Patents

Literature

333results about "Tube/lamp vessel filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

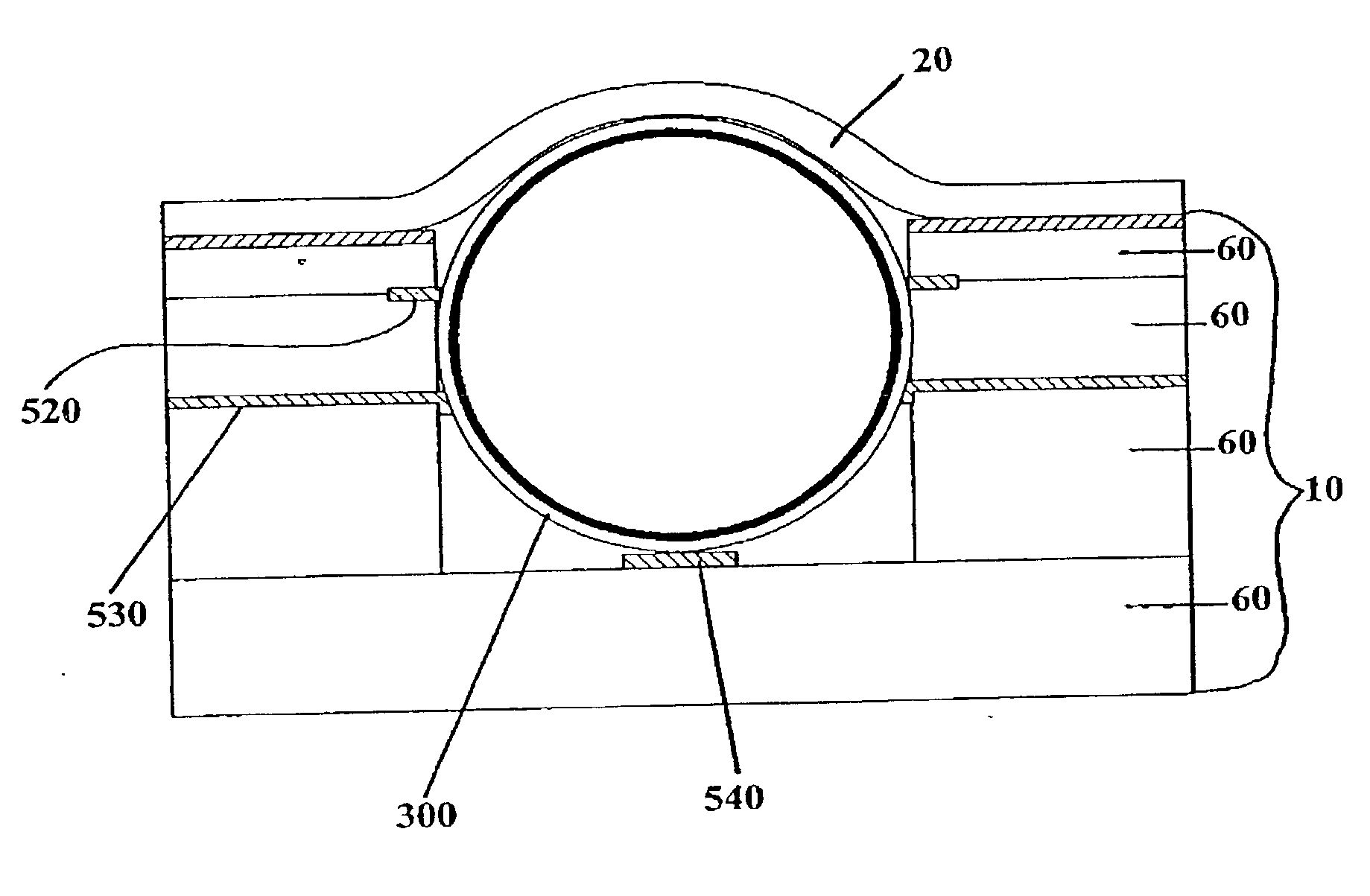

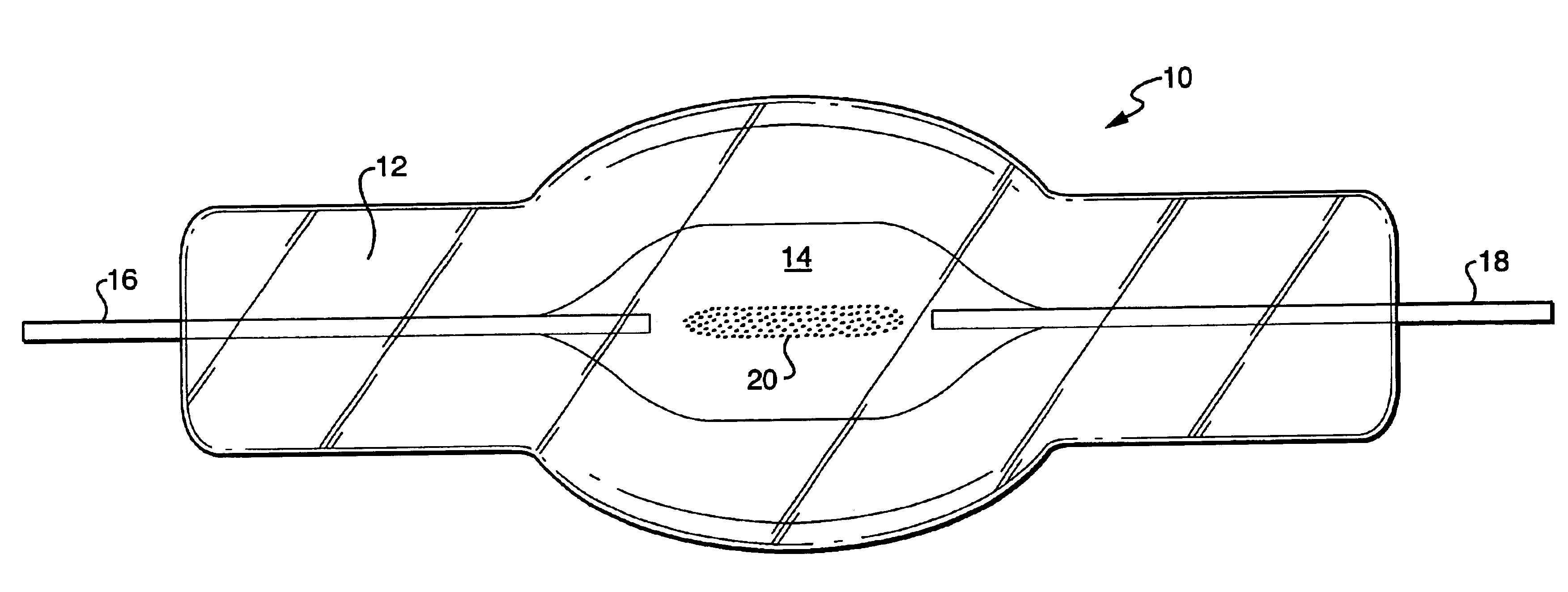

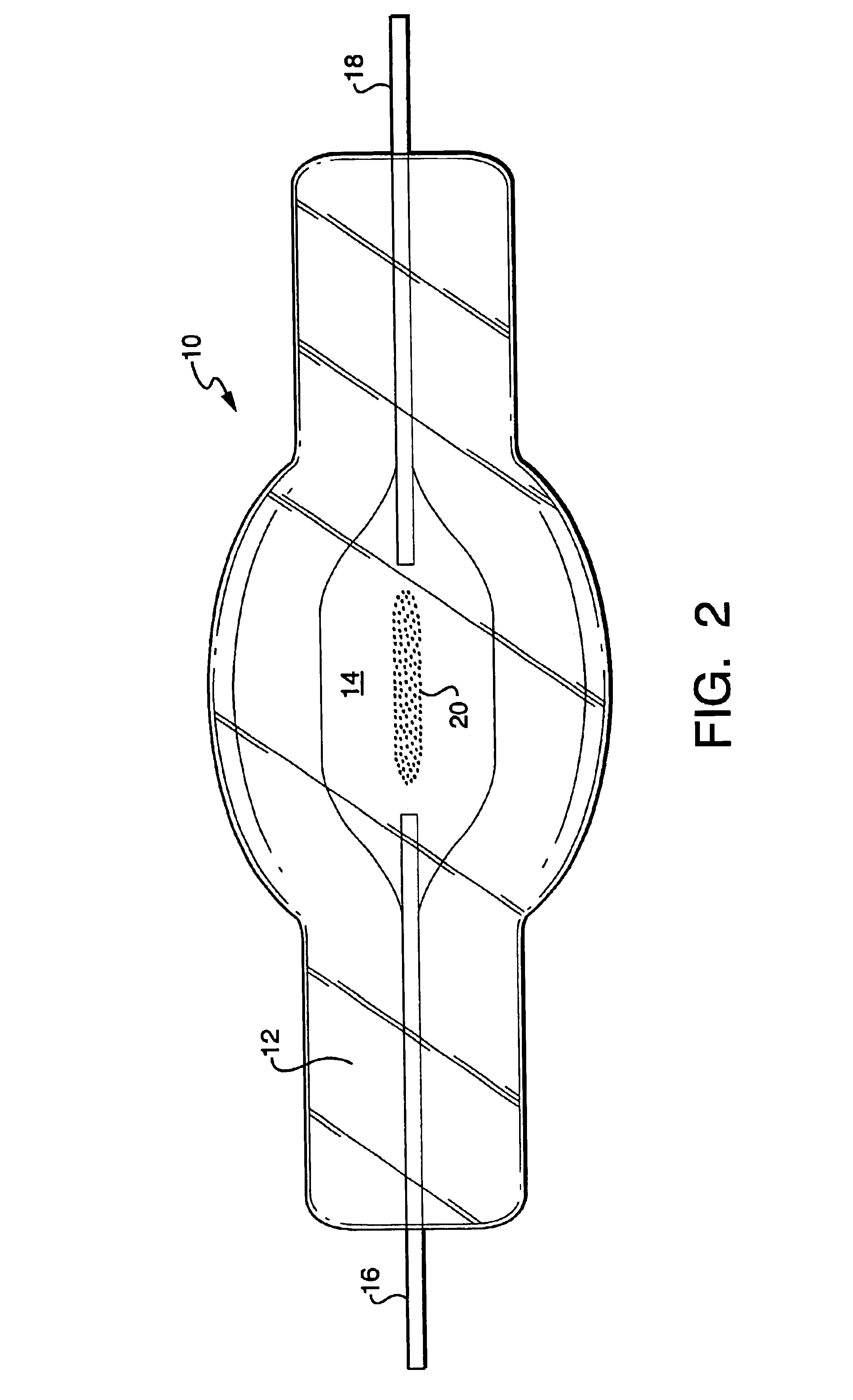

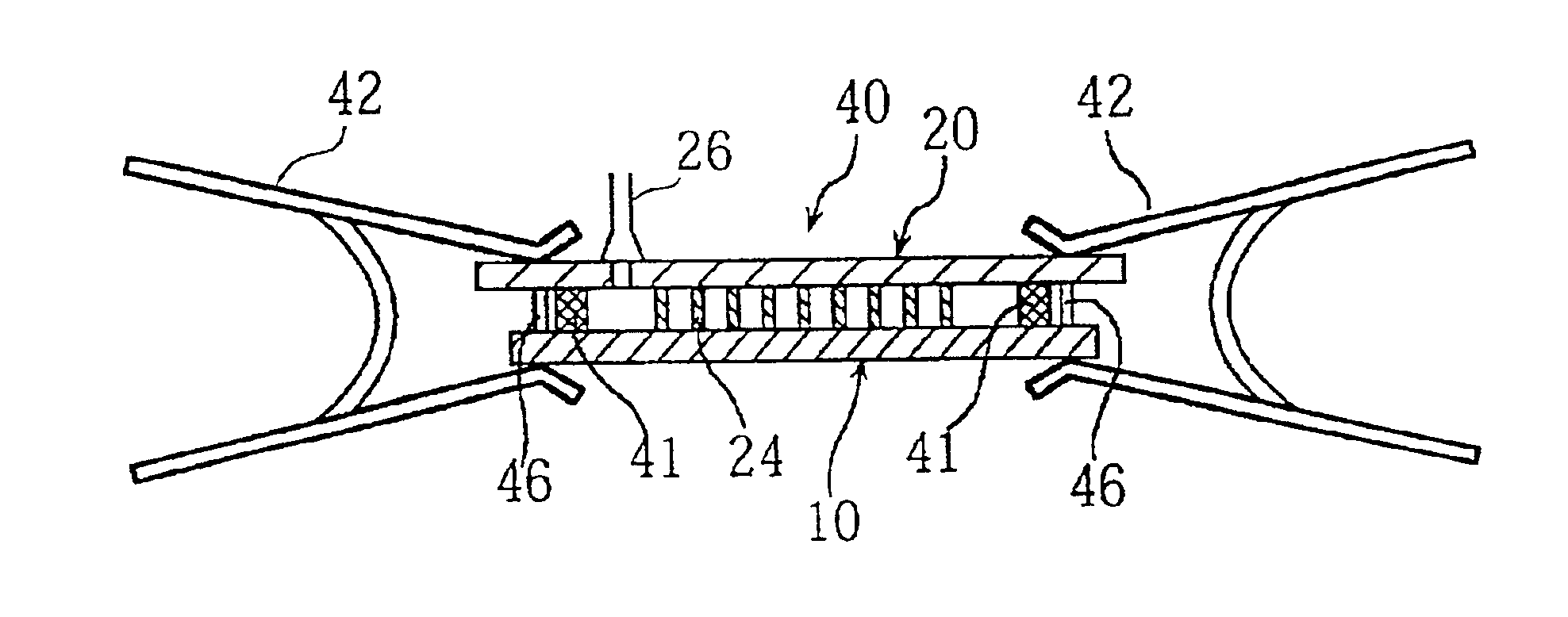

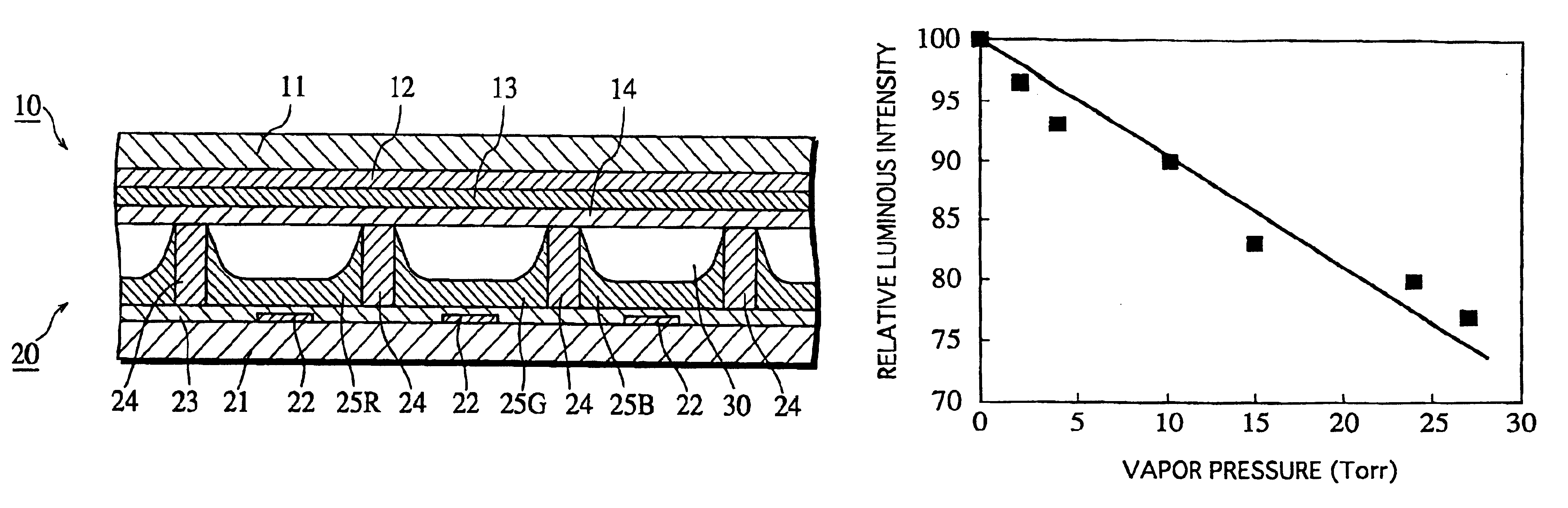

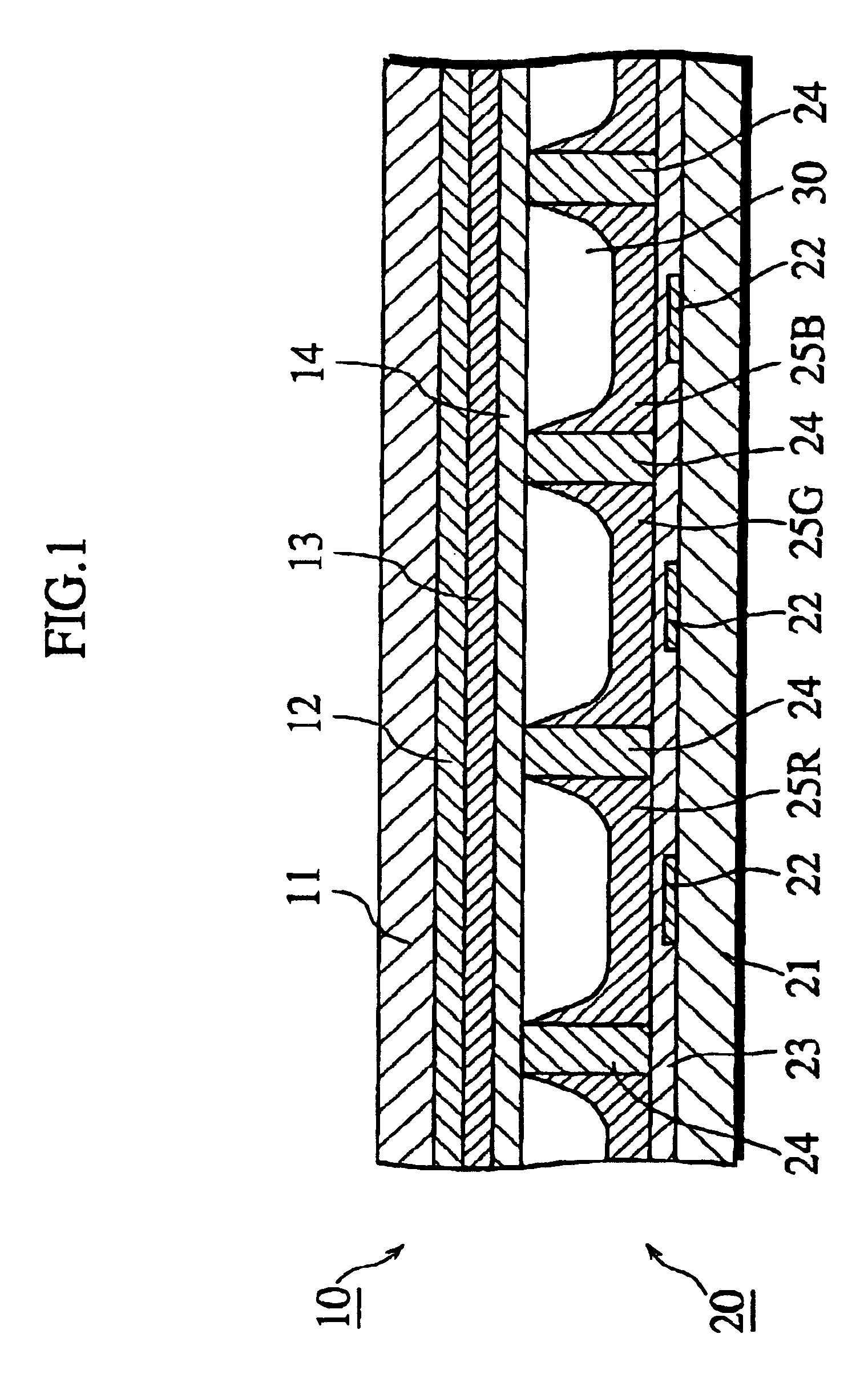

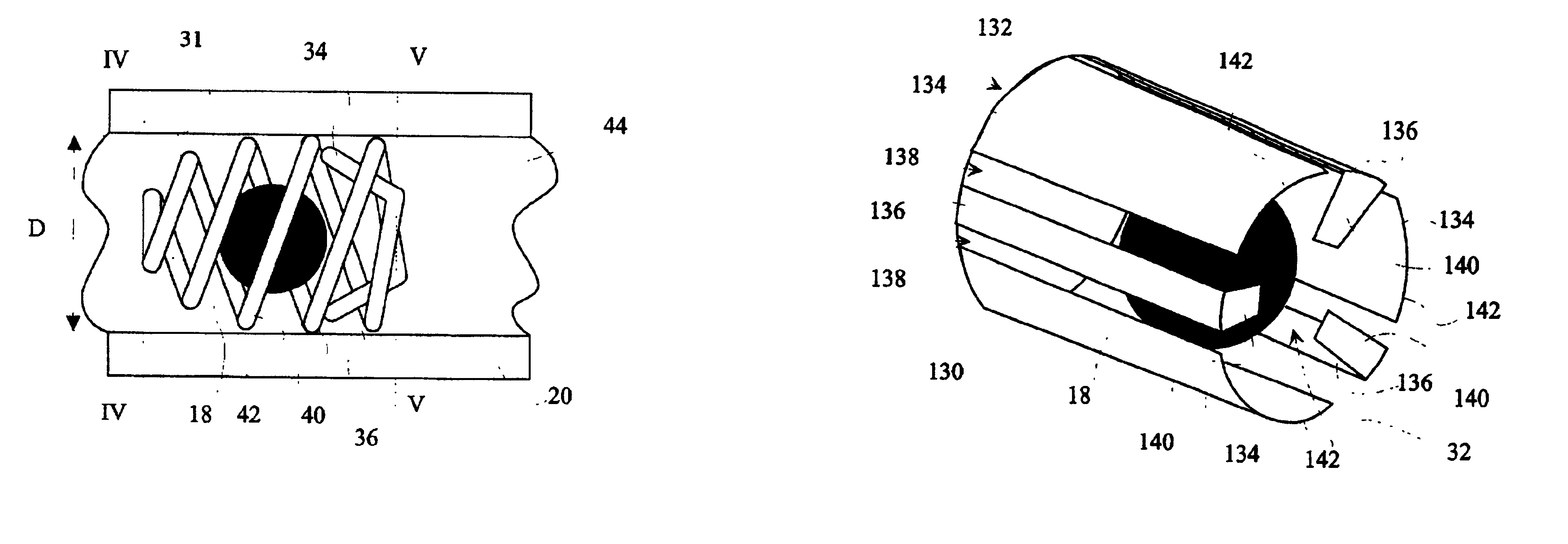

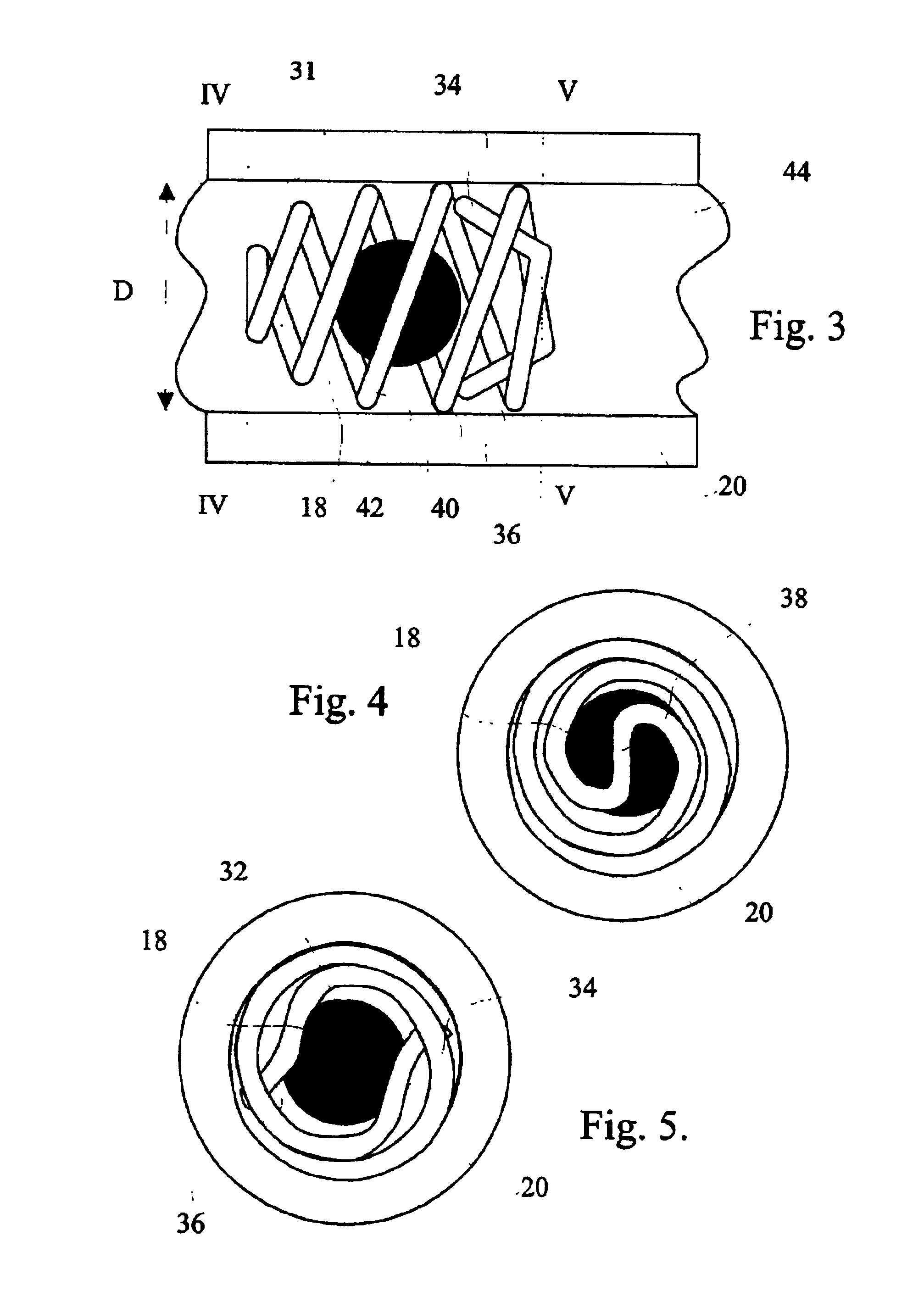

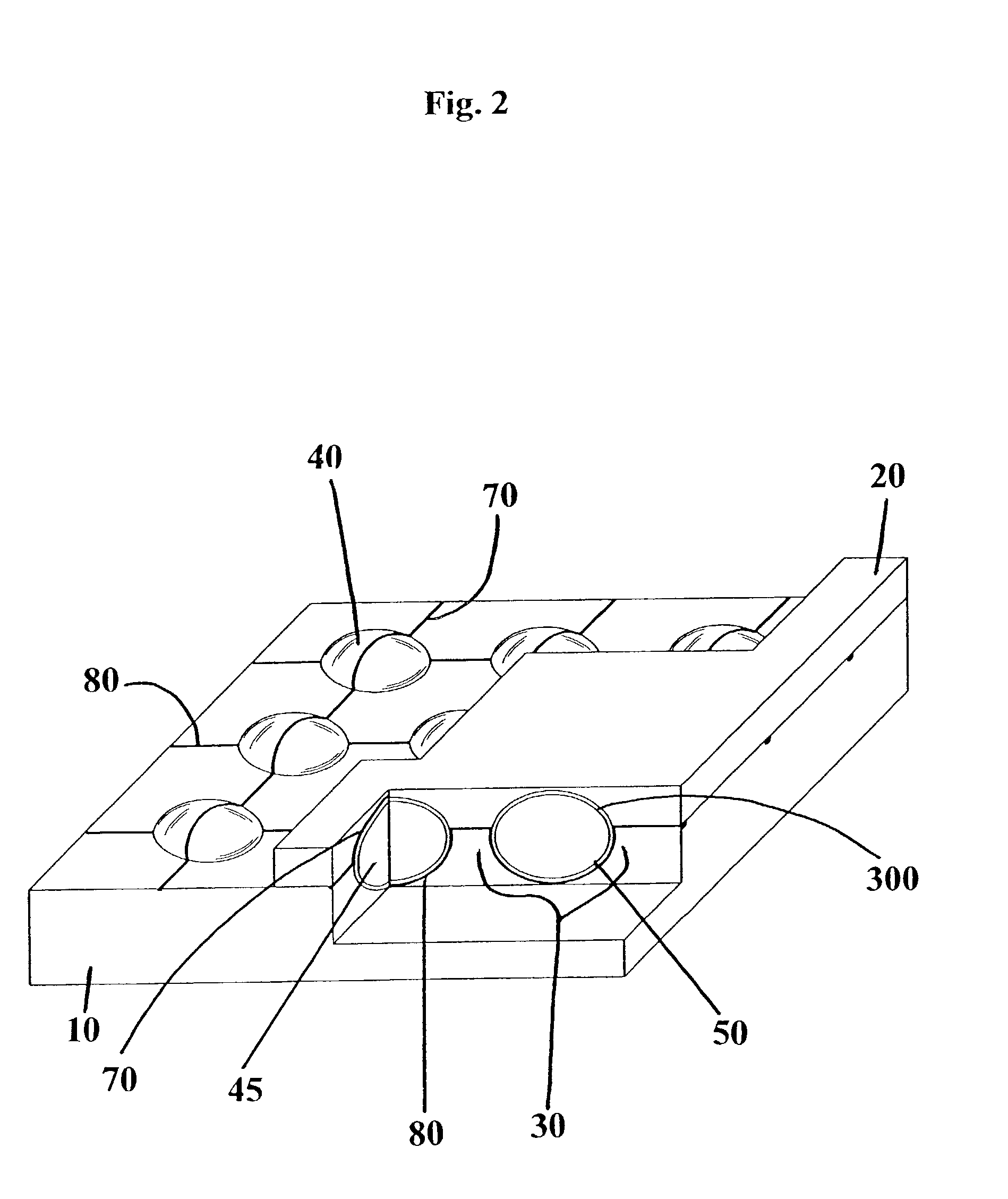

Use of printing and other technology for micro-component placement

InactiveUS6796867B2Sufficient resolutionManufactured very thinTelevision system detailsMechanical apparatusEngineeringImproved method

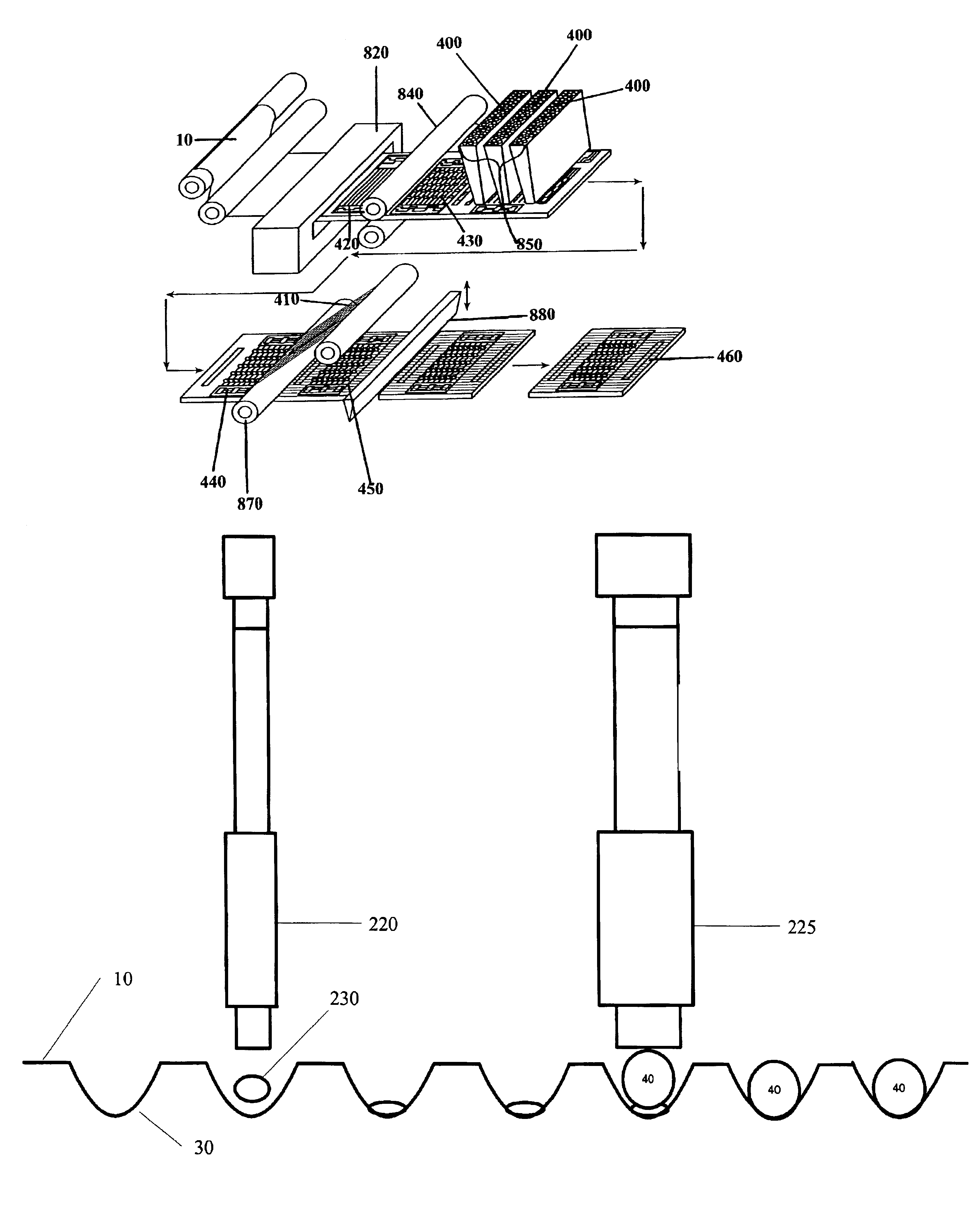

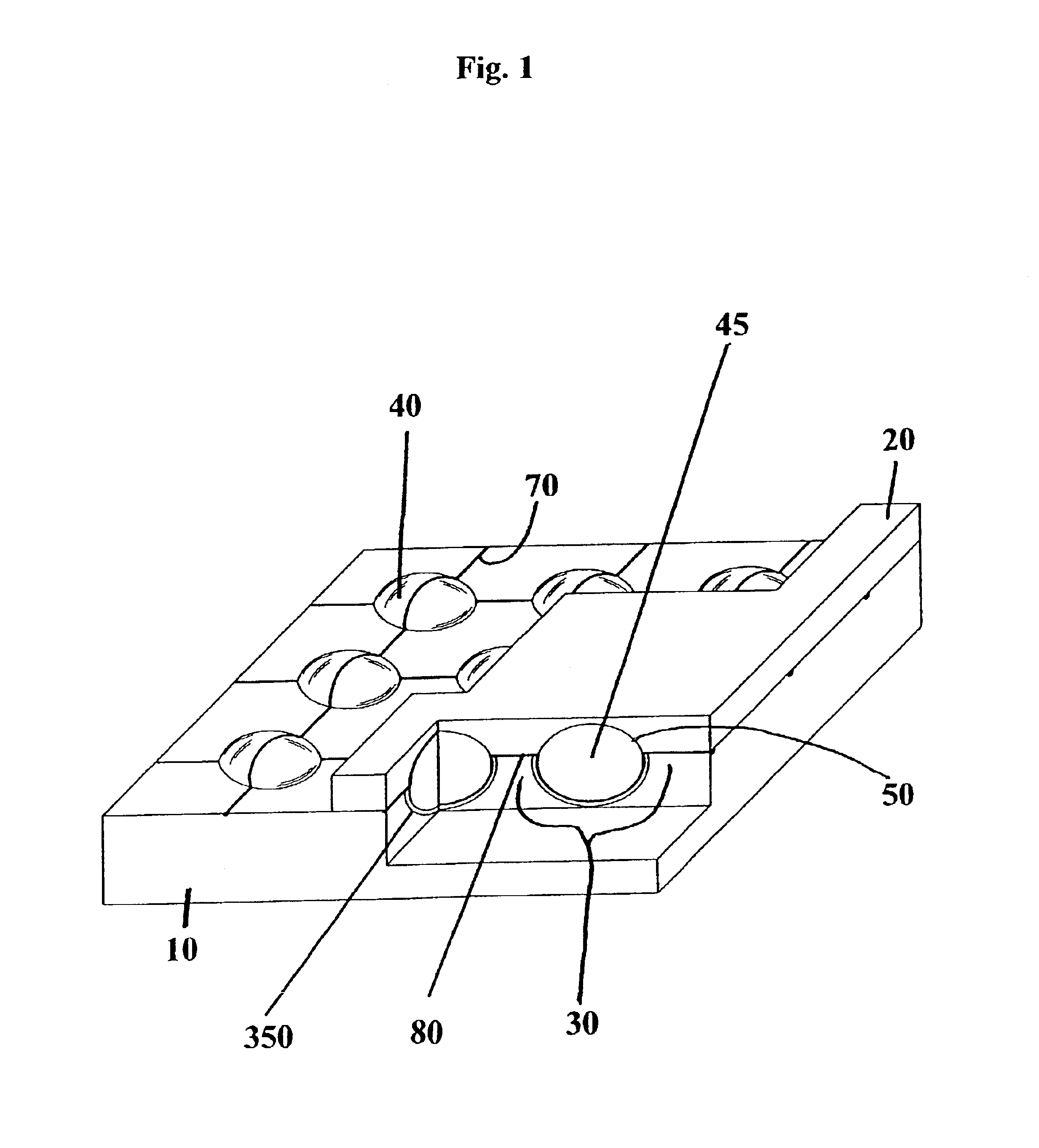

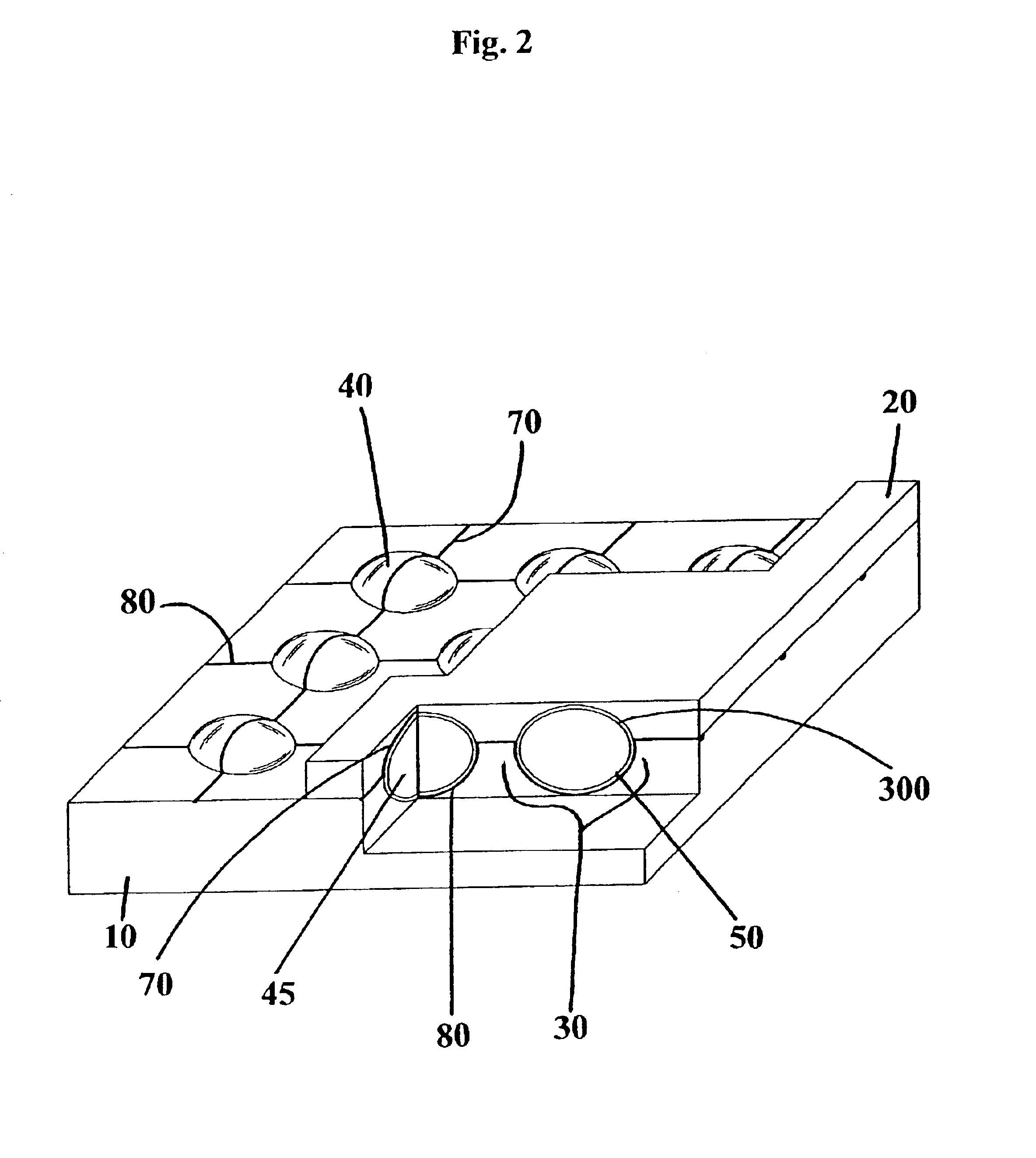

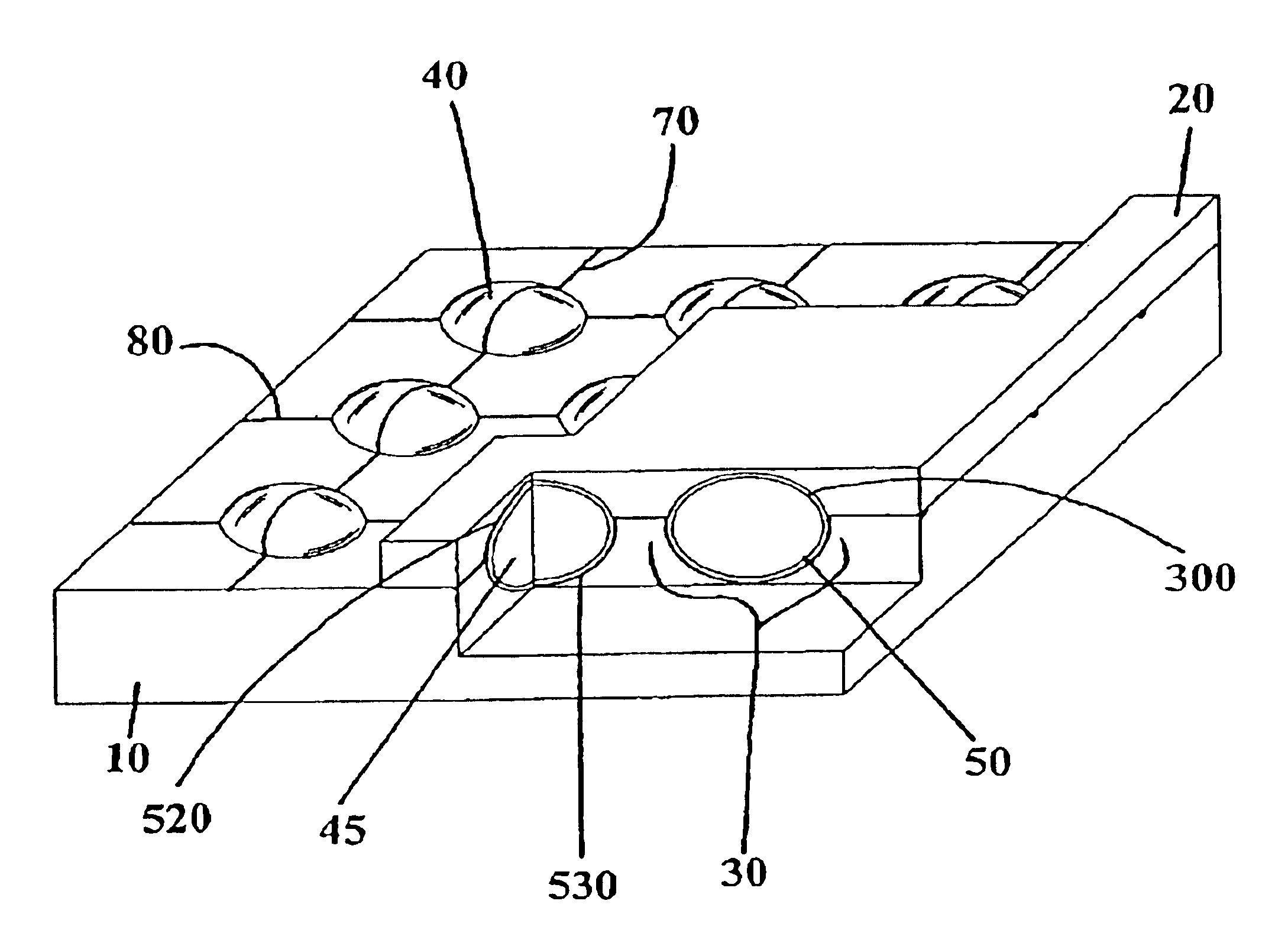

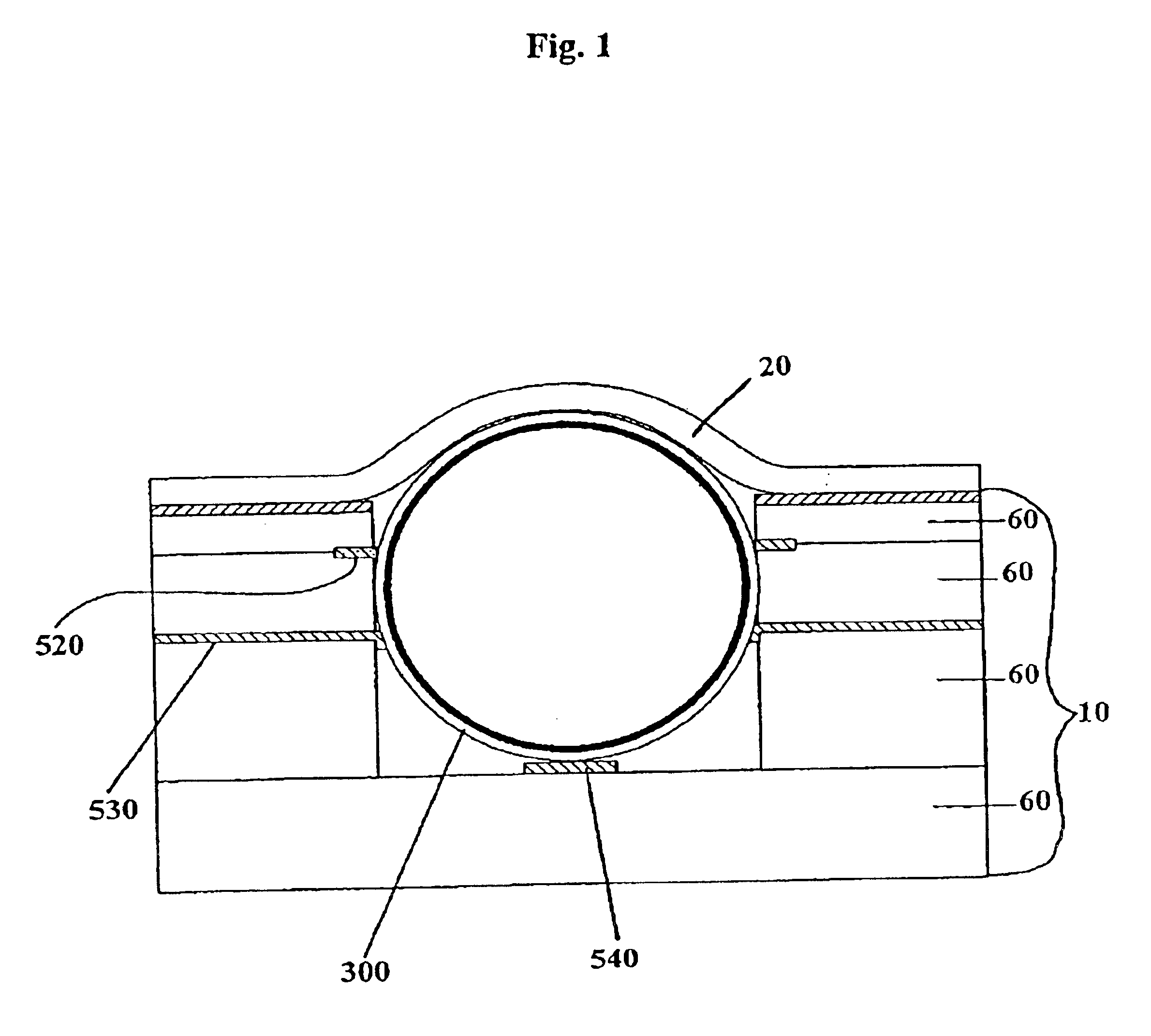

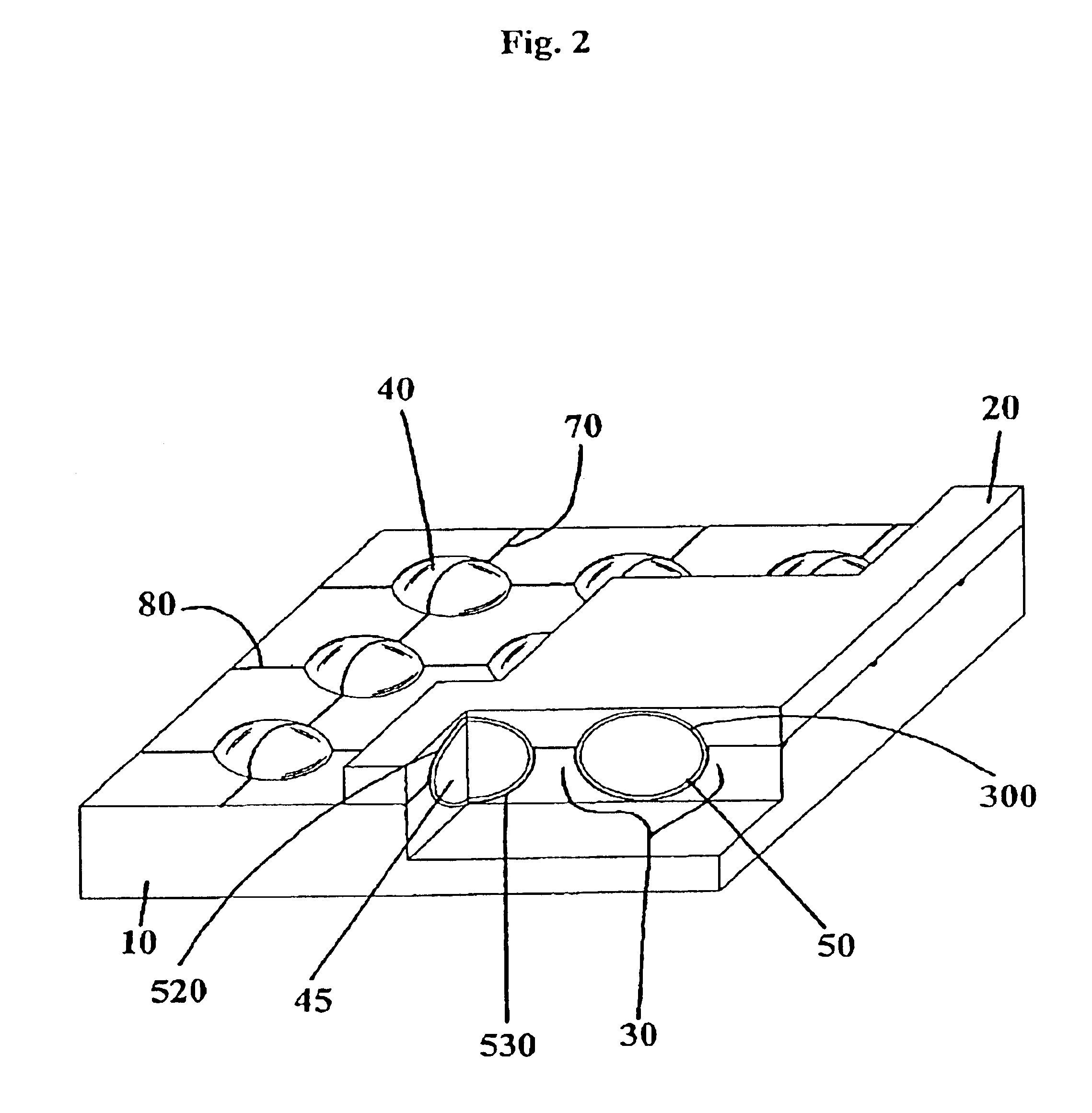

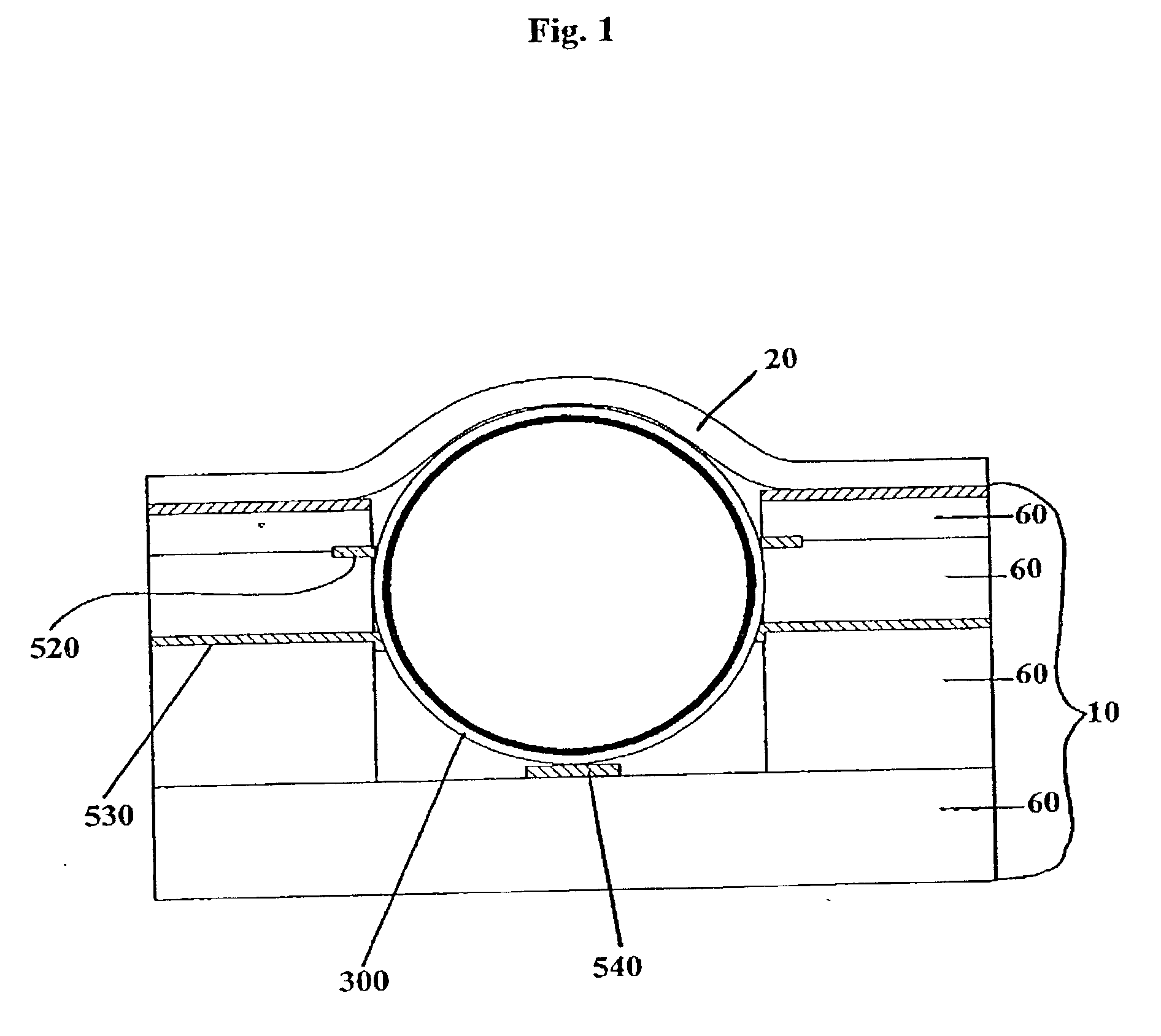

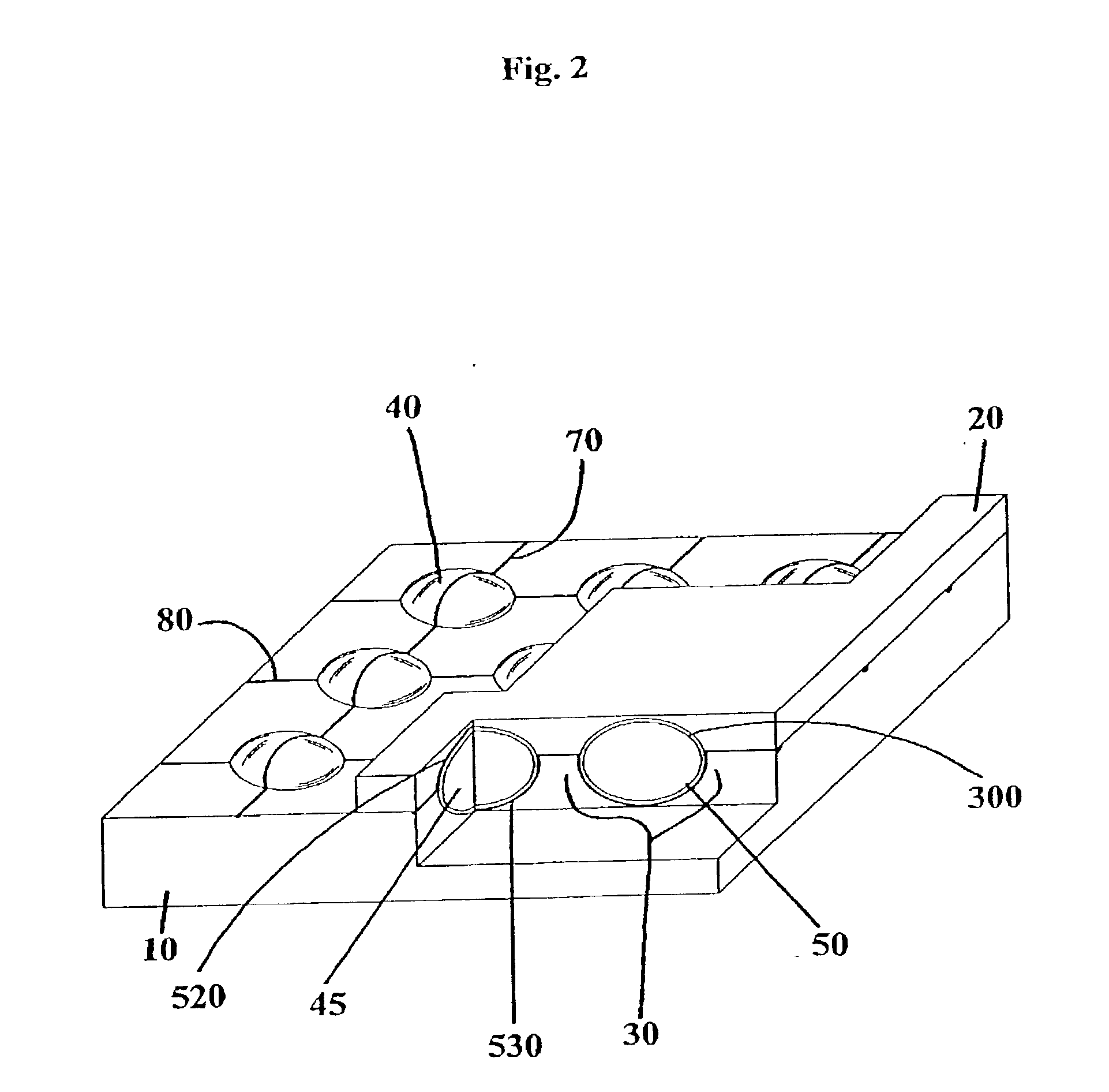

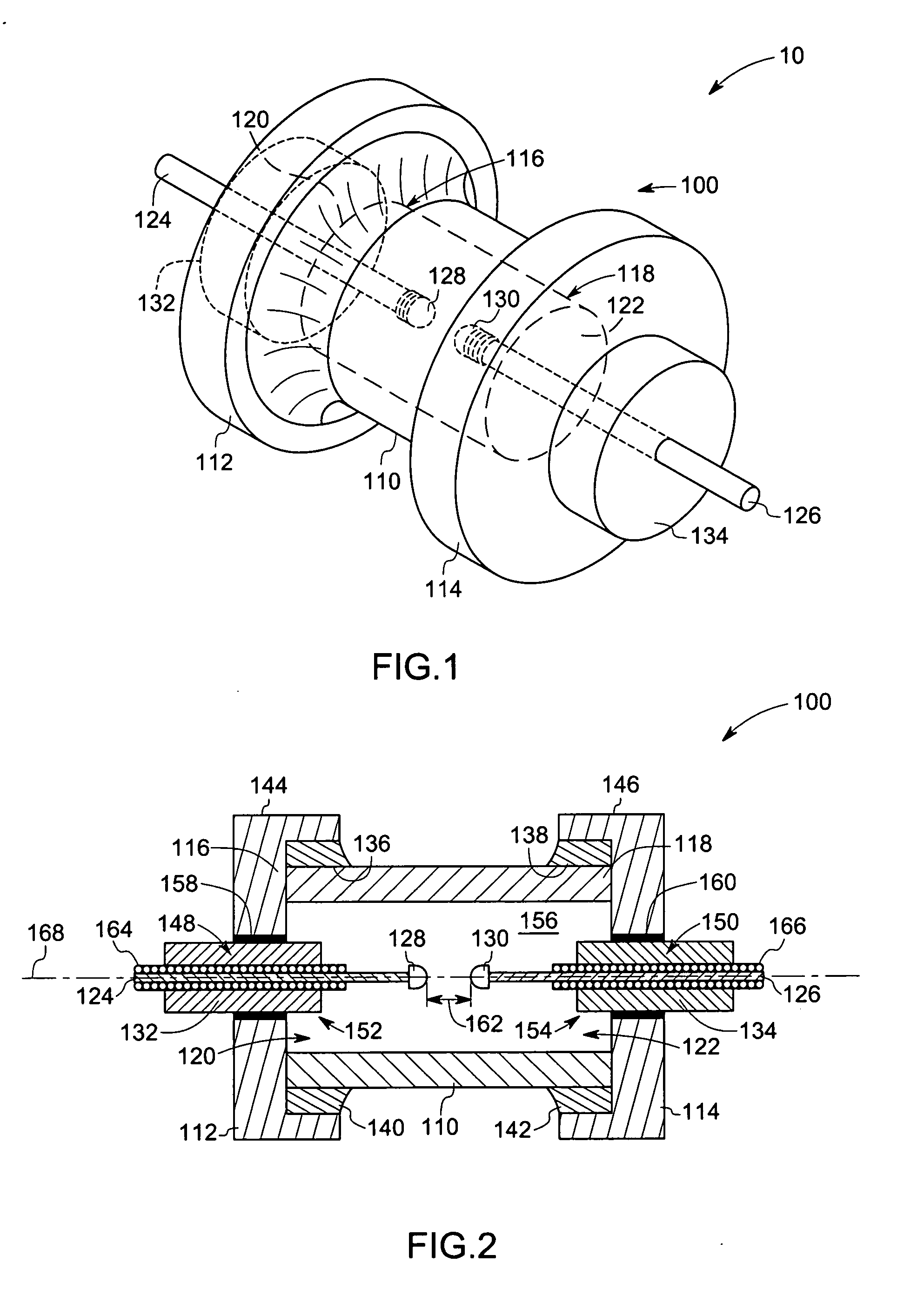

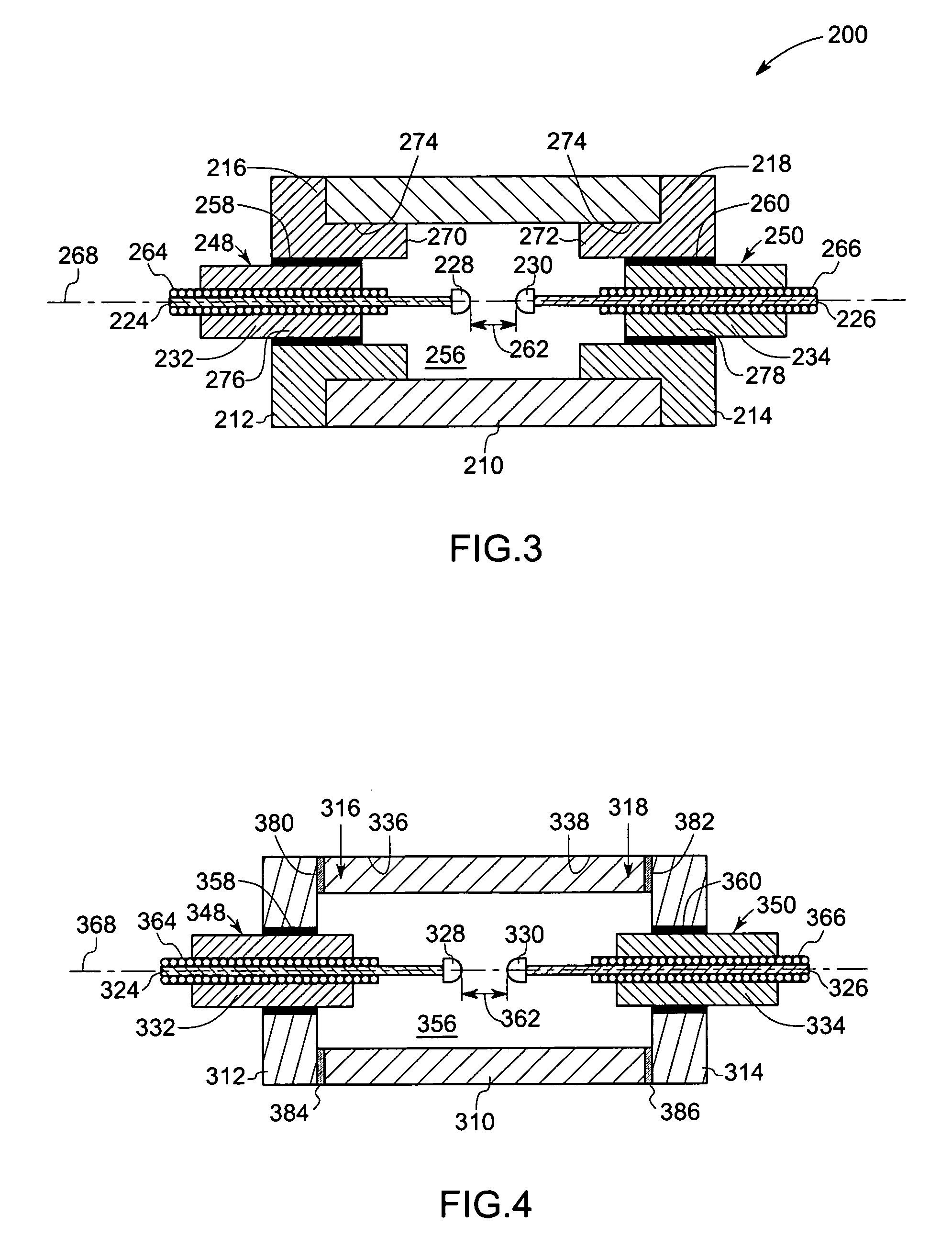

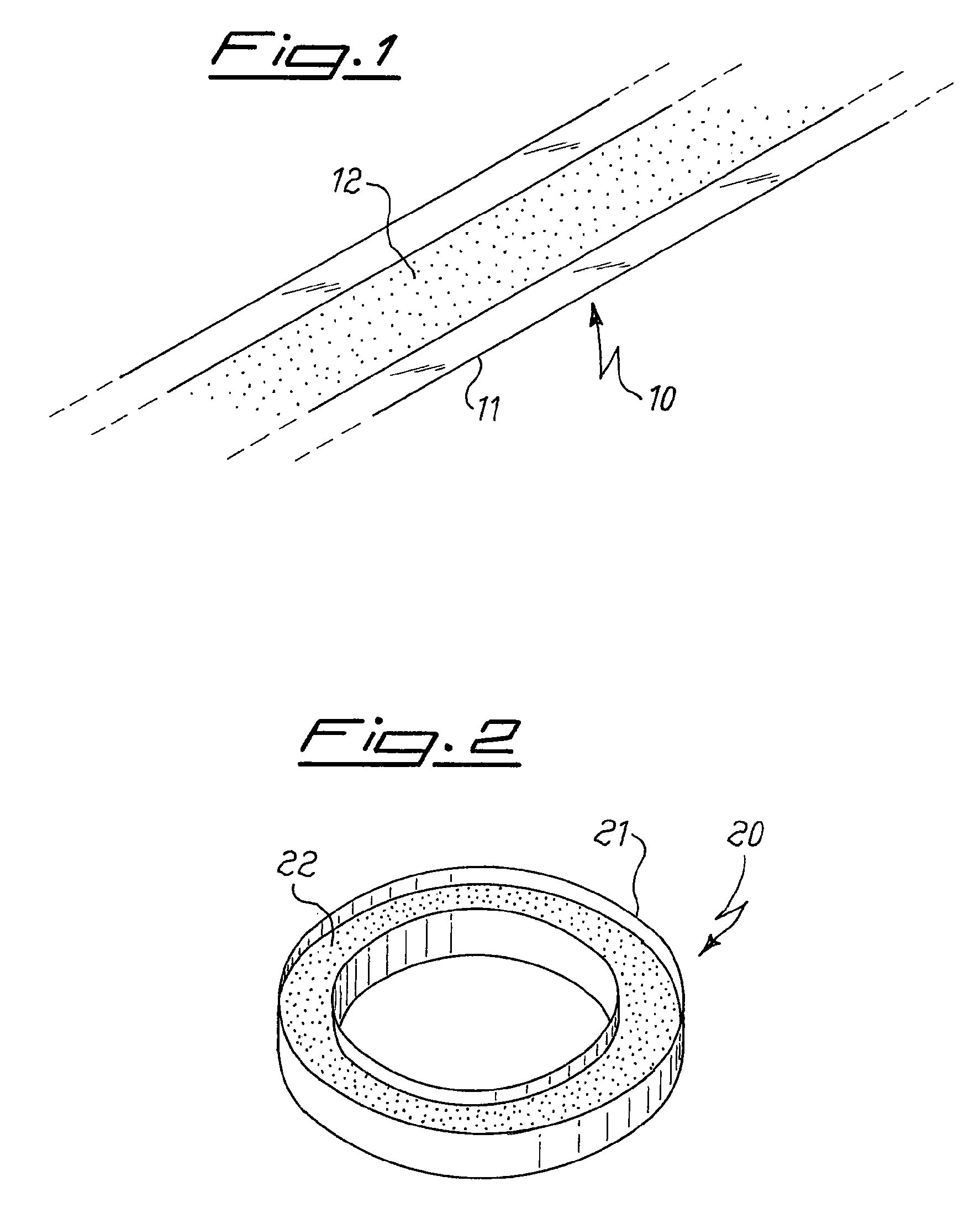

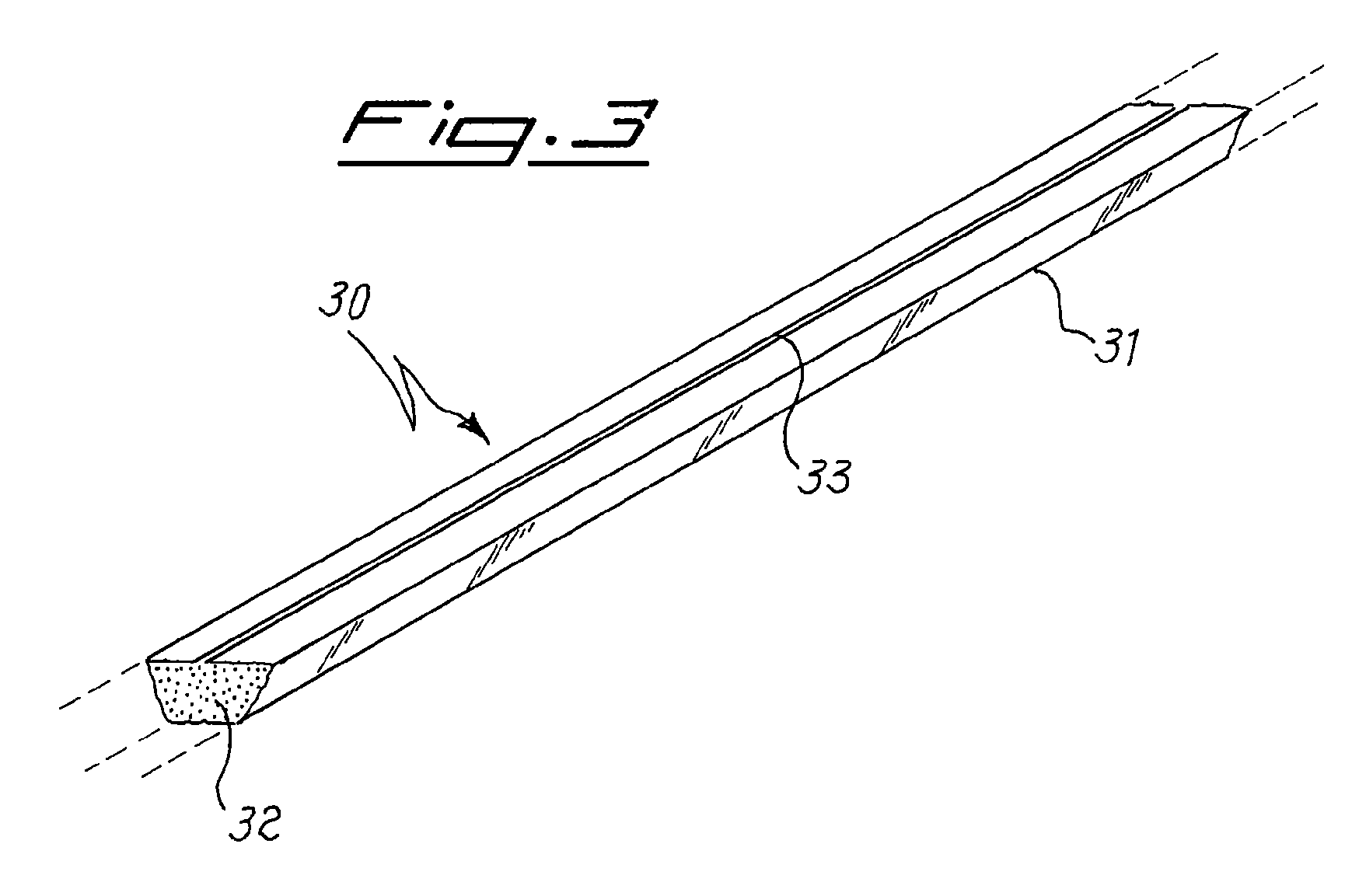

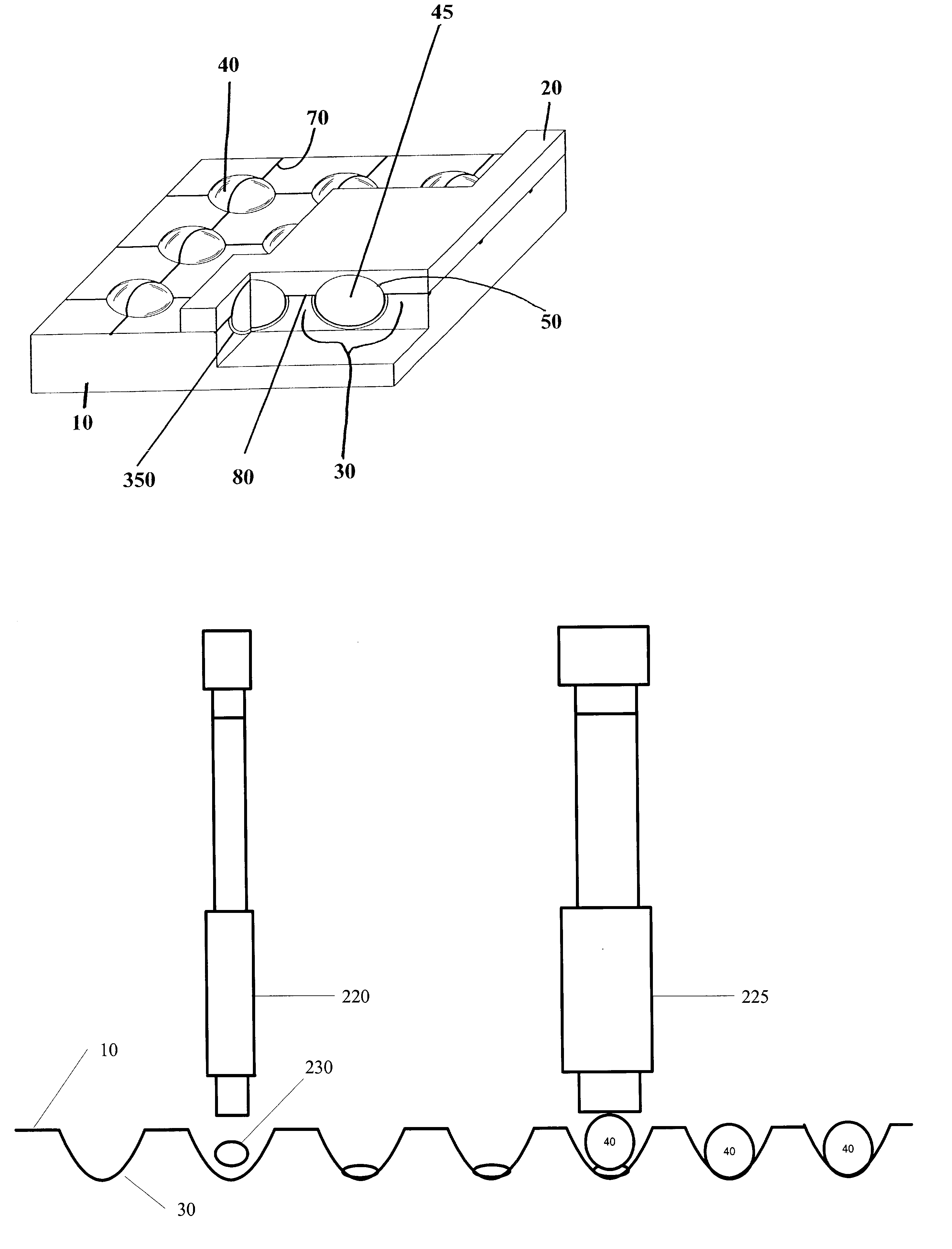

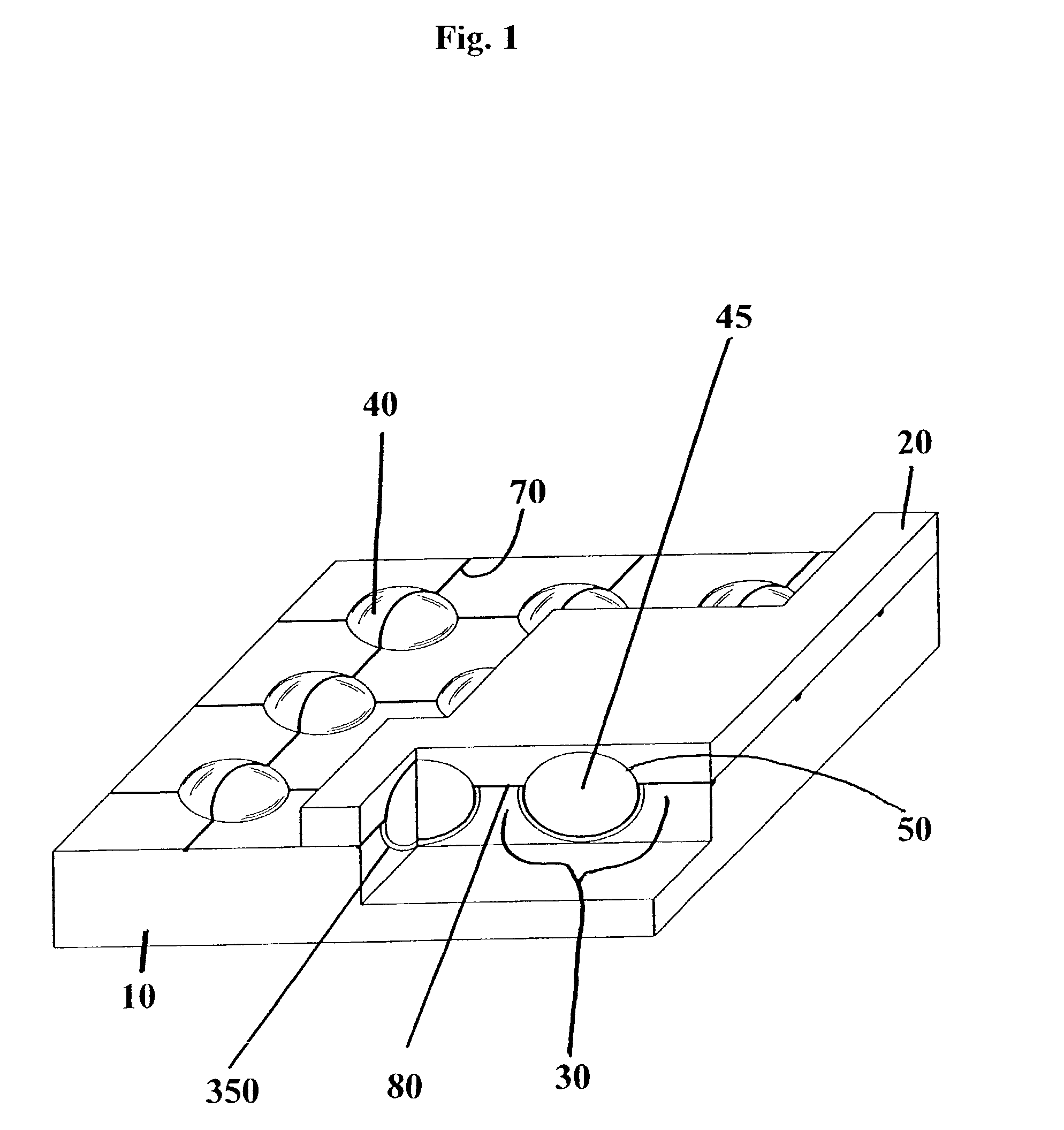

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of manufacturing a light-emitting panel is also disclosed, which uses a web fabrication process to manufacturing light-emitting displays as part of a high-speed, continuous inline process.

Owner:LEIDOS

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS6822626B2Sufficient resolutionManufactured very thinFixed microstructural devicesVolume/mass flow measurementEngineeringPre testing

Owner:LEIDOS

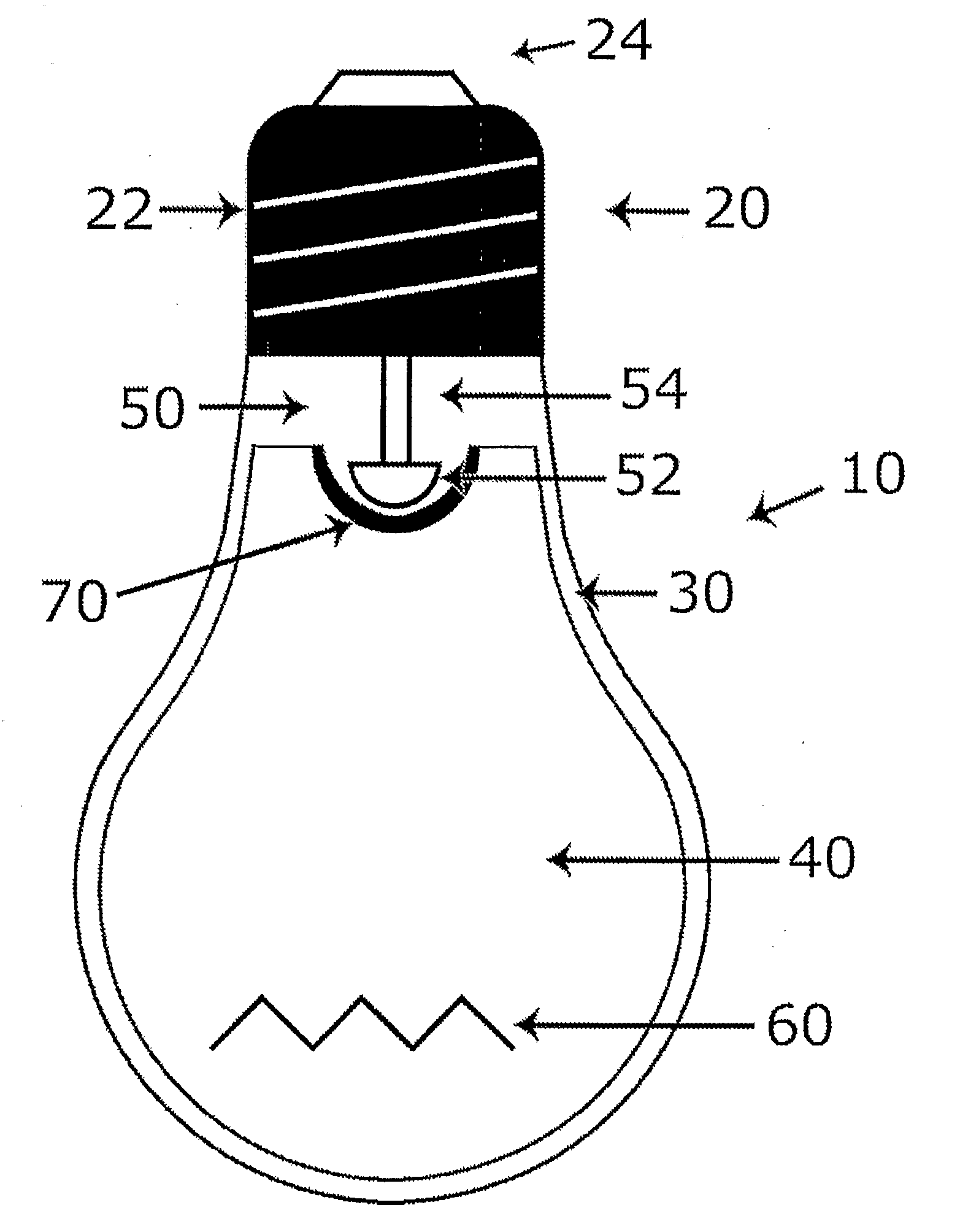

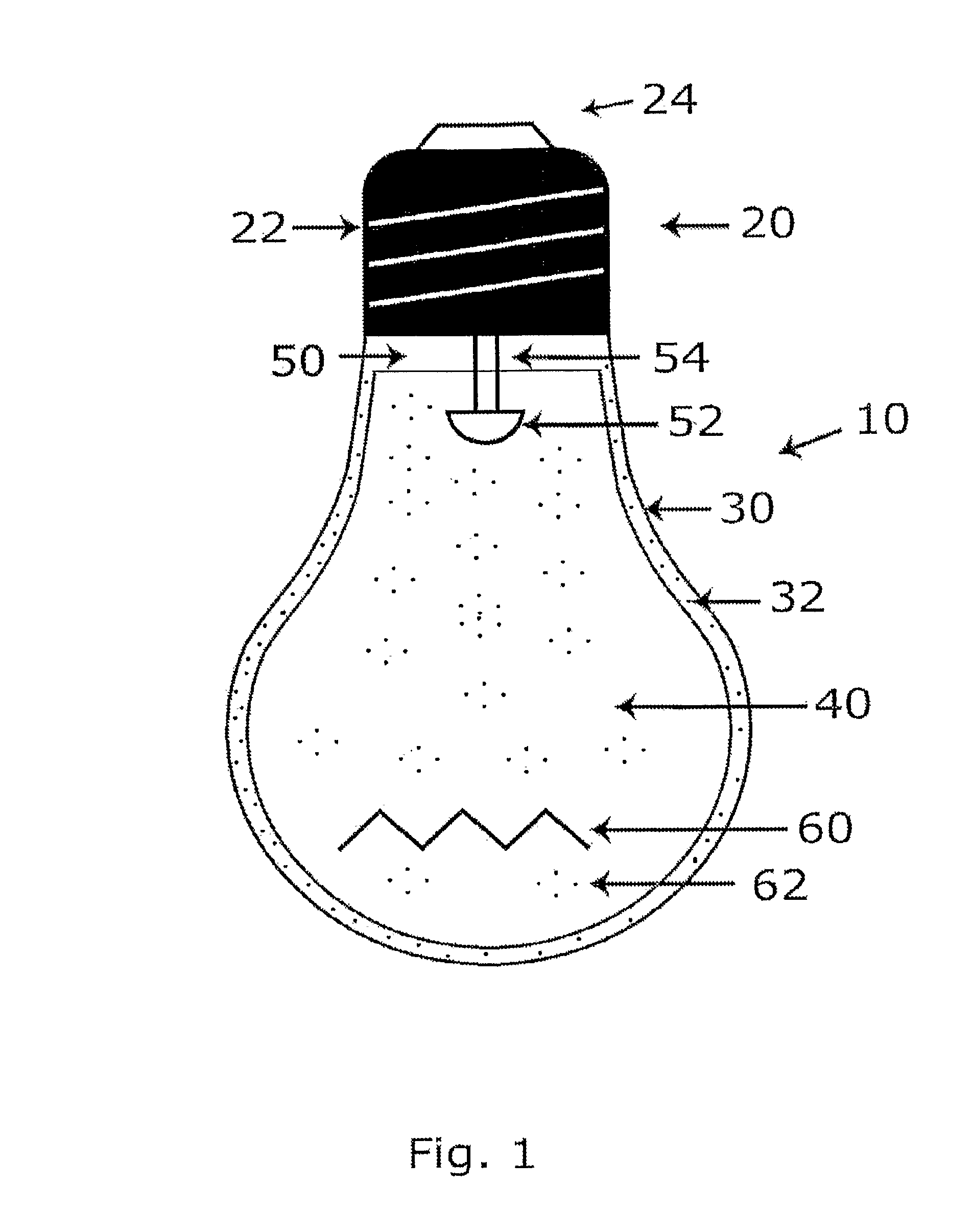

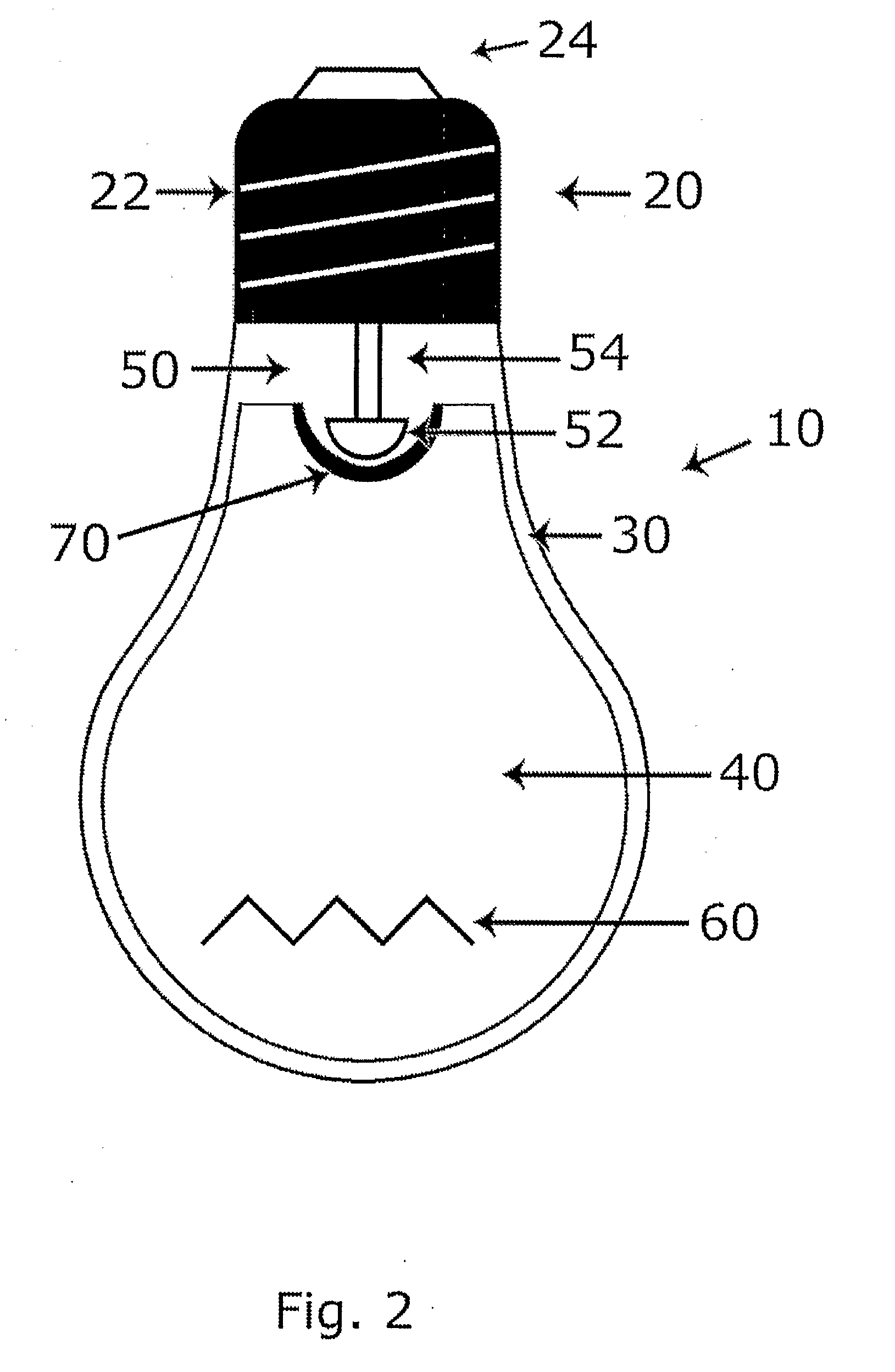

System and method for design of projector lamp

InactiveUS20060001346A1Electric discharge tubesElectroluminescent light sourcesBiomedical engineeringProjector

A lamp comprising an arc envelope and an end structure coupled to the arc envelope, and wherein the end structure comprises at least one opening adapted to support an arc electrode and to receive a dosing material into the arc envelope.

Owner:GENERAL ELECTRIC CO

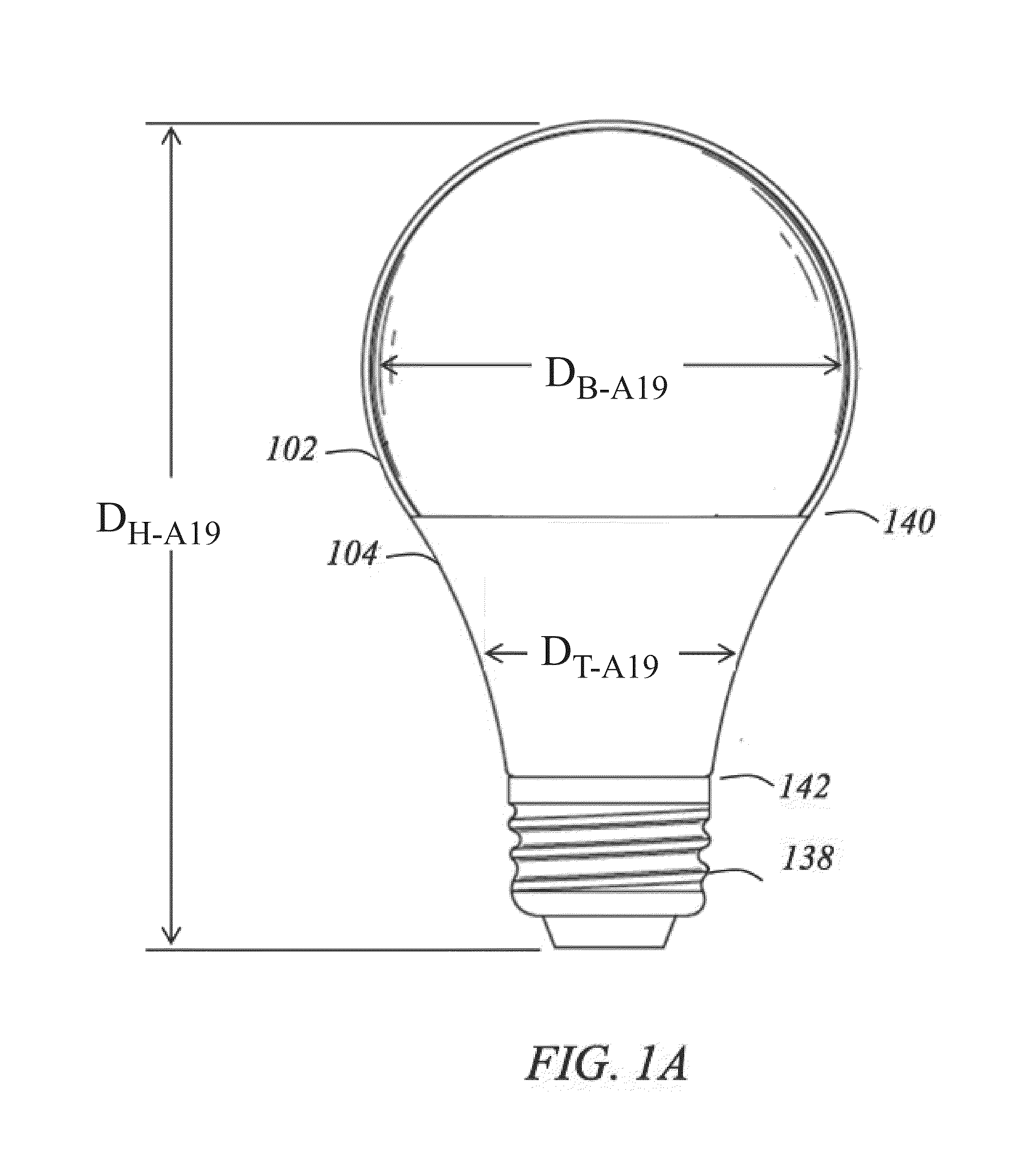

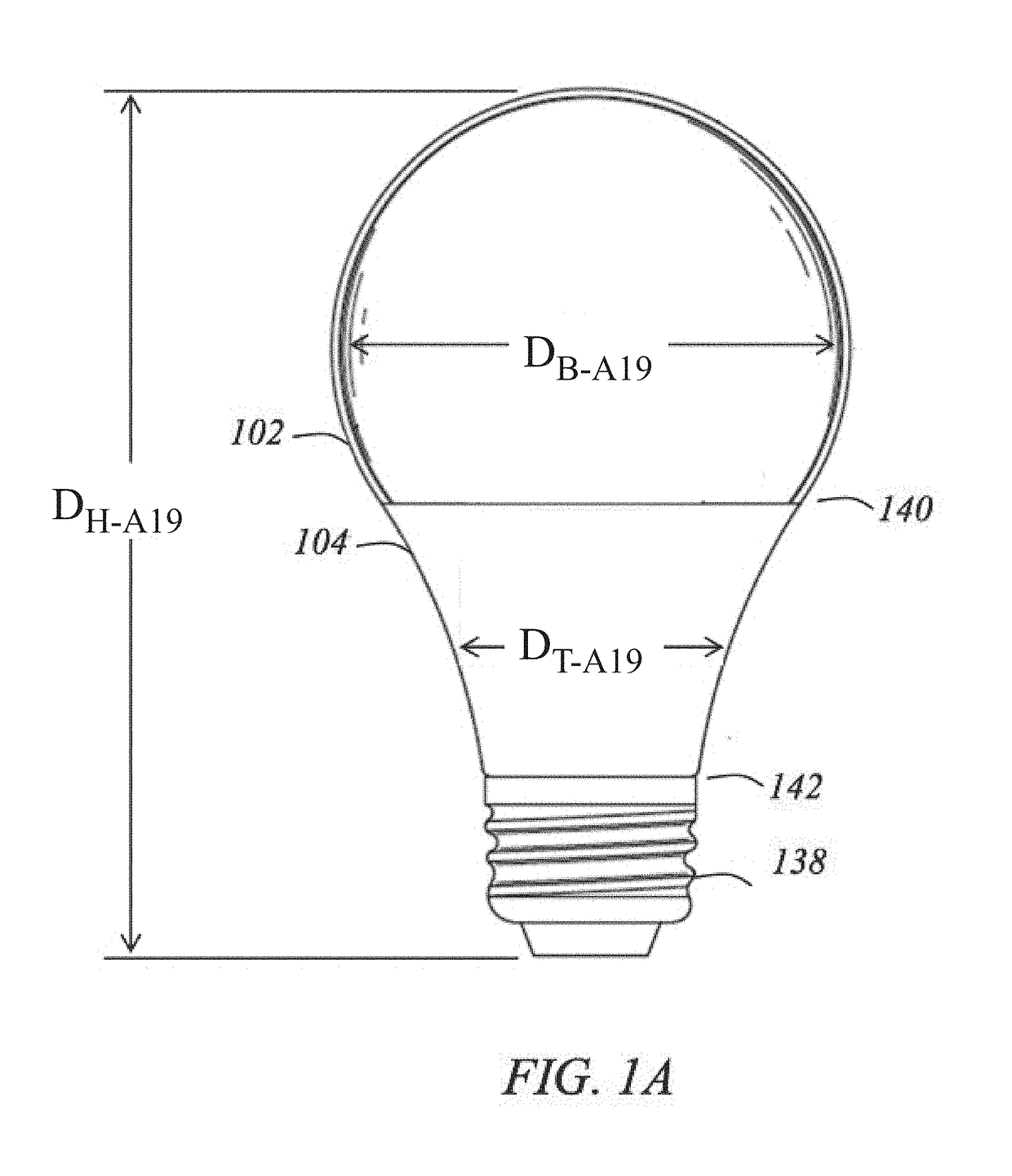

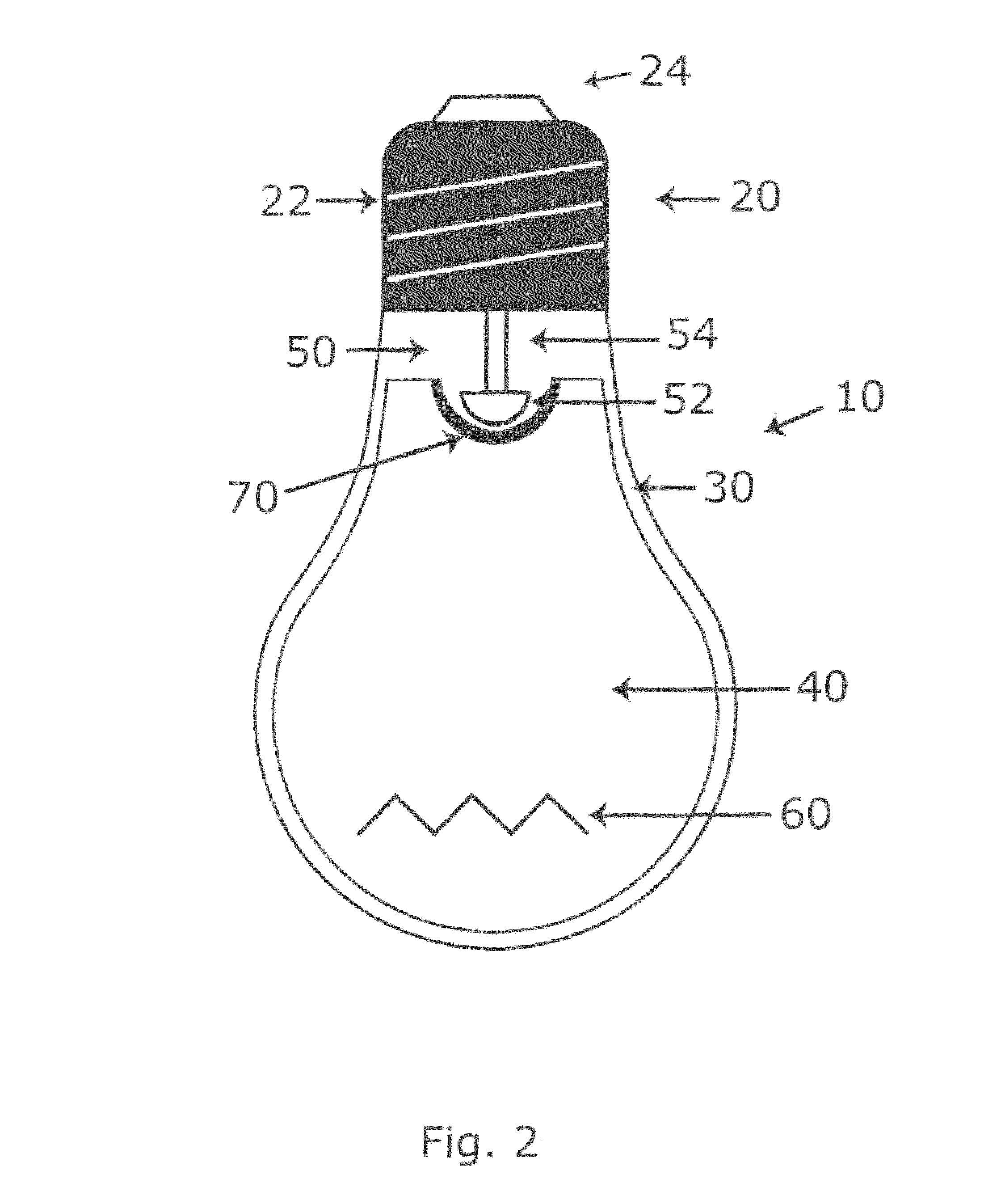

Plastic LED bulb

InactiveUS20090257220A1Coupling device connectionsPoint-like light sourcePlastic materialsEngineering

Owner:SWITCH BULB CO INC

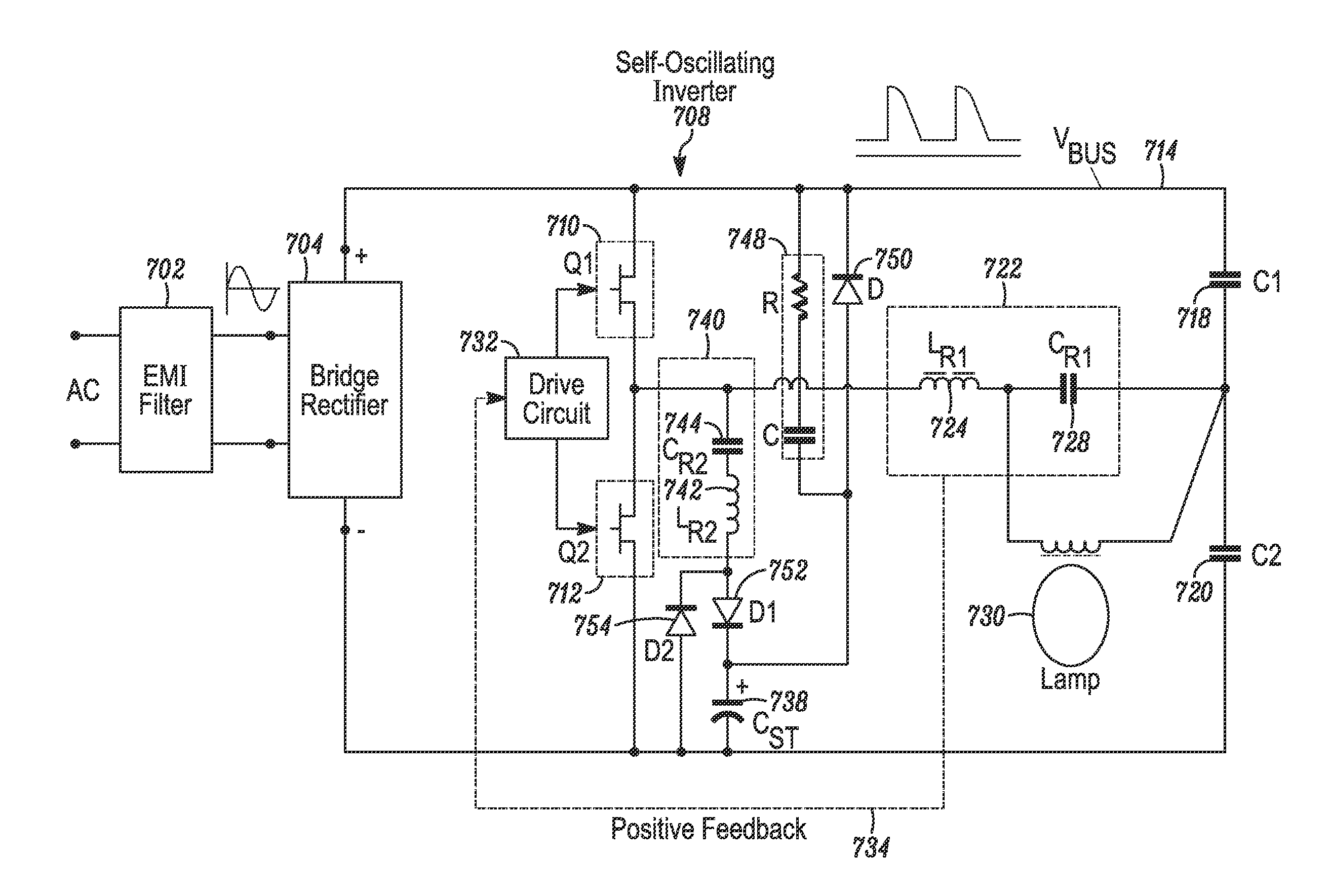

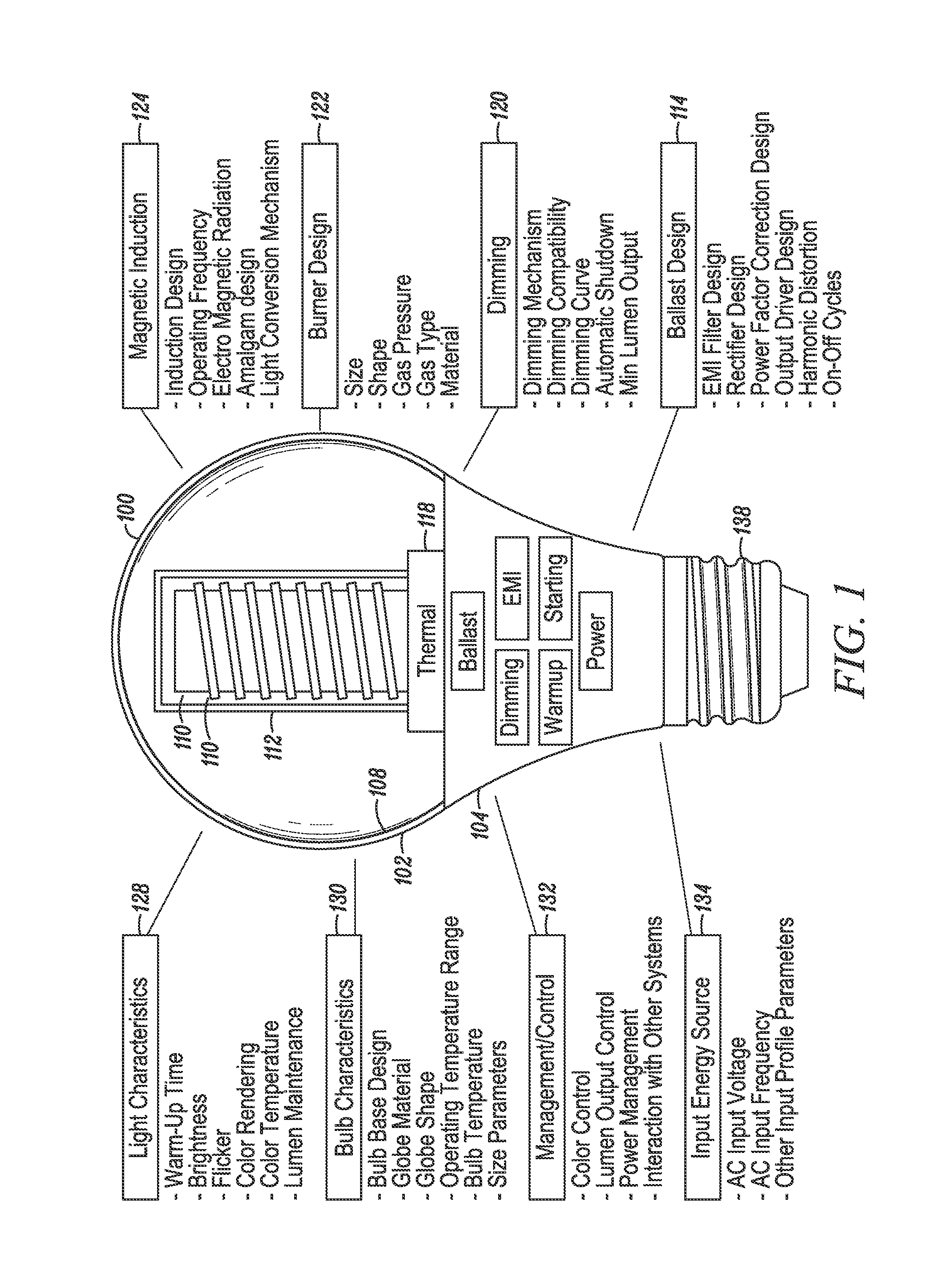

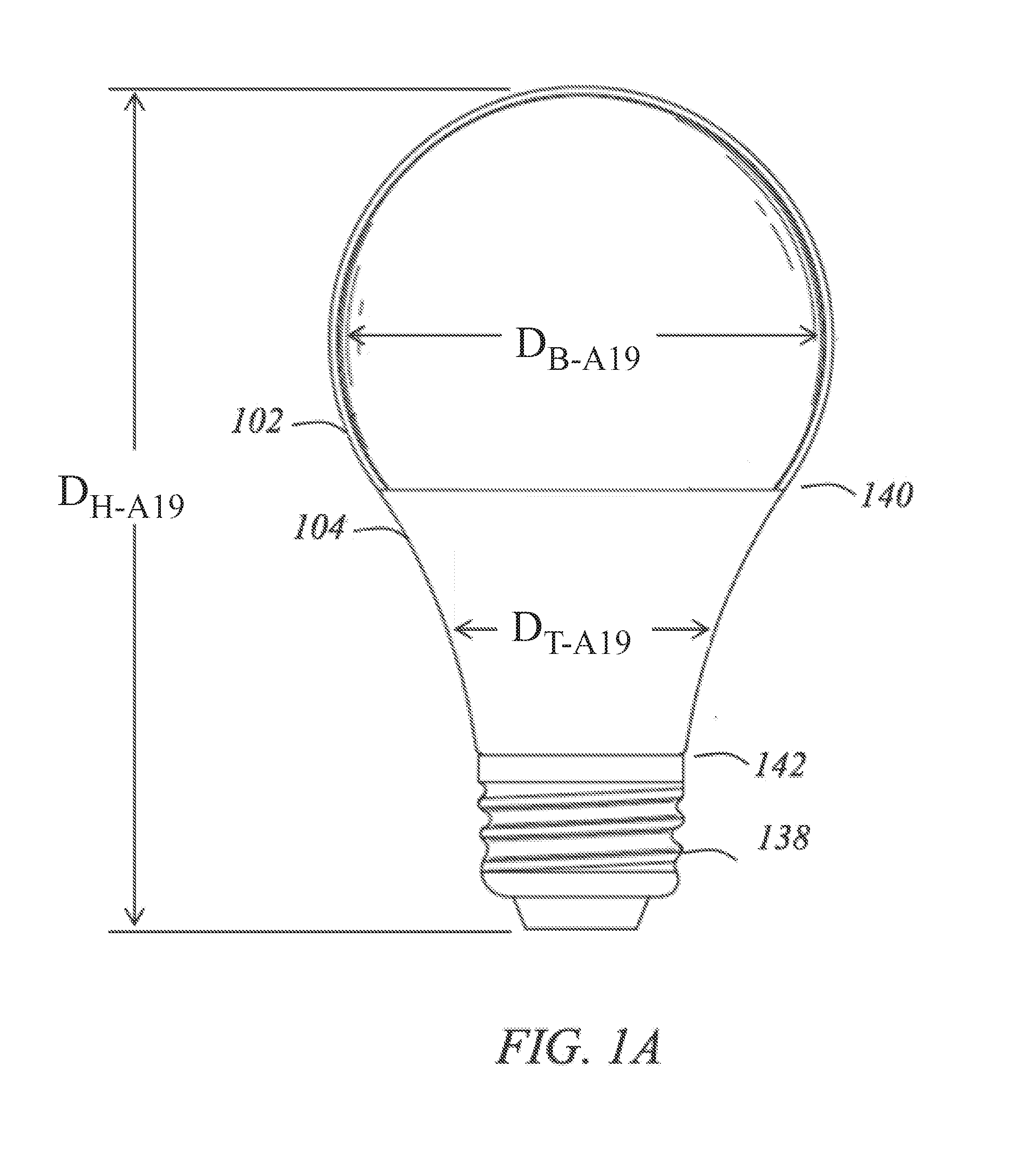

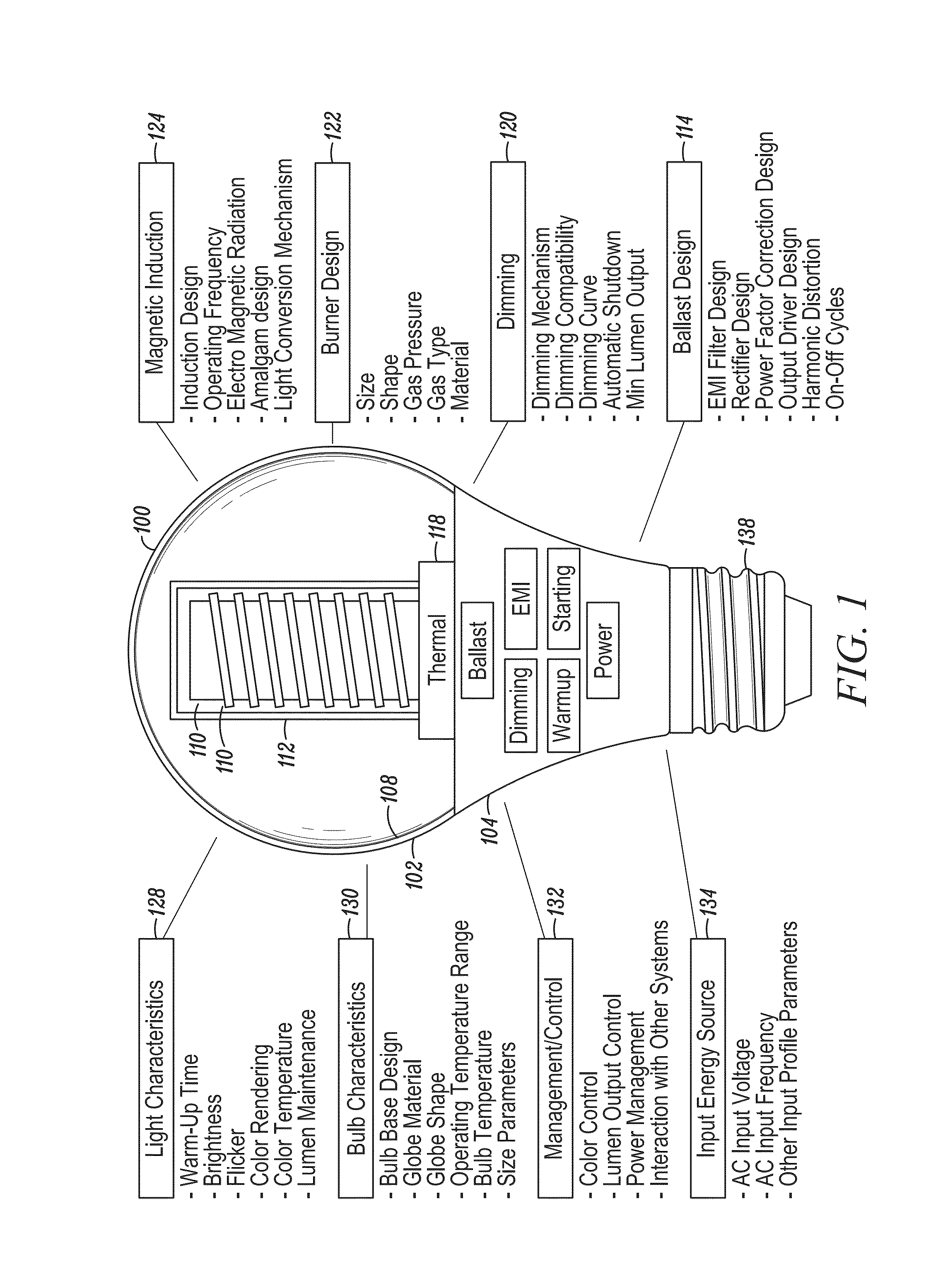

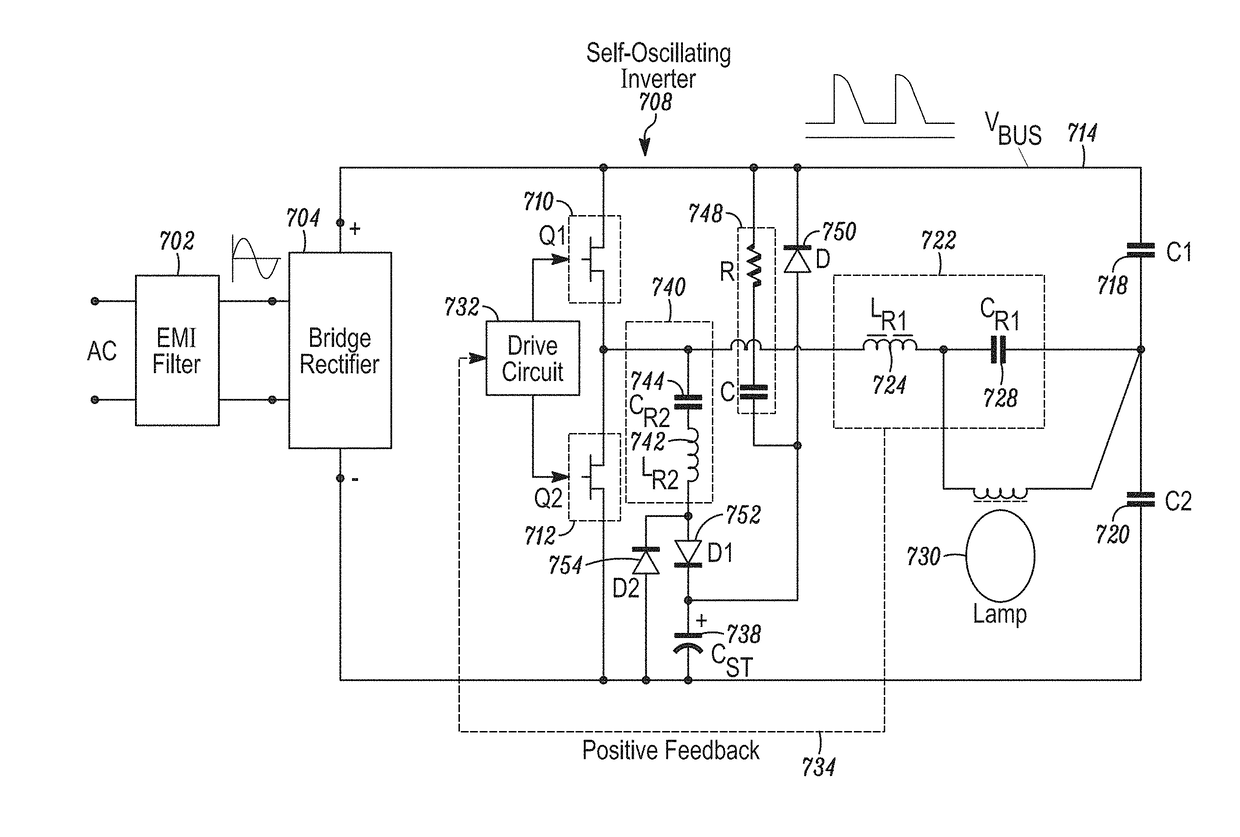

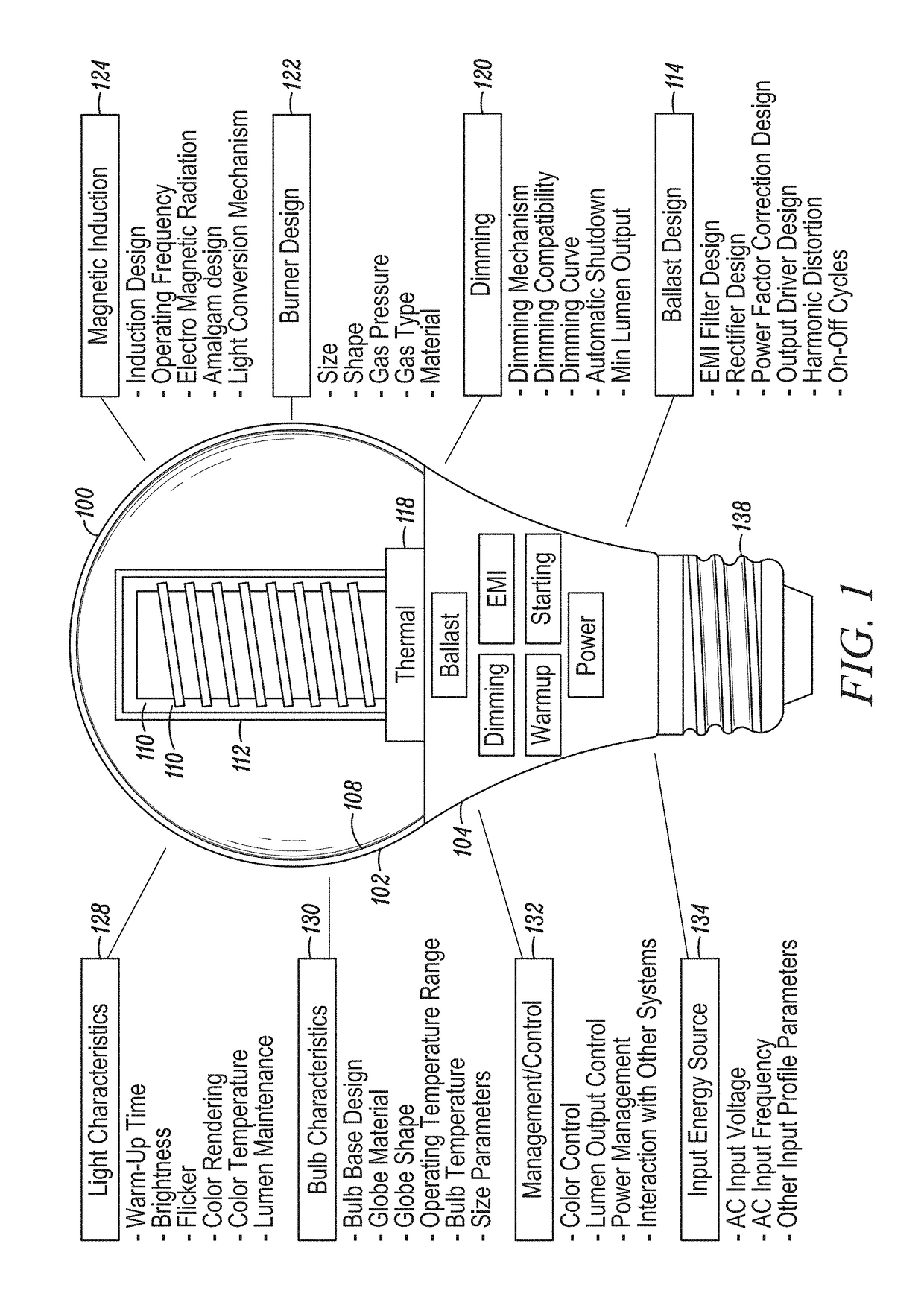

Induction RF fluorescent lamp with processor-based external dimmer load control

InactiveUS20140368109A1Operational flexibilitySmall sizeEfficient power electronics conversionElectric discharge tubesElectricityElectrical conductor

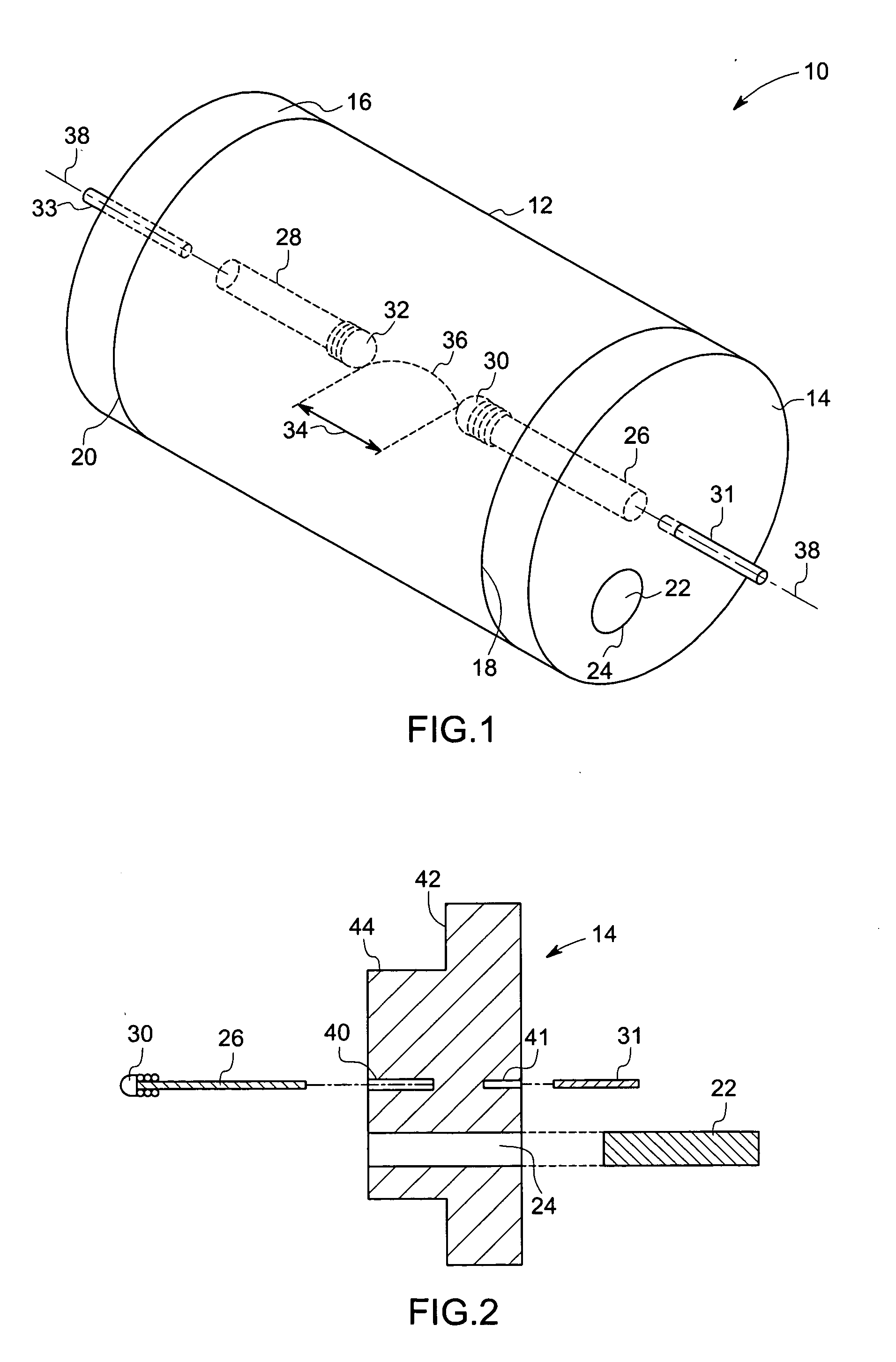

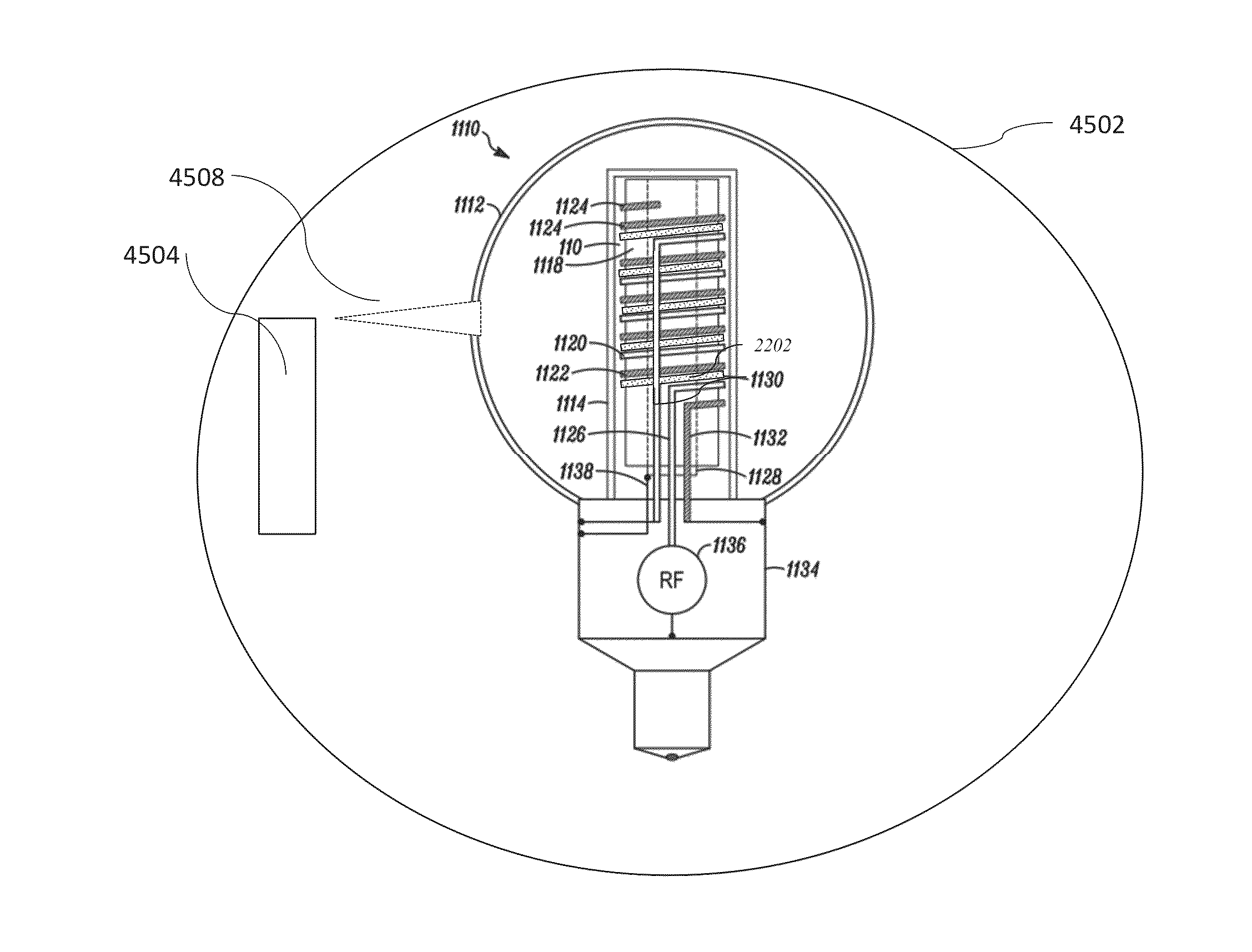

A processor controlled induction RF fluorescent lamp, where the control processor runs a load control algorithm at least for switching the electrical load for connection to an external dimming device, the lamp comprising a vitreous envelope filled with an ionizable gas mixture; a power coupler comprising at least one winding of an electrical conductor; and an electronic ballast providing appropriate voltage and current to the power coupler.

Owner:LUCIDITY LIGHTS

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS20040175854A1Sufficient resolutionManufactured very thinFixed microstructural devicesVolume/mass flow measurementEngineeringPre testing

Owner:LEIDOS

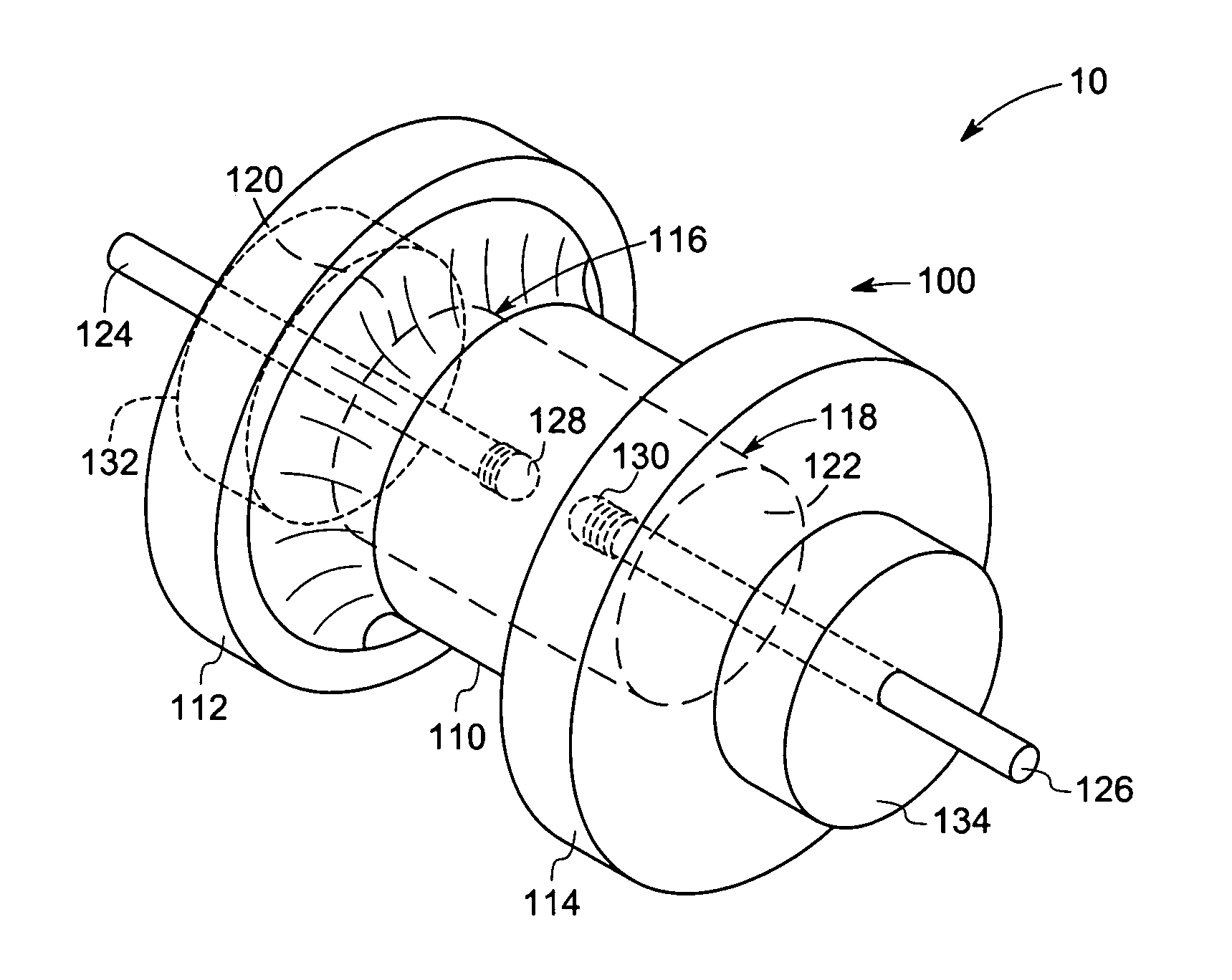

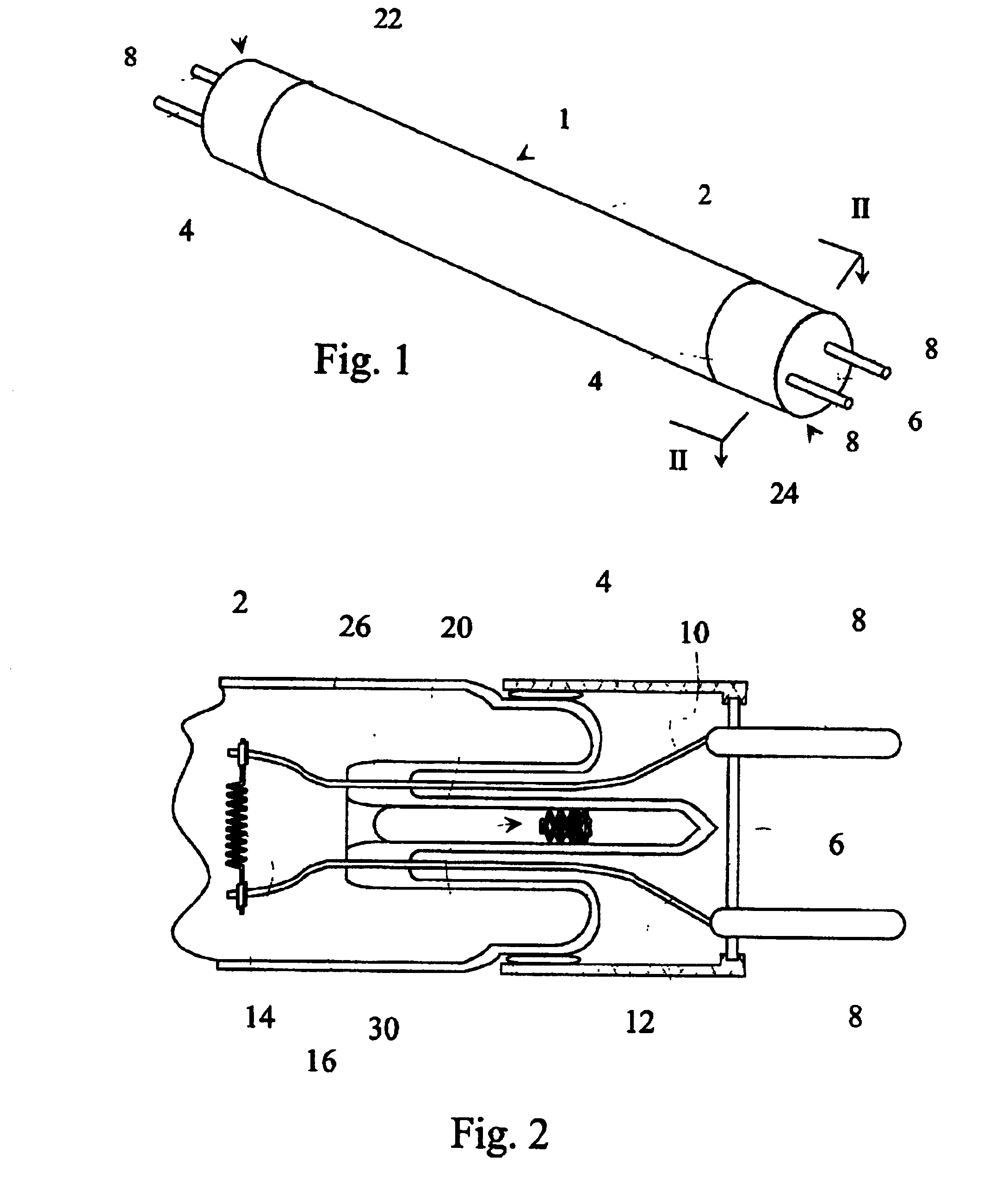

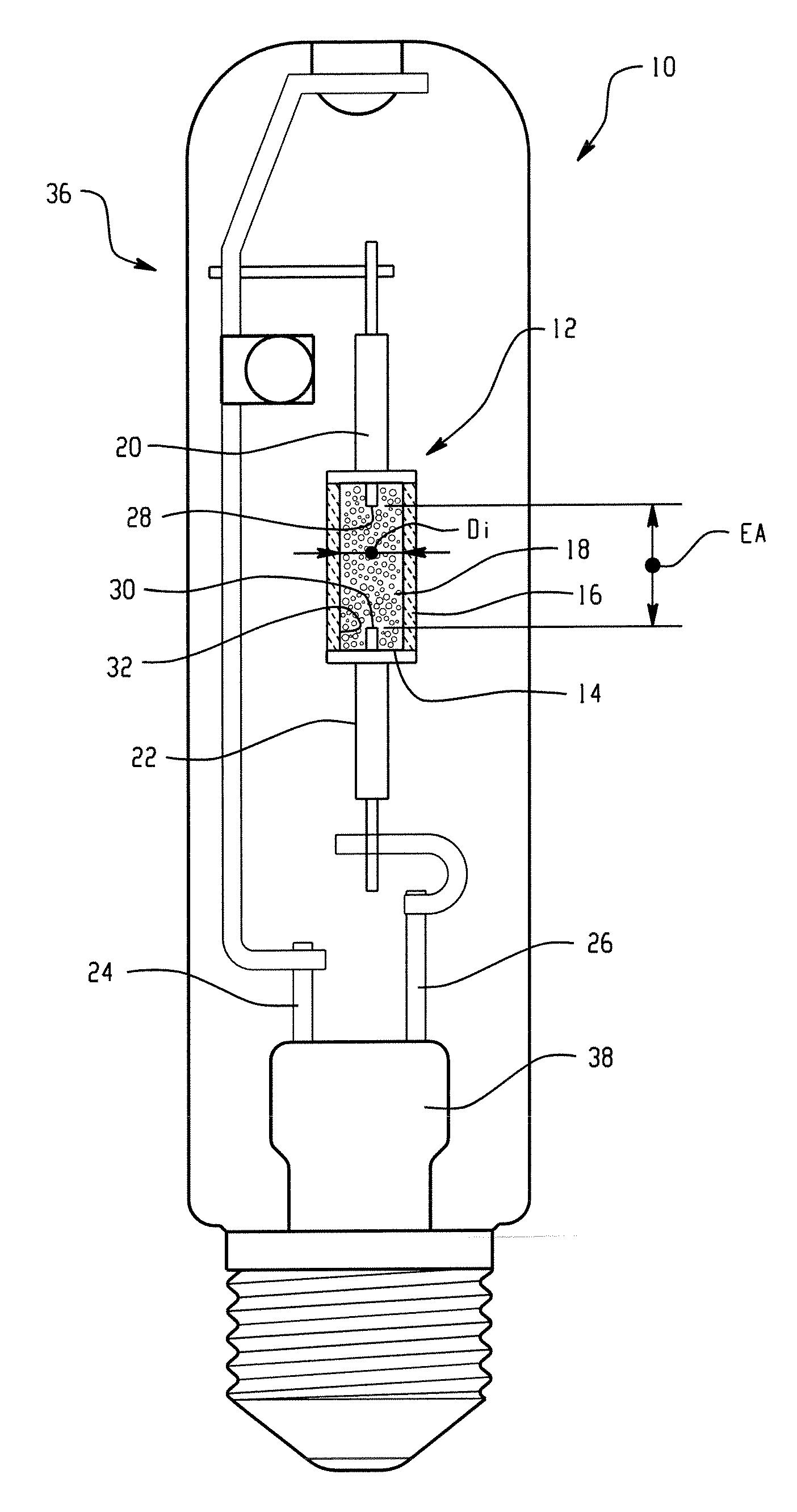

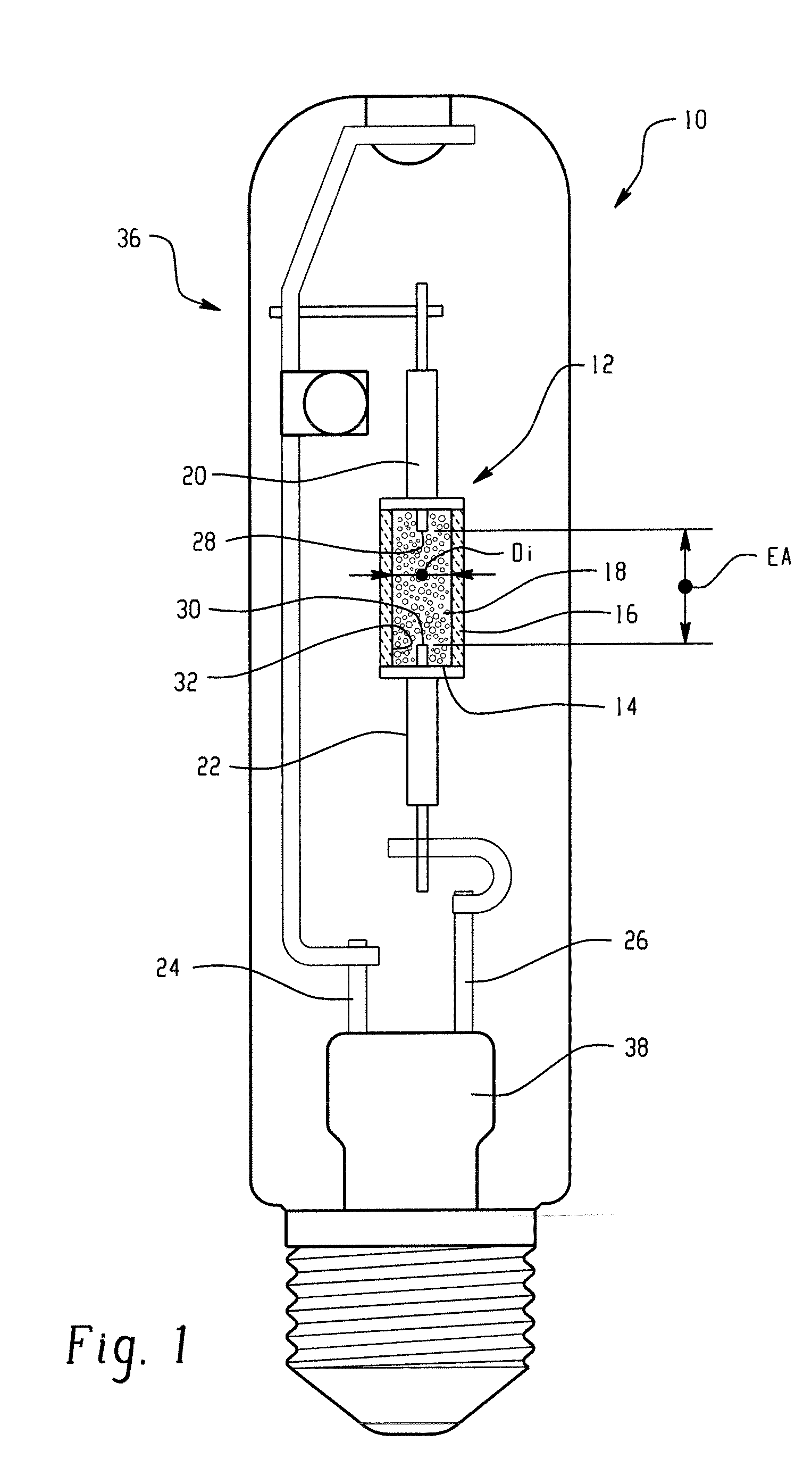

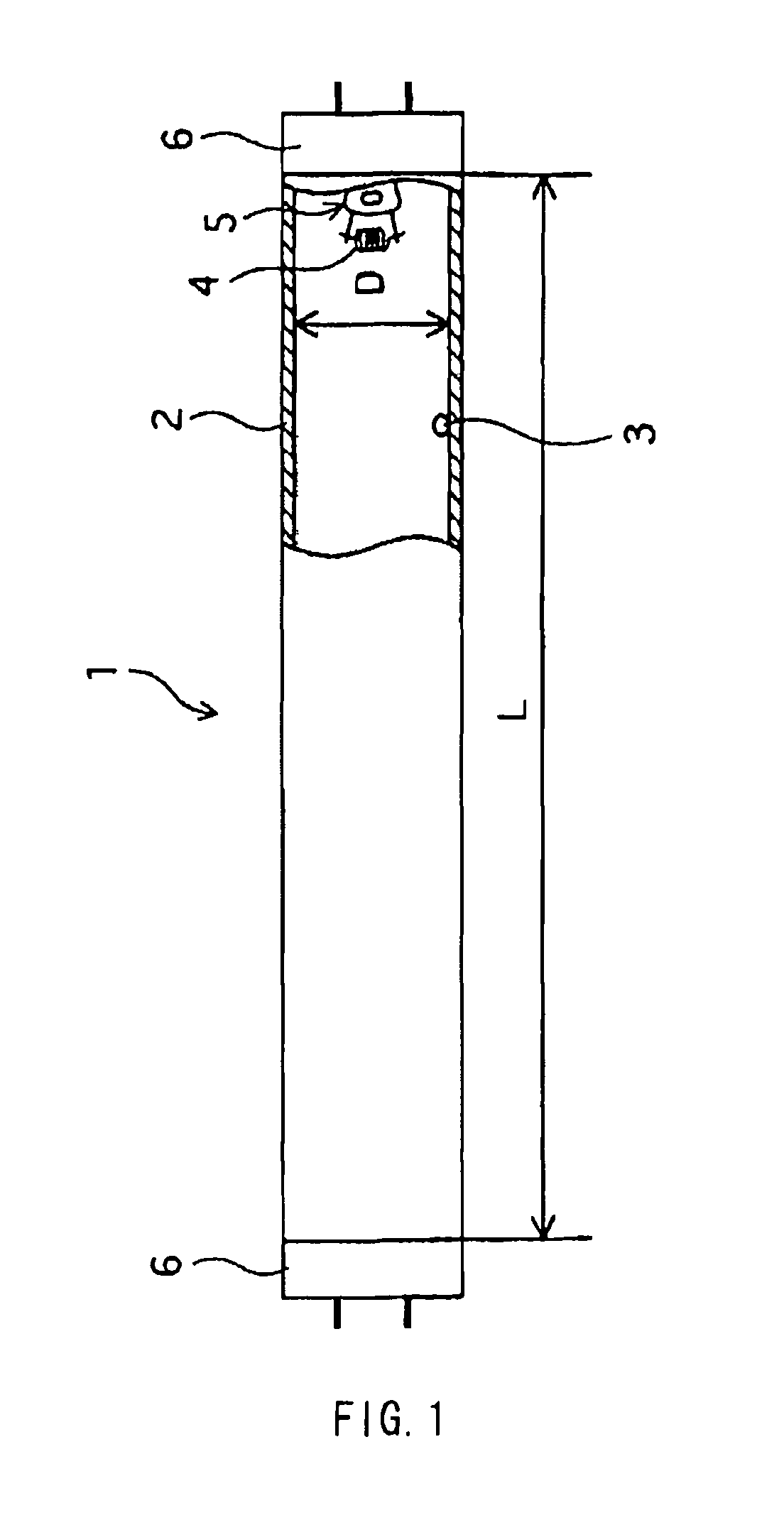

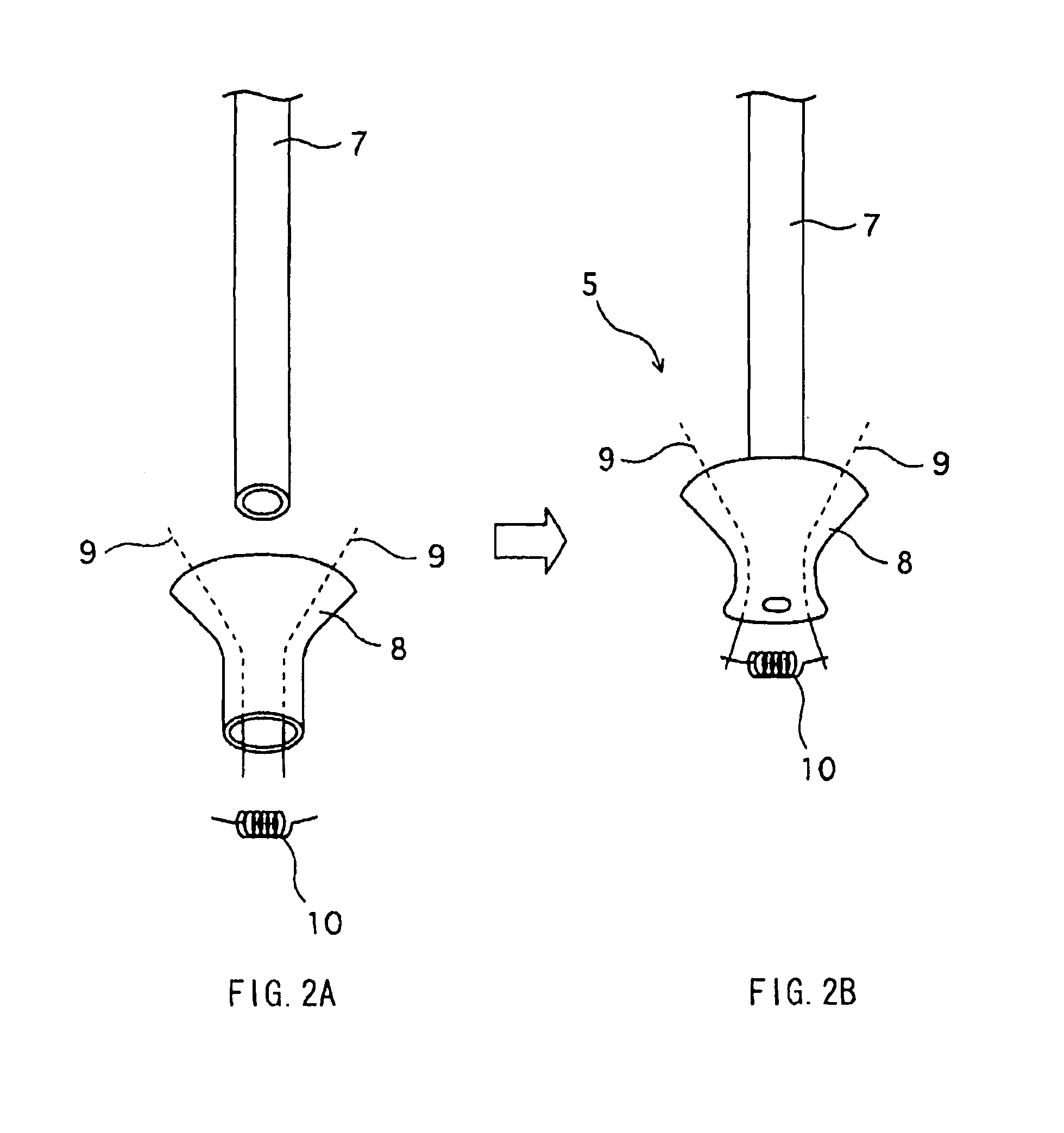

Induction RF fluorescent lamp with helix mount

InactiveUS20140375203A1Operational flexibilitySmall sizeEfficient power electronics conversionElectric discharge tubesRe entrantFluorescent lamp

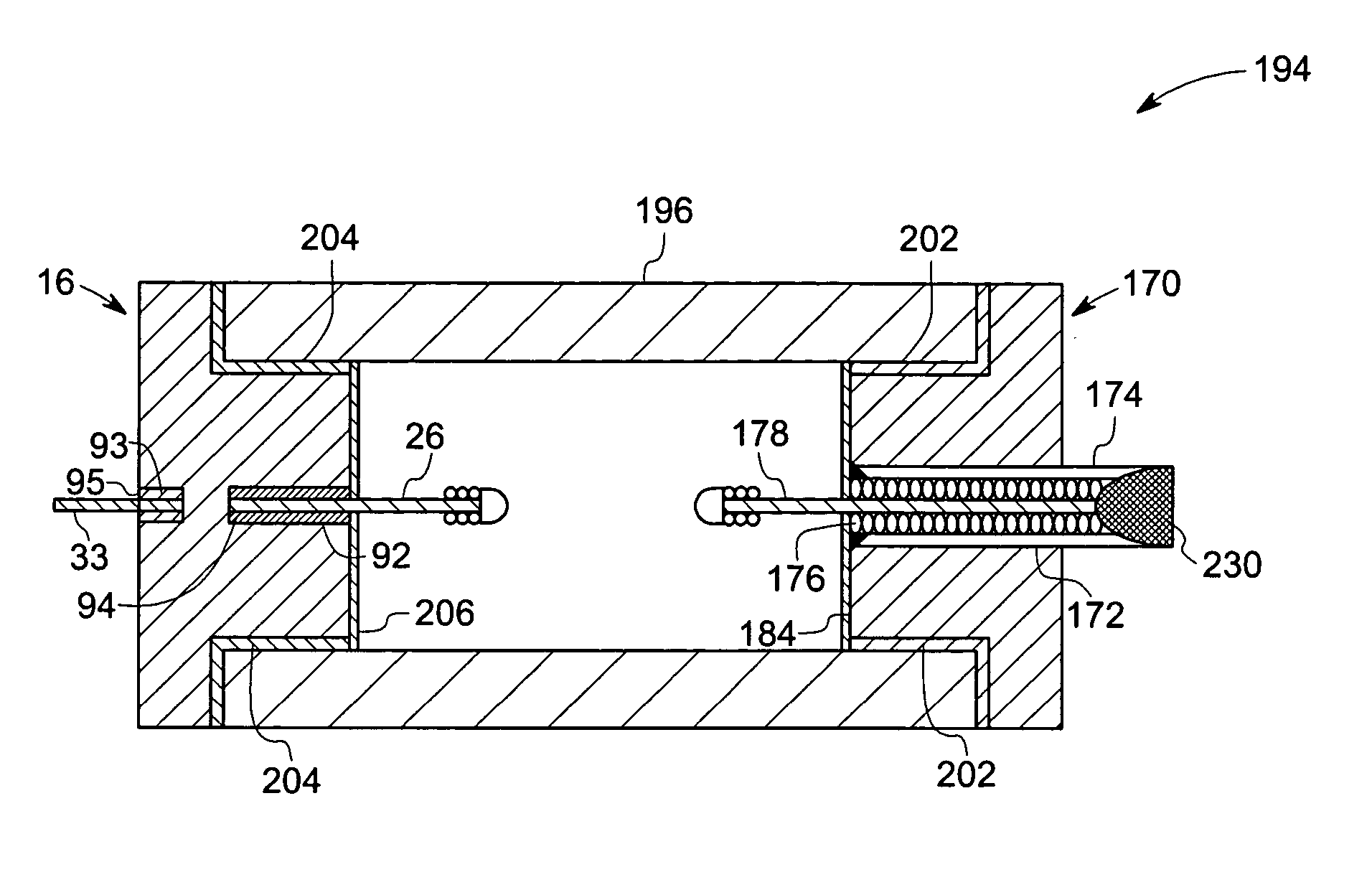

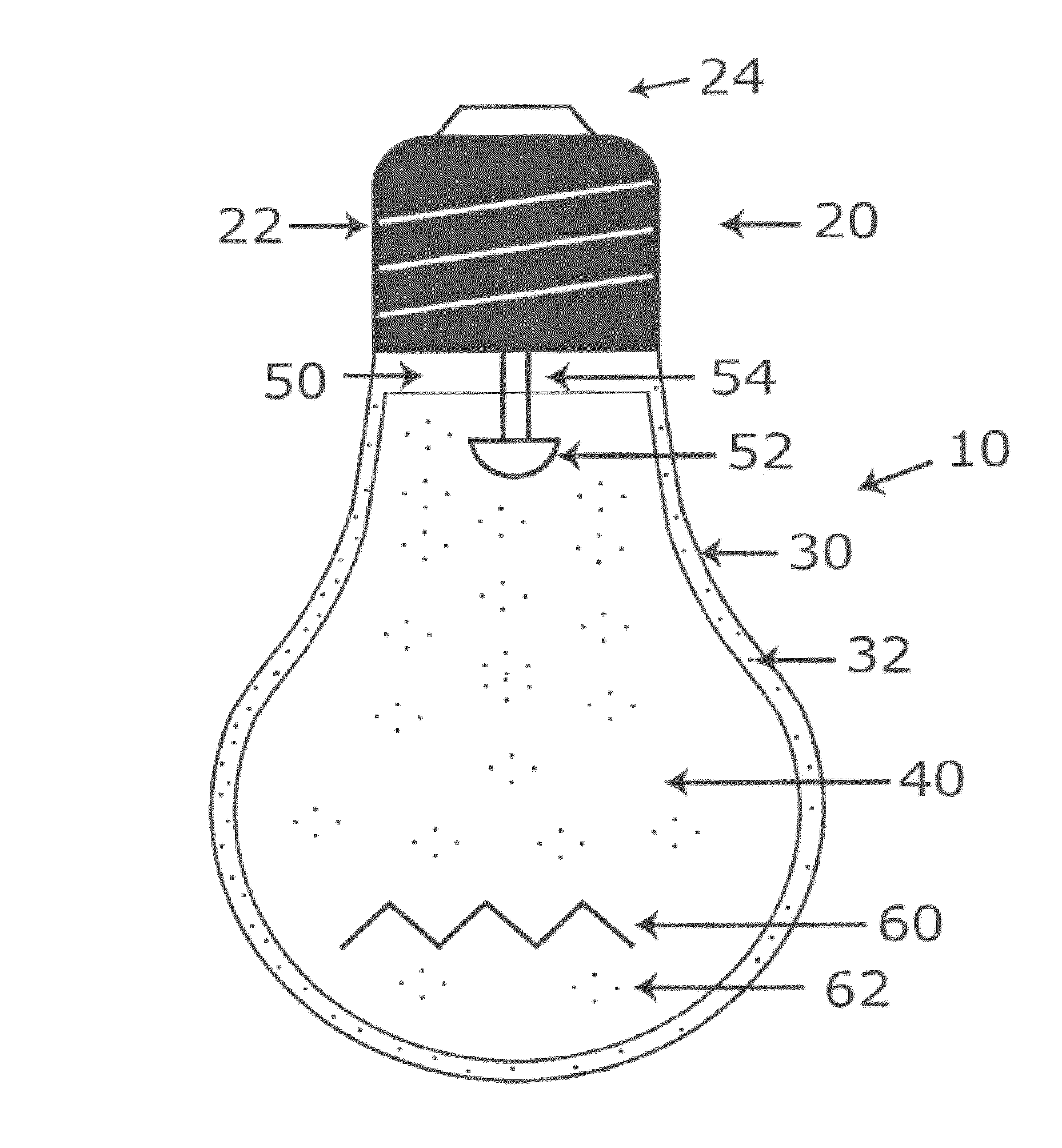

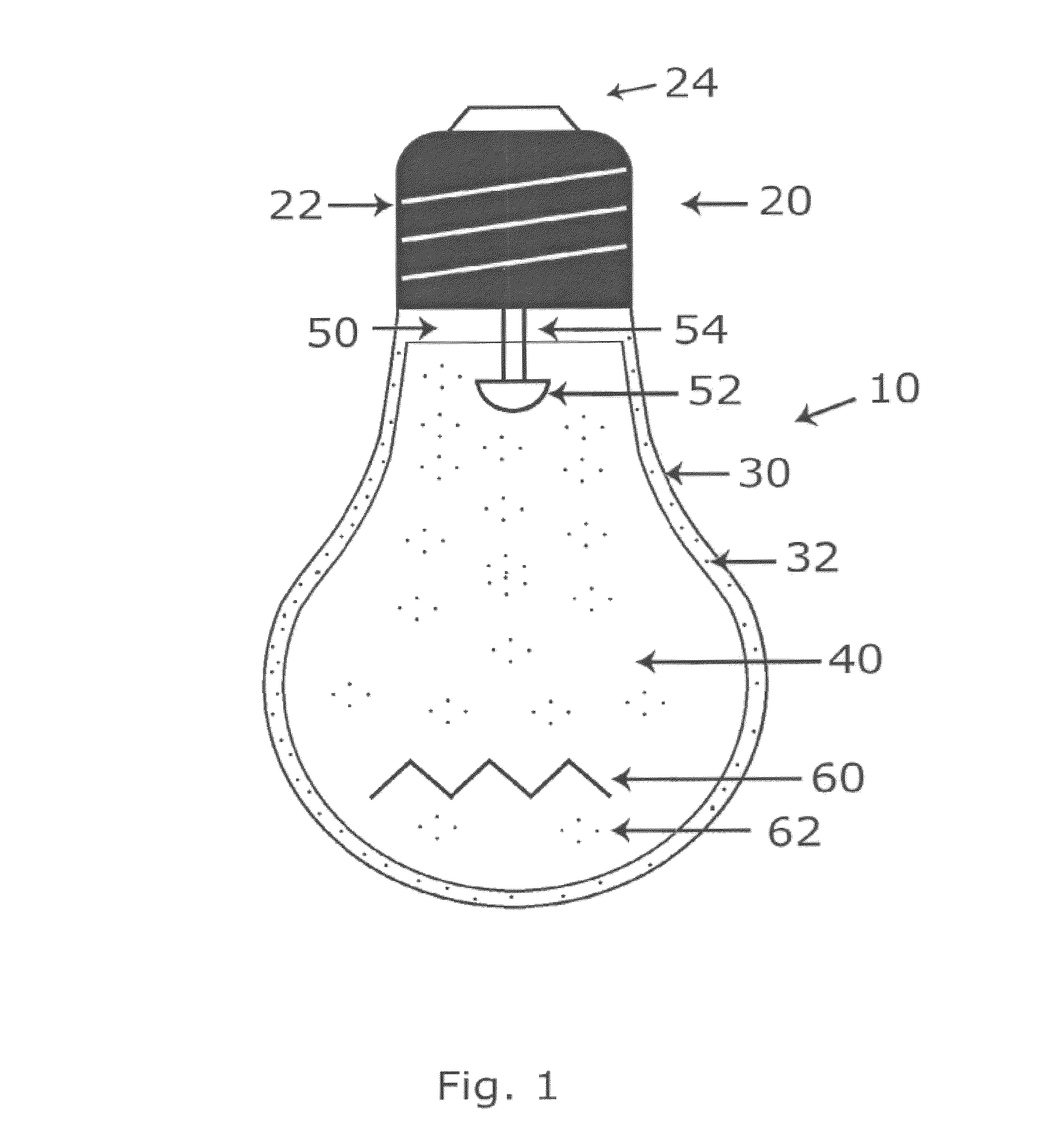

An induction RF fluorescent lamp, comprising: a lamp envelope with a re-entrant cavity and evacuation tube; a power coupler, wherein the power coupler is located inside the re-entrant cavity; an electronic ballast, wherein the electronic ballast provides appropriate voltage and current to the power coupler; and an amalgam held within a capsule located above the power coupler within the lamp envelope, wherein the capsule is positioned with a mount comprising at least one wire attached to the capsule and having at least two wire ends extending from the capsule into the evacuation tube with contact made between the wire ends and the interior surface of the evacuation tube of the re-entrant cavity.

Owner:LUCIDITY LIGHTS

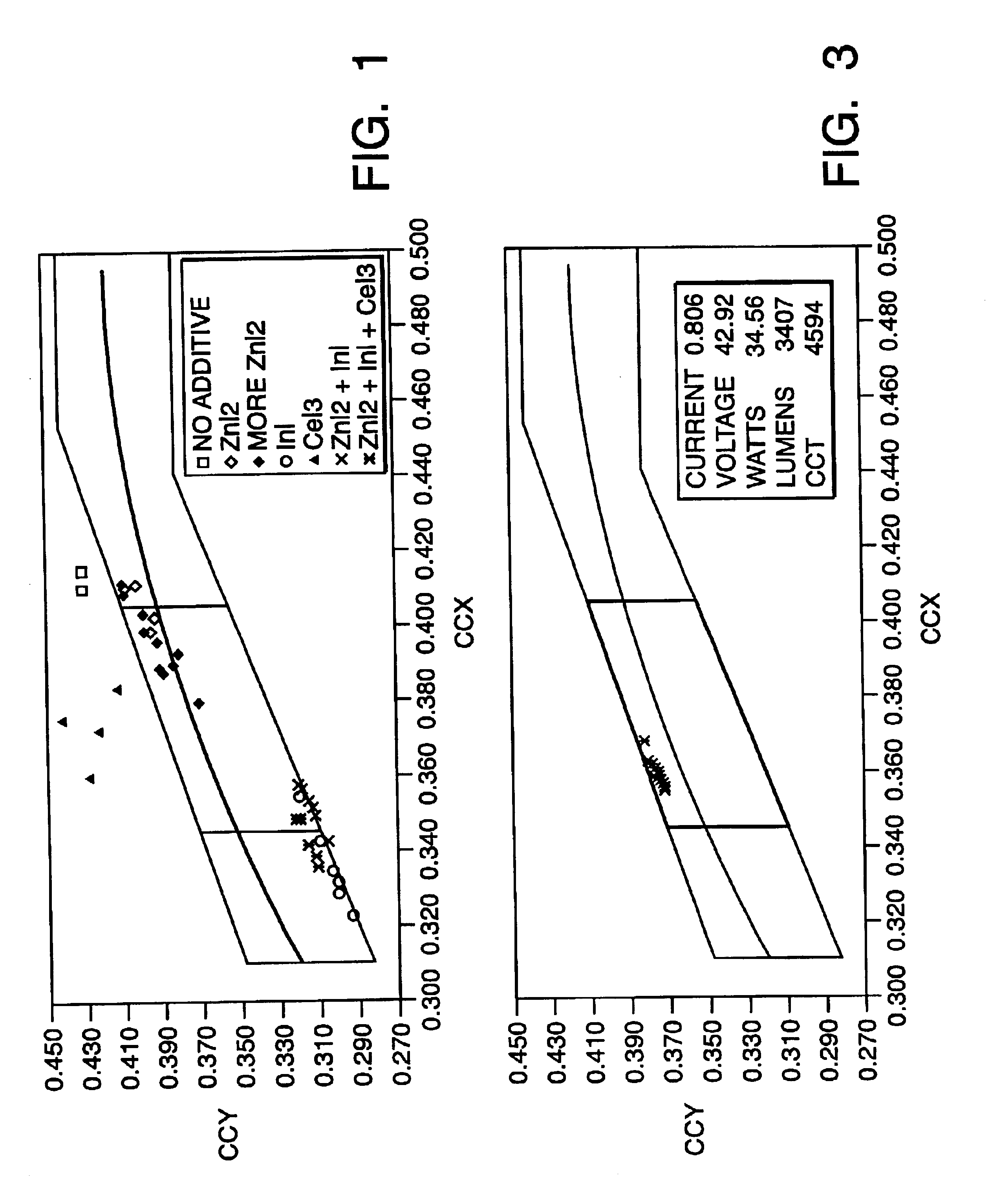

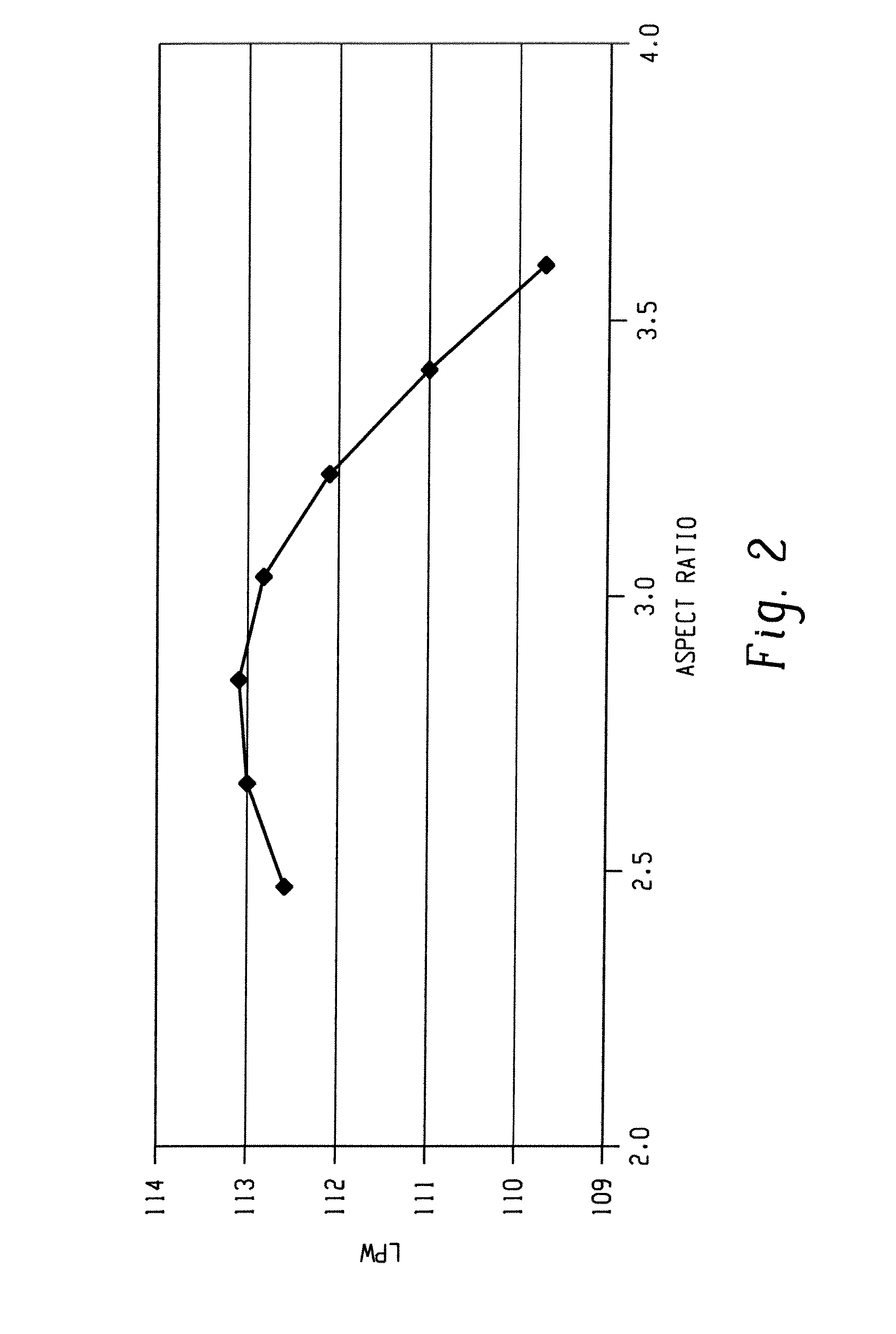

Mercury free discharge lamp with zinc iodide

A compact fused silica, electroded HID lamp for automotive forward lighting, which contains no mercury. The lamps voltage, approximately 40 volts, is developed in this lamp by vaporizing zinc iodide instead of mercury. A compromise between voltage and luminous flux is achieved through the choice of the sodium scandium (Na:Sc) molar ratio, between 4.5:1 and 6:1 and a zinc iodide (ZnI2) dose of 2 to 6 micrograms per cubic millimeter that permits the lamp to operate within the North America, European and Japanese automotive color specifications for white light. The voltage in the lamp can be controlled according to the zinc iodide doping level without seriously impacting the visible spectrum otherwise provided by the other known dopants in the lamp.

Owner:OSRAM SYLVANIA INC

Fast start fluorescent light bulb

ActiveUS20170358441A1Enriching the flag amalgam with mercuryShorten the timeEfficient power electronics conversionElectric discharge tubesIndiumAlloy

An RF fluorescent lamp, comprising a bulbous vitreous portion of the RF fluorescent lamp comprising a vitreous envelope filled with a working gas mixture, a power coupler to induce an alternating electric field within the vitreous envelope, an electronic ballast, and a mercury amalgam accommodating structure mounted within the lamp envelope and adapted to absorb power from the electric field to rapidly heat and vaporize an amalgam of mercury to rapidly illuminate the lamp envelope during a turn-on phase of the RF fluorescent lamp, wherein the structure is comprised of a substrate material coated with a mixture of indium and gold.

Owner:LUCIDITY LIGHTS

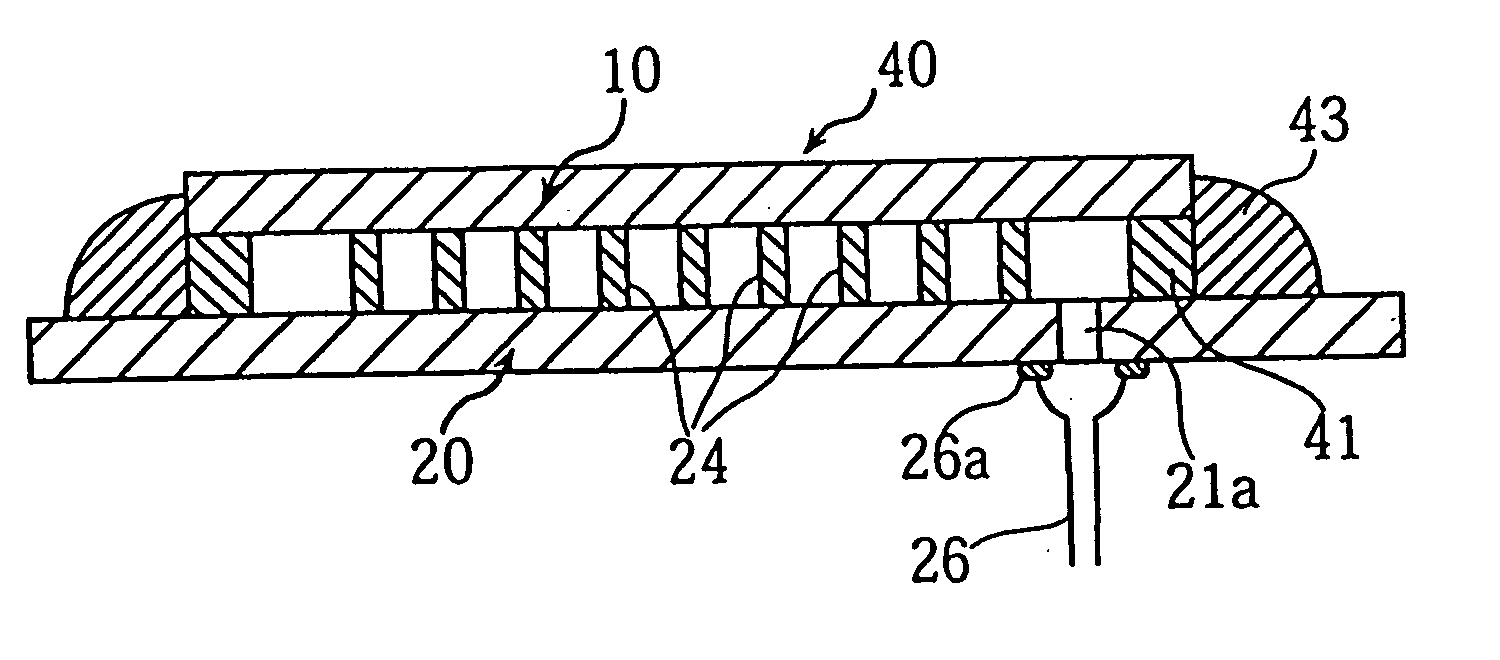

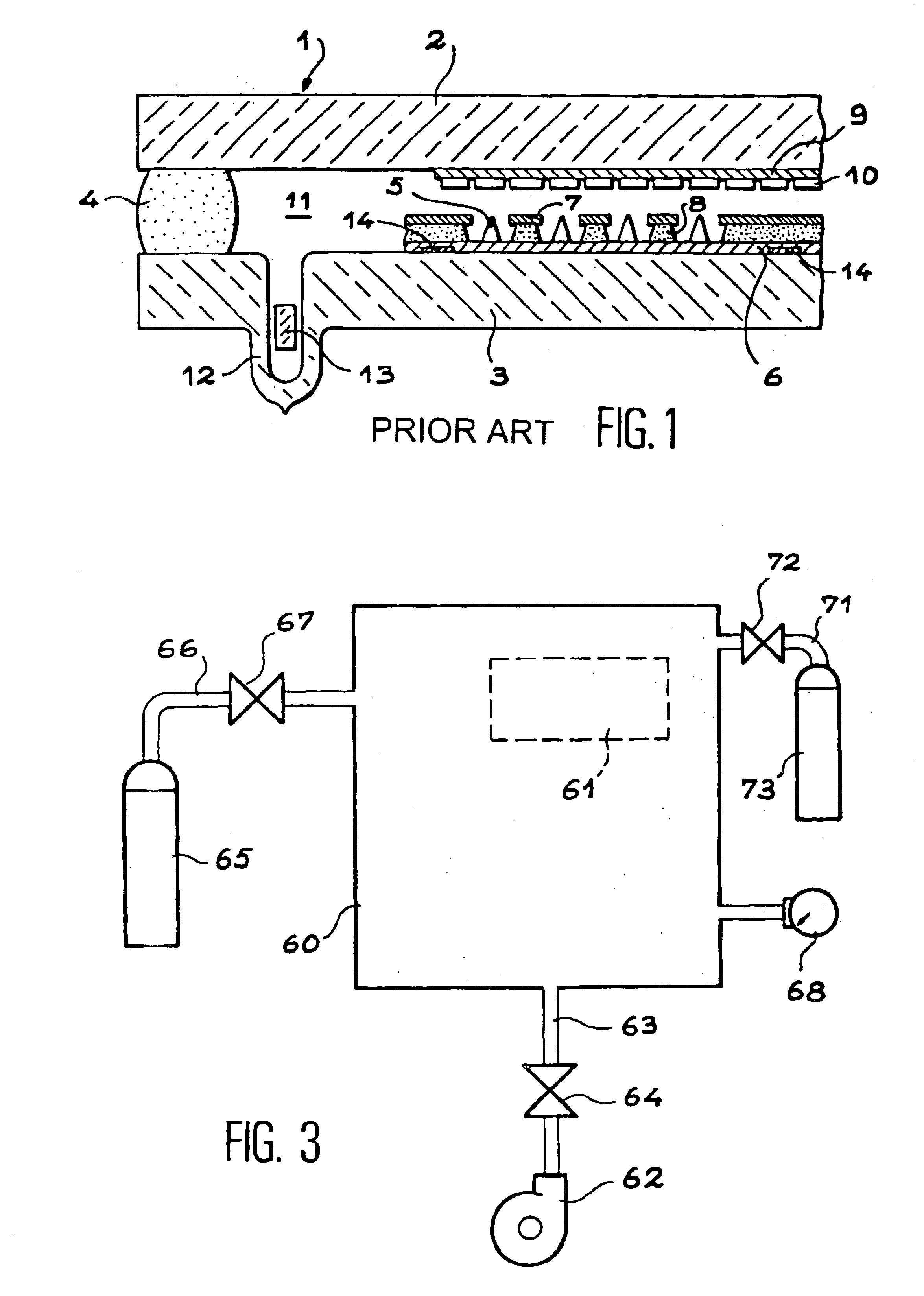

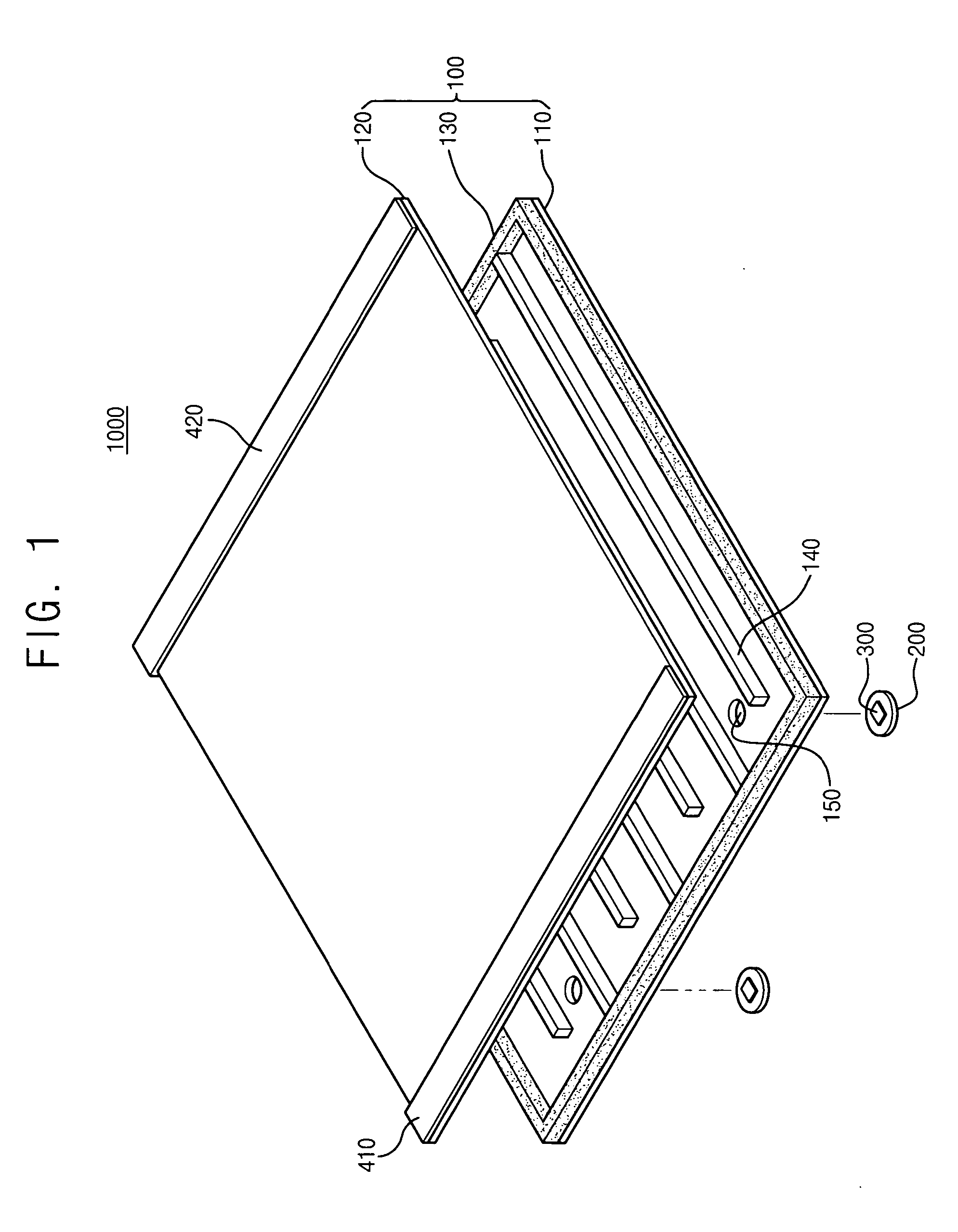

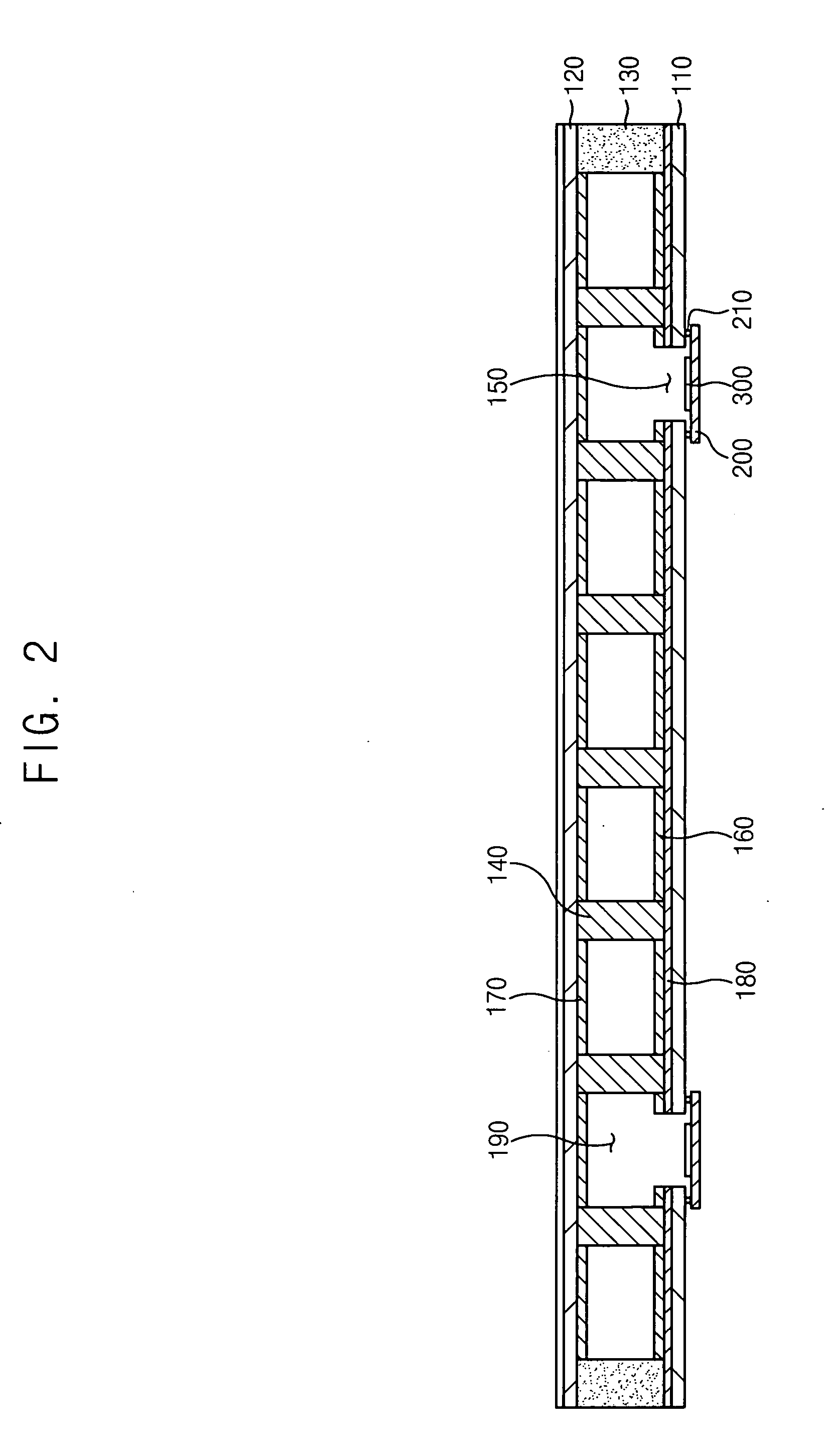

Sealing method and apparatus for manufacturing high-performance gas discharge panel

InactiveUS6848964B1Reduce pressureEnsure processTube/lamp vessel fillingAlternating current plasma display panelsEngineeringLaser beams

A method is provided to steadily produce a gas discharge panel, such as a PDP, in which a panel and the top of the barrier ribs are in intimate contact in entirety. First a surrounding unit for the gas discharge panel is formed, then a process for sealing the surrounding unit with a sealing material inserted between two panels at the rim is performed while pressure is adjusted so that pressure inside the surrounding unit is lower than pressure outside. With this construction, the panels constituting the surrounding unit are bonded together while they are pressurized from outside. As a result, a panel and the top of the barrier ribs on the other panel are bonded together while they are in intimate contact in entirety. To fully acquire these effects, it is preferable that the adjustment of pressure starts before the sealing material hardens. During, before, or after the sealing step, an energy such as laser beams or ultrasonic waves may be radiated onto the top of the barrier ribs to bond a panel and the top of the barrier ribs in entirety almost without a gap between them.

Owner:PANASONIC CORP

Sealing method and apparatus for manufacturing high-performance gas discharge panel

InactiveUS20050151475A1Reduce pressureAvoid deformationElectroluminescent light sourcesAlternating current plasma display panelsEngineeringLaser beams

A method is provided to steadily produce a gas discharge panel, such as a PDP, in which a panel and the top of the barrier ribs are in intimate contact in entirety. First a surrounding unit for the gas discharge panel is formed, then a process for sealing the surrounding unit with a sealing material inserted between two panels at the rim is performed while pressure is adjusted so that pressure inside the surrounding unit is lower than pressure outside. With this construction, the panels constituting the surrounding unit are bonded together while they are pressurized from outside. As a result, a panel and the top of the barrier ribs on the other panel are bonded together while they are in intimate contact in entirety. To fully acquire these effects, it is preferable that the adjustment of pressure starts before the sealing material hardens. During, before, or after the sealing step, an energy such as laser beams or ultrasonic waves may be radiated onto the top of the barrier ribs to bond a panel and the top of the barrier ribs in entirety almost without a gap between them.

Owner:PANASONIC CORP

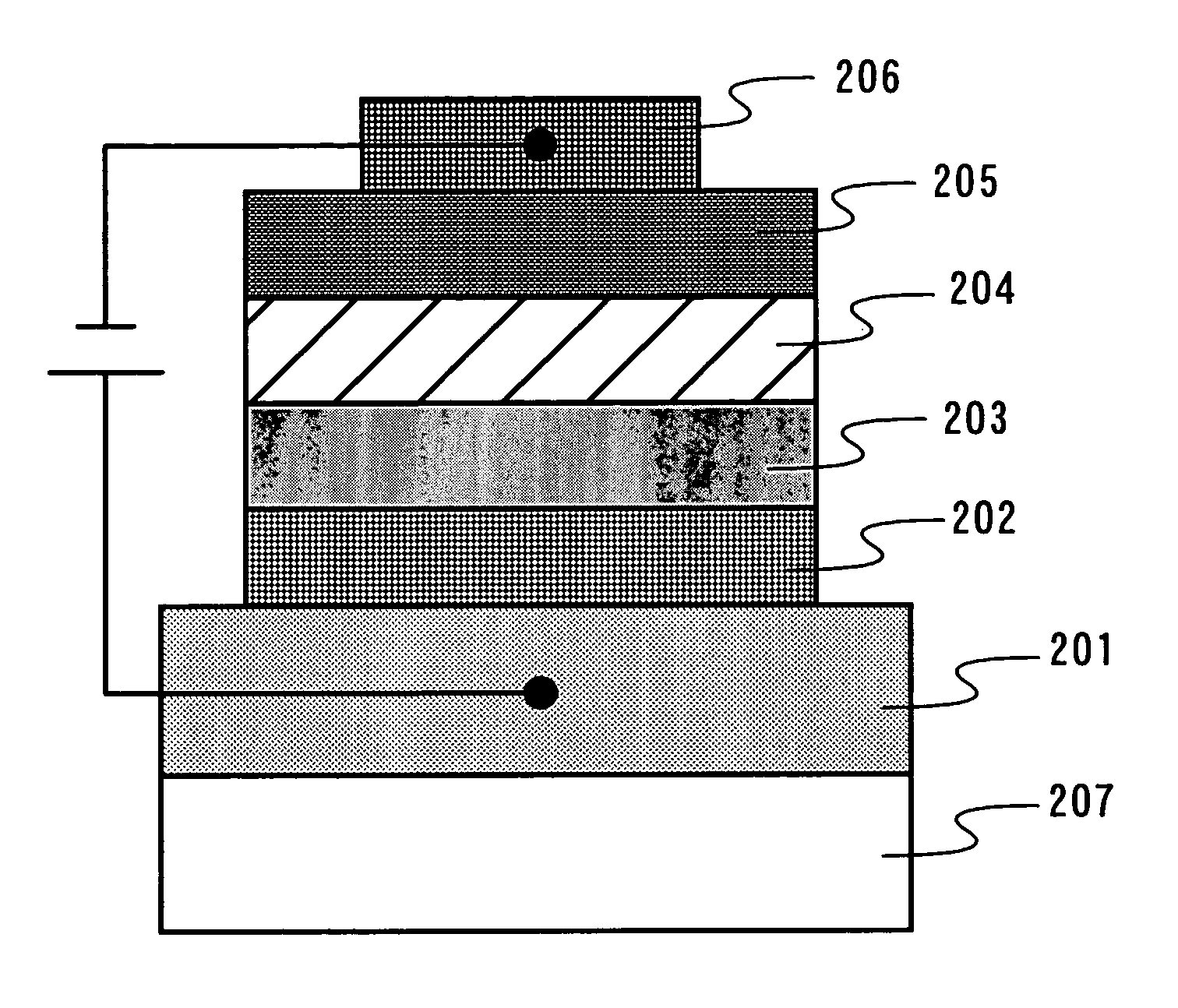

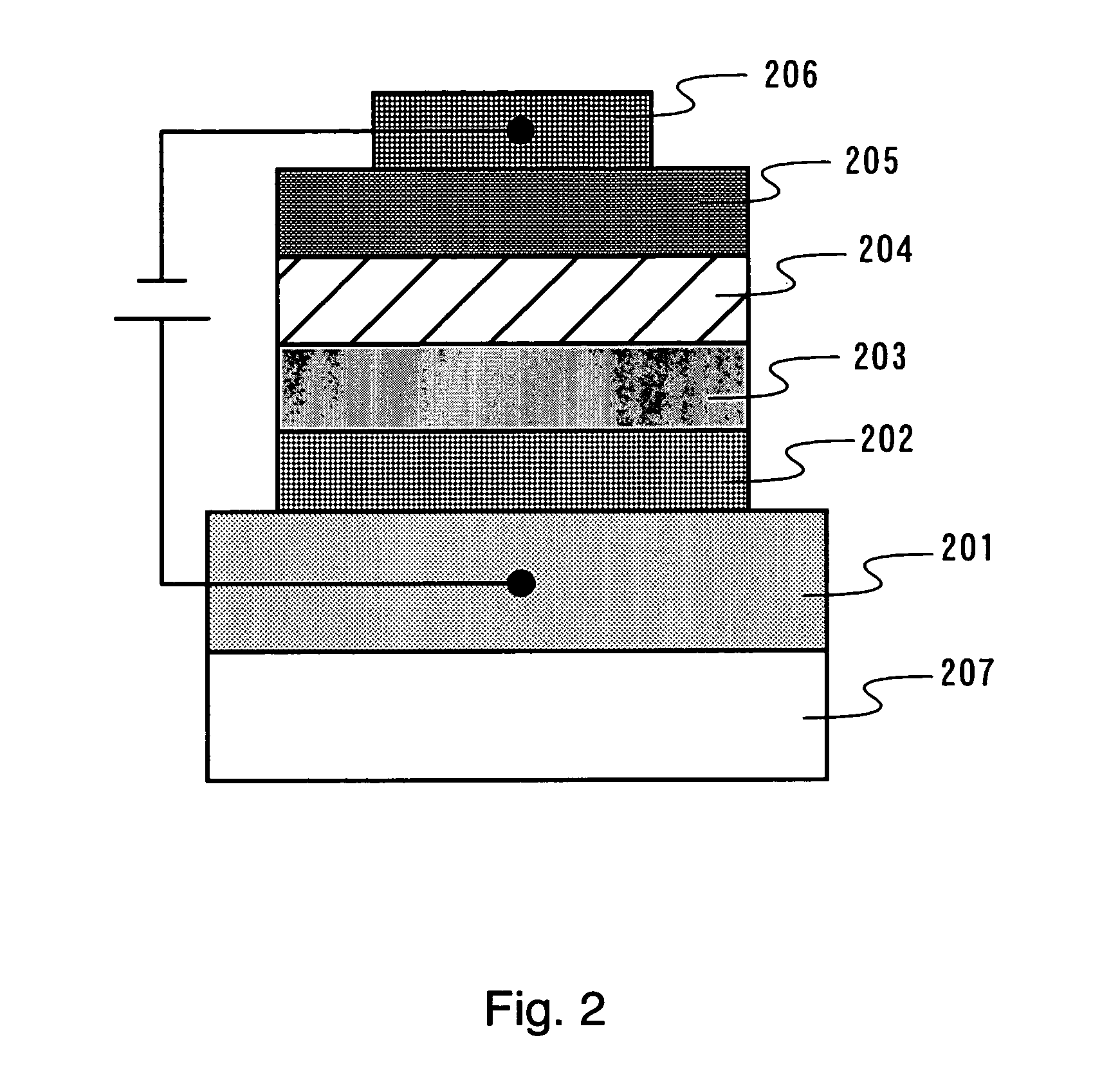

Light emitting element and method for manufacturing the same

InactiveUS7059928B2Alleviates deterioration of luminanceDeterioration of luminance is smallMultiplex communicationElectroluminescent light sourcesPhthalocyanineOrganic compound

In order to provide a light emitting device and an electronic equipment which suppress luminance deterioration, and have long life, the invention does not form an organic compound layer which is composed of a hole injection layer, a hole transport layer, a light emitting layer, an electron transport layer, an electron injection layer and so on, and electrodes in vacuum-through, as in a conventional vacuum deposition method, but after a hole injection layer, which comprises phthalocyanine, is formed, it is exposed to gas atmosphere. In particular, copper phthalocyanine is exposed to oxygen atmosphere. By this method, provided is an organic light emitting element which has long life, and by using the above-described organic light emitting element, a light emitting device and an electronic equipment are fabricated.

Owner:SEMICON ENERGY LAB CO LTD

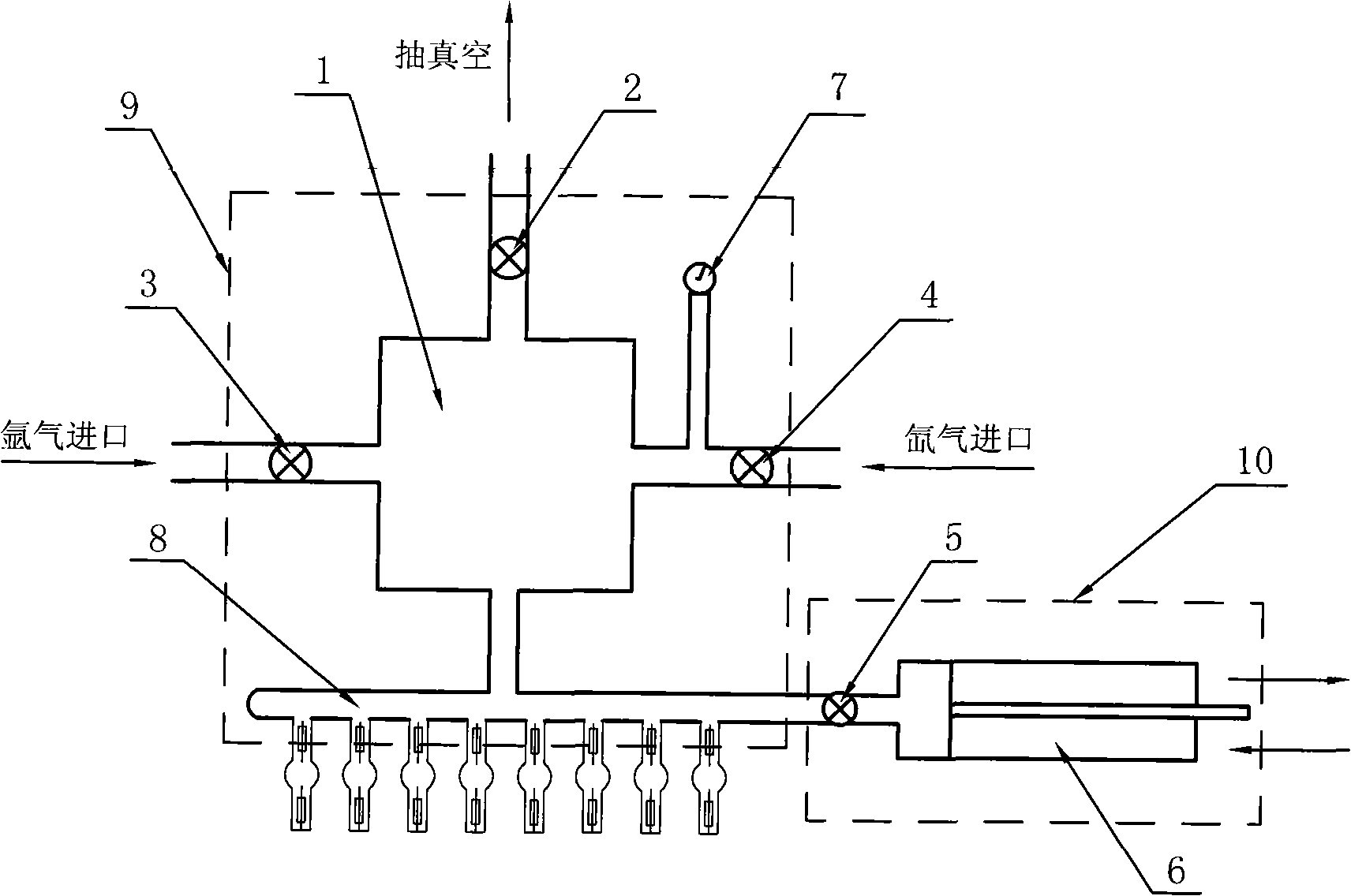

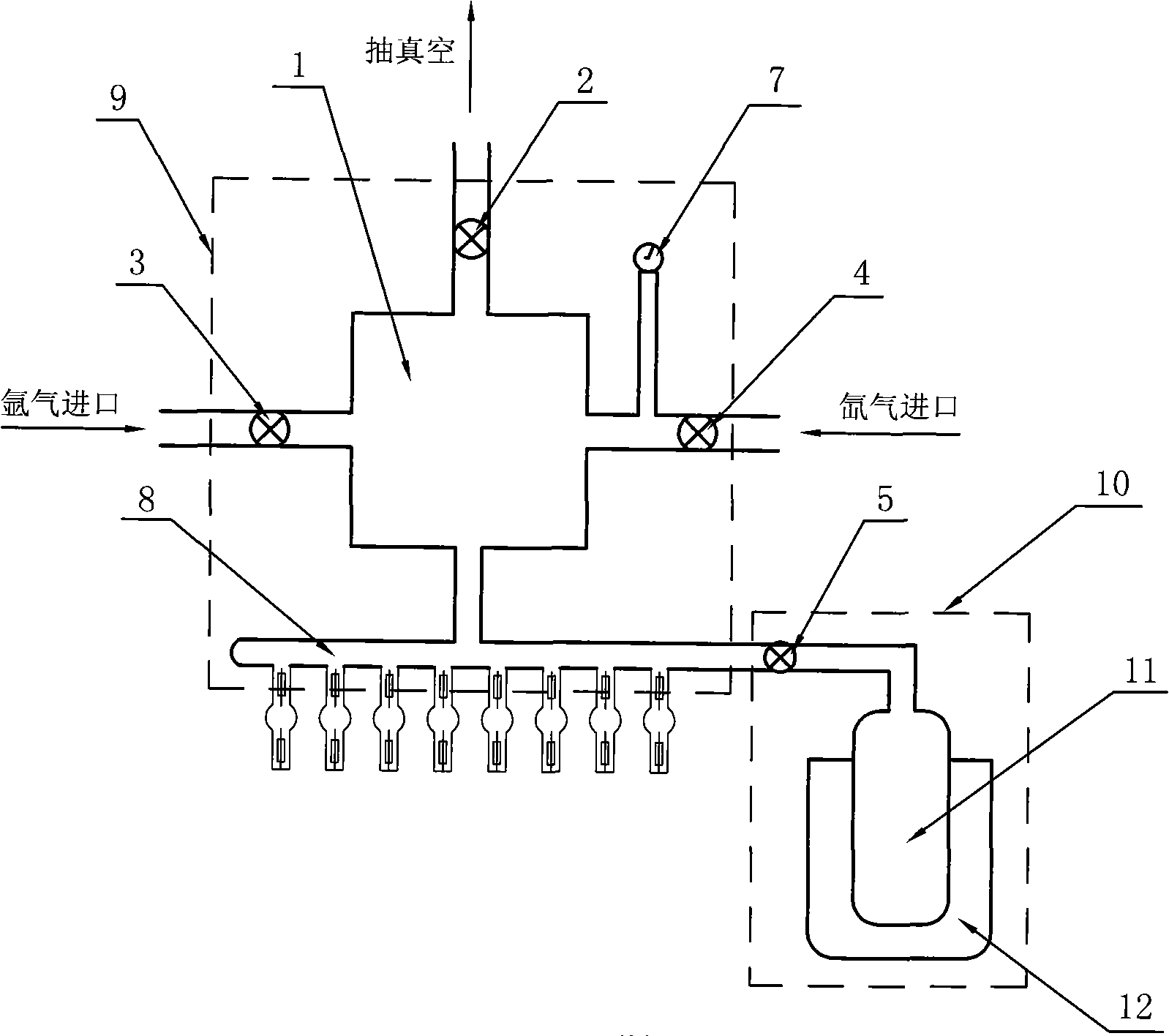

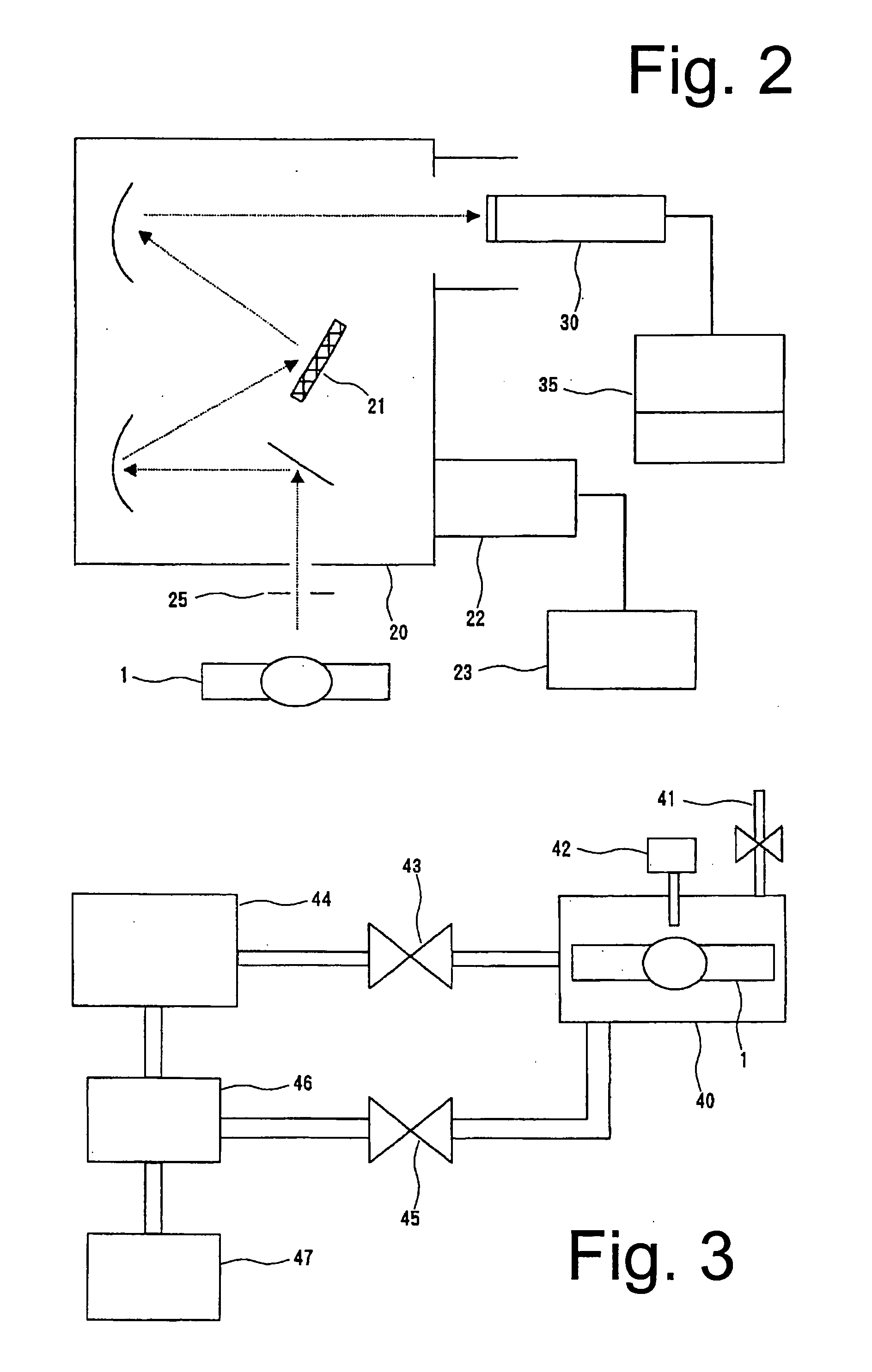

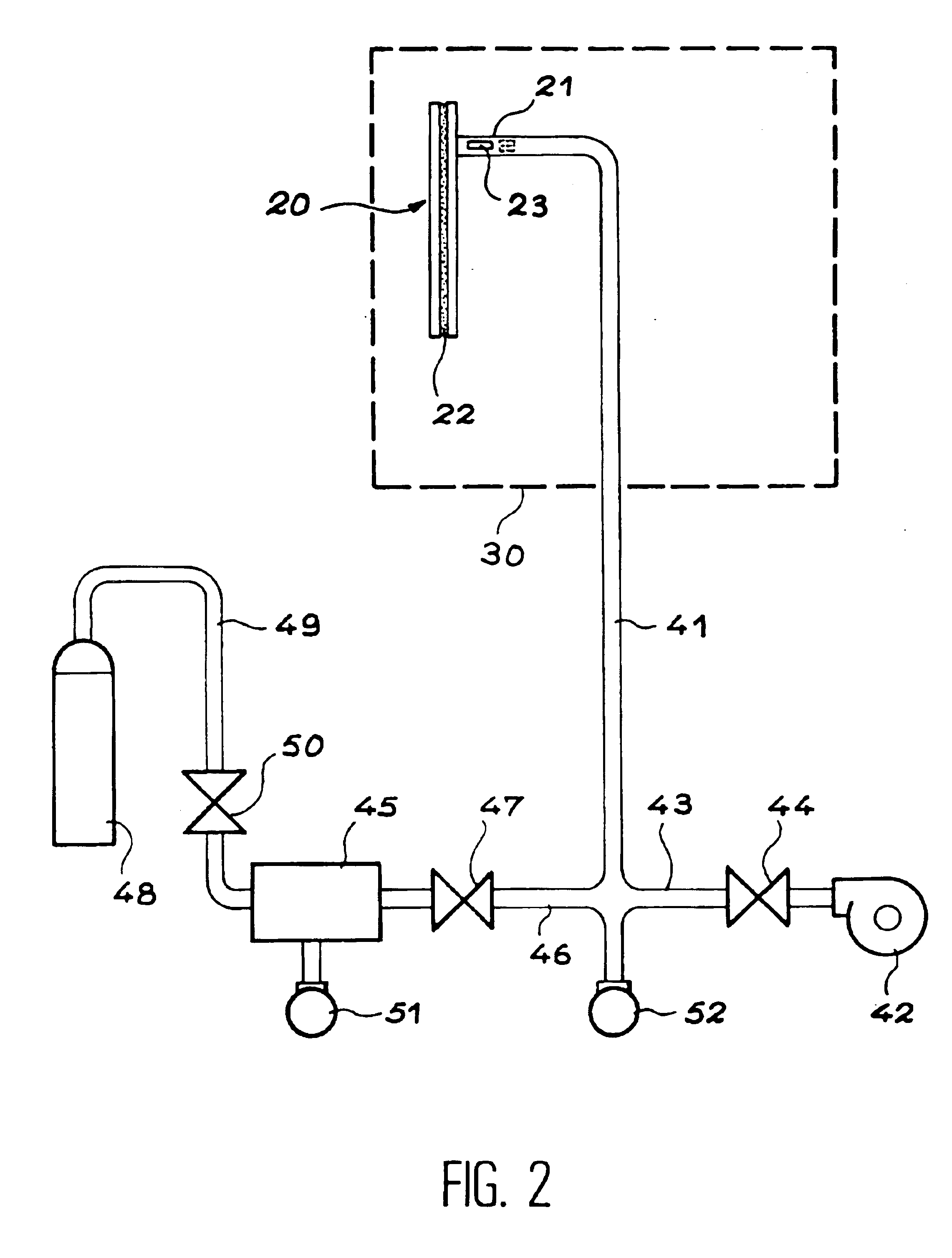

A charging and discharging method and device based on Xe gas

InactiveCN101266903AReduce wasteImprove recycling ratesTube/lamp vessel fillingTube/lamp vessels exhaustionVacuum pumpingCharge discharge

The invention discloses a gas charge-discharge method and device capable of adequately using xenon gas, comprising: using a recovery system connected with a charge-discharge system in parallel to collect and store the xenon gas remained in the charge-discharge system as charging gas for next batch of arc tubes. The device is composed of a charge-discharge system and a recovery system for collecting the xenon gas. The charge-discharge system comprises a four-way connector, three valves respectively connected with the four-way connector, and a arc tube arranging pipe; three valves are respectively connected with a vacuum pumping device, a flushing gas inlet and a working gas (xenon gas) inlet; a plurality of arc tubes to be charged can be disposed on the arc tube arranging pipe simultaneously; the recovery system is disposed on one end of the arc tube arranging pipe, composed by a recovery device and a valve, the valve is disposed between the arc tube arranging pipe and the recovery device. The invention can effectively enhance the utilization rate of xenon gas during xenon gas lamp manufacture, by increasing the utilization rate from under existing 30% up to over 95%.

Owner:浙江新光阳照明股份有限公司

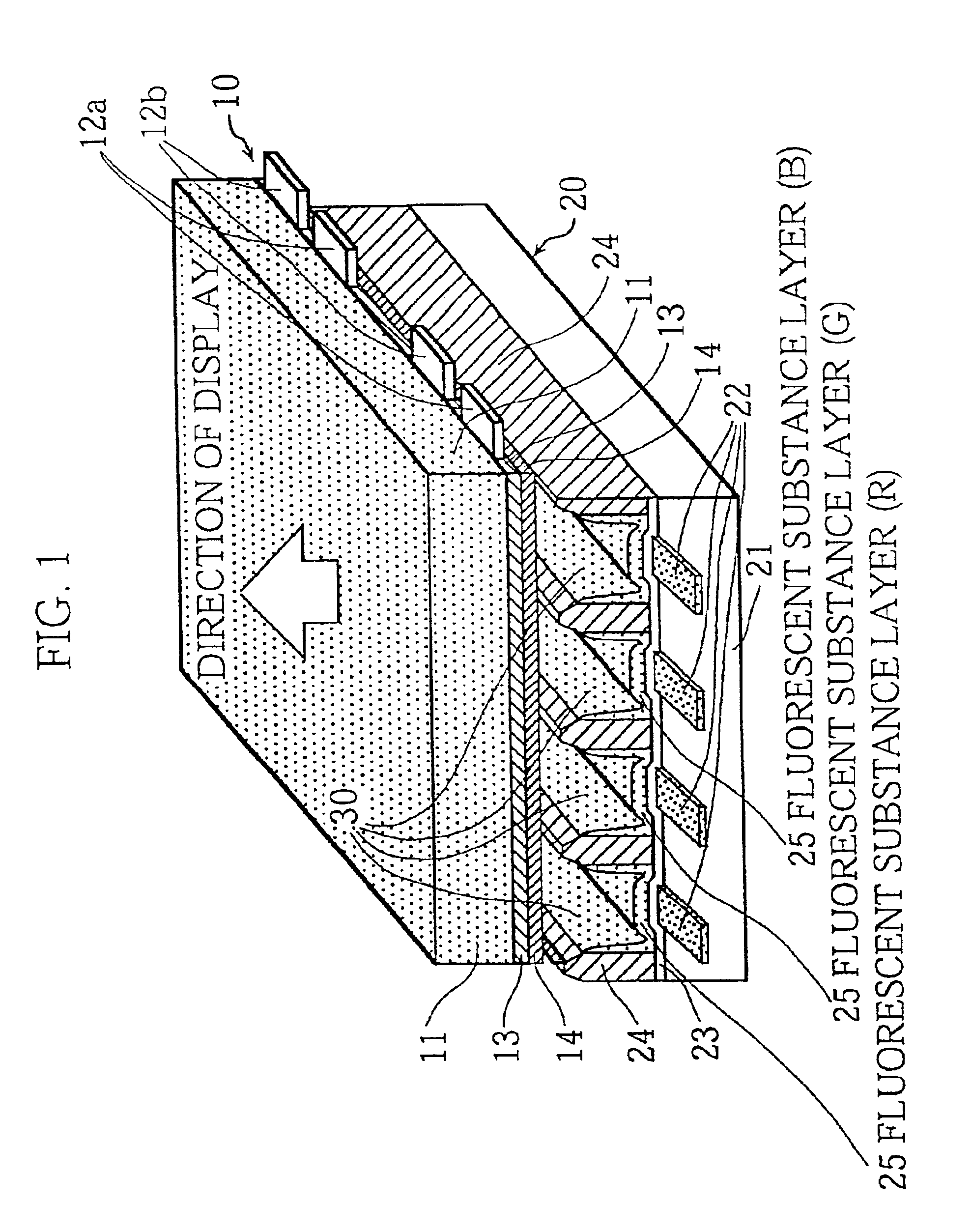

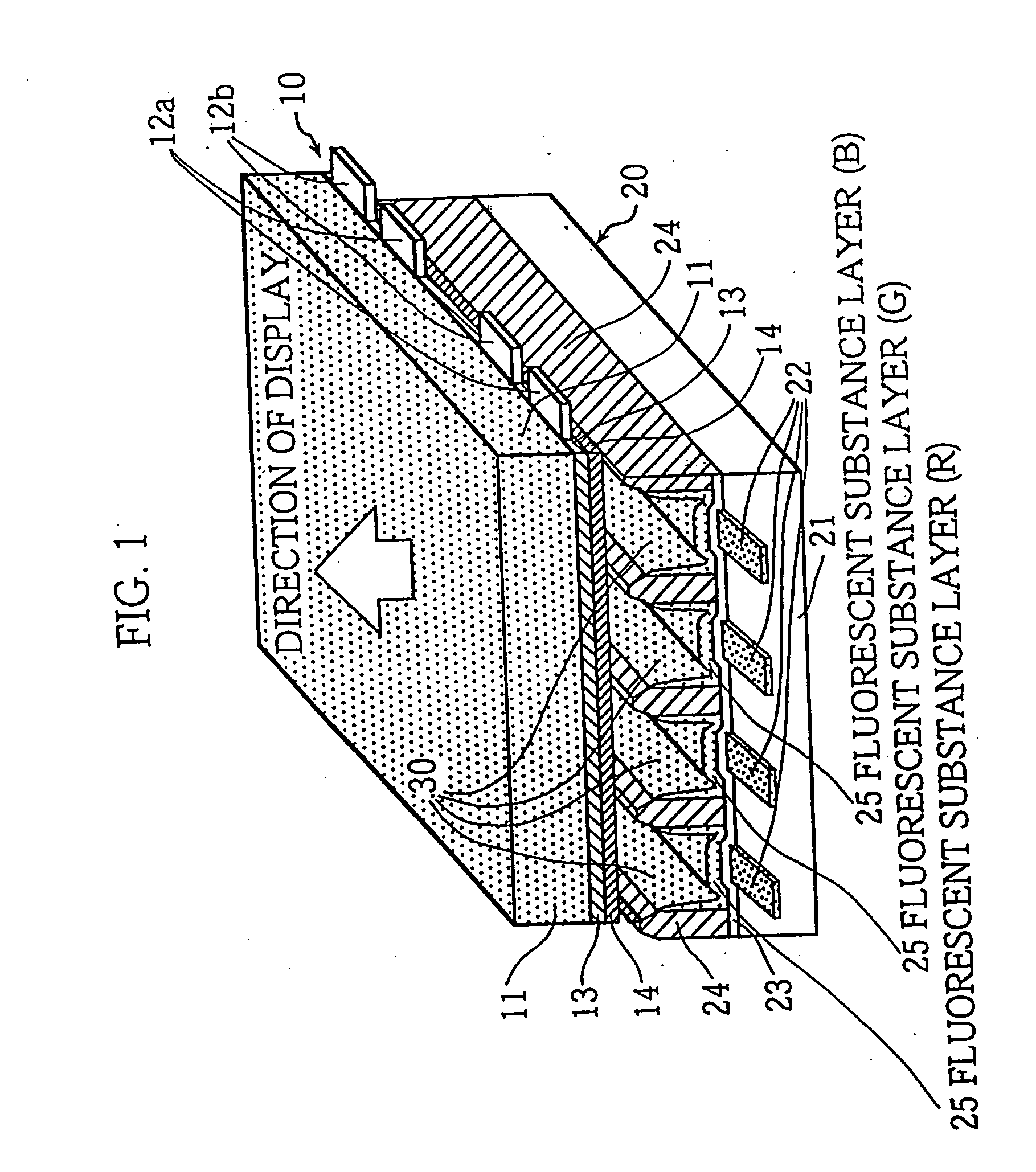

Discharge light-emitting device and method manufacture thereof

InactiveUS6744208B2Reduce voltageEasy dischargeTube/lamp vessel fillingAlternating current plasma display panelsElectric dischargeWater vapor

A discharge light-emitting device includes a gas-filled discharge spaces (30) to use electric discharge in the gas. The gas contains at least 0.01-1% water vapor by volume. The specified amount of water vapor decreases discharge voltage markedly. Water vapor is introduced between a sealing step and an evacuation step so that the gas-filled discharge spaces can finally contain a desired amount of water vapor.

Owner:PANASONIC CORP

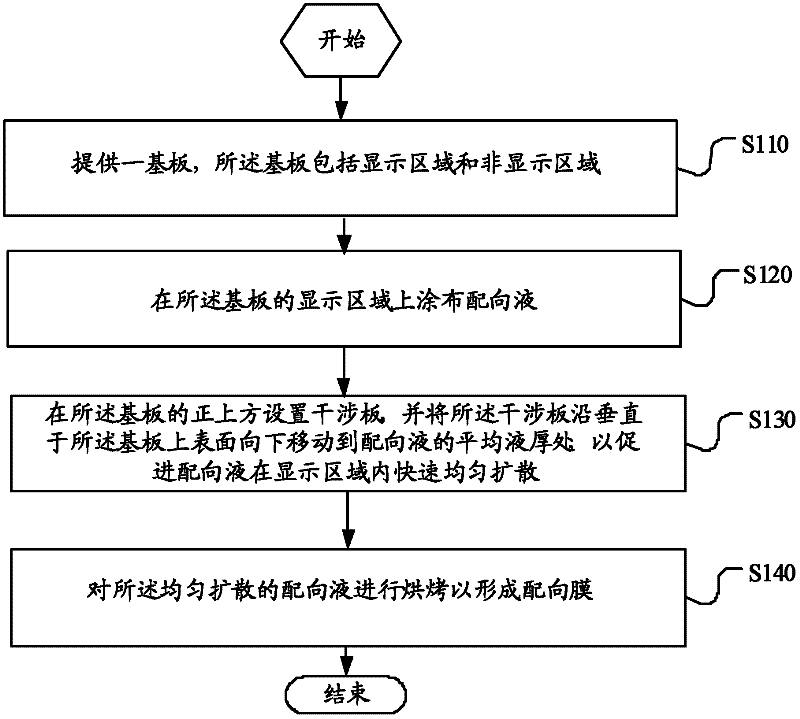

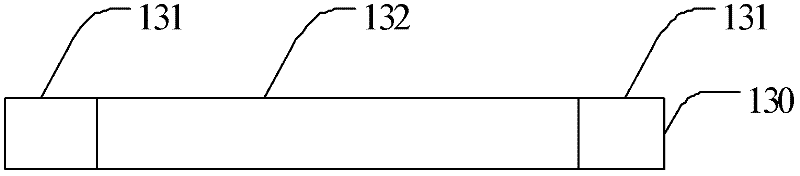

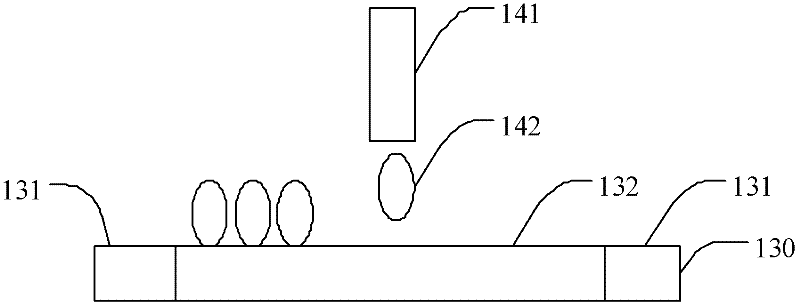

Method for preparing distribution film and equipment

InactiveCN102314024AGuaranteed thicknessImprove uniformityTube/lamp vessel fillingNon-linear opticsComposite material

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

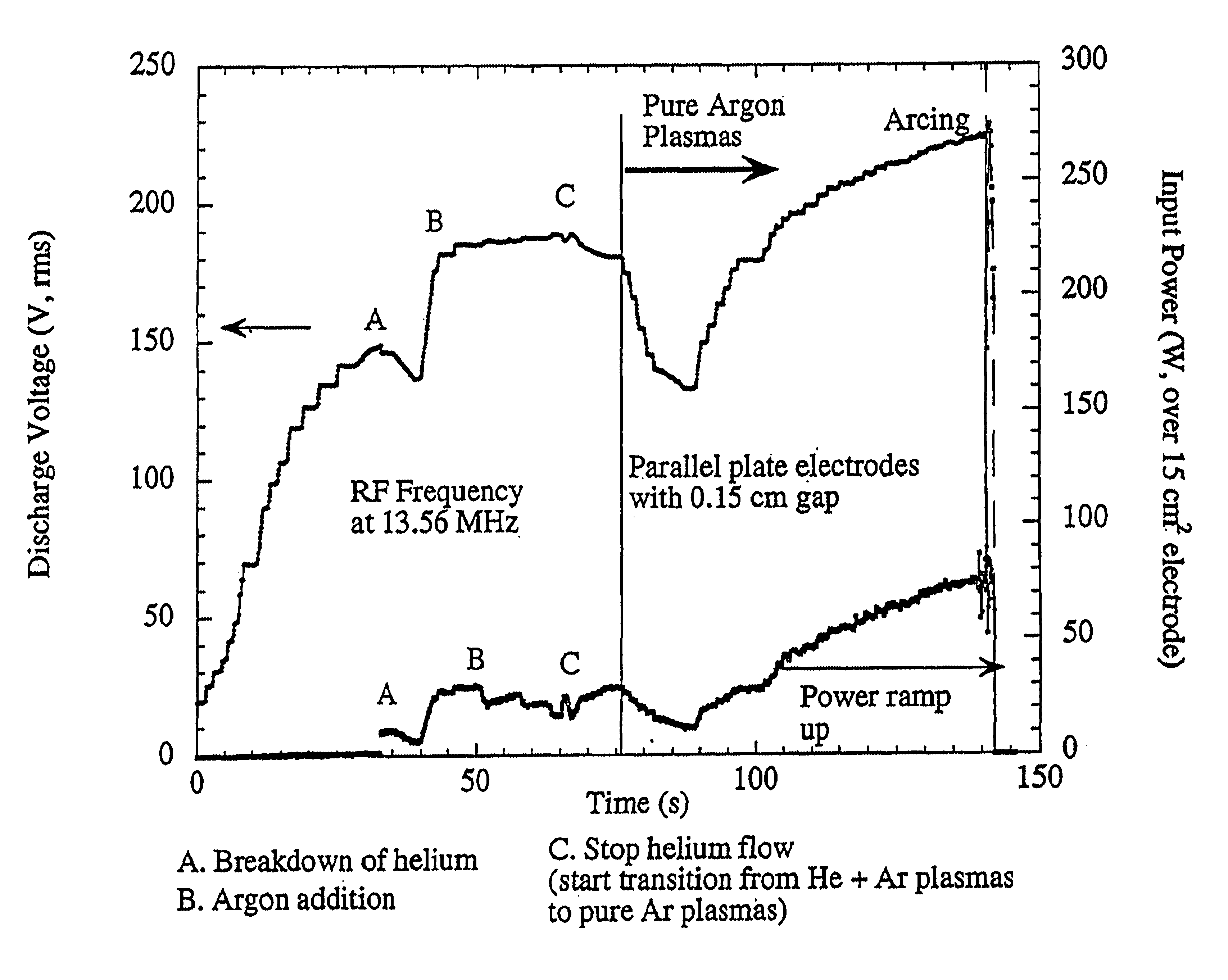

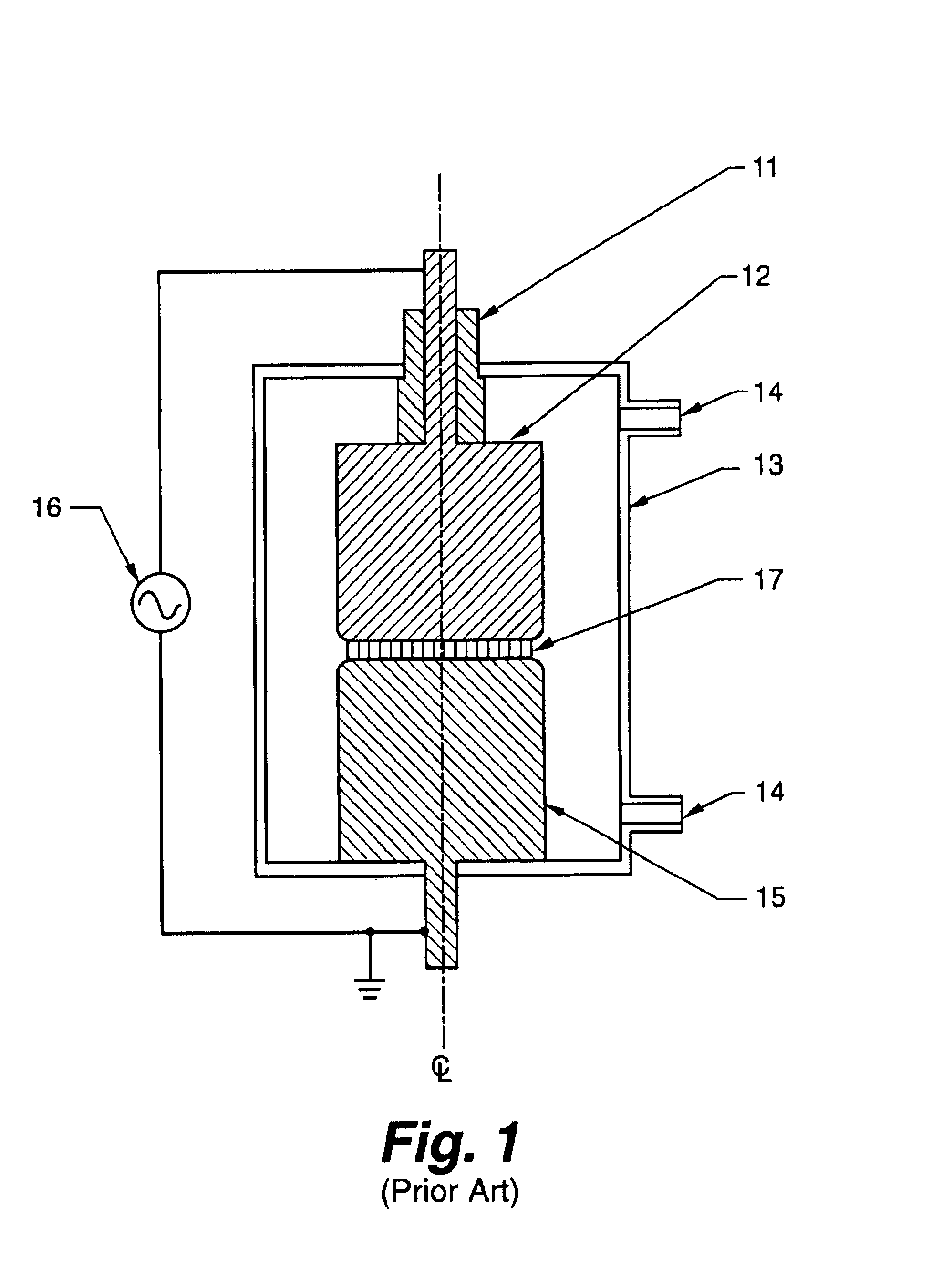

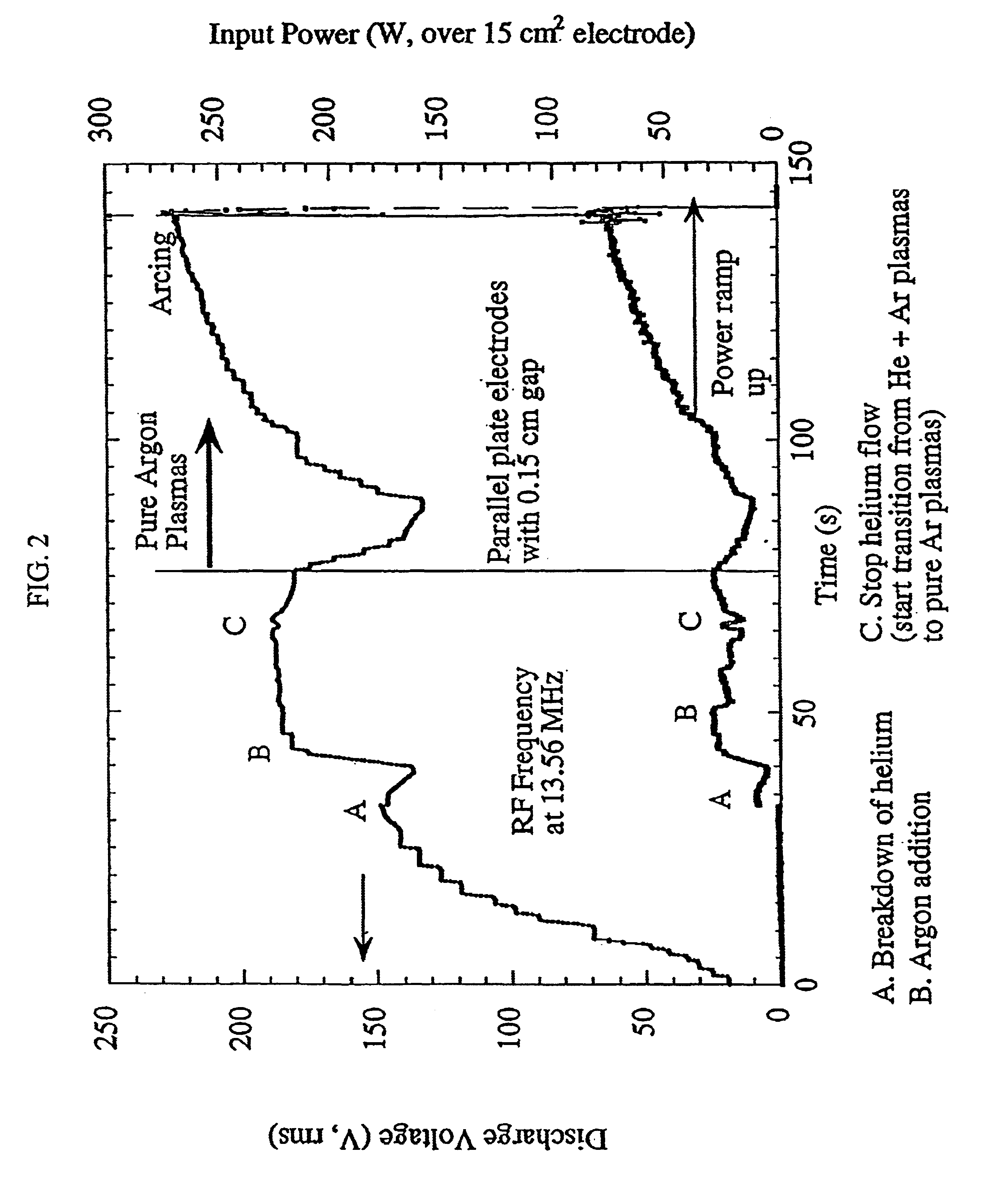

Production of stable, non-thermal atmospheric pressure rf capacitive plasmas using gases other than helium or neon

The present invention enables the production of stable, steady state, non-thermal atmospheric pressure rf capacitive α-mode plasmas using gases other than helium and neon. In particular, the current invention generates and maintains stable, steady-state, non-thermal atmospheric pressure rf α-mode plasmas using pure argon or argon with reactive gas mixtures, pure oxygen or air. By replacing rare and expensive helium with more readily available gases, this invention makes it more economical to use atmospheric pressure rf α-mode plasmas for various materials processing applications.

Owner:TRIAD NAT SECURITY LLC

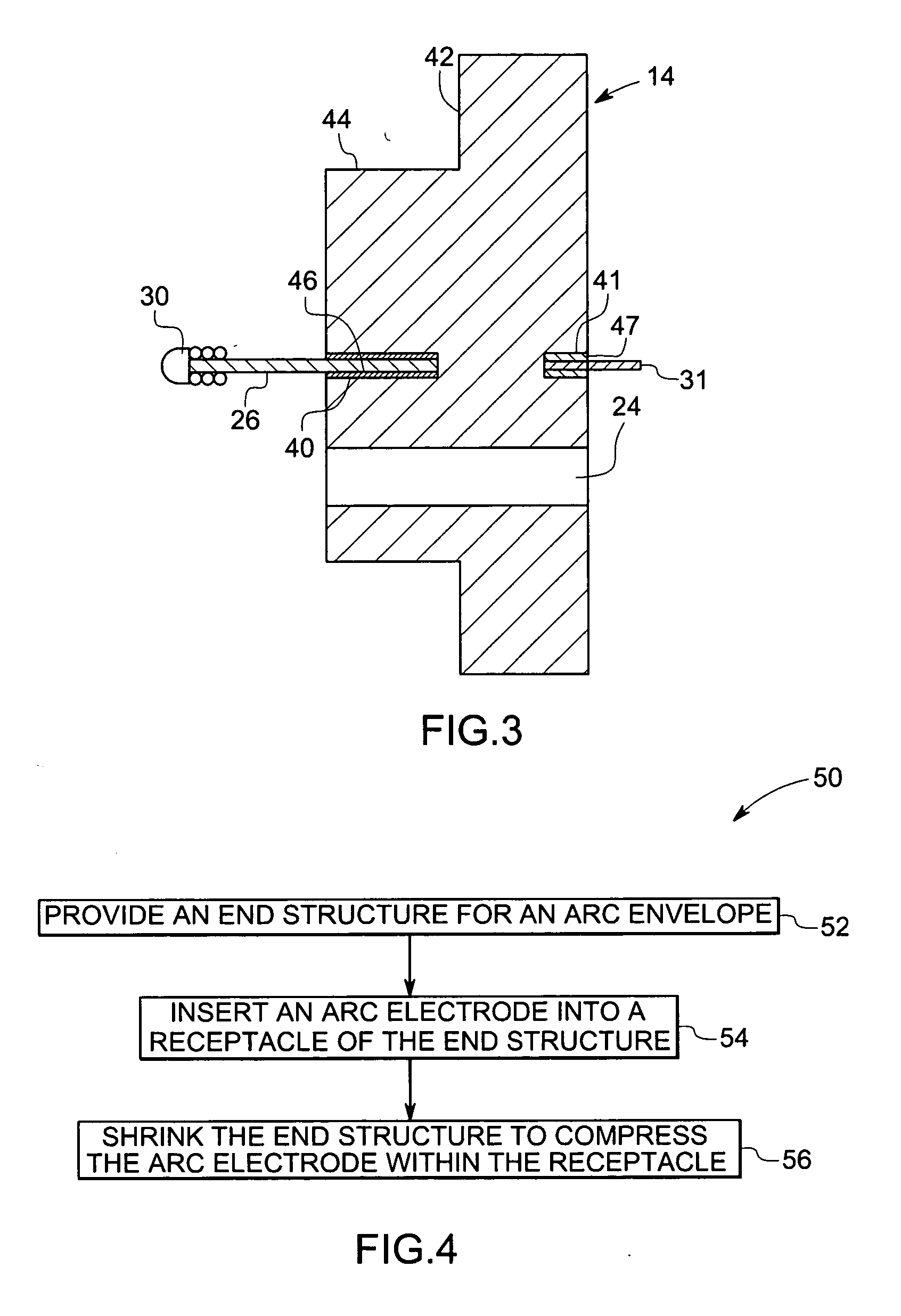

Ceramic lamp having molybdenum-rhenium end cap and systems and methods therewith

InactiveUS20070001610A1Improve performanceElectroluminescent light sourcesTube/lamp vessel fillingRheniumBiomedical engineering

A lamp comprising an arc envelope and a molybdenum-rhenium end structure coupled to the arc envelope.

Owner:GENERAL ELECTRIC CO

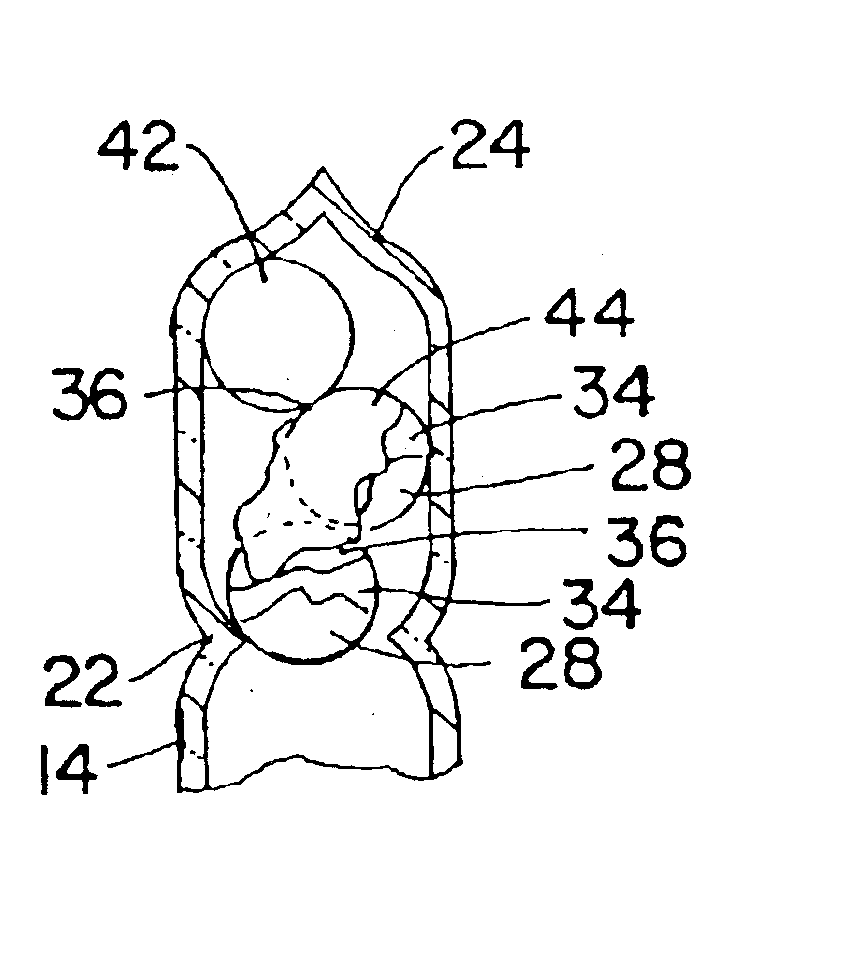

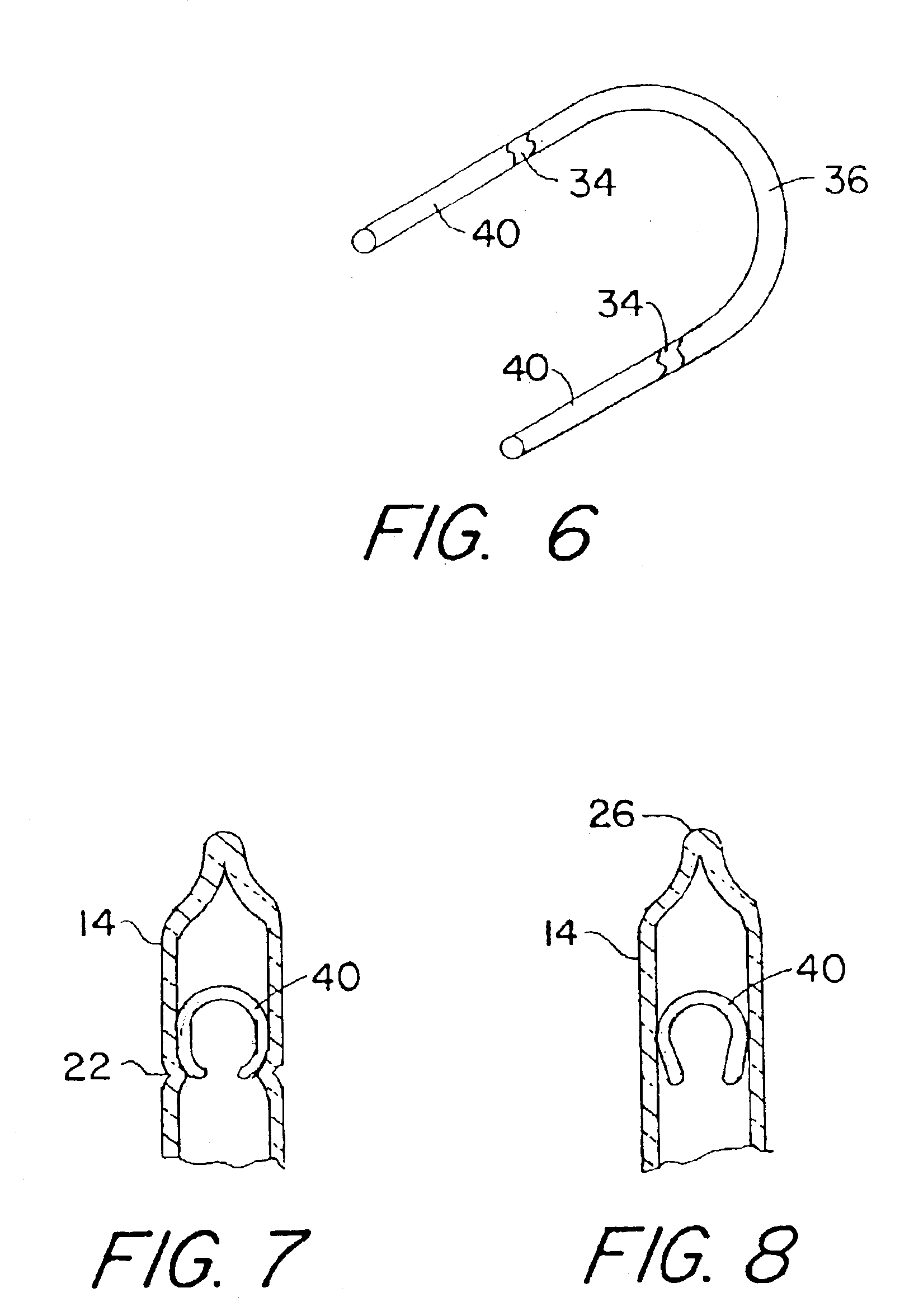

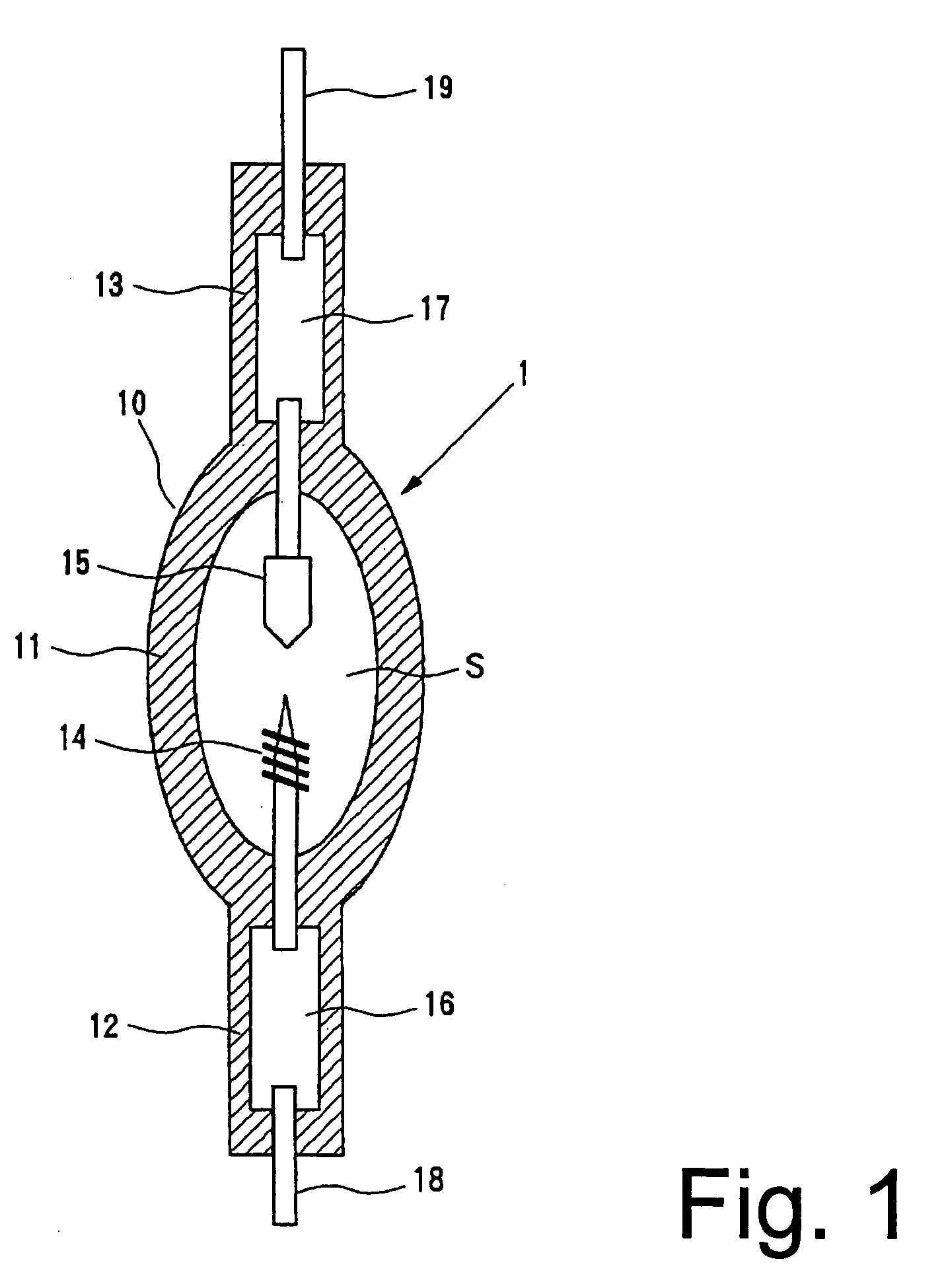

Device and method for retaining mercury source in low-pressure discharge lamps

InactiveUS6906460B2Improve manufacturing productivityMercury contamination of the production equipment remains lowElectric lighting sourcesTube/lamp vessel fillingElectric lightEngineering

A device for retaining a mercury source in the discharge space of a low-pressure discharge lamp is disclosed. The mercury source retaining device comprises a holder, which has an inner space communicating with the discharge space and a receiver opening for receiving a mercury source. The retaining device further comprises resilient clamping means for clamping the holder in a tubular space segment of the discharge space and resilient retaining means at least partially blocking the receiver opening. The resilient retaining means are adapted for allowing a passage of the mercury source in a direction towards the inner space of the holder, but block the movement of the mercury source through the receiver opening in a direction out of the holder.

Owner:GENERAL ELECTRIC CO

Street lighting lamp with long life, high efficiency, and high lumen maintenance

InactiveUS20110031879A1Improve efficiencyHigh lumen maintenanceElectroluminescent light sourcesTube/lamp vessel fillingCeriumEffect light

A lamp includes a discharge vessel and electrodes extending into the discharge vessel. The lamp further includes an ionizable fill sealed within the vessel. The fill includes an inert gas and a halide component. The halide component includes a sodium halide, a thallium halide, at least one of a calcium halide and a strontium halide, and at least one of a rare earth halide. The rare earth halide is selected from the group consisting of lanthanum, cerium, praseodymium, samarium and neodymium, and combinations thereof.

Owner:GENERAL ELECTRIC CO

Use of printing and other technology for micro-component placement

InactiveUS20030207645A1Sufficient resolutionManufactured very thinTelevision system detailsMechanical apparatusEngineeringImproved method

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. An improved method of manufacturing a light-emitting panel is also disclosed, which uses a web fabrication process to manufacturing light-emitting displays as part of a high-speed, continuous inline process.

Owner:LEIDOS

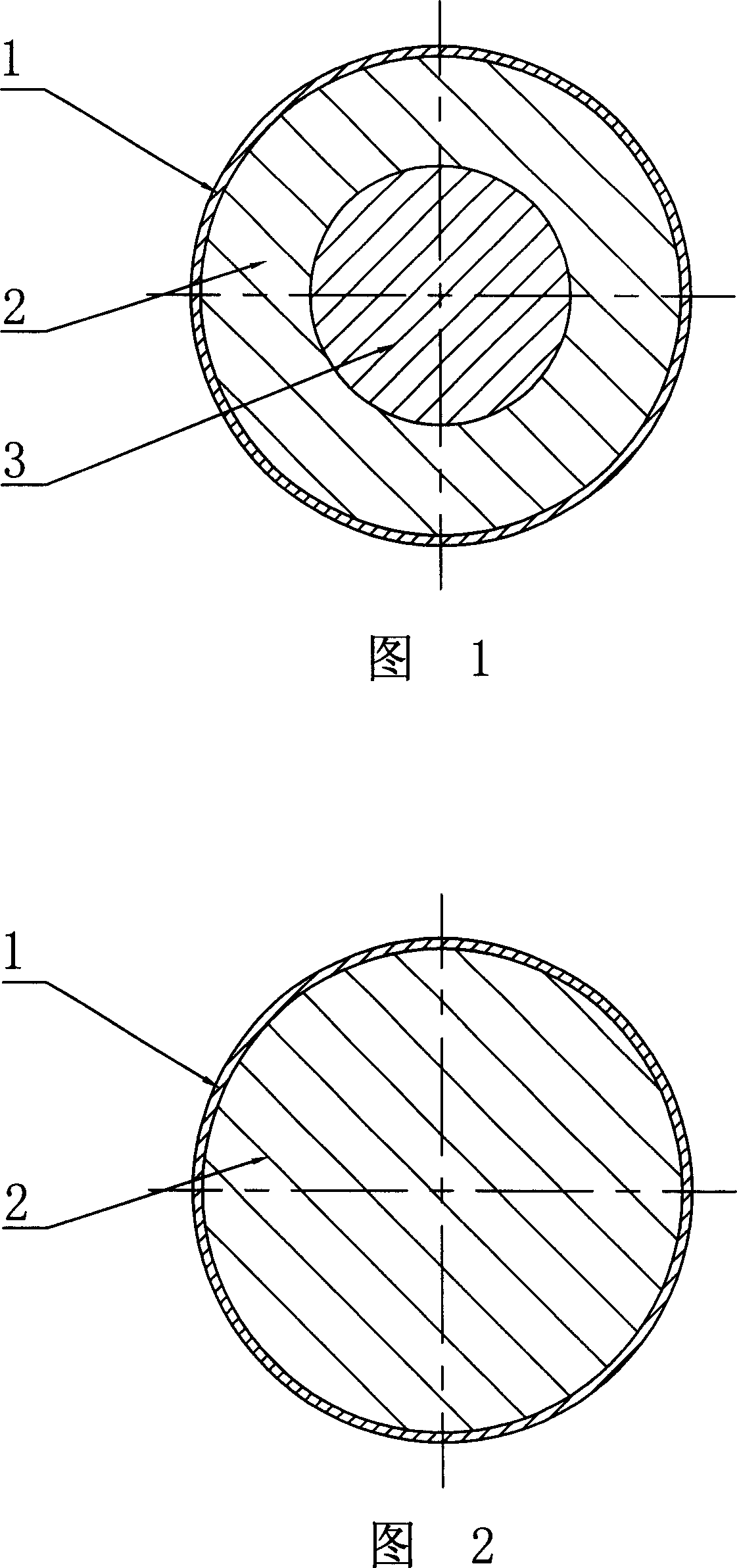

Mercury releasing apparatus for fluorescent lamp

InactiveCN101000848ANot volatileImprove securityTube/lamp vessel fillingGas discharge lamp detailsUltravioletAlloy

A mercury release device used on fluorescent lamp is prepared as covering compact film on external surface of amalgam layer, forming said amalgam layer by binary or above alloy material, forming said film by one or multiple of binary or above alloy not containing mercury and metal oxide as well as salt or fluorescent powder.

Owner:GAOYOU GAO HE PHOTOELECTRIC EQUIP

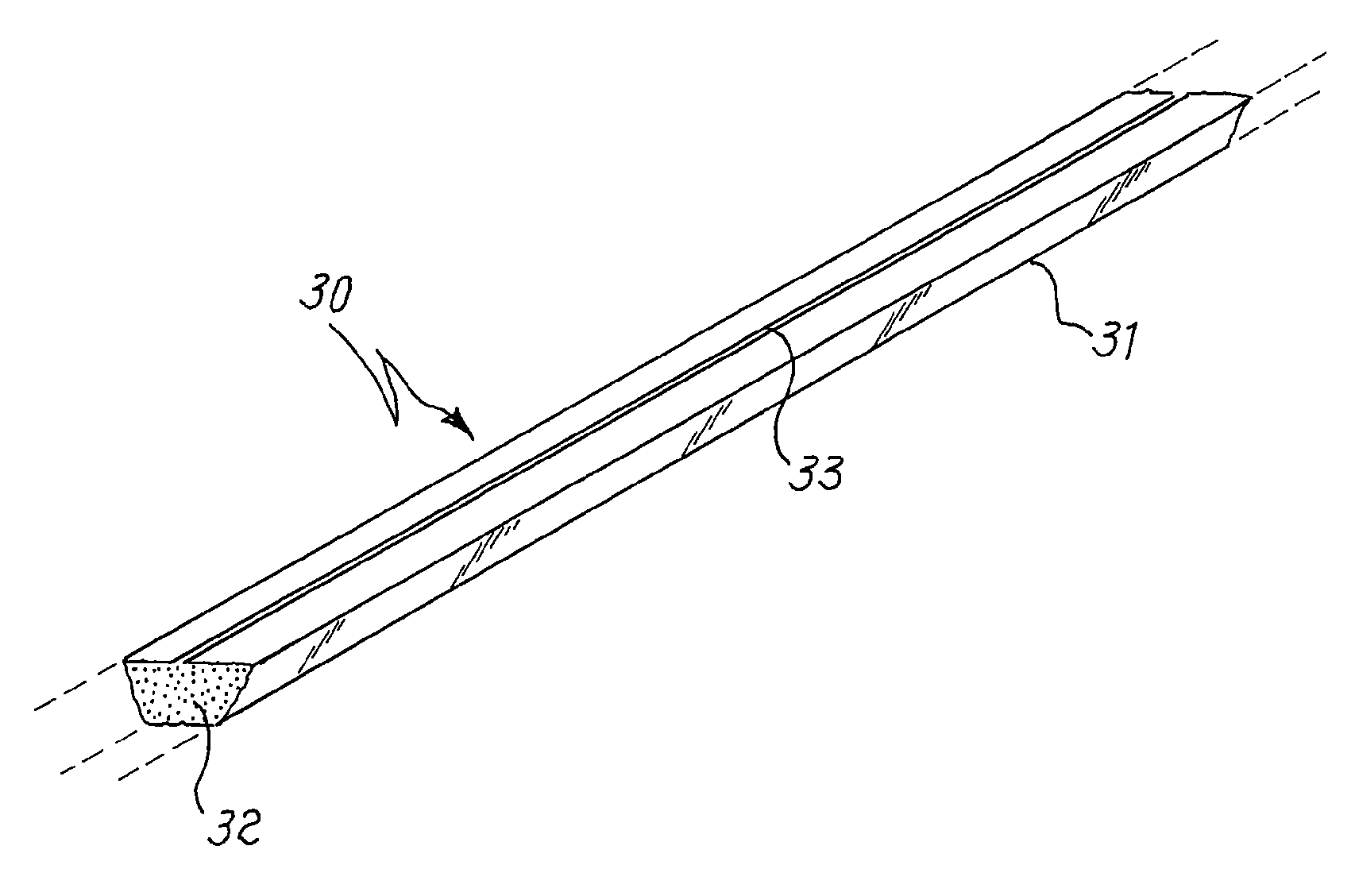

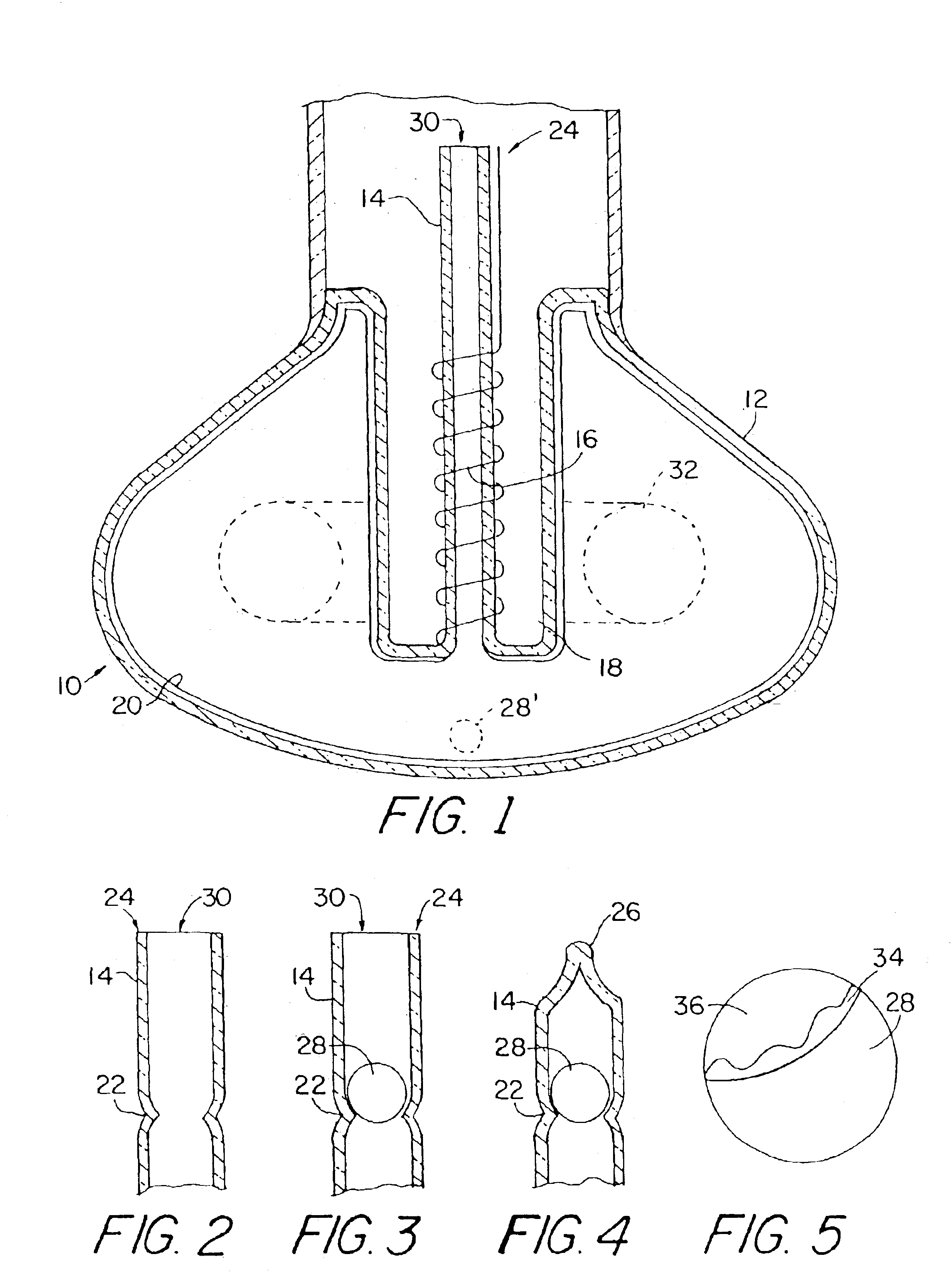

Method for introducing mercury into a fluorescent lamp during manufacture and a mercury carrier body facilitating such method

InactiveUS6913504B2Tube/lamp vessel fillingTube/lamp vessels exhaustionMetal coatingMetallic materials

Method for introducing a limited amount of mercury into a fluorescent lamp during manufacture thereof includes the steps of forming the lamp with an exhaust tubulation therein open at an end thereof, exhausting the interior of the lamp through the exhaust tubulation, placing a body of metal material not reactive with mercury in the exhaust tubulation open end, the body having a coating of metal which amalgams with mercury, over a selected surface area of the body, and having mercury on the coated area of the body, such that a limited amount of the mercury is retained by the metal coating, and sealing the open end of the exhaust tubulation, whereby the amount of mercury retained on the body and introduced into the lamp is limited by the surface area of the metal coating on the body.

Owner:OSRAM SYLVANIA INC

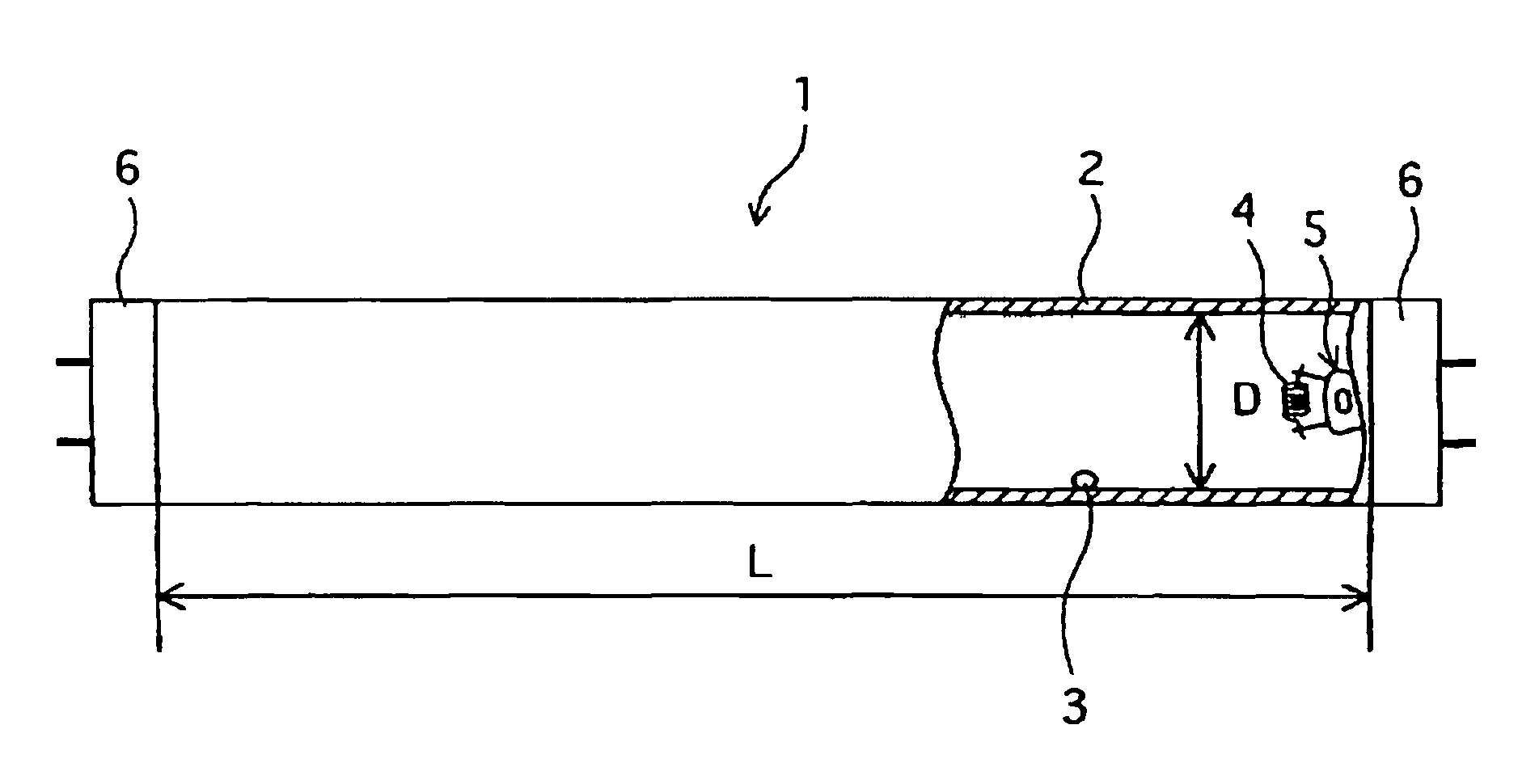

Fluorescent lamp, luminaire and method for manufacturing fluorescent lamp

InactiveUS7538479B2Solve easy peelingDischarge tube luminescnet screensElectroluminescent light sourcesNoble gasPhosphor

A fluorescent lamp is configured so that a glass bulb has a phosphor film formed on its internal face, and a rare gas and an amalgam pellet are enclosed therein. The amalgam pellet contains zinc, tin, and mercury as principal components, one amalgam pellet is enclosed in the glass bulb, and the amalgam pellet has a weight of not more than 20 mg. The fluorescent lamp satisfies the relationship expressed as: 45×(1−A)≦x≦55×(1−A), 75A≦y≦85A, 45−30A≦z≦55−30A, and x+y+z≦100, where x represents a content of zinc contained in the amalgam pellet in percent by weight, y represents a content of tin therein in percent by weight, and z represents a content of mercury therein in percent by weight. This configuration allows the fluorescent lamp to be characterized in that an amount of released mercury that is necessary for the first lighting of the fluorescent lamp is secured, and that the phosphor film is less prone to being peeled due to the amalgam.

Owner:PANASONIC CORP

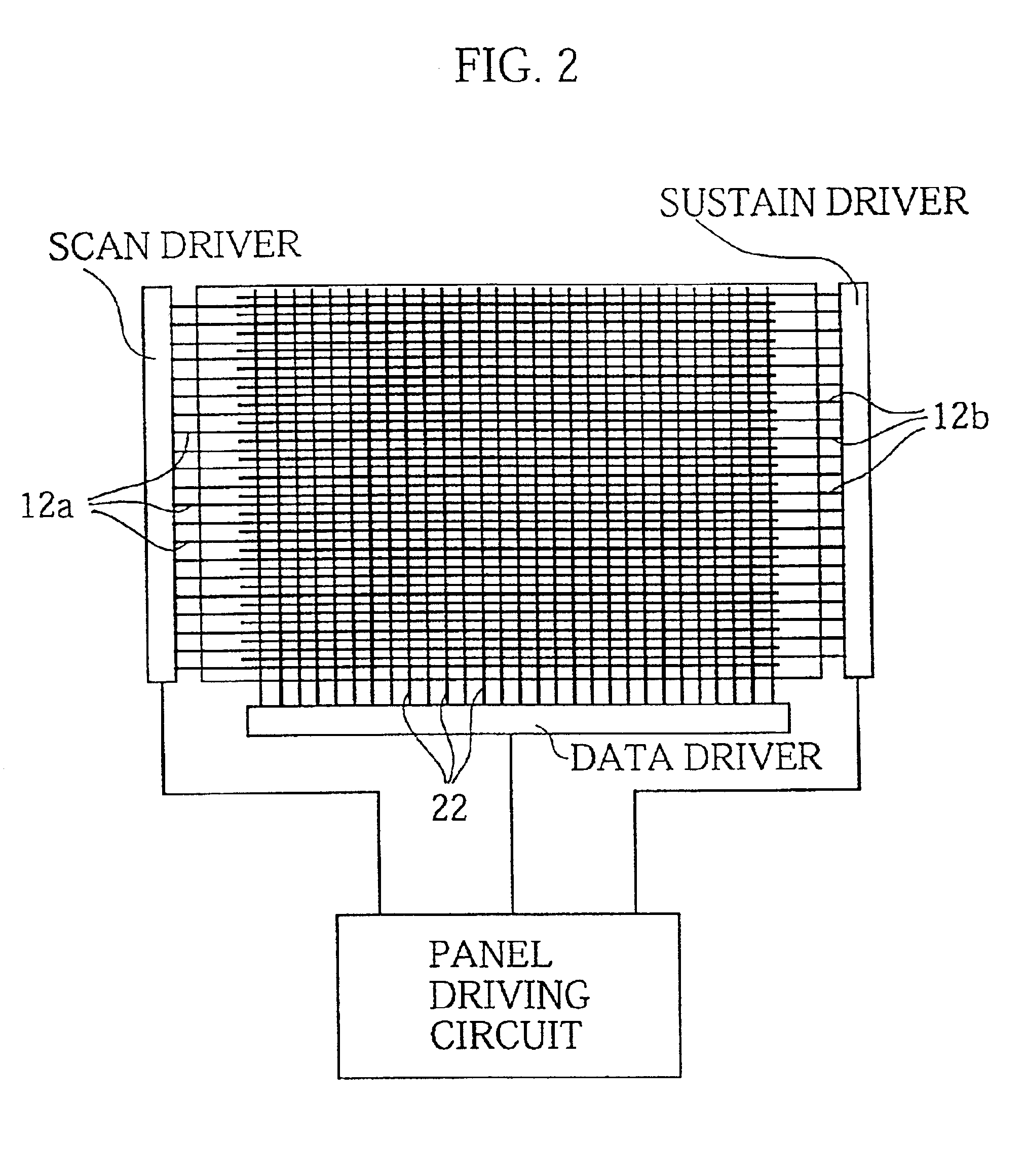

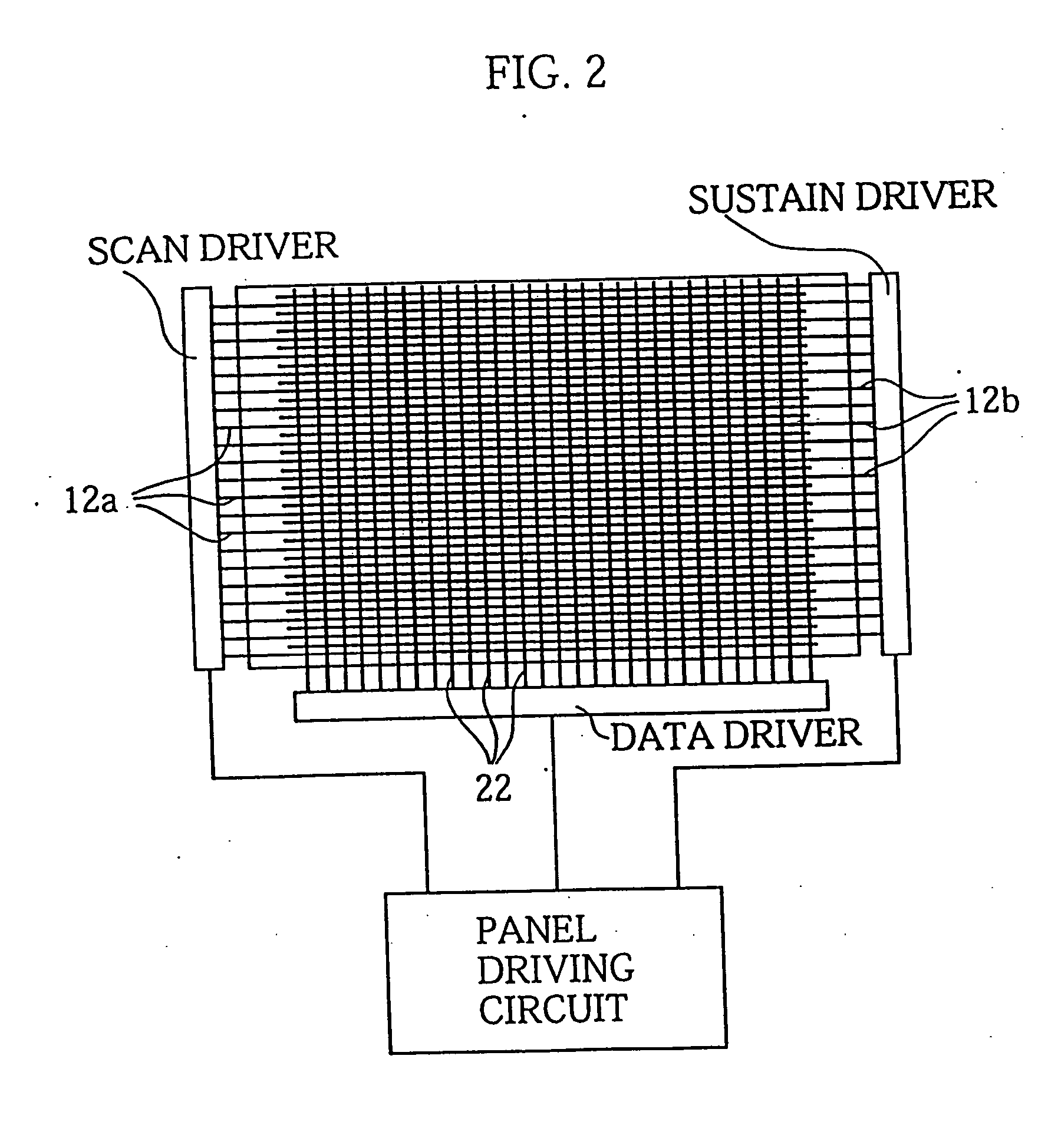

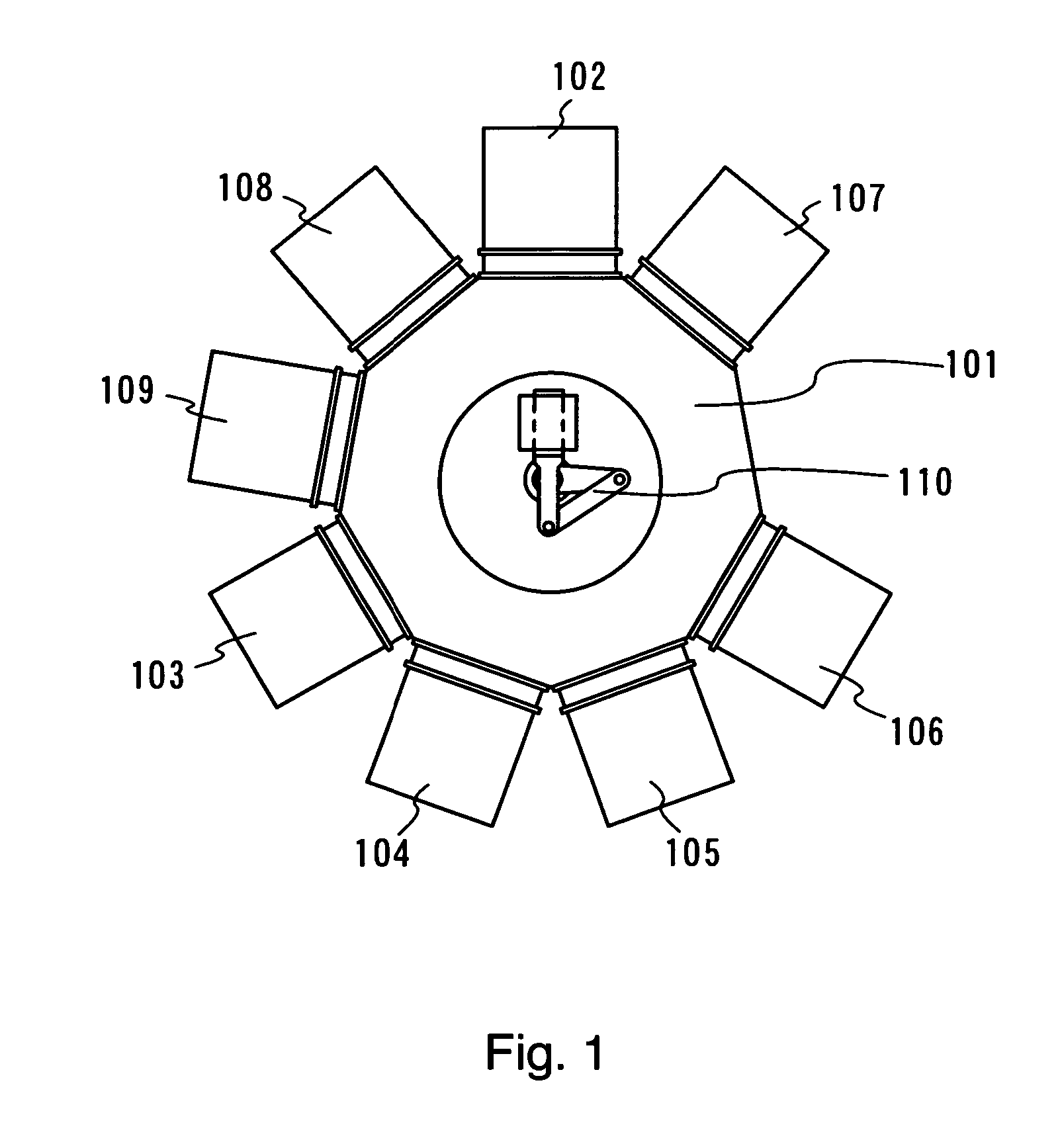

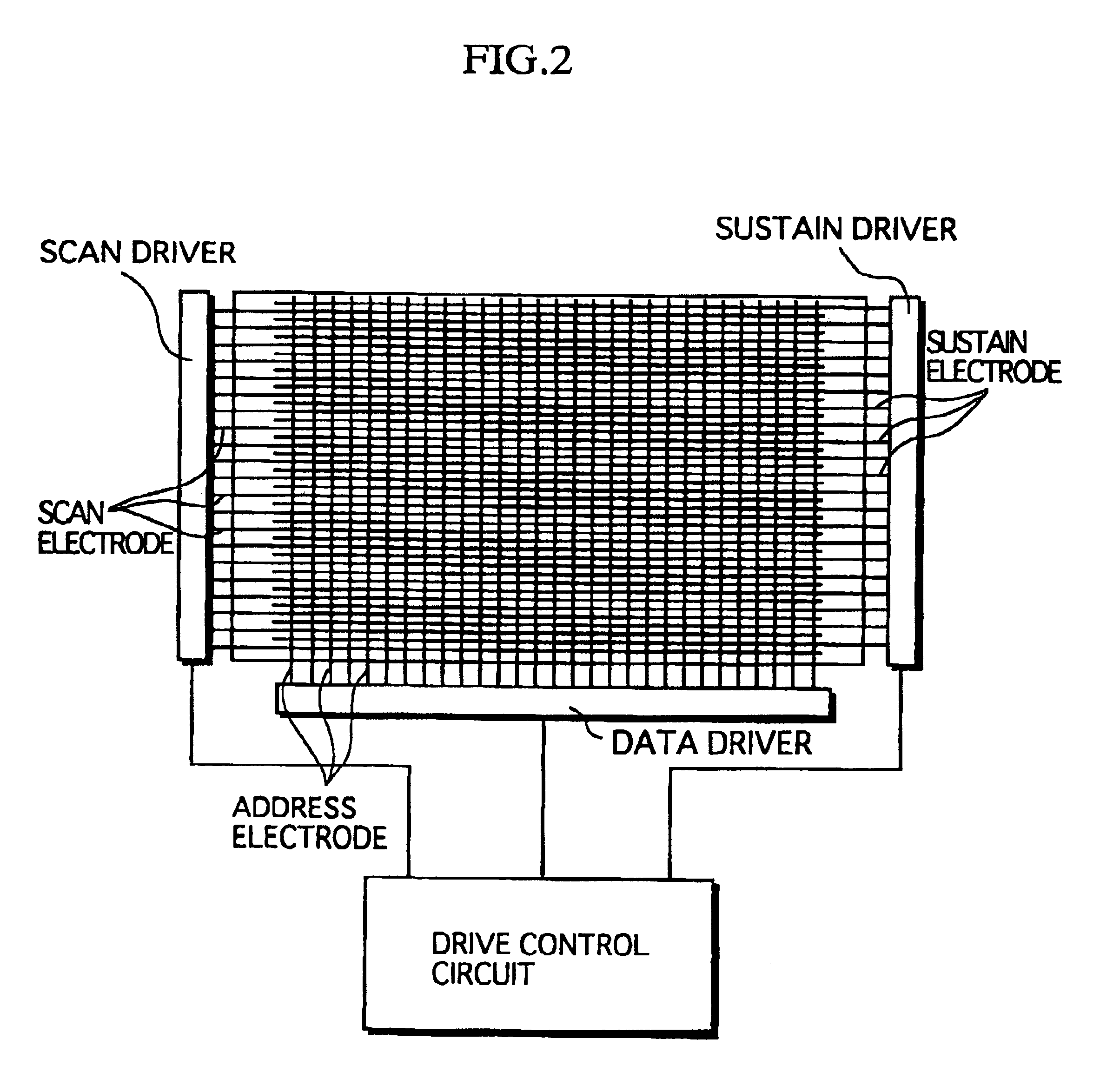

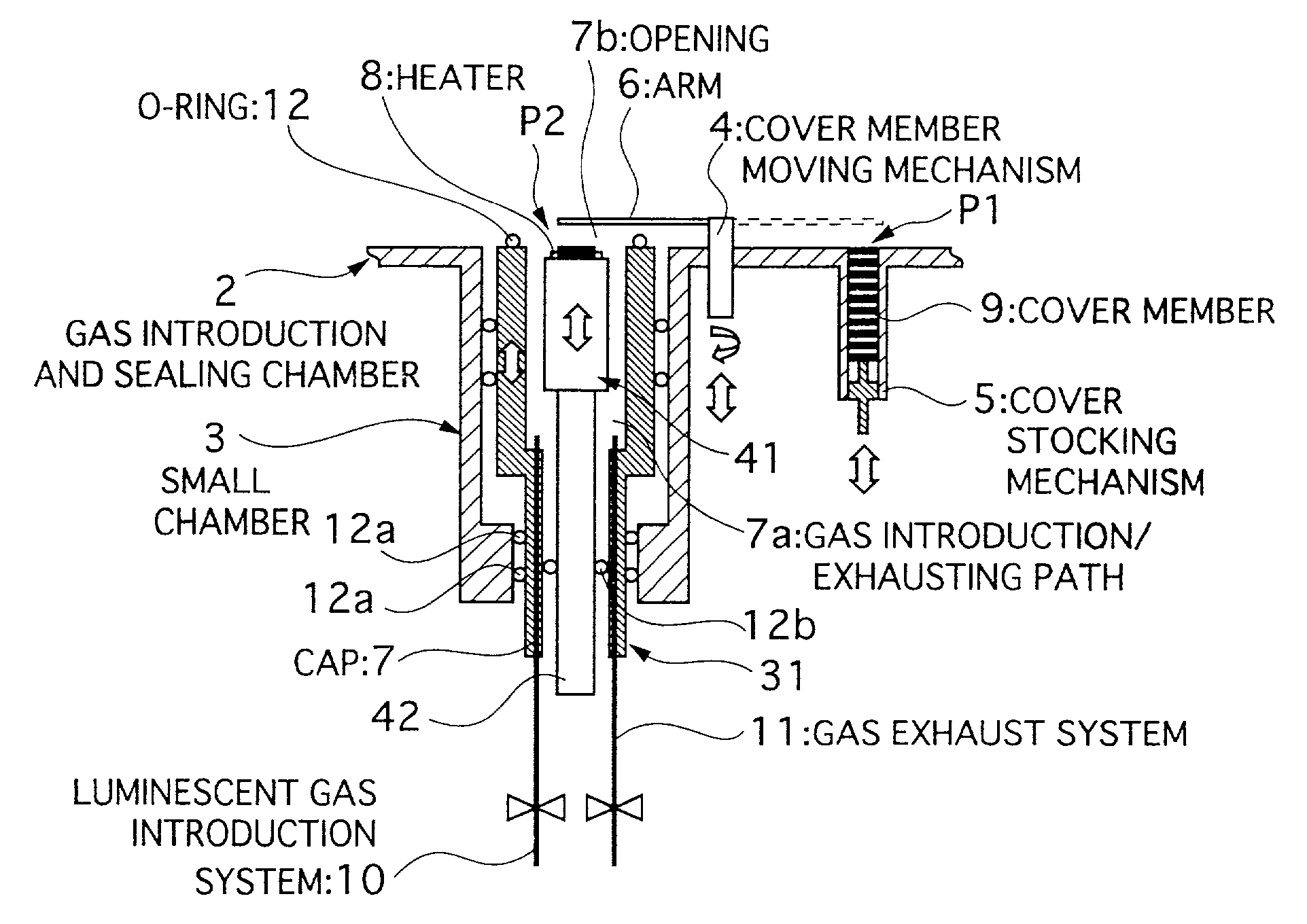

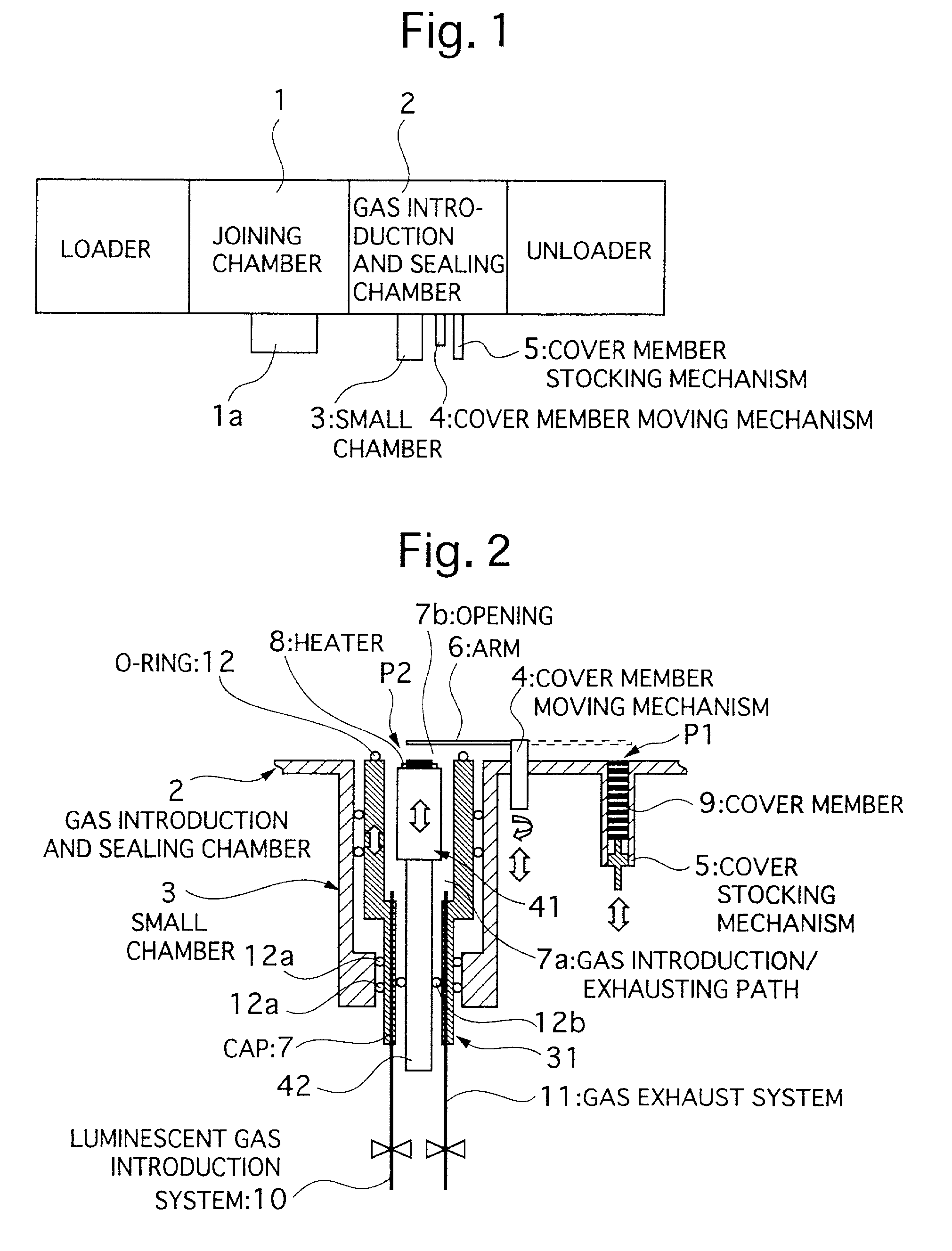

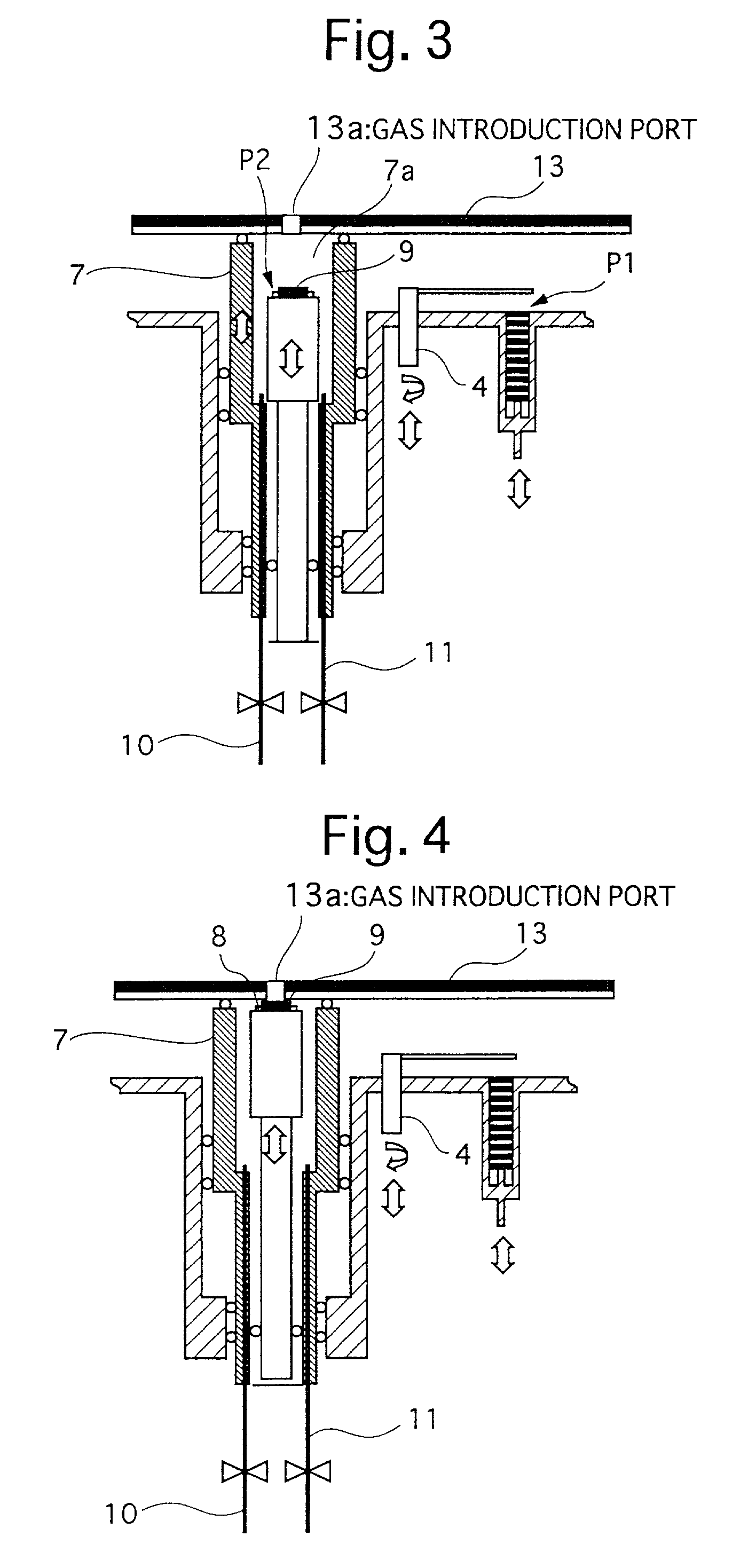

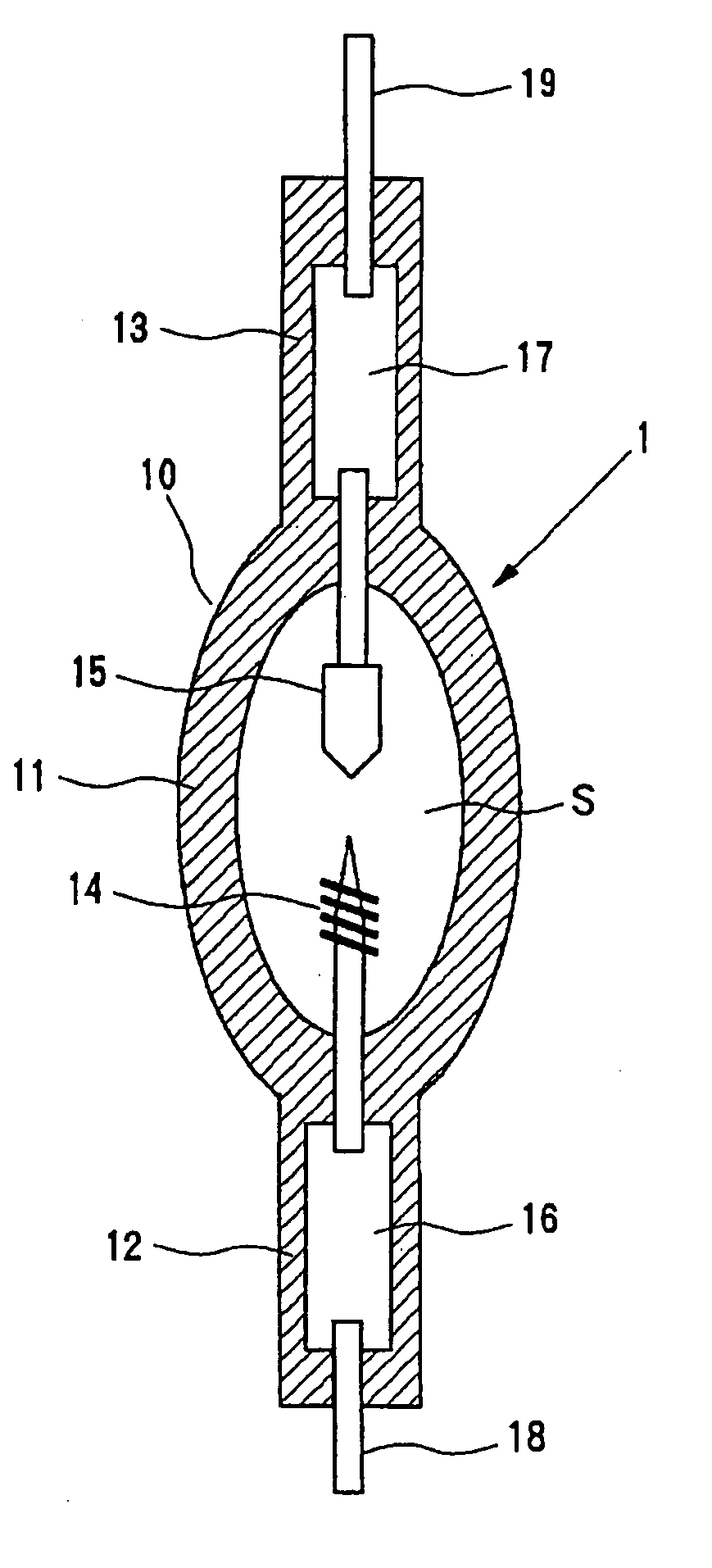

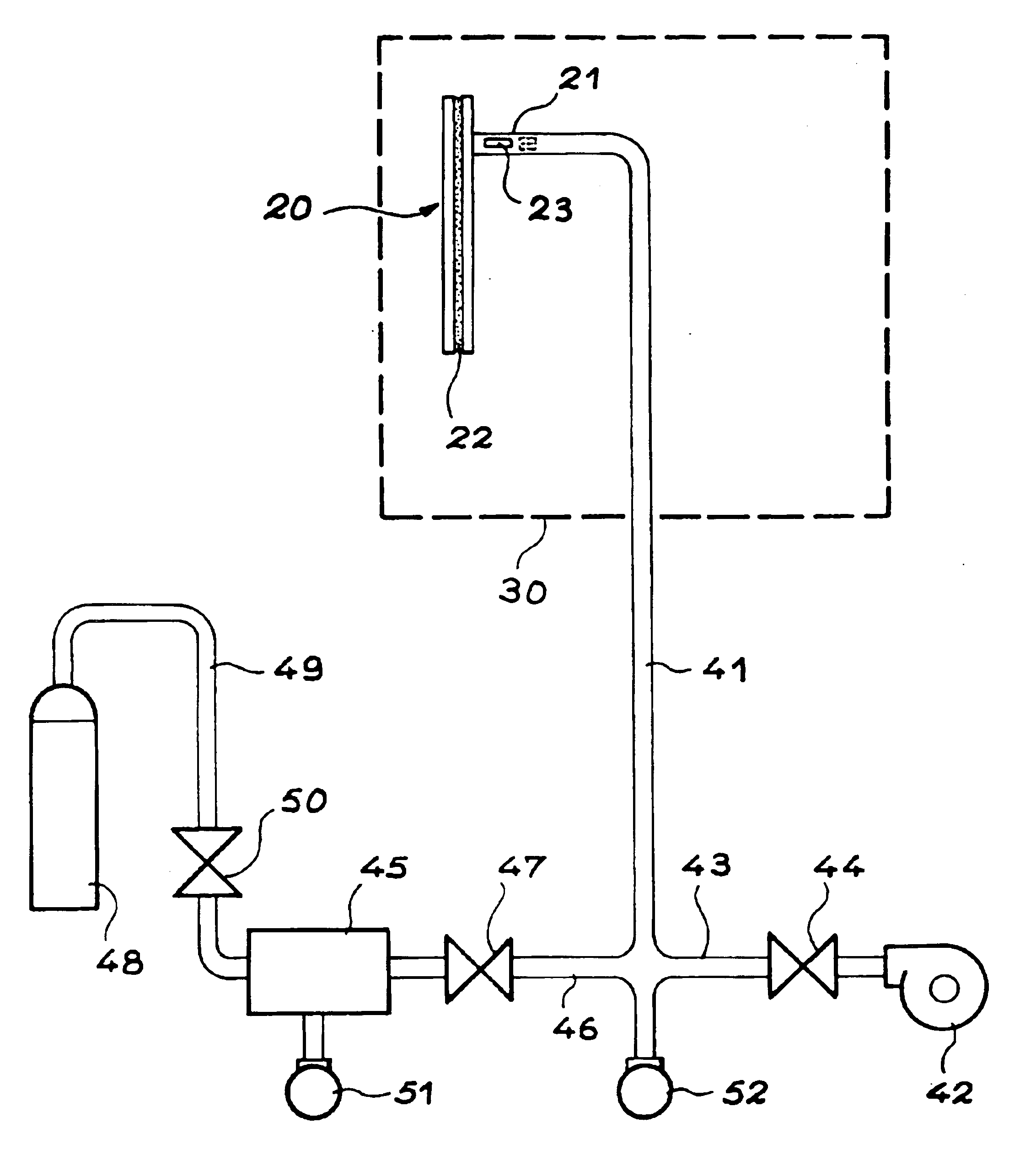

Plasma display panel manufacturing apparatus and manufacturing method

InactiveUS6997769B2Gas discharge connecting/feedingSealing tube apparatusManufactured apparatusProduct gas

The apparatus for manufacturing a plasma display panel having a first mechanism for supplying a cover member formed by a metal sheet to which low-melting-point glass is applied to a first location within the gas introduction and sealing chamber, a second mechanism provided in the gas introduction and sealing chamber for moving the cover member from the first location to a second location which is over a heating apparatus provided in the gas introduction and sealing chamber, a third mechanism provided in the gas introduction and sealing chamber for performing vacuum exhausting an inside of the plasma display panel and then introducing a luminescent gas into the plasma display panel, and a fourth mechanism provided in the gas introduction and sealing chamber for heating the metal sheet to which the low-melting-point glass is applied by using the heating apparatus, so that the gas introduction port is sealed by the low-melting-point glass.

Owner:PANASONIC CORP

Discharge lamp

ActiveUS20040090183A1Blackening and devitrification of suppressedHigh lumen maintenanceElectroluminescent light sourcesTube/lamp vessel fillingGas-discharge lampNoble gas

A discharge lamp which maintains a high lumen maintenance factor even when operated for a long time is obtained in a discharge lamp which has a silica glass discharge vessel and a pair of opposed electrodes in the discharge vessel and in which the discharge vessel is filled with at least 0.15 mg / mm<3 >mercury, a rare gas with argon as the main component, and 2x10<-4 >mumole / mm<3 >to 7x10<-3 >mumole / mm<3 >bromine by meeting the following conditions when feeding a direct current of 5 mA between the electrodes and a glow discharge produced: 1.0x10<-4><=B / A<=1.2X10<-1 > Condition (1) c / a<=1.4X10<-1 > Condition (2) d / a<=1.2X10<-2 > Condition (3) e / a<=1.4X10<-2 > Condition (4) where a is the emission intensity of the argon with a wavelength of 668 nm, b is the emission intensity of OH with a wavelength of 309 nm, c is the emission intensity of hydrogen (H) with a wavelength of 656 mm, d is the emission intensity of C2 with a wavelength of 517 nm, and e is the emission intensity of CH with a wavelength of 431 nm

Owner:USHIO DENKI KK

Field emission device using a reducing gas and method for making same

InactiveUS6888294B1Maintain vacuumExcellent stateGas filling substance selectionPump componentsField emission deviceElectron source

The invention concerns a device comprising at least one field effect electron source within a sealed structure, which encompasses an internal space that contains a reducing gas whose purpose is to prevent oxidation of the emissive material of the electron source, whereby the reducing gas is a gas with the formula NxHy where x=1 or 2 and y=3 or 4, and which is advantageously under a pressure of between 10−8 and 10−1 mbar. It also concerns manufacturing processes for such a device and apparatuses for implementing these processes.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

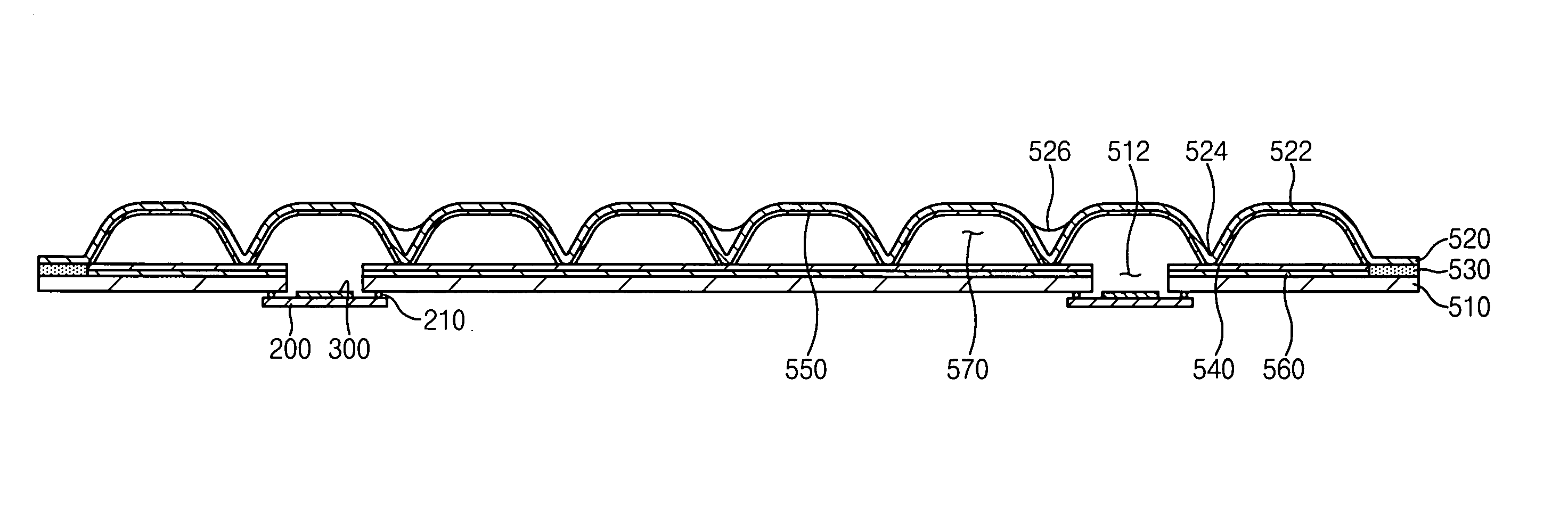

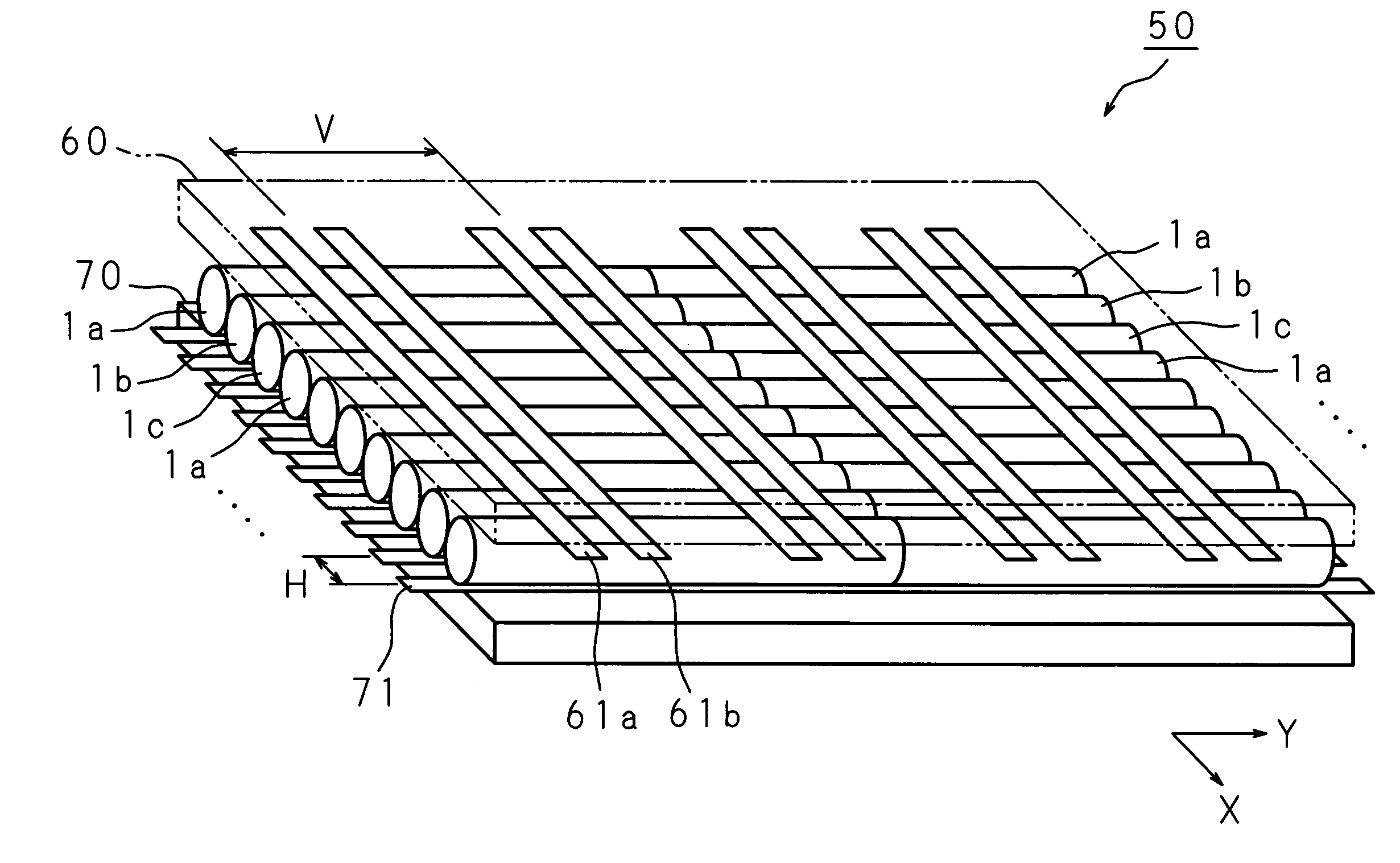

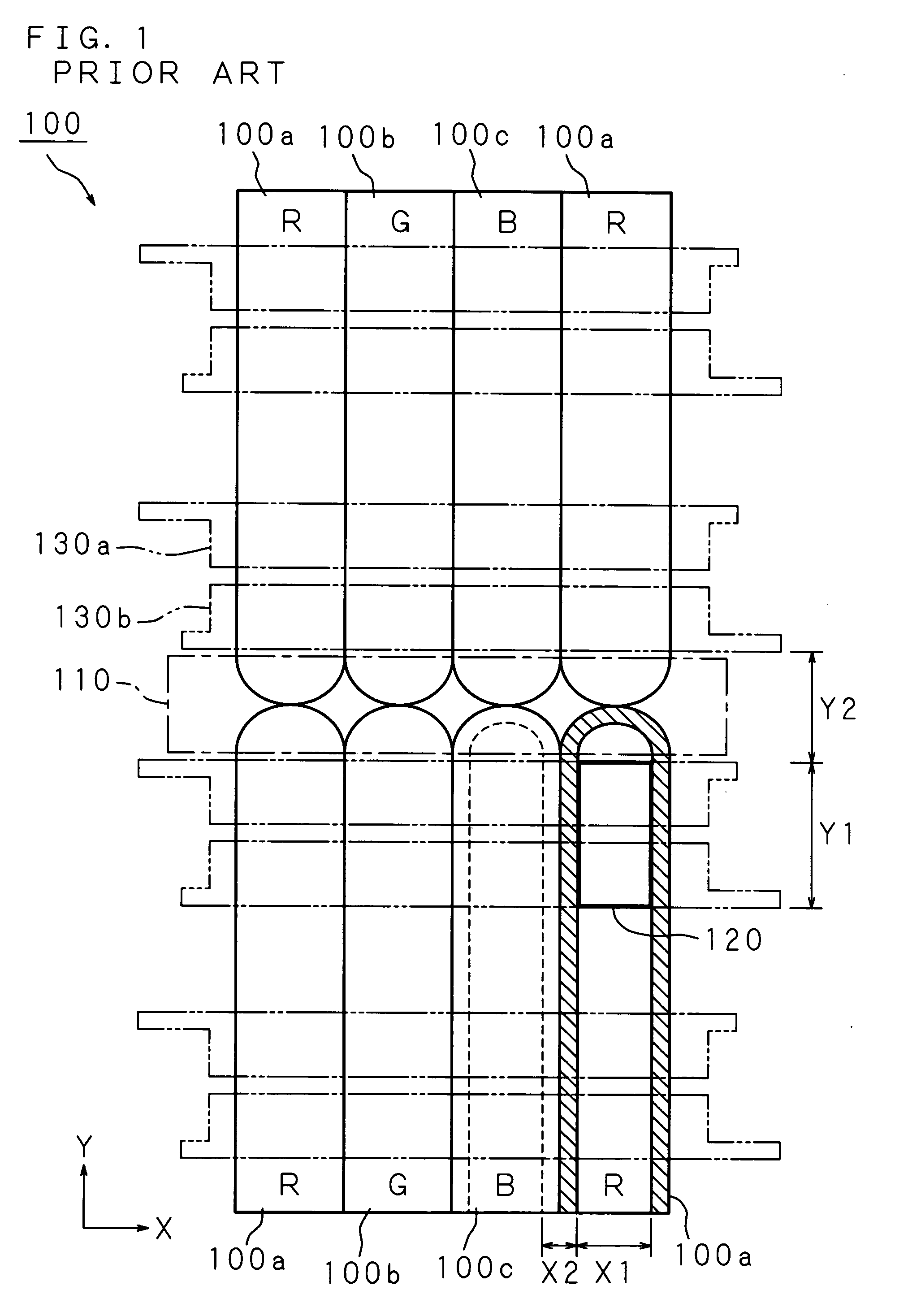

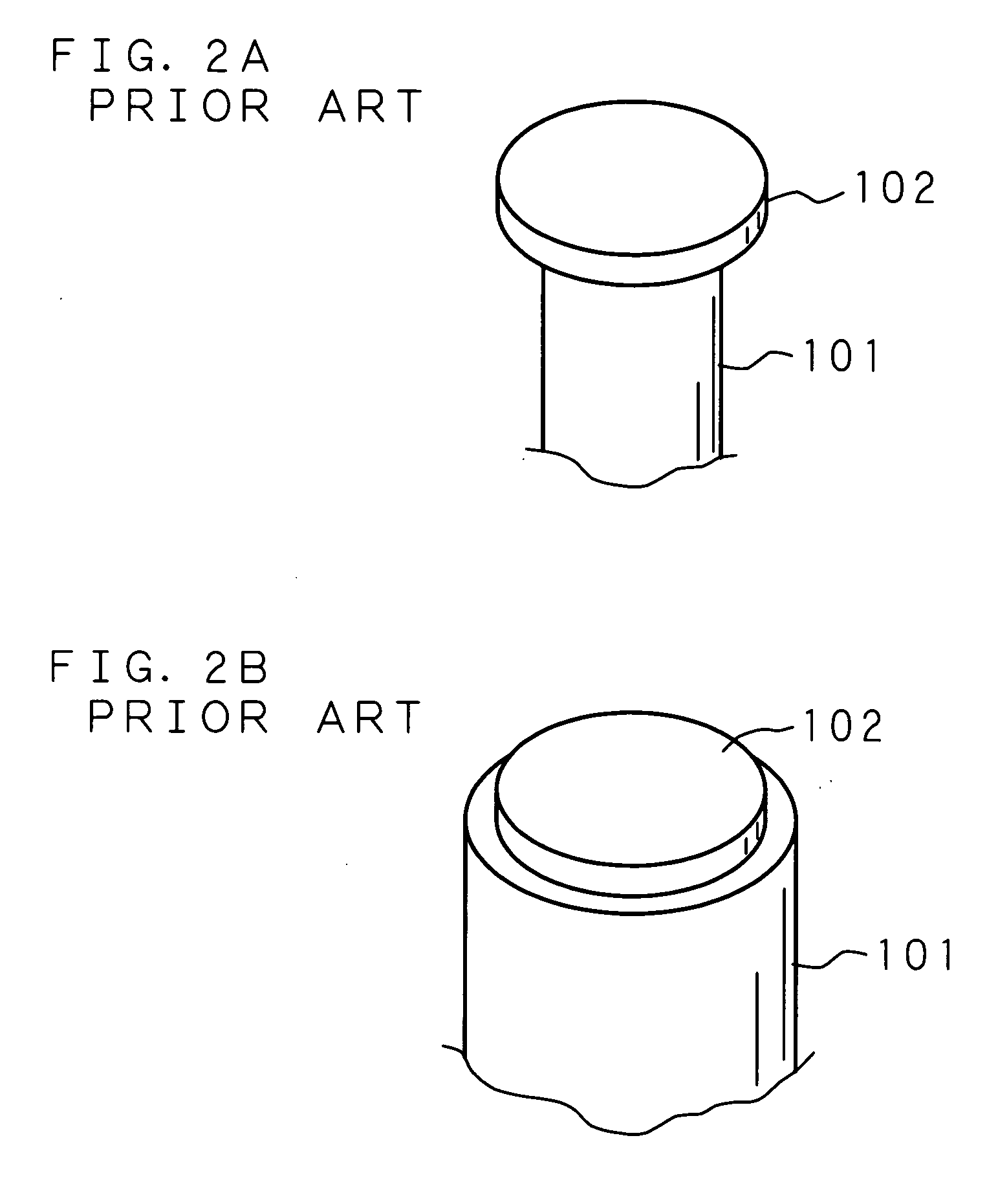

Planar light source device, method for manufacturing the same, and display device having the same

A display device comprises a planar light source device comprising a light source body having multiple opening portions for air exhaust and injection of the discharging gases, at least one affixing member being affixed to the light source body and sealing each of the multiple opening portions, at least one getter being on the at least one affixing member and corresponding to each of the multiple opening portions, and first and second electrodes being formed on opposing edges defining the outer surface of the light source body, a display unit displaying images using light from the planar light source device, and an inverter applying discharging voltages to the first and second electrodes for driving the planar light source device. According to this configuration, the present invention may reduce the thickness of the planar light source device and improve getting efficiency of the impurities and emitting efficiency of mercury by increasing the surface area of the getter.

Owner:SAMSUNG ELECTRONICS CO LTD

Manufacturing method of gas discharge tube, gas discharge tube, and display device

InactiveUS20060119247A1Reduce brightness unevennessInhibit deteriorationTube/lamp screens manufactureTube/lamp vessel fillingPhosphorDisplay device

A method of manufacturing a gas discharge tube by closing an opening of a glass tube by forming a glass layer with outer peripheral shape identical to the outer peripheral shape of the glass tube on an end face of the glass tube. An open end face (opening) of the glass tube is pressure-welded to a dry film containing a low melting point glass powder and a binder resin, and then the glass tube is lifted up to transfer the dry film for closing the opening to the end face of the glass tube. A phosphor support member is inserted into the glass tube from a side opposite to the end face and then an end of the phosphor support member is caused to adhere to the dry film. The binder resin is burnt off, and the dry film is vitrified to produce a low melting point glass layer.

Owner:SHINODA PLASMA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com