Ship ballasting wastewater purification method

A waste water purification and ballast technology, applied in chemical instruments and methods, natural water treatment, water/sewage treatment, etc., can solve the problems of reduced energy efficiency, low water conductivity, power consumption, etc., to improve the purification effect and improve the purification effect. flow, the effect of increasing liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

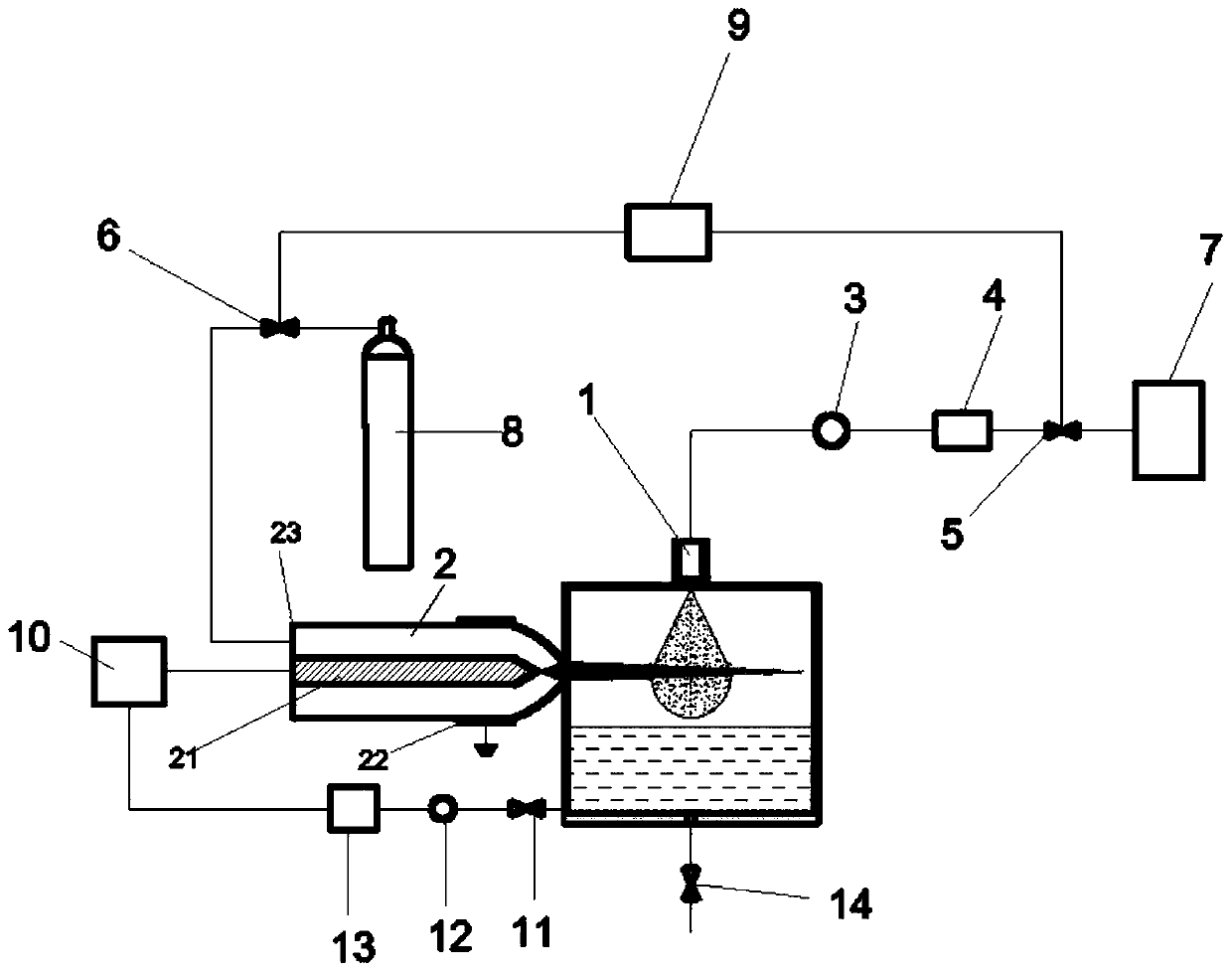

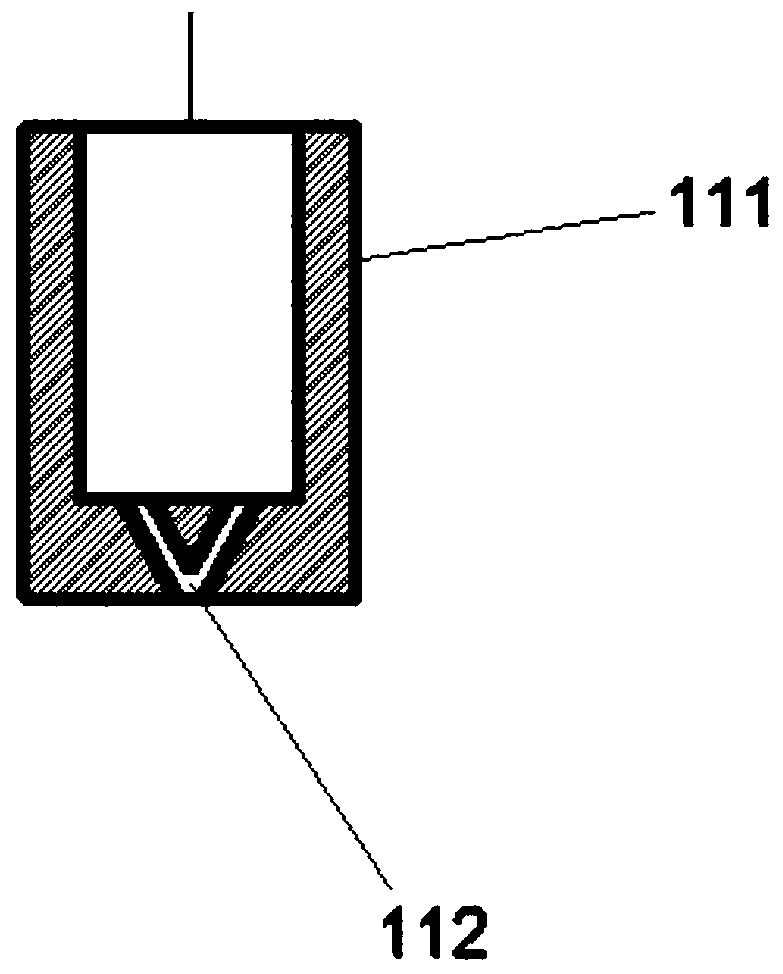

[0027] This embodiment provides a purification device, including: a liquid processor, an unbalanced plasma jet actuator, a flow meter, a filter, a liquid flow control valve, a gas flow control valve, a liquid storage tank, a high-pressure gas cylinder, and a valve opening Electronic controller, plasma power supply, detection port control valve 11, detection port reflux pump 12, detector 13 and water treatment tank; the liquid processor is connected to the liquid storage tank through a flow meter, a filter, and a liquid flow control valve in sequence , the liquid flow control valve is also connected to one end of the valve opening electronic controller, the other end of the valve opening electronic controller is connected to the gas flow control valve, and the gas flow control valve is located between the high-pressure gas cylinder and the unbalanced On the pipeline between the plasma jet actuators, the unbalanced plasma jet actuator is connected to the plasma power supply, the ...

Embodiment 2

[0033] The present embodiment provides a method for purifying ship ballast wastewater, comprising the following steps:

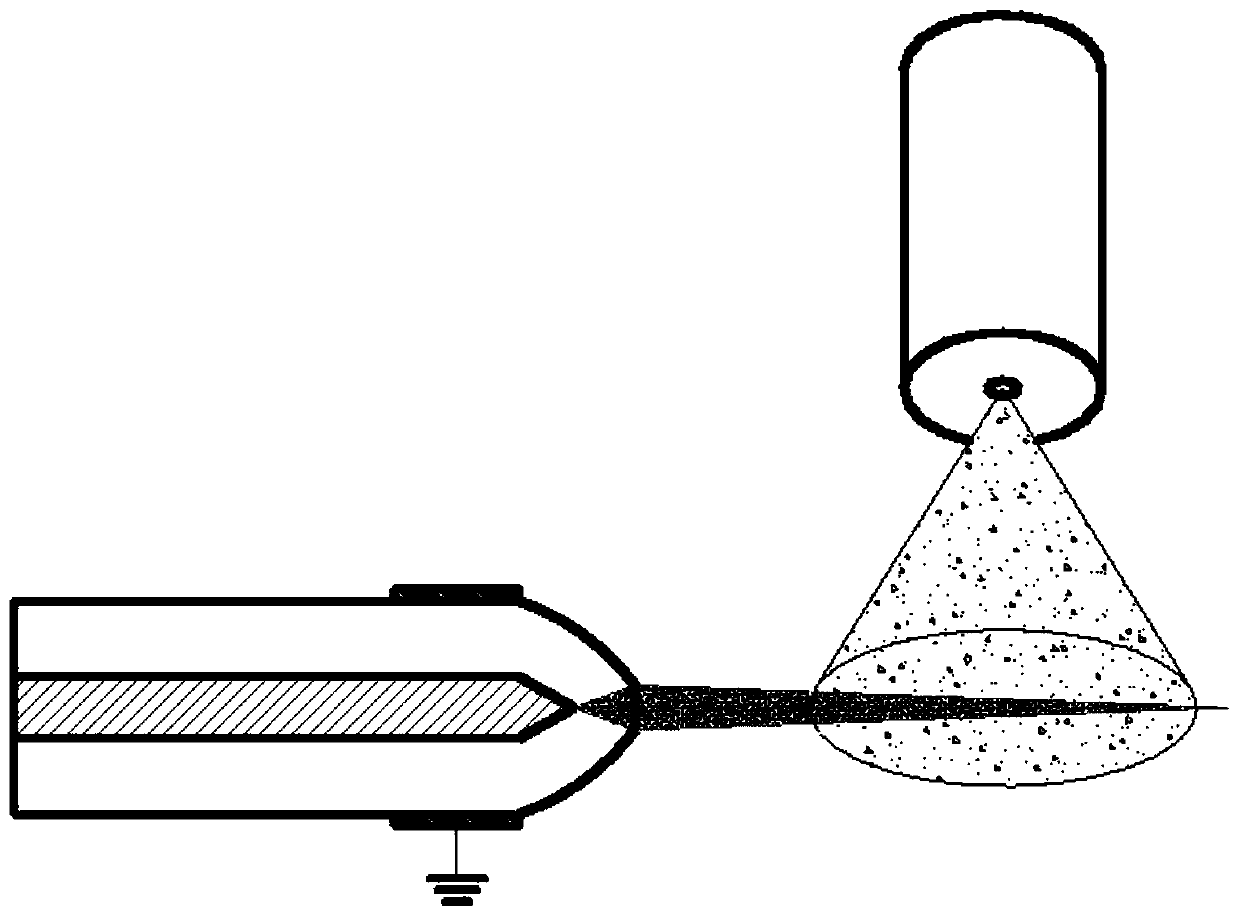

[0034] 1. The plasma power supply 10 supplies power to the high-voltage electrode 21 (or 22 ), and forms an electric field in the space between the high-voltage electrode 21 and the ground electrode 22 .

[0035]2. The valve opening electronic controller 9 controls the gas flow control valve 6 to open, and the high-pressure gas in the high-pressure gas cylinder 8 enters the electric field space through the gas flow control valve 6 to form a plasma jet and eject it.

[0036] 3. The valve opening electronic controller 9 controls the liquid flow control valve 5 to open, and the liquid to be treated in the liquid storage tank 7 passes through the liquid flow control valve 5, the filter 4, and the flow meter 3. The spray is ejected in the form of a spray, and the entire spray field passes through the non-equilibrium plasma jet region.

[0037] 4. Under the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com