Patents

Literature

118 results about "Plasma water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The liquid portion of the blood, the plasma, is a complex solution containing more than 90 percent water. The water of the plasma is freely exchangeable with that of body cells and other extracellular fluids and is available to maintain the normal state of hydration of all tissues.

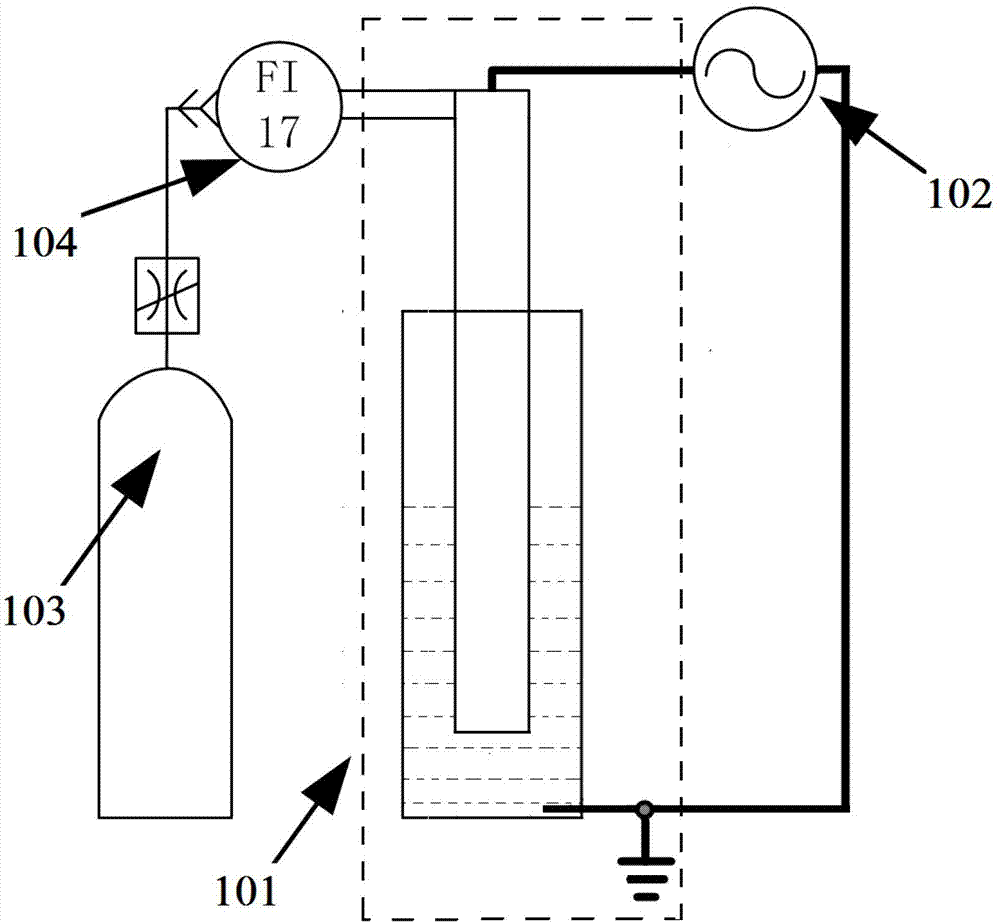

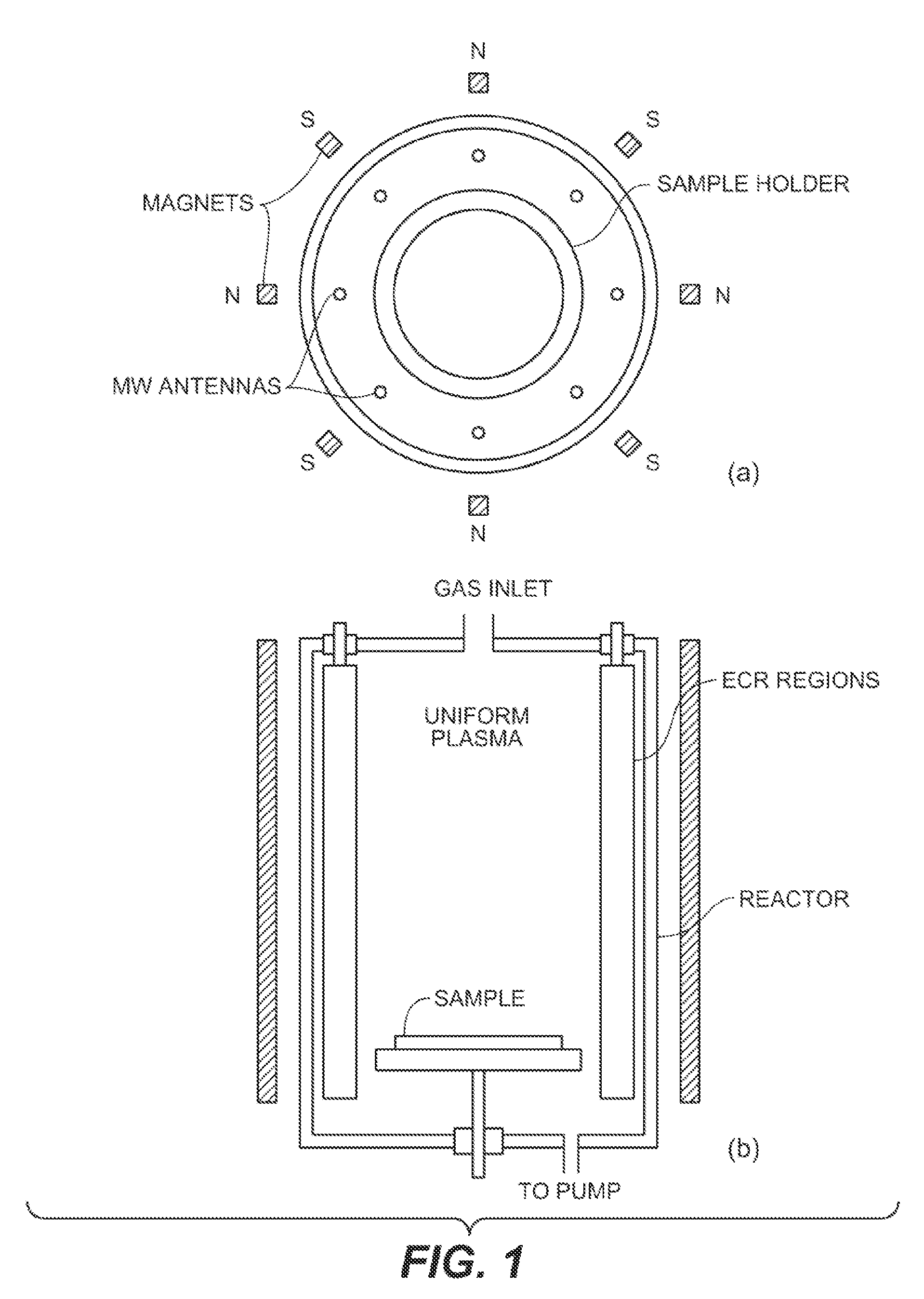

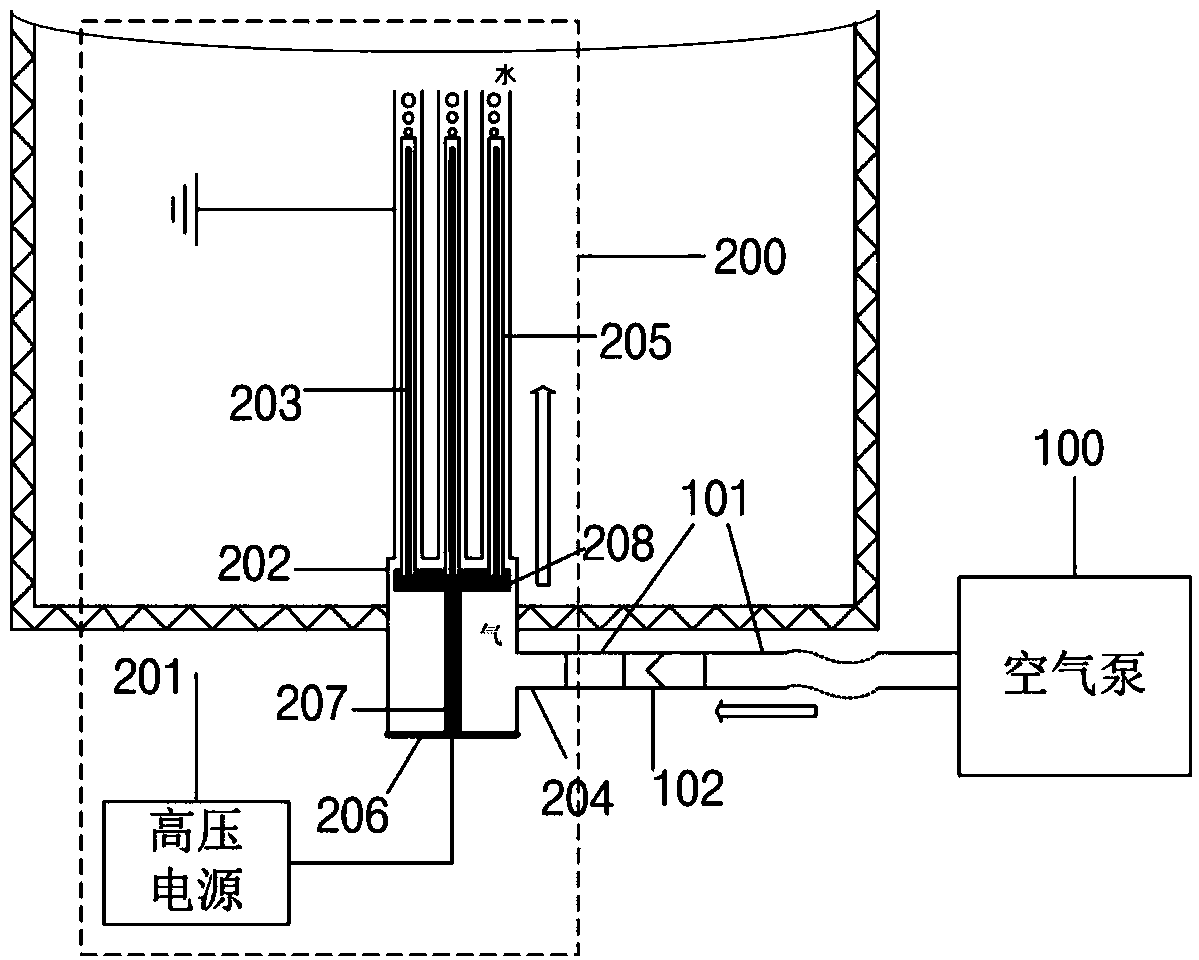

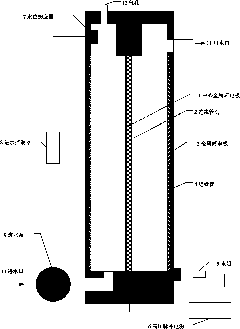

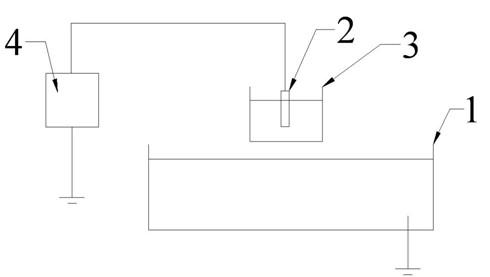

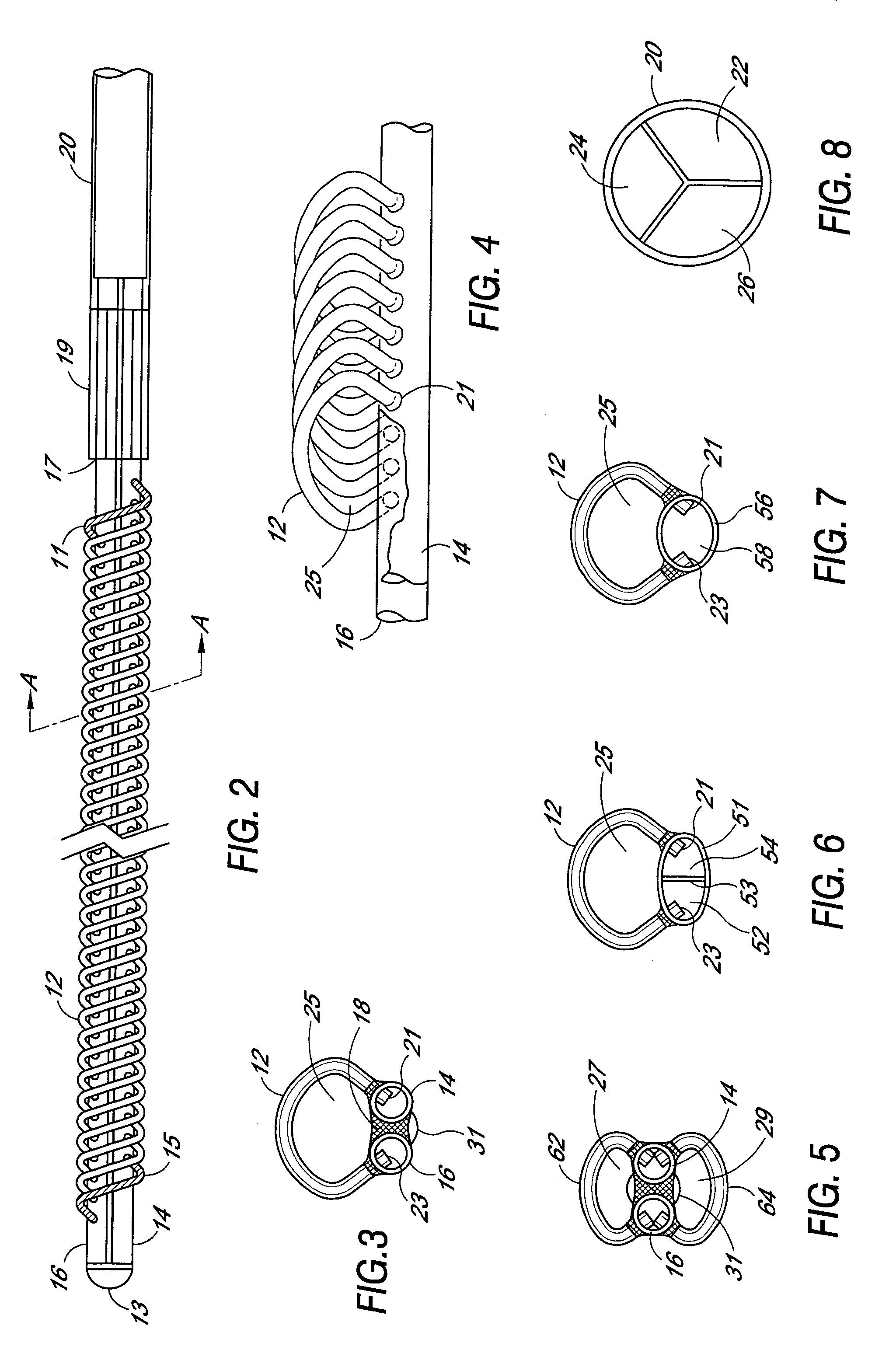

Enhanced-type capillary-needle discharging plasma water treatment device

ActiveCN102897892AAvoid problems with limited depth of actionAvoid lostWater/sewage treatment by irradiationWater/sewage treatment by magnetic/electric fieldsCapillary TubingEngineering

The invention relates to an enhanced-type capillary-needle discharging plasma water treatment device, which belongs to the technical field of the application of low-temperature plasma, and relates to a constant-pressure plasma discharging reaction device for water treatment, and the enhanced-type capillary-needle discharging plasma water treatment device is characterized by comprising a reaction container and a discharging device, wherein the discharging device consists of a metal capillary power electrode, an insulation medium pipe, a metal end cover suspension electrode and an air chamber and is arranged inside the reaction container; working gas enters the metal capillary and the insulation medium pipe through the air chamber, gas discharging plasma is generated inside the insulation medium pipe between a needle-shaped pipe orifice on the lower end of the metal capillary and a metal end cap under the effect of high-voltage power supply, a generated product enters solution to be treated through small holes on the metal end cap, and solution inside the reaction container is purified; and the enhanced-type capillary-needle discharging plasma water treatment device has advantages that the utilization rate of active substances is high, the universality for different solutions to be treated is strong, the stability is good, easiness in integration is realized, and the exciting source requirement of the plasma is reduced.

Owner:TSINGHUA UNIV

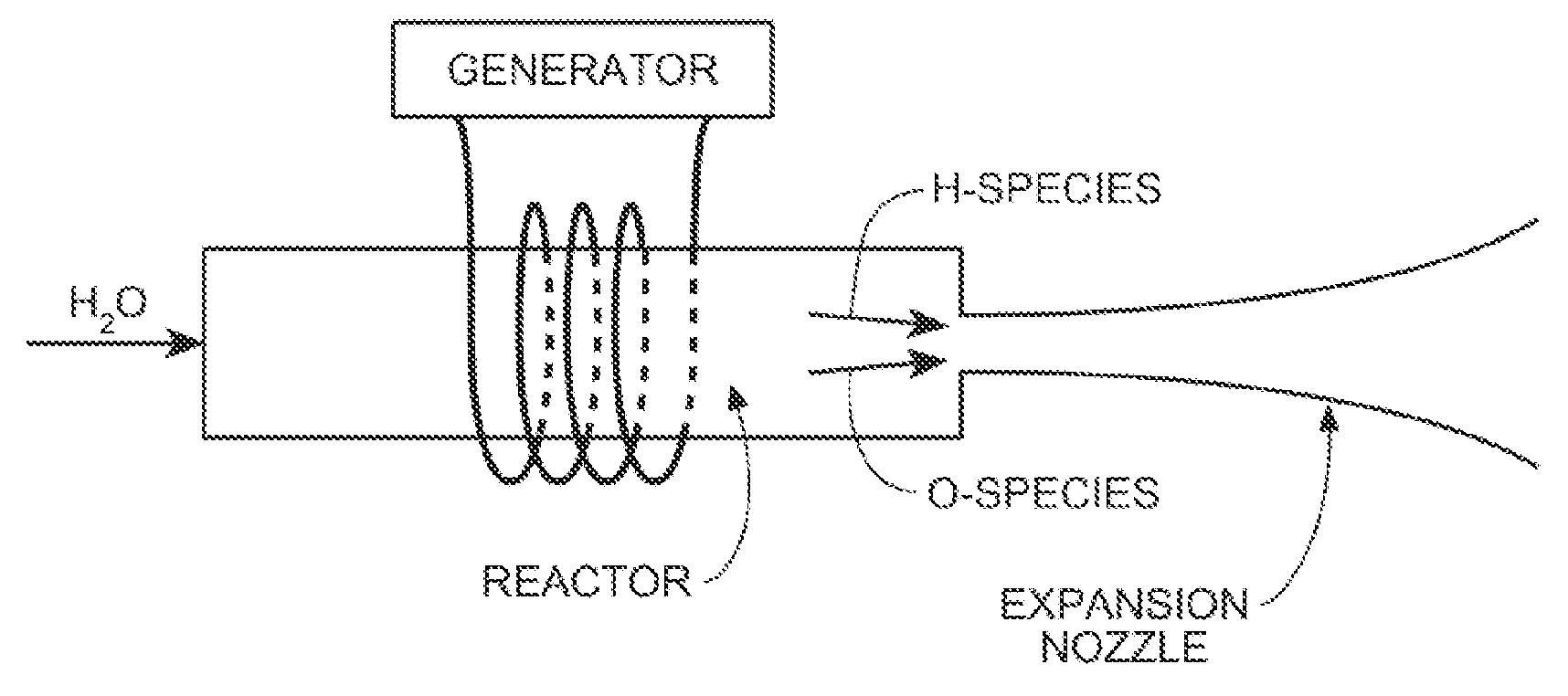

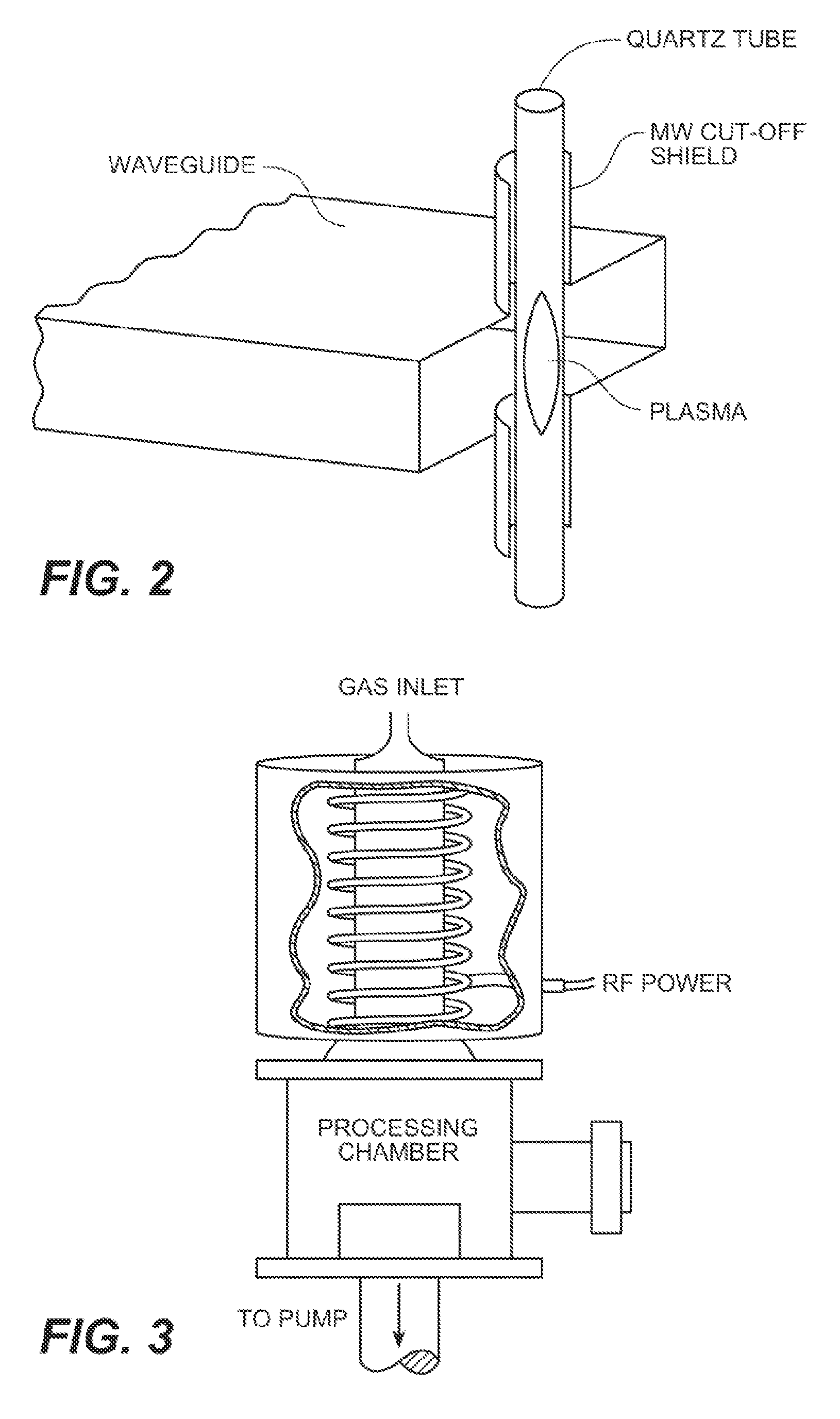

Method for generating hydrogen from water or steam in a plasma

Water molecules, preferably in the form of steam or water vapor, are introduced into a plasma. The plasma causes the water molecules to dissociate into their constituent molecular elements of hydrogen and oxygen. To prevent recombining of the constituent molecular elements, the hydrogen and oxygen are separated from each other. Various devices may be employed to effect this separation. Once separated, the molecular components are prevented from recombining with each other or with other elements by using standard separation techniques normally employed for separating dissimilar gaseous species.

Owner:BAR GADDA

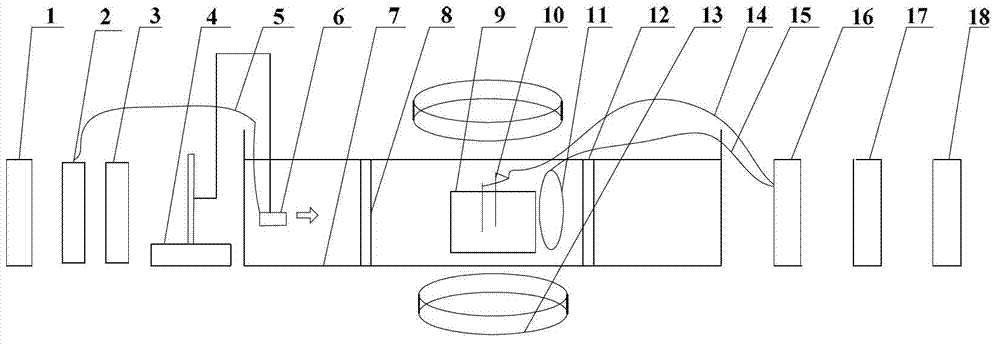

Magnetic, acoustic and electric imaging system and imaging method

ActiveCN102805621AGood removal effectImprove imaging resolutionUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringSonificationElectromotive force

The invention discloses a magnetic, acoustic and electric imaging system and an imaging method. The system comprises an excitation source, a synchronization trigger control module (1), a water tank (7), a three-dimensional scanning platform and a signal detection system; the excitation source produces induced electromotive force in a sample to be detected; the synchronization trigger control module (1) synchronizes and controls the excitation source, the three-dimensional scanning platform and the signal detection system; decoupling plasma water or an insulation oil solution is accommodated in the water tank; the three-dimensional scanning of an ultrasonic transmitting probe is realized by the three-dimensional scanning platform; the signal detection system detects weak electric signals; and the excitation source is controlled by the synchronization trigger control module (1) to produce the induced electromotive force in the sample to be detected. By the transmission mode of ultrasonic waves in the sample to be detected, the combined action area of an acoustic source and a static magnetic field can be accurately positioned, and the electric current density of every moment is acquired by a gradual progressive mode by a time progressive method, so that the information of the electric current density of the whole acoustic wave spreading path can be acquired.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

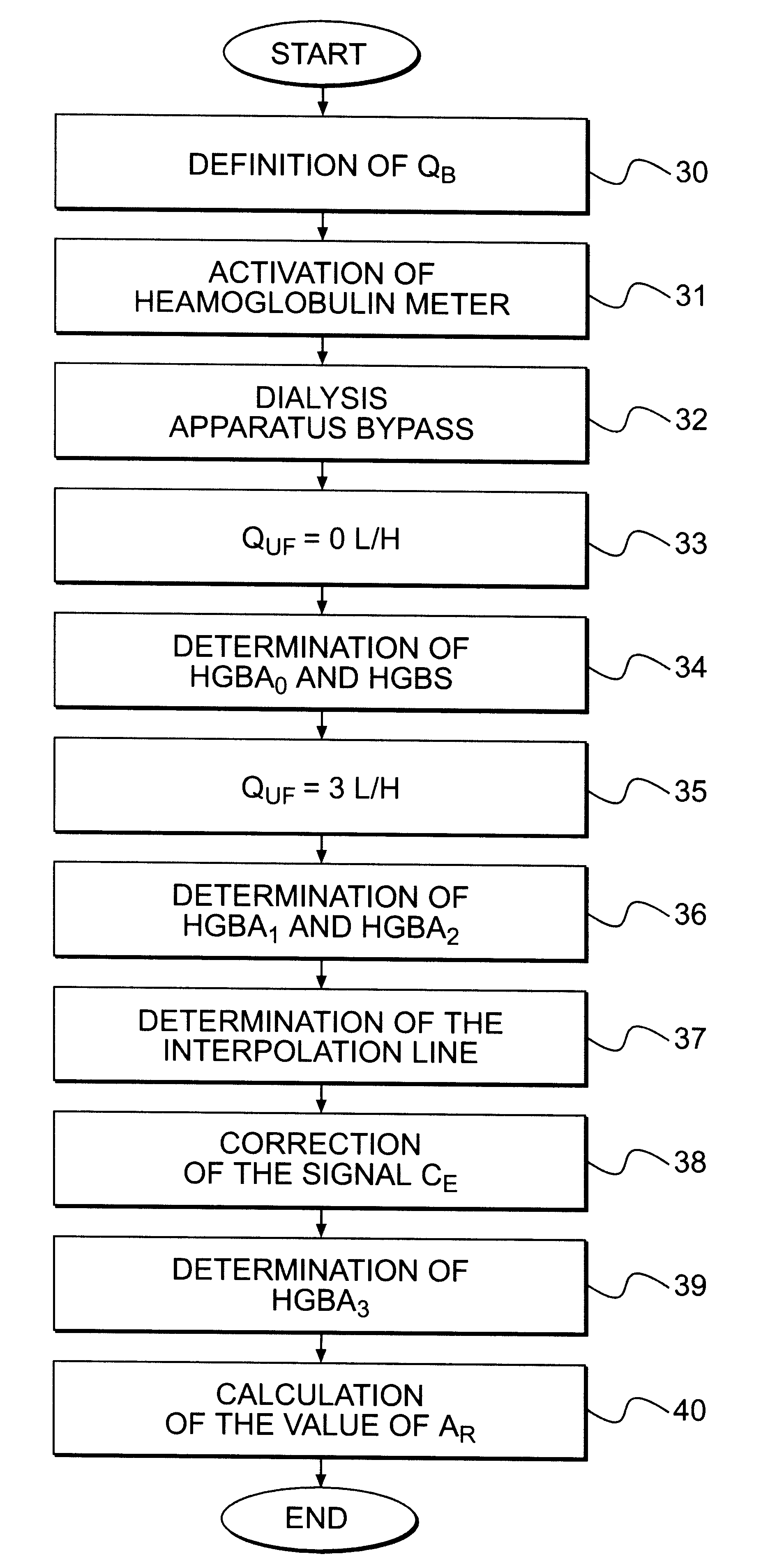

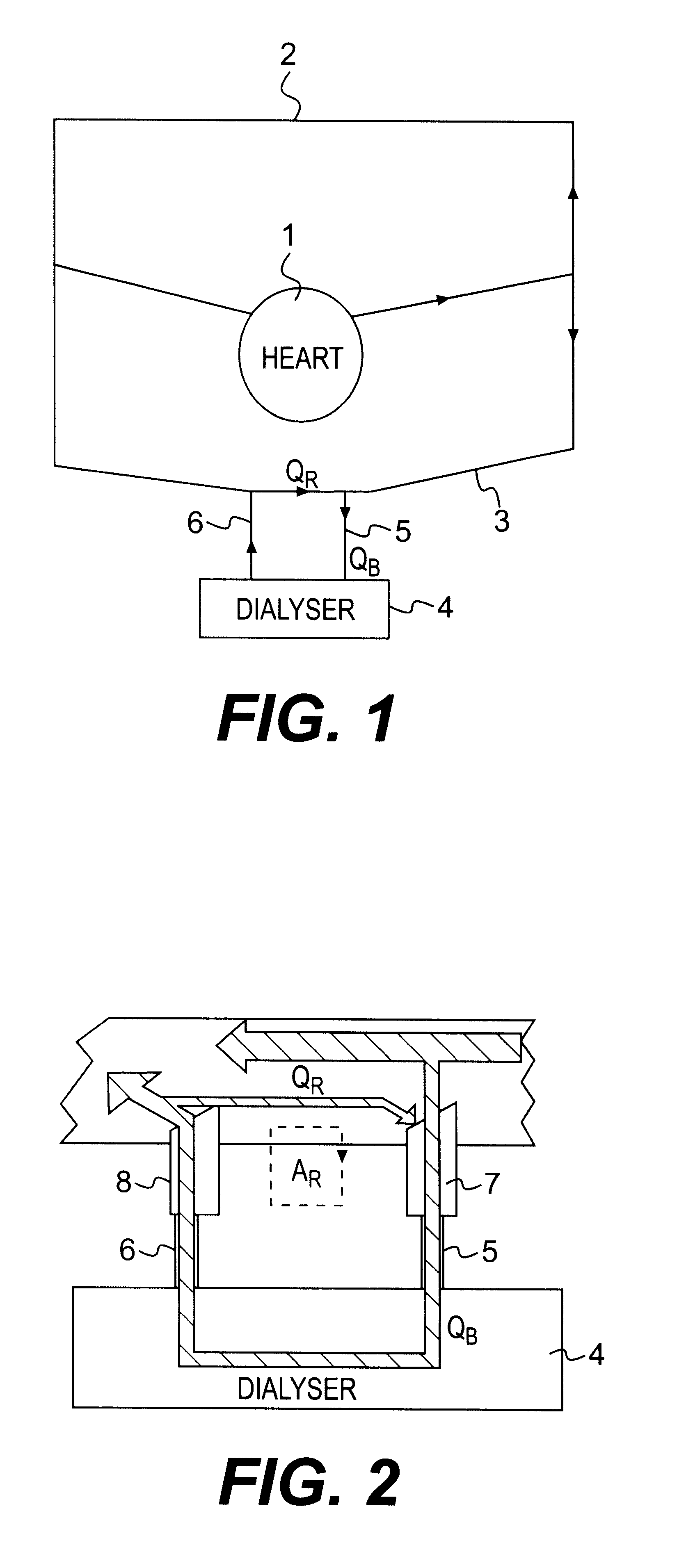

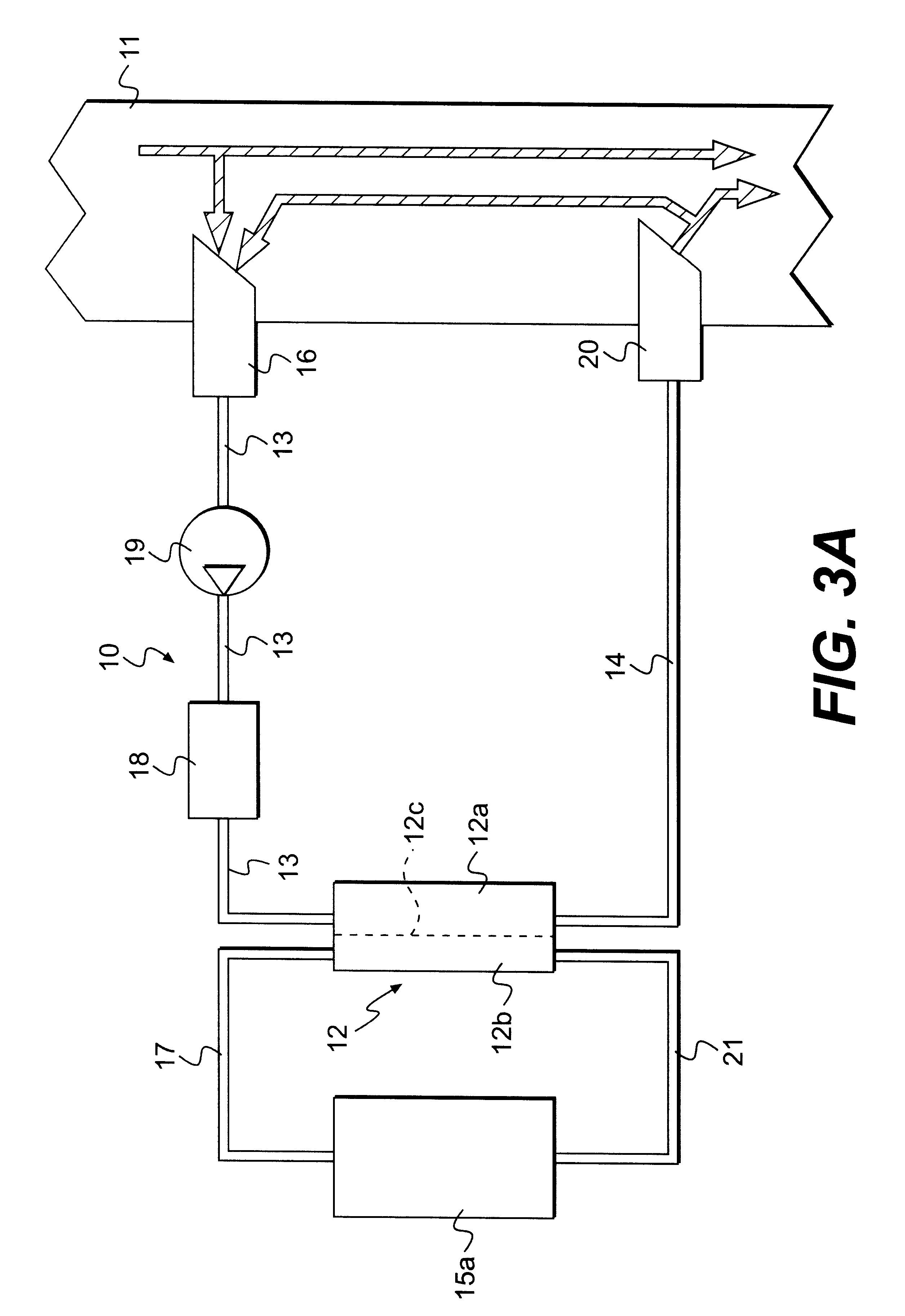

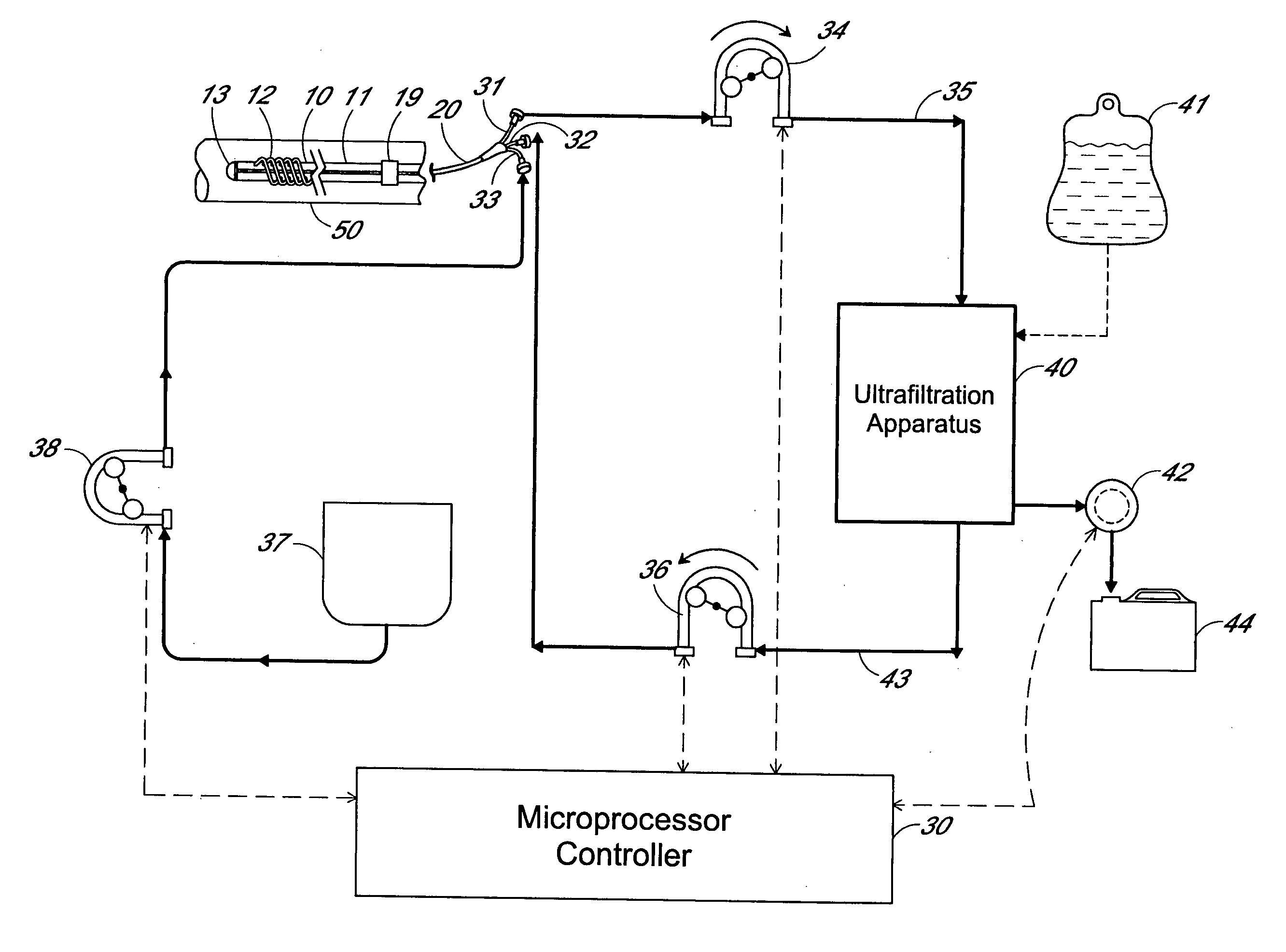

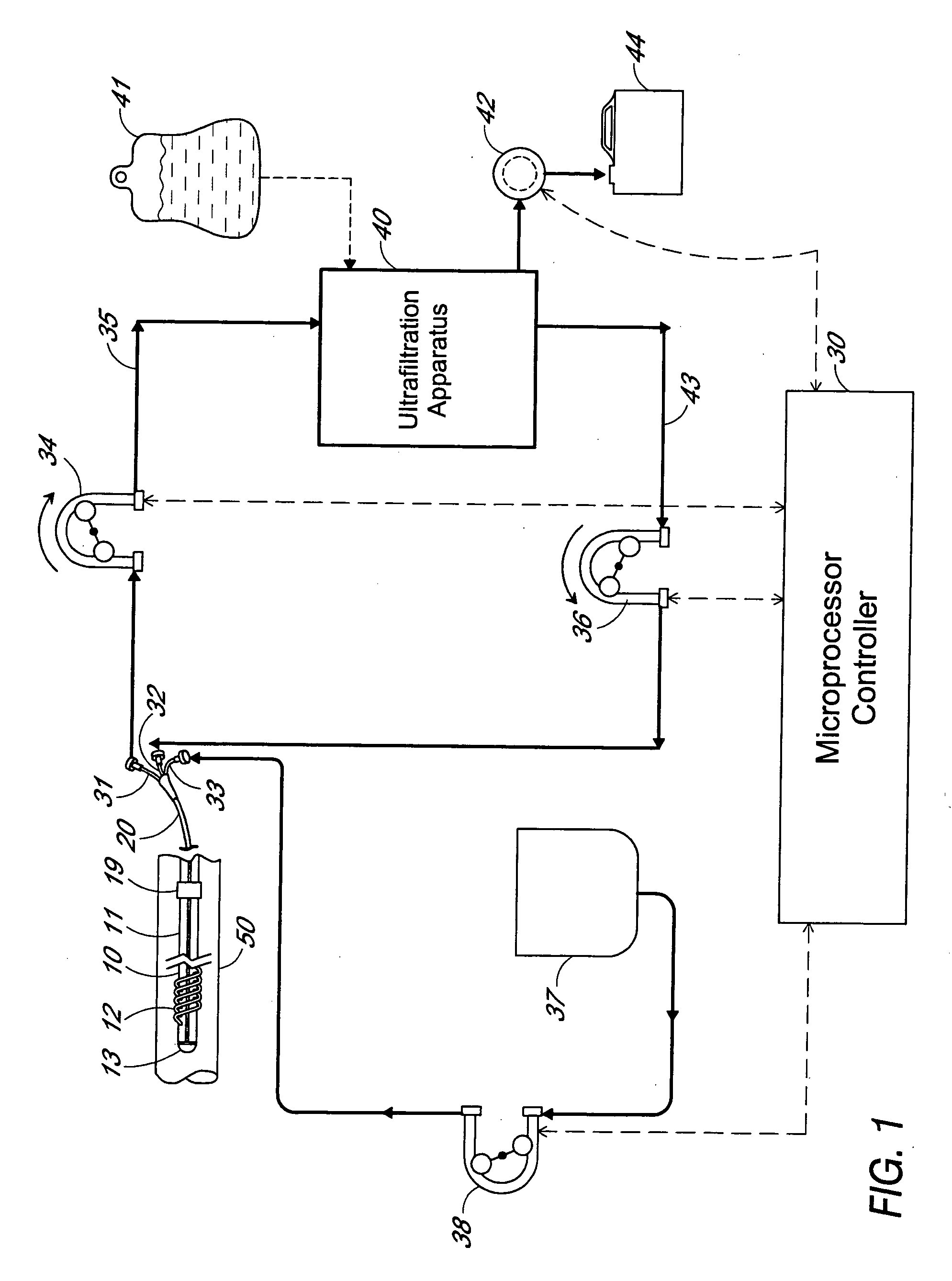

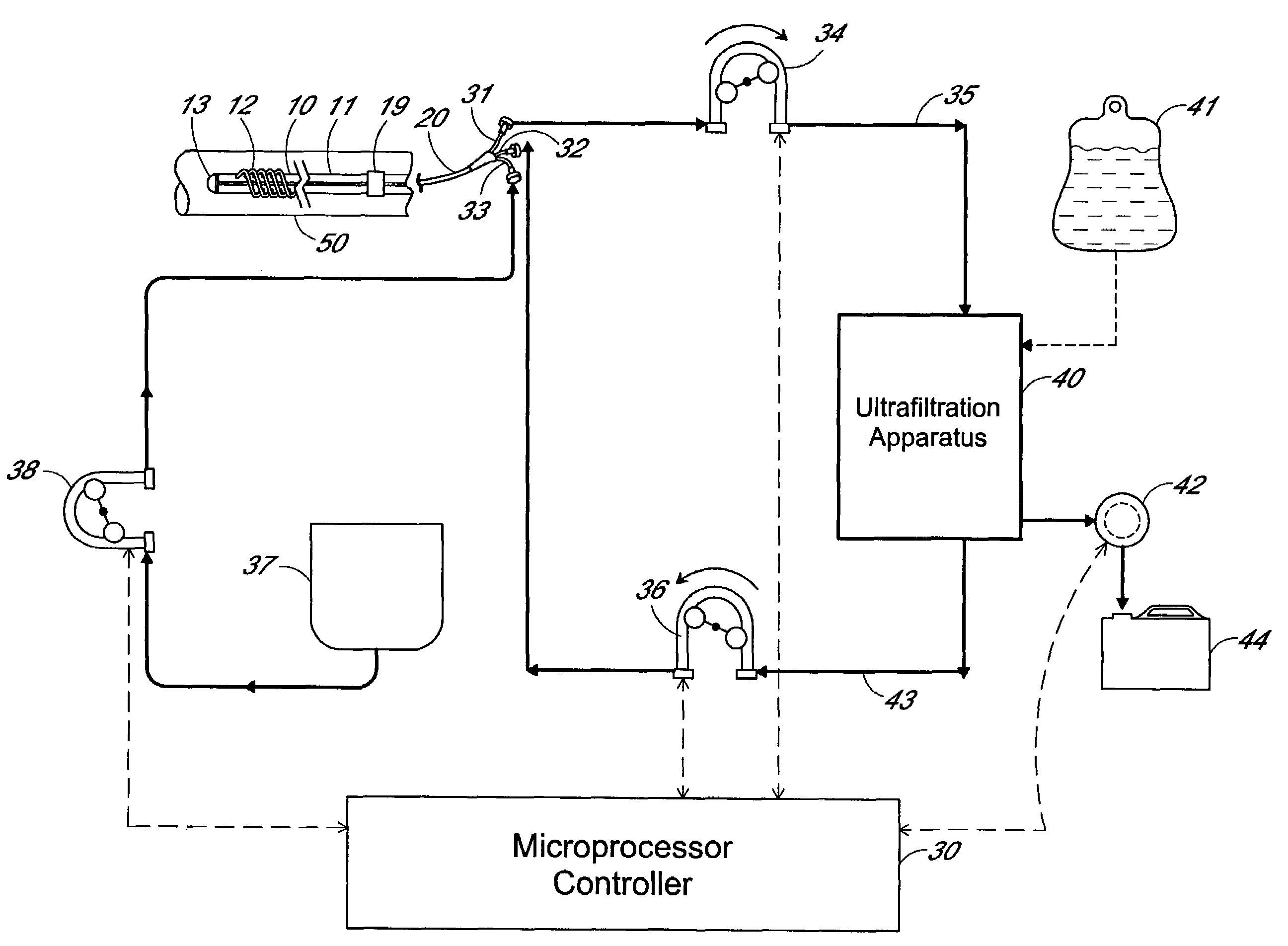

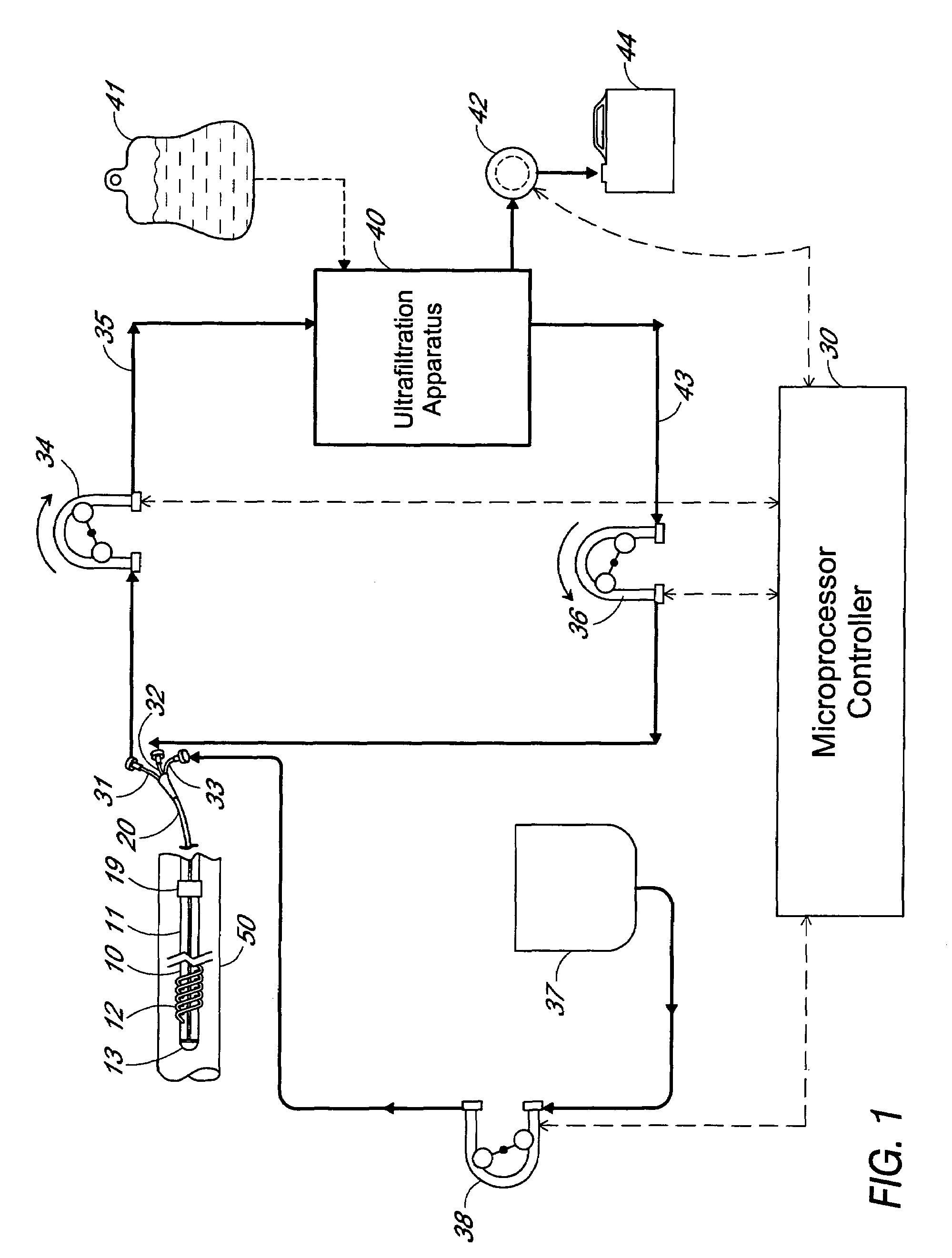

Method for determining the recirculation of blood in a vascular access and a system for implementing same

In an extracorporeal blood treatment system, non-treated blood may be withdrawn from a patient through an arterial line connected to a first compartment of a blood treatment apparatus. The blood treatment apparatus also includes a second compartment separated from the first component by a semi-permeable membrane. Treated blood may be returned to the patient through a venous line connected to the second compartment. In order to determine blood recirculation, i.e., a mixture of treated blood and non-treated blood in the arterial line, the ultrafiltration rate of plasma water through the semi permeable membrane of the treatment apparatus may be temporarily increased or decreased, and the resulting variation of the blood concentration, i.e., of the ratio of the volume of the plasma volume to the blood volume, is determined. The extent of the mixture of the treated blood and the non-treated blood in the arterial line may then be calculated as a function of the blood flow rate in the treatment apparatus, of the amplitude of the variation of the ultrafiltration rate, and of at least two values of the blood concentration, determined before and during the variation of the ultrafiltration flow rate, respectively.

Owner:BAXTER HEALTHCARE SA

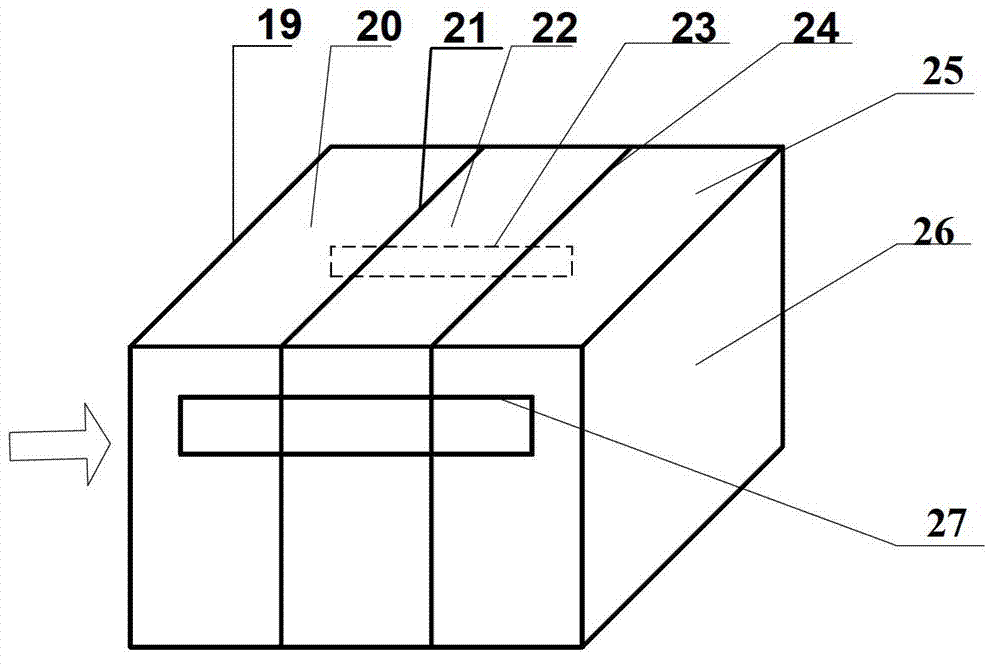

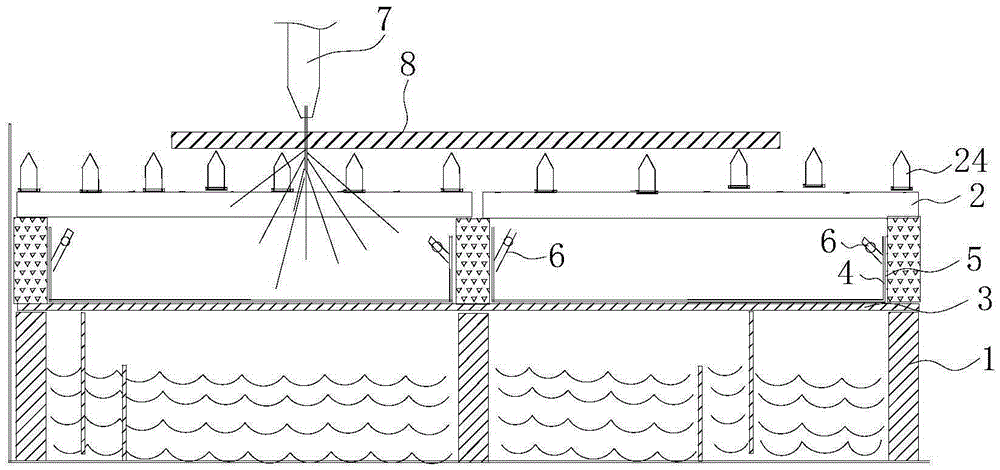

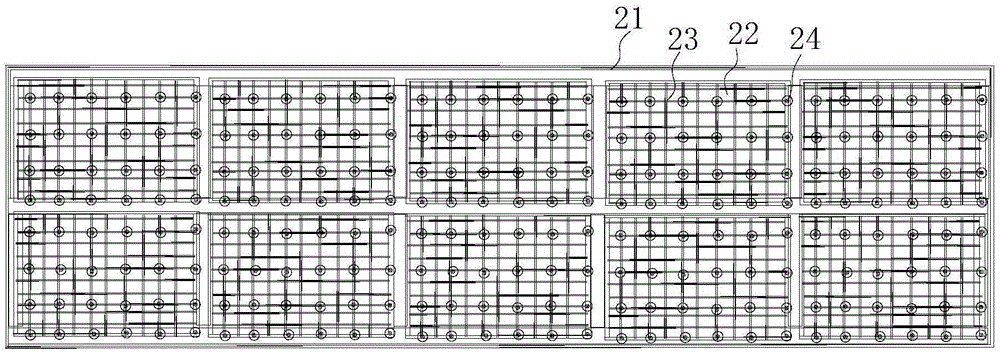

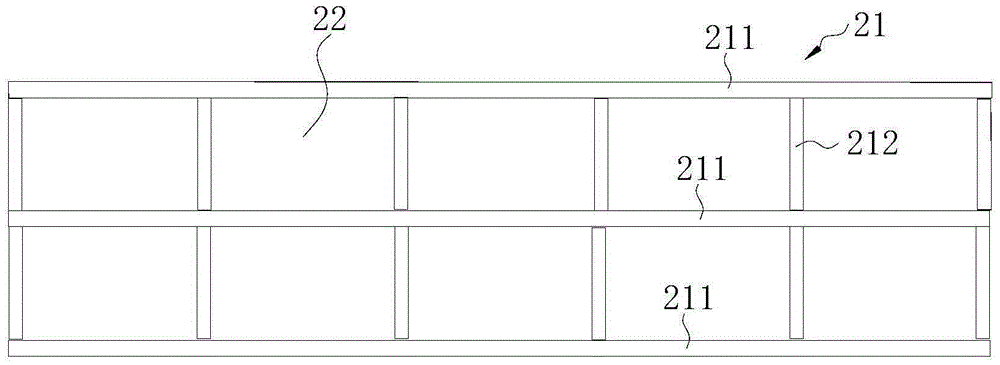

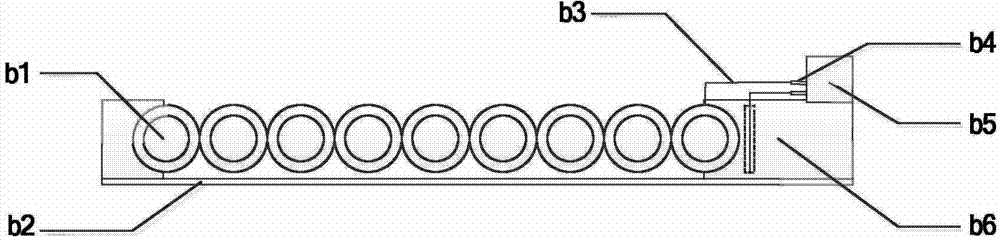

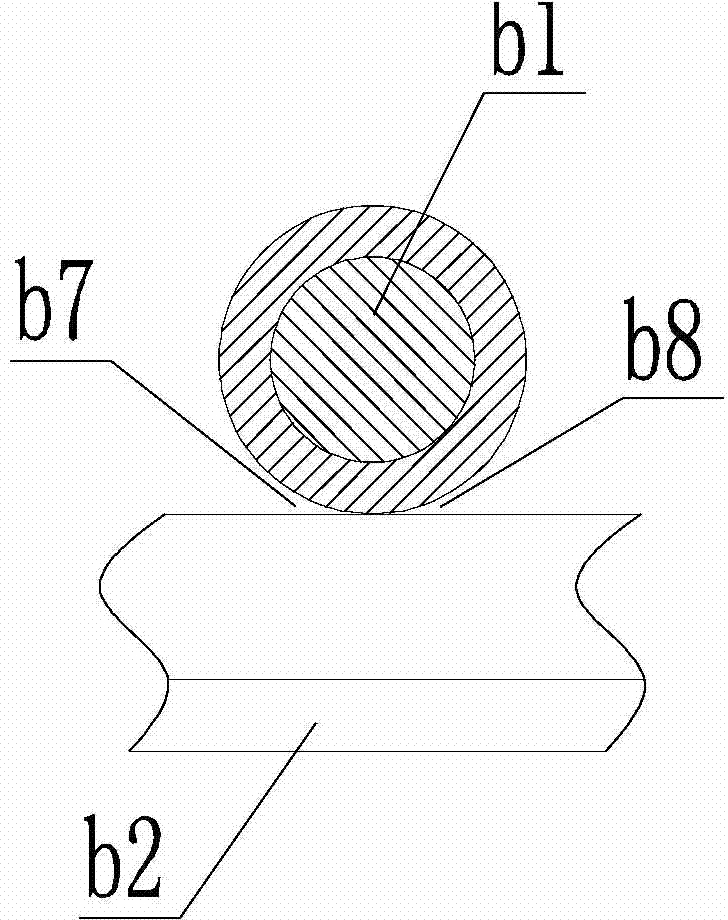

Plasma water bed cutting platform assembly

ActiveCN105397255AMeet the needs of different heights in different locationsMeet the needs of different heightsUsing liquid separation agentPlasma welding apparatusSlagEngineering

The invention discloses a plasma water bed cutting platform assembly. The plasma water bed cutting platform assembly comprises a water tank, a supporting platform, a water-stop sheet and a dust hopper, wherein the supporting platform is slantwise arranged above the water tank along the length direction of the supporting platform; the water-stop sheet is arranged between the water tank and the supporting platform; one end of the water-stop sheet communicates with the dust hopper; a gap exists between the dust hopper and the side wall of the water tank; the dust hopper is arranged between the supporting platform and the water tank and is located at the slantwise low end of the supporting platform; the supporting platform comprises a frame; a plurality of installing locations are uniformly arranged on the frame; a grid plate is detachably arranged at each installing location; a plurality of supporting nails are uniformly distributed on each grid plate along the length direction of the supporting platform; and the lengths of the supporting nails increase sequentially from the high end of the supporting platform to the low end of the supporting platform, so that a horizontal supporting surface is formed at one ends, being far away from the grid plates, of the plurality of supporting nails. The plasma water bed cutting platform assembly has the beneficial effects that the plasma water bed cutting platform assembly is simple in structure, can quickly discharge slag, has low pollution and can be used permanently, the slag is less likely to adhere to the surface of a platform, and cutting platform materials do not need to be changed.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

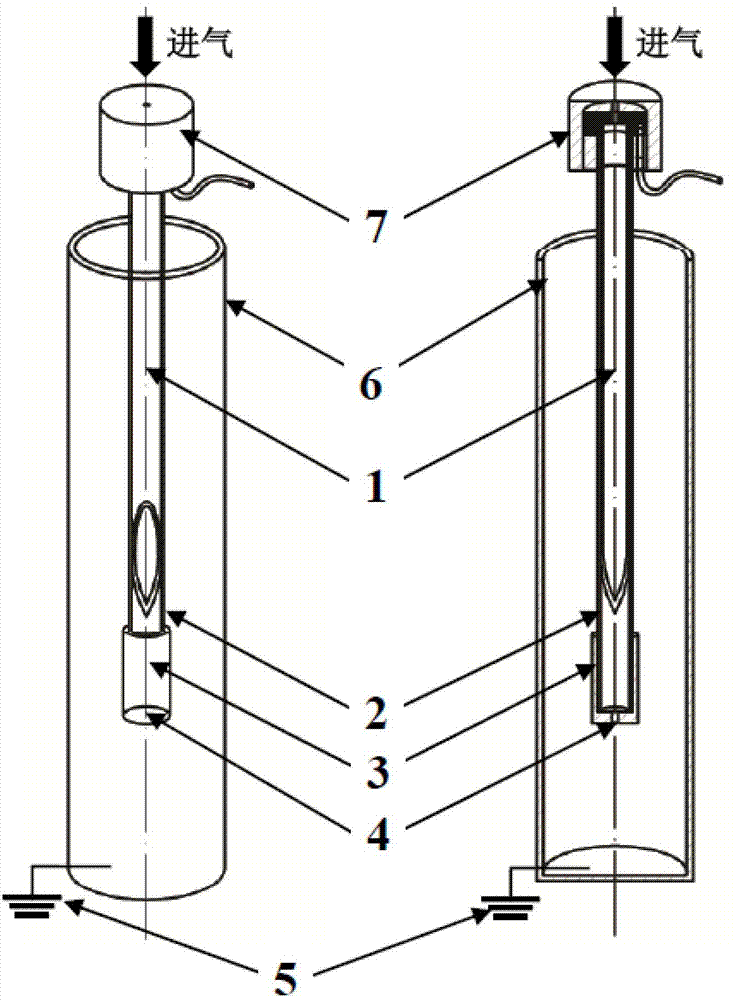

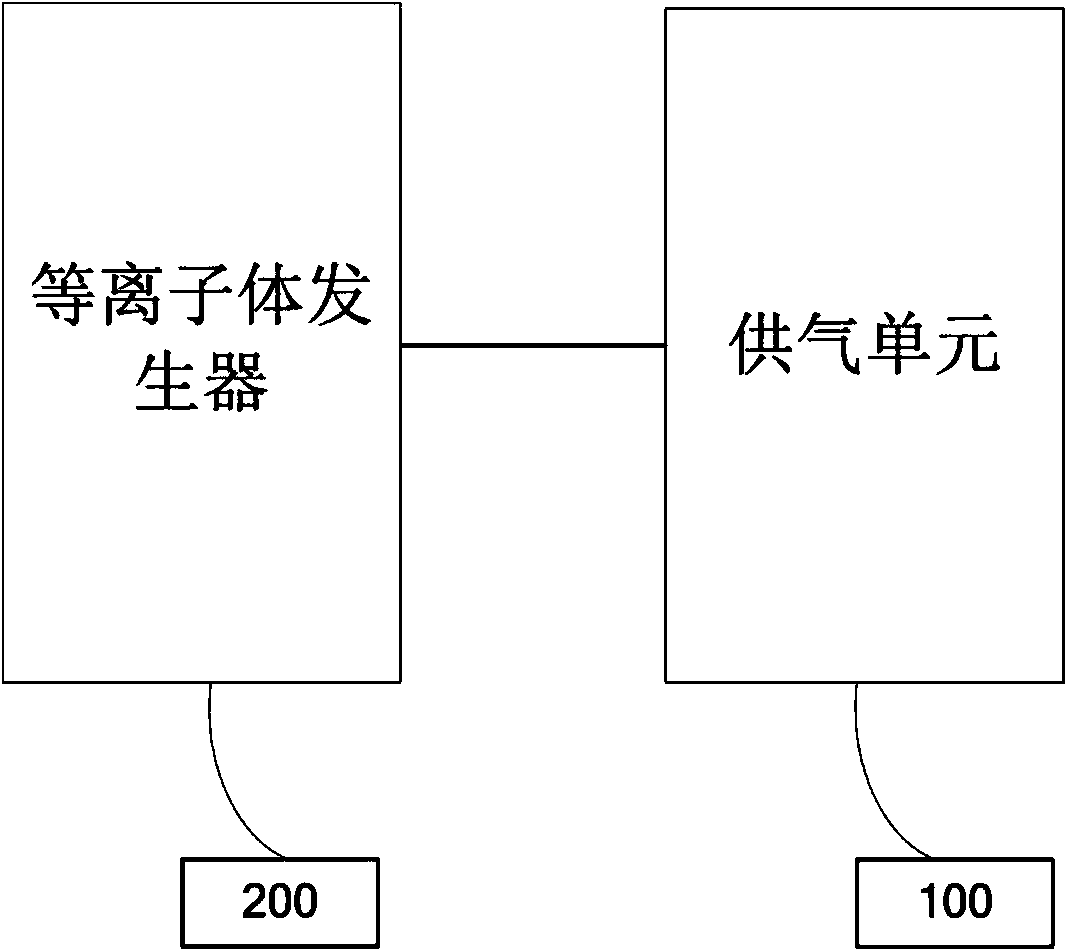

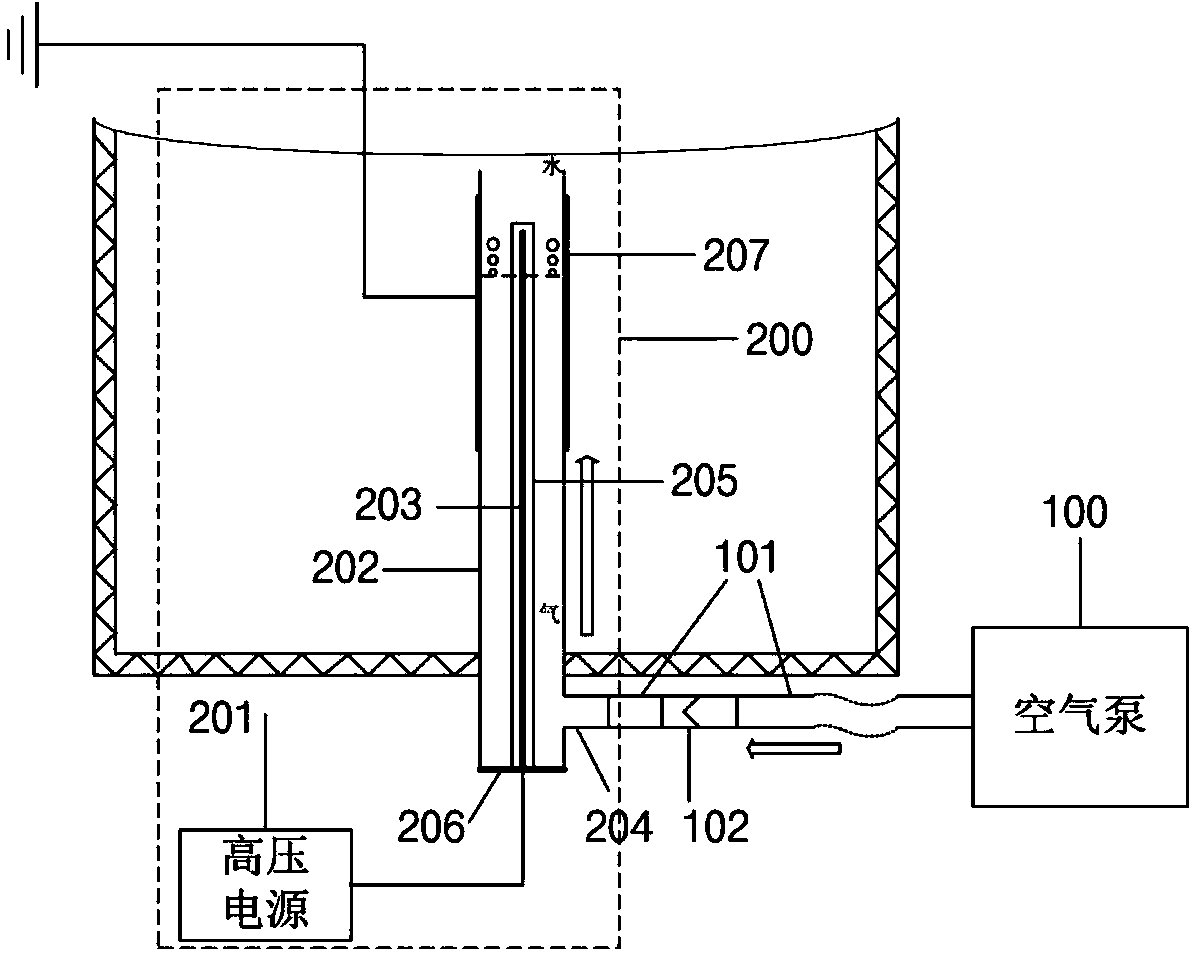

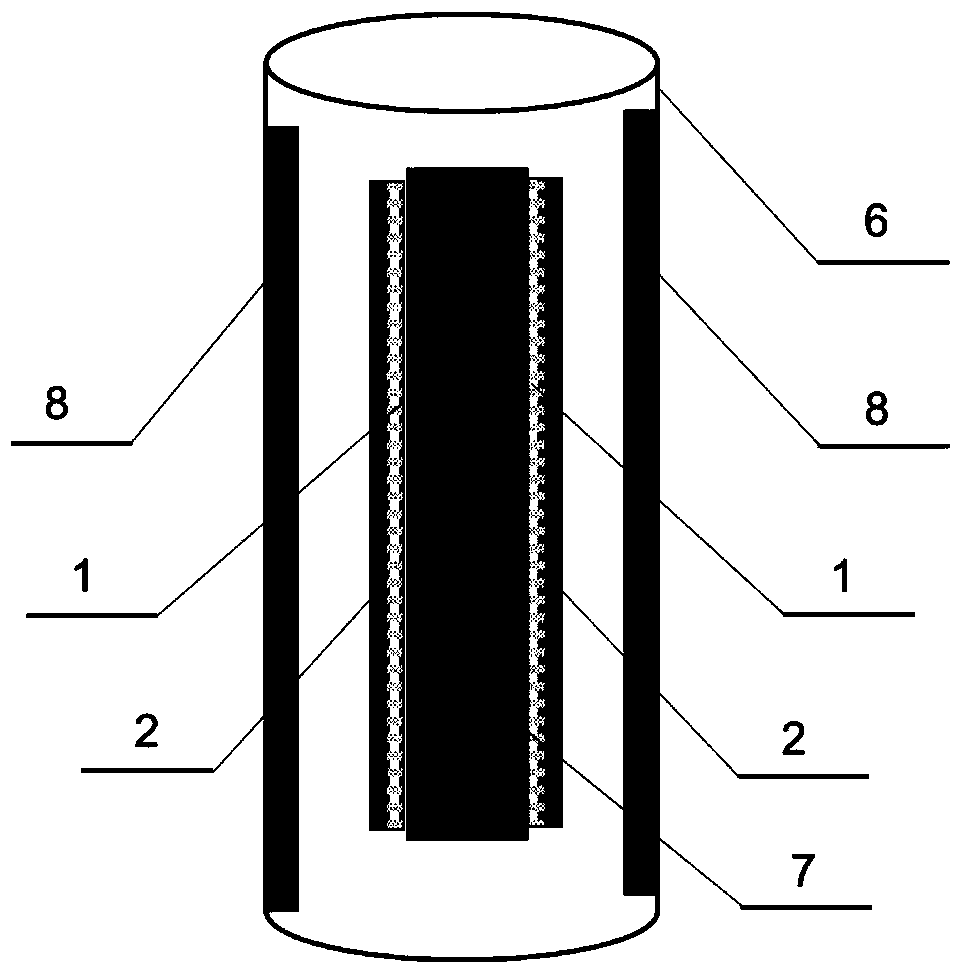

Plasma water treatment device

ActiveCN104211137ANo toxic residueImprove purification effectWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsGlass coverGas phase

The invention discloses a gas-liquid two-phase discharge plasma water treatment device. The device comprises a gas supply unit and a plasma generator. The plasma generator comprises a high-voltage power supply, high-voltage electrodes and a discharge cavity. The front end of the discharge cavity is connected to an air inlet provided with a one-way valve, and the back end is open and contacts with the water to be treated; and the outside of the high-voltage electrodes are provided with a glass cover as the medium. When working, an air supply unit introduces air into the discharge cavity, wherein the cavity end is an aqueous phase and the cavity front is a gas phase; the high-voltage electrodes in a two-phase mixed environment produce plasma through high-voltage discharge. The device adopts gas-liquid two-phase discharge, retains the advantage of easy production in traditional gas phase discharge, and increases the contact surface of discharge products and liquid; and electric field, ultraviolet radiation, hydroxyl radical, oxygen atoms under different excitation conditions and other active particles produced by discharge can rapidly and directly act on the liquid.

Owner:XI AN JIAOTONG UNIV

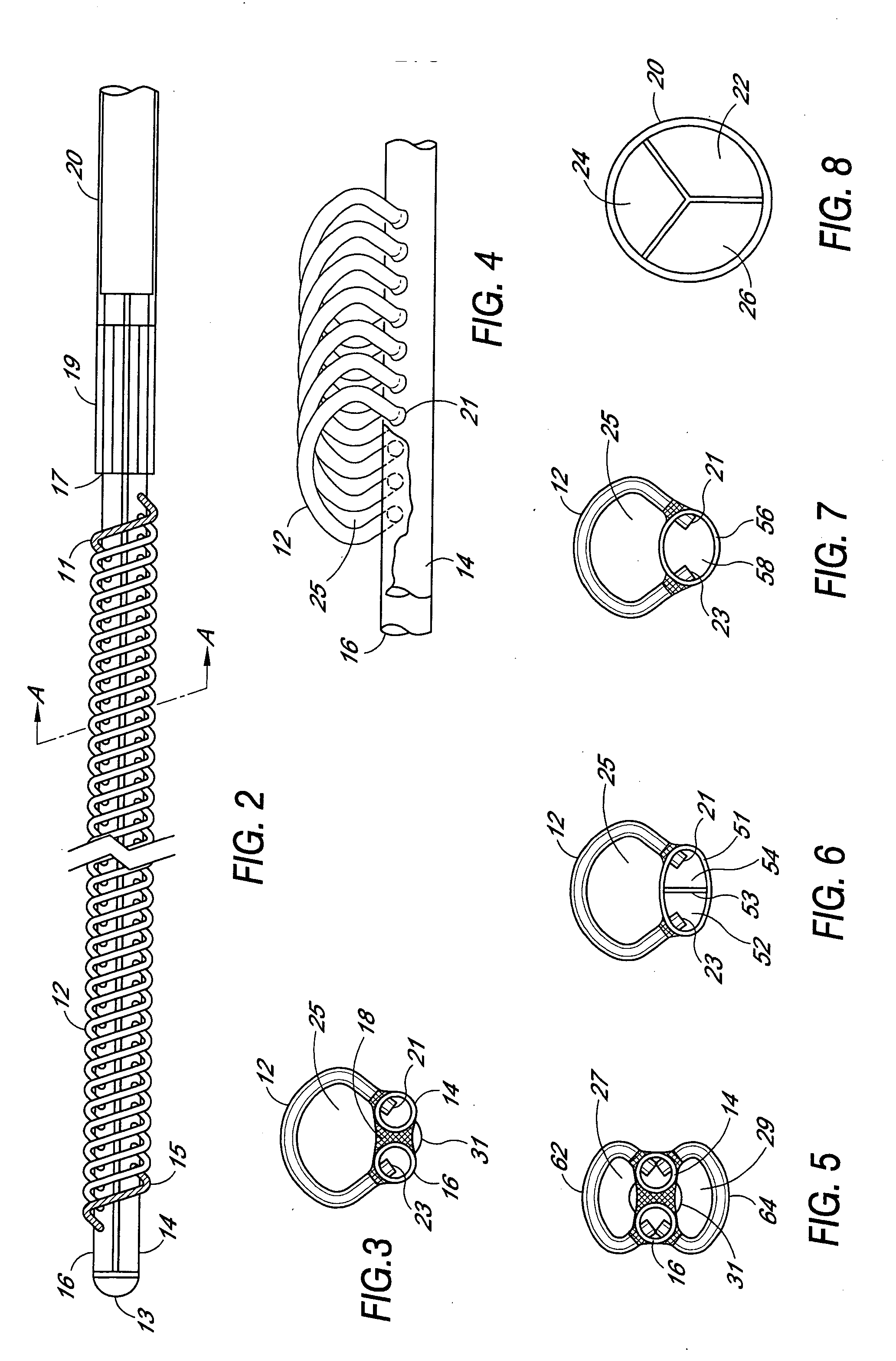

Method and apparatus for patient fluid management

InactiveUS20050215936A1Low mass densityIncrease mass densityMembranesSemi-permeable membranesFiberSieving coefficient

Patient fluid management is carried out by separating plasma from whole blood in vivo via an implantable filter device comprising one or more elongated hollow tubes and a plurality of elongated microporous fibers having an interior lumen extending along the length thereof, each fiber having a first and second end secured to the one or more elongated hollow tubes by passing plasma through the fiber wall from the outer wall surface to the inner wall surface and to the interior fiber lumen, directing the separated plasma to an ultrafiltration apparatus having a sieving coefficient cutoff between about 1×104 and about 6∴104 daltons, separating plasma water and selected plasma components, from the separated plasma, and directing the treated plasma to the patient.

Owner:TRANSVIVO

Method for preparing radar wave-absorbing composite material based on carbon nanometer film

The invention provides a method for preparing a radar wave-absorbing composite material based on a carbon nanometer film, comprising the following steps of: mixing carbon nanotubes and an anion surface dispersant, grinding the mixture in a mortar, pouring the grinded mixture into a beaker, and adding plasma water; dispersing and defoaming an obtained mixed solution in a magnetic stirrer; adding graphene oxide into plasma water to preparing a solution, and ultrasonically dispersing; mixing a carbon nanotube solution and the graphene oxide solution, centrifuging the mixture after ultrasonically dispersing by an ultrasonic cell disruption instrument, and compacting and solidifying residue after vacuum pumping filtration of a supernatant of the carbon nanotube and graphene oxide solution; heat-treating; adding a carbon nanometer film into an acetone weak solution of a resin for pre-infiltrating, and then drying; and adding the carbon nanometer filmed with layer pre-infiltration into an innermost layer of an aluminium alloy mould, laying a layer of carbon fiber / resin pre-infiltrated material in the medium, locking the mould, and molding by mould compression. A radar wave reflection rate of the radar wave-absorbing composite material based on the carbon nanometer film in a frequency range from 8GHz to 18GHz is lower than -10- -20dB.

Owner:SHENYANG AEROSPACE UNIVERSITY

Plasma water treatment method

InactiveCN1367140AImprove degradation rateWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by oxidationCavitationPhosphate

In the water to be treated, a soluble phosphate and / or a photocatalyst of mixture formed from Pt, Ag, Pd, Au or Ru metal and sulfur compound as active component or sulfur compound in which the metal ions of Fe(3+), V(4+) or Ru (3+) is doped are added, the above-mentioned materials can raise the effects of high-temp. pyrolysis, photochemical oxidation, hydroelectric cavitation degradation and supercritical water oxidation produced in the discharge process so as to greatly raise the water treatment effect.

Owner:EAST CHINA UNIV OF SCI & TECH

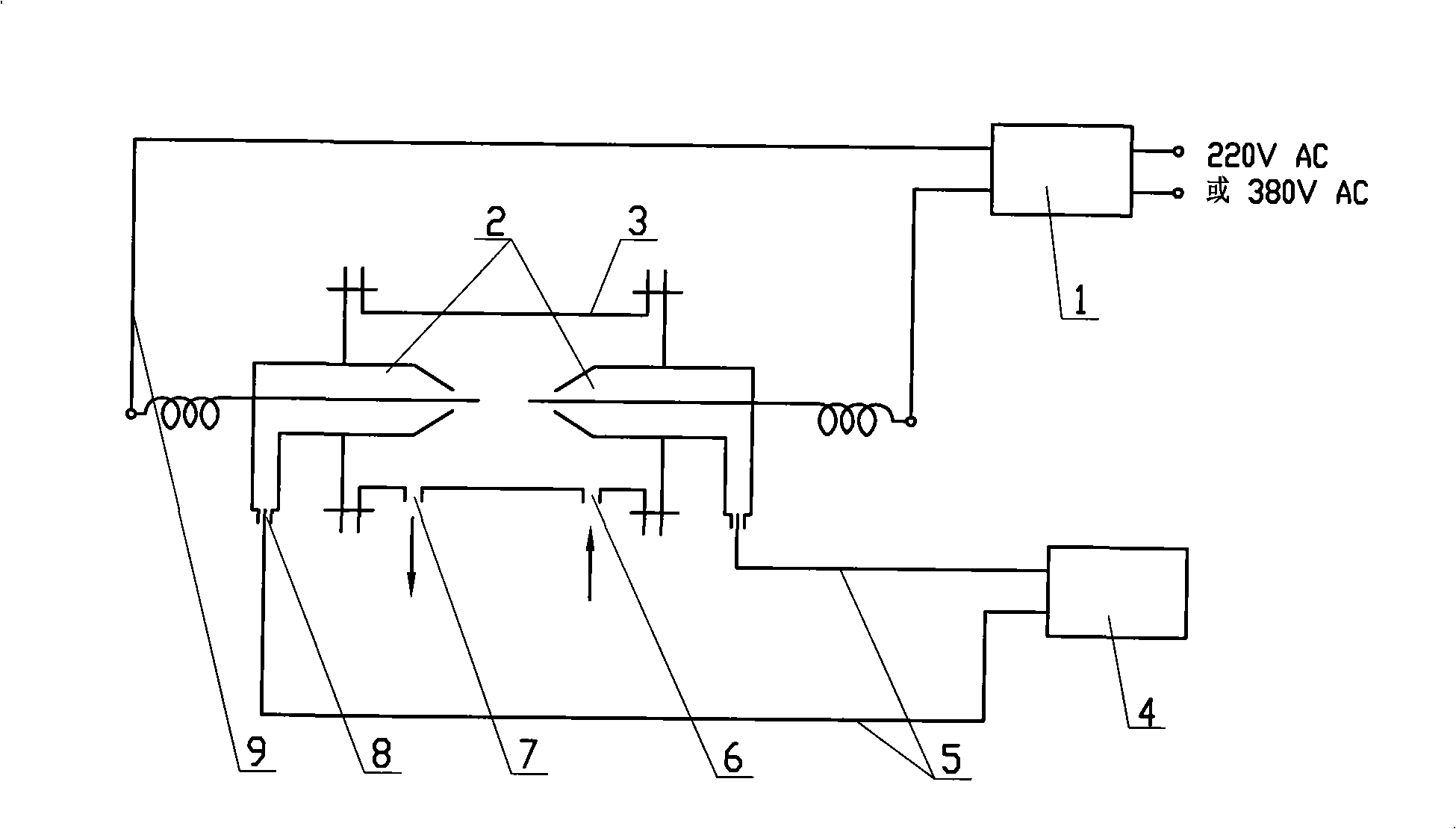

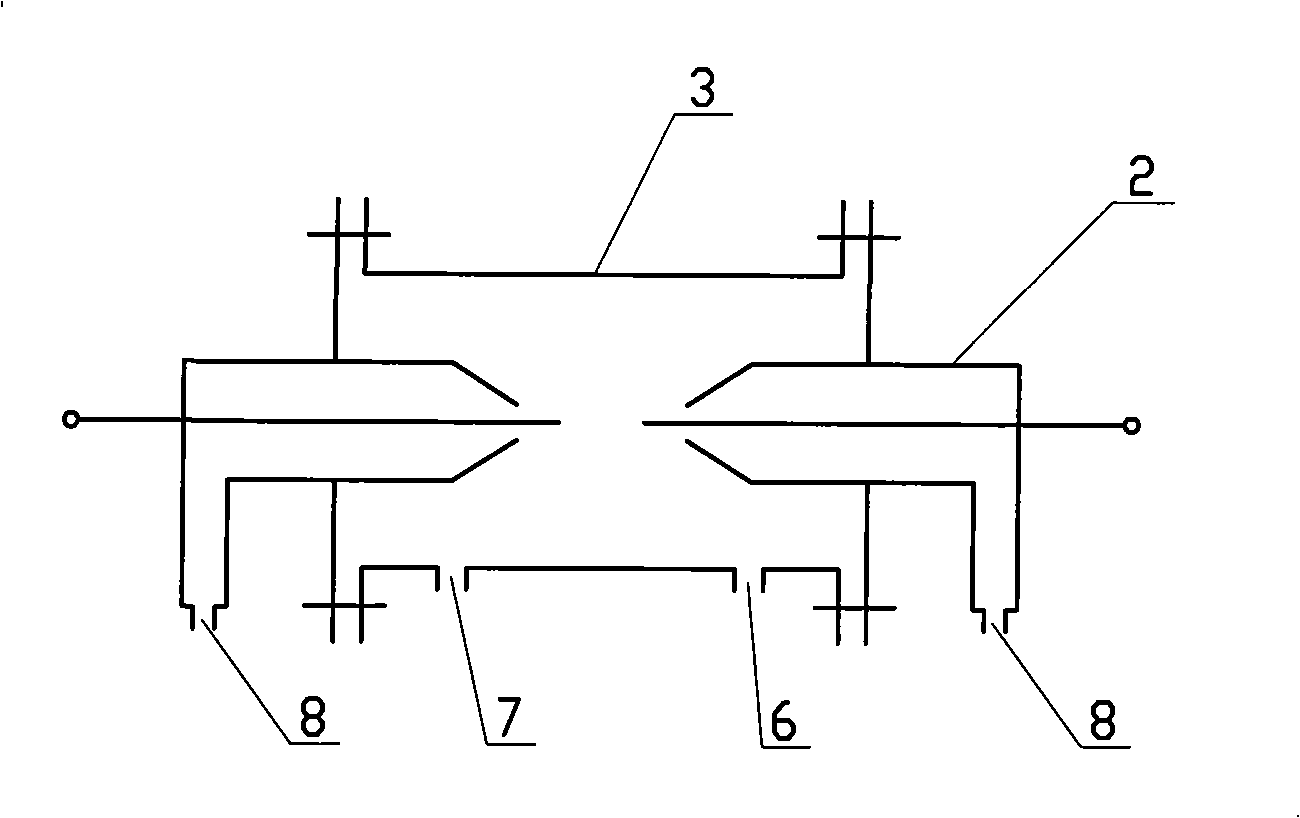

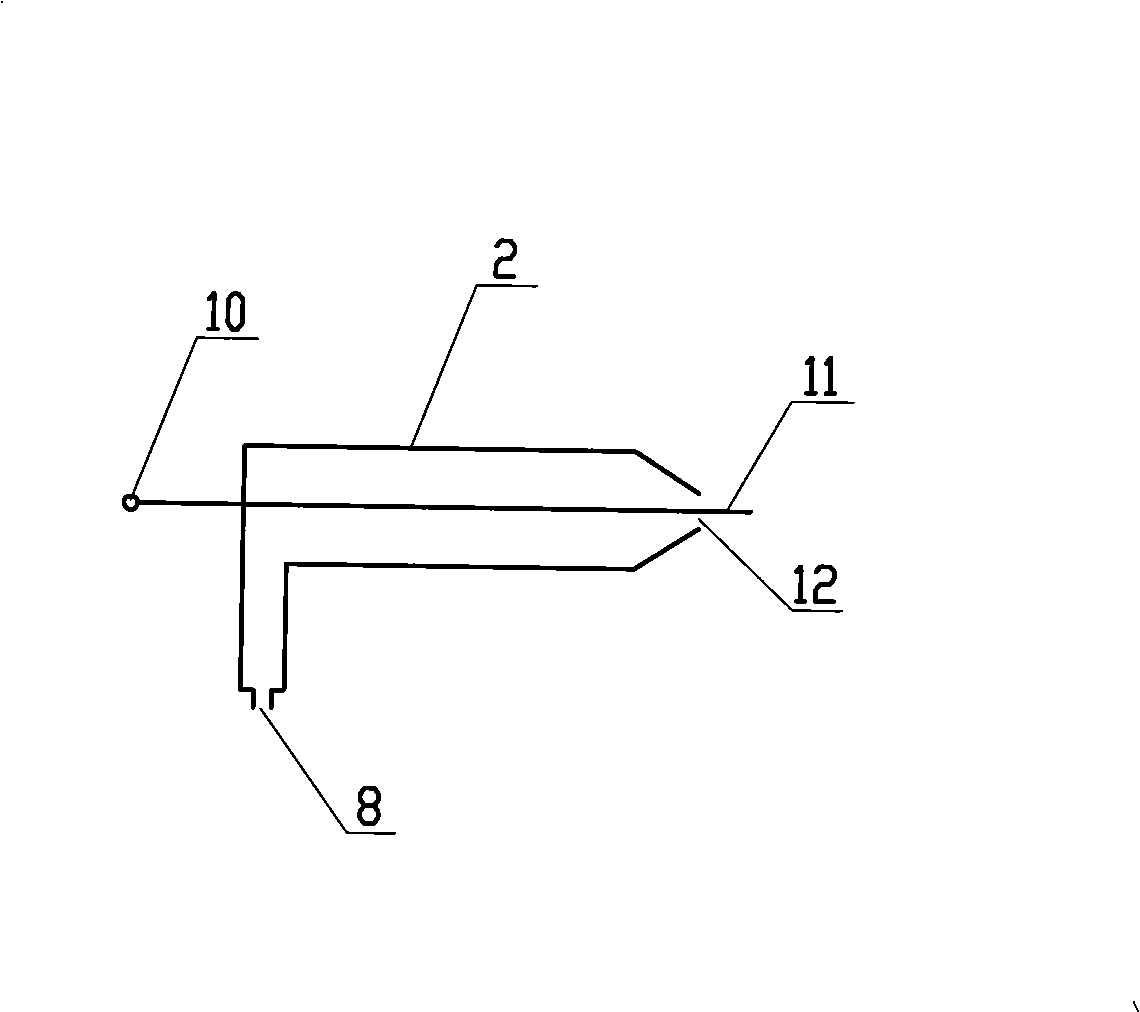

Plasma water treatment method and device thereof

InactiveCN101254960AEasy to handleImprove efficiencyWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsWater processingTreated water

The invention relates to a plasma water treatment method and a device thereof. The plasma water treatment method comprises the following steps: the water to be treated is communicated into a plasma reactor; the air supply of the plasma reactor is switched on; the power supply of the plasma reactor is switched on, the plasma reactor generates plasma by which the water is treated; and the treated water is discharged. The plasma water treatment device comprises the plasma reactor, a water inlet opening and a water outlet opening which are arranged on the plasma reactor, and at least a pair of plasma arc discharge guns which are oppositely arranged and connected with the air supply and the power supply. The invention provides the plasma water treatment method which can consecutively generate the plasma with high efficiency, and provides the plasma water treatment device with simple structure.

Owner:汪峰

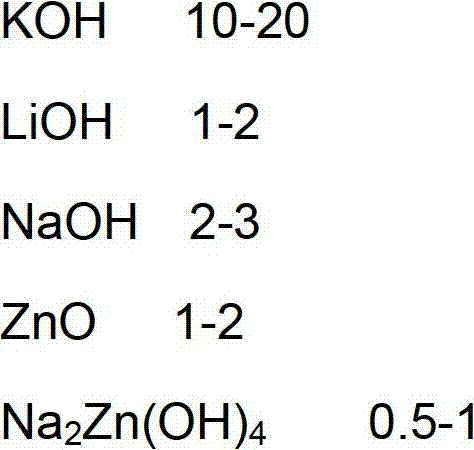

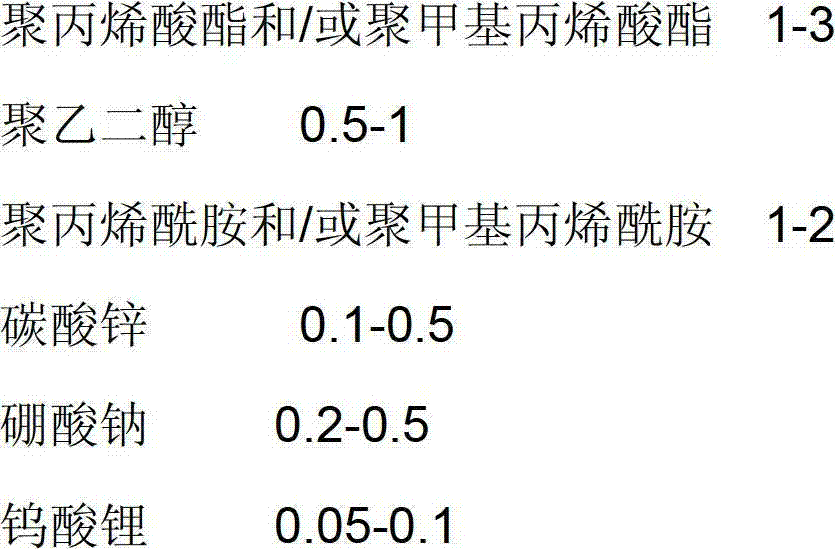

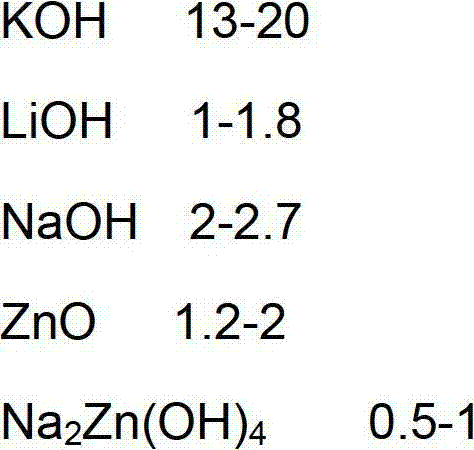

Preparation method of electrolyte of alkaline zinc battery

InactiveCN102832419AReduce corrosionHigh activityAlkaline accumulatorsPhysical chemistryPolyethylene glycol

The invention relates to a preparation method of an electrolyte of an alkaline zinc battery, a basic solution comprises the following components: KOH, LiOH, NaOH, ZnO, Na2Zn(OH)4 and plasma water; an addictive comprises the following components: polyacrylate, polyethylene glycol, polyacrylamide, zinc carbonate, sodium borate and lithium tungstate. The method comprises the following steps: adding the above components which accounts for 1-3% of mass of the basic solution in the basic solution, heating and fully stirring to obtain the electrolyte of alkaline zinc battery. The alkaline zinc battery by using the electrolyte has the advantages of good performance and long usage life.

Owner:SHANGHAI JINZHONG INFORMATION TECH

Cyanide-free silver plating solution additive

The invention relates to a cyanide-free silver plating solution additive which comprises the following components by ratio: 0.1-10g / l of brightener, 5-10g / l of leveling agent, 100-600g / l of complexing agent and the balance of plasma water, wherein the brightener is one or mixture of more in nitrogen-containing compound, triazole, benzotriazole, 2-hydroxypyridine, pyridine, 22 dipyridyl, 1, 10-phenanthroline, triethylene tetramine and diethylene triamine according to any ratio; the leveling agent is one or mixture of more in aromatic hydrocarbon compounds, naphthalene, 1-methylnaphthalene, 1, 4-naphthoquinone and 1-naphthol according to any ratio; the complexing agent is one or mixture of more in disodium ethylenediamine tetraacetate, niacin, aminosulfonic acid and potassium pyrophosphate according to any ratio. The cyanide-free silver plating solution additive has the beneficial effects that the plating solution is stable, low in toxicity and good in dispersing ability; the obtained plating layer is bright and fine as well as good in binding force; the technology adopts the environment-friendly organic additive which does not contain heavy metal and sulfide; the plating layer is good in corrosion resistance. Furthermore, the cyanide-free silver plating solution additive can be directly used for parts such as brass, copper, chemical nickel and the like, preplating is not needed, and the binding force is also guaranteed.

Owner:HANGZHOU WIN WIN TECH CO LTD

Synthesis of artificial marble lacquer

The present invention relates to a composite imitation marble lacquer. The natural stone wall decoration material has the defects of large usage, high construction difficulty, poor safety, large color variation, monotone colors, high cost, etc. The composite imitation marble lacquer can replace the natural stone wall decoration material to resolve the defects. The composite imitation marble lacquer is mainly prepared with the following materials: colored sand, silicone-acrylate emulsion, plasma water, cellulose, organic amine, ethylene glycol, multi-functional assistant, defoamer, mildew preventive and filming assistant. The composite imitation marble lacquer has the following advantages: natural resources are saved, and the cost is low; the colors of the natural colored sand cannot easily be faded, moreover, the colors are diversified, the color variation is little, and the composite imitation marble lacquer is applicable to the decoration of the outer walls of buildings with various building styles and ethnical styles and has a natural and noble decoration effect and a high decoration grade; the composite imitation marble lacquer can seep into various basal surfaces, firmly adhere to the outer walls and resist cracking, and after being soaked in water for thirty days, the composite imitation marble lacquer does not turn into white and is not flaked; construction and filming cannot be affected by low-temperature and humid climates; as dense, transparent finish, the composite imitation marble lacquer can extremely resist stain, and the surface can be washed.

Owner:徐敏

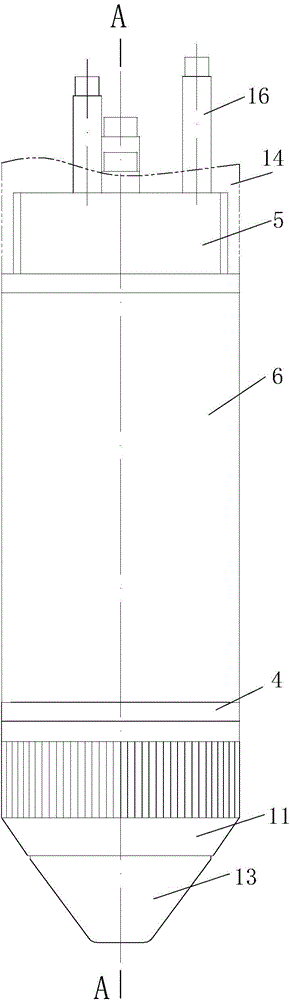

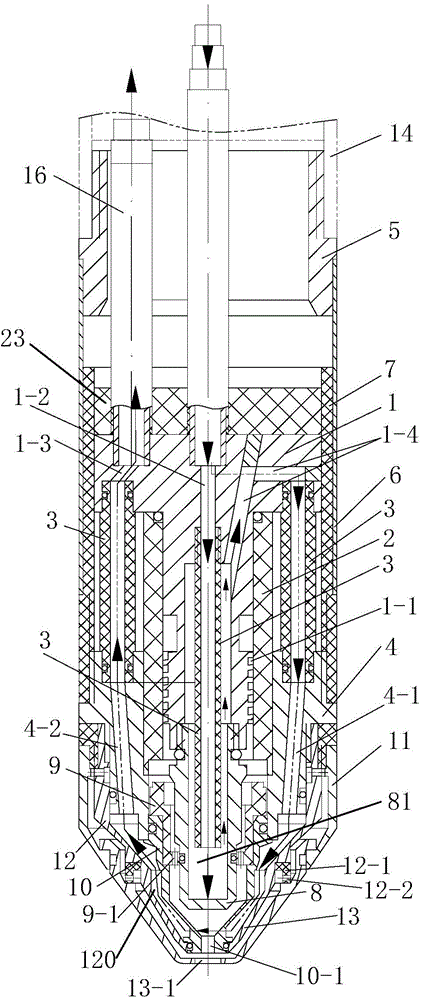

Large liquid phase high pressure pulse discharging water processor

InactiveCN101798132AEasy to processEasy to replaceWater/sewage treatment by magnetic/electric fieldsWater processingHigh pressure

The invention belongs to the water processing technical field, which discloses a large liquid phase high pressure pulse discharging plasma water processor. The invention is characterized by a coaxial electrode structure which is formed by a metal rod the diameter of which is more than 2 mm and a metal cylinder. A metal rod electrode is sleeved with an insulating pipe with a minute gap the width of which is 20 to 100 microns. The diameter of the metal cylinder is more than 45mm, which is sleeved with a insulating pipe externally and grounded through a resistance. Water to be processed is sent to the electrode structure through an inflow pump and a water level inductor senses water level and controls inflow quantity. The pulse high voltage of more than 20kv is added to the central metal rod electrode. The insulating pipe minute gap on the central metal rod electrode generates local high electric field and causes discharge, consequently the discharging plasma is generated in the water to be processed in the cylinder. According to the actual requirement, a plurality of electrodes can be connected in series. The processing of the central electrode has the advantages of simple manufacture, convenient replacement and the ability of reuse. The invention has strong processing capability and can reduce the power supply device cost greatly.

Owner:DALIAN UNIV OF TECH

Production method of medical polyurethane antibacterial nano-silver coating

InactiveCN107583112AGood dispersionIncrease contentCatheterCoatingsVacuum dryingAntibacterial property

A production method of a medical polyurethane antibacterial nano-silver coating comprises the following steps: (1) dissolving dopamine in Tris-HCl buffer solution with the concentration being 0.015-0.025 mol / L and the pH value being 7.5-9, and carrying out a reaction at 20-30 DEG C in a dark environment for 25-35 min, wherein a dosage ratio of the dopamine to H2O is (800-1000) mg : 100 ml; (2) adding polyurethane to a solution obtained in the step (1), carrying out a reaction at 20-30 DEG C in a dark environment, taking out the polyurethane, flushing the polyurethane with plasma water, and drying the flushed polyurethan in a vacuum drying box; and (3) adding polyurethan obtained in step (2) into a silver ammonia solution, reducing silver nitrate with glucose as a reducing agent, and carrying out ultrasonic vibration cleaning to obtain the antibacterial polyurethane. The polyurethane nano-silver coating has the advantages of obvious antibacterial property, high content, high density, good dispersivity, no shedding and fast production speed.

Owner:NANCHANG UNIV

Glow discharge plasma water treatment method and device

ActiveCN103754994AEasy to handleImprove processing efficiencyWater/sewage treatment using germicide/oligodynamic-processElectricityWastewater

The invention discloses a glow discharge plasma water treatment method comprising the following steps: after to-be-treated wastewater is subjected to mechanical treatment, water surface electrodes having the same potential are placed on the wastewater surface, the water surface electrodes are each cylindrical in shape, an insulating medium externally wraps the water surface electrodes, and the water surface electrodes are connected to a positive electrode or a negative electrode of a power source; an underwater electrode connected to the positive electrode or the negative electrode of the power source is placed in the wastewater, and is an exposed conductive material; the water surface electrodes are directly contacted with the wastewater, and a gap is formed between the outer surface of each water surface electrode and the water surface; after the power supply is switched on and an initial discharge voltage is reached, glow discharge is generated in the gaps, plasma and active particles are generated, and the wastewater is deep treated by utilizing the plasma and the active particles. The invention also provides a corresponding plasma water treatment device aiming at the plasma water treatment method. The method and the device are suitable for various water treatment, besides, can remove microbes and bacteria in the wastewater, and can remove peculiar smell radiated by the wastewater.

Owner:BEIJING RUIYUDA TECH

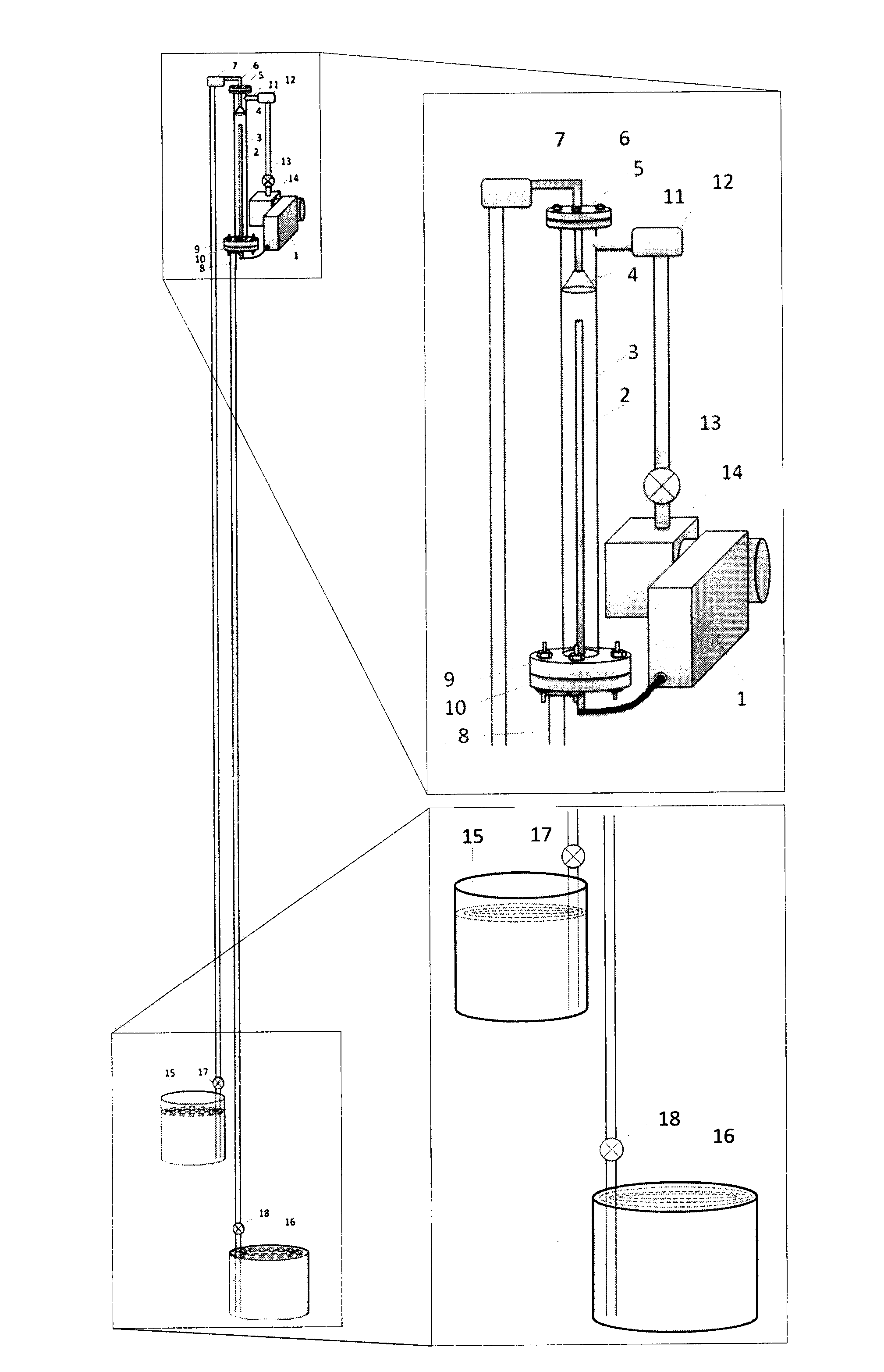

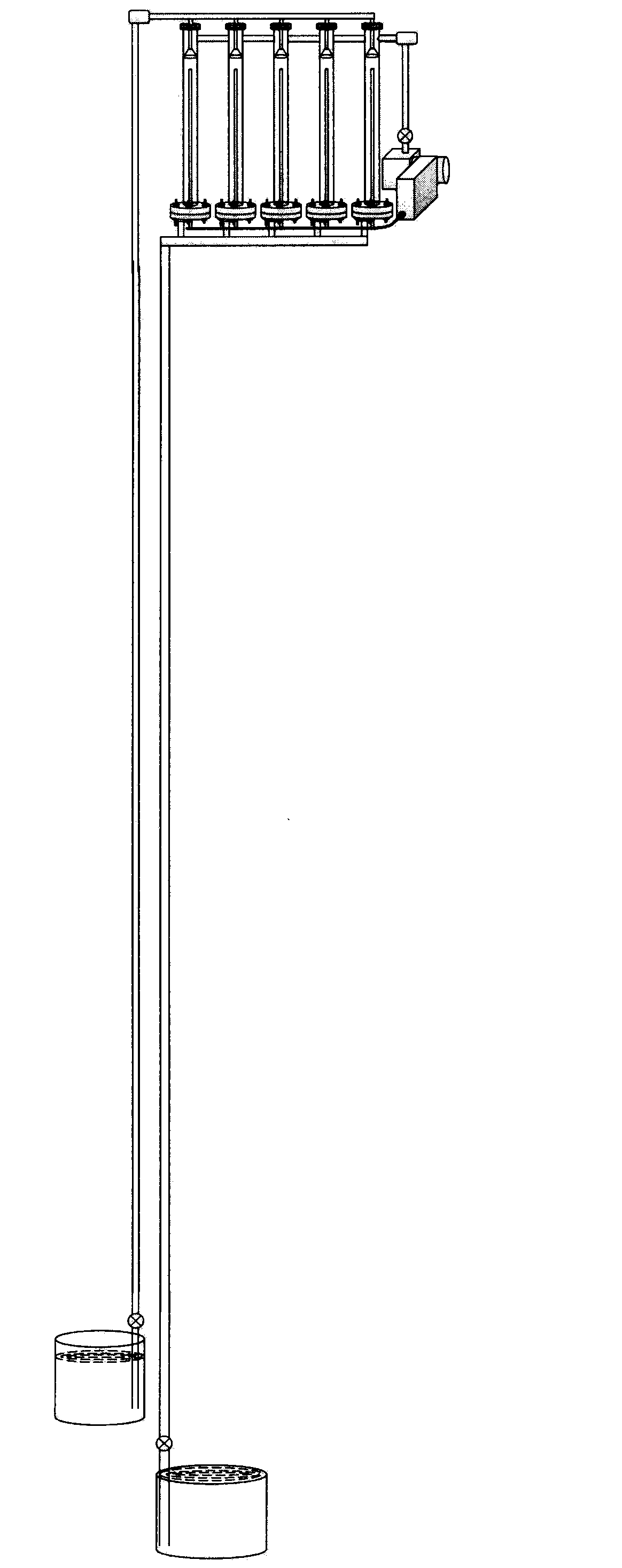

Low-pressure discharge plasma water treating apparatus and method

ActiveCN104058480AReduce volumeHigh activityWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsHigh activityExhaust pipe

The invention relates to a low-pressure discharge plasma water treating apparatus, mainly comprising a discharge power supply, a high voltage electrode, a reactor, an atomization sprinkler, a water inlet pipe, a water outlet pipe, a water flow monitor, an air exhaust pipe, an air valve, a vacuum pump, a sewage pool and a clean water reservoir. According to the invention, without a water pump, a low pressure environment in the reactor can be maintained via only one vacuum pump under the condition that water flows through the reactor; electro-discharge is carried out in the low pressure environment, and large-volume, high-activity and non-thermal equilibrium plasma is generated; the treating apparatus can effectively remove pollution sources like heavy metal ions, organic matters and microbes in water, has high treatment efficiency, is generally applicable to sewages having different pollution degrees and produced by different industries and provides activated water for special industries. The invention further relates to a plasma water treating method which realizes low pressure discharge under the condition that a water cycle between the interior of the reaction chamber and the outside is maintained without usage of a forced exhaust type water pump. With the method, system energy consumption is greatly reduced.

Owner:江苏先竞等离子体技术研究院有限公司

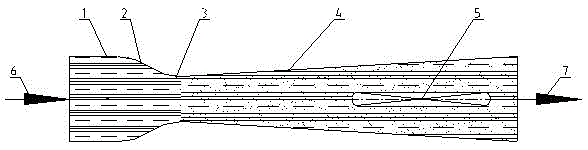

Cavitation plasma water treatment device and method

InactiveCN105461006AEasy to handleSignificant fogging phenomenonWater/sewage treatment by irradiationSpecific water treatment objectivesPlasma generatorTherapeutic effect

The invention relates to a cavitation plasma water treatment device and method. The device comprises a Venturi tube. The Venturi tube comprises an inlet section (1), a contraction section (2), a mouthpiece section (3) and a diffuser (4). A plasma generator (5) is arranged in the diffuser (4). Water enters the inlet section (1) from an inlet (6) of the Venturi tube, then enters the contraction section (2), enters the mouthpiece section (3) and flows into the diffuser (4). The plasma generator (5) is arranged in the diffuser (4) to act on water and cavitation bubbles in the water, and produces a water treatment effect. According to the cavitation plasma water treatment device and method, plasma is applied in the cavitation environment for water treatment, the technical constriction is simple, the cavitation liquid conveying negative factors are changed into plasma working conditions, the plasma water treatment effect is greatly enhanced, and advantages which cannot be replaced with pure plasma water treatment appear.

Owner:李芳 +1

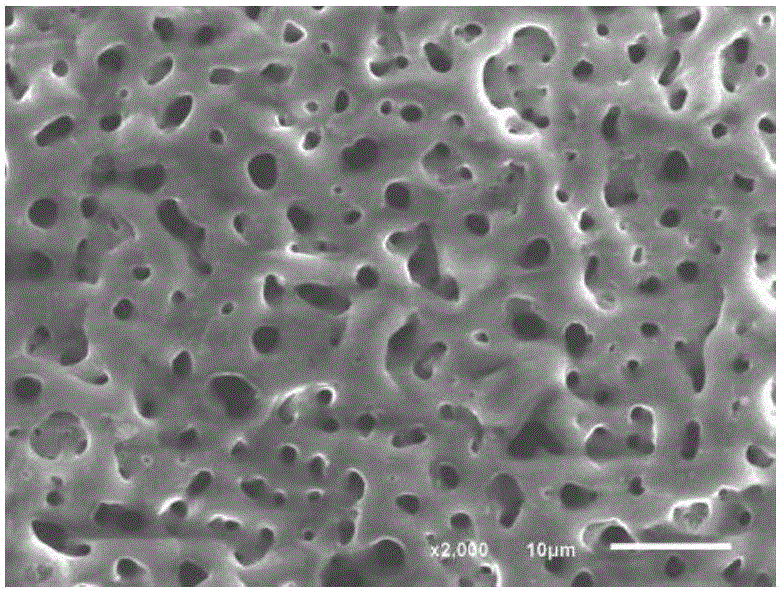

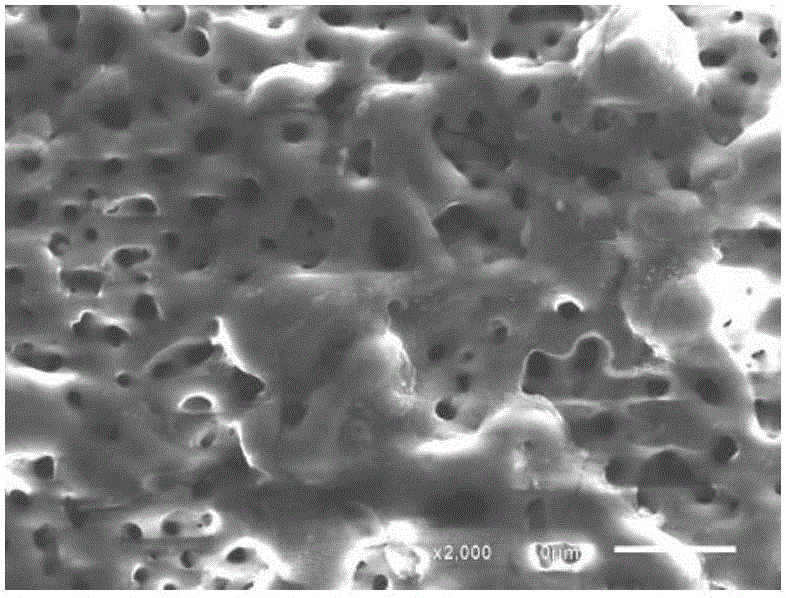

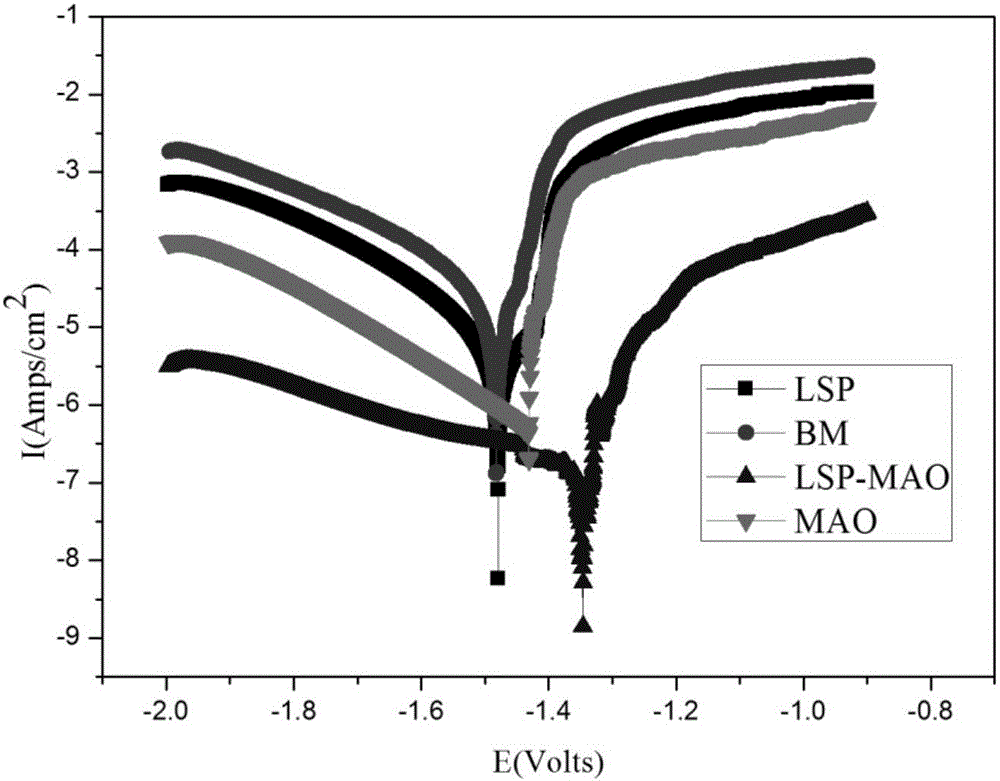

Method for preparing bio-coating on surface of magnesium alloy by combining laser shock with micro-arc oxidation

InactiveCN106119750AImprove physical and chemical propertiesImprove mechanical propertiesAnodisationMicro arc oxidationPlasma electrolytic oxidation

Disclosed is a method for preparing a bio-coating on the surface of a magnesium alloy by combining laser shock with micro-arc oxidation. The method comprises the following steps of (1) pretreatment of a magnesium alloy substrate; (2) laser shock strengthening, specifically, laser is directed at the surface of a sample, a to-be-strengthened area is a rectangular area on the surface of the sample, the wavelength lambda 1 of a laser is 1064 nm, the pulse width tau1 is 20 ns, the energy Q is 2J, the spot diameter D1 is 3 mm, laser spots are distributed in a non-spaced continuous overlapping mode, and the coverage rate of adjacent spots is 50%; and the periphery of the strengthened area of the processed sample is rubbed off by use of a pregrinder, the processed sample is placed into absolute ethyl alcohol or acetone for ultrasonic cleaning, and then the sample is taken out, washed with deionized water, naturally dried, and finally packaged in a sealed mode; and (3) micro-arc oxidation, specifically, the sample with the surface strengthened by laser shock in the step (2) is submerged into an electrolyte as a positive pole, a micro-arc oxidation stainless steel electrolytic bath serves as a negative pole, a constant-pressure mode is adopted, the electrolyte is subjected to reaction for 10-20 min at the temperature of 20-30 DEG C, and after the experiment is completed, the sample is taken out, washed with plasma water and dried.

Owner:ZHEJIANG UNIV OF TECH

Amino acid cleansing cream containing multiple plant ingredients

InactiveCN106236690AStable efficacyGood effectCosmetic preparationsToilet preparationsGlycerolDisodium cocoamphodiacetate

The invention discloses amino acid cleansing cream containing multiple plant ingredients. The amino acid cleansing cream is prepared from the following materials in proportion with a common preparation method of the amino acid cleansing cream: 17-19% of glycerol, 10-12% of sodium cocoyl glycinate, 9-11% of alkyl polyglucoside, 8-10% of cocamidopropyl betaine, 4-6% of N-lauroyl-L-sodium glutamate, 2-4% of disodium cocoamphodiacetate, 1.5-2.5% of cholesteryl hydroxystearate, 1.5-2.5% of a macromolecule positive ion conditioner, 0.8-1.2% of glyceryl stearate, 0.7-0.9% of saccharides isomerate, 2-4% of natural plant extract, and the balance of plasma water. Through the strict selection and concentration ratio, the synergistic effect of the various materials is played excellently. The amino acid cleansing cream has the advantages that the amino acid cleansing cream is low in irritation, moderate in cleaning performance and good in skin friendliness, and a user feels comfortable after washing with the amino acid cleansing cream and does not feel dry or tight.

Owner:FUJIAN MENGJIAOLAN DAILY CHEM

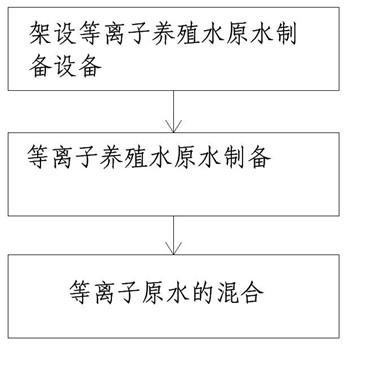

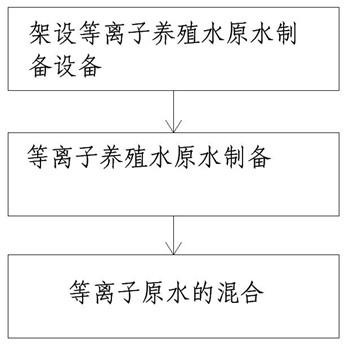

Method of preparing plasma aquaculture water

InactiveCN102487880AIncrease oxygen contentLong-lasting self-cleaningPisciculture and aquariaSludgeEconomic benefits

The invention discloses a method of preparing plasma aquaculture water, which mainly includes: setting up raw plasma water preparation equipment, preparing raw plasma water and mixing the raw plasma water. The method has the advantages that the plasma aquaculture water prepared by the method is high in oxygen content, dissolved oxygen in the water is maintained more than saturated for a long time, no air pump needs to be used, allowable fishes and shrimps per unit volume are denser, economic benefit is higher, the plasma aquaculture water can be self-clean for a long time and capable of continuously purifying, extra organics in the water can be degraded for a long time to maintain health of the water, no drug needs to be added, the aquaculture water capable of continuously disinfecting has no side effects to waters and fishes, controlling various fish diseases can be realized without adding antibiotics and various drugs, no cleaning of pond sludge is needed, the aquaculture water and the pond sludge are in reaction complementation, and the pond sludge which is modified needs no clearing.

Owner:苏州超等环保科技有限公司

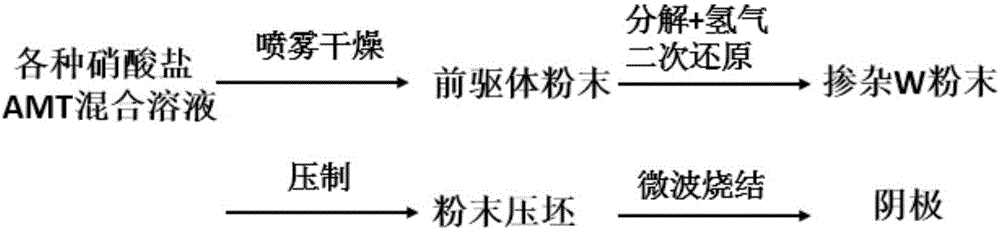

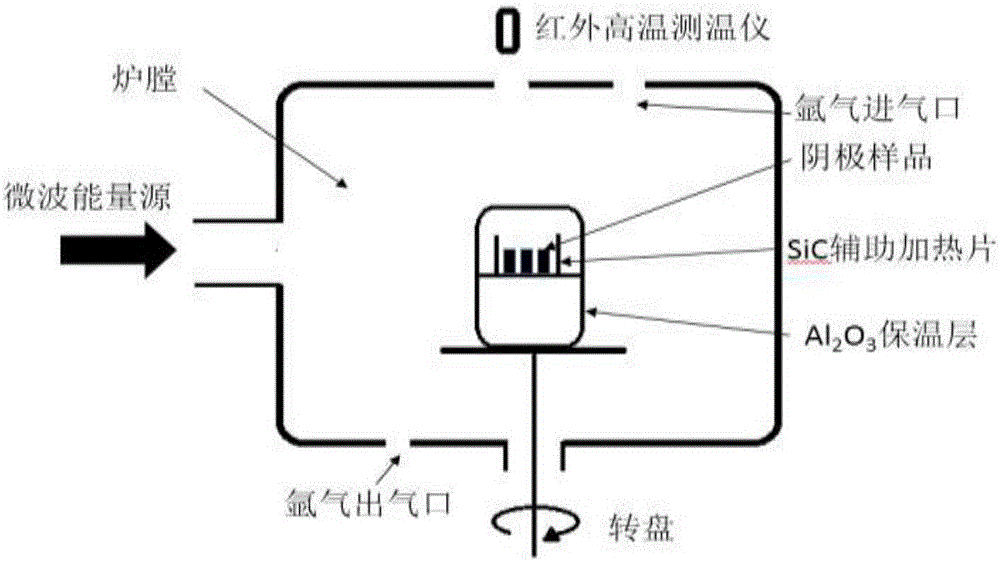

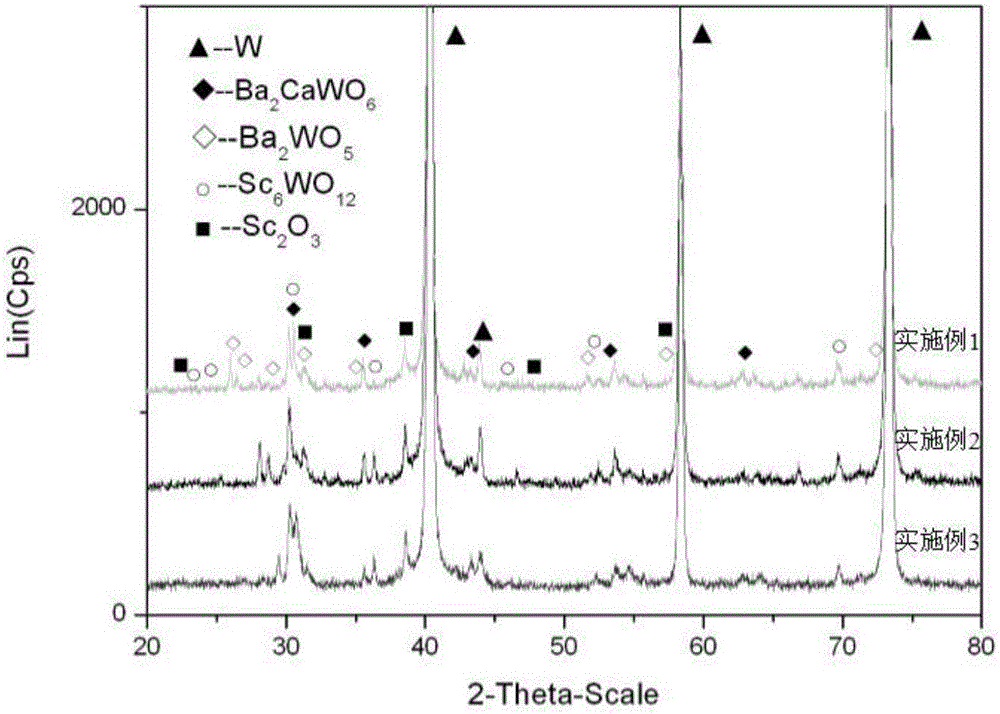

Preparation method of pressing type scandium containing dispenser cathode based on microwave sintering

InactiveCN106041069AUniform structureFine grainX-ray tube electrodesThermionic cathodesDecompositionRare earth

The invention belongs to the technical field of rare earth indissolvable metal cathode materials, and relates to a preparation method of a pressing type scandium containing dispenser cathode based on microwave sintering. The preparation method comprises the steps that various kinds of nitrate and ammonium metatungsten are dissolved in plasma water to be prepared into an evenly-mixed solution, and precursor powder with even particles is obtained through spray drying; then the precursor powder is subjected to decomposition and secondary reduction to obtain doped tungsten powder with elements distributed evenly; and finally a microwave sintering method is used for preparing the cathode through one-time sintering. Sintering one-time forming of the cathode is finally achieved, the sintering shrinkage ratio is remarkably reduced, the sintering time is greatly shortened, the structure is uniform, repeatability is good, and excellent launching performance is achieved at the temperature being 950 DEG C.

Owner:BEIJING UNIV OF TECH

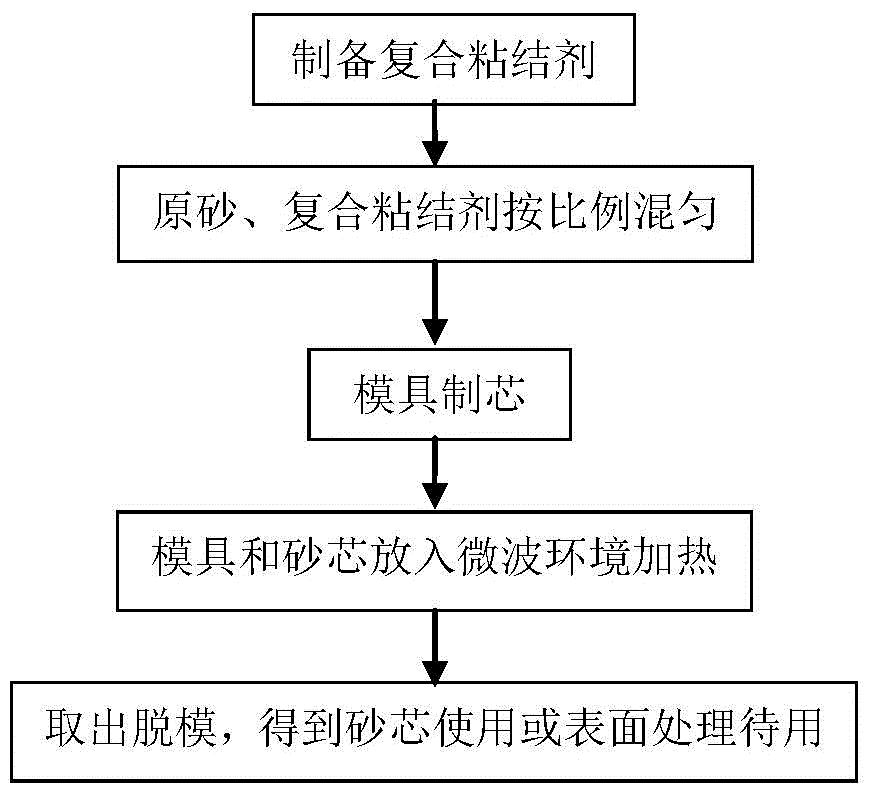

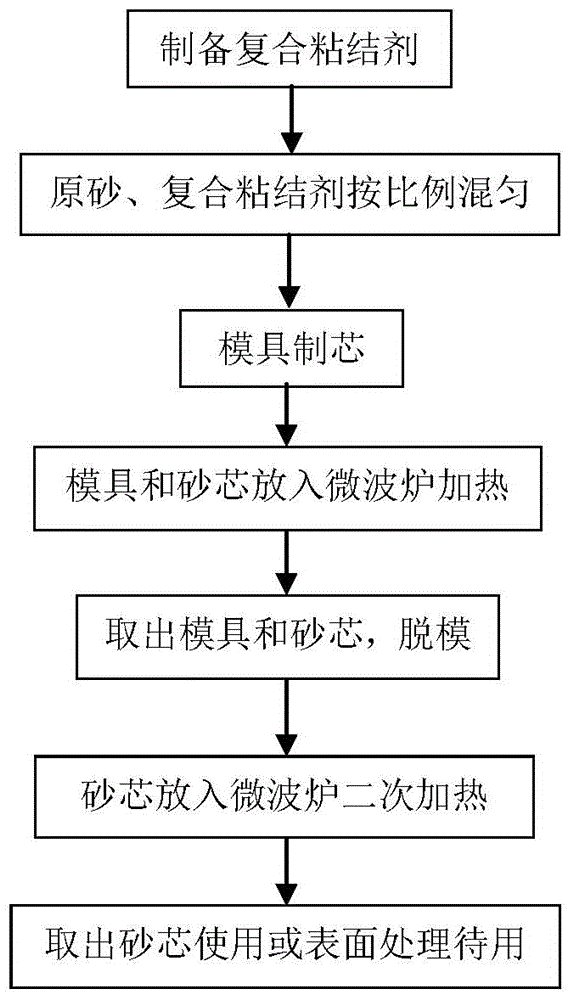

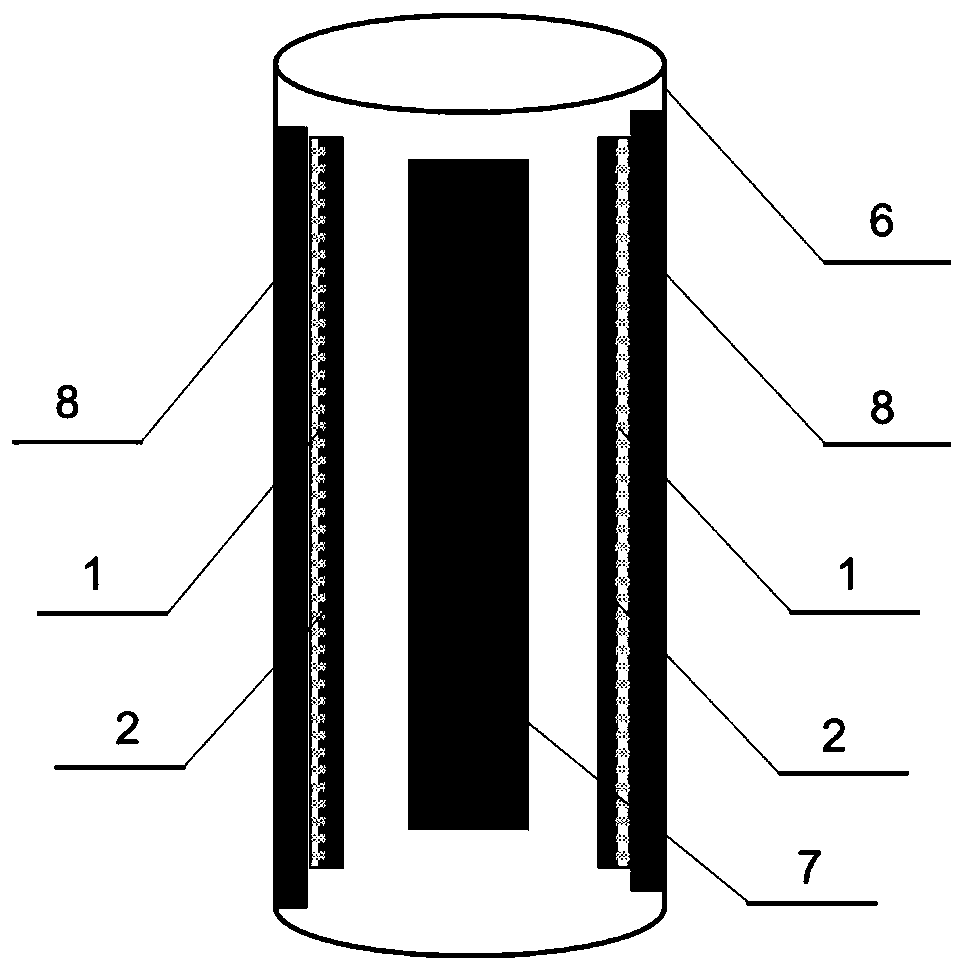

Preparation method of water-soluble sand core used for aluminium alloy or magnesium alloy thin wall complex casting

ActiveCN104475685ASolve difficult cleaning problemsEasy to recycleFoundry mouldsFoundry cores5005 aluminium alloyMoisture resistance

The invention discloses a preparation method of a water-soluble sand core used for an aluminium alloy or a magnesium alloy thin wall complex casting, and the method is as follows: (a) at room temperature, preparing magnesium sulfate heptahydrate and plasma water into a 20% to 30% magnesium sulfate aqueous solution, adding specific amount of octadecahydrate aluminum sulfate and an additive into the 20% to 30% magnesium sulfate aqueous solution, and heating to 60 to 80 DEG C to prepare a compound binder; (b) premixing homogeneously foundry raw sand, adding a composite binder to obtain mixture core sand; (c) putting the obtained mixture core sand into a core making mould, then putting the mixture core sand together with the mould into microwave environment for heating, removing and demoulding to obtain a water-soluble sand core product. By the method, the water-soluble sand core with good room temperature strength, moisture resistance, chemical stability and low gas-forming amount can be produced, and the water-soluble sand core especially has excellent water soluble collapsibility after casting, and causes no damage to the casting and no pollution to the environment.

Owner:HUAZHONG UNIV OF SCI & TECH

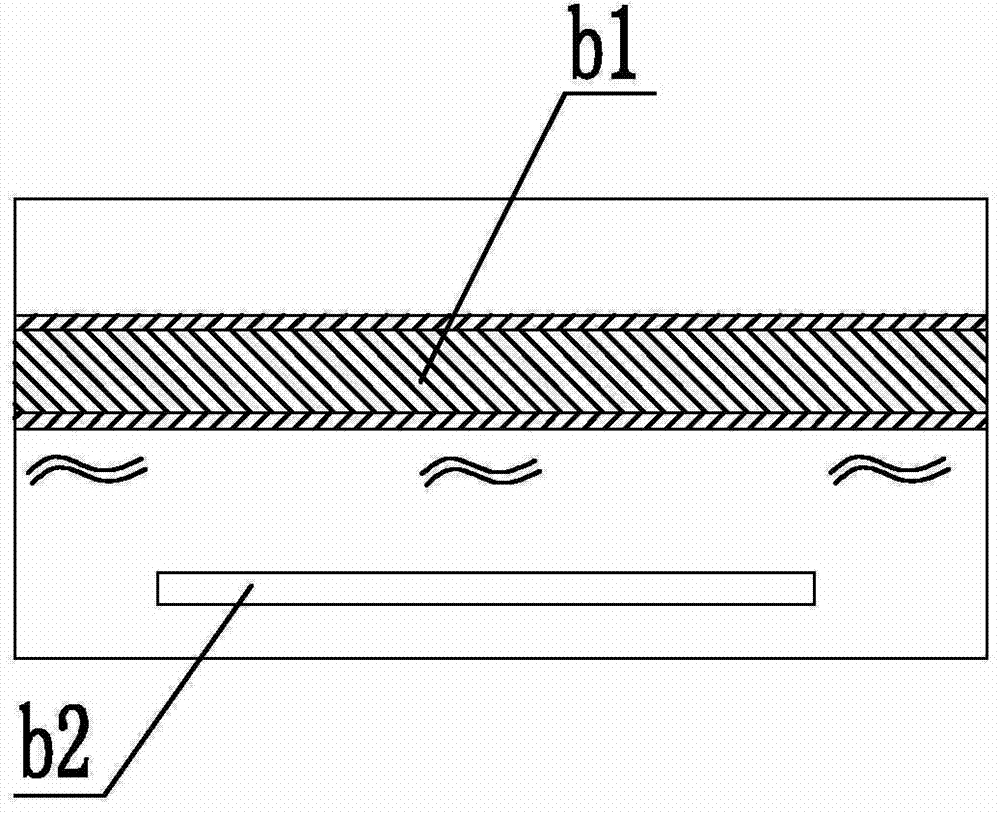

Water distribution and catalysis integrated falling film discharge plasma water treatment device

ActiveCN109942059AStable stateImprove energy efficiencyWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment using germicide/oligodynamic-processWater storage tankGas phase

The invention discloses a water distribution and catalysis integrated falling film discharge plasma water treatment device, belongs to the technical field of liquid treatment. The device comprises a discharge plasma electrode system, a high-voltage power supply and a water storage tank., wherein the discharge plasma electrode system is connected with the high-voltage power supply; a water body tobe treated is stored in the water storage tank; and water body is injected or circularly injected is through a water pump; and the electric plasma electrode system is divided into two forms of a corona (streamer) discharge plasma electrode system and a dielectric barrier discharge plasma electrode system according to that whether the system is an insulating medium or not. According to the device provided, discharge plasma occurs in a gas-phase environment with no influence of parameters of the water body to be treated, so that the plasma state is stable; the liquid film is uniformly distributed, the thickness of a porous material is adjusted to adjust liquid-holding thickness of the liquid film, so that the residence time of the water body in a reactor is prolonged; and the porous materialis utilized to integrate the water distribution and a catalyst carrier, so that the energy consumption and the operation cost are both reduced.

Owner:DALIAN UNIV OF TECH

Method and apparatus for patient fluid management

Owner:TRANSVIVO

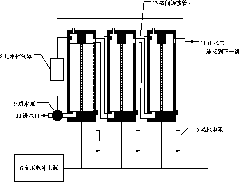

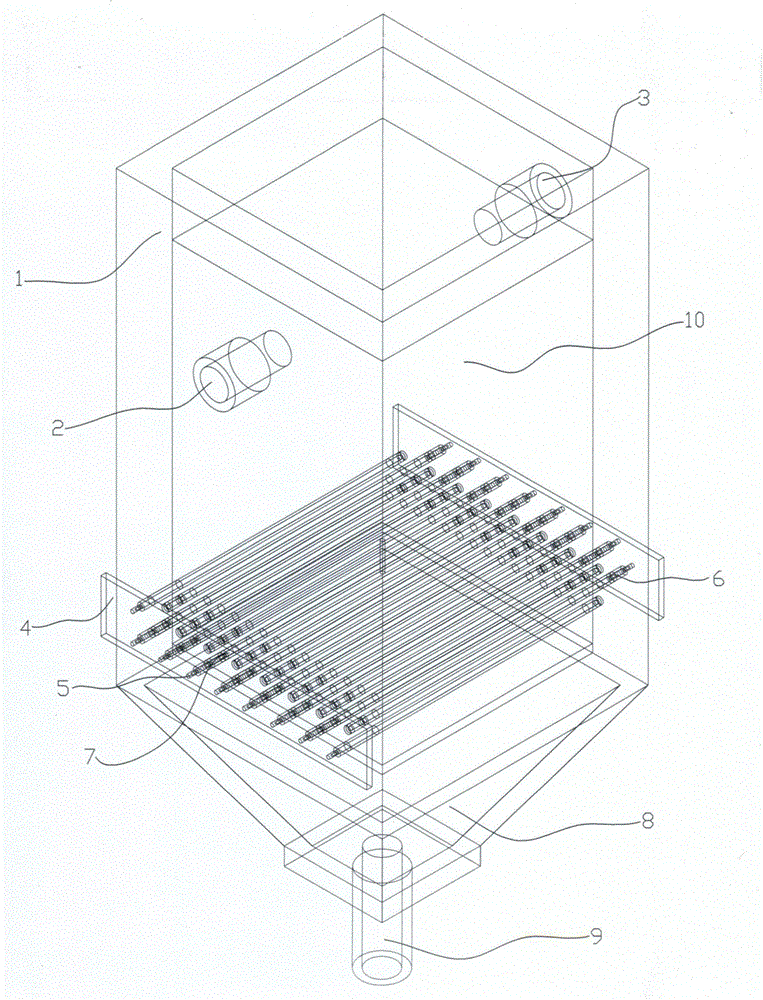

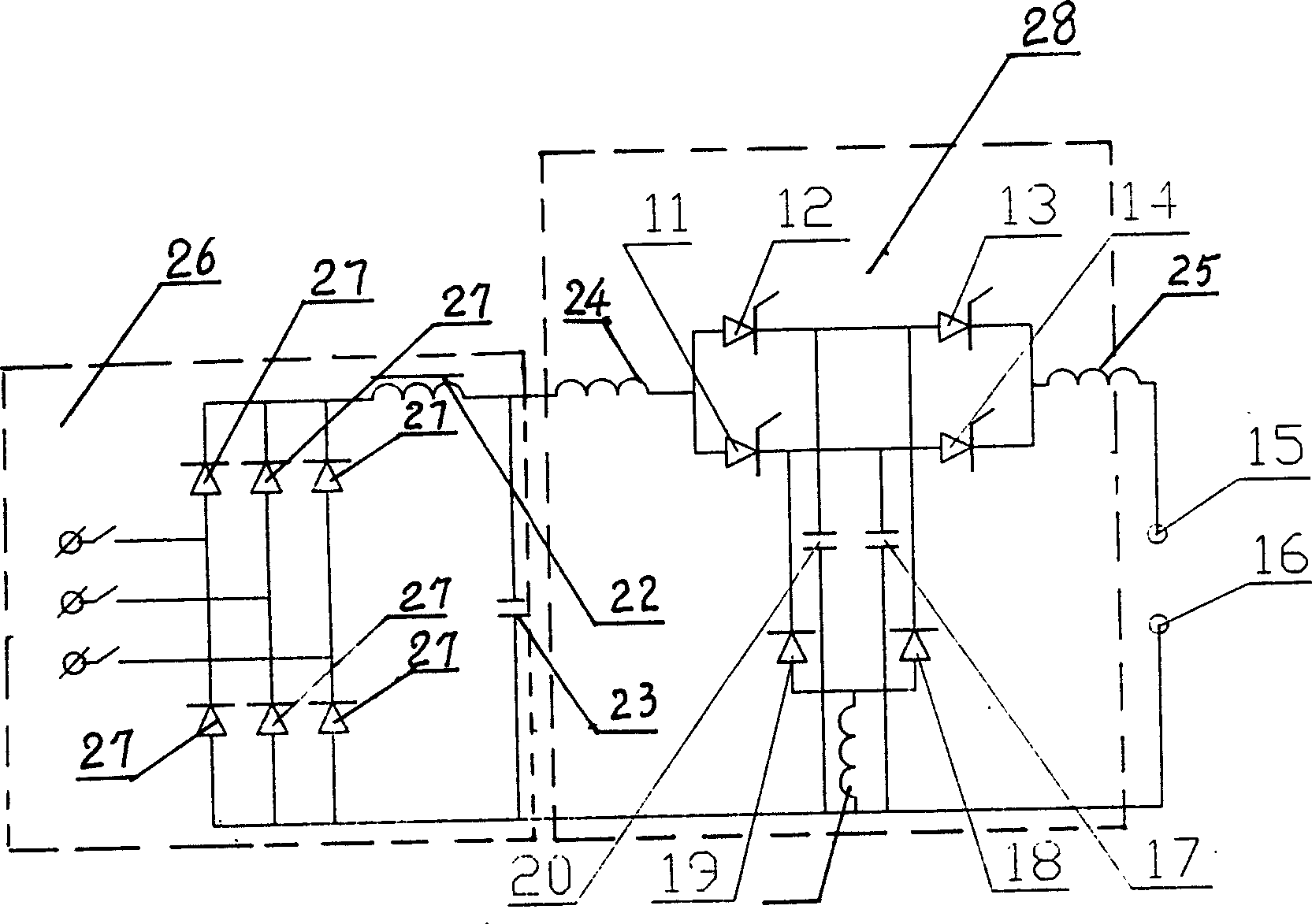

Plasma water processing system

PendingCN106430399AReduce the temperatureImprove uniformityWater/sewage treatment by irradiationPlasma techniqueEngineeringHigh pressure

A plasma water processing system includes a medium body box body, a water inlet pipe, a water outlet pipe, medium pipes, a first PCB, a second PCB, high-voltage electrodes, ground electrodes and a gas inlet; the medium body box body comprises a first cavity and a second cavity, a partition board between the first cavity and the second cavity is provided with a plurality of small through holes distributed at intervals, and the small through holes are used for communicating the first t cavity and the second cavity; the upper part of the first cavity is provided with the water inlet pipe and the water outlet pipe, and the bottom of the second cavity is provided with a gas inlet pipe; the lower parts of a left side wall plate and a right side wall plate of the first cavity are provided with a plurality of rows of holes in relative dislocation, and horizontal corresponding positions, opposite to the holes, on the inner surface of the lower parts of the wall plates of the first cavity are provided with blind holes; the medium pipe is inserted in each hole to the corresponding blind hole, and all the medium pipes form equal-interval curtain wall structures in the first cavity; metal electrodes in the left medium pipes are all connected on the first PCB, and the first PCB is connected with the high-voltage electrodes through wires; metal electrodes in the right medium pipes are all connected on the second PCB, and the second PCB is connected with the ground electrodes by wires.

Owner:DALIAN NATIONALITIES UNIVERSITY

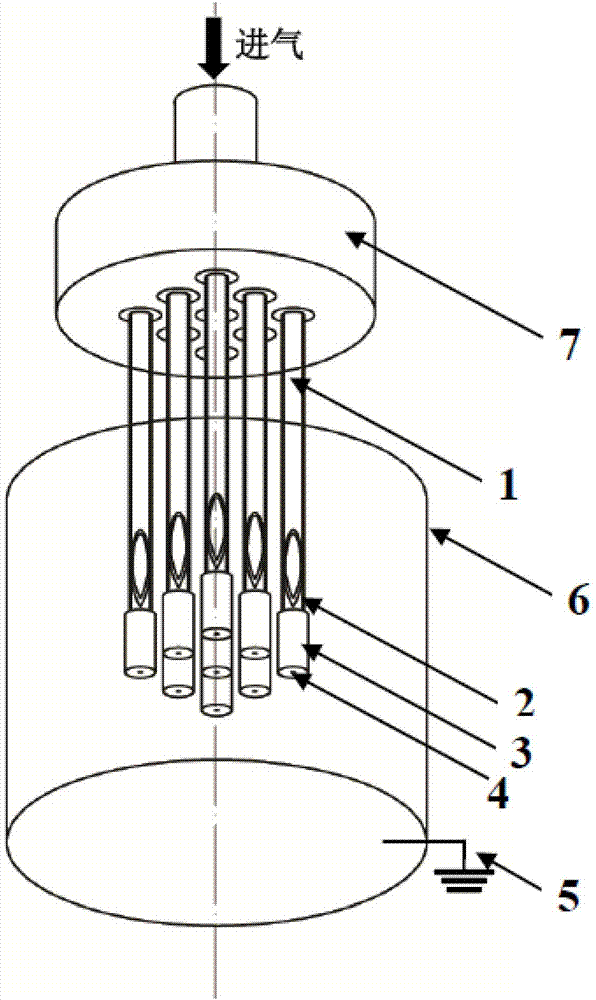

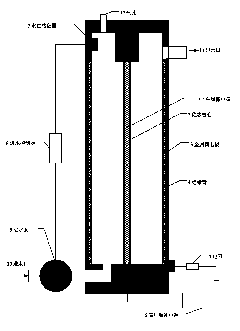

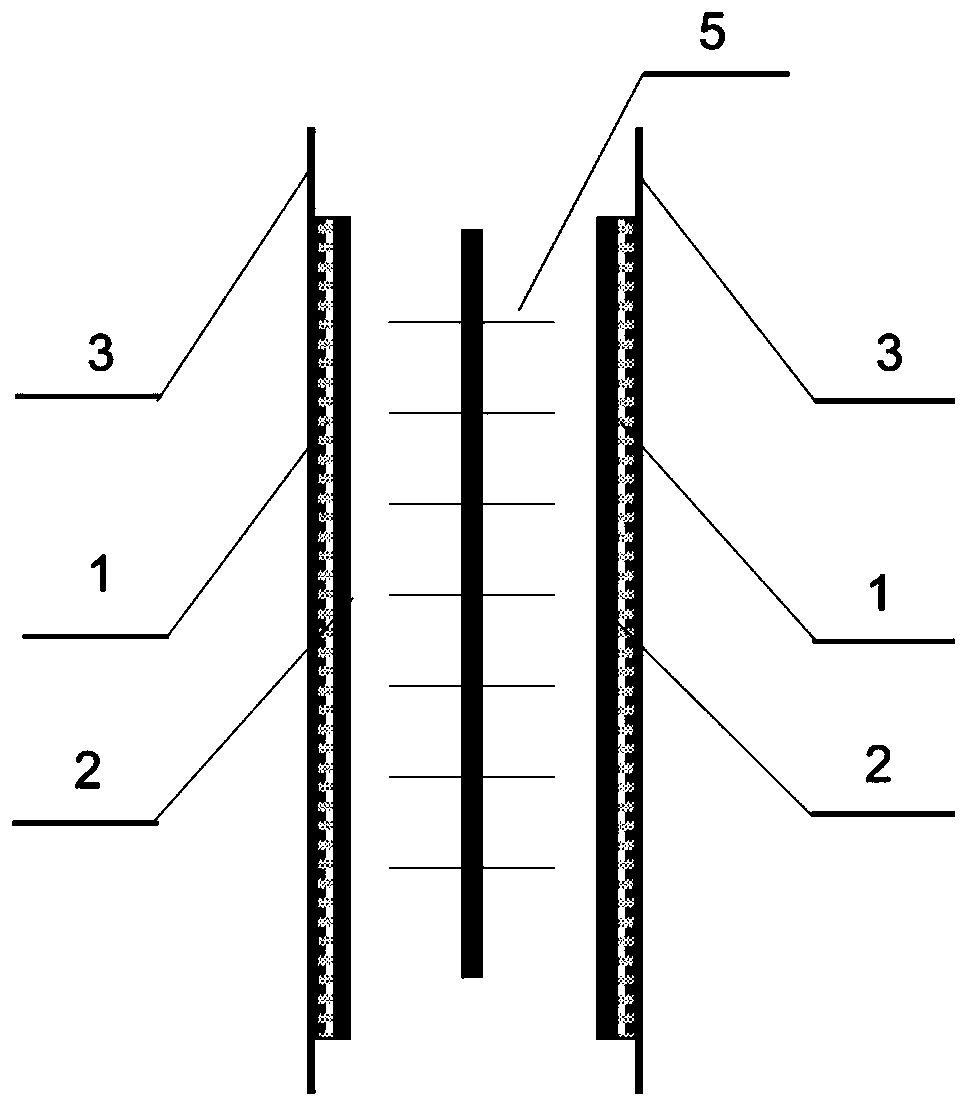

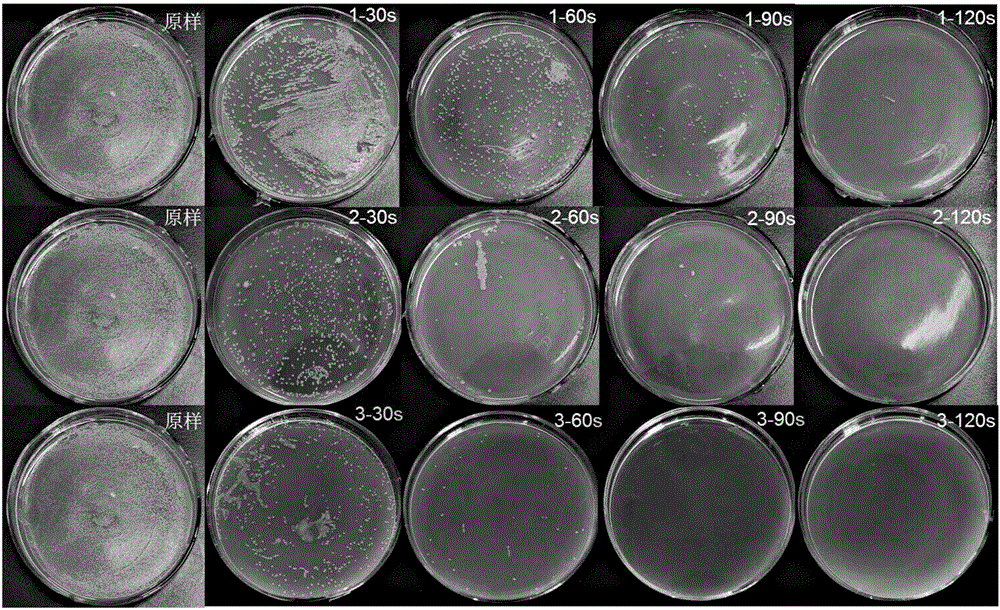

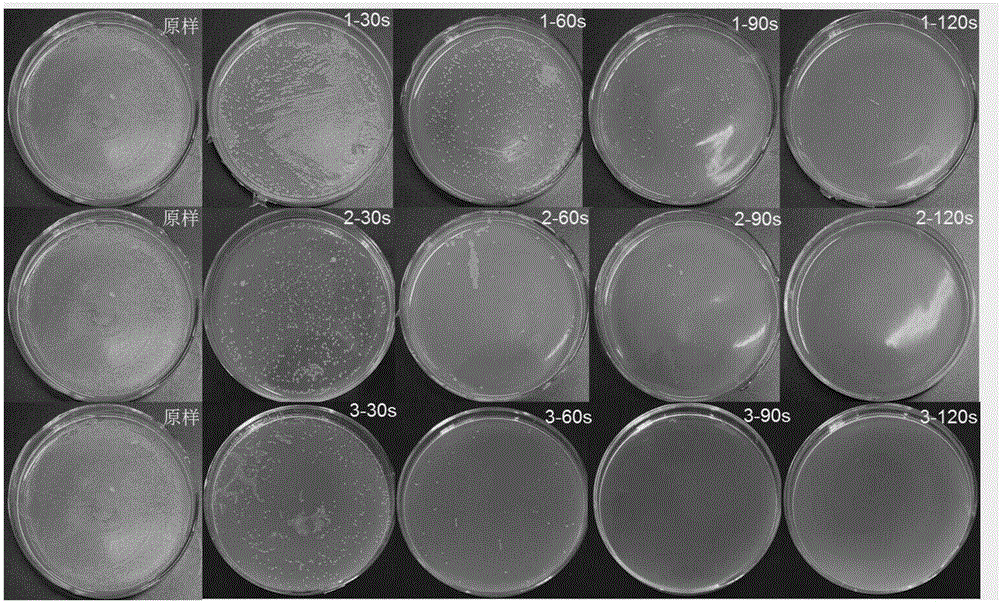

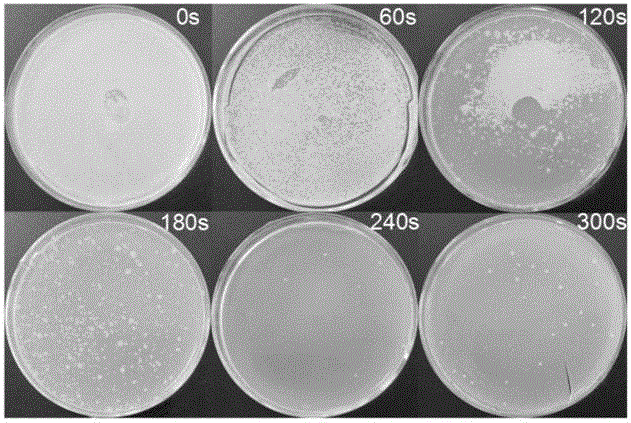

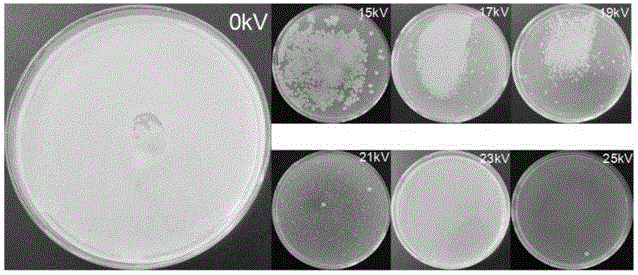

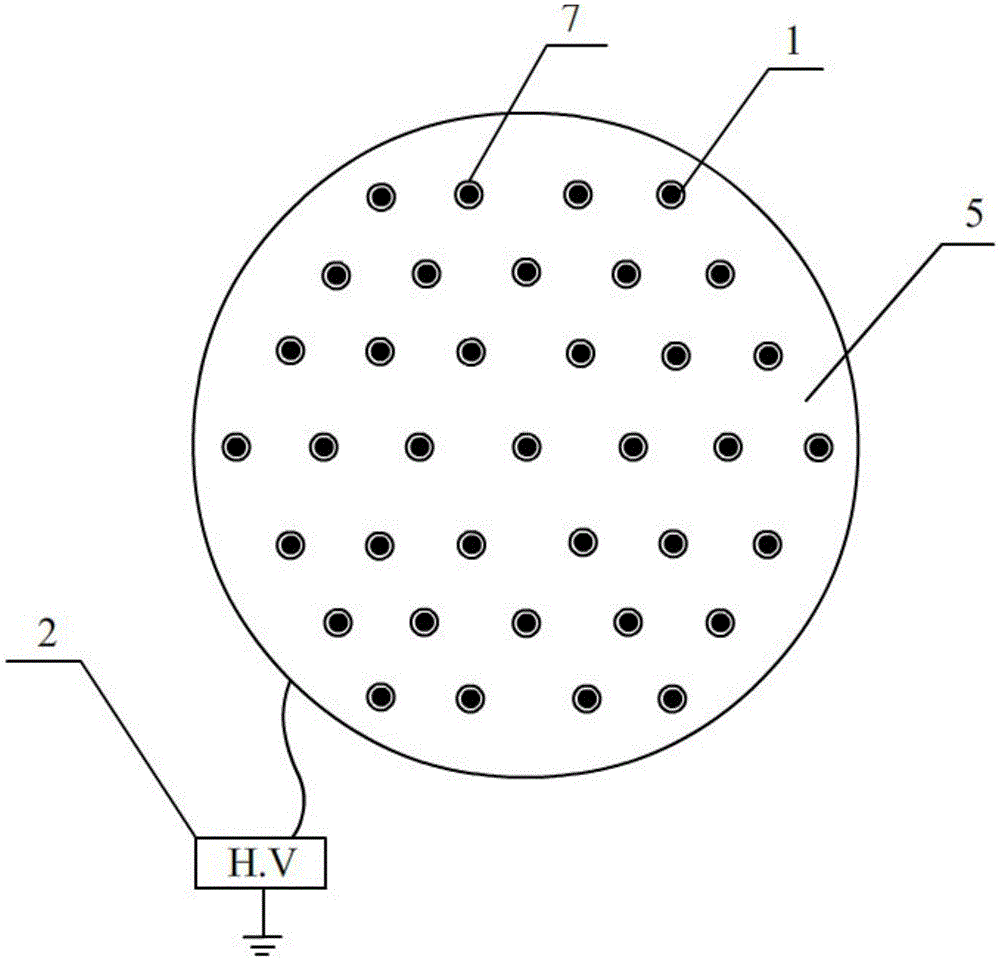

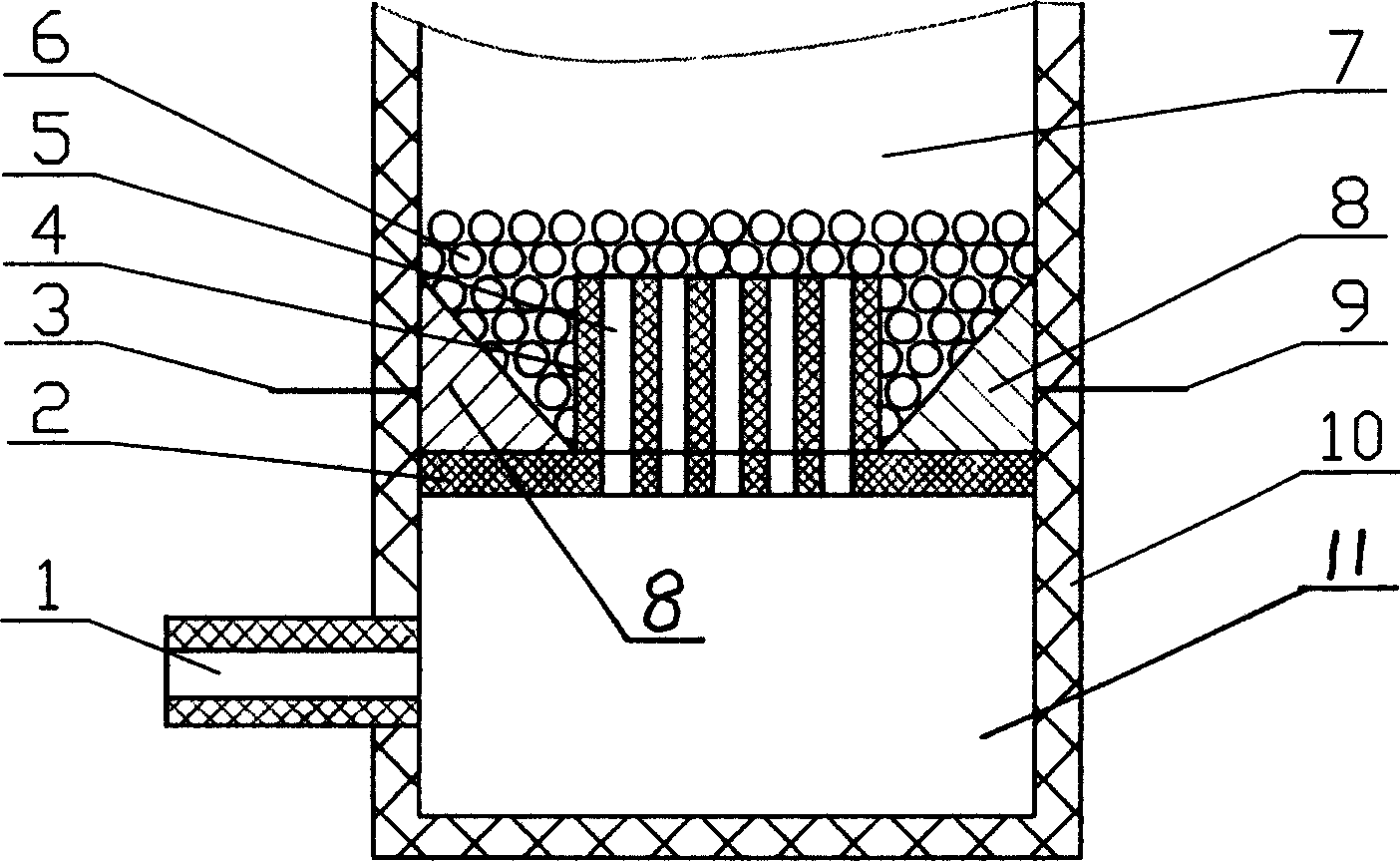

Plasma water preparation method and preparation device for speculum sterilization

The invention relates to a plasma water preparation method and preparation device for speculum sterilization. The device comprises high-voltage electrodes, a high-voltage power supply, a ground electrode, a ground line, a printed circuit board (PCB) and a container, wherein the PCB is of a round plate structure, a plurality of through holes are uniformly formed on the surface of the PCB, insulation dielectric pipes with single openings are arranged in the through holes, the orifices of the insulation dielectric pipes are flush with the through holes, the high-voltage electrodes are arranged in the insulation dielectric pipes, made of conductive metal and connected with the high-voltage power supply, the top ends of the high-voltage electrodes are in welding connection with the PCB, the container is arranged below the PCB and is of a cylindrical structure, the annular metal ground electrode sleeves the outer wall of the bottom end of the container, the ground electrode is grounded via the ground line, and all insulation dielectric pipes loaded with the high-voltage electrodes are inserted into the container. The device has the advantages of a reasonable design, wide application, high sterilization efficiency and the like.

Owner:DALIAN NATIONALITIES UNIVERSITY

Plasma water spray cutting gun

ActiveCN104084683ATimely coolingAchieve coolingWelding/cutting auxillary devicesAuxillary welding devicesInlet channelEngineering

The invention discloses a plasma water spray cutting gun which comprises a cutting gun body. The cutting gun body is provided with a shell, an insulating cylinder, a conductor, an electrode, a distributor and a nozzle, and the insulating cylinder, the conductor, the electrode, the distributor and the nozzle are assembled in the shell. A gap area between the distributor and the electrode serves as an airflow distribution channel, the nozzle is arranged at the bottom of the distributor, an air inlet channel is disposed in the conductor, the nozzle and the periphery of the bottom end of the electrode form an air outlet channel, the bottom end of the nozzle is provided with a plasma flame ejection hole, and the air inlet channel, the airflow distribution channel, the air outlet channel and the plasma flame ejection hole are sequentially communicated to form an airflow channel; a water spray ejecting hole is formed in the portion, opposite to the plasma flame ejection hole, of the bottom of the shell, a water spray generation channel is formed in the cutting gun body, and the water spray ejection hole is communicated with the water spray generation channel. The plasma water spray cutting gun can achieve plasma cutting of parts to be cut, can cool the parts to be cut in a water-cooling mode at the same time, avoids smoke, dust, strong light and harmful gas generated in the cutting process, and improves environmental friendliness during cutting.

Owner:CHANGZHOU WULIAN ELECTRIC WELDING & CUTTING EQUIP

Electric pulse minitype plasma water treatment method and equipment

InactiveCN1459421AReduce processing timeSave raw materialsWater/sewage treatment by magnetic/electric fieldsEngineeringElectrical impulse

A process for treating sewage by electric pulse micro plasma features that the sewage is loaded in a reactor equipped with metallic load, and electric pulses are applied to it. Its apparatus is composed of a reactor and a current pulse generator. It can remove various pollutants including heavy metals, petrochemical pollutant, lubricating coolant, organic substance, toxin, microbes, etc..

Owner:大连动静科技有限公司

Method for preparing hydrophobic melamine foam

A method for preparing hydrophobic melamine foam is characterized by including the following steps that firstly, melamine and formaldehyde are mixed and reacted to obtain precondensate, the precondensate, a hardening agent, a nonionic surface active agent, a foaming agent, a light stabilizer and deionized water are mixed to form foaming liquid, the foaming liquid foams for 1-3 min to form a foam body through microwave radiation at the temperature of 40-70 DEG C, is cured for 7-25 min and is annealed for 25-60 min, and a melamine foam semi-finished product is obtained; secondly, dimethyl silicone oil, a silane coupling agent and plasma water are prepared into a hydrophobic solvent; thirdly, the prepared hydrophobic solvent is evenly sprayed on the melamine foam semi-finished product through a sprayer; fourthly, the foam sprayed with the hydrophobic solvent is dried for 5-15 min under the microwave condition, moisture and steam are exhausted through an air blower, and the hydrophobic melamine foam body is obtained. The preparation method has the advantages of improving foam hydrophobic performance, expanding the application field and being easy and convenient to operate.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com