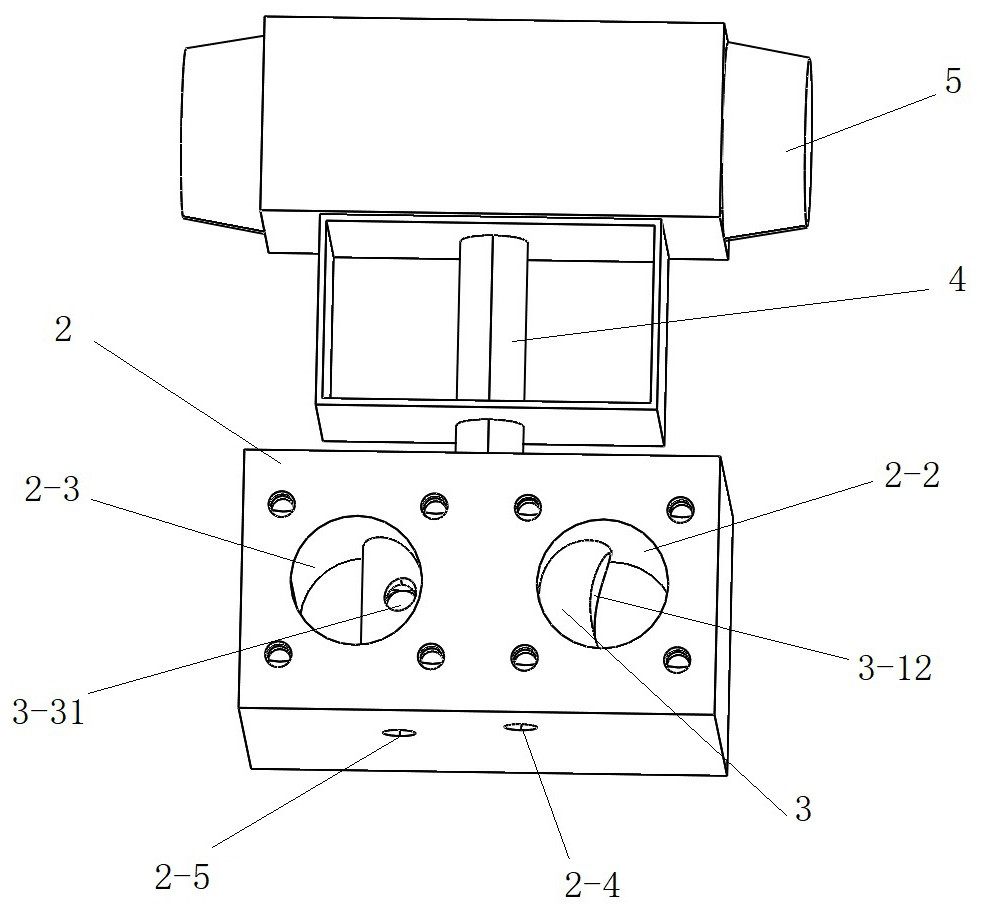

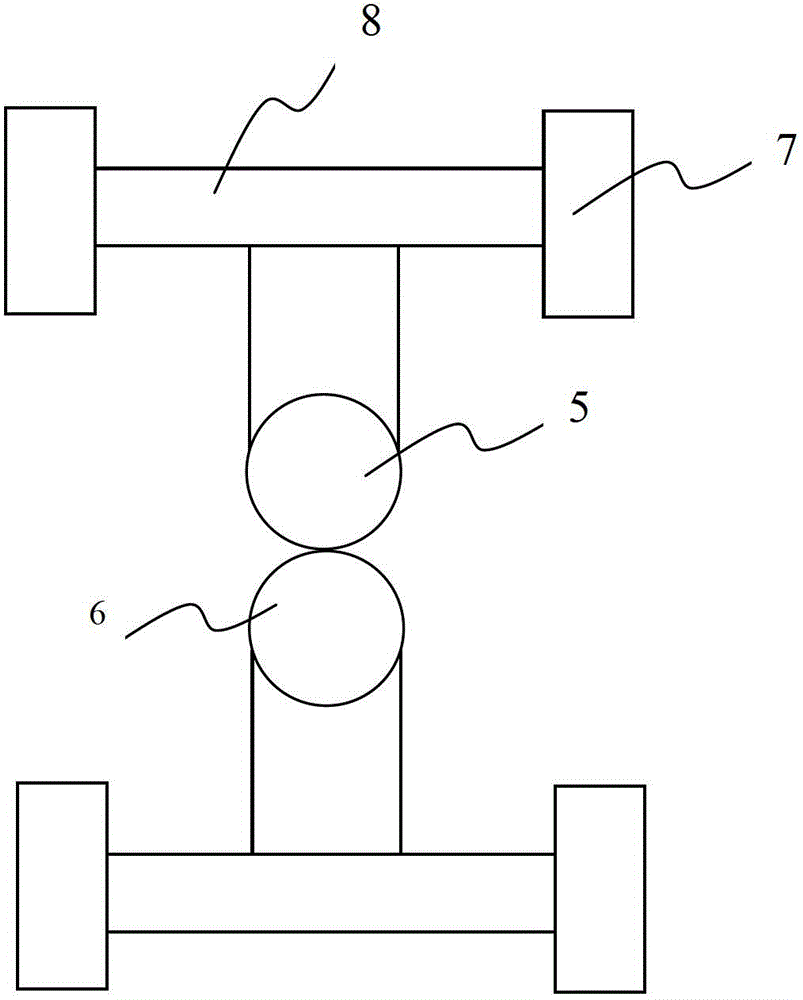

Magnetic exchange valve

InactiveCN103851002AChange parametersIncrease the cross-sectional area of the flow channelServomotor componentsMagnetic exchangeMechanical engineering

The invention discloses a magnetic exchange valve which comprises an armature (1), a coil (2), a push rod (4), a valve core (5) and a valve body (7), wherein the push rod (4) and the valve core (5) are mounted inside the valve body (7), the push rod (4) is connected with the valve core (5), the armature (1) is mounted at the top of the push rod (4), and the coil (2) is mounted at the lower end of the armature (1). According to the magnetic exchange valve provided by the invention, the cross section area of a runner is increased, the liquid flow is increased, and parameters of an electromagnet are changed, so as to reduce power dissipation and increase direction-changing frequency.

Owner:DALIAN QIANBAO CAST IRON FOUNDRY

A propellant management device for use in a propellant tank

ActiveCN104691786BPromote circulationSimple structureCosmonautic propulsion system apparatusOrbitPropellant tank

Owner:BEIJING INST OF CONTROL ENG

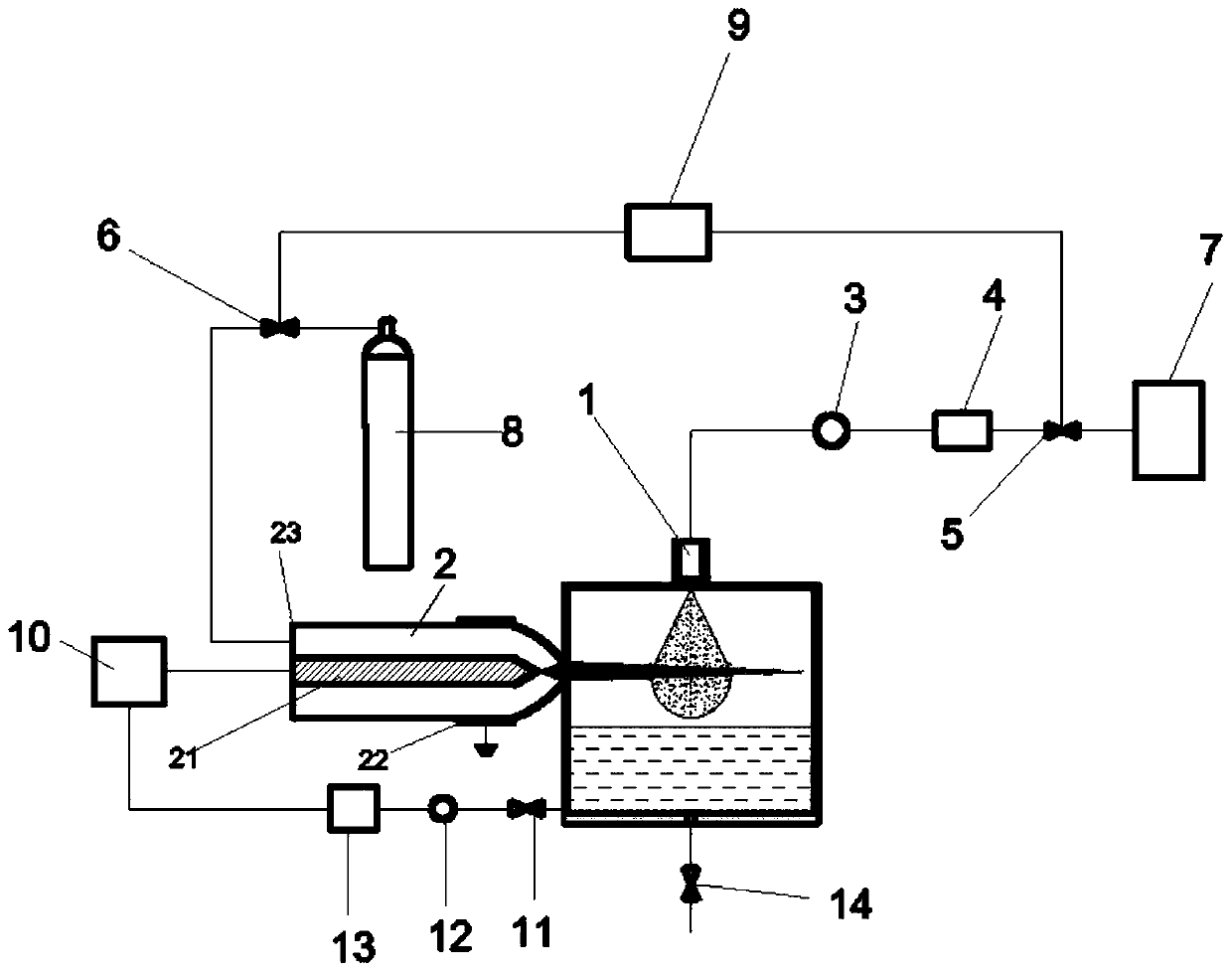

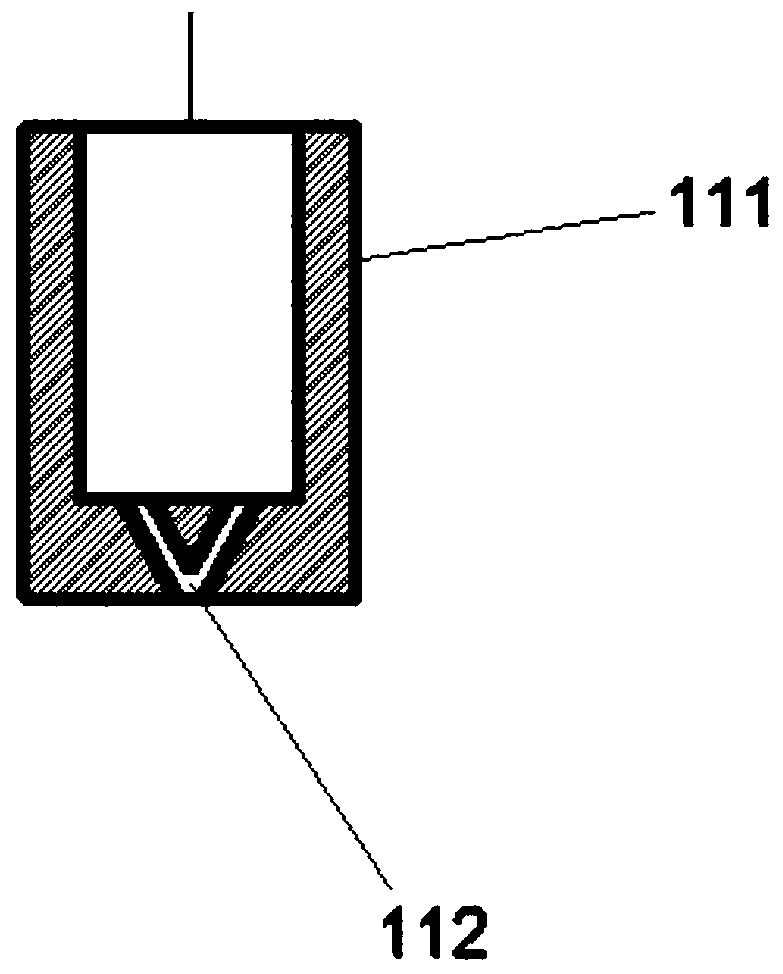

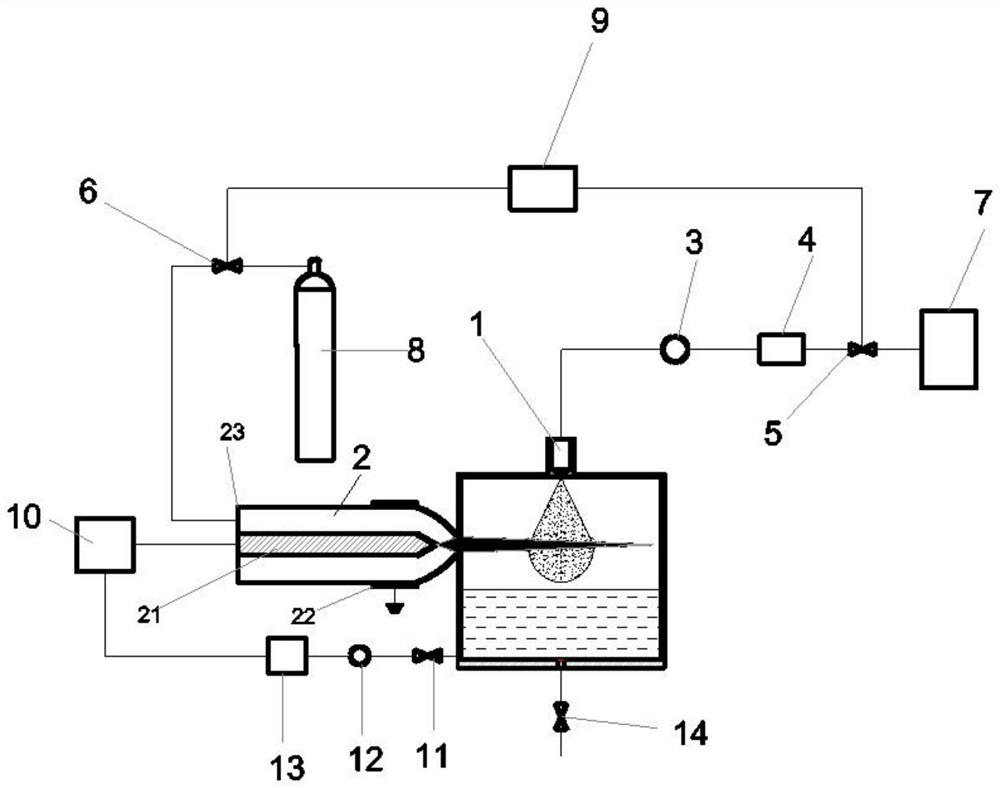

Ship ballasting wastewater purification method

ActiveCN110482646AImprove purification efficiencyLarge liquid flowWater/sewage treatment by irradiationSpecific water treatment objectivesPlasma jetPurification methods

The invention discloses a ship ballasting wastewater purification method. The method comprises the following steps: S1, an electric field is formed in a space between a high-voltage electrode and a grounding electrode; S2, high-pressure gas in the high-pressure gas cylinder enters the electric field space through a gas flow control valve, and plasma jet flow is formed and sprayed out; S3, a to-be-treated liquid in a liquid storage tank passes through a liquid flow control valve, a filter and a flow meter and then is sprayed out in a spraying mode under the action of a liquid processor, and allspraying fields pass through an unbalanced plasma jet flow area; S4, under the effect of the non-equilibrium plasma jet flow, target purification substances contained in the liquid drop particles inthe atomization field are killed; S5, a detection port control valve is turned on, and the purified liquid is pumped out by a detection port reflux pump, and fed into a detector; and S6, the purifiedliquid is analyzed by the detector. A detection mechanism is additionally arranged to further improve the purification effect.

Owner:DALIAN NATIONALITIES UNIVERSITY

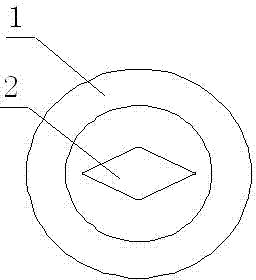

Connecting port of infusion bag

InactiveCN102247290AUniform thicknessNo uneven heatingPharmaceutical containersMedical packagingEngineeringRhomboid

The invention discloses a connecting port of an infusion bag, comprising a body, wherein the body is provided with a longitudinal through hole; a connecting part is arranged at one end of the body; an outlet part is arranged at the other end of the body; the connecting part is provided with two wings, and convex ribs are arranged on the two wings; one section of transitional part for connecting the outlet part with the connecting part is arranged in the middle of the body; the thickness wall of the transitional part is transitioned from thickness to thinness between the outlet part and the connecting part; a through hole is in a rhomboid shape in the connecting part; from top to bottom, the width of the through hole is transitioned from width to narrowness; and the two wings are thin wings. By adopting the rhomboid design and producing the two wings into the thin wings, the thickness of the side wall of the connecting part at the connecting port of the infusion bag is kept uniform; during heat sealing, the non-uniformity during heating is avoided, favorable heat sealing performance is obtained and materials are saved; meanwhile, by adopting the design of the transitional part, the materials are further saved.

Owner:江苏金扬子包装科技有限公司

Valve element component of safety valve

InactiveCN107503785AIncrease drainage flowImprove unloading capacityMine roof supportsEngineeringSafety valve

The invention discloses a valve element component of a safety valve. The valve element component comprises a valve body, a valve element in movable arrangement, a valve sleeve sleeving the valve element and positioned inside the valve body and a compression screw positioned inside the valve body and used for limiting the valve element and the valve sleeve, the valve element comprises a liquid incoming section and a guide section which are axially arranged sequentially, outer diameter of the liquid incoming section is greater than that of the guide section, the valve sleeve sleeves the liquid incoming section, the compression screw sleeves the guide section, and a first liquid passing hole, a second liquid passing hole, a third liquid passing hole and a fourth liquid passing hole which are axially arranged sequentially are formed in the liquid incoming section. The valve element is axially limited through the compression screw, and a limiting structure on the valve element is positioned inside the compression screw and matched with the same, so that requirements on wall thickness of the liquid incoming section of the valve element are lowered; an inner cavity of the liquid incoming section of the valve element can be arranged to be large to enable liquid passing flow of the valve element component to be large, so that increasing of liquid discharging flow of the safety valve is facilitated.

Owner:HONGDA INTELLIGENT MACHINERY CO LTD

Two-position five-way negative pressure switching valve

PendingCN112161085ADoes not affect the vacuum stateSimple structureMultiple way valvesValve housingsWater storageWater storage tank

The invention provides a two-position five-way negative pressure switching valve. The valve comprises a valve body and a valve element, wherein an inner cavity matched with the valve element in shapeis formed in the valve body, the valve element is limited in the inner cavity of the valve body, the outer surface of the valve element is tightly attached to the inner wall of the inner cavity of thevalve body, the valve body is provided with an inlet channel, a first outlet channel, a second outlet channel, a first ventilation hole channel and a second ventilation hole channel, and the first ventilation hole channel and the second ventilation hole channel are communicated with outside atmosphere respectively; when the valve element is located at a first working position, the inlet channel is communicated with the first outlet channel, the inlet channel is isolated from the second outlet channel, and the second outlet channel is communicated with the second ventilation hole channel; andwhen the valve element is located at a second working position, the inlet channel is communicated with the second outlet channel, the inlet channel is isolated from the first outlet channel, and the first outlet channel is communicated with the first ventilation hole channel. The valve is connected between a separator of a vacuum system and two water storage tanks, any working position can enableone water storage tank to be communicated with the separator and store water, and the other water storage tank is isolated from the vacuum system and drains water.

Owner:NINGBO BAOSI ENERGY EQUIP

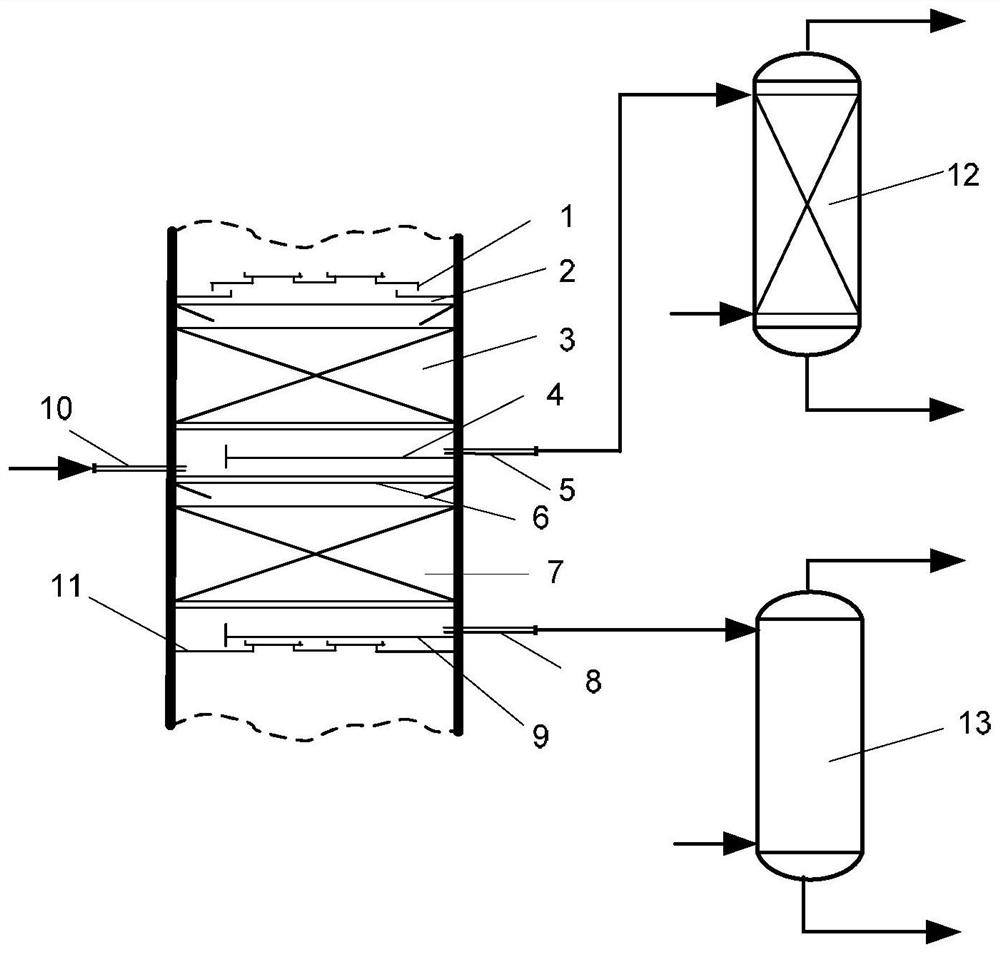

Method for increasing yield of aviation kerosene fraction by adjusting catalytic cracking main fractionating tower

ActiveCN112500882AReduce the amount of modification worksLess investmentHydrocarbon distillationKeroseneDiesel fuel

The invention relates to a method for increasing the yield of aviation kerosene fraction by modifying a catalytic cracking main fractionating tower. The method comprises the following steps that: S1,a plurality of tower plates above a light diesel oil extraction hopper and below a top cycle extraction hopper are removed, and a filler A and an oil collecting tank A are arranged from top to bottom,wherein an aviation kerosene fraction can be extracted from the oil collecting tank A and sent to an aviation kerosene refining device; S2, a plurality of tower plates below a rich absorption oil inlet are removed, and a liquid distributor B, a filler B and an oil collecting tank B are arranged from top to bottom, wherein a light diesel fraction can be extracted from the oil collecting tank B; and S3, an aviation kerosene fraction stripping tower utilizes an original heavy diesel oil stripping tower, the aviation kerosene fraction enters the aviation kerosene fraction stripping tower to be stripped, the aviation kerosene fraction is cooled and sent to the aviation kerosene refining device, and the 95% distillation point of the aviation kerosene fraction is controlled according to the extraction amount of the aviation kerosene fraction. The aviation kerosene extraction line of the qualified aviation kerosene distillation range is added to the catalytic device fractionating system by modifying part of tower trays of the catalytic cracking device fractionating tower and other measures, existing conditions of an old original device are fully utilized, the modification work amount is reduced, investment is saved, and important guiding significance is achieved for aviation kerosene production increase of refinery enterprises.

Owner:PETROCHINA CO LTD +1

A method for purifying ship ballast wastewater

ActiveCN110482646BImprove purification efficiencyLarge liquid flowWater/sewage treatment by irradiationSpecific water treatment objectivesPlasma jetPurification methods

Owner:DALIAN NATIONALITIES UNIVERSITY

A continuous membrane treatment method for alkali press liquid in viscose fiber production process

ActiveCN110559861BStart running smoothlyIncreased hemifiber contentReverse osmosisProcess engineeringNanofiltration

The invention relates to a continuous membrane treatment method for alkali squeeze liquid in the viscose fiber production process, including the steps of material preparation, feeding, and system operation; wherein, in the process of system operation, a cleaning step is also included: the first stage The nanofiltration membrane module is switched out from the nanofiltration membrane system for cleaning, other nanofiltration membrane modules are operating normally, and the alkali squeeze liquid or the concentrated liquid produced by the upper nanofiltration membrane module skips the cleaning nanofiltration membrane module. After cleaning, the nanofiltration membrane module is connected back to the nanofiltration membrane system in series; and so on, the nanofiltration membrane modules at all levels are cleaned separately. The invention is a set of continuous membrane treatment process with automatic operation and cleaning, which changes the batch intermittent operation mode adopted by the traditional technology, can effectively improve the utilization rate of the nanofiltration membrane, reduce the cleaning times of the nanofiltration membrane, and prolong the service life of the nanofiltration membrane .

Owner:唐山三友远达纤维有限公司

Hard mouth tube of infusion bag

InactiveCN102293714AUniform thicknessNo uneven heatingPharmaceutical containersMedical packagingBiomedical engineeringDiamond

The invention discloses a hard mouth tube of an infusion bag, which comprises a body, and a through hole in the vertical direction is arranged on the body, one end of the body is a connection part, and the other end is an outlet part, and there is a section in the middle of the body for The transition part connecting the outlet part and the connection part, the said through hole is circular in the outlet part and oblate rhombus in the connection part, and the wall thickness of the transition part transitions from thick to thin from the outlet part to the connection part. The flat diamond-shaped design makes the thickness of the side wall of the connection part of the hard mouth tube of the infusion bag uniform, so that heat sealing will not be uneven, the heat sealing quality is good, and materials are saved. At the same time, the design of the transition part further saves materials.

Owner:江苏金扬子包装科技有限公司

A hydrodynamic radial bearing and a centrifugal pump

ActiveCN109944871BFloat quicklyIncrease pressurePump componentsSliding contact bearingsMechanical engineeringMechanics

The invention provides a hydrodynamic radial bearing provided with an axial-flow pressurizing structure and a centrifugal pump. The hydrodynamic radial bearing comprises a shaft sleeve and a bearing body matched with the inside of the shaft sleeve; the bearing body comprises two opposite end surfaces and a side surface located between the two opposite end surfaces; and the axial-flow pressurizingstructure is arranged on the side surface of the bearing body, is close to at least one of the two opposite end surfaces and is far away from the central area of the side surface. Compared with the prior art, the hydrodynamic radial bearing has the advantages that a pressurizing device is added to the front part of the hydrodynamic radial bearing, the cavitation phenomenon which is caused easily in a general hydrodynamic bearing is restrained, and the reliability of the bearing is improved remarkably.

Owner:XI AN JIAOTONG UNIV

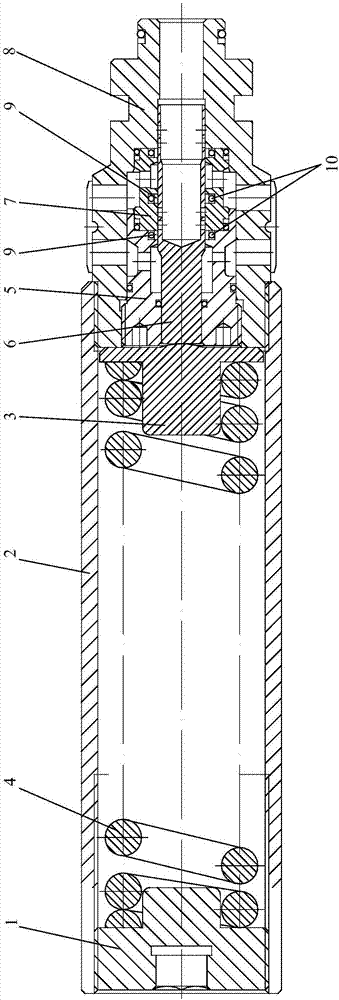

Medium-high lift full-cross-flow submersible mixed-flow electric pump

PendingCN114718880ASimple supporting structureUnderwater work is stablePump componentsRotary non-positive displacement pumpsMixed flowElectric machine

The invention provides a medium-high lift full-cross-flow submersible mixed-flow electric pump, and relates to the field of water pumps. The medium-high-lift full-cross-flow submersible mixed-flow electric pump comprises an outer pipe, a driving motor is arranged in the outer pipe, the lower end of the driving motor is fixedly connected with a planetary reducer, the output end of the driving motor is connected with the input end of the planetary reducer, blades are arranged below the planetary reducer, and the output end of the driving motor is connected with the input end of the planetary reducer. The paddle is fixed to the output end of the planetary reducer, a variable-diameter section is arranged on the lower portion of the outer pipe, the paddle is located above the variable-diameter section, the side wall of the outer pipe is sleeved with a sleeve, the sleeve is located at the variable-diameter section, a plurality of openings are formed in the side wall of the sleeve at equal angles, and anchoring mechanisms are arranged on the inner sides of the openings. The electric pump is provided with the anchoring mechanism, the electric pump is supported, and a component dissolved in water is adopted, so that triggering of the anchoring mechanism is simplified.

Owner:TAIZHOU TAIFENG PUMP IND

Pneumatic operation and remote monitoring system for tanker filling and exhausting

ActiveCN103538814BGuaranteed accuracyImprove reliabilityLarge containersItem transportation vehiclesMonitoring systemCharge and discharge

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

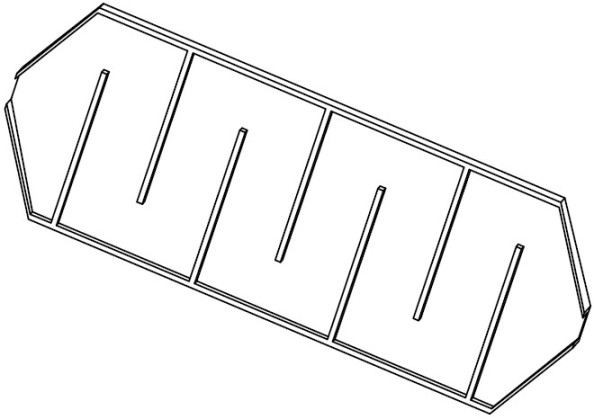

Valve body blank

The invention relates to a directional control valve, in particular to a valve body blank, which comprises a main flow passage, control flow passages and oil inlet flow passages, wherein the main flow passage is arranged in the middle of a valve body, the control flow passages are arranged above the main flow passage and the oil inlet flow passages are arranged below the main flow passage. Four edges at the upper end of the valve body are slope surfaces. Two rectangular bulges are respectively arranged adjacent to the middle positions on the slope surfaces on the two sides of two short edges at the upper end. A platform is arranged on the edge of each slope surface. L-shaped grooves are arranged on the two sides of the long edges at the upper end, i.e. at four corners. Semicircular grooves are arranged in the middle of the long edges. An upper end surface is provided with two control oil holes. A left end surface and a right end surface are respectively provided with two flow passage holes, i.e. an auxiliary oil hole and a main flow passage hole, wherein auxiliary oil holes are respectively formed in the rectangular bulges of the slope surfaces of the upper end, and main flow passage holes are respectively formed in the middle and the edges of the main flow passage holes are bell-mouth-shaped. A lower end surface is provided with two auxiliary oil holes and four oil inlets, wherein the two auxiliary oil holes and the four oil inlets are transversely arranged in two rows at positions close to two sides. The drift diameter of the oil inlet flow passages is phi 28mm. The valve body blank has the advantages of simple structure, material saving, large flow and enough hydraulic force.

Owner:南通华东油压科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com