Patents

Literature

151 results about "Low-pressure discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-pressure discharges are discharges made under gas pressures from a few millitorr to a little less than atmospheric. They have the benefit of less power requirement of sustenance of the discharge as volume-recombination rates are lower.

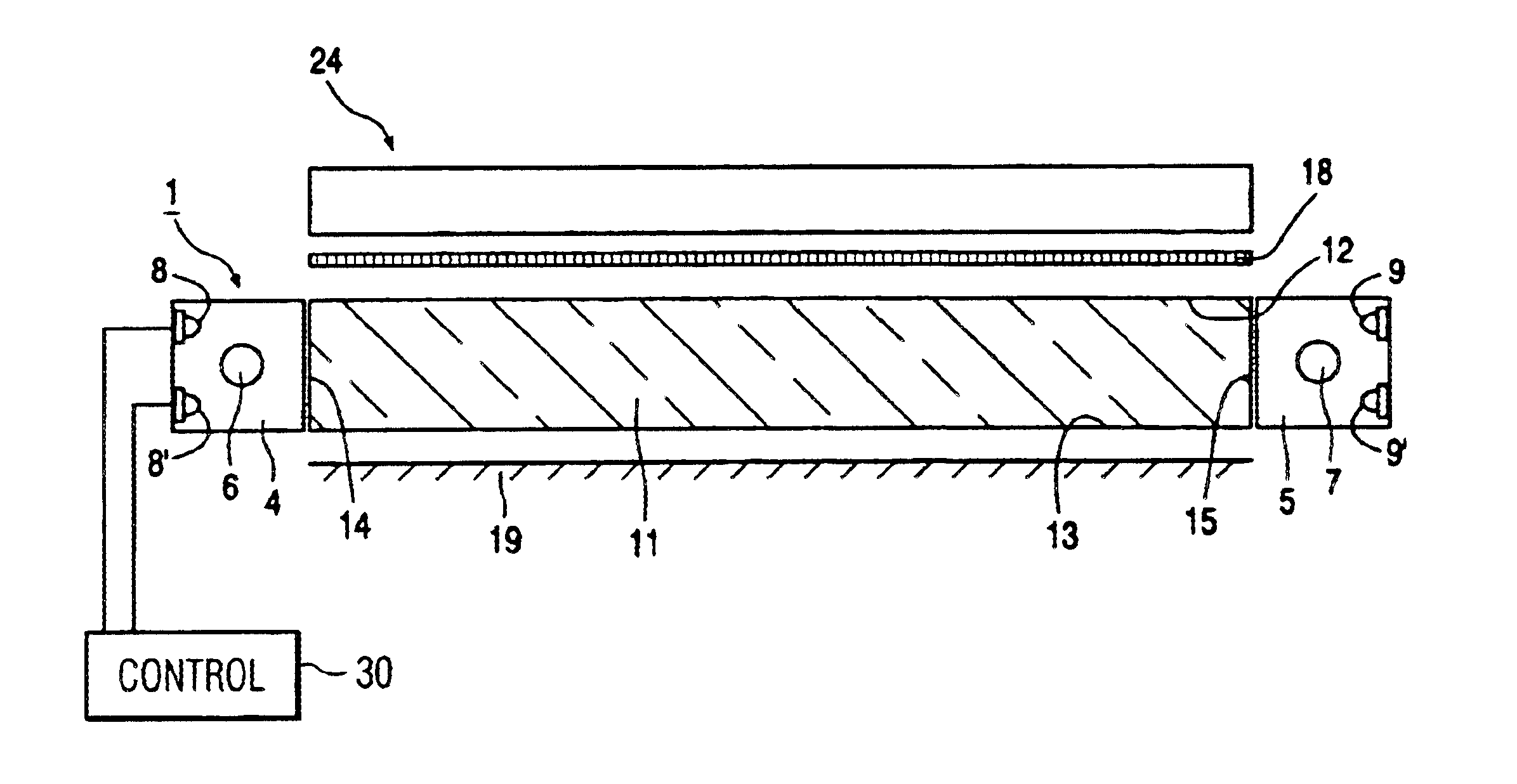

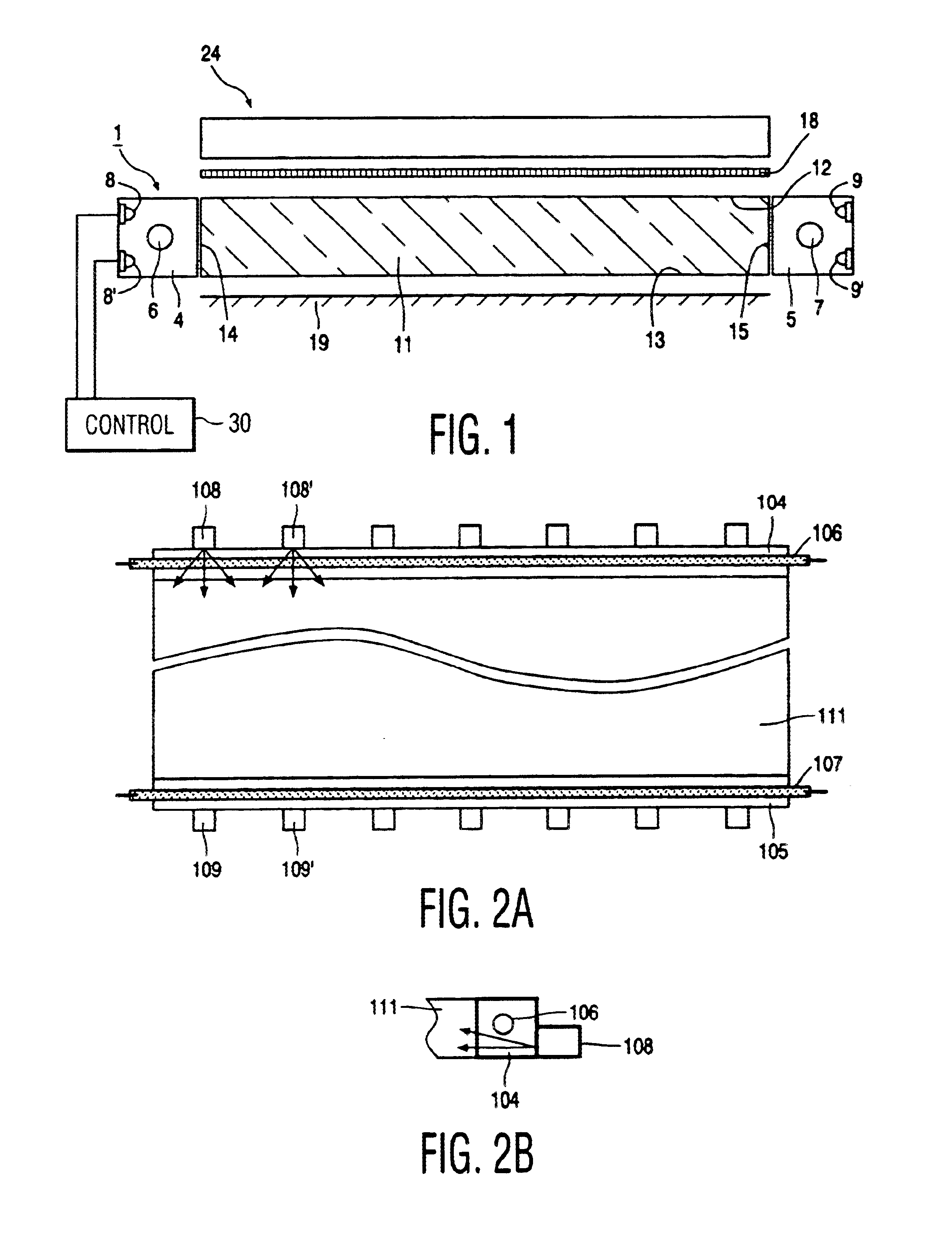

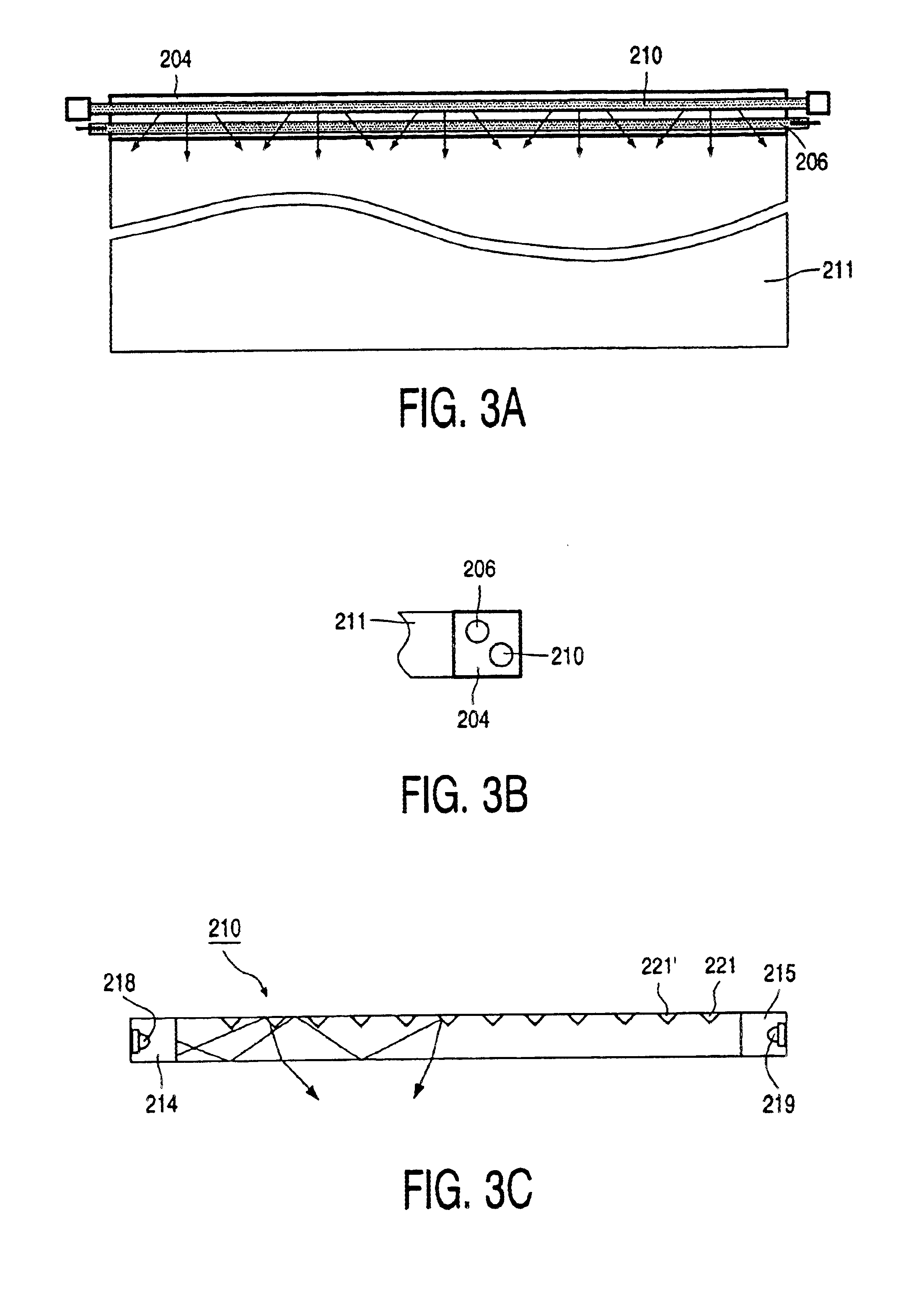

Illumination system and display device

InactiveUS6840646B2Improve image contrastSharp contrastLighting applicationsMechanical apparatusDisplay deviceLuminous flux

A back lighting system for illuminating a display device comprises a light-emitting panel (1) and a light source (6) for coupling light into the light-emitting panel. The light source comprises a low-pressure discharge lamp (6; 7). The light source additionally comprises a plurality of LEDs (8, 8′, . . . ; 9, 9′, . . . ) for selectively setting the color temperature of the light emitted by the light source. Preferably, the LEDs increase the color temperature of the light emitted by the light source. Preferably, the light emitted by the back lighting system ranges from 6,000 to 10,500 K. Preferably, the LEDs are blue light emitting LEDs, each preferably having a luminous flux of at least 5 lm. The color point of an image to be displayed on a display screen of the display device is set by the back lighting system, thus enabling an optimum contrast to be achieved for the image to be displayed by the display device.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

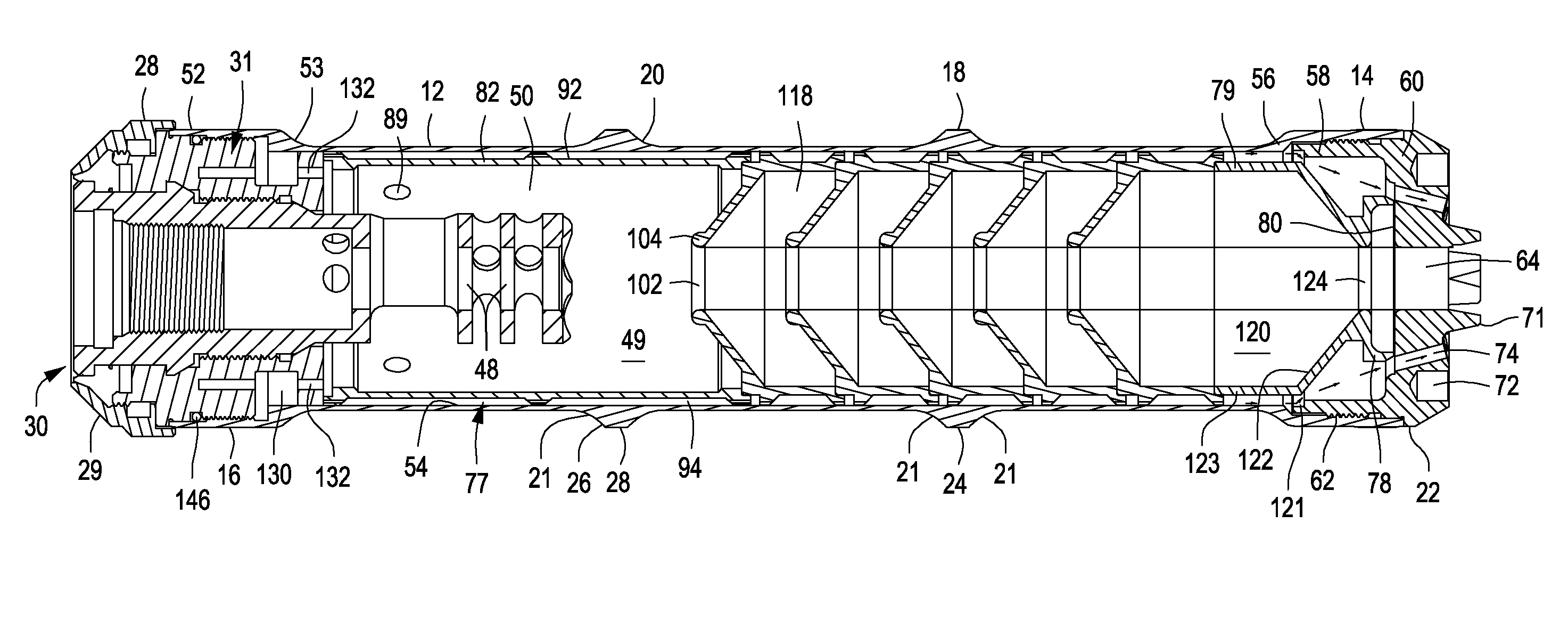

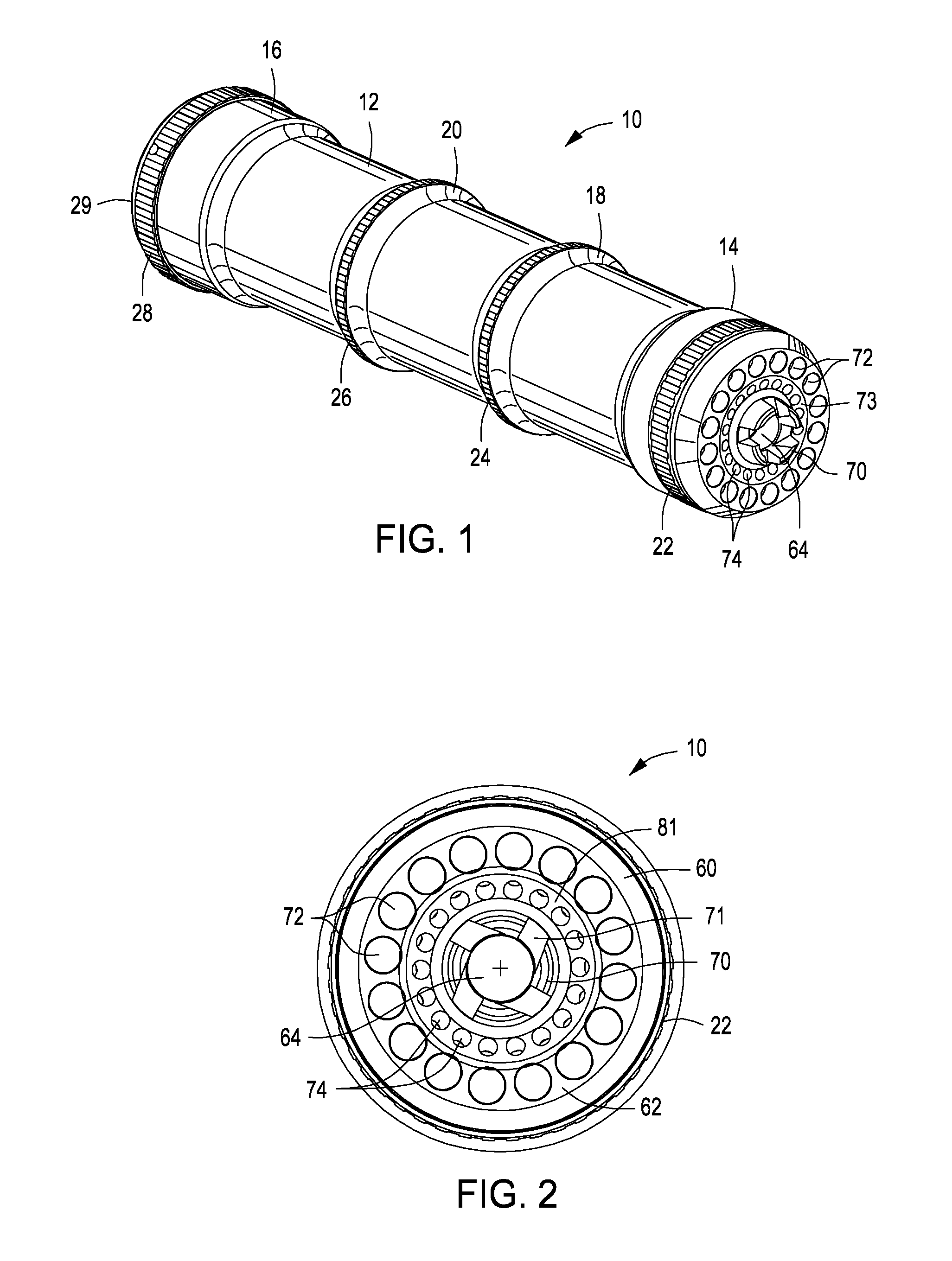

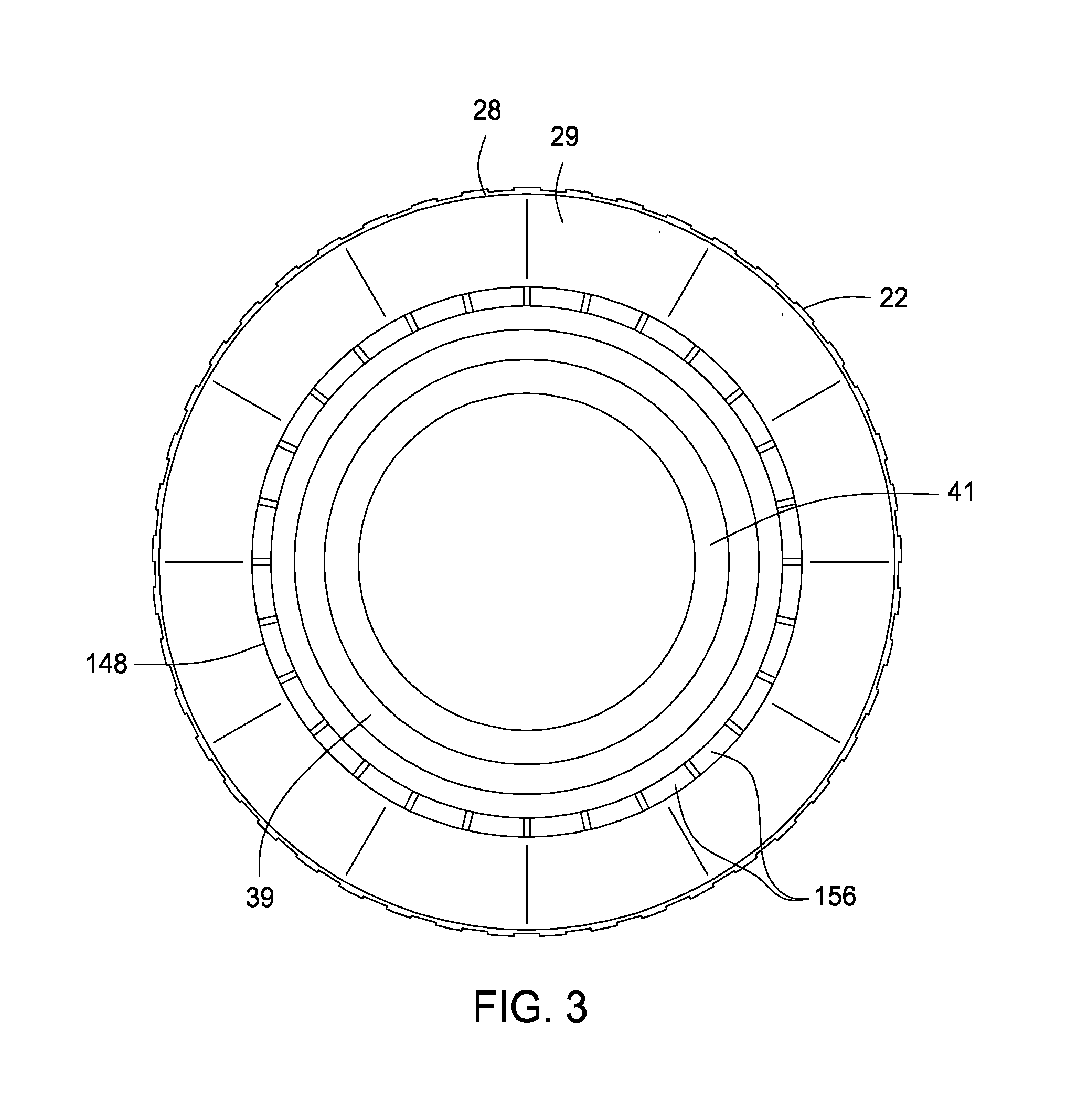

Firearm sound and flash suppressor having low pressure discharge

A firearm noise suppressor and flash hider device having a tubular housing having left hand threaded components. A suppressor mount securing and aligning the tubular housing relative to a firearm barrel. A number of propellant gas handling members within the housing define aligned projectile ports and baffle chambers to permit projectile movement and slow the progress of propellant gas as it traverses the internal chamber. These gas handling members define primary and secondary flow paths within the housing to divide the propellant gas discharge from the barrel and minimize gas pressure and volume of flow, resulting in lower propellant pressure, minimized noise and propellant flash. The primary and secondary flow paths each have separate discharge openings at the forward end of the suppressor.

Owner:LARUE MARK C

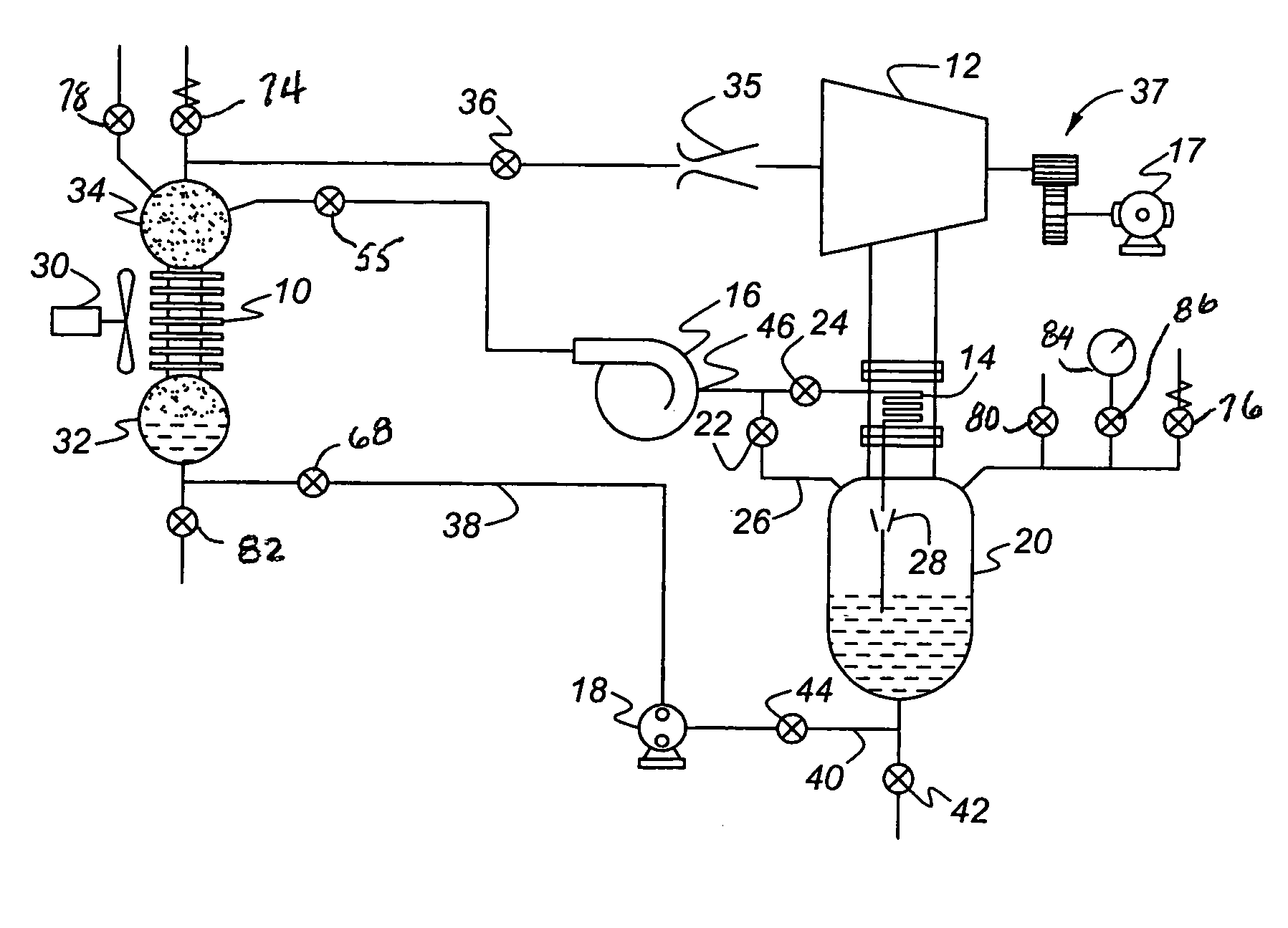

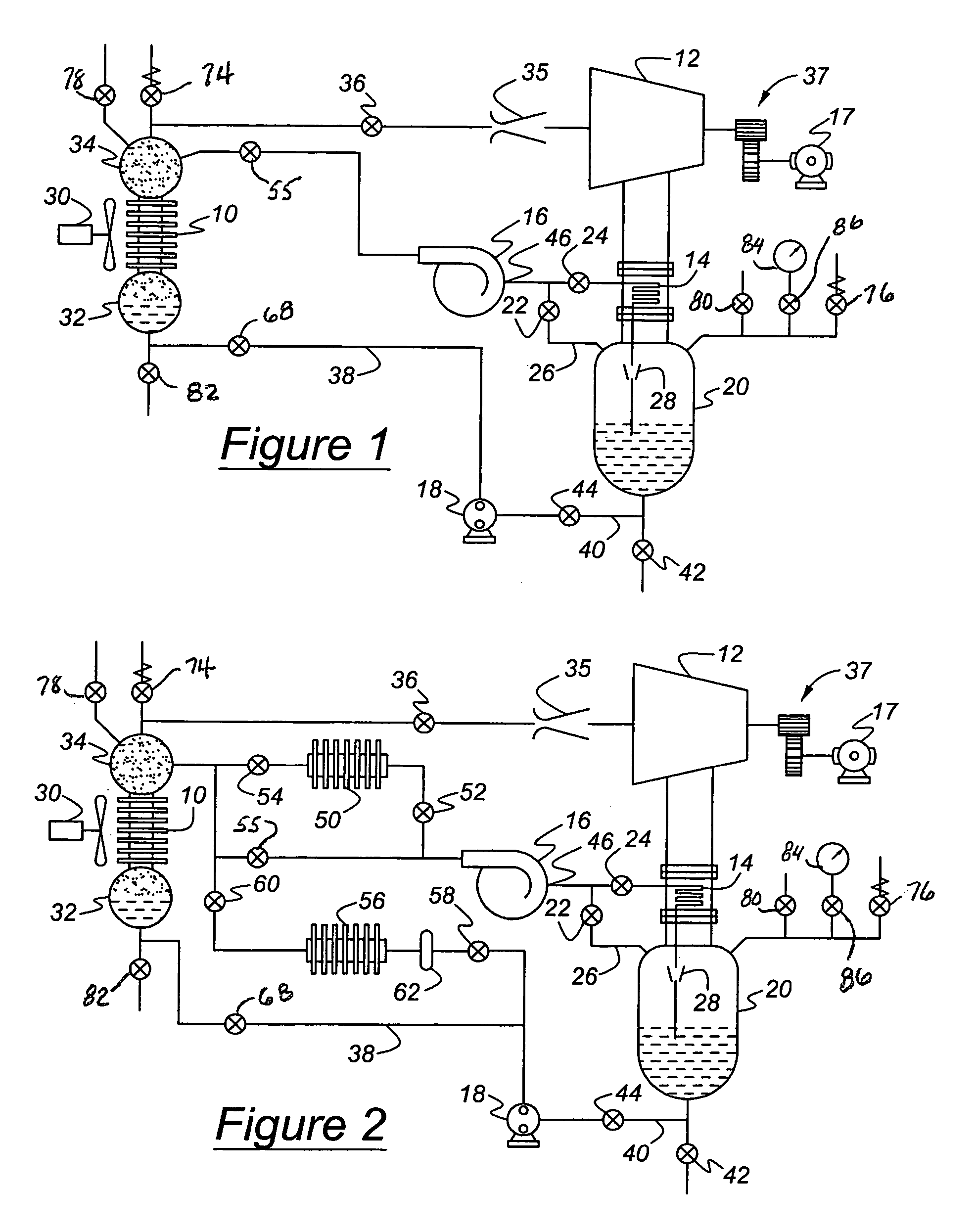

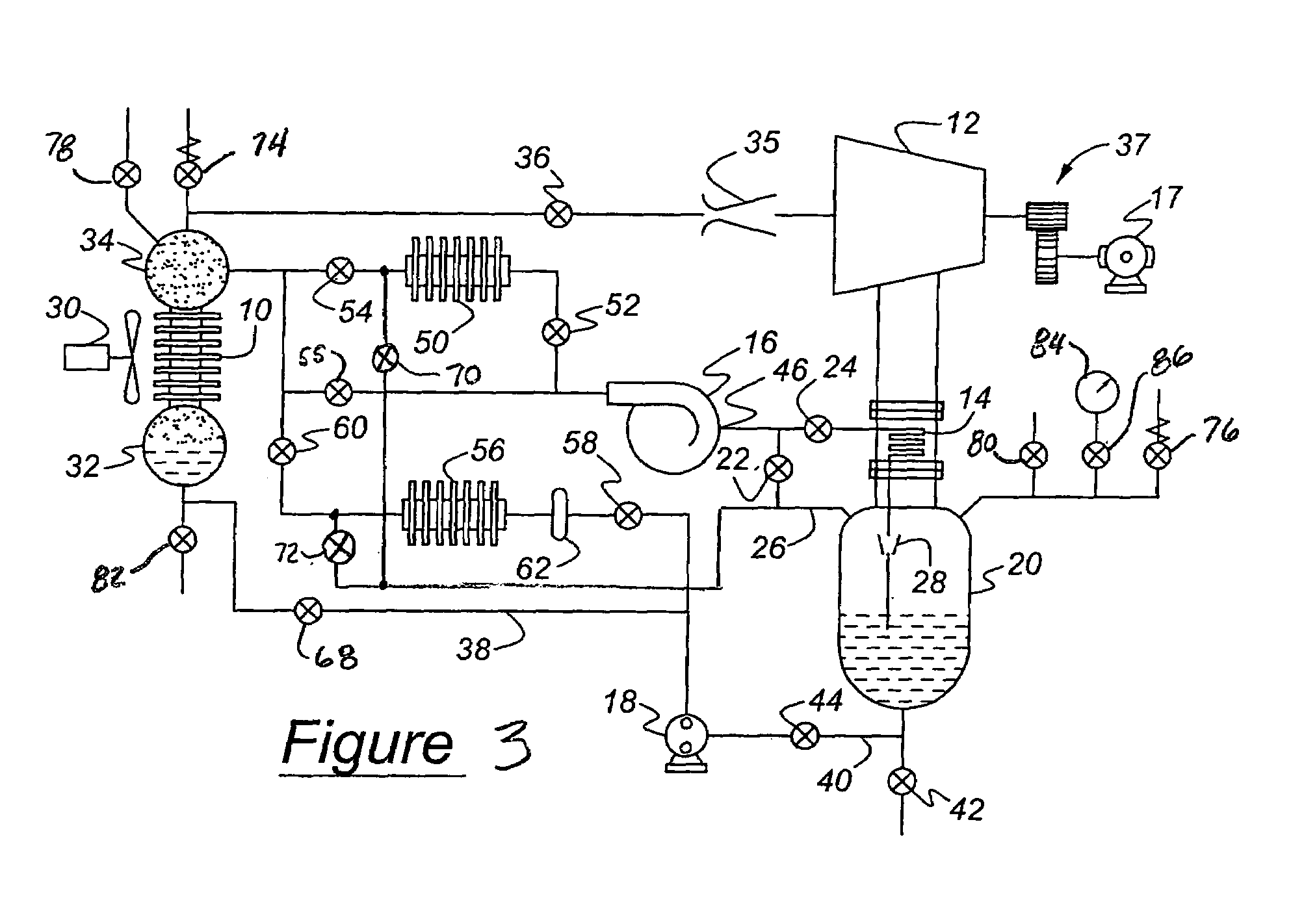

Low temperature heat engine

InactiveUS7010920B2Efficient methodReciprocating combination enginesCombination enginesWorking fluidCompressed fluid

A method for producing power to drive a load (17) using a working fluid circulating through a system that includes a prime mover (12) having an inlet and an accumulator (20) containing discharge fluid exiting the prime mover. A stream of heated vaporized fluid is supplied at relatively high pressure to the prime mover inlet and is expanded through the prime mover (12) to a lower pressure discharge side where discharge fluid enters an accumulator (20). The discharge fluid is vaporized by passing it through an expansion device (28) across a pressure differential to a lower pressure than the pressure at the prime mover discharge side. Latent heat of condensation in the discharge fluid being discharged from the prime mover is transferred by a heat exchanger (14) to discharge fluid that has passed through the expansion device (28). Vaporized discharge fluid, to which heat has been transferred from fluid discharged from the prime mover, can be returned through a compressor (20) and vapor drum (34) to the prime mover inlet. Vaporized discharge fluid can be removed directly from the accumulator (20) by a compressor (16) where it is pressurized slightly above the pressure in the vapor drum (34), to which it is delivered directly, or it can be passed through a heat exchanger (50) where the heat from the compressed fluid is transferred to an external media after leaving the compressor (16) in route to the vapor drum (34). Liquid discharge fluid from the accumulator (20) is pumped to a boiler liquid drum (32), then to the vapor drum (34) through a heat exchanger (10). The liquid discharge fluid may be expanded through an orifice (62) to extract heat from an external source at heat exchanger (56) and discharged into the vapor drum (34) or the accumulator (20), depending on its temperature upon leaving heat exchanger (56).

Owner:TERRAN TECH

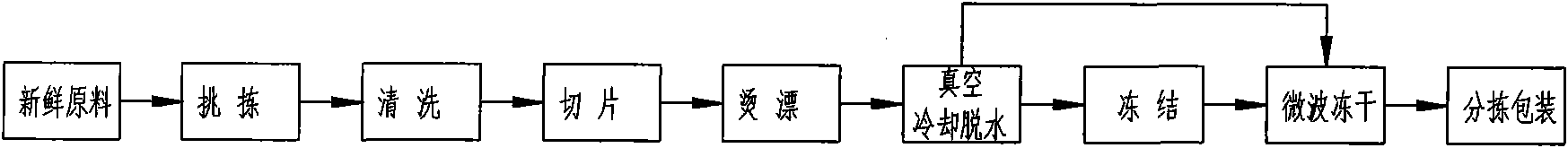

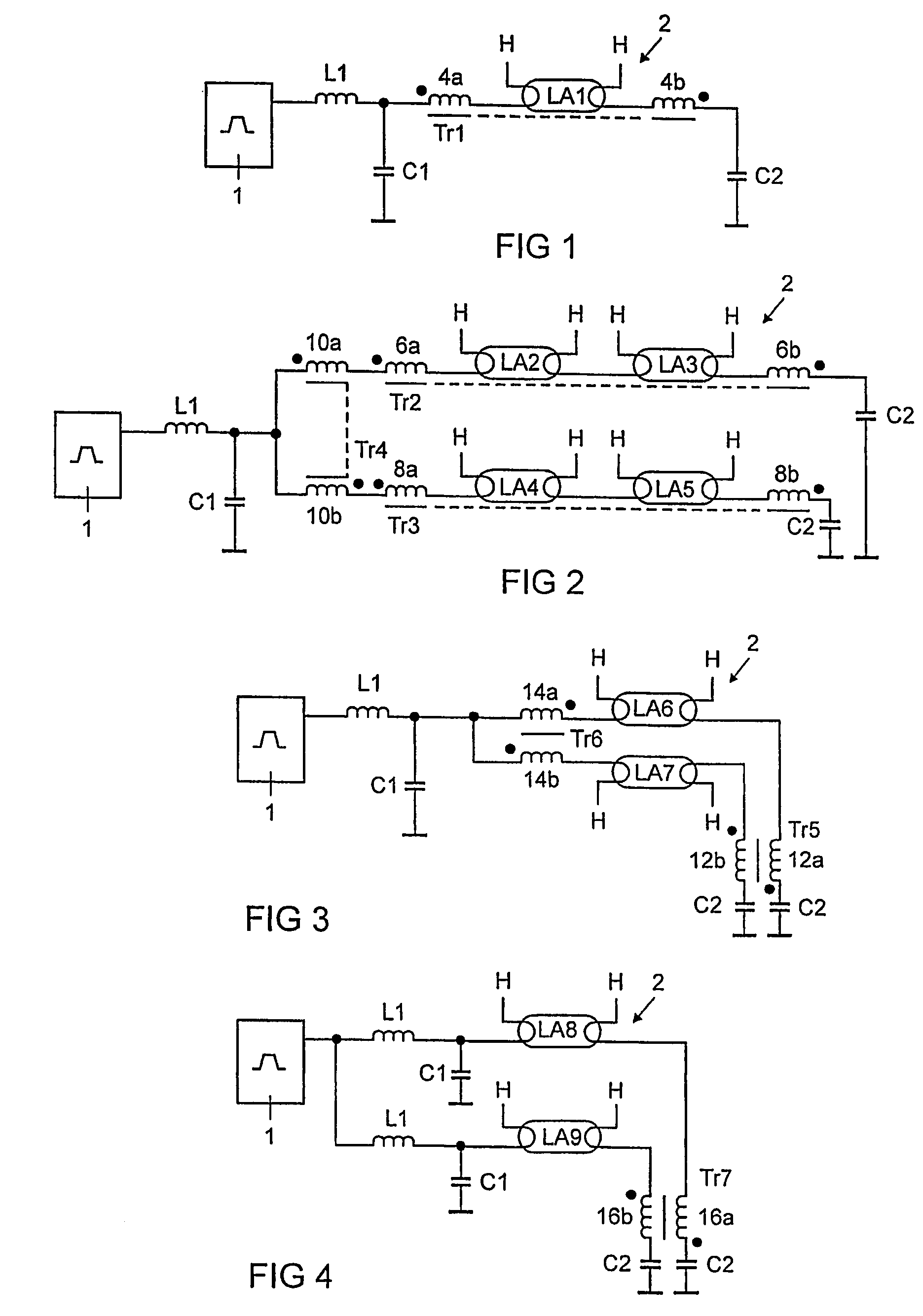

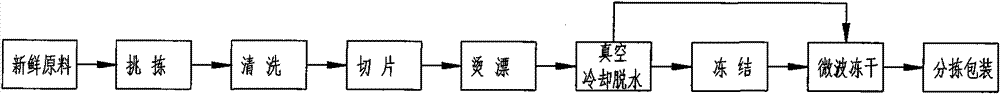

Microwave freeze-drying and dehydrating method of fruits and vegetables

InactiveCN101849573AShort drying time for dehydrationReduce energy consumptionFruit and vegetables preservationMicrowaveFreeze-drying

The invention relates to a microwave freeze-drying and dehydrating method of fruits and vegetables, belonging to the field of a fruit and vegetable food treatment technology. The method comprises the following steps of: cleaning, blanching, pre-drying, freezing, microwave freeze-drying and taking out. The method is suitable for various forms of freeze-drying products, integrates blanching and cooling working procedures into a whole, does not need the cooling working procedure after blanching, not only is thorough to blanch and cool, but also has high speed, especially removes partial internal water at the same time of removing water on the surface of materials, and avoids forming crystals on the surface of the materials in the freezing process, thereby being beneficial to increasing the microwave freeze-drying speed and effectively restraining the microwave low-pressure discharge problem in the early freeze-drying process.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

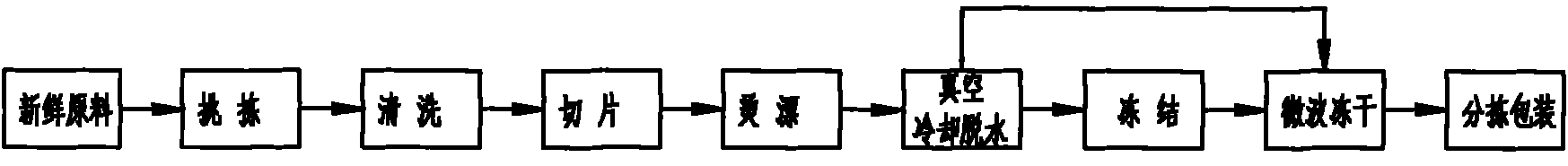

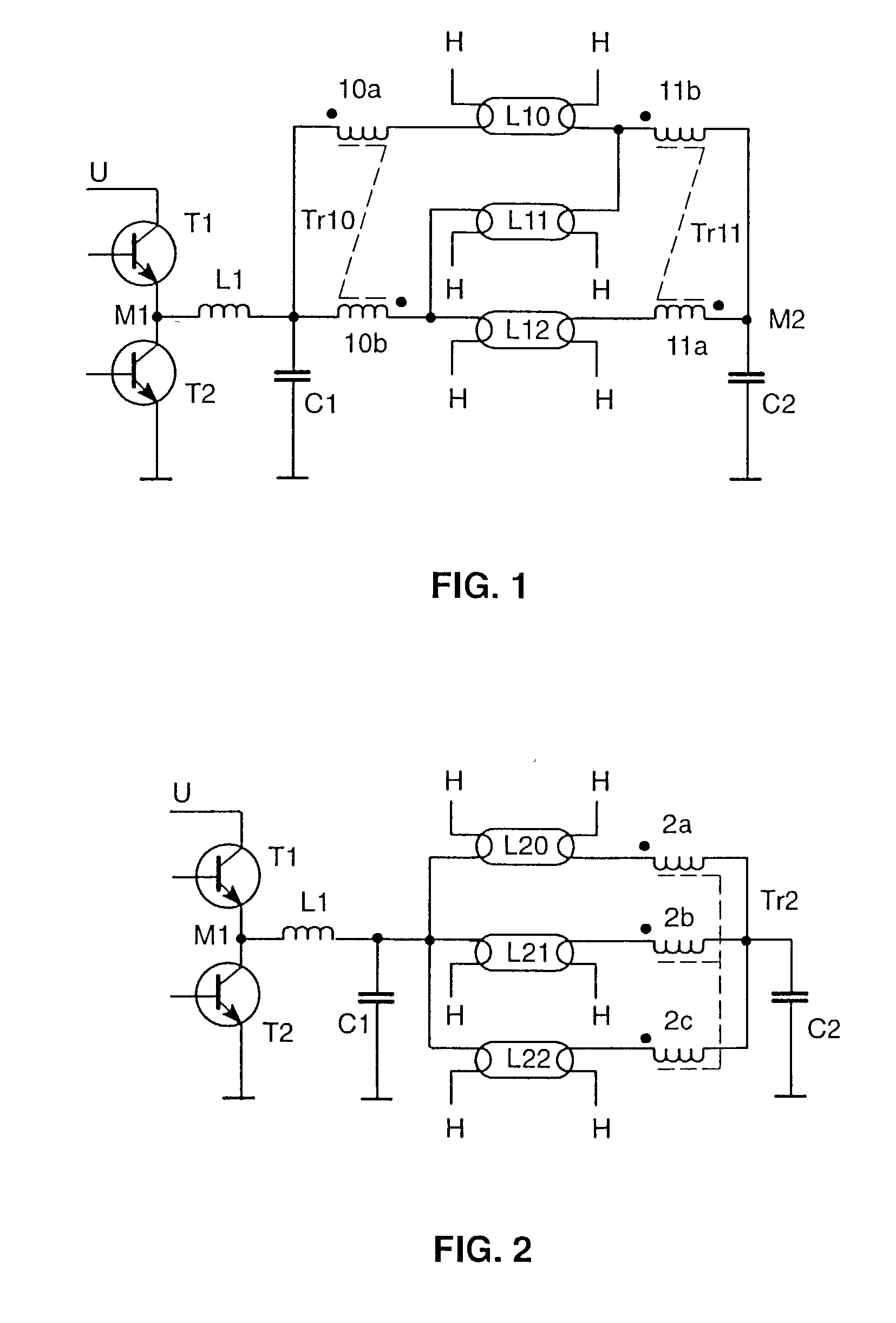

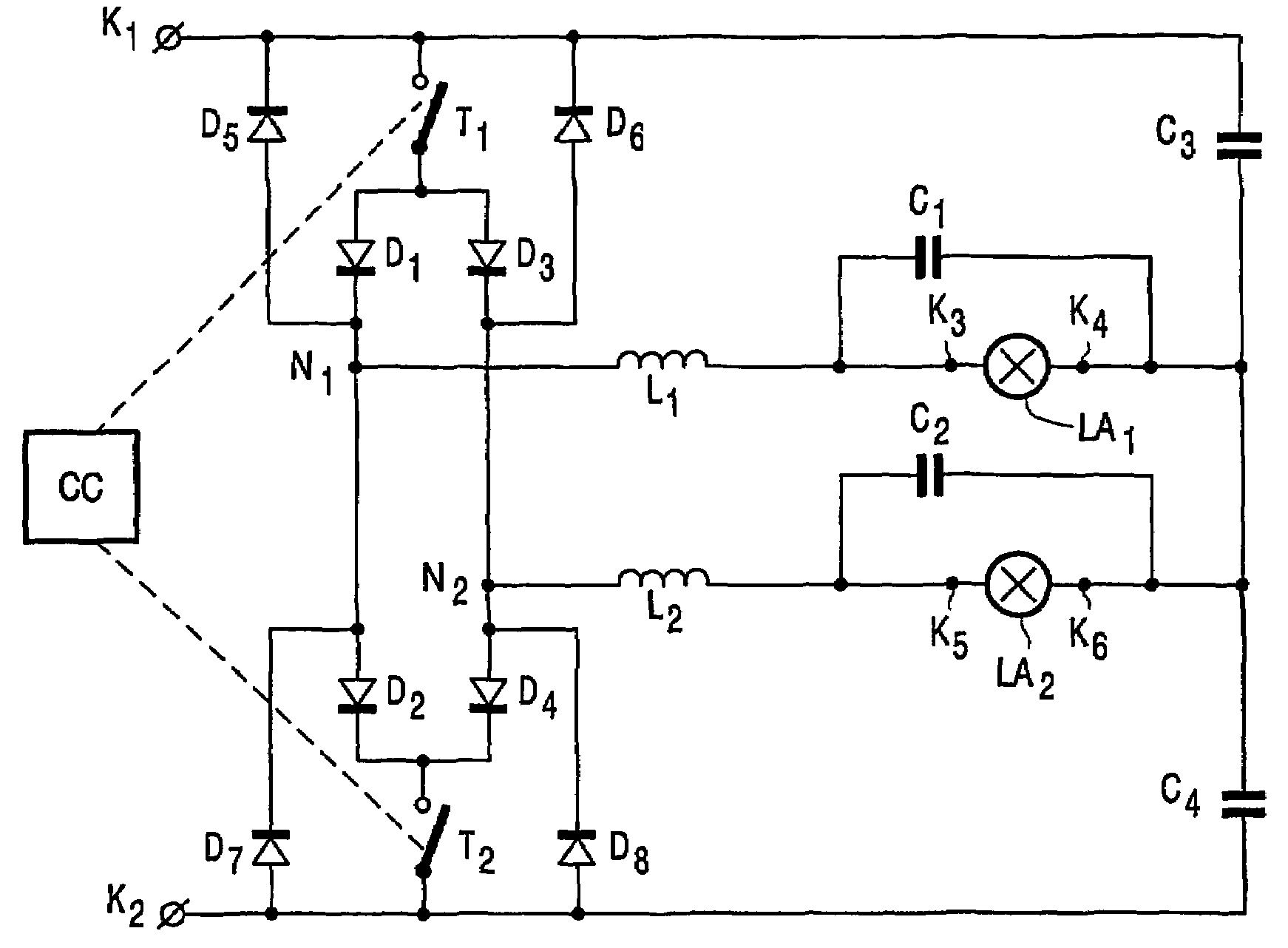

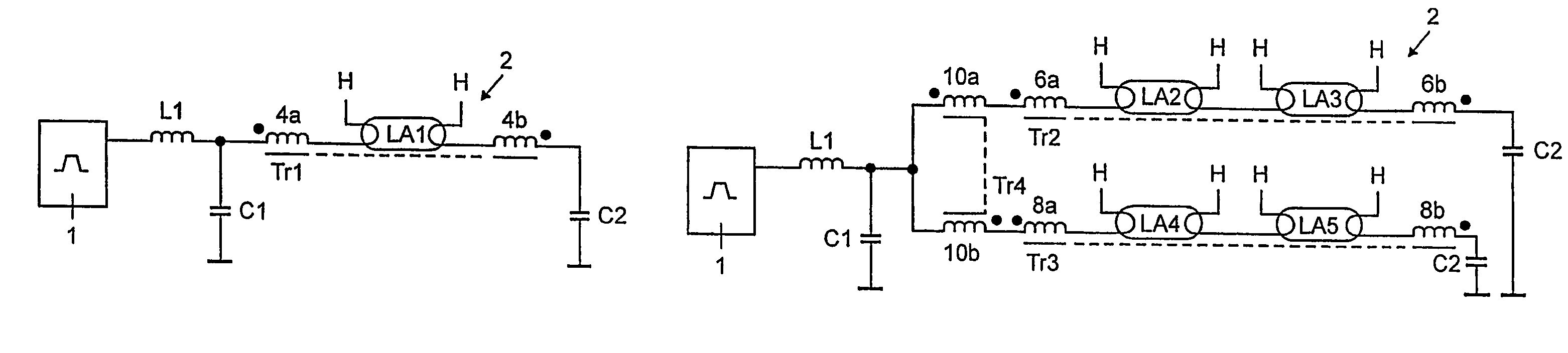

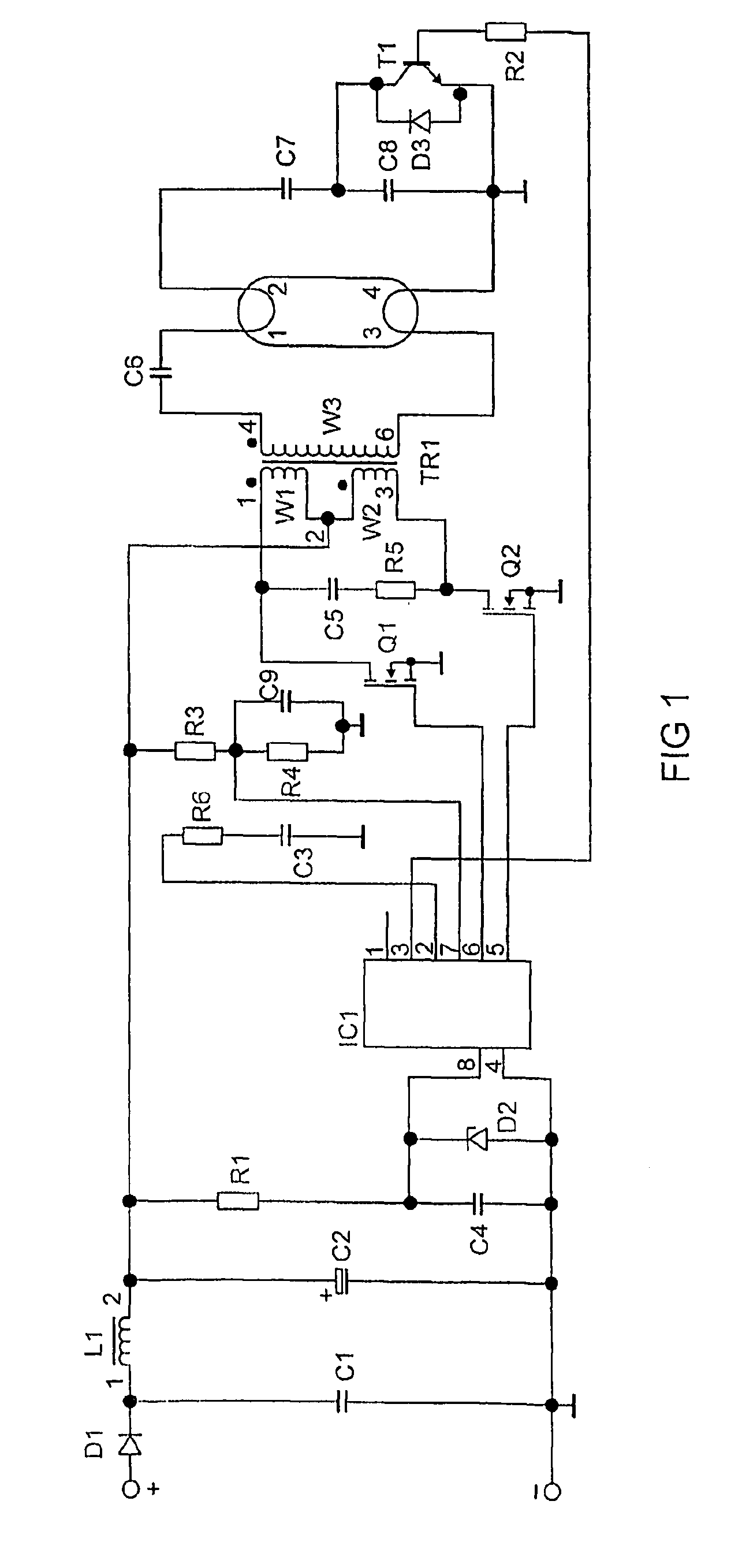

Ballast for operating at least one low-pressure discharge lamp

InactiveUS20030015974A1Lowers the potential of the lamp terminalEnsure balanceElectrical apparatusElectric light circuit arrangementTransformerParasitic capacitance

The invention relates to a ballast for operating at least one low-pressure discharge lamp, preferably a three- or four-lamp ballast. In order for all parallel- or series-connected low-pressure discharge lamps (L40-L43) to shine equally bright even in the case of strong dimming, the ballast according to the invention has a transformer (Tr40) for balancing the currents in the lamp branch circuits and a transformer (Tr41) for compensating the losses owing to parasitic capacitances.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

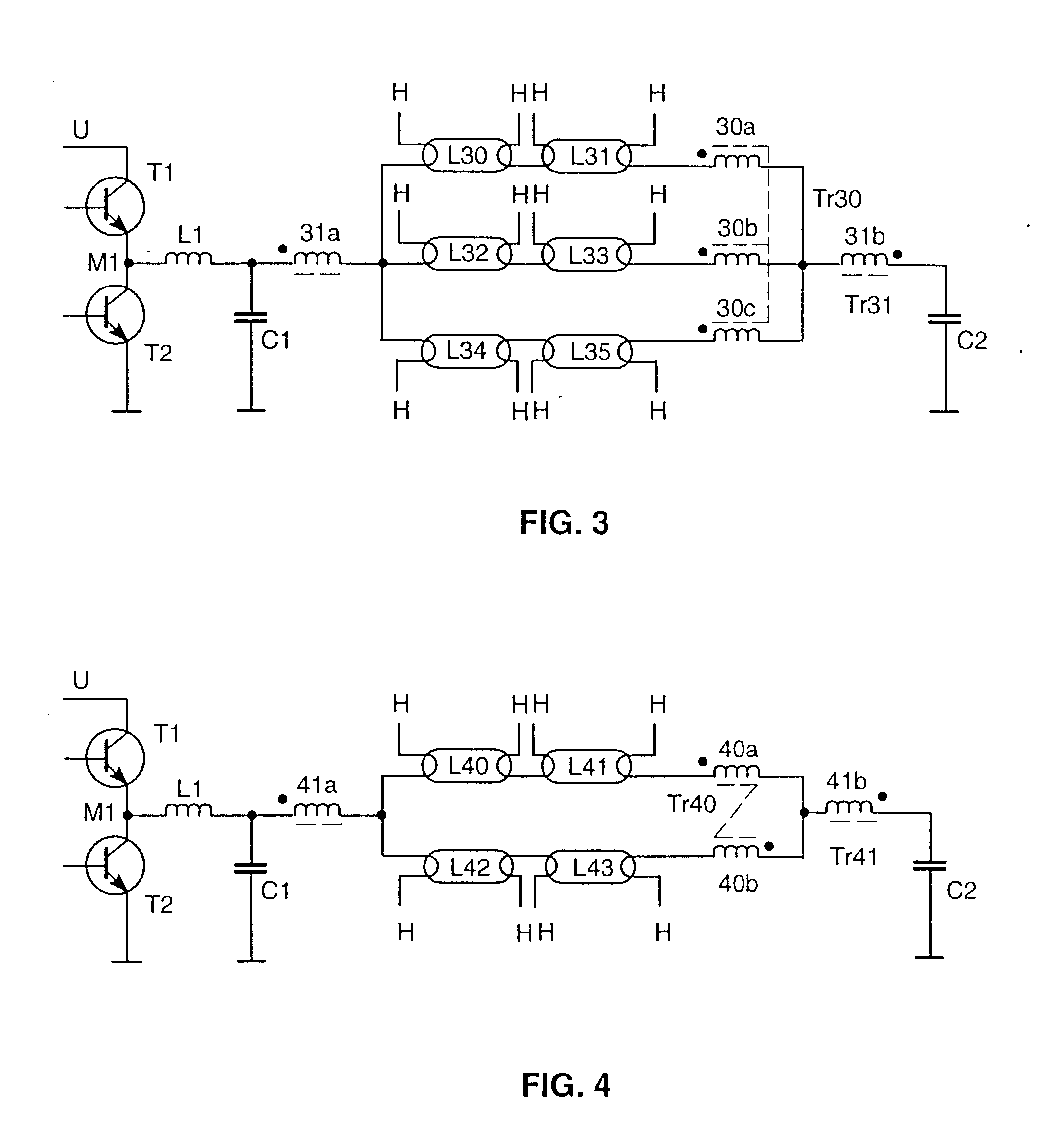

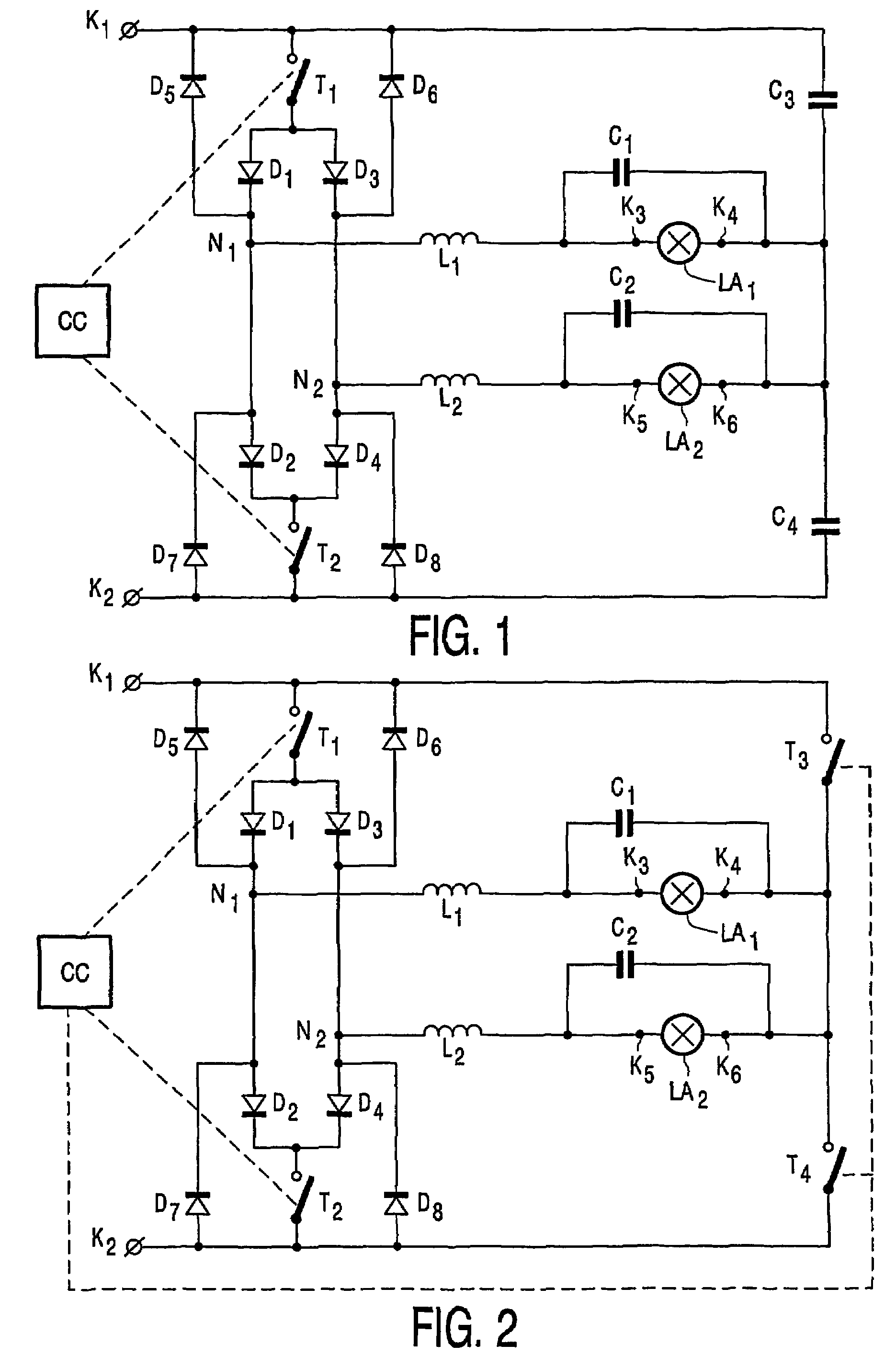

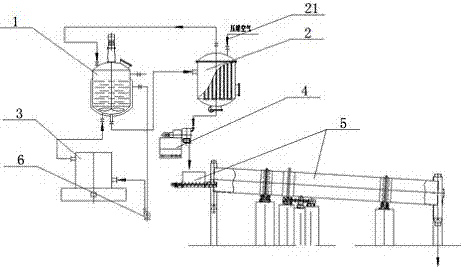

Circuit arrangement for operating discharge lamps

InactiveUS7164237B2Small differenceDifference in power consumptionElectric light circuit arrangementGas discharge lamp usageFull bridgeOperation mode

A DC-AC converter in a half bridge configuration is used for operation with high pressure discharge lamps as well as low pressure discharge lamps. The converter consists in two switches (T1-T2) serially connected through a first series of diodes (D1, D2) and a second series of diodes (D3,D4) to which at their middle points (N1, N2) a first and a second lamp loads (L1,L2,LA1,LA2) are connected. Furthermore, the second terminals of the lamp loads are connected to the middle point of a series of capacitors (C3,C4) which are also connected to the terminals (Ki,K2) of the supply voltage source. The converter includes also four diodes (D5,D6,D7,D8) which shunt the switches (T1,T2) and their respective series of diodes (D1,D2,D3,D4). The switches (T1,T2) are controlled by a controller (CC) which renders alternatively conductive at low frequency the two switches (Ti,T2). In the first operating state, the first switch (T1) is rendered conductive and non-conductive at a high-frequency while the second switch (T2) is maintained in a non-conductive state, in the second operating state the second switch (T2) is rendered conductive and non-conductive at high-frequency while the first switch (T1) is maintained in a non-conductive state. The series of two capacitors (C3,C4) can be replaced by a series of two switches (T3,T4) in order to obtain a full bridge configuration of the converter. The particular configuration of the network and its operating mode allow to drive the lamp loads in such a way that the difference in power consumed by the lamps is comparatively small.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

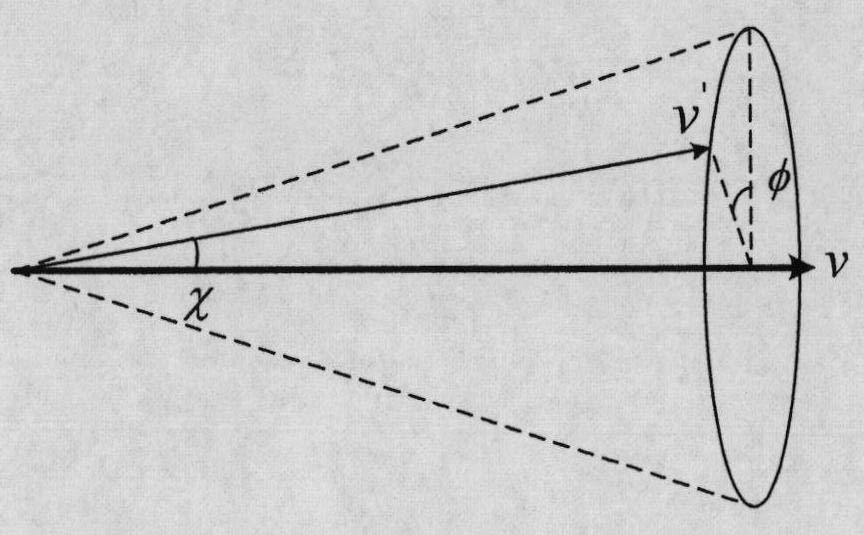

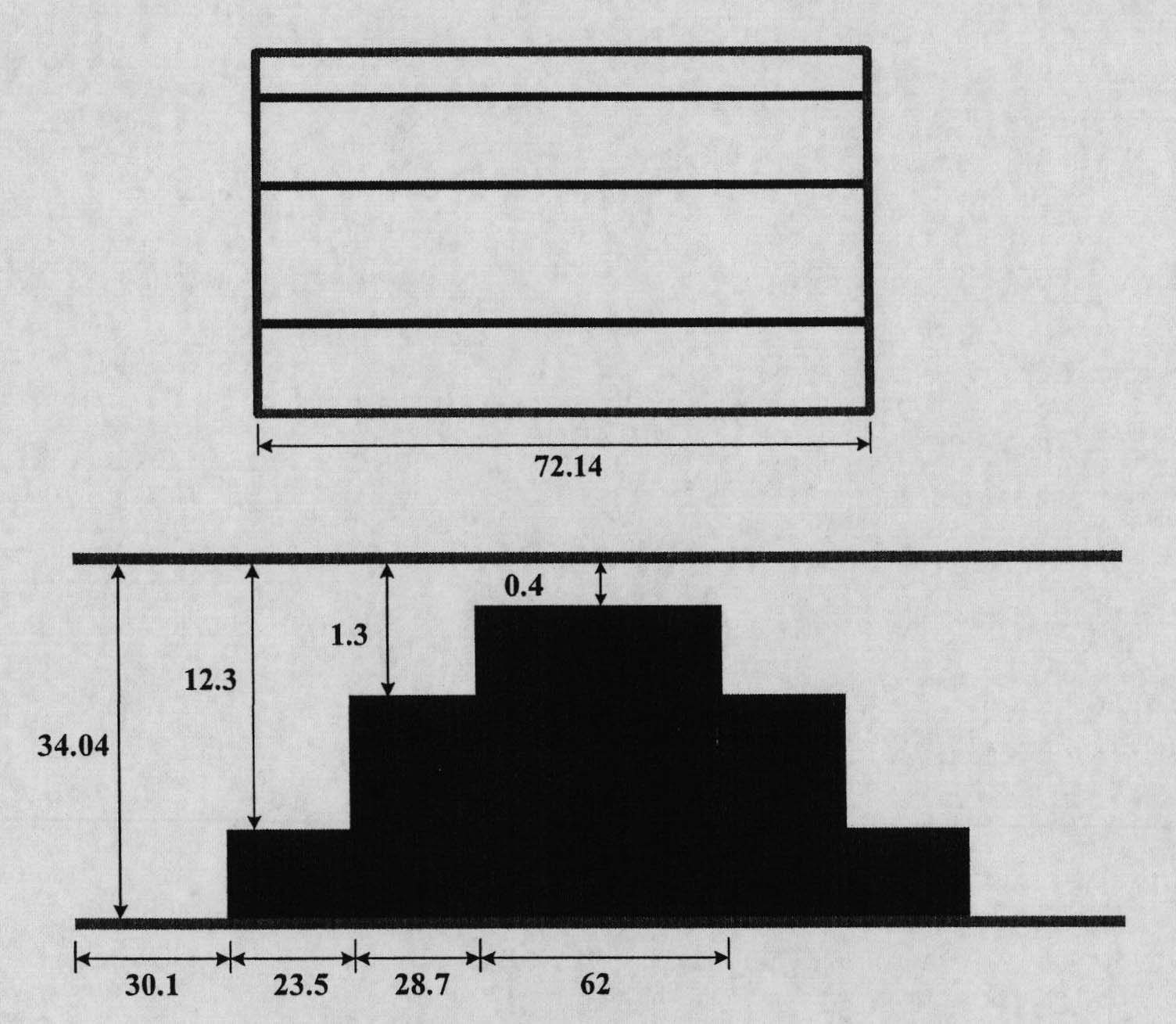

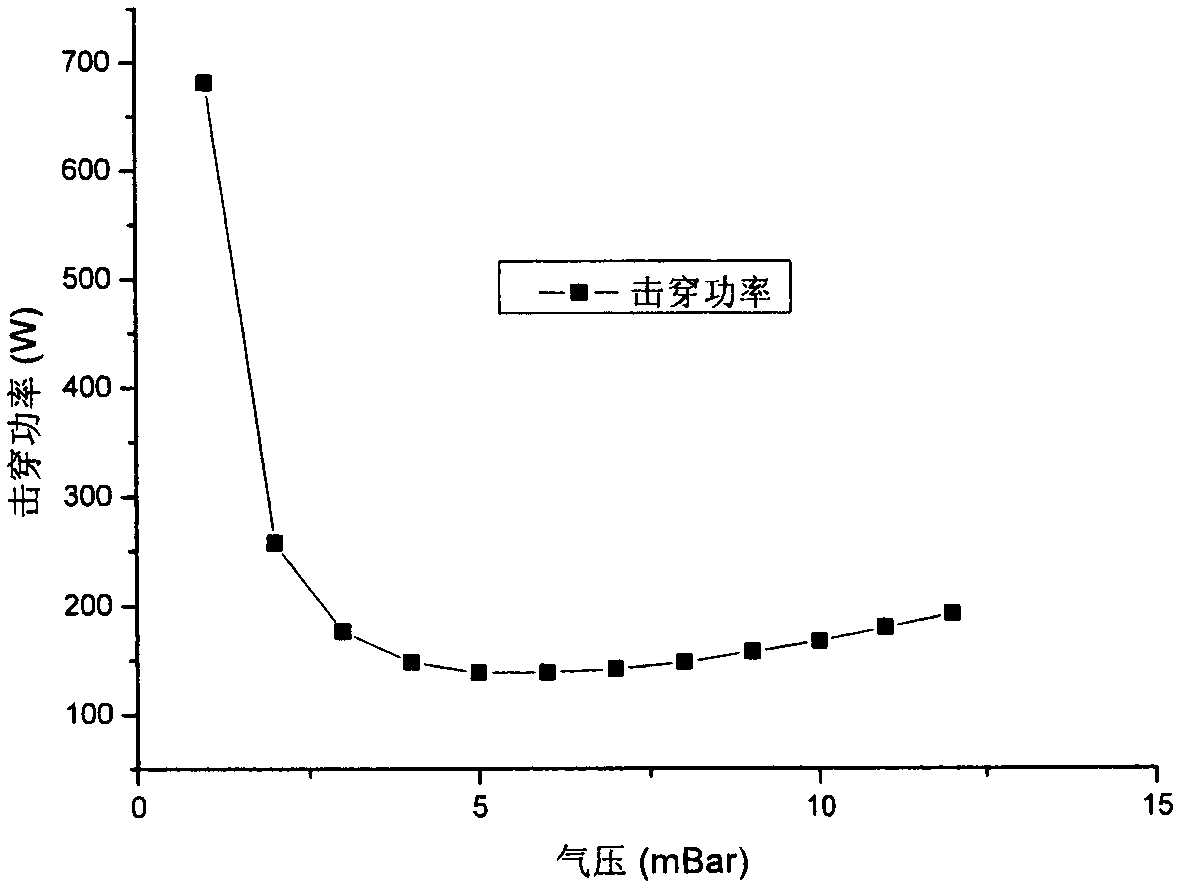

Space microwave component low pressure discharge value simulation method

ActiveCN102567780AShorten the design cycleReduce development costsBiological modelsThermodynamicsMicrowave

The invention relates to a space microwave component low discharge value simulation method, which includes steps as follows: establishing a low pressure discharge numerical model of a space microwave component, performing accurate numerical analysis aiming at the motion process of discharged particles during low pressure discharge as well as the total discharged particle number, and obtaining the low pressure discharge threshold value of the space microwave component. According to the invention, the second electron multiplication effect on a metal surface of a space microwave component is taken into consideration, and the discharge threshold value of an intersected stage under a low pressure environment and between the discharge under a vacuum environment and the discharge under a high pressure environment can be analyzed. Meanwhile, all collision types dominating an air space in the microwave component are taken into consideration and the accuracy of the low pressure discharge numerical simulation method in the space microwave component is ensured. Through the method, repeated tests for obtaining the low pressure discharge threshold value of the space microwave component are avoided, the design period is shortened, the preparation cost is reduced, and the method is extremely suitable for analyzing the numerical part of the low pressure discharge in the space microwave component.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

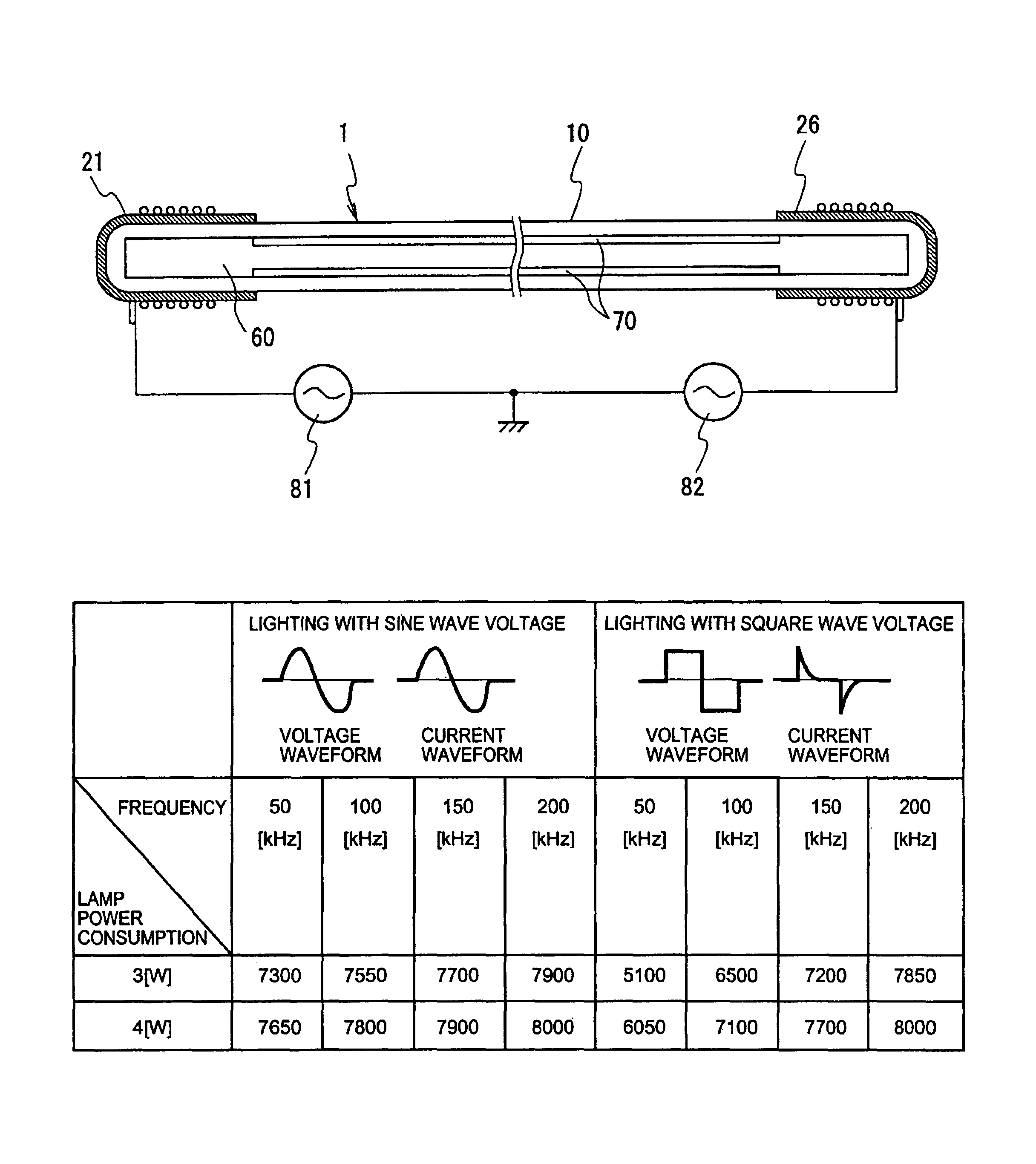

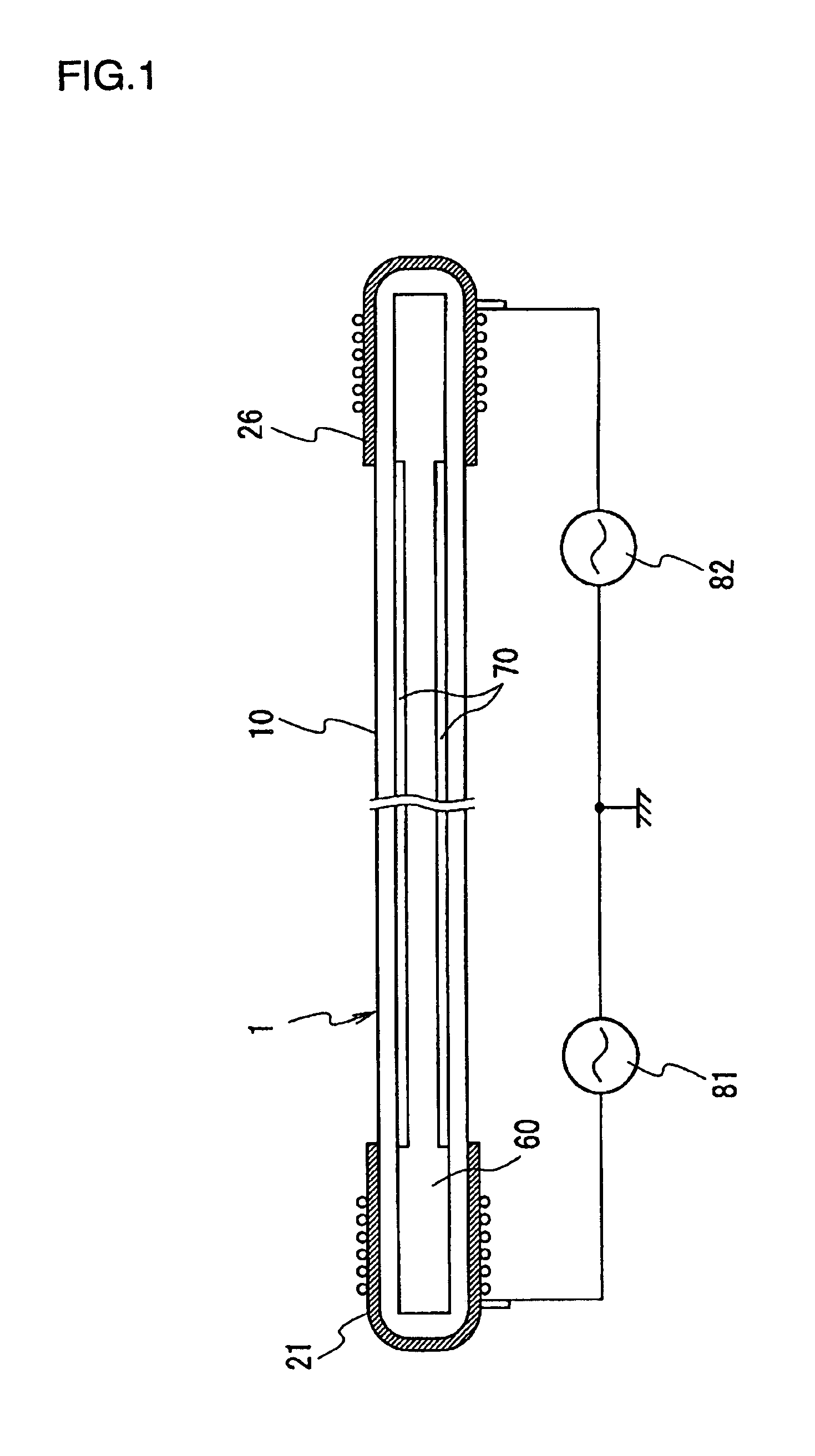

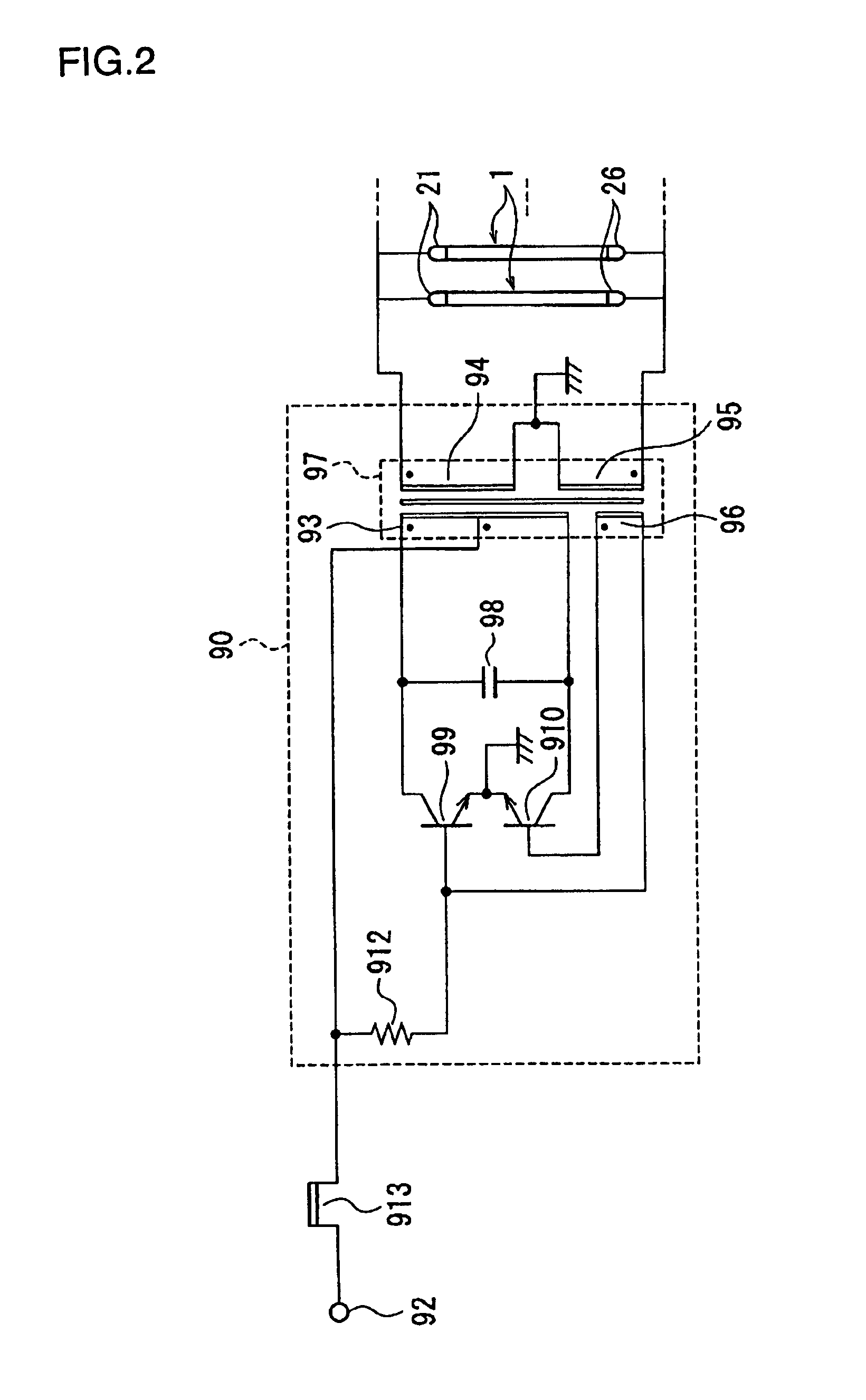

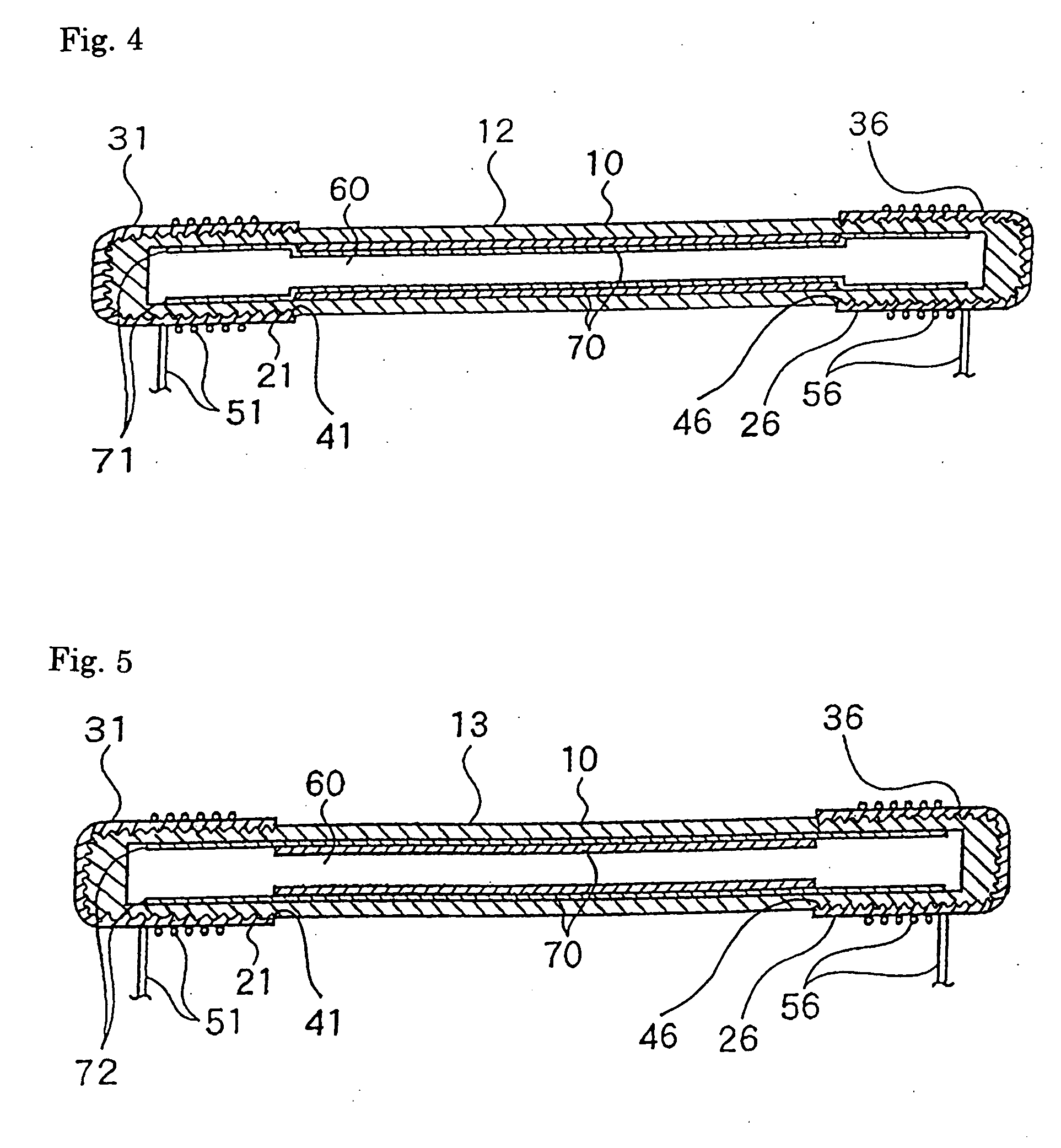

Illuminating device

InactiveUS6914391B2Easy to assembleReduce frequencyElectrical apparatusElectric light circuit arrangementHigh frequency powerNoble gas

An illuminating device according to an embodiment of the present invention includes a dielectric barrier discharge type low pressure discharge lamp 1 composed of a tubular glass lamp vessel 10, in which mercury and rare gas are enclosed, a first and a second electrode 21,26, which are made of electrically conductive layer, are provided on an outer surface of both ends of the tubular glass lamp vessel 10 and a high frequency power source of a floating output type 81,82, which supplies a sine wave voltage between the first and the second electrodes of the dielectric barrier discharge type low pressure discharge lamp 1 having a neutral point of the sine wave voltage being grounded, and which supplies a frequency in a range from 40 kHz to 100 kHz.

Owner:HARISON TOSHIBA LIGHTING CORP

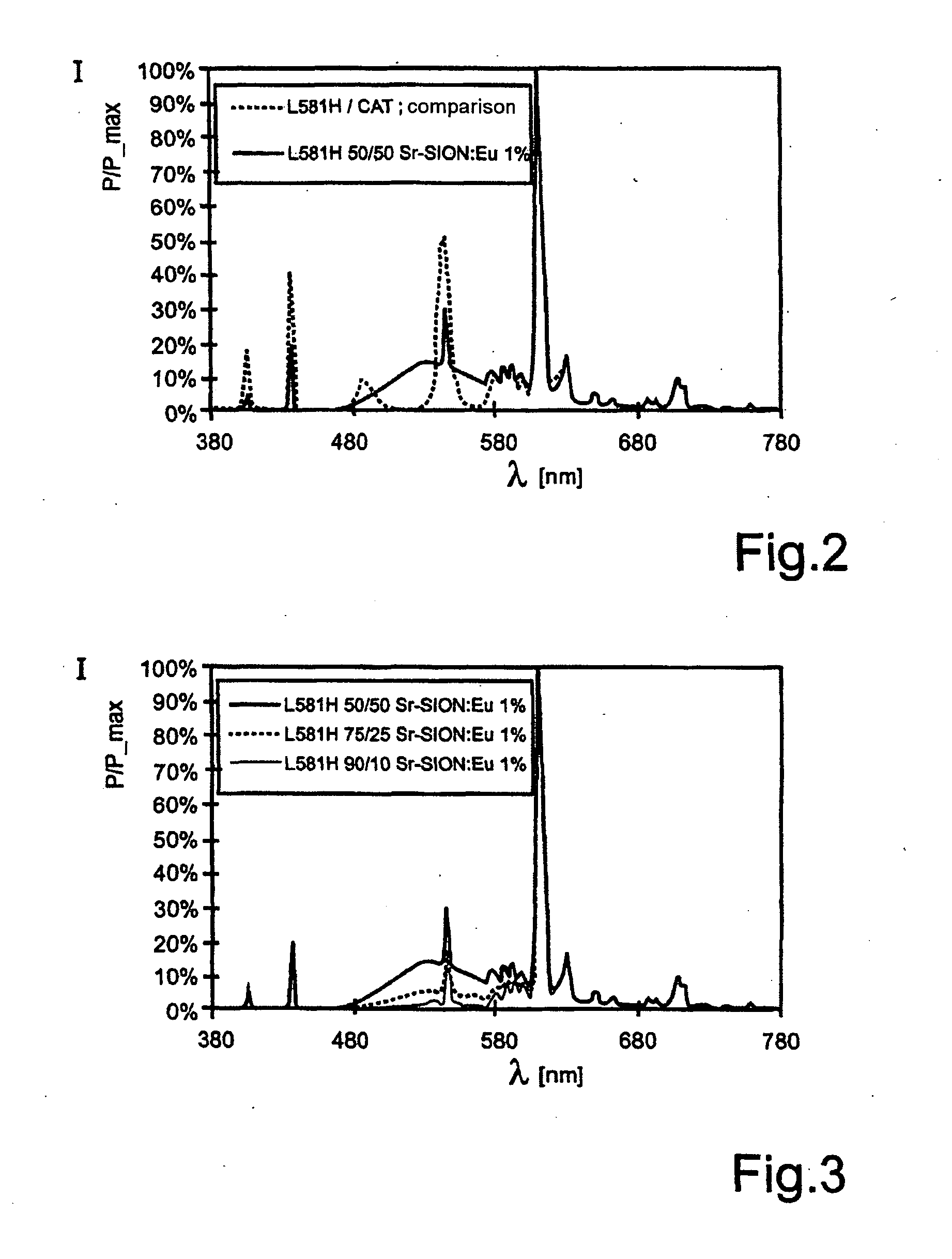

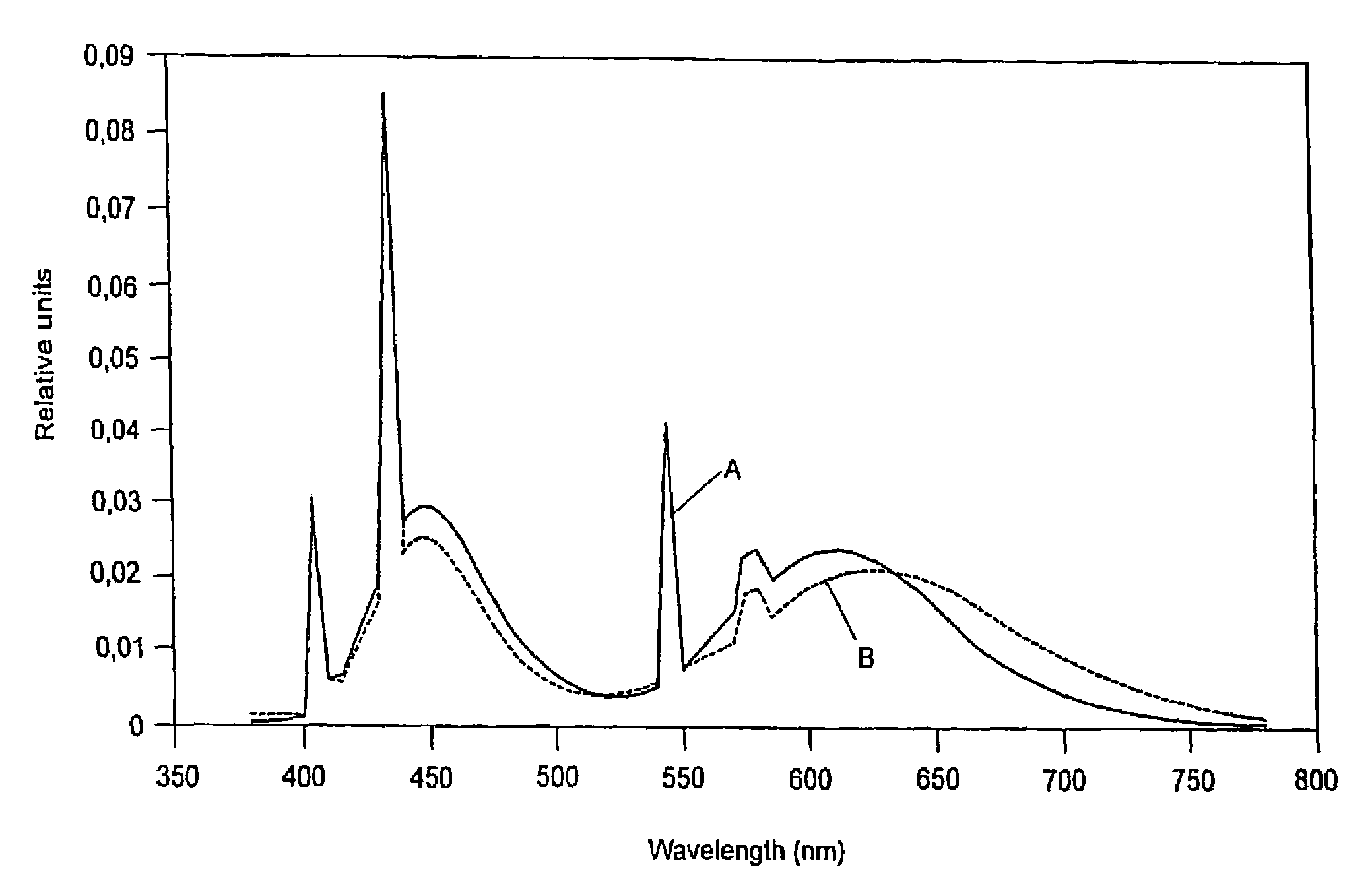

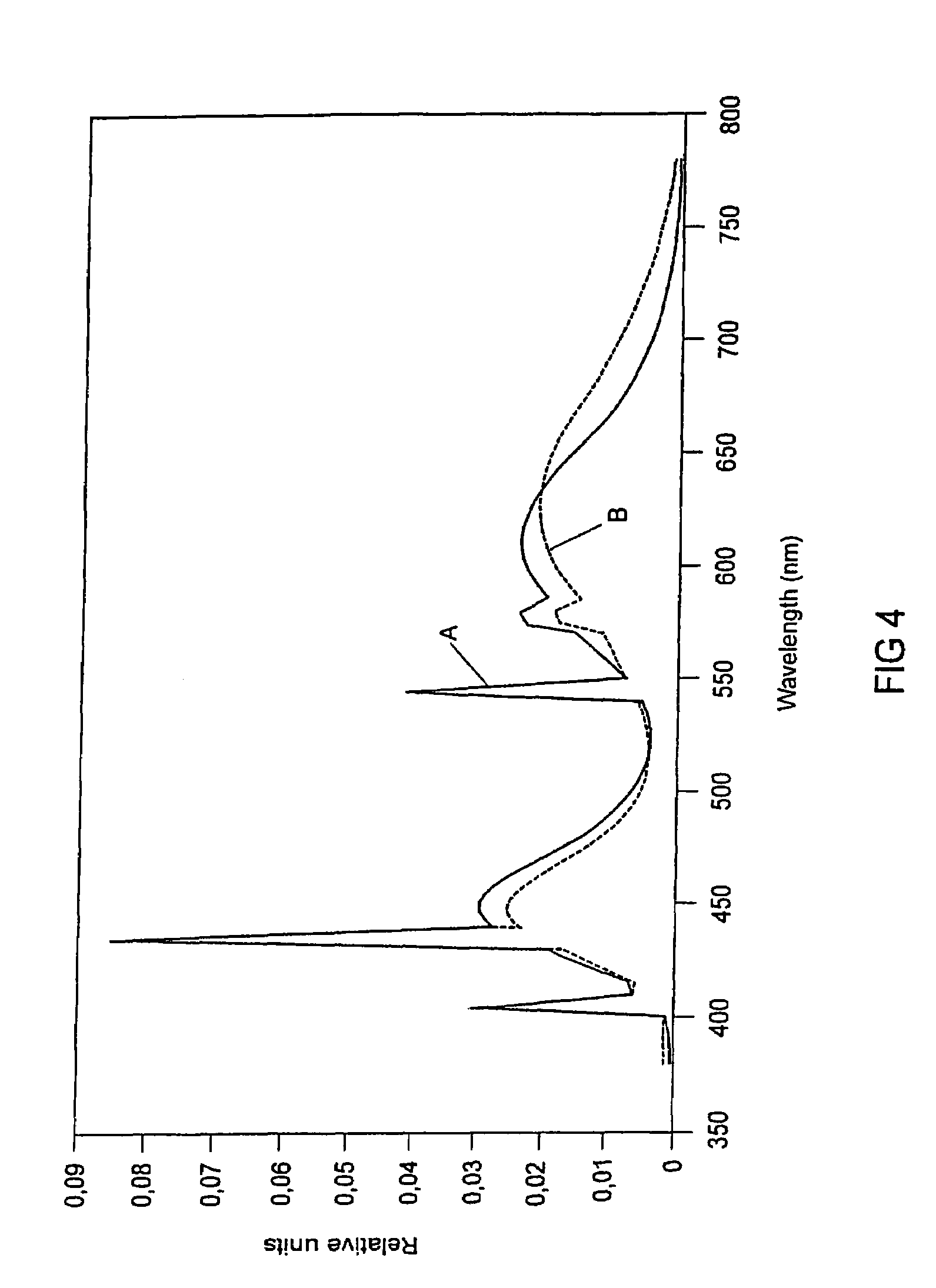

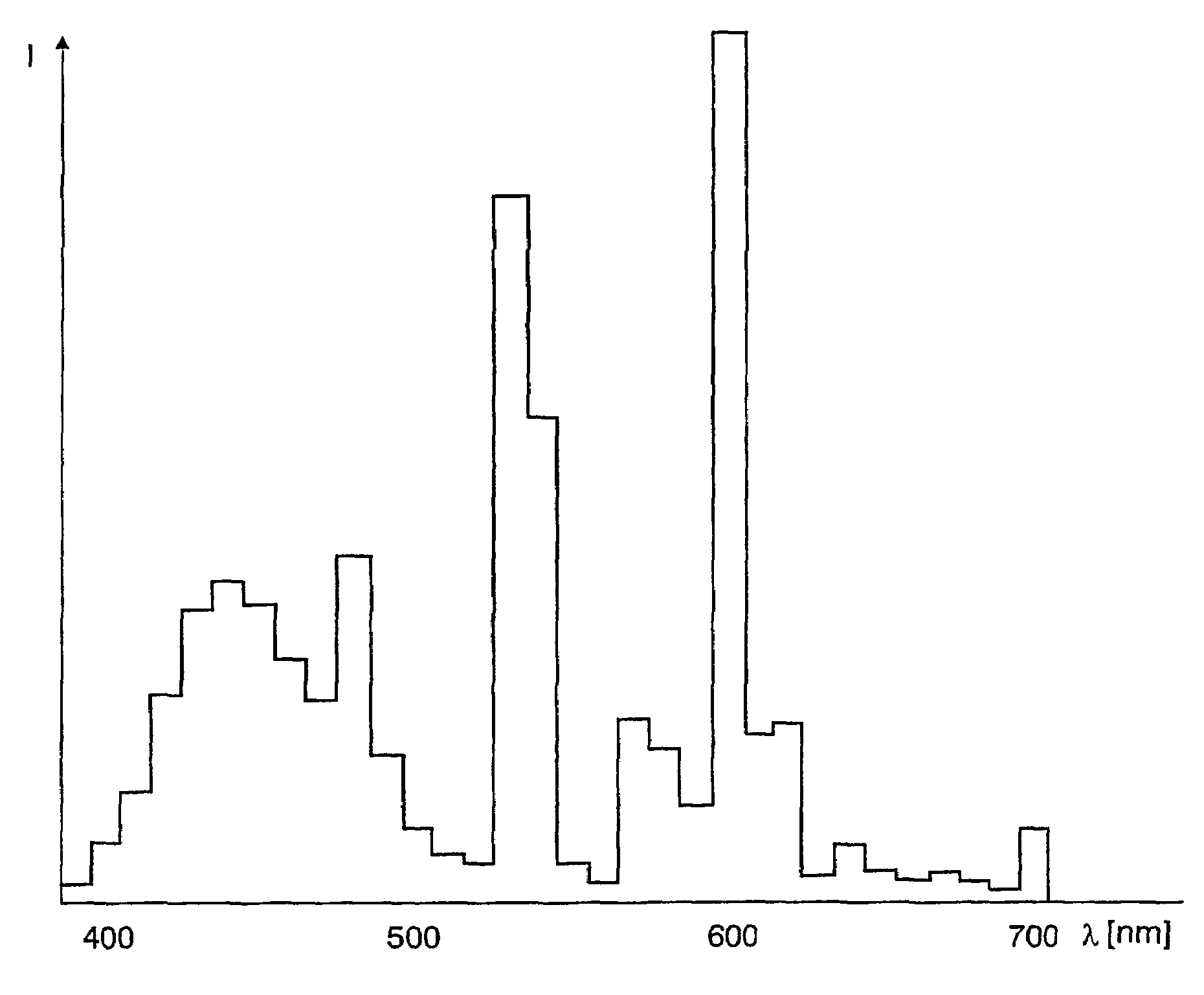

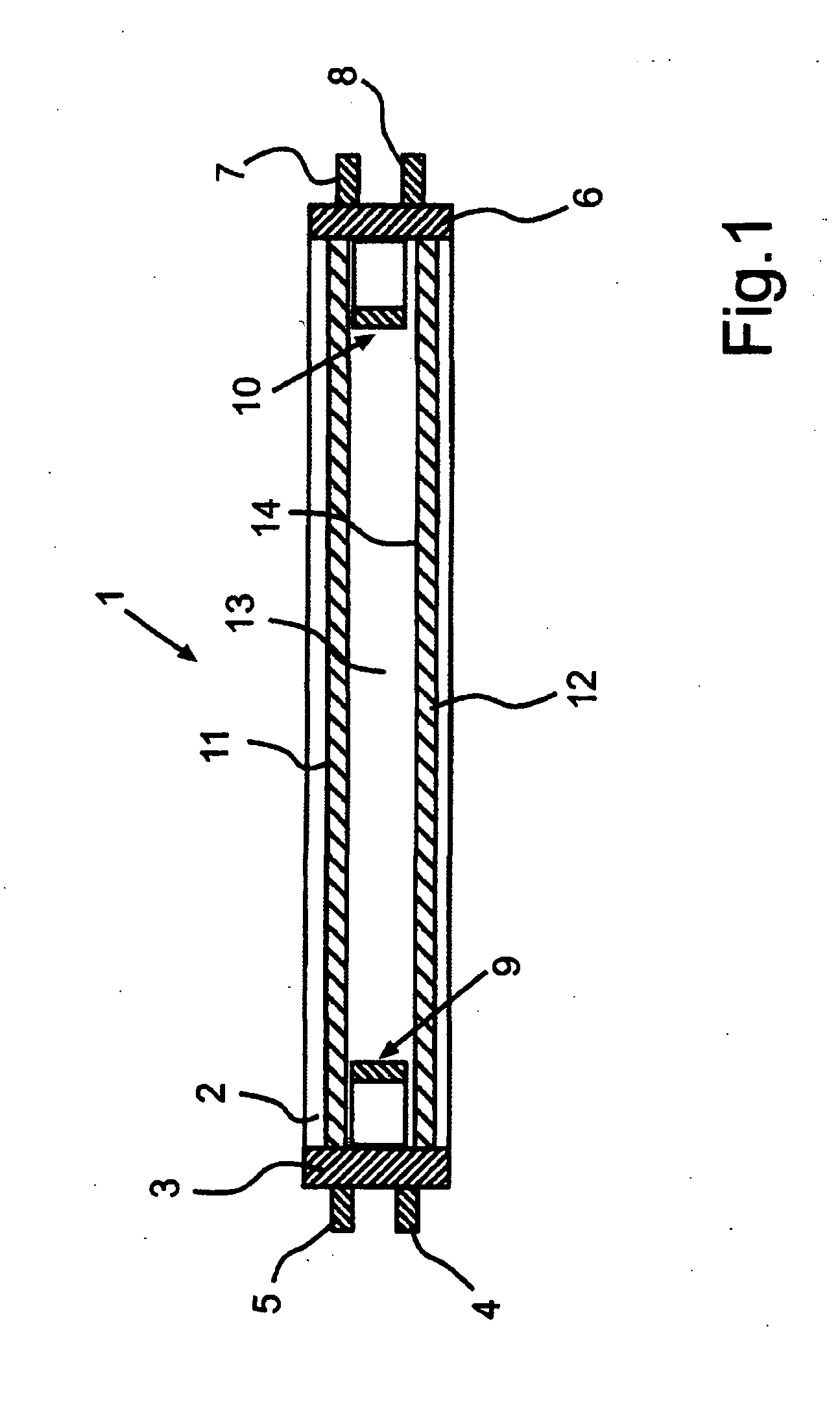

ILLUMINANT MIXTURE FOR A DISCHARGE LAMP AND DISCHARGE LAMP, IN PARTICULAR AN Hg LOW-PRESSURE DISCHARGE LAMP

InactiveUS20100102704A1Energy efficiencyGood colorDischarge tube luminescnet screensLamp detailsUltravioletPhotochemistry

The invention relates to an illuminant mixture for a discharge lamp (1) with a first and at least one second illuminant composition, said first illuminant composition having an emission spectrum in the green to yellow spectral range and having a first illuminant compound, devoid of Tb and designed to absorb the UV radiation emitted by an Hg source. The invention also relates to a discharge lamp (1) with a discharge vessel (2) and an illuminant layer (12) applied thereto, said layer containing the illuminant mixture according to the invention.

Owner:LEDVANCE GMBH

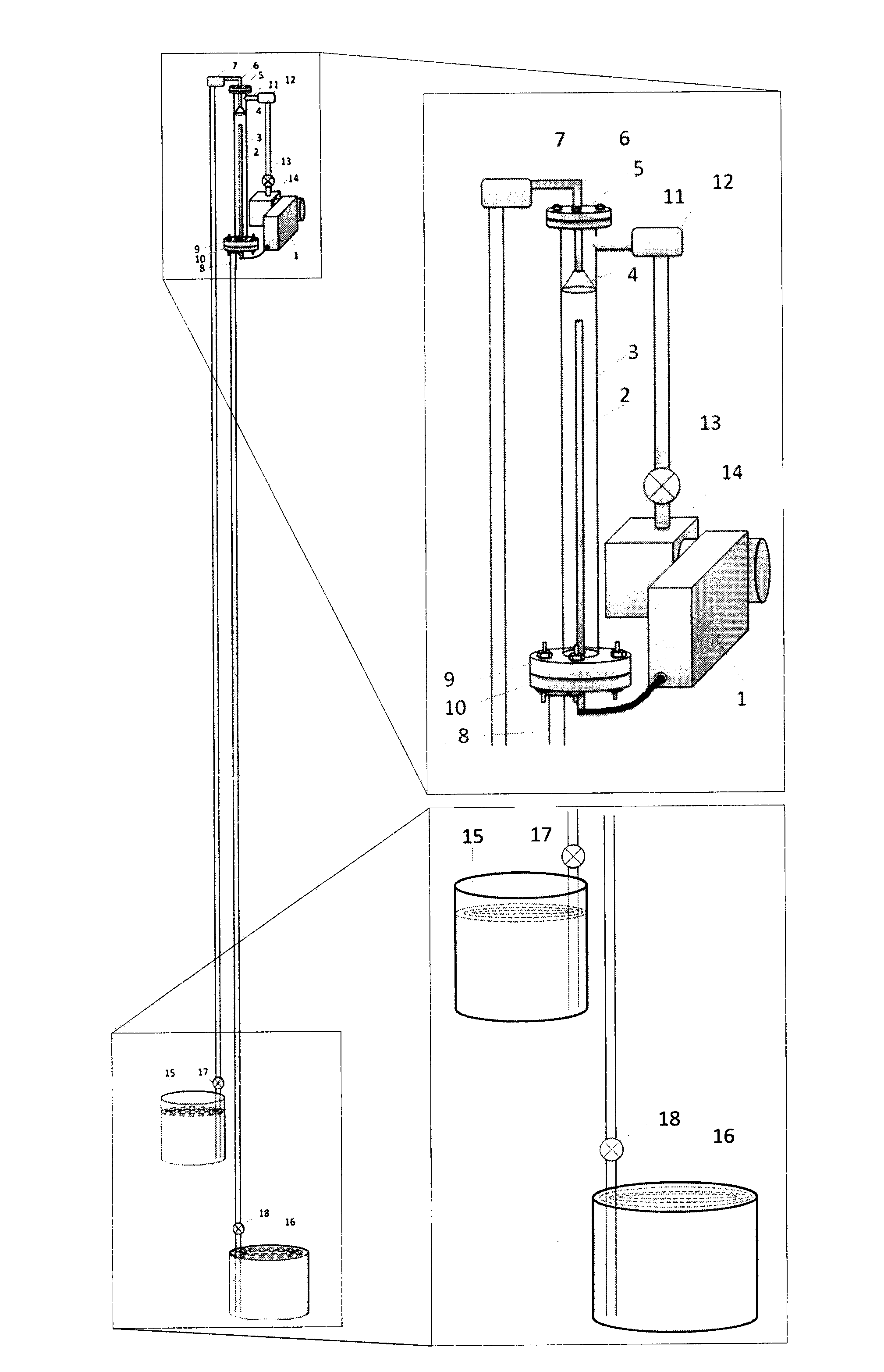

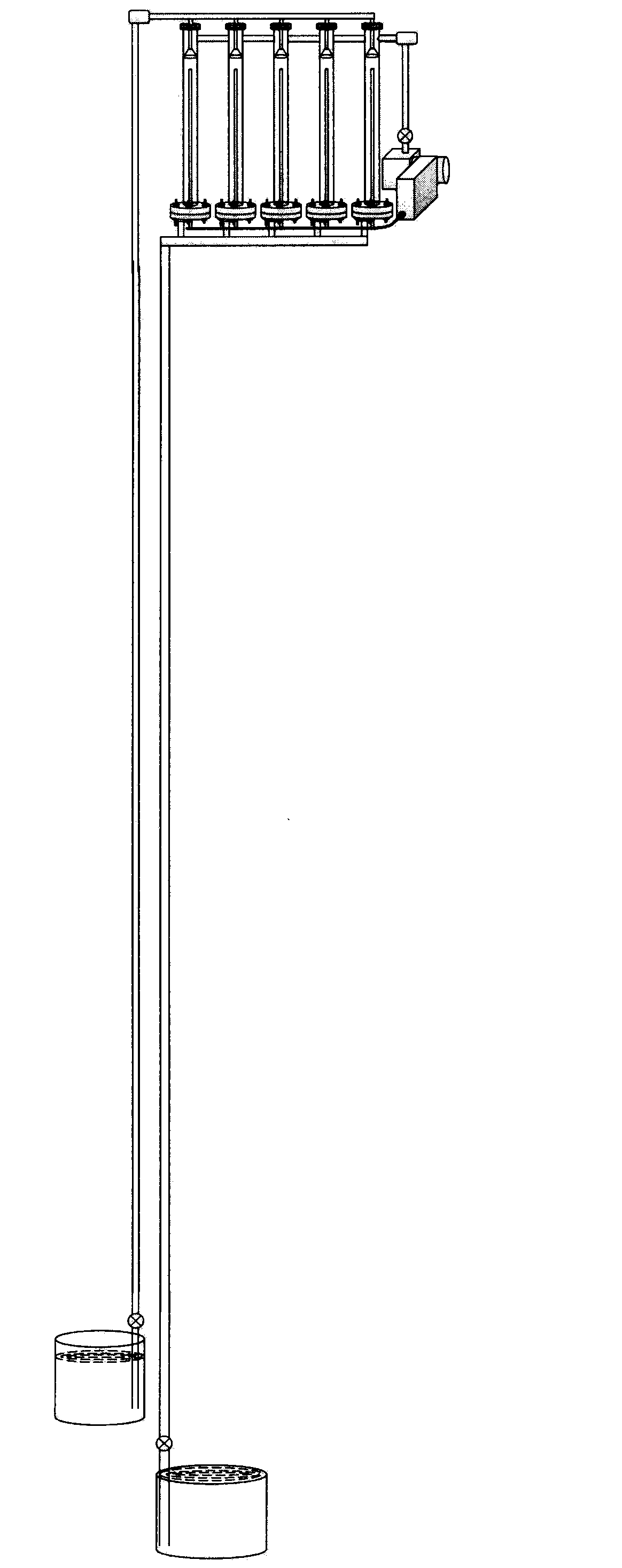

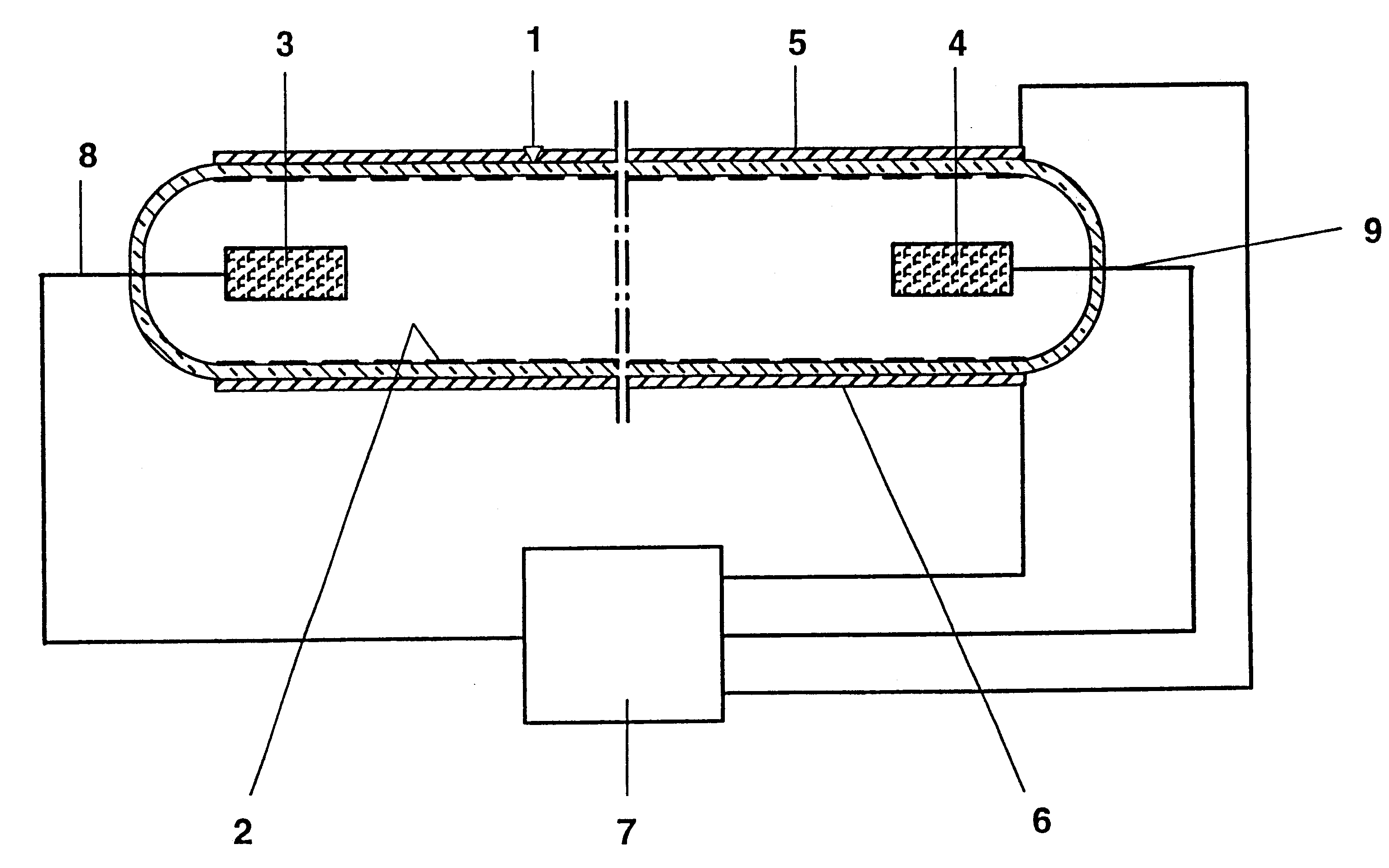

Low-pressure discharge plasma water treating apparatus and method

ActiveCN104058480AReduce volumeHigh activityWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsHigh activityExhaust pipe

The invention relates to a low-pressure discharge plasma water treating apparatus, mainly comprising a discharge power supply, a high voltage electrode, a reactor, an atomization sprinkler, a water inlet pipe, a water outlet pipe, a water flow monitor, an air exhaust pipe, an air valve, a vacuum pump, a sewage pool and a clean water reservoir. According to the invention, without a water pump, a low pressure environment in the reactor can be maintained via only one vacuum pump under the condition that water flows through the reactor; electro-discharge is carried out in the low pressure environment, and large-volume, high-activity and non-thermal equilibrium plasma is generated; the treating apparatus can effectively remove pollution sources like heavy metal ions, organic matters and microbes in water, has high treatment efficiency, is generally applicable to sewages having different pollution degrees and produced by different industries and provides activated water for special industries. The invention further relates to a plasma water treating method which realizes low pressure discharge under the condition that a water cycle between the interior of the reaction chamber and the outside is maintained without usage of a forced exhaust type water pump. With the method, system energy consumption is greatly reduced.

Owner:江苏先竞等离子体技术研究院有限公司

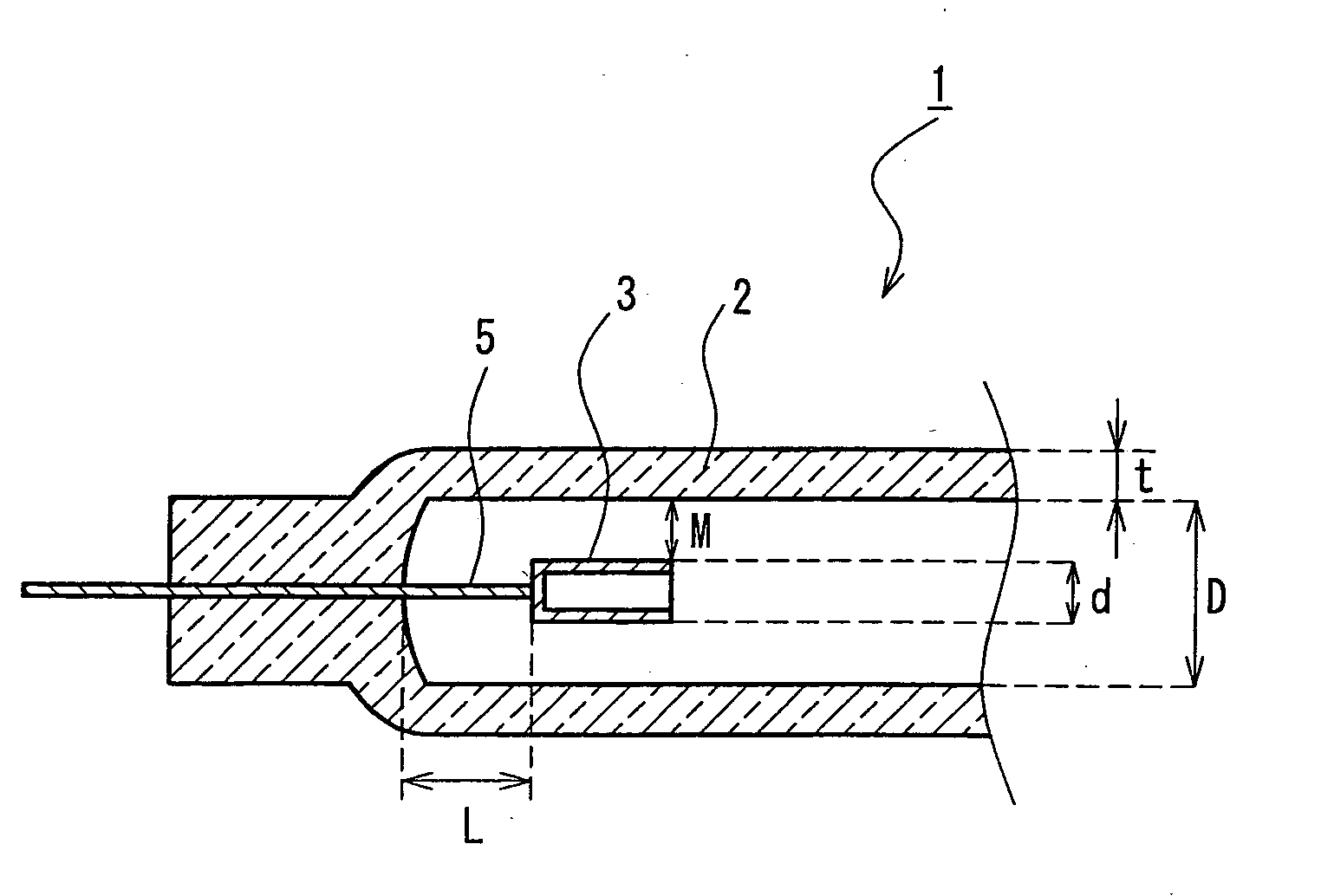

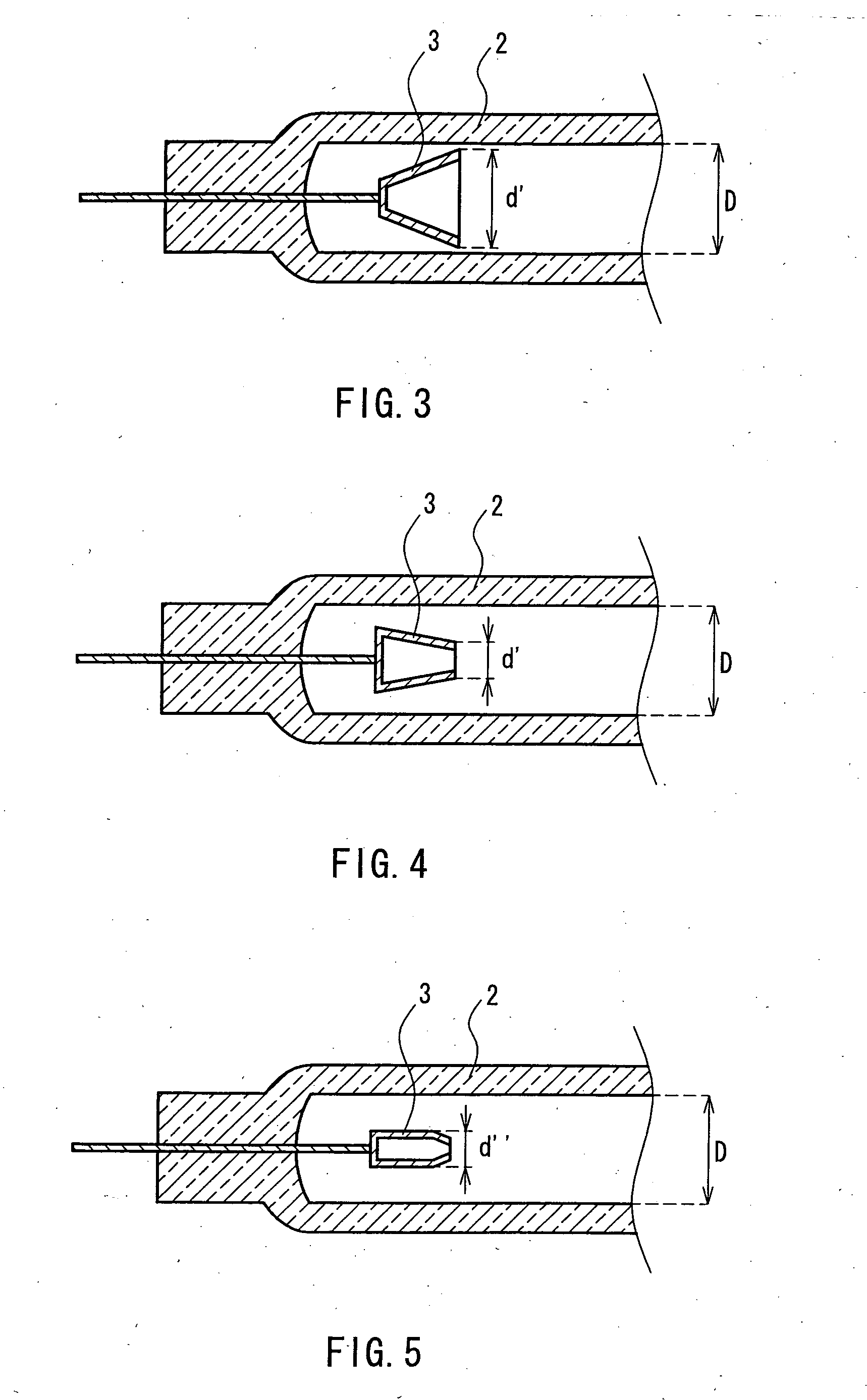

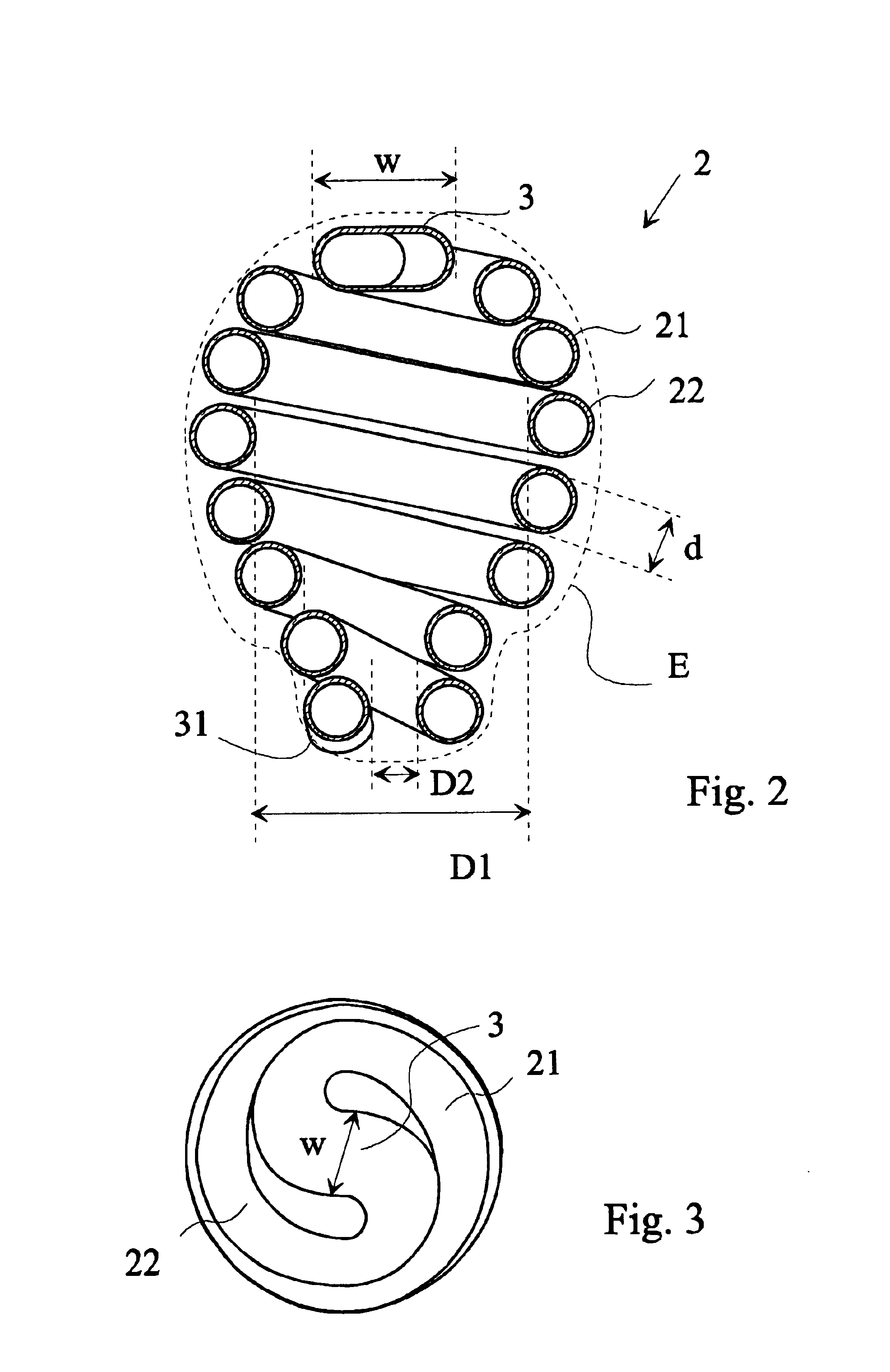

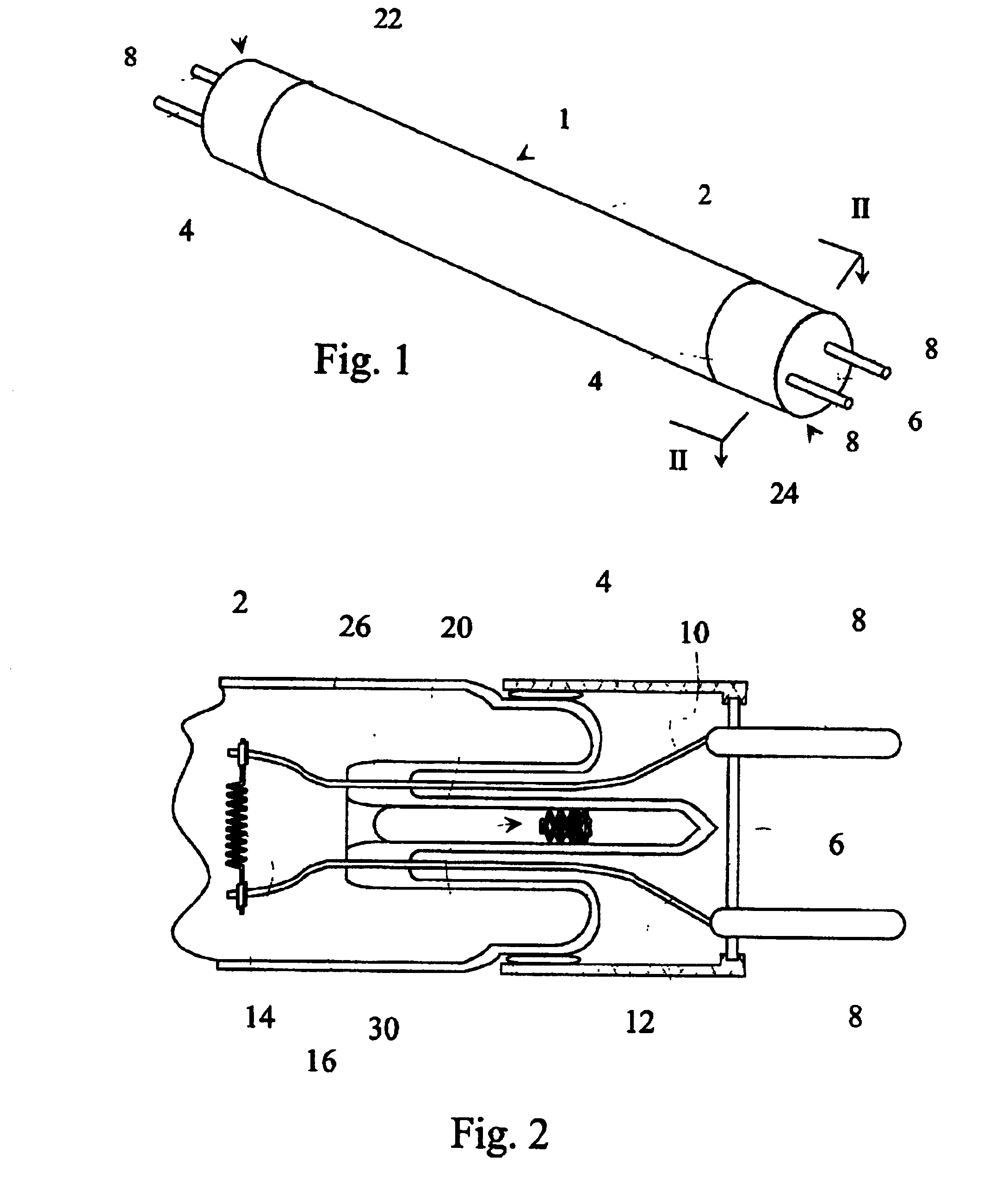

Low-pressure dischage lamp and back light device using same

InactiveUS20050077830A1Discharge tube luminescnet screensElongate light sourcesNoble gasLamp current

A low-pressure discharge lamp (1) is provided that includes a glass tube (2) having an inner diameter in a range of 1 to 5 mm and a pair of electrodes (3) disposed at end portions in the glass tube (2). The pair of electrodes (3) contain at least one transition metal selected from transition metals of Groups IV to VI. Mercury and a rare gas containing argon and neon are sealed in an inner portion of the glass tube (2). A relationship between a cathode glow discharge density J and a composition index α of the sealed rare gas of the low-pressure discharge lamp (1) satisfies the following expression α≦J=I / (S·P2)≦1.5α(where S represents an effective discharge surface area (mm2) of an electrode, I represents a RMS lamp current (mA), P represents a pressure (kPa) of a sealed rare gas, and α represents a composition index of a sealed rare gas that is a constant expressed by α=(90.5A+3.4N)×10−3 when a total of a composition ratio A of argon and a composition ratio N of neon is expressed by A+N=1). Thus, sputtering of a small-sized electrode is suppressed thereby to suppress consumption of a rare gas sealed in a lamp so as to increase a life time, and a decrease of an emitted luminous flux is prevented.

Owner:PANASONIC PHOTO & LIGHTING CO LTD +1

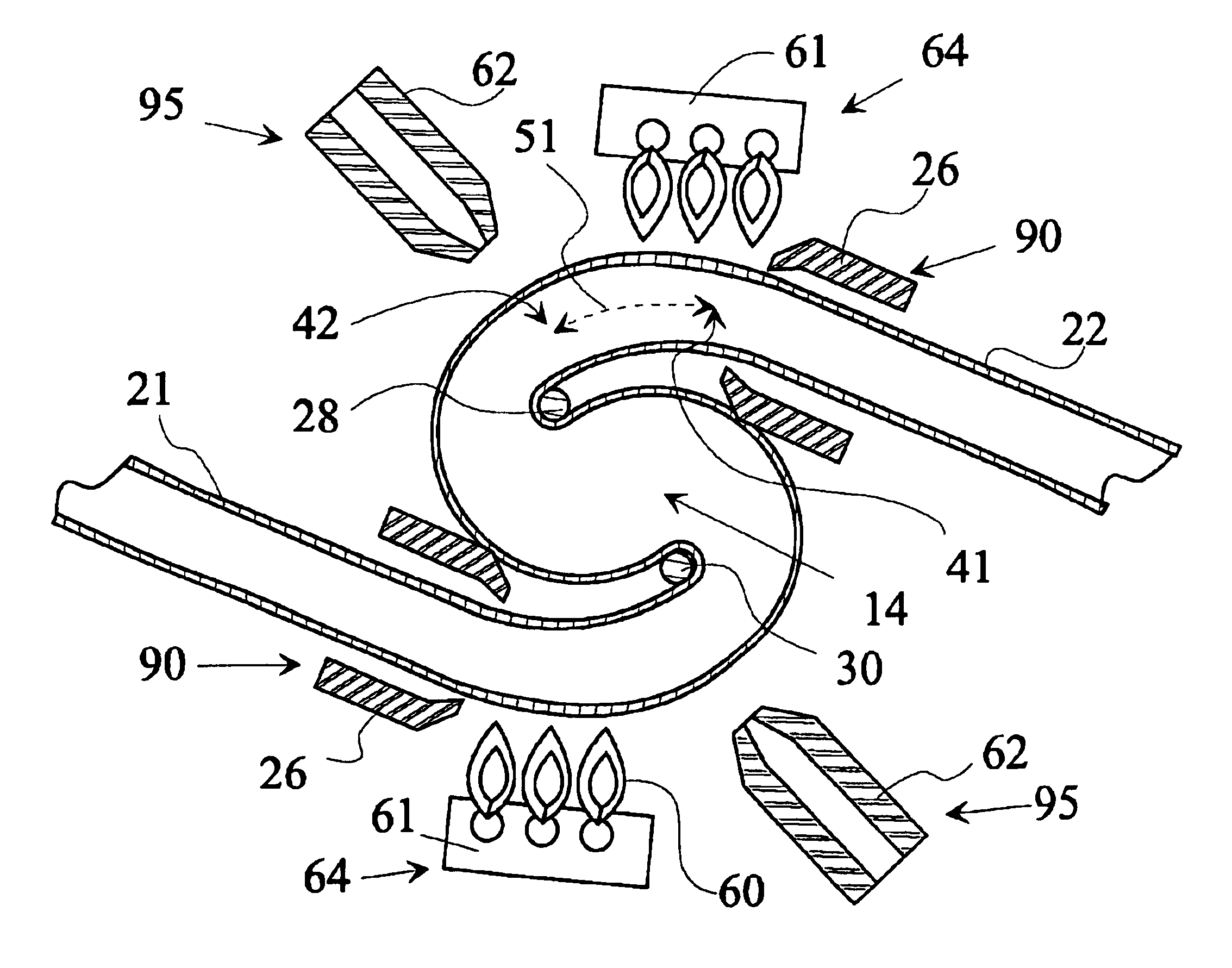

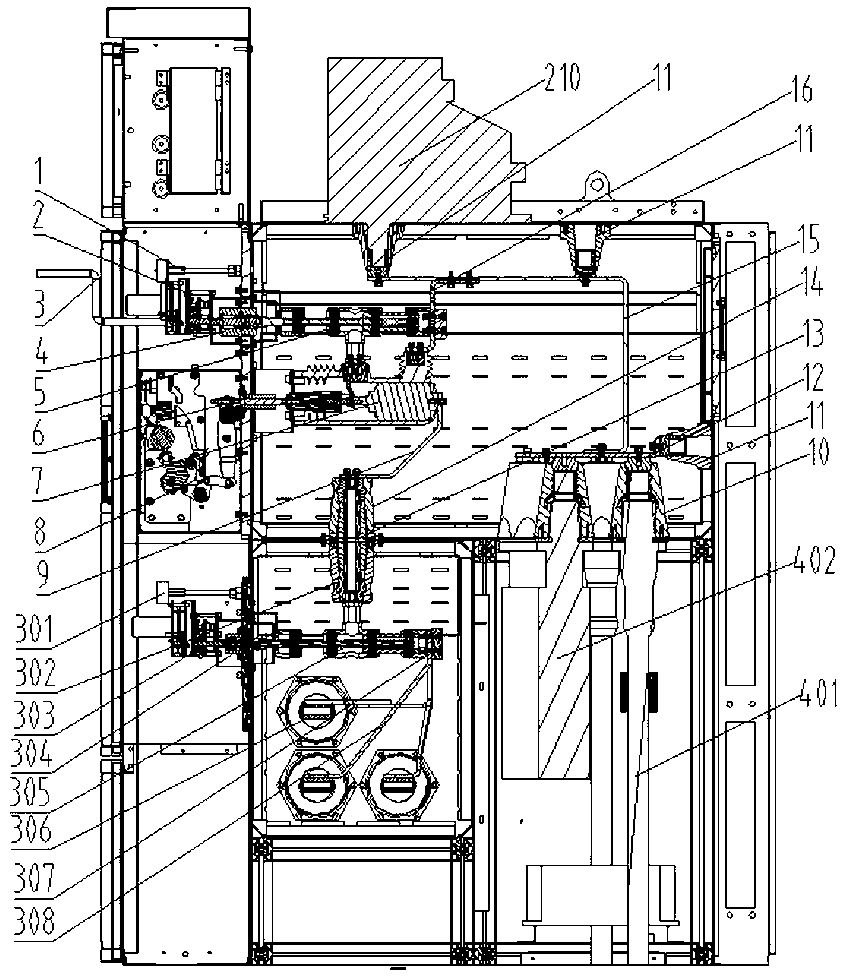

Method of and apparatus for forming discharge tubes of low-pressure discharge lamps

InactiveUS6935137B2Well formedSimple structureVessels or leading-in conductors manufactureGlass reforming apparatusElectric lightEngineering

There is disclosed a method for forming a discharge tube for a low-pressure discharge lamp. In the method, an end of a section of the discharge tube is fastened with first clamping means, and a second end of the section in held in an oriented position. The section is heated to a softening temperature, and a bending moment is exerted on the section between the first end and the second end for achieving the desired radius or direction of curvature of the section. The holding of the second end of the section and the exertion of the bending moment on the section are effected at least partly with another re-solidified section of the discharge tube which is adjacent to the softened first section. An apparatus for performing the method is also disclosed. The apparatus comprises first and second clamping means for positioning the ends of a bending section of the discharge tube in an oriented position relative to each other, and for exerting a bending moment on the ends. The second clamping means is also used for positioning the ends of a starting bending section relative to each other. Heating means are provided for heating the bending section to a softening temperature, and controllable support means for positioning the first and second clamping means. Control means are used for synchronizing the operation of the controllable support means. The first and second clamping means and the heating means are suitable for achieving a desired radius or direction of curvature of the bending sections heated to the softening temperature.

Owner:GENERAL ELECTRIC CO

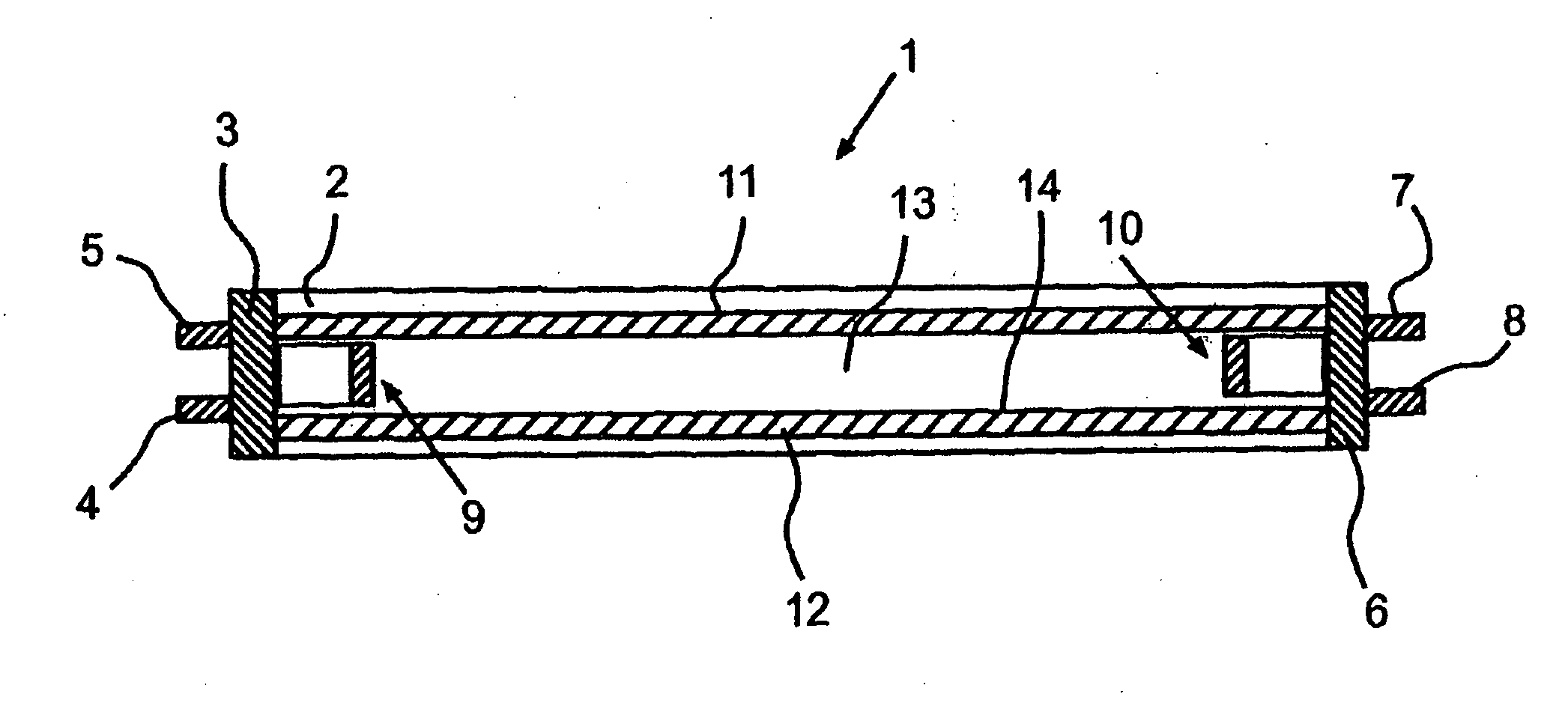

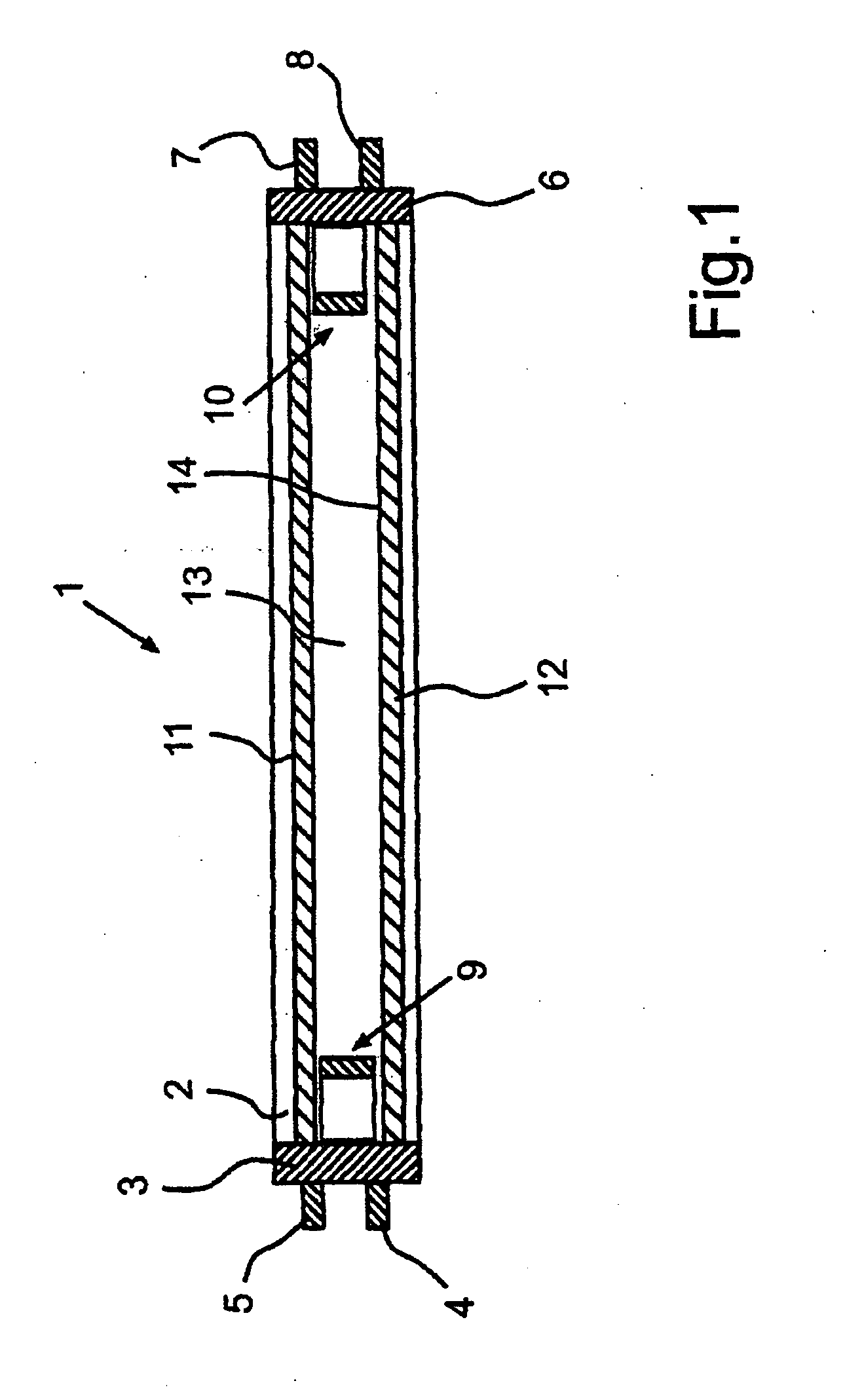

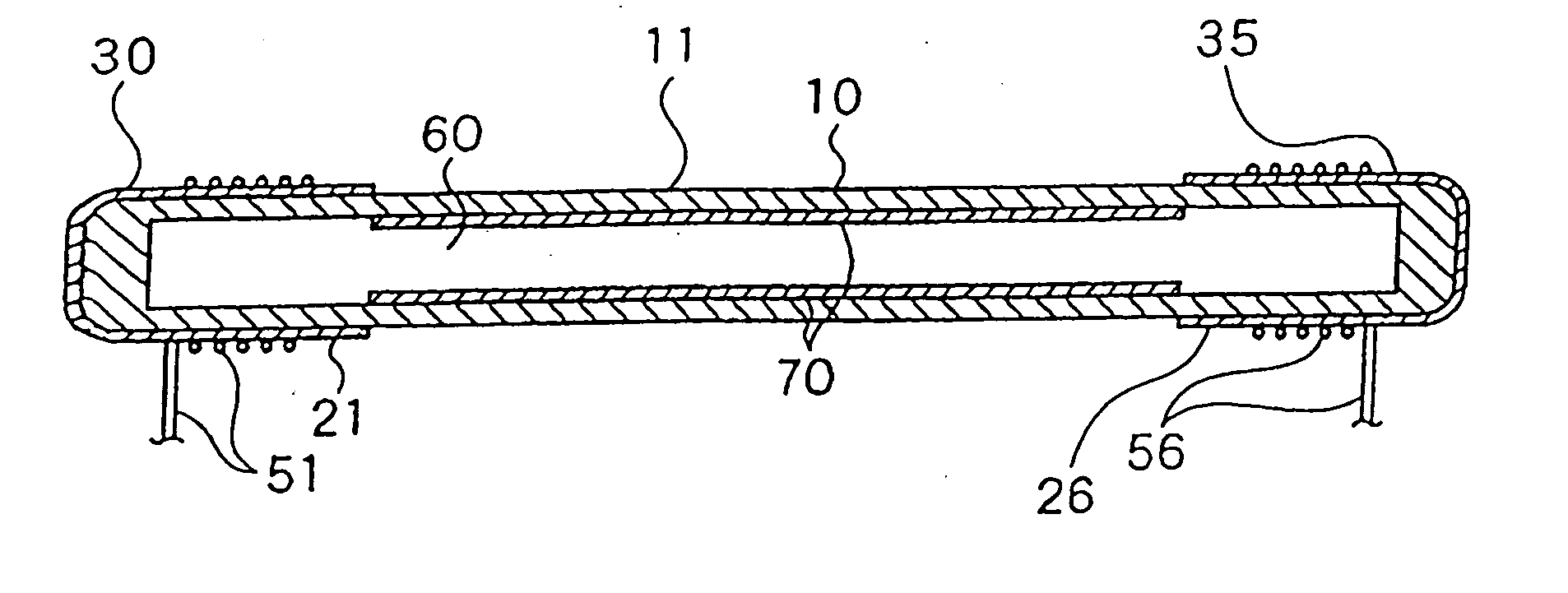

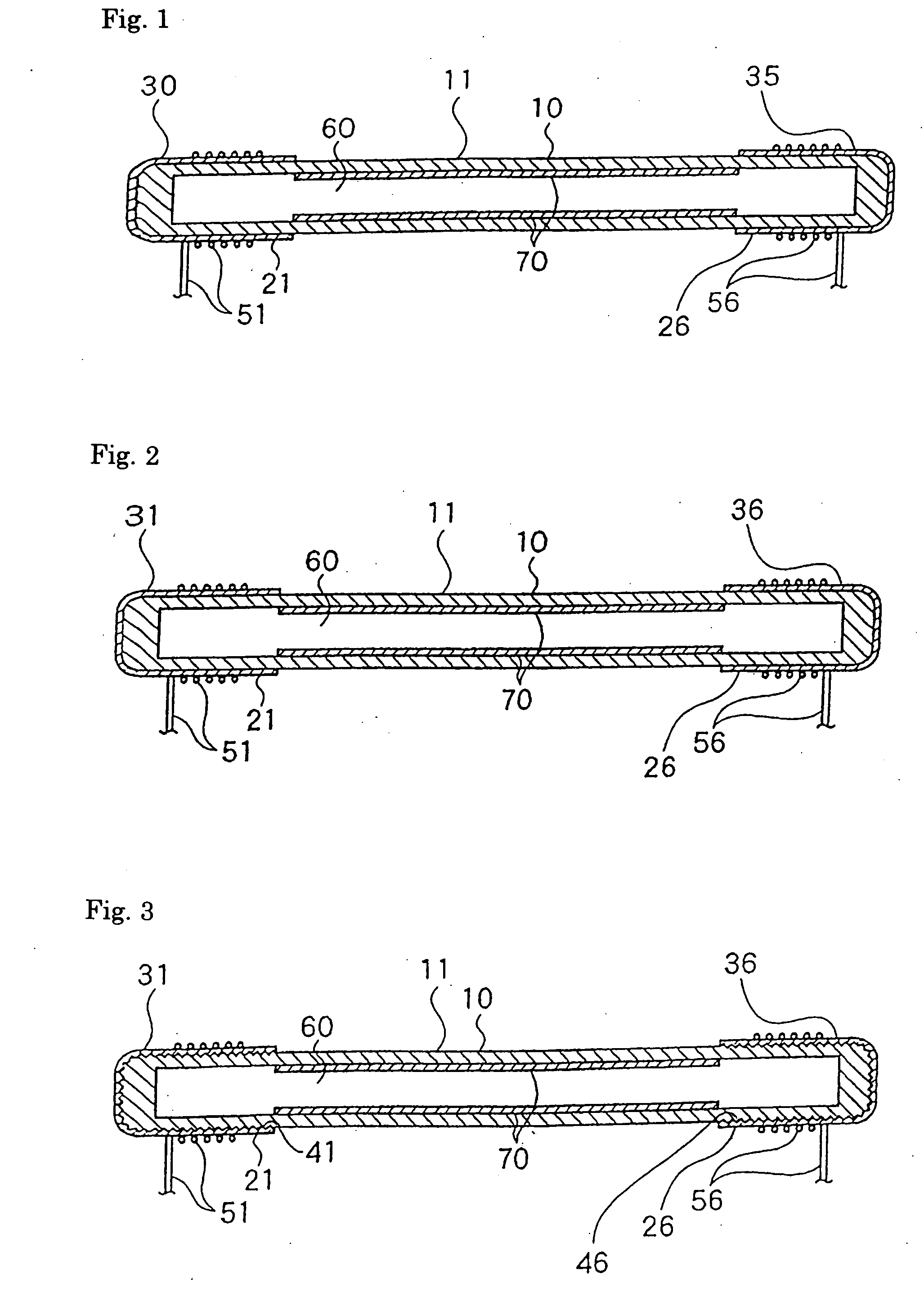

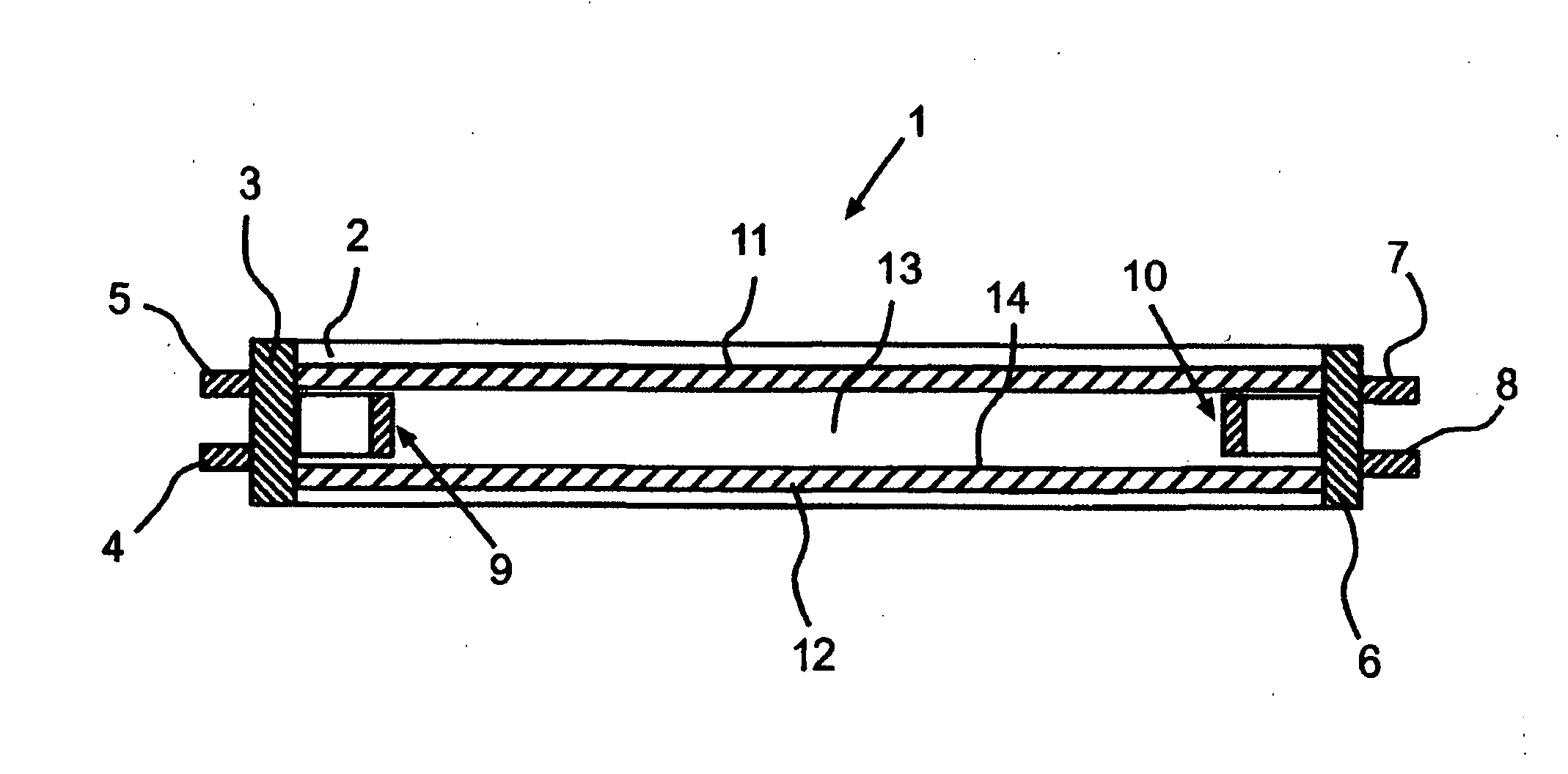

Low- Voltage discharge lamp and its manufacturing method

InactiveUS20060055326A1Improve efficiencyLow costTube/lamp screens manufactureGas-filled discharge tubesElectrical conductorElectric light

A low-pressure discharge lamp having a tubular glass lamp vessel 10, on an outer surface of which conductor layers are formed as electrodes 21 and 26. The ultrasonic solder dipping layers 31 and 36 are formed at both ends of the vessel 10 as conductor layers. The end surfaces of the glass lamp vessel are blasted and ultrasonic solder dipping layers are formed on the blasted surfaces 41 and 46 by ultrasonic solder dipping. Conductor layers forme external electrodes 21 and 26, which are in contact with the glass surface more strongly. A low-pressure discharge lamp having the conductor layers of a uniform thickness can be mass-produced at low cost.

Owner:HARISON TOSHIBA LIGHTING CORP

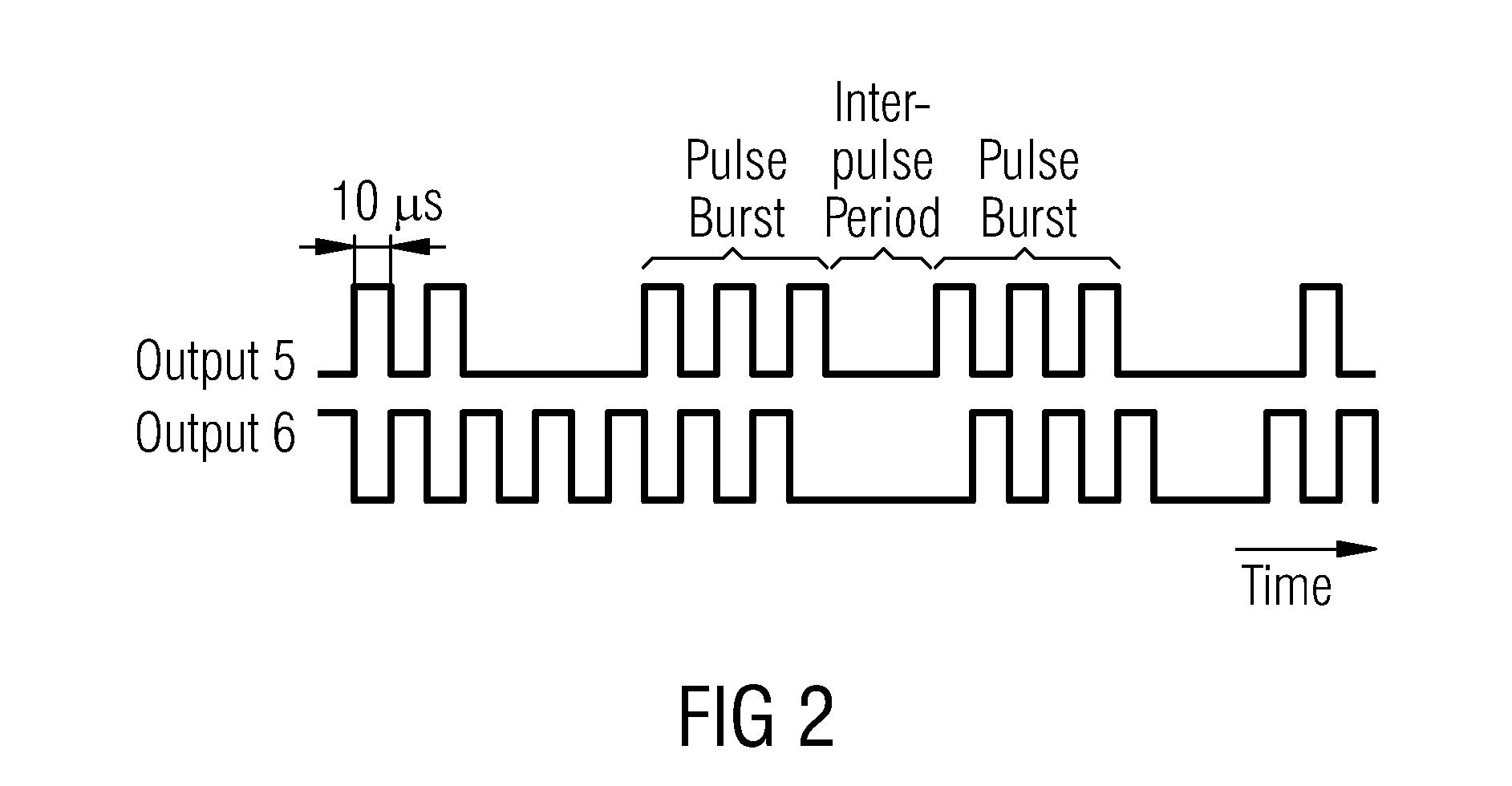

Method for operating a discharge lamp

InactiveUS6259214B1High light yieldGood dimming effectGas-filled discharge tubesMultiple discharge path lampsLight beamCold cathode

An operating method, in particular a dimming method for a discharge lamp. In order to set the maximum brightness, two outer electrodes (5,6), for example, are used to generate in the discharge lamp a dielectrically impeded discharge which, through the formation of xenon excimers, emits UV radiation which is converted into light with the aid of fluorescent materials (2). In order to permit intense dimming of the discharge lamp, two cold cathodes (3, 4) are used to generate a xenon low-pressure discharge emitting UV beams, and the dielectrically impeded discharge is switched off. Both types of discharge are preferably excited by high-voltage pulses which are generated by an operating unit (7). Dimming is preferably performed by blanking pulse trains.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

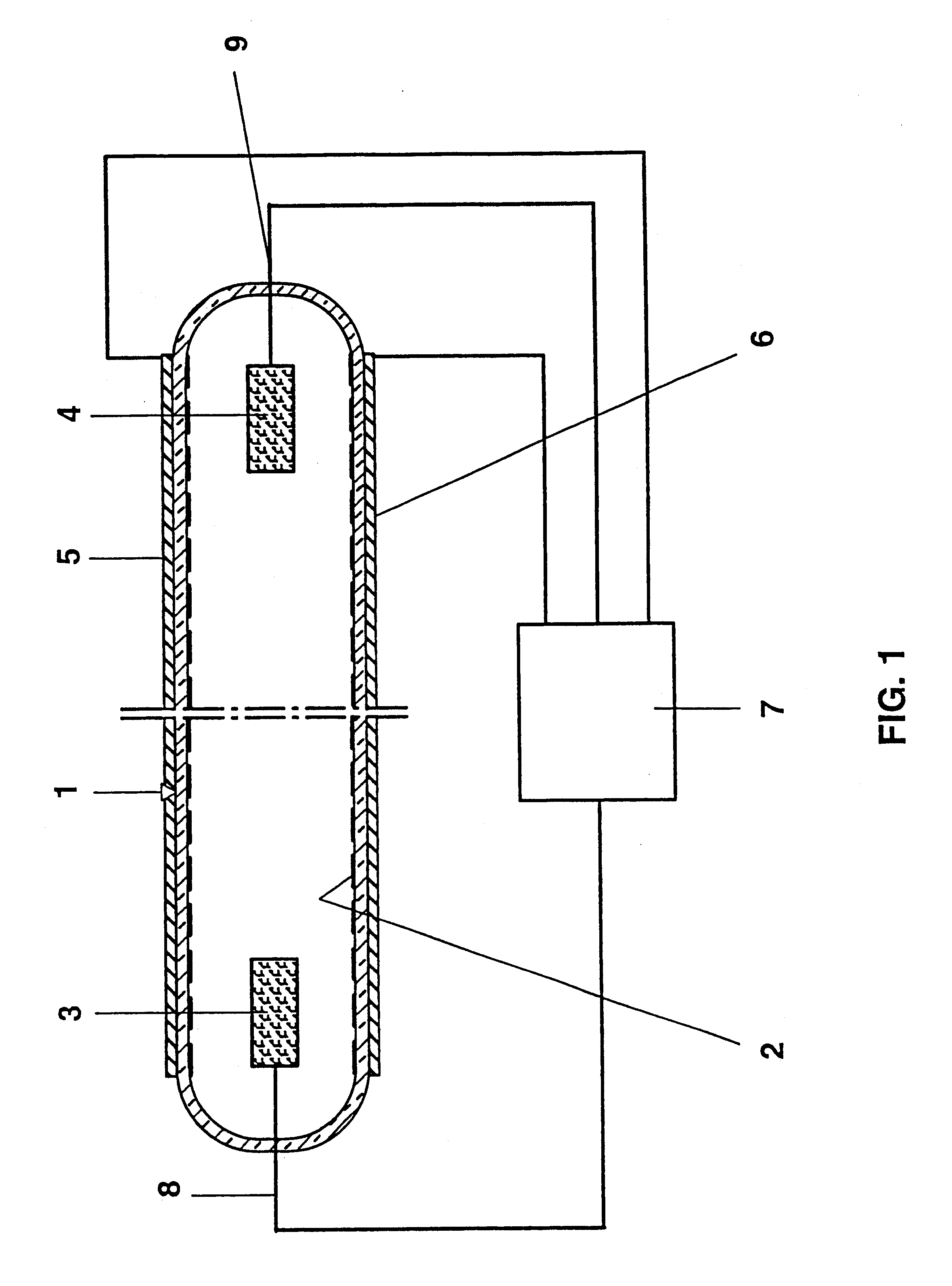

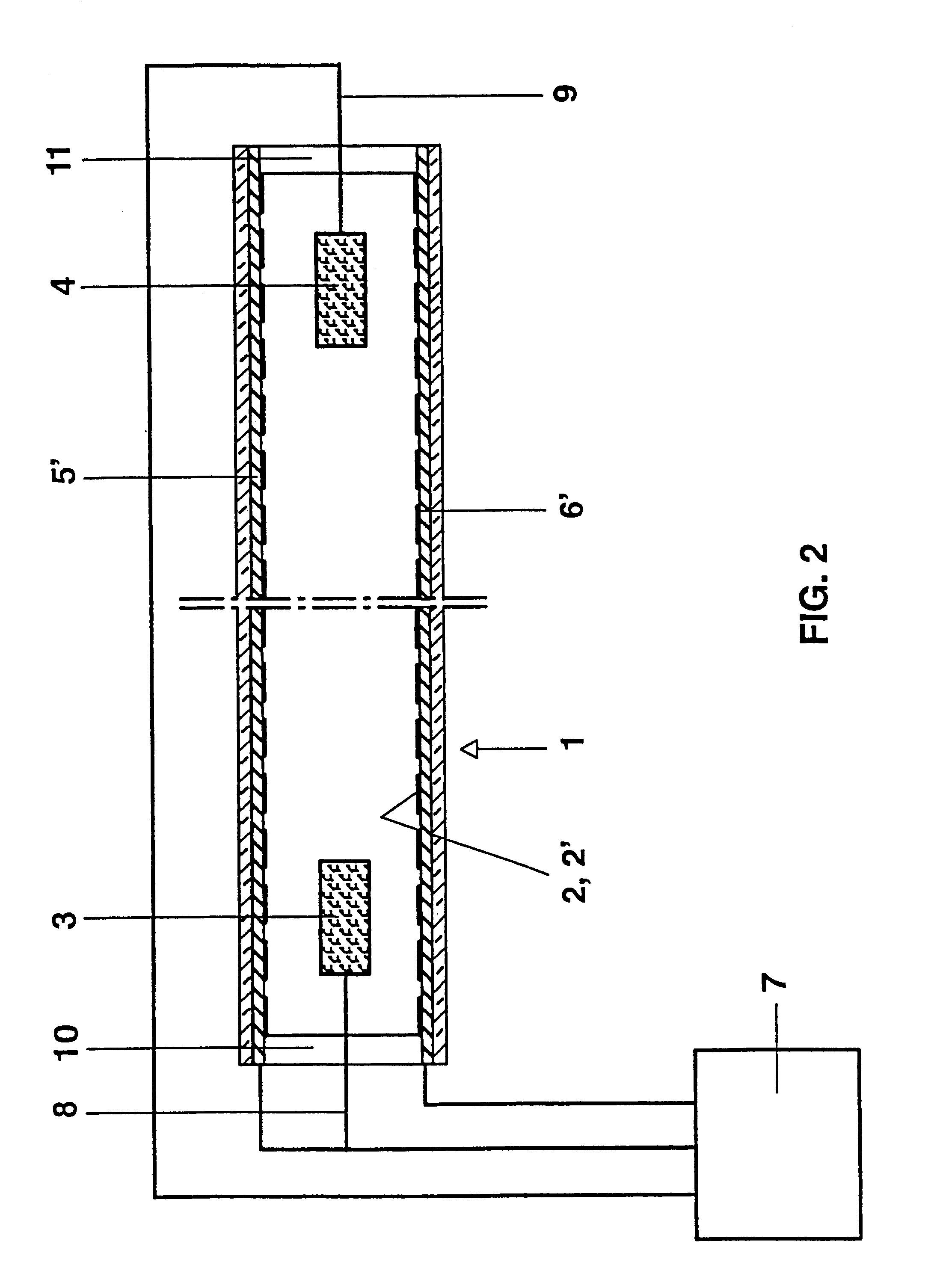

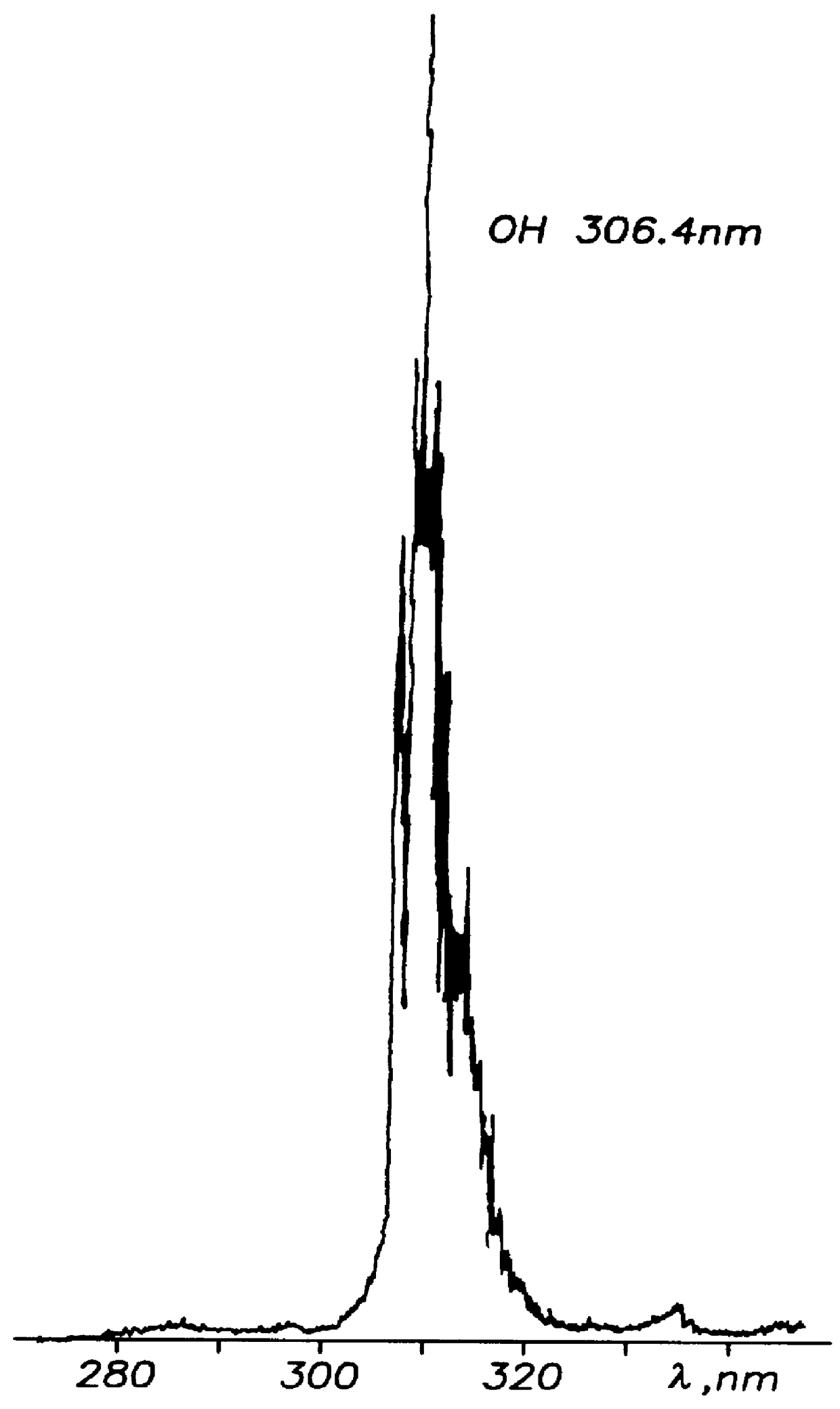

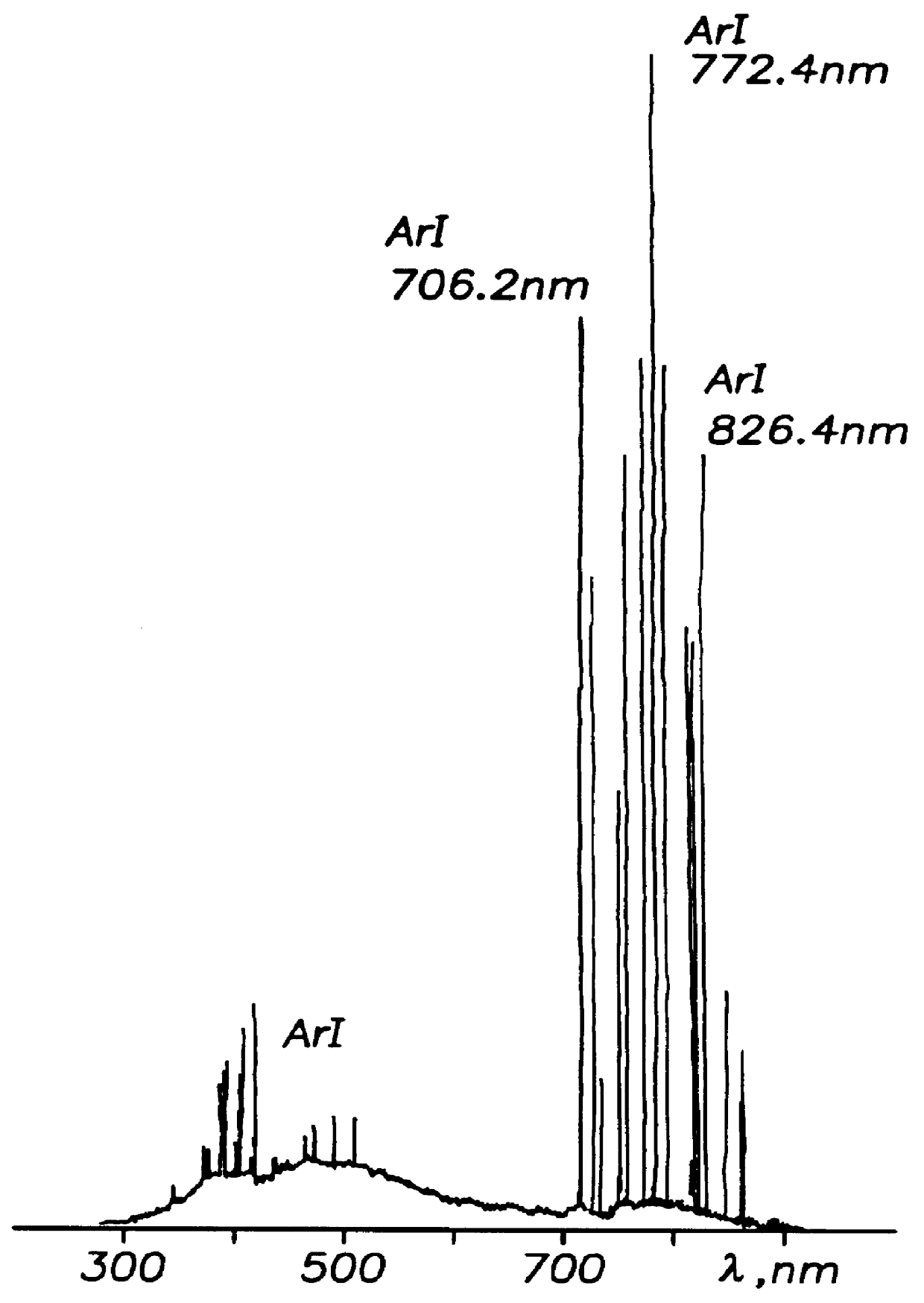

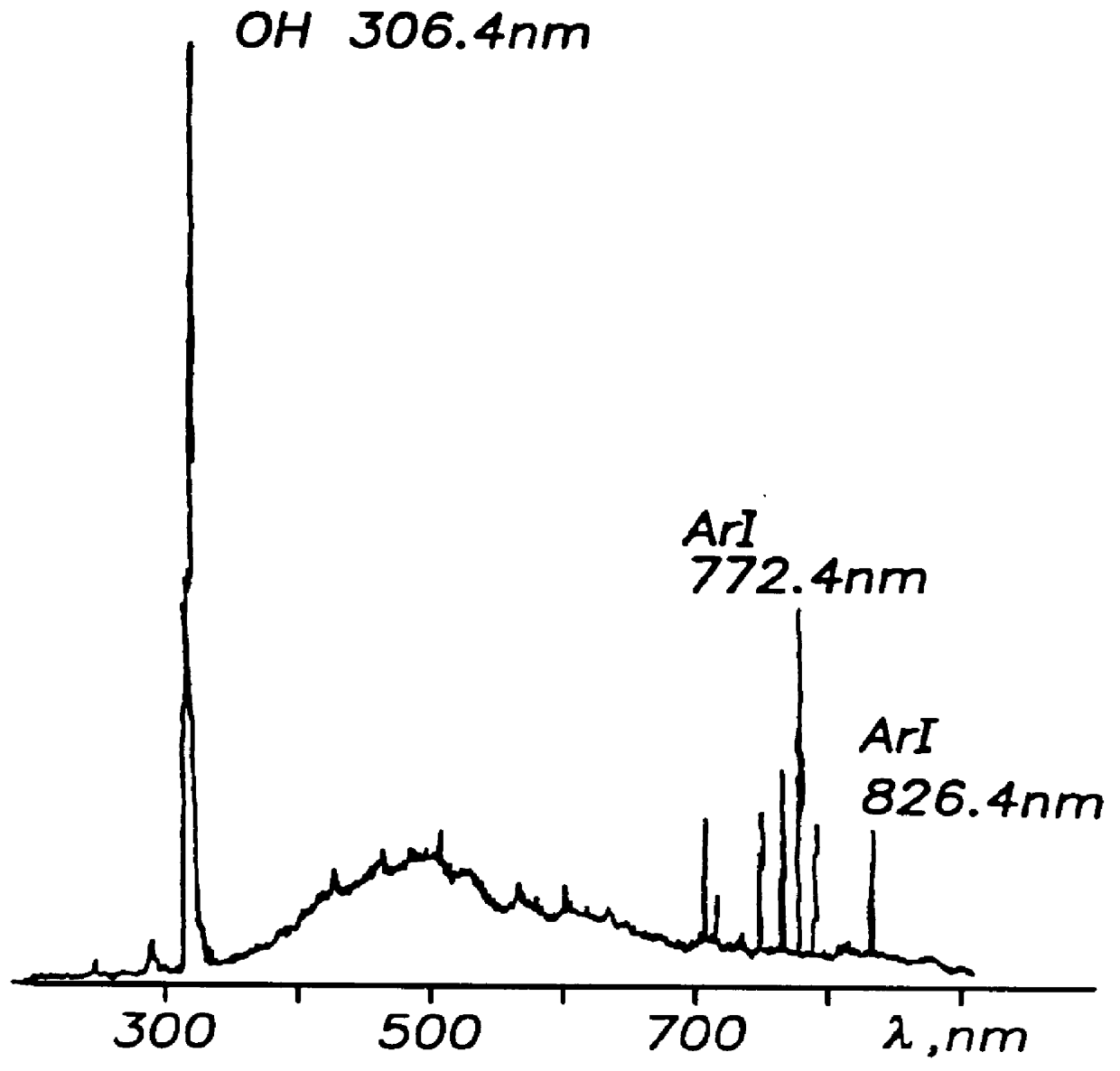

Discharge lamp with HO radicals as radiating additives

InactiveUS6040658AExpand the usable rangeSolid cathode detailsGas discharge lamp detailsOptical radiationElectric discharge in gases

PCT No. PCT / RU96 / 00203 Sec. 371 Date Apr. 20, 1998 Sec. 102(e) Date Apr. 20, 1998 PCT Filed Jul. 26, 1996 PCT Pub. No. WO97 / 05646 PCT Pub. Date Feb. 13, 1997The method of producing optical radiation and a discharge lamp for that purpose pertain to electrical technology, specifically to methods of producing radiation in the visible spectrum resulting from electrical discharge in gas, and to low-pressure discharge lighting lamps of various types. The proposed method of producing optical radiation, and the associated discharge lamp, extend the available range of environmentally clean lighting systems. The method involves creating a gas discharge in an inert gas atmosphere with a radiating additive in an optically transparent tube. A novelty of the method lies in the use as a radiating additive of the HO radical. The discharge lamp comprises an optically transparent tube (1) filled with an inert gas and a radiating additive. Also novel is the use as a radiating additive of an HO source obtainable from water or group II metal alkalis.

Owner:AKTSIONERNOE OBSCHESTVO ZAKRYTOGO TIPA NAUCHNO TEKHNICHESKOE AGENTSTVO INTELLEKT

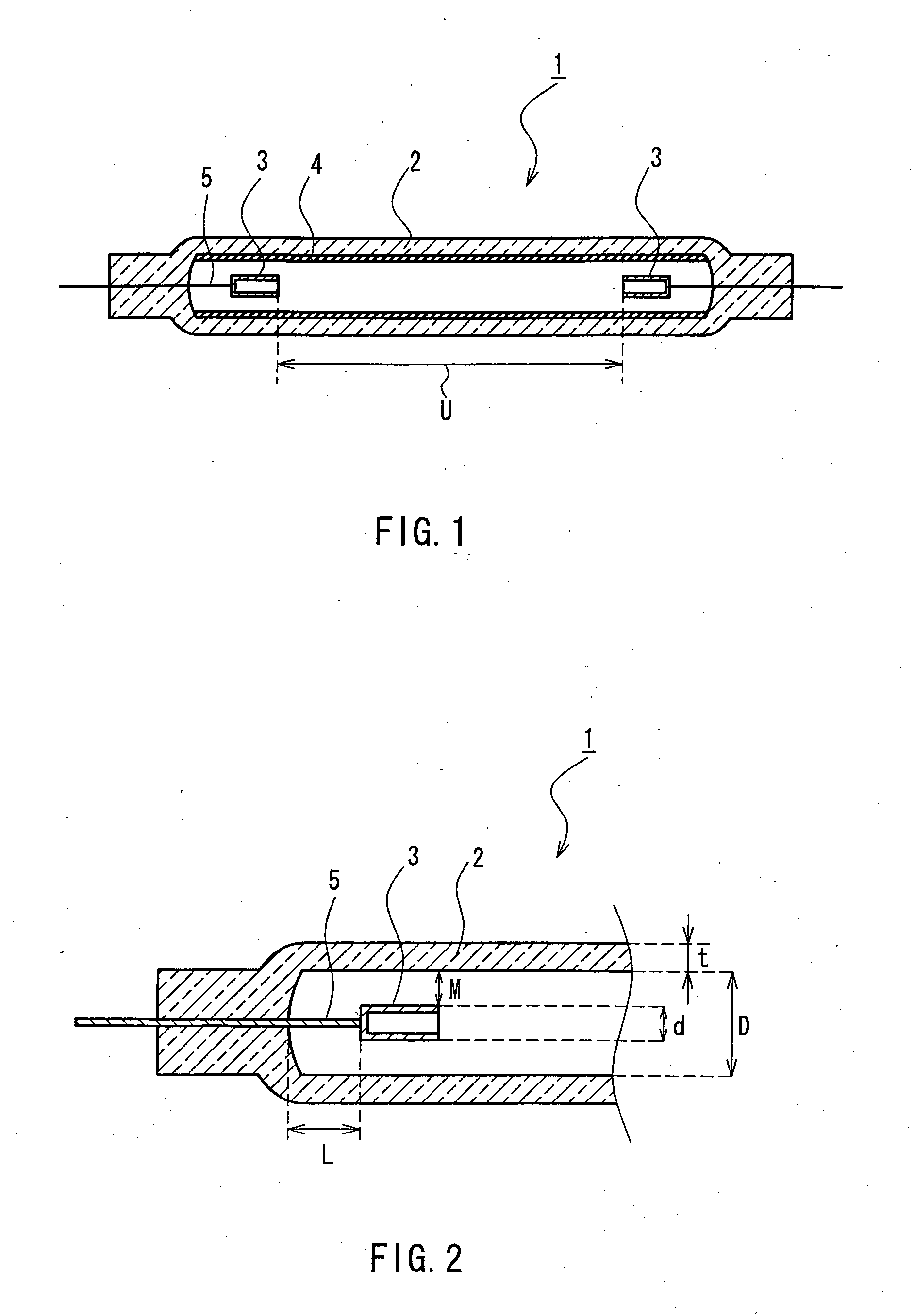

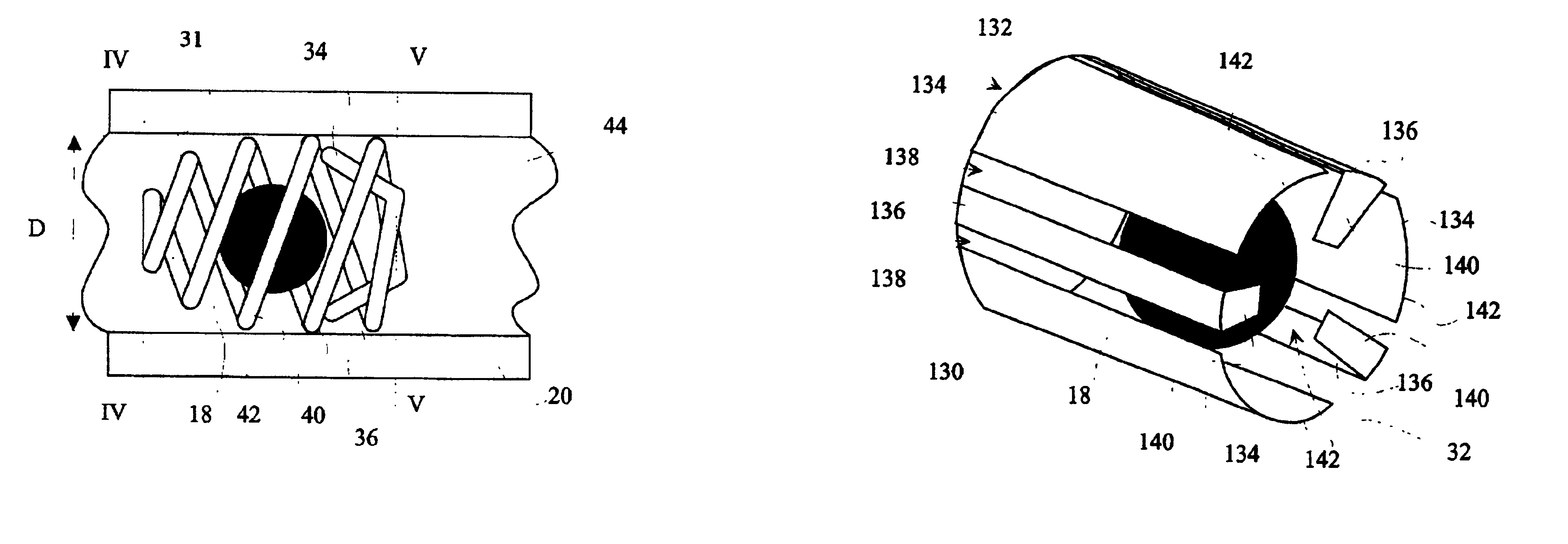

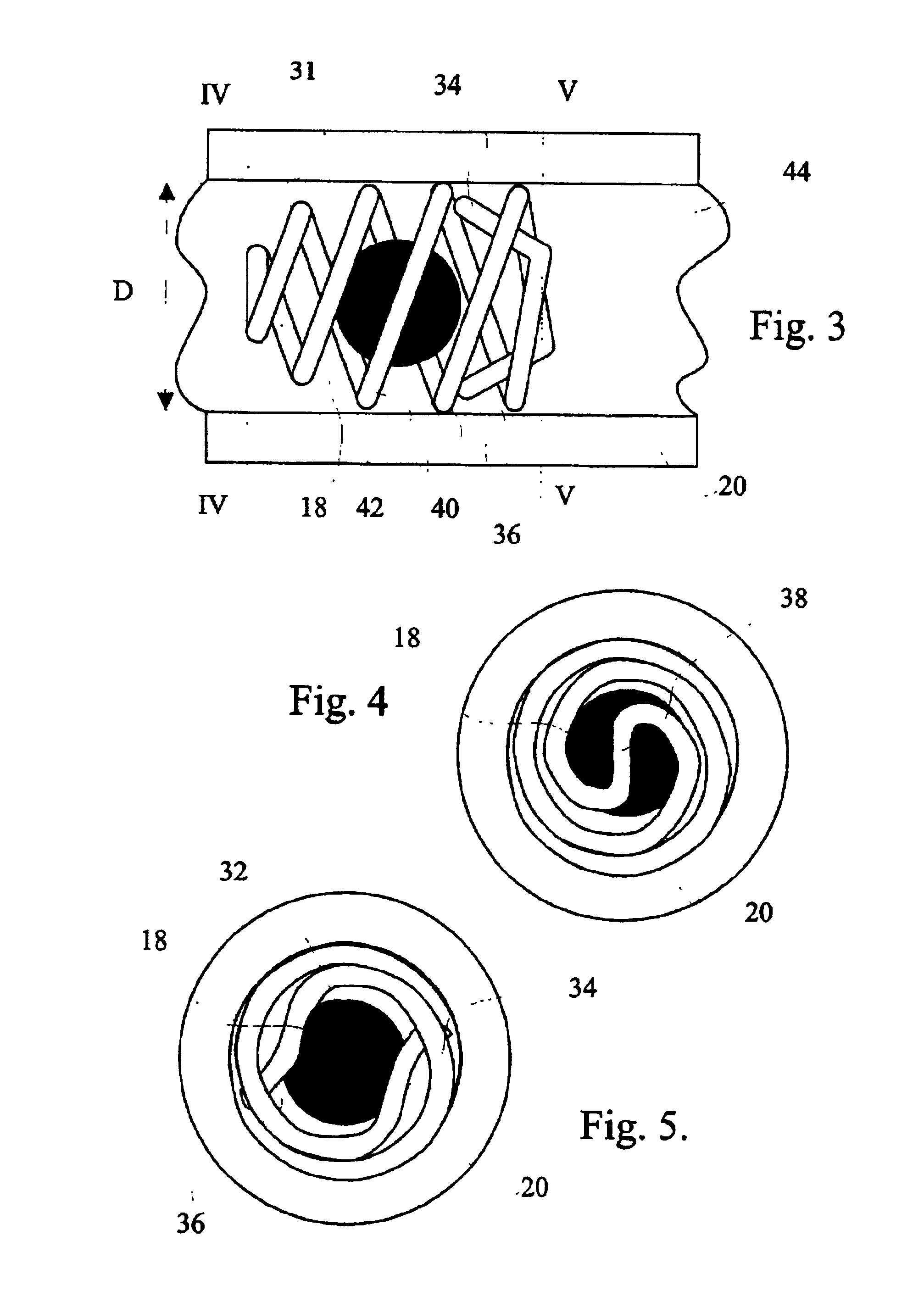

Device and method for retaining mercury source in low-pressure discharge lamps

InactiveUS6906460B2Improve manufacturing productivityMercury contamination of the production equipment remains lowElectric lighting sourcesTube/lamp vessel fillingElectric lightEngineering

A device for retaining a mercury source in the discharge space of a low-pressure discharge lamp is disclosed. The mercury source retaining device comprises a holder, which has an inner space communicating with the discharge space and a receiver opening for receiving a mercury source. The retaining device further comprises resilient clamping means for clamping the holder in a tubular space segment of the discharge space and resilient retaining means at least partially blocking the receiver opening. The resilient retaining means are adapted for allowing a passage of the mercury source in a direction towards the inner space of the holder, but block the movement of the mercury source through the receiver opening in a direction out of the holder.

Owner:GENERAL ELECTRIC CO

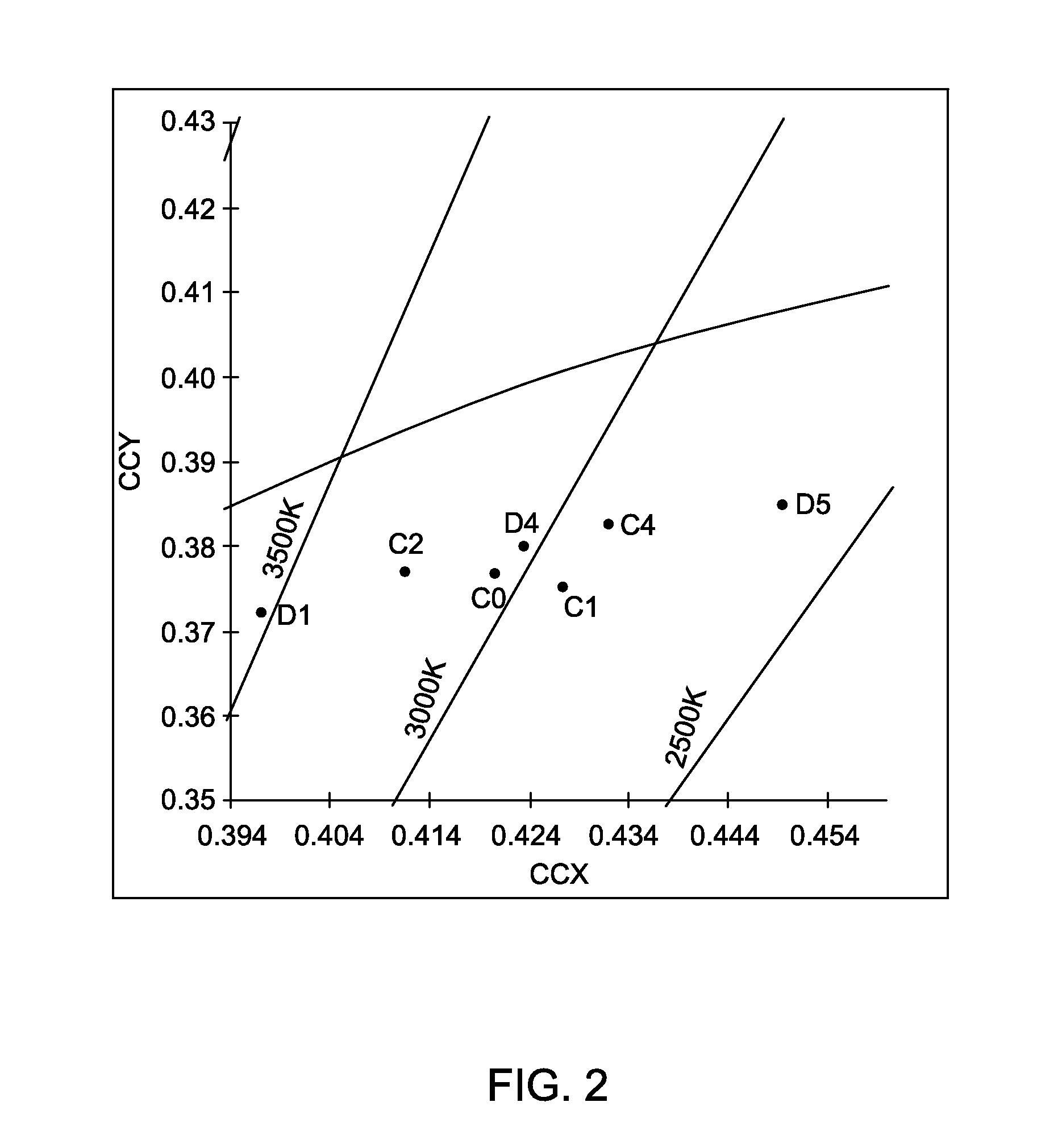

Lamp with enhanced chroma and color preference

InactiveUS20120098411A1Evenly enhanced chromaImprove preferenceDischarge tube luminescnet screensLamp detailsColor preferencesComputer science

Disclosed herein are low pressure discharge lamps having enhanced chroma and color preference. improved color quality scale, especially at elevated color temperatures, is provided. The light generated by the light-emitting elements of the lamp, when the lamp is energized, has Color Preference Scale values, as well as delta chroma values for fifteen color samples of the Color Quality Scale, within select parameters.

Owner:GENERAL ELECTRIC CO

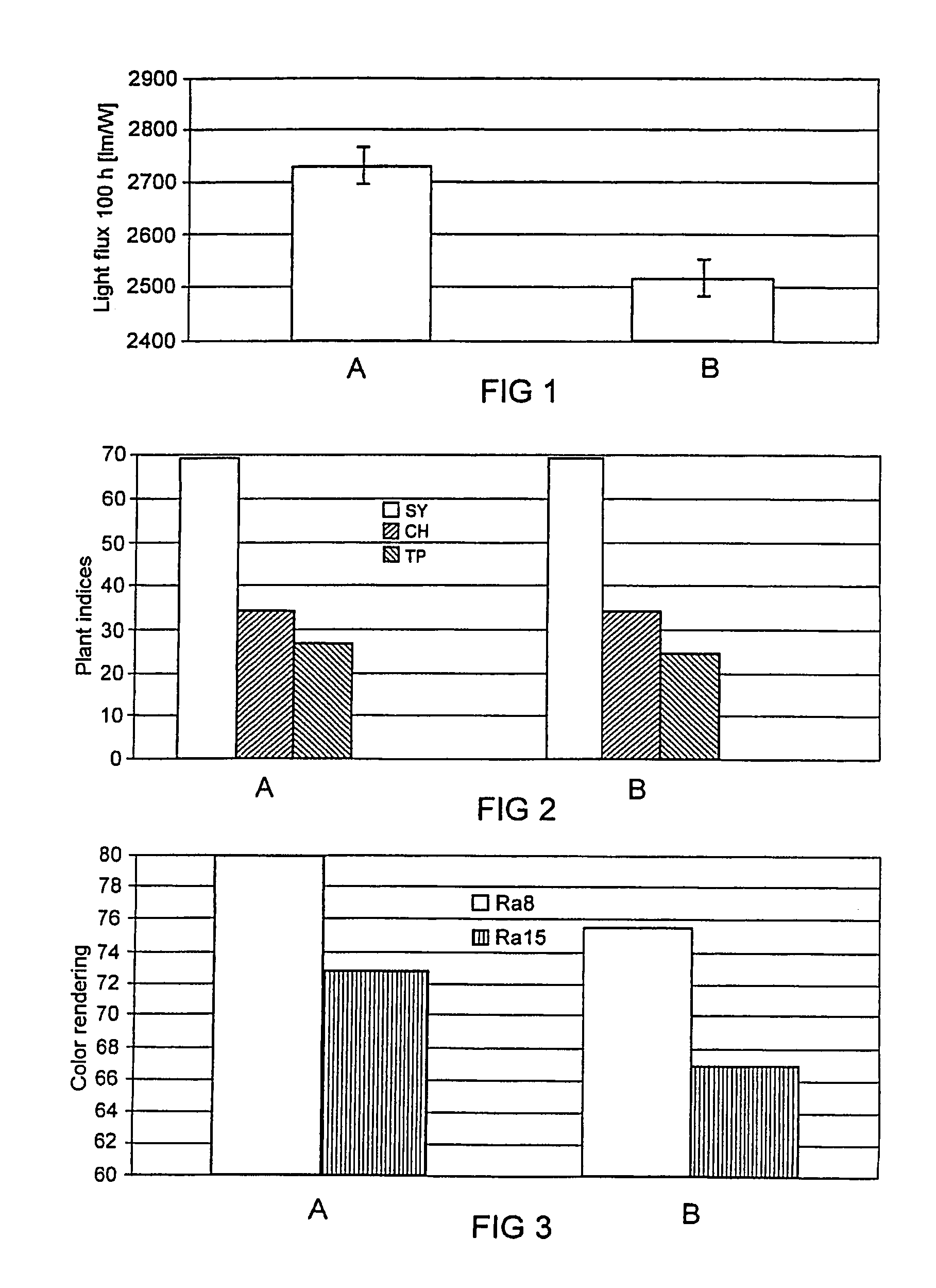

Phosphor coating composition for a mercury low-pressure discharge lamp for illuminating plants

InactiveUS7259509B2Novel compositionDischarge tube luminescnet screensLamp detailsNoble gasFluorescence

Owner:LEDVANCE GMBH

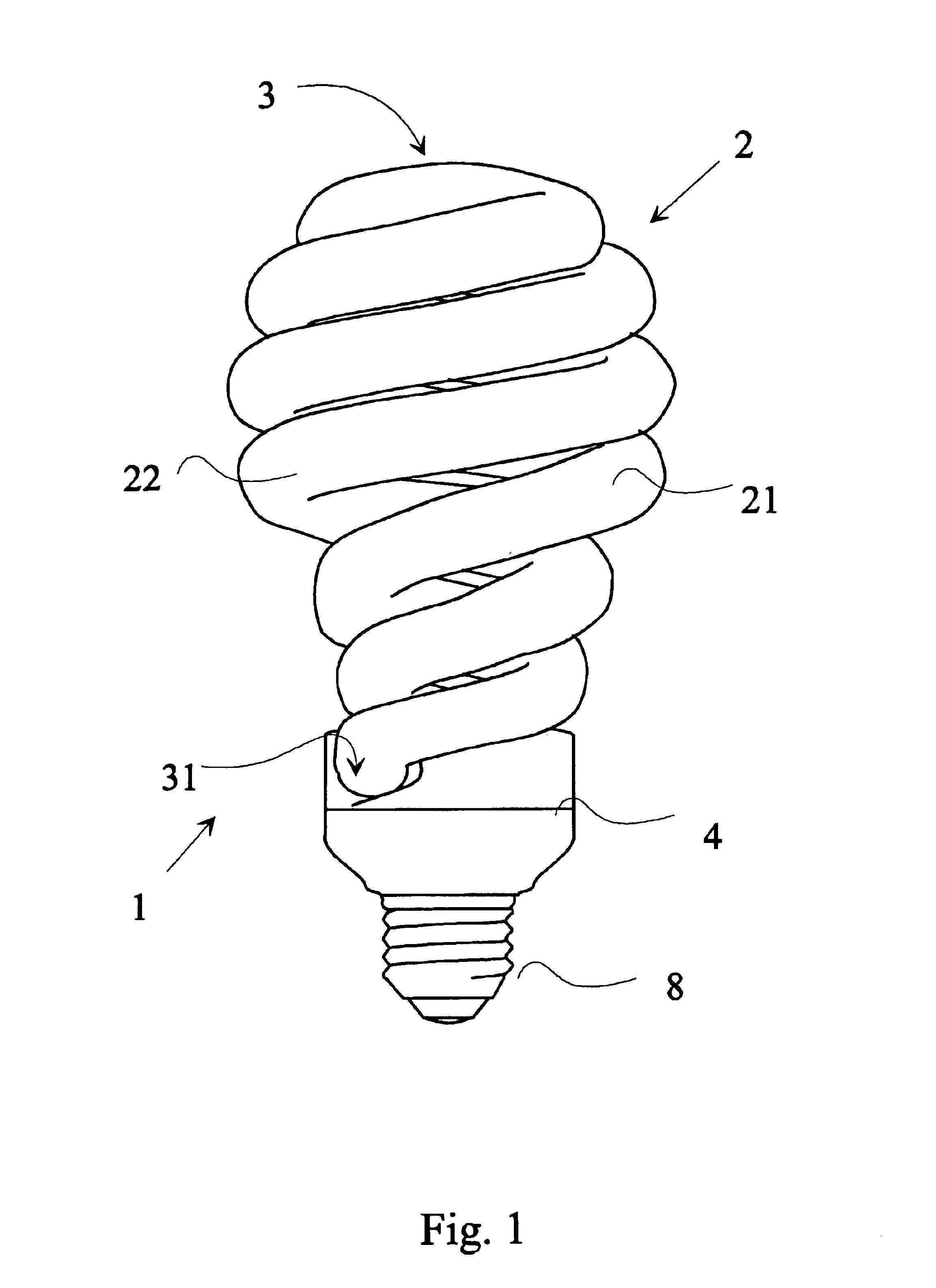

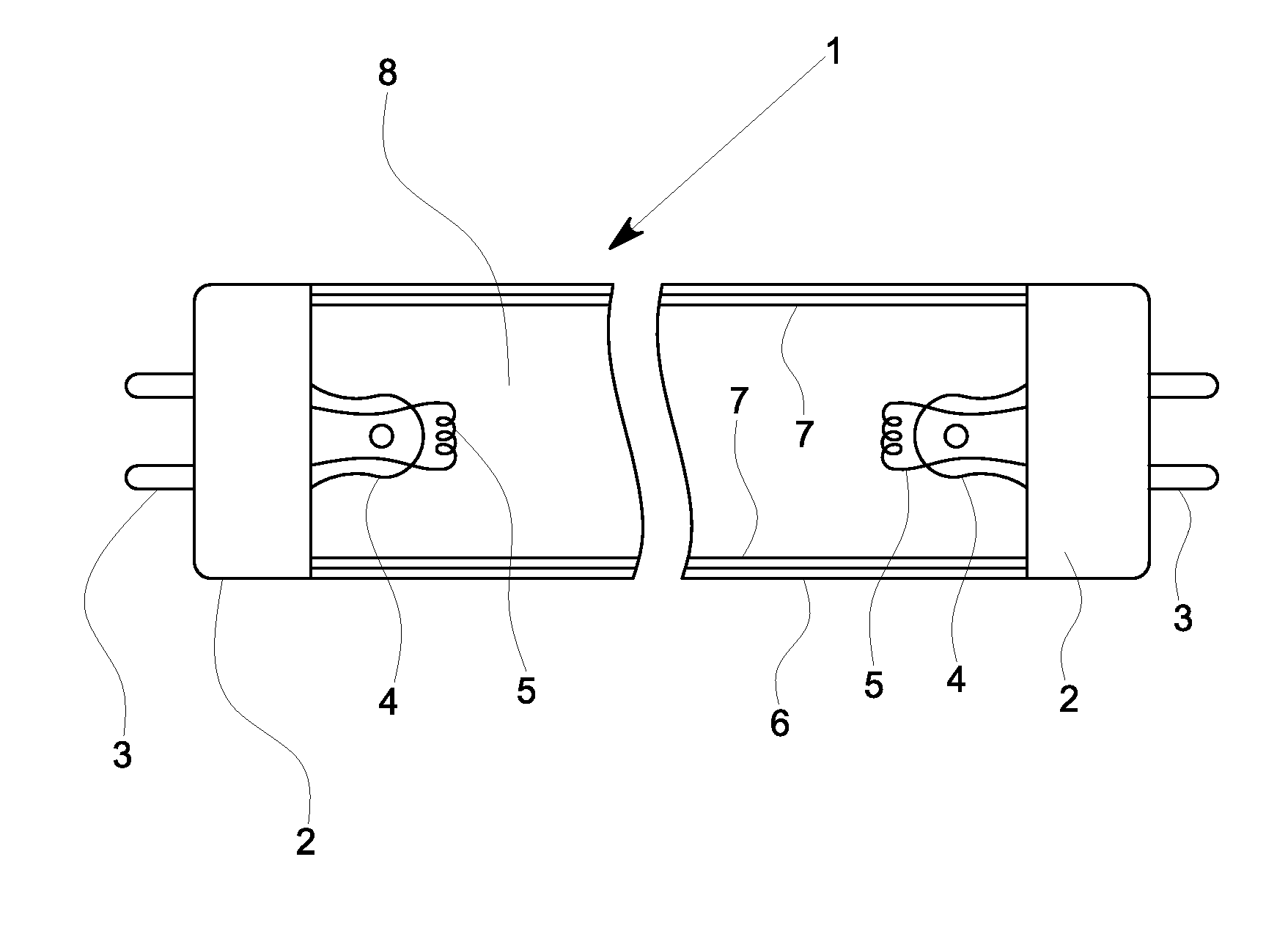

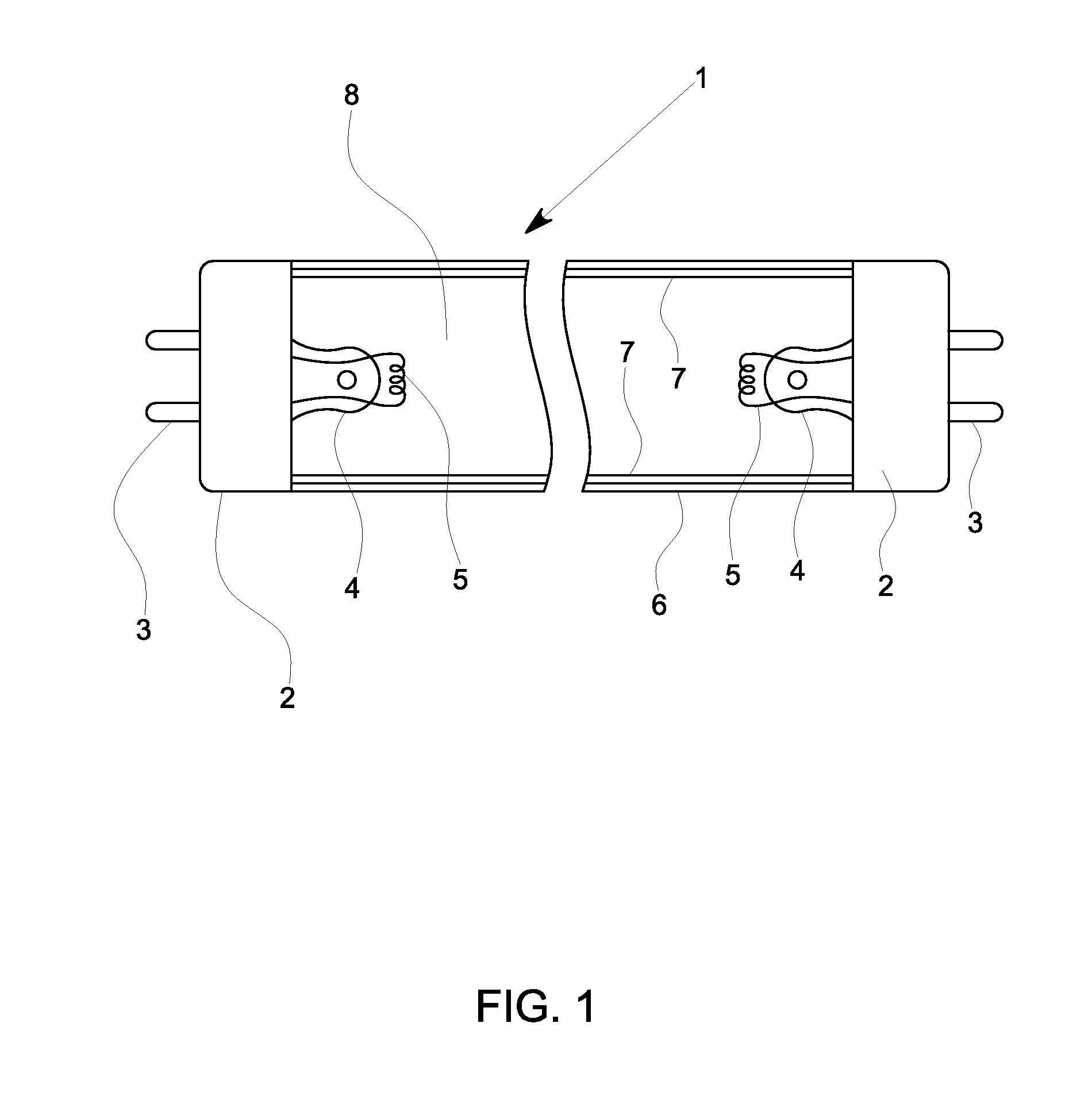

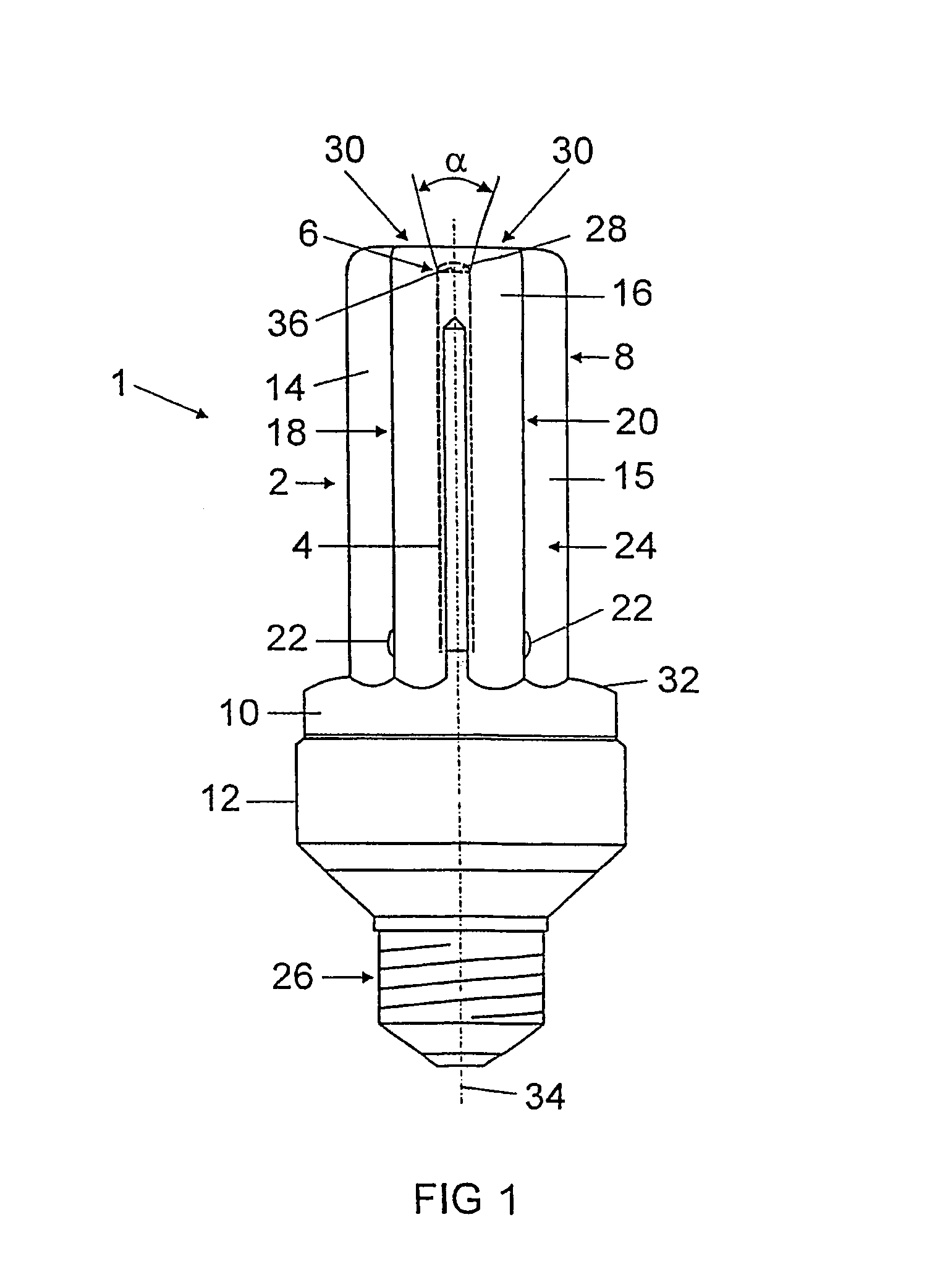

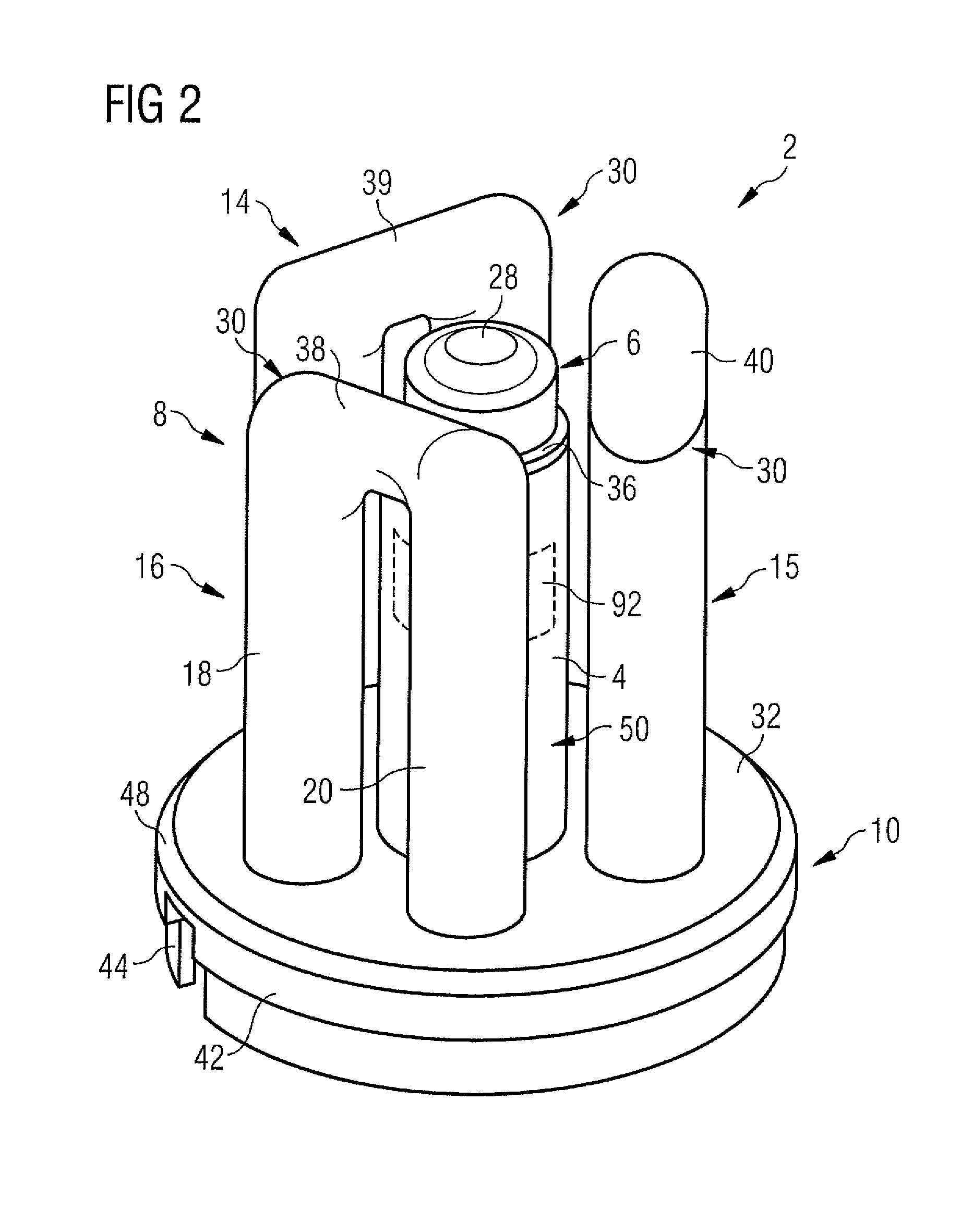

Lamp arrangement

InactiveUS7862200B2Accelerate emissionsLight source combinationsLighting support devicesLight-emitting diodeLow-pressure discharge

A lamp arrangement is disclosed, with at least one low-pressure discharge lamp, in particular, a compact fluorescent lamp to generate a main illumination with at least one discharge bulb, fitted in a socket and at least one alternative light source, in particular, a light diode arrangement with at least one light diode (LED) for generation of an alternative illumination. According to the invention, the light diode arrangement is at least partly arranged in the vicinity of cold spots on the low pressure discharge lamp.

Owner:OSRAM GMBH

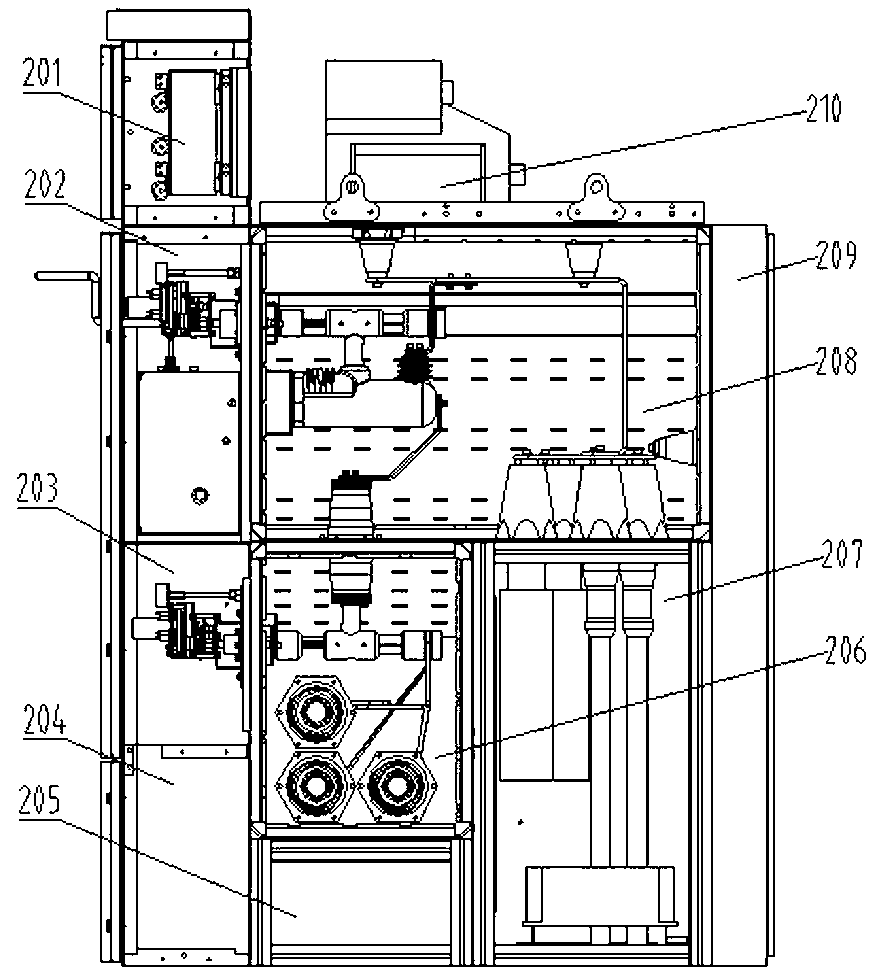

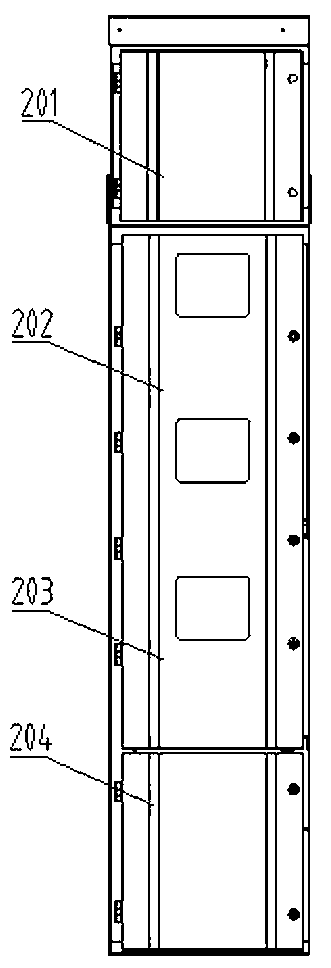

Intelligent inflatable high-pressure vacuum switch cabinet for metro

ActiveCN102916362AEnsure safetyMeet the requirements of intelligenceSwitchgear arrangementsElectrical bondingHigh pressure

An intelligent inflatable high-pressure vacuum switch cabinet for a metro comprises a low-pressure chamber, an upper mechanism operation chamber, a lower mechanism operation chamber, a lower maintenance chamber, a lower pressure discharging chamber, a main bus inflating chamber, a cable mounting chamber, a vacuum circuit breaker inflating chamber and a rear pressure discharging chamber. The intelligent inflatable high-pressure vacuum switch cabinet is characterized in that a main conductive return circuit is sealed in the main bus inflating chamber and the circuit breaker inflating chamber, each of the inflating chambers is provided with one three-position isolating / earthing switch inside, and the main bus inflating chamber and the circuit breaker inflating chamber are electrically connected via a middle connector. Under overhauling condition or outage condition, the two three-position isolating / earthing switches can be earthed to effectively protect safety of maintainers during maintaining. When serious fault happens to the circuit breaker chamber which cannot be overhauled on site, the three-position isolating / earthing switch of the main bus inflating chamber can be separated, relative connecting pieces can be removed, the vacuum circuit breaker inflating chamber can be drawn out and replaced by a spare separation chamber, power supply can be quickly recovered, and the critical defects that a single air-chamber switch cabinet cannot be maintained on site and outage time is long are overcome.

Owner:HUNAN FENGRI ELECTRIC GROUP

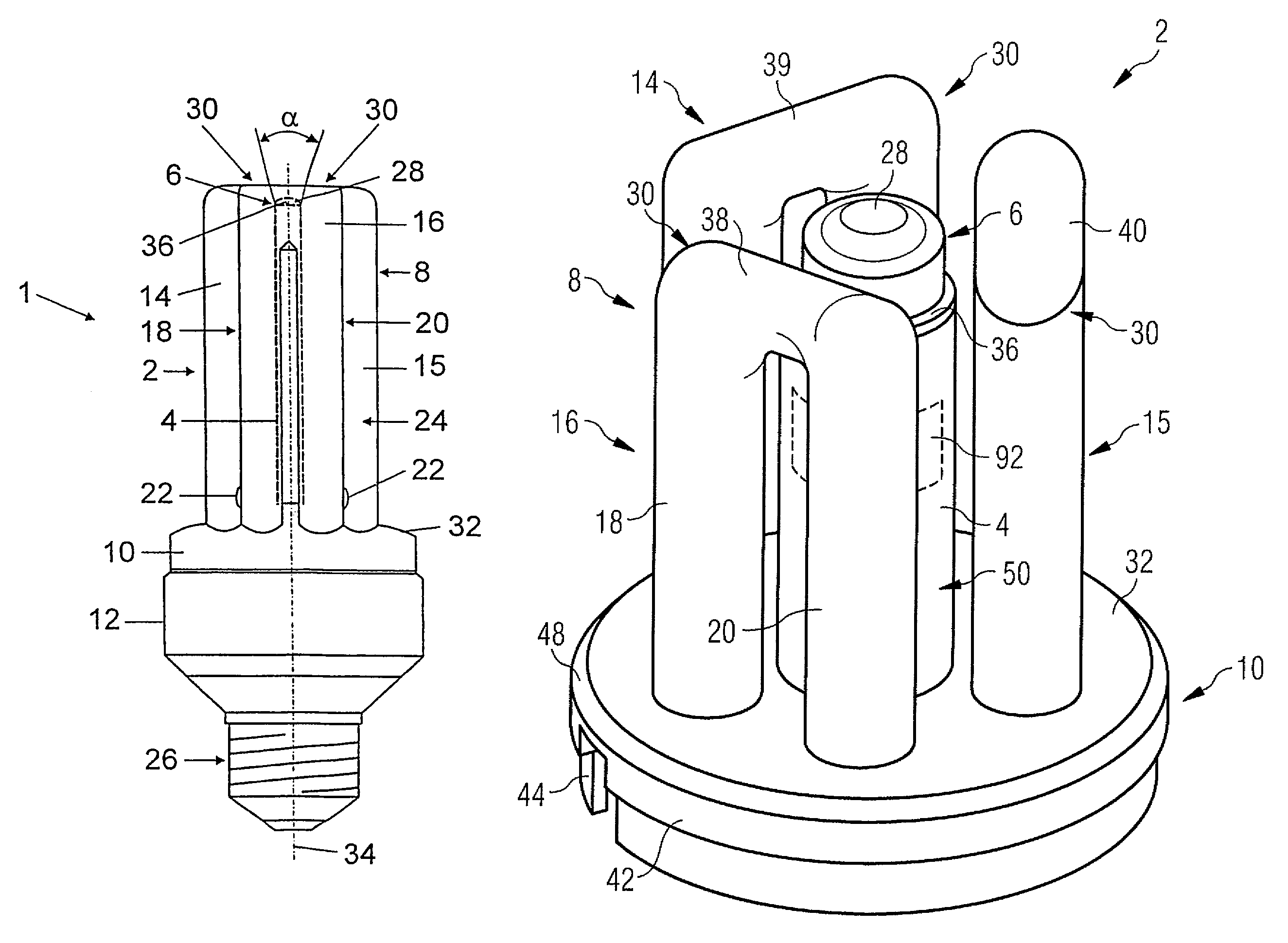

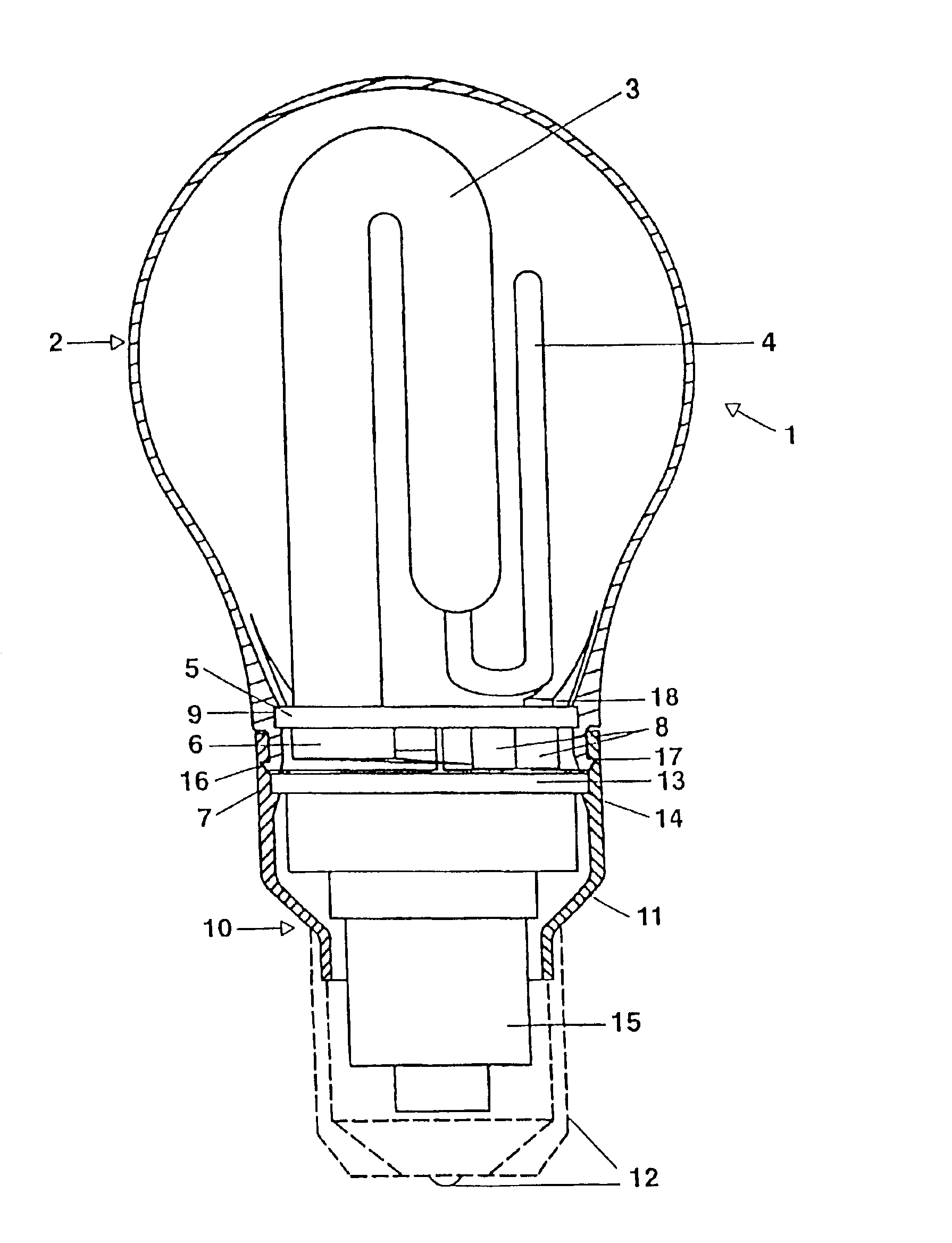

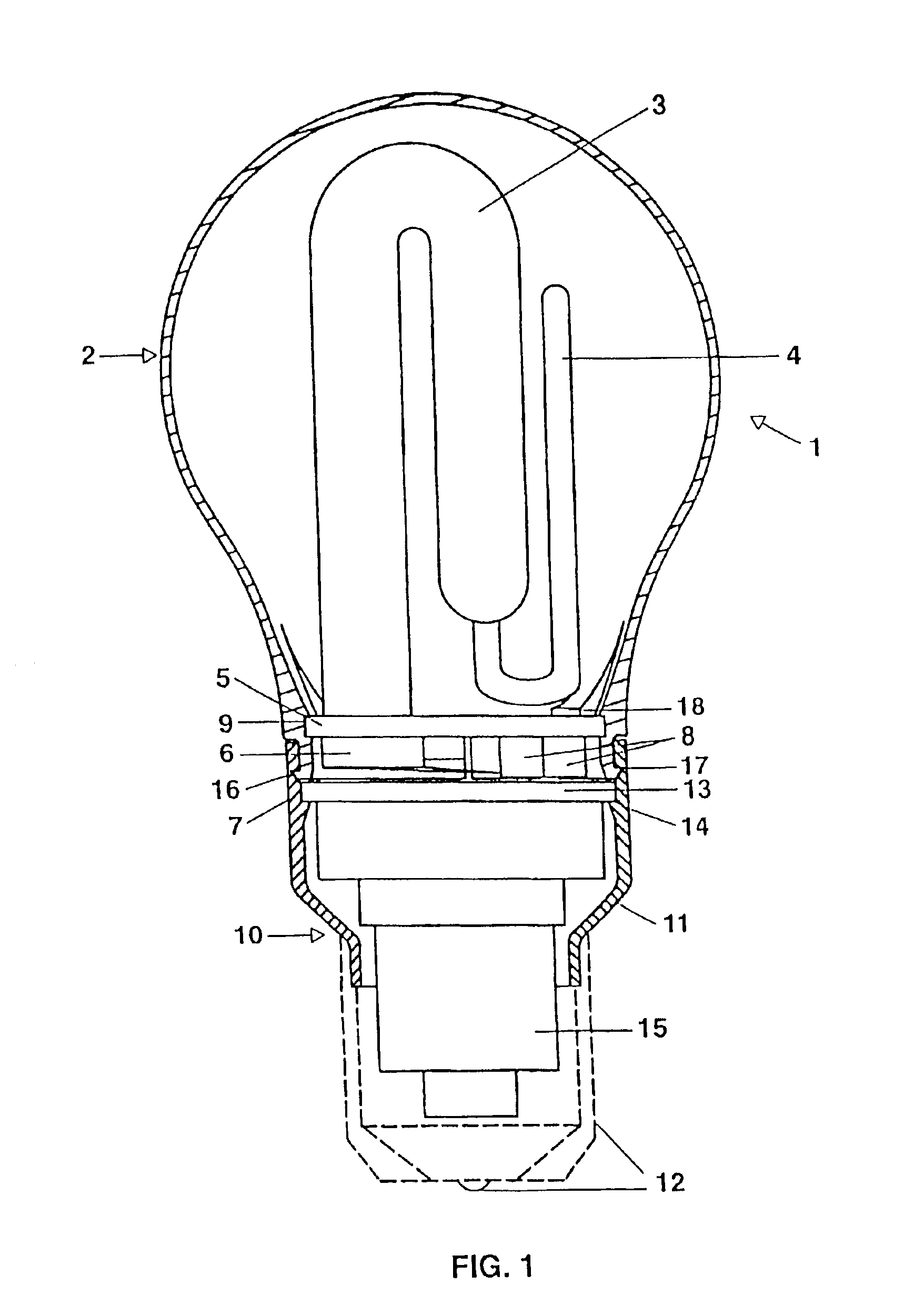

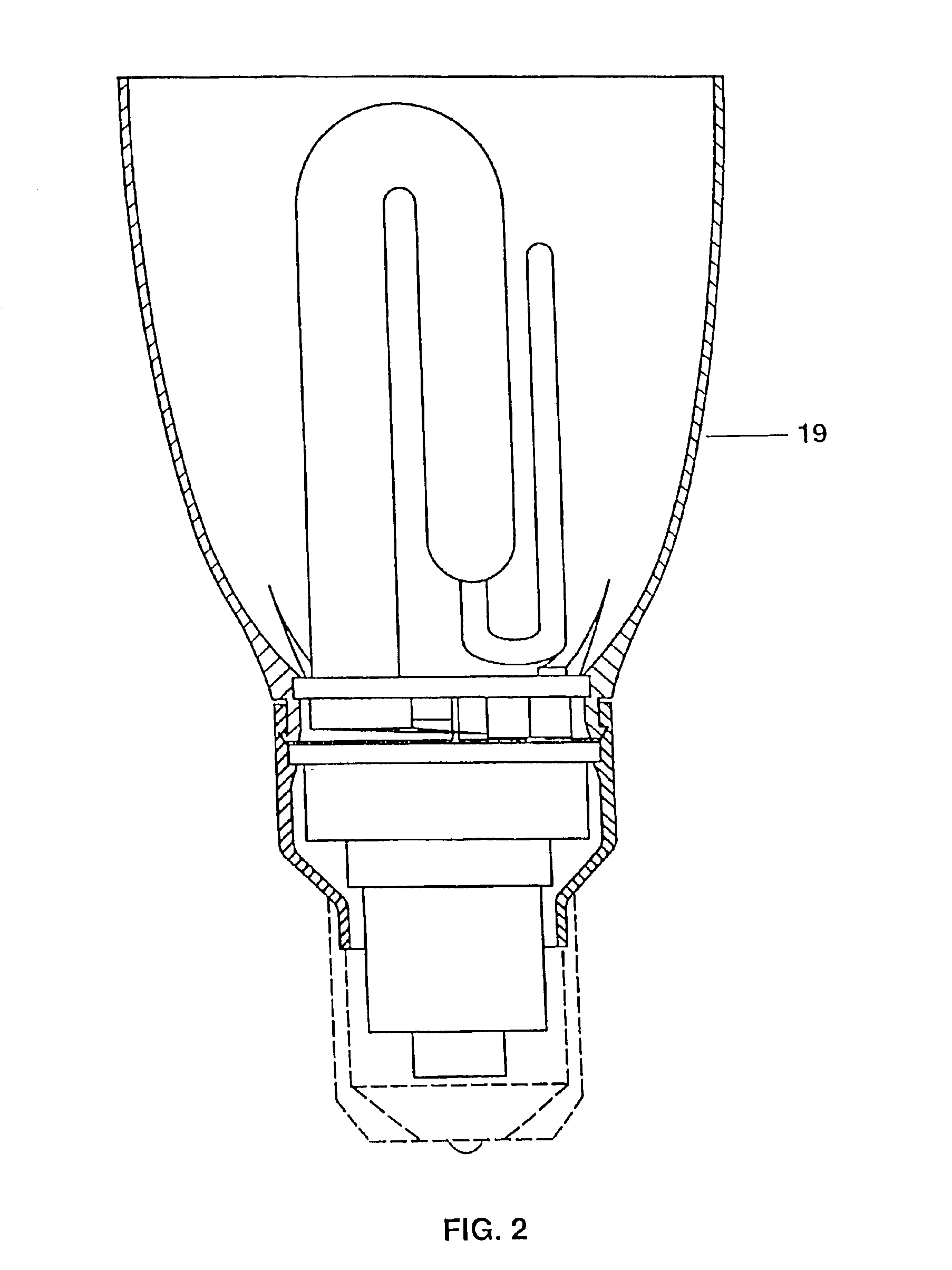

Compact low-pressure discharge lamp

InactiveUS6919671B2Easy to changeCompact structureCoupling device connectionsDischarge tube luminescnet screensElectrical connectionEngineering

The invention relates to a compact low-pressure discharge lamp (1) comprising a discharge vessel (3) with electrodes and power supply leads (7), a discharge vessel mount on which the discharge vessel is mounted, and a cap (10), which comprises a housing (11), connecting contacts (12) and a mounting plate (13) with a ballast apparatus (15), with the mounting plate being fitted with the ballast arrangement in the interior of the cap housing, and having connections for electrical connection of the mounting plate to the power supply leads and to the connecting contacts. The discharge vessel mount in this case comprises a plate (5) which is mounted in a further mount, with the further mount in turn being mounted on the housing of the cap. The further mount may be in the form of an enveloping bulb (2) or a reflector for the discharge vessel, or in the form of a closure cap (20) for the cap housing.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

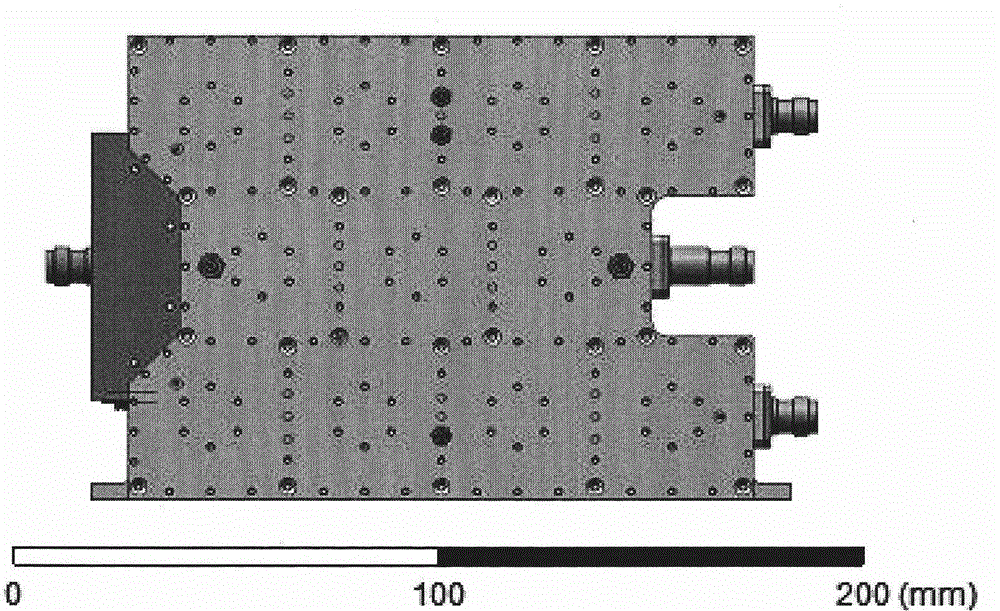

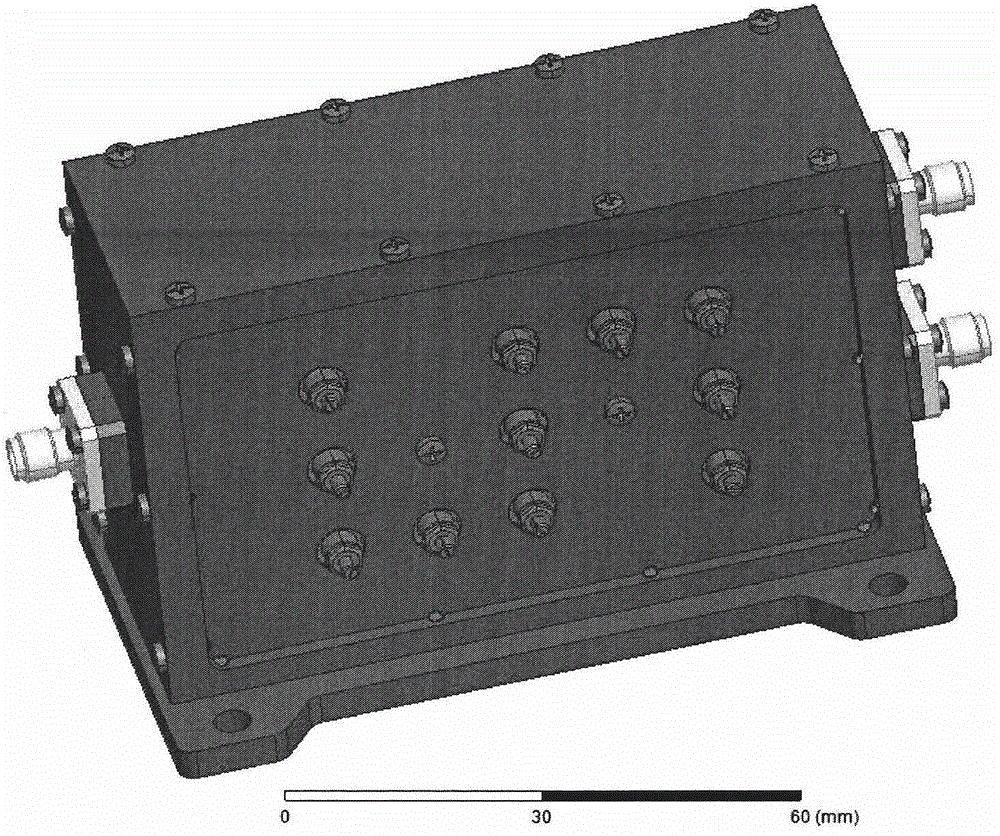

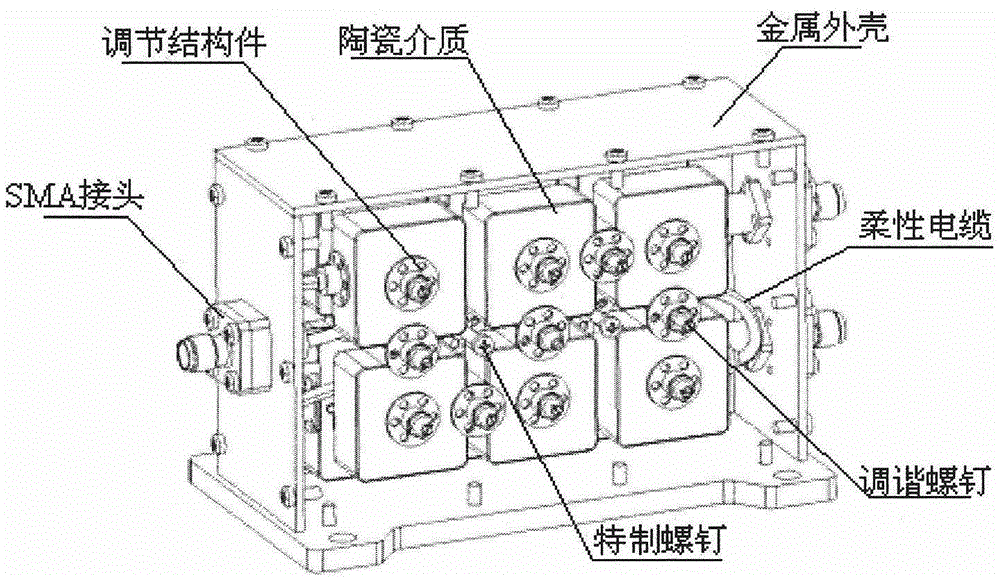

Satellite-borne S-band duplexer

InactiveCN105896001AImprove reliabilityImprove performanceWaveguide type devicesDielectricLow voltage

The invention provides a satellite-borne S-band duplexer which adopts an all-dielectric waveguide filter structure to realize high-power low-voltage discharge resistance. The satellite-borne S-band duplexer comprises tuning screws, a flexible cable, tuning structural members, an SMA connector, a metal shell, special screws and an all-dielectric waveguide filter structure, wherein the all-dielectric waveguide filter structure adopts a channel filter which is composed of two H-plane waveguide stepped coupling and filtering channels, and each H-plane waveguide stepped coupling and filtering channel adopts a ceramic dielectric waveguide filter. Therefore, the satellite-borne S-band duplexer provided by the invention is small in size, simple in structure and high in low pressure power capacity, and does not have a low pressure discharge phenomenon. Meanwhile, the power endurance capacity of products is improved, the mechanics environment resisting performance of a ceramic dielectric is increased, an integrated structure design is realized, the mechanics environment resisting performance is enhanced, and the reliability of the duplexer is improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

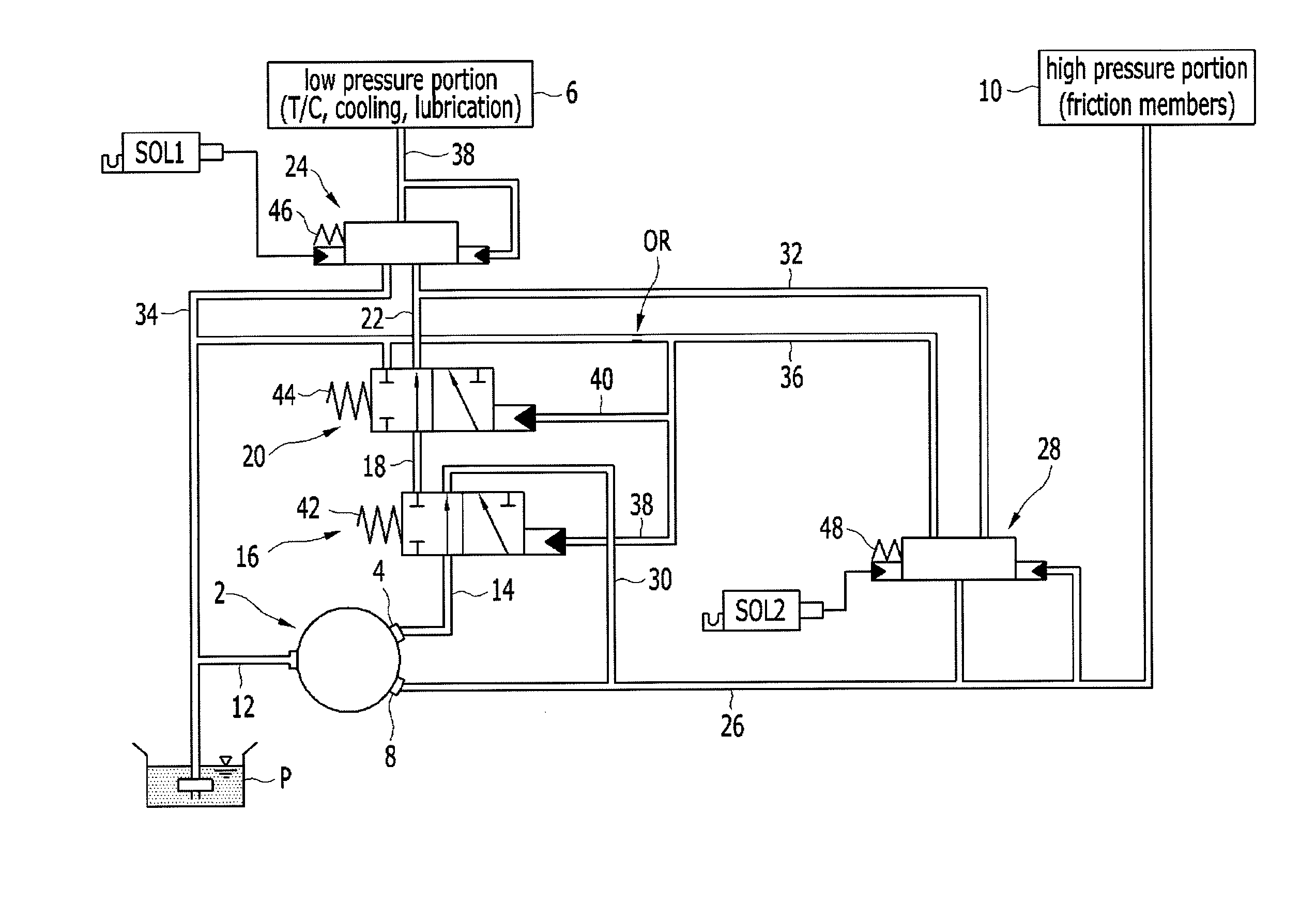

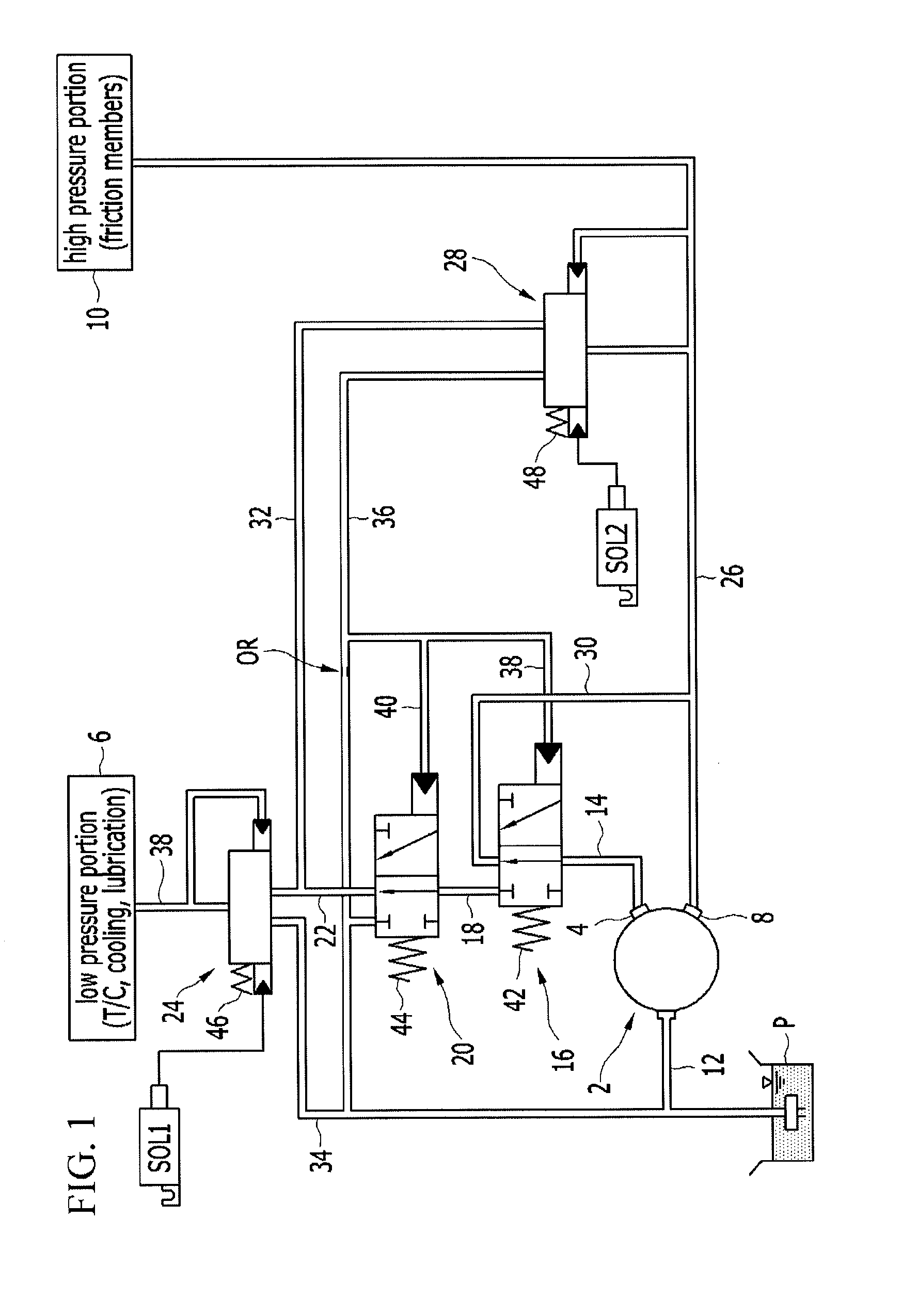

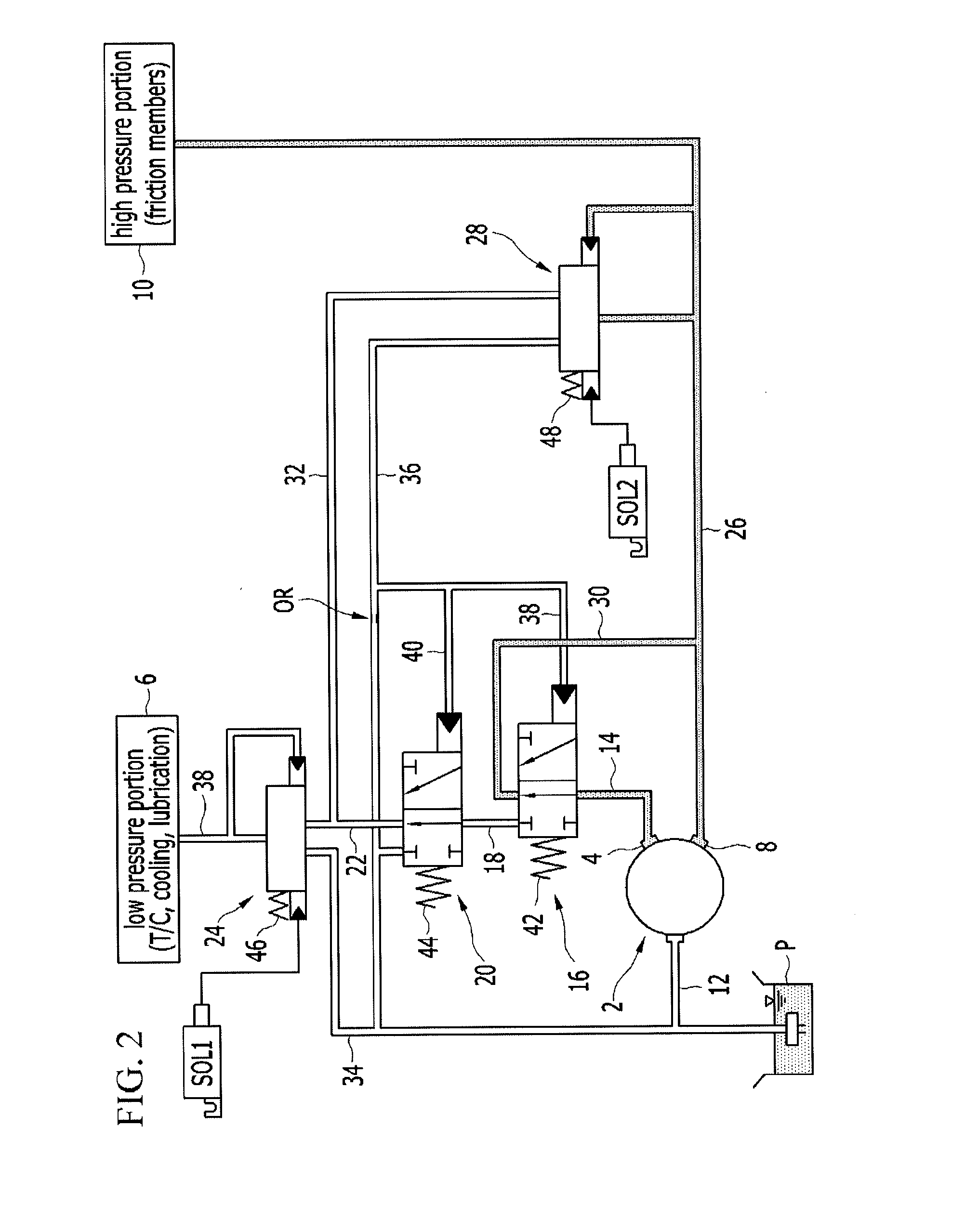

Hydraulic pressure supply system of automatic transmission for vehicle

ActiveUS9500277B2Minimizing driving lossImprove fuel economyGear lubrication/coolingGearing controlAutomatic transmissionHydraulic pump

A hydraulic pressure supply system of an automatic transmission for a vehicle may include a hydraulic pump receiving oil stored in an oil pan through an input line, generating hydraulic pressure, and discharging the generated hydraulic pressure in the oil through a low-pressure discharge port and a high-pressure discharge port, a first switch valve switching a first switch hydraulic line in order to supply the hydraulic pressure discharged from the low-pressure discharge port of the hydraulic pump selectively to the low pressure portion or the high pressure portion, a second switch valve switching a second switch hydraulic line in order to selectively supply the hydraulic pressure supplied from the first switch valve to the low pressure portion or to return the hydraulic pressure supplied from the first switch valve to the oil pan, a low-pressure regulator valve, and a high-pressure regulator valve.

Owner:HYUNDAI MOTOR CO LTD

Phosphor composition for a low-pressure discharge lamp with high color temperature

InactiveUS7670507B2Physical improvementEnhances spiritual well-beingDischarge tube luminescnet screensLamp detailsPhosphoric acidManganese

A phosphor composition for a low-pressure discharge lamp with a high light yield and a high color temperature contains phosphors which emit in the red wavelength region, including yttrium oxide doped with europium or gadolinium-zinc-magnesium pentaborate doped with cerium and manganese, phosphors which emit in the green wavelength region including lanthanum phosphate doped with cerium and terbium and / or cerium-magnesium aluminate doped with terbium and / or cerium-magnesium pentaborate doped with terbium, and optionally a phosphor which emits in the blue wavelength region of the barium-magnesium aluminate doped with europium type. The phosphor composition additionally contains at least one phosphor which emits in the blue or blue-green wavelength region selected from the group consisting of manganese-strontium-barium-magnesium aluminate doped with manganese and europium or barium-magnesium aluminate doped with europium and manganese and strontium aluminate doped with europium and strontium-barium-calcium chloroapatite doped with europium and strontium borophosphate doped with europium.

Owner:LEDVANCE GMBH

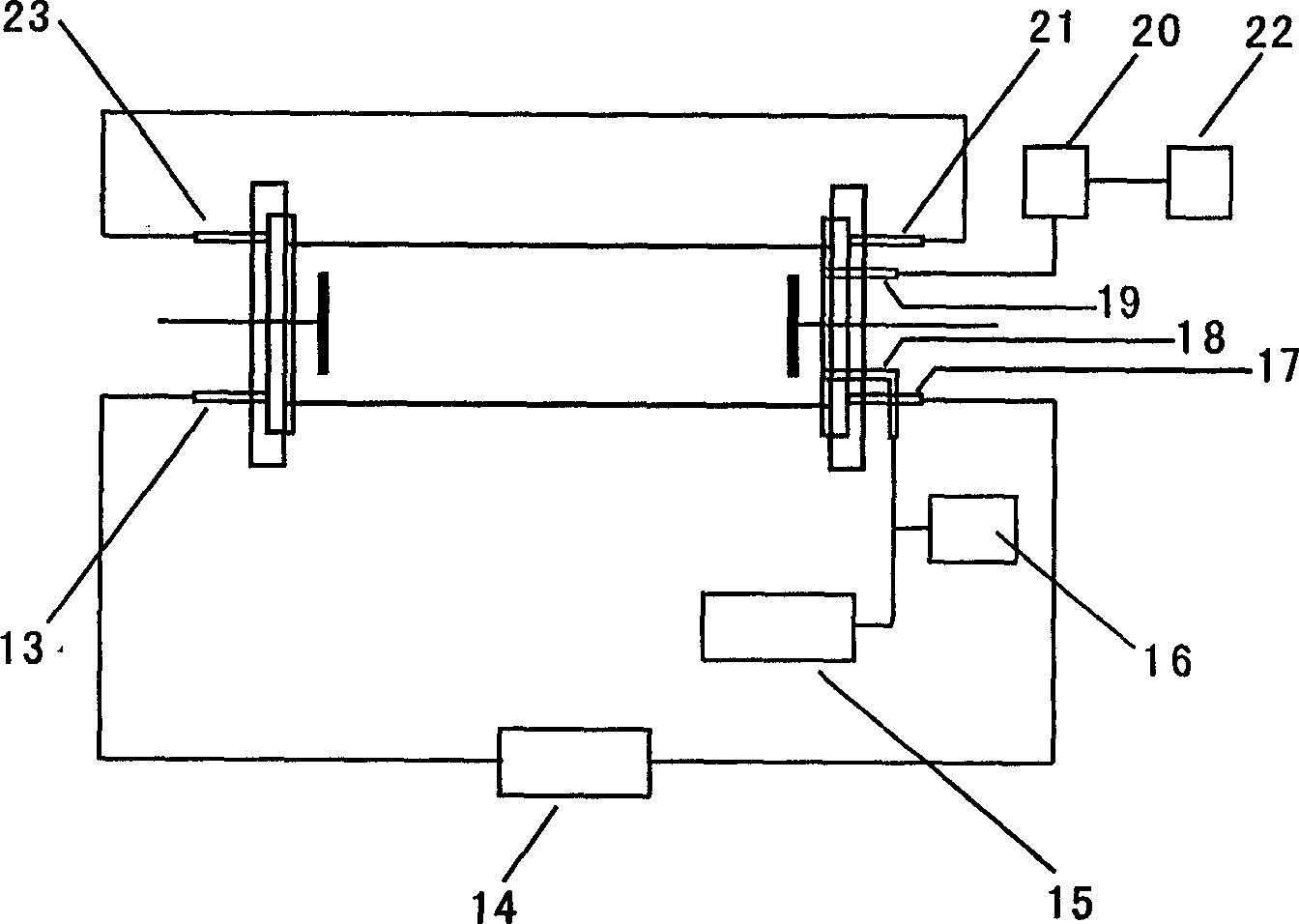

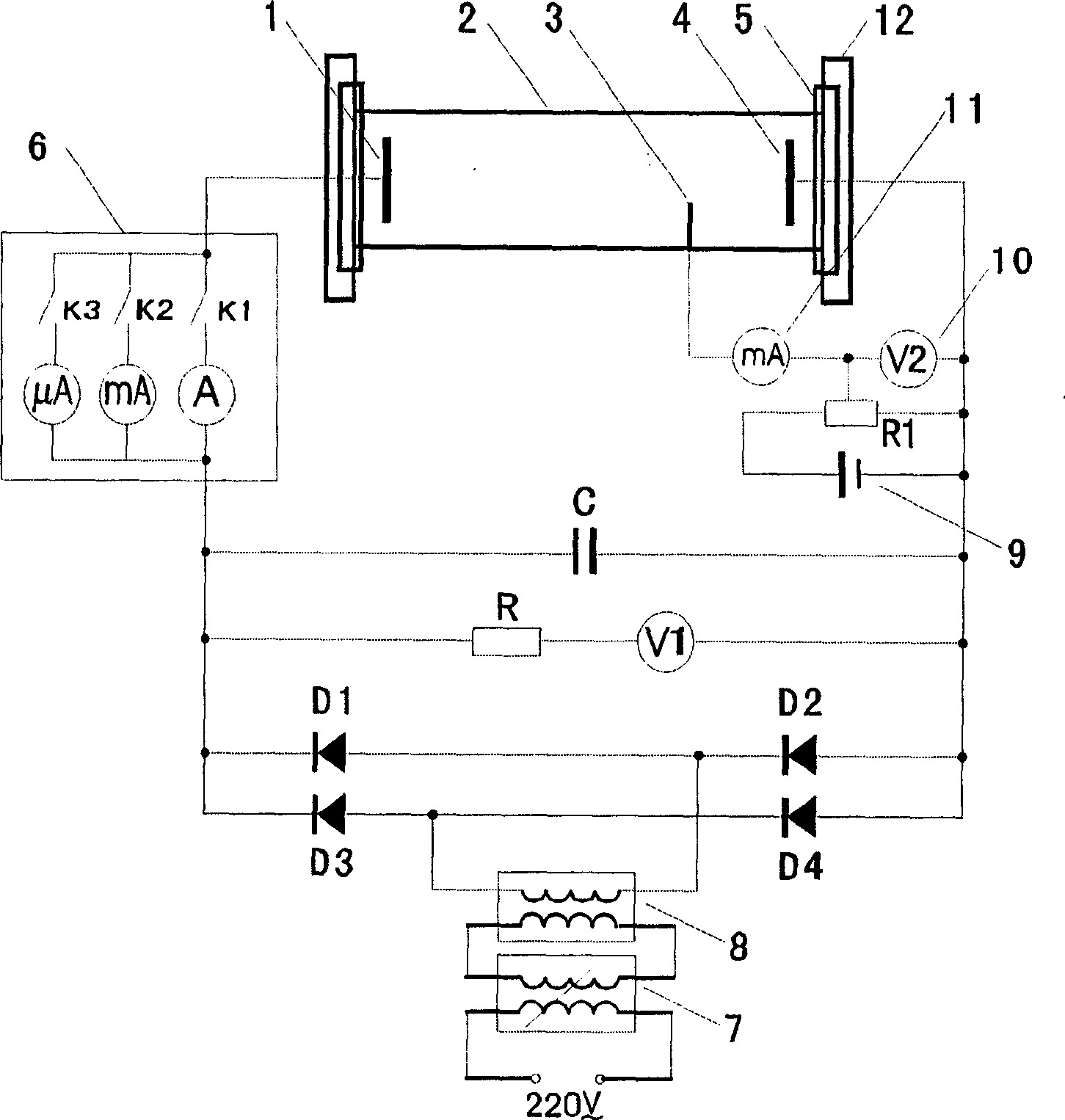

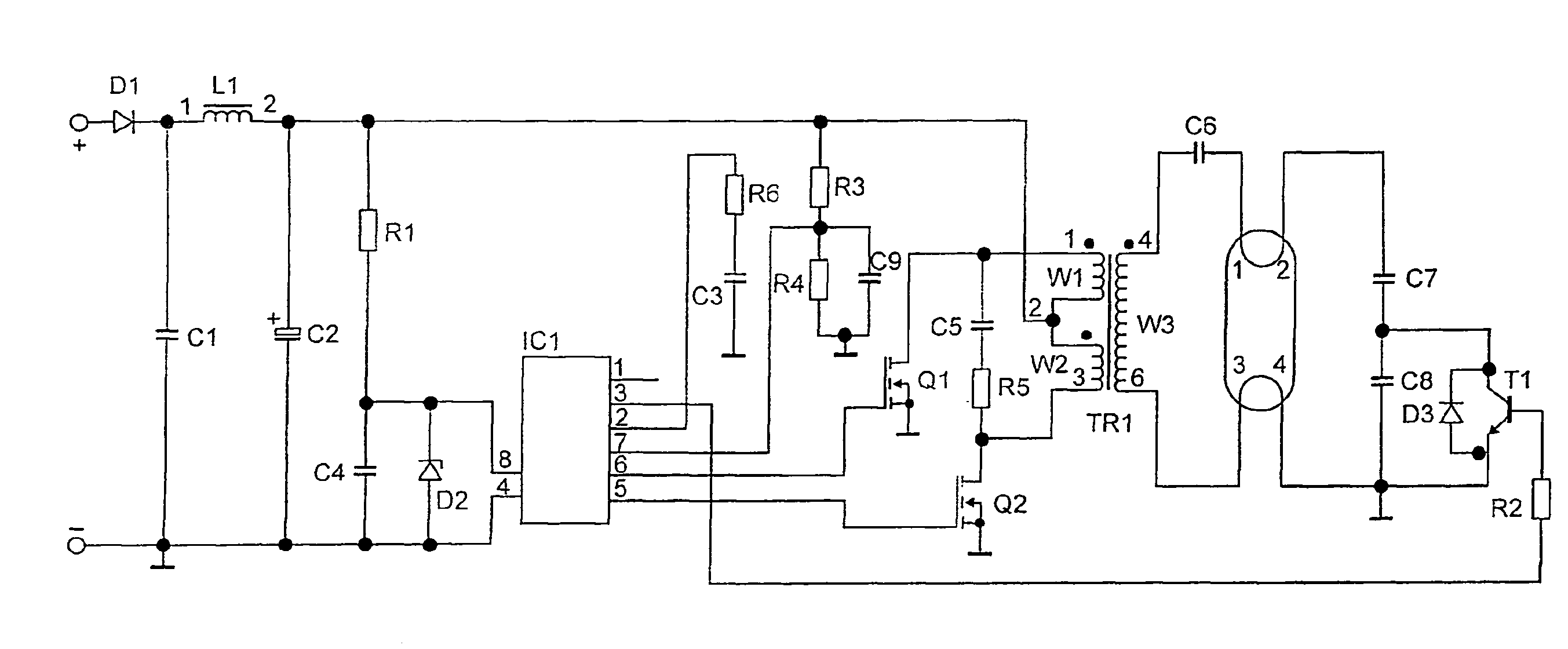

Experiment apparatus for researching DC glow plasma

InactiveCN1825388ATransparent structureSuitable for researchEducational modelsLow voltageEngineering

The invention is a test device for researching a direct current (DC) glow plasma, mainly comprising DC glow discharge mechanism and supporting circuit, where the glow discharge mechanism at least comprises a low voltage discharge tube embedded with discharge electrodes, embedded with test probe and provided with gas intake and gas charging inlet as well as charged with at least one operating gas of air, H2, CO2, and N2, the gas intake is connected to a vacuum pump and able to keep the vacuum in the low voltage discharge tube at 10Pa-400Pa, and the gas charging inlet is connected through a flowmeter to an operating gas source, two axial ends in the low voltage discharge tube are provided with discharge electrodes moving in the 50-150 mm range of the axis and two ends of the low voltage discharge tube are fixed through two brackets and provided with two water cooled seats each connected through circulating water to a circulating pump; and the invention has characters of compact structure, convenient to operating, very high cost / trade-off, suitable to make batch production, beneficial to spreading, etc.

Owner:HANGZHOU DAHUA INSTR MFG CO LTD

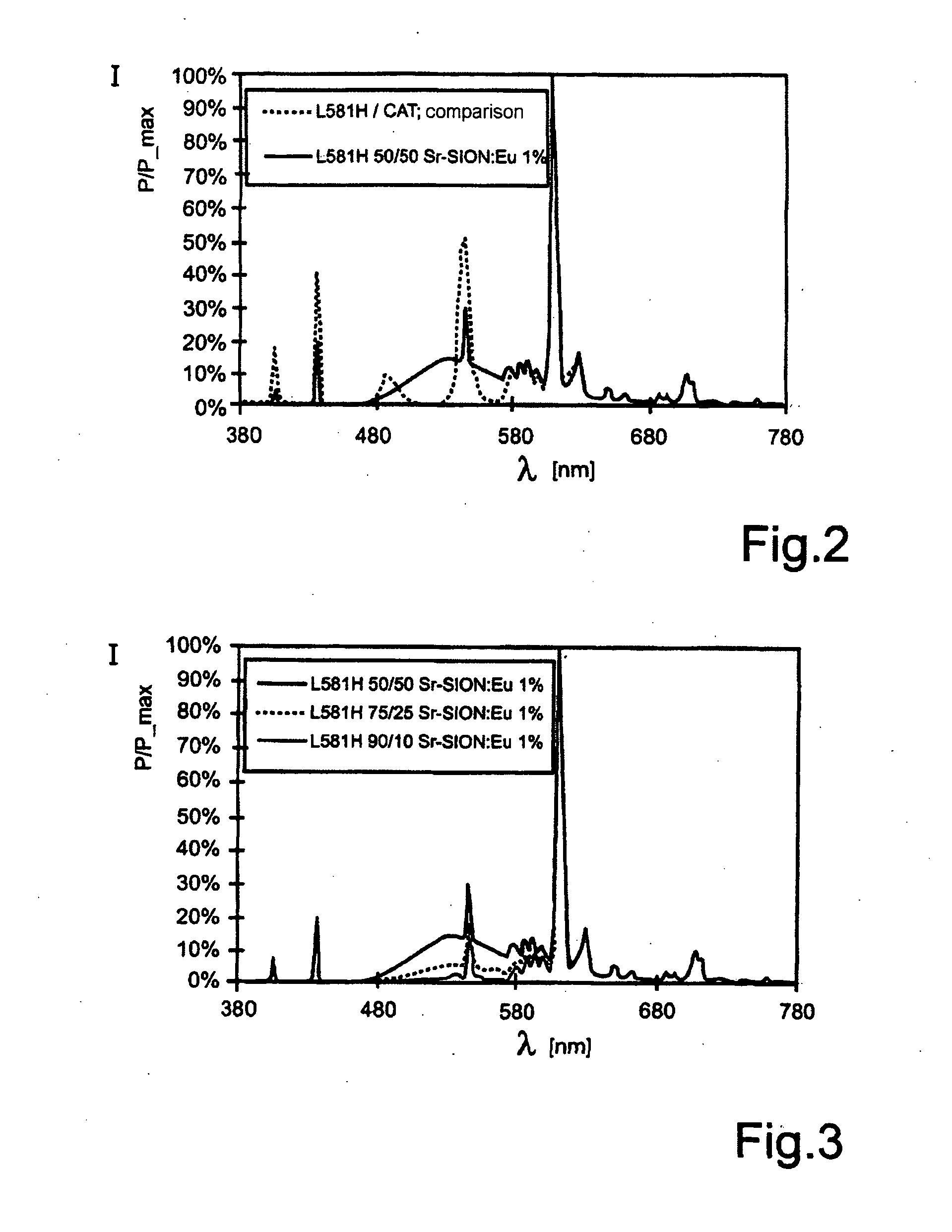

Illuminant mixture for a discharge lamp and discharge lamp, in particular an hg low-pressure discharge lamp

InactiveUS20100141114A1Low color temperatureSolve low luminous efficiencyDischarge tube luminescnet screensLamp detailsOptoelectronicsLow-pressure discharge

The invention relates to an illuminant mixture for a discharge lamp (1) with a first and second illuminant compound, said first illuminant compound having an emission spectrum in the yellow and / or green spectral range and being designed to absorb the UV radiation emitted by an Hg source and to absorb the radiation emitted by the Hg source in the blue spectral range. The invention also relates to a discharge lamp comprising an illuminant layer containing the aforementioned illuminant mixture.

Owner:OSRAM GMBH

Electronic ballast

InactiveUS7675242B2Low production costUniform lightElectrical apparatusElectric lighting sourcesTransformerEngineering

An electronic ballast for the operation of a lamp arrangement includes at least one lamp, in particular, a low-pressure discharge lamp and at least one transformer for balancing the lamp currents, whereby the transformer has two windings, provided for one or more lamps of the lamp arrangement. The transformer is embodied as a saturation balancing choke.

Owner:OSRAM GMBH

Process for separating magnesium sulfate monohydrate from magnesium-containing solution and equipment thereof

InactiveCN106946276AAccurate separationEfficient separationMagnesium sulfatesSolubilitySodium sulfate

A process and equipment for separating magnesium sulfate monohydrate in magnesium-containing solution, it relates to a chemical separation and extraction of magnesium sulfate monohydrate equipment and process, in particular to a process for separating magnesium sulfate monohydrate in magnesium-containing solution and its equipment. The feed port of the high-temperature and low-pressure crystallization tank is connected to the discharge port of the filter, and the filter is provided with a compressed air inlet. It is connected with heat conduction oil filter and heat conduction oil circulation pump, and the precipitation outlet of the filter is connected to the rotary drying furnace through an automatic centrifuge. The present invention is a method for separating zinc and magnesium based on the different solubility of zinc sulfate and magnesium sulfate in zinc sulfate solution at different temperatures and pressures. The solubility of zinc sulfate changes when the temperature and pressure change. Not much, and magnesium sulfate has a high solubility at low temperature and normal pressure, so this special property of magnesium sulfate is used. The invention makes it possible to apply the magnesium-containing solution in the industries of electrolytic zinc, zinc sulfate, zinc carbonate, active zinc oxide, sodium sulfate, etc., and accurately and efficiently separate the magnesium sulfate monohydrate.

Owner:刘向东

Electronic Ballast For A Low-Pressure Discharge Lamp With A Micro-Controller

InactiveUS20090212712A1High voltageAvoid unnecessary energy consumptionElectrical apparatusElectric light circuit arrangementMicrocontrollerElectronic switch

Owner:OSRAM GMBH

Microwave freeze-drying and dehydrating method of fruits and vegetables

InactiveCN101849573BShort drying time for dehydrationReduce energy consumptionFruit and vegetables preservationMicrowaveFreeze-drying

The invention relates to a microwave freeze-drying and dehydrating method of fruits and vegetables, belonging to the field of a fruit and vegetable food treatment technology. The method comprises the following steps of: cleaning, blanching, pre-drying, freezing, microwave freeze-drying and taking out. The method is suitable for various forms of freeze-drying products, integrates blanching and cooling working procedures into a whole, does not need the cooling working procedure after blanching, not only is thorough to blanch and cool, but also has high speed, especially removes partial internalwater at the same time of removing water on the surface of materials, and avoids forming crystals on the surface of the materials in the freezing process, thereby being beneficial to increasing the microwave freeze-drying speed and effectively restraining the microwave low-pressure discharge problem in the early freeze-drying process.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com