Patents

Literature

83 results about "Lumen maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

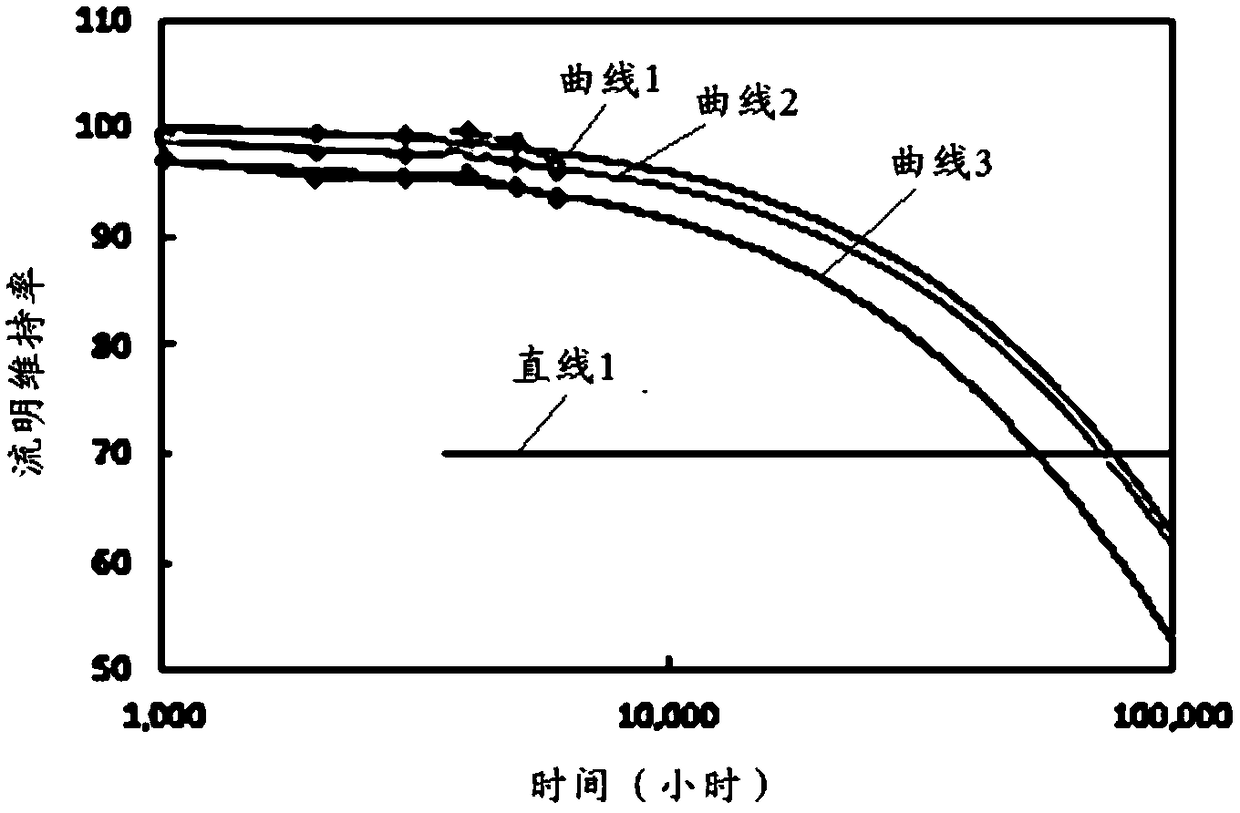

In LED lighting, lumen maintenance is the luminous flux remaining (expressed as a percentage of the initial output) at any selected elapsed operating time. Lumen depreciation is the luminous flux lost over time, and thus the complement of lumen maintenance.

Moisture-resistant phosphor and associated method

Owner:GE LIGHTING SOLUTIONS LLC

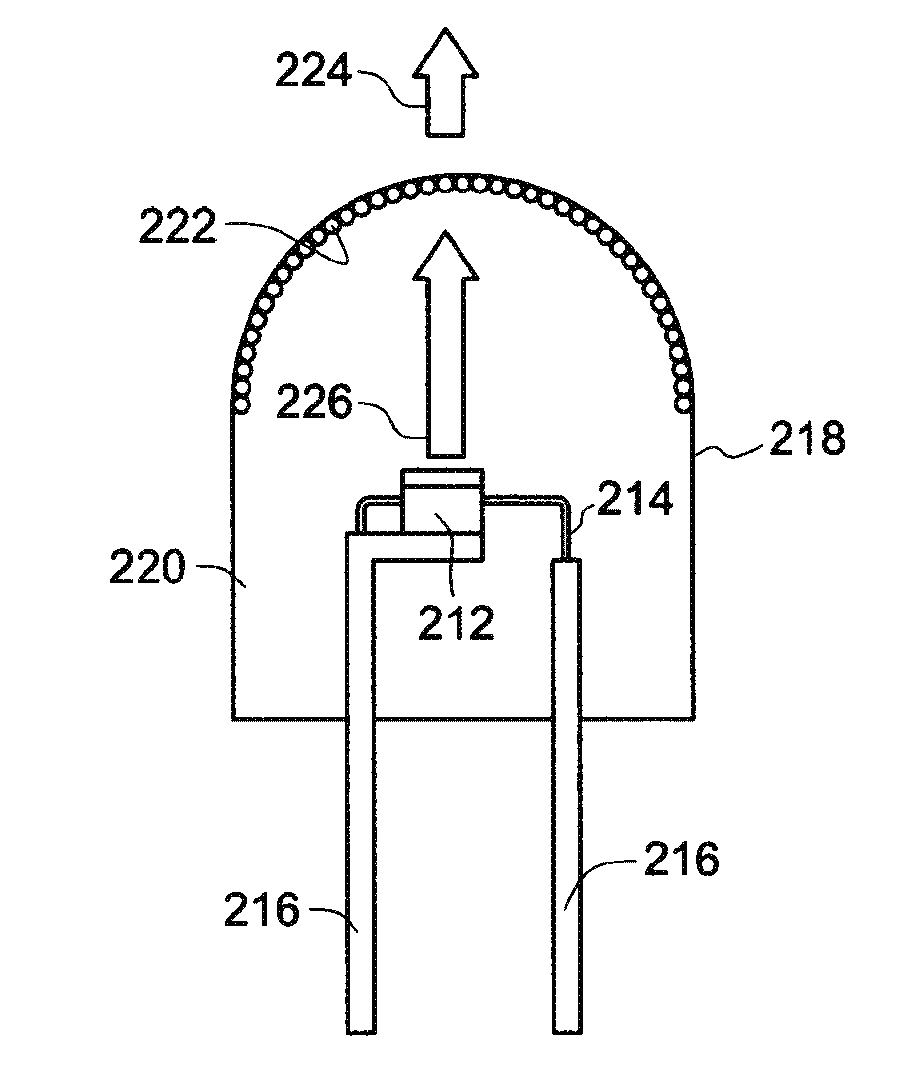

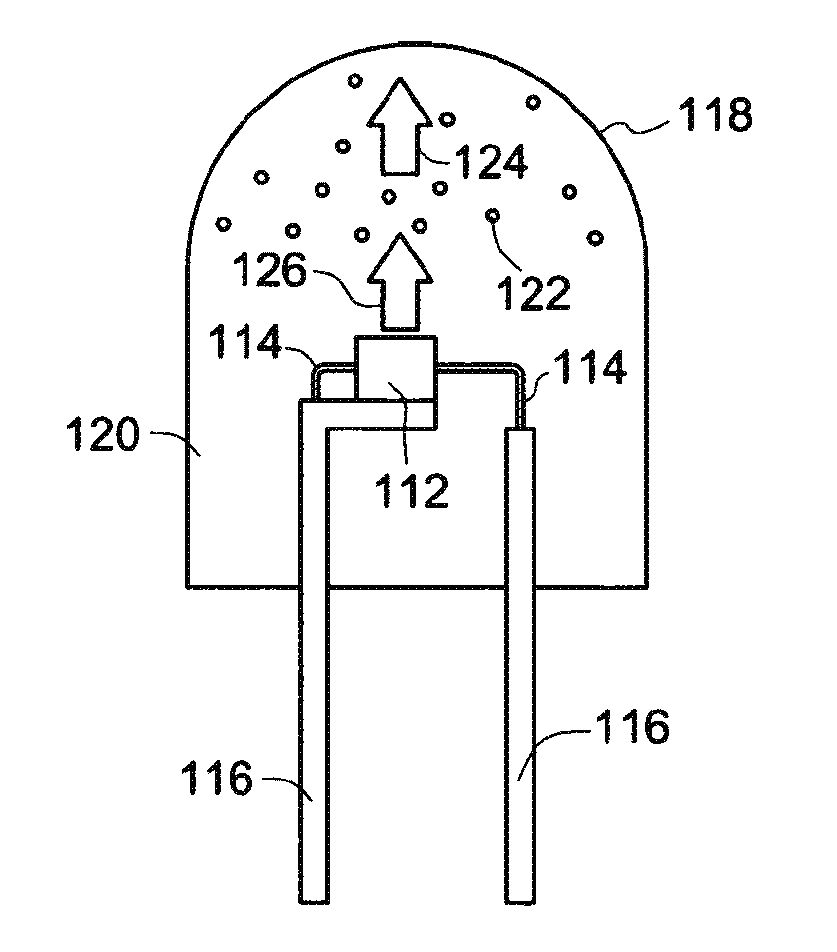

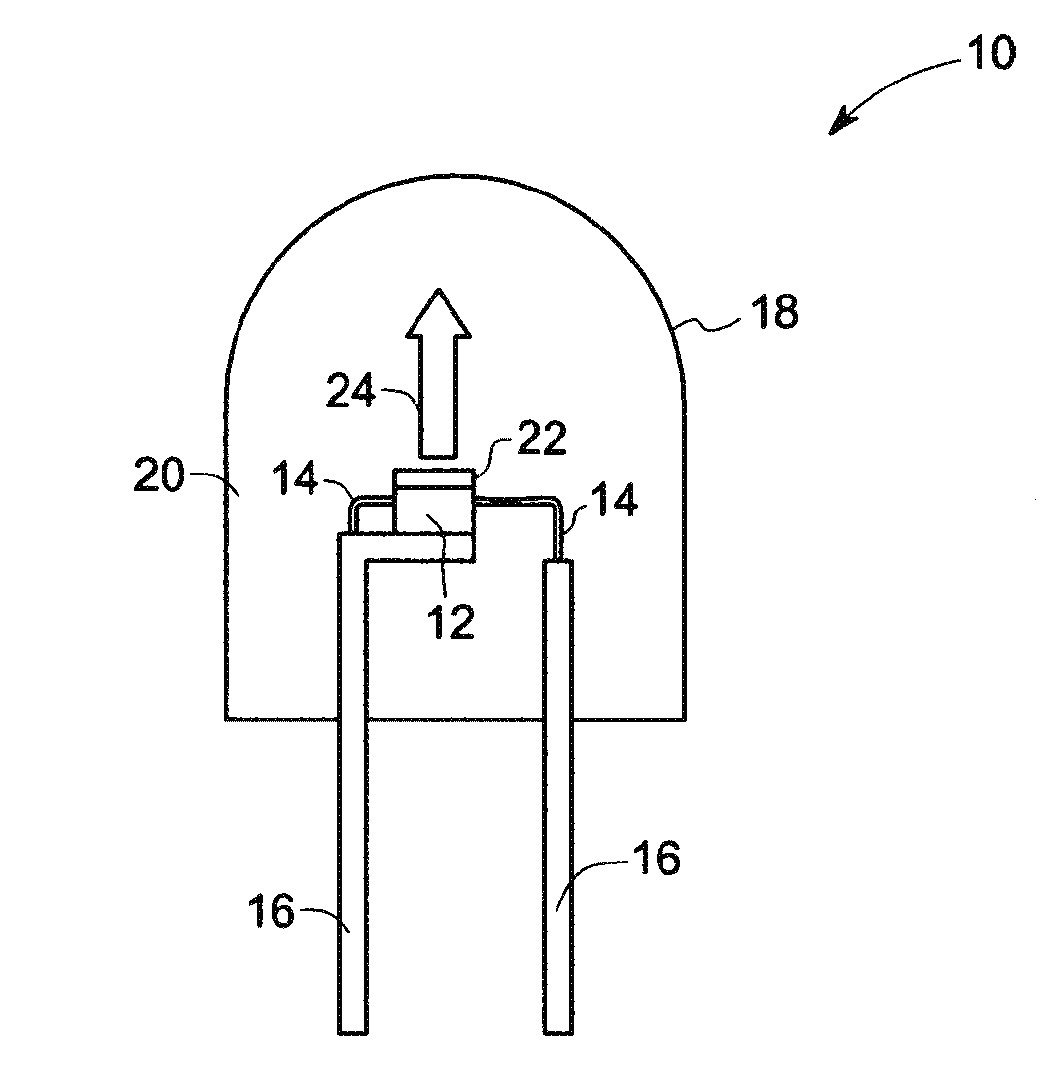

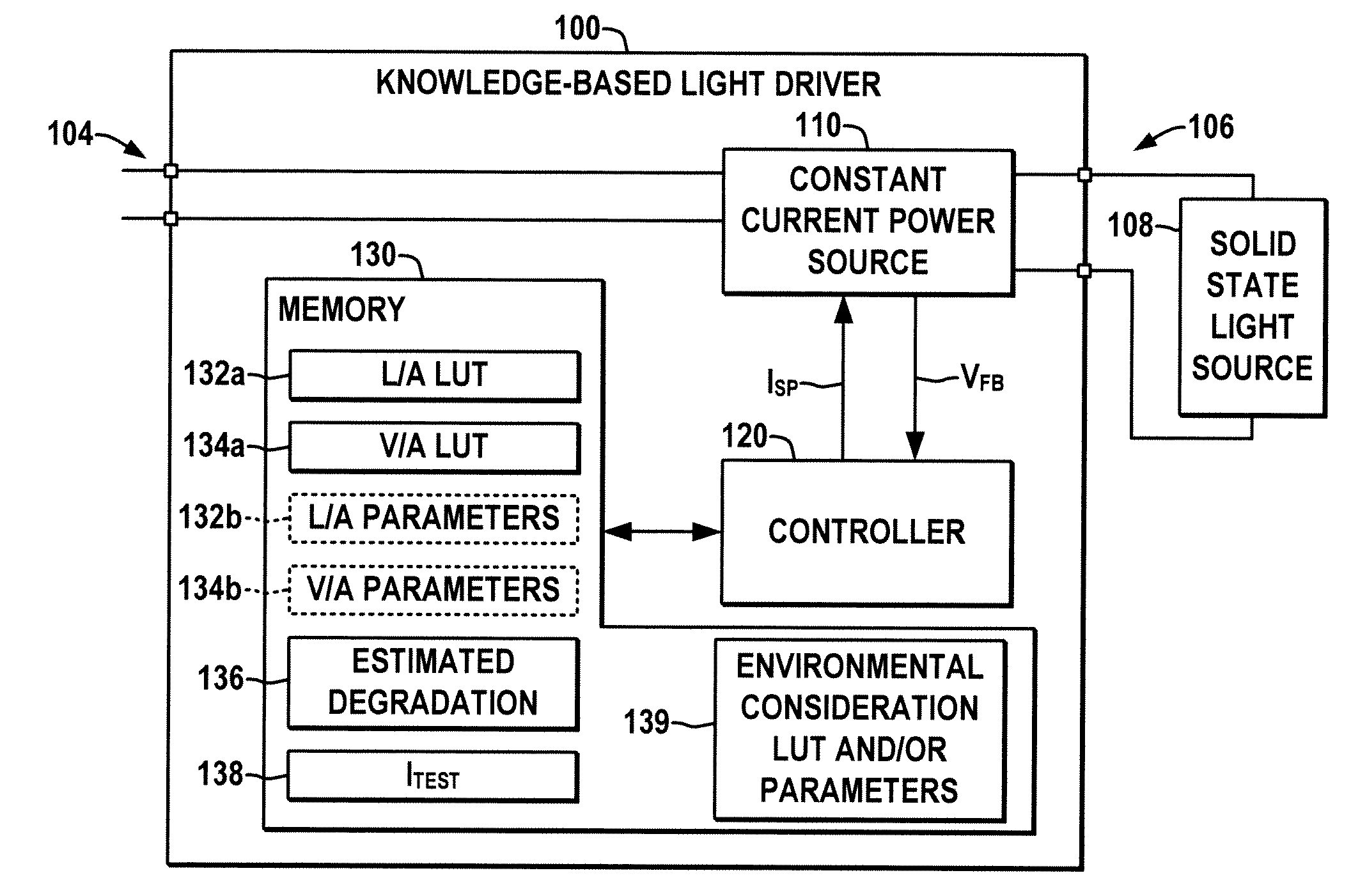

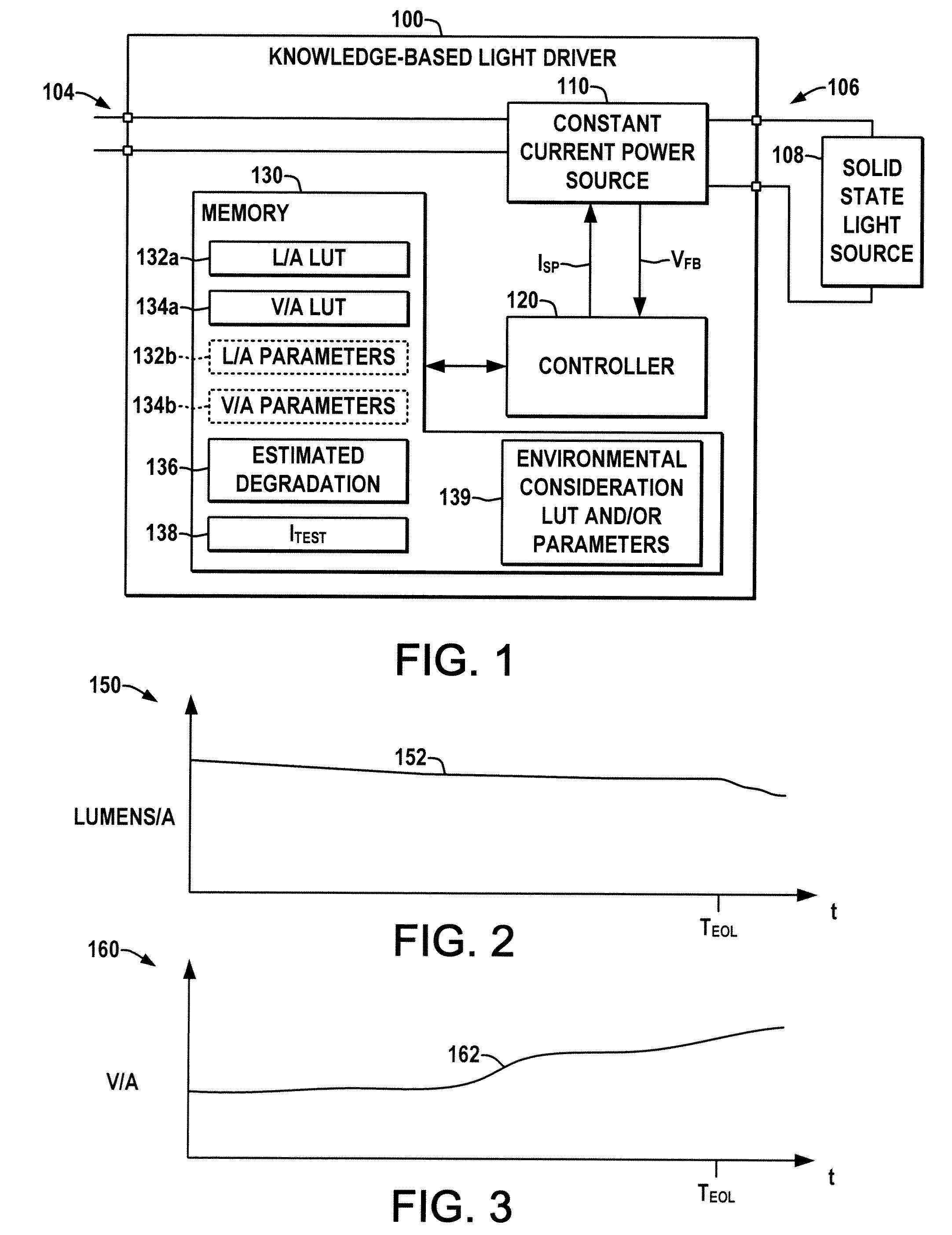

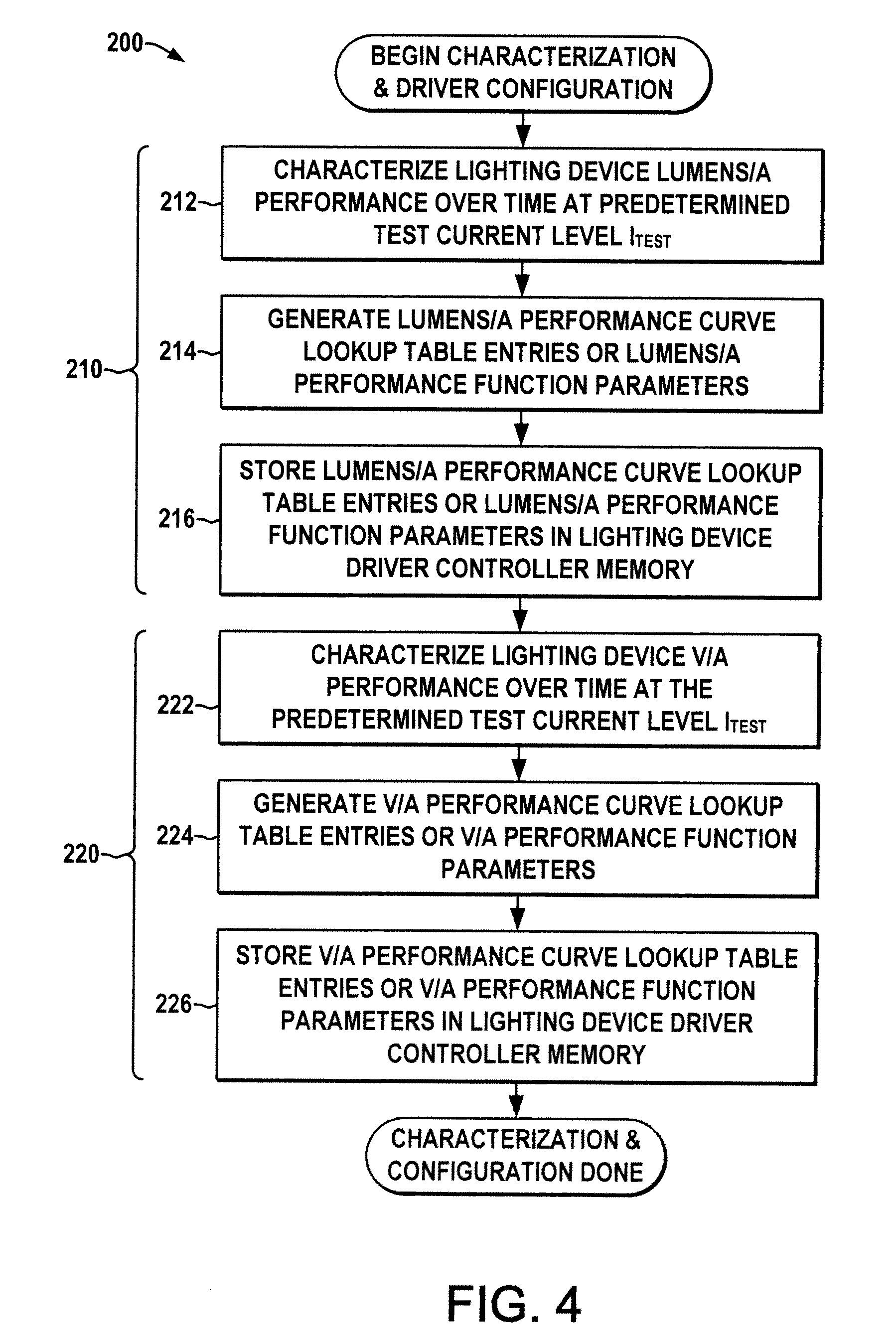

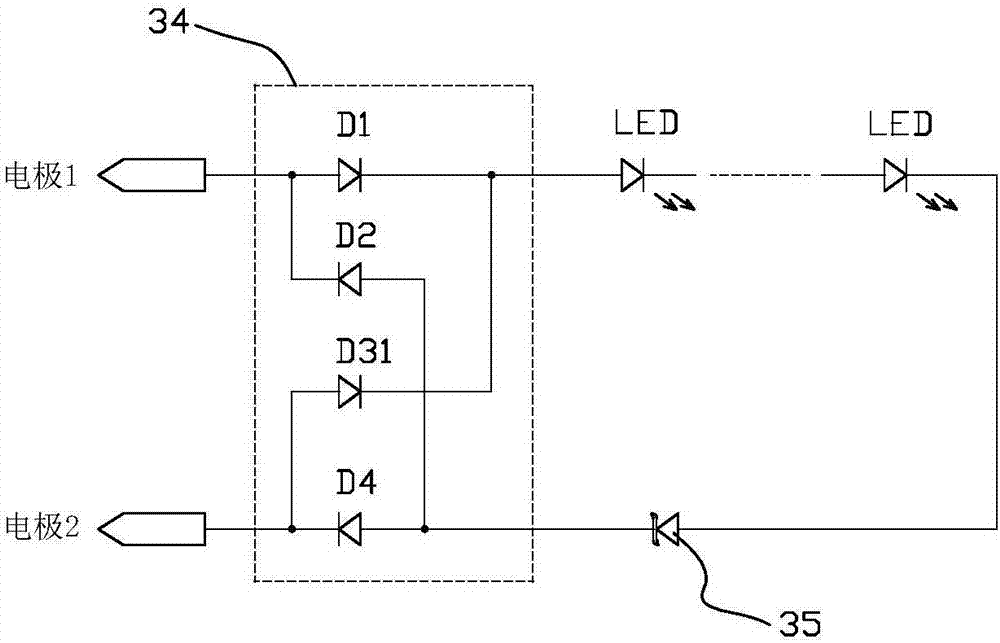

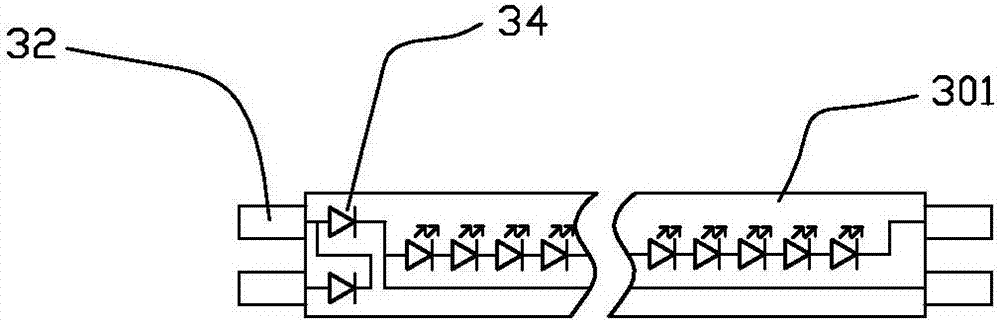

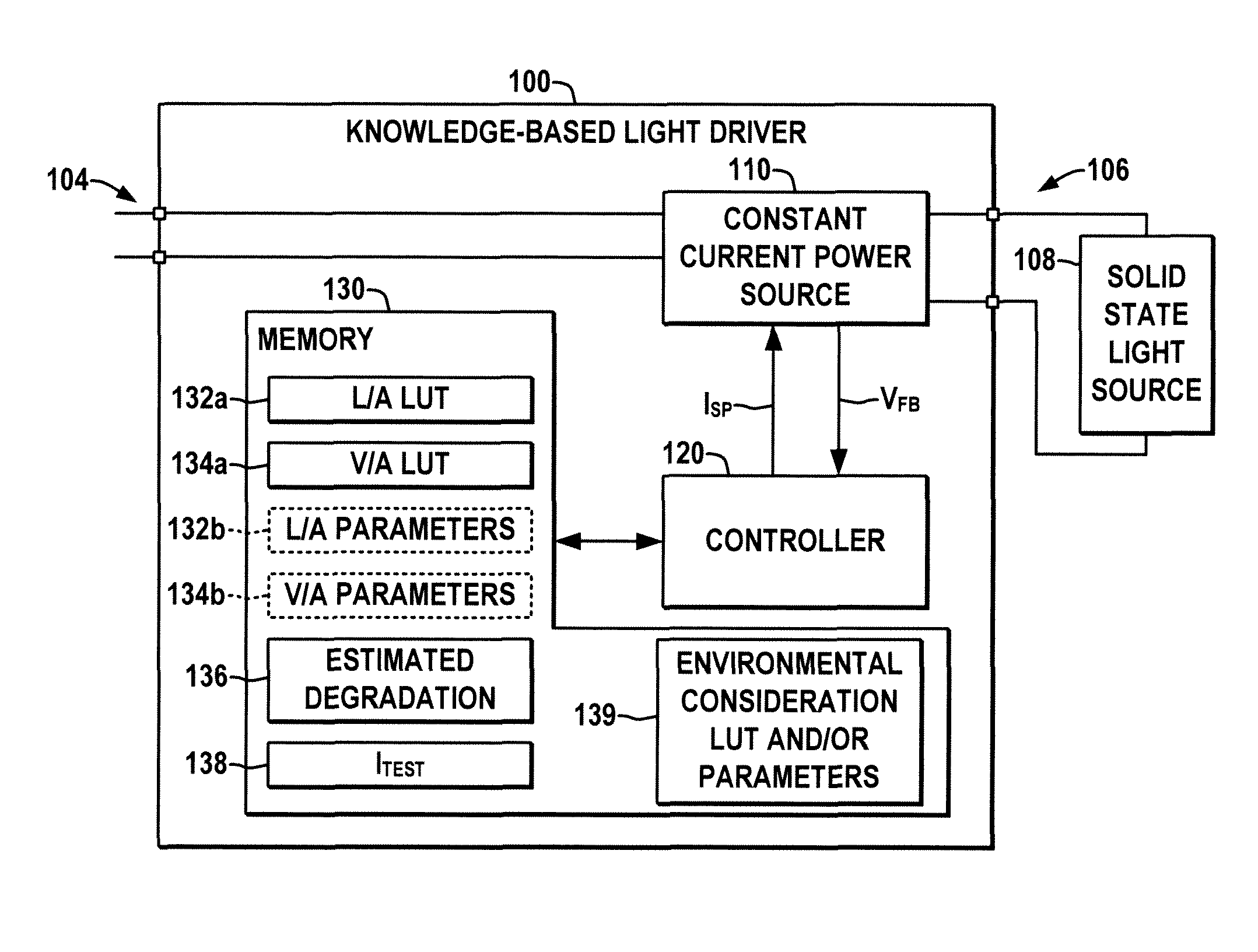

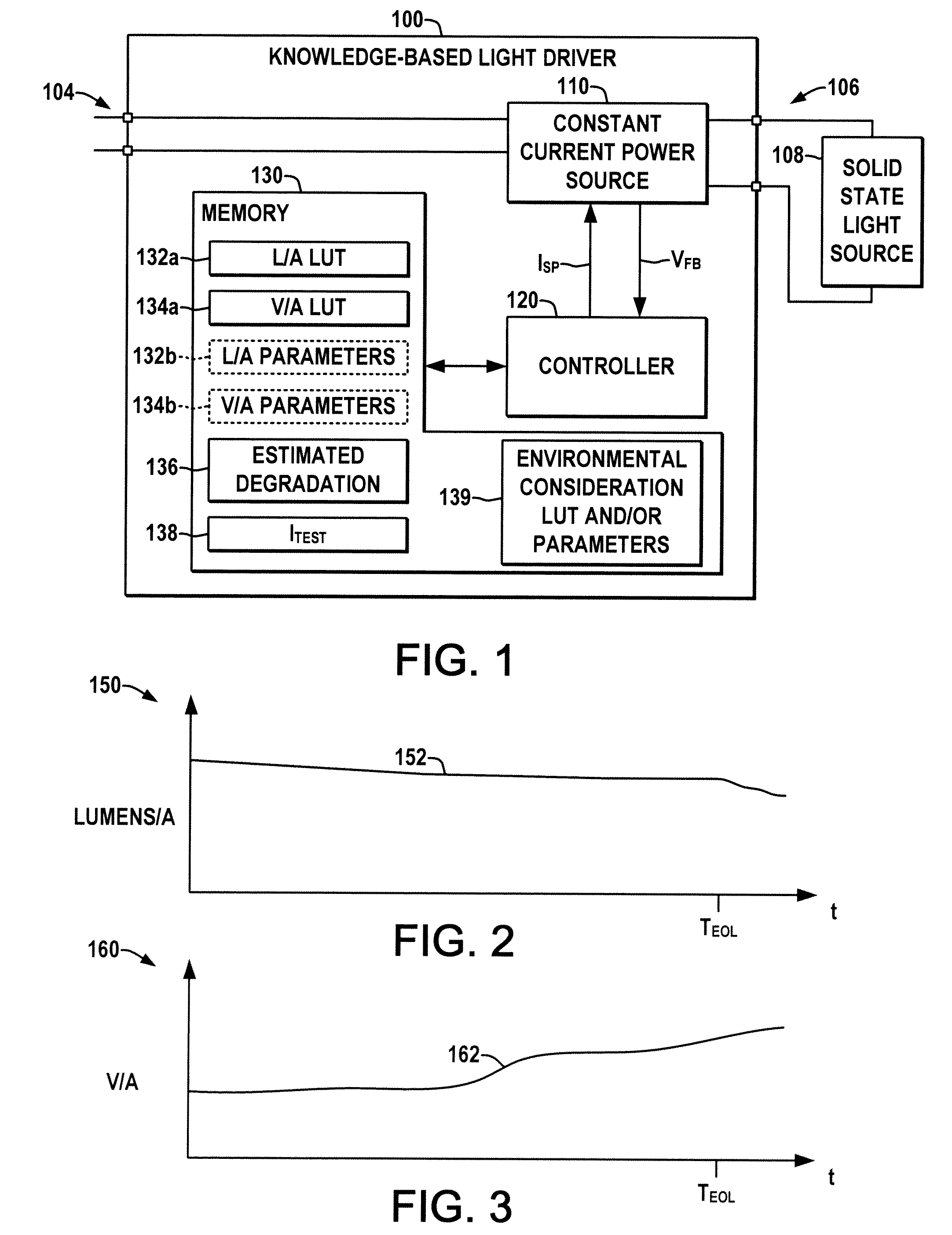

Knowledge-based driver apparatus for high lumen maintenance and end-of-life adaptation

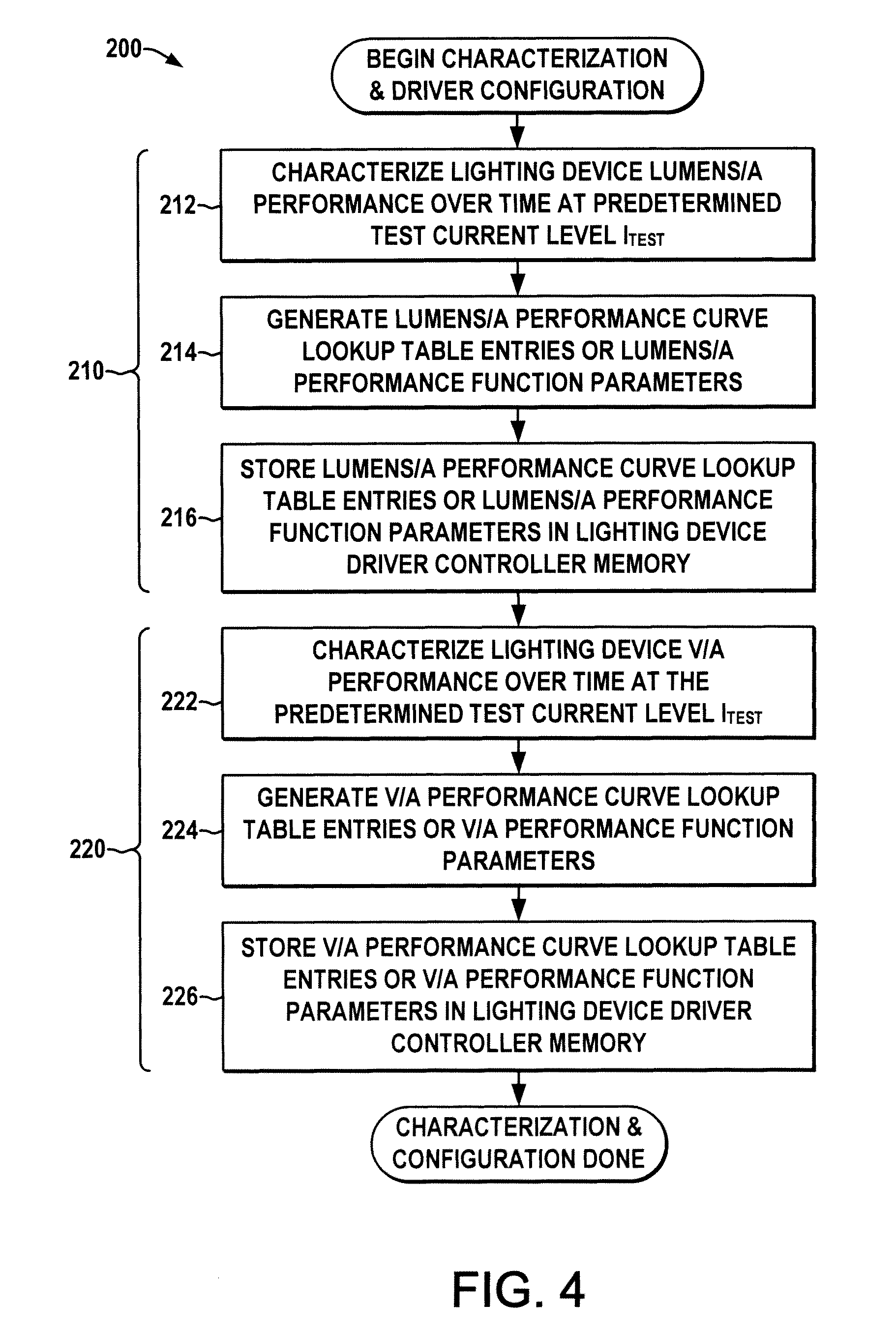

ActiveUS20110089855A1Facilitate constant lumen operationAccuracyElectrical apparatusStatic indicating devicesDriving currentLumen maintenance

A knowledge-based driver is provided for powering a solid-state light source with a constant current, including a memory that stores lumens per amp and volts per amp performance characterizations of the light source over time, and a controller that operates in a test mode to estimate the light source degradation based on voltage feedback obtained at a predetermined test current value, and to adjust the drive current in normal operating mode according to the estimated device degradation to implement constant lumens control without external optical feedback components.

Owner:GE LIGHTING SOLUTIONS LLC

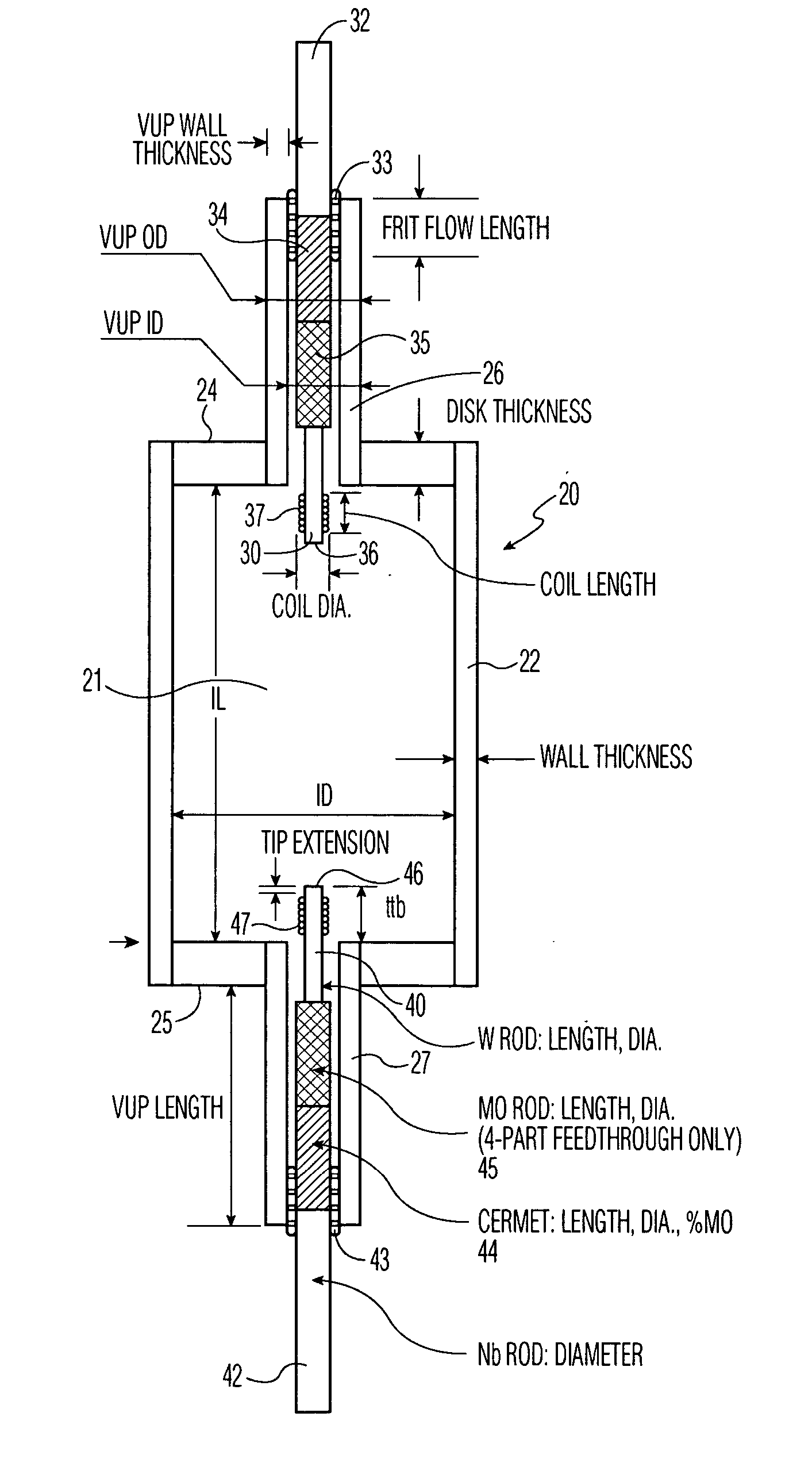

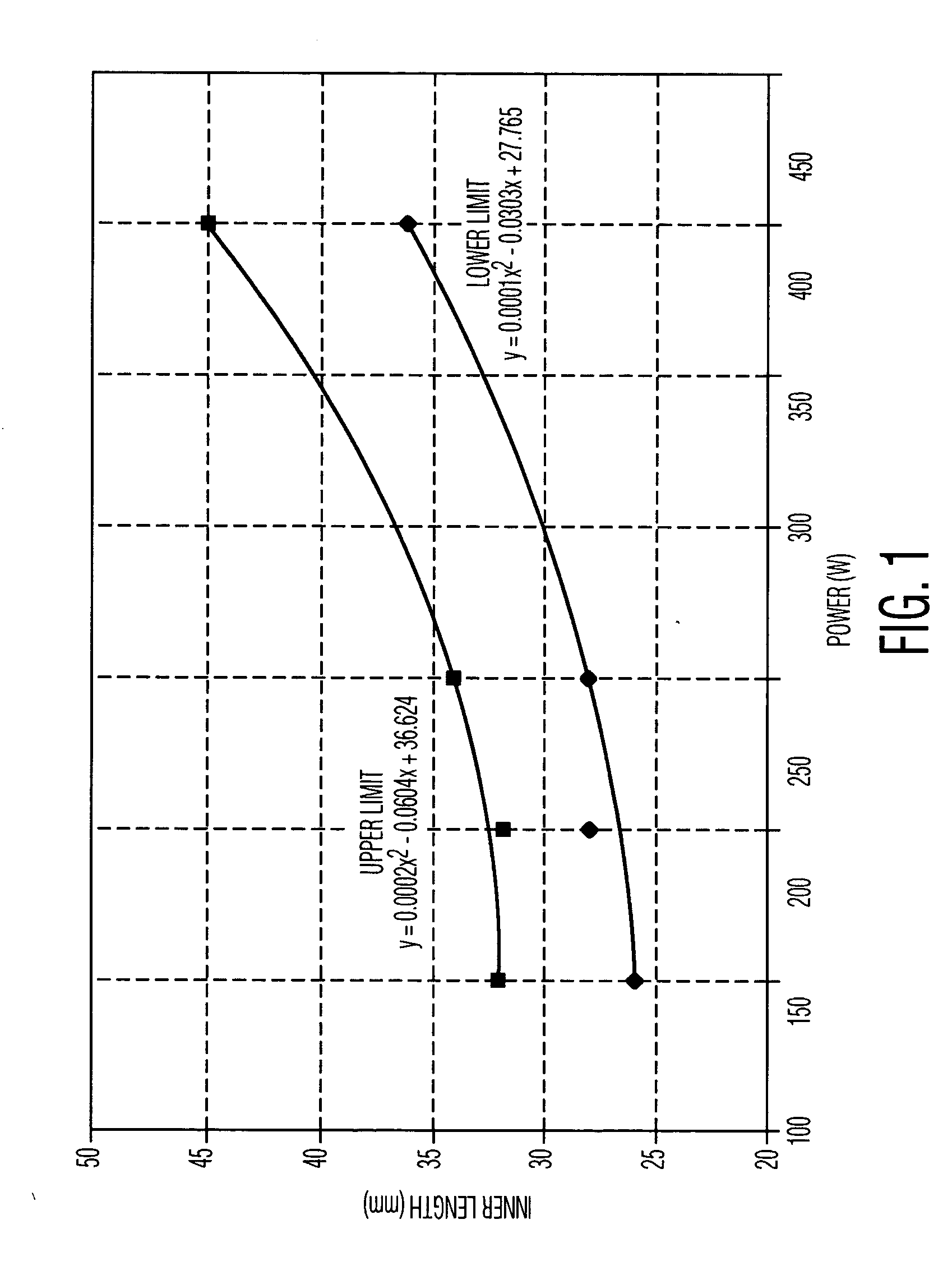

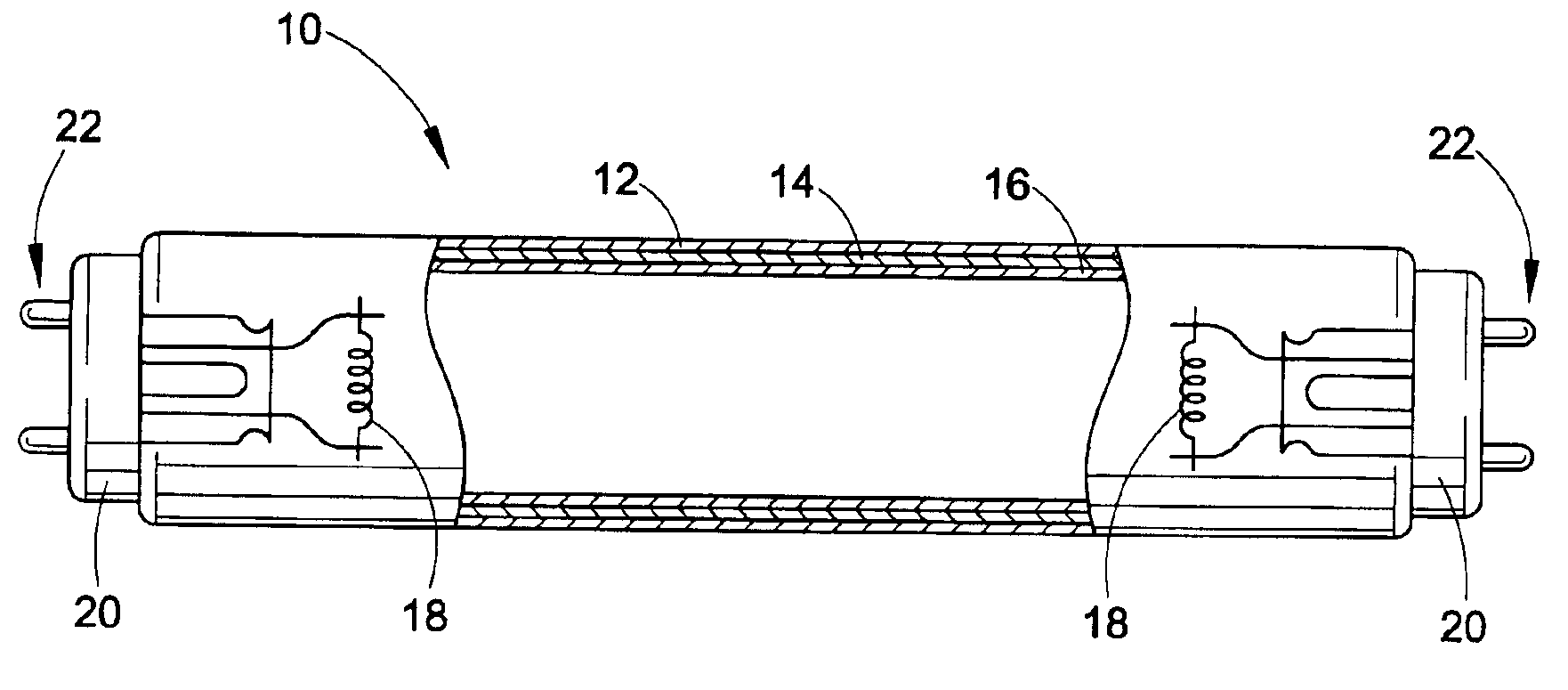

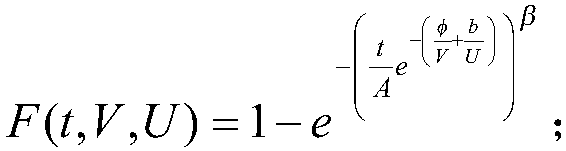

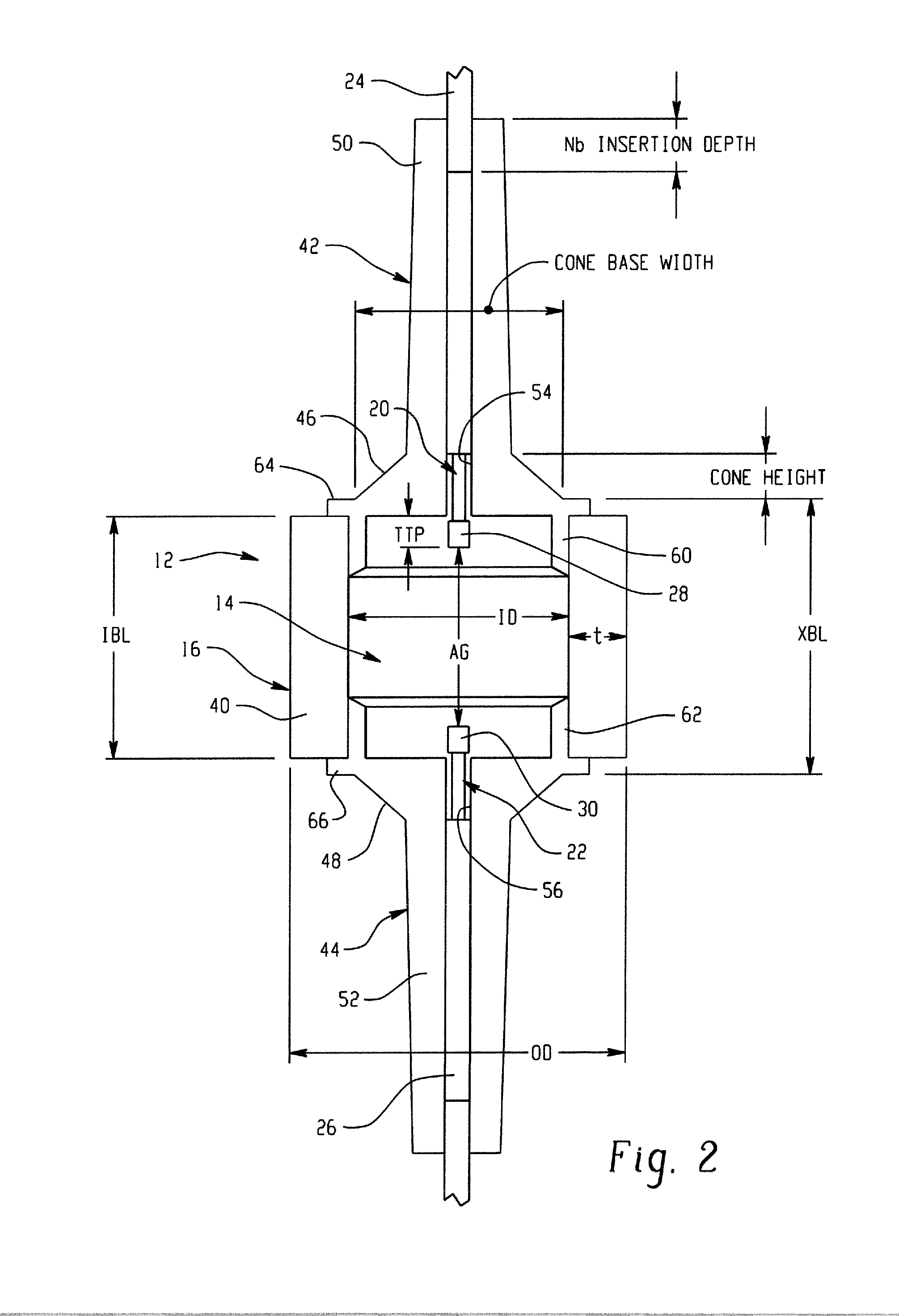

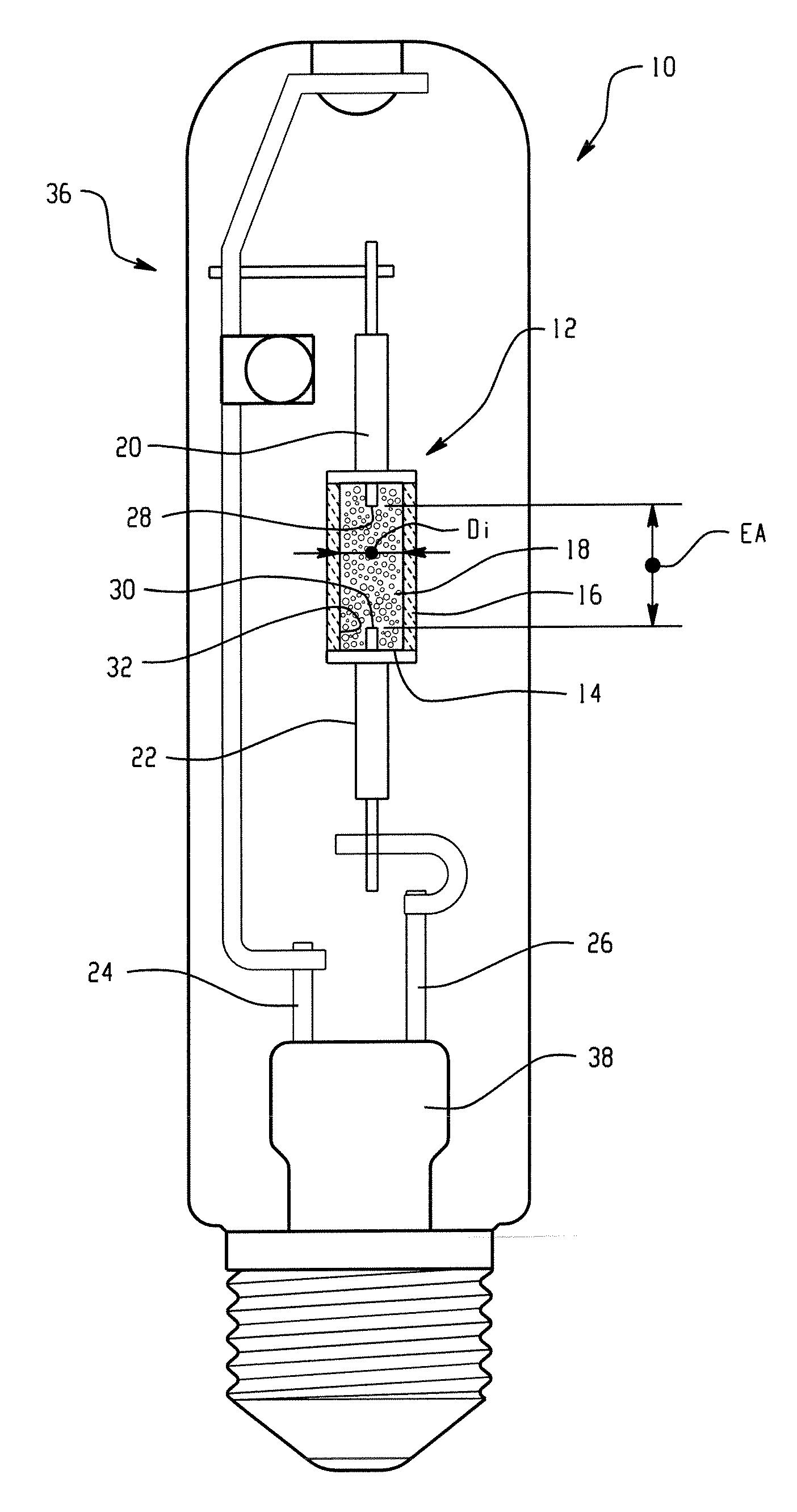

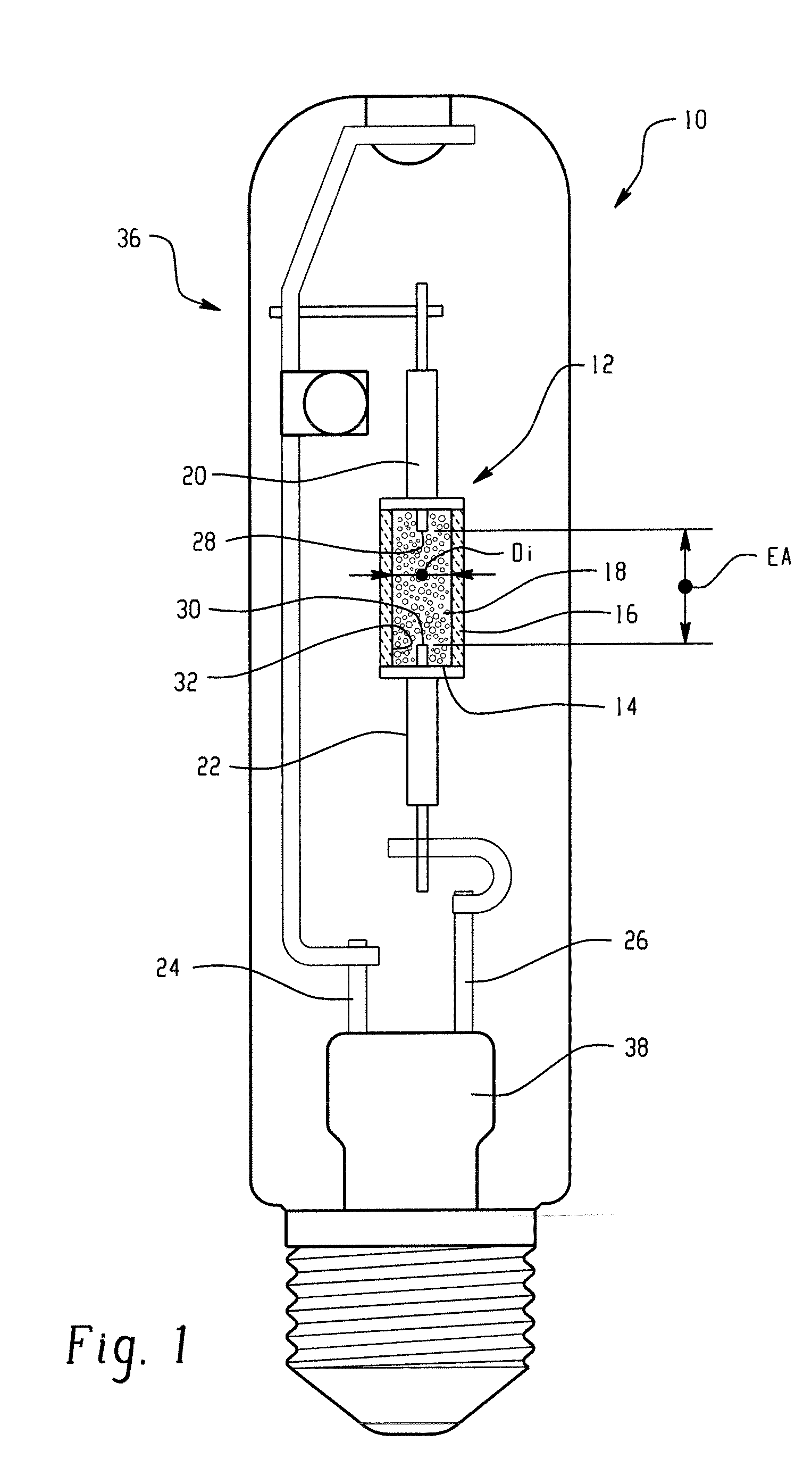

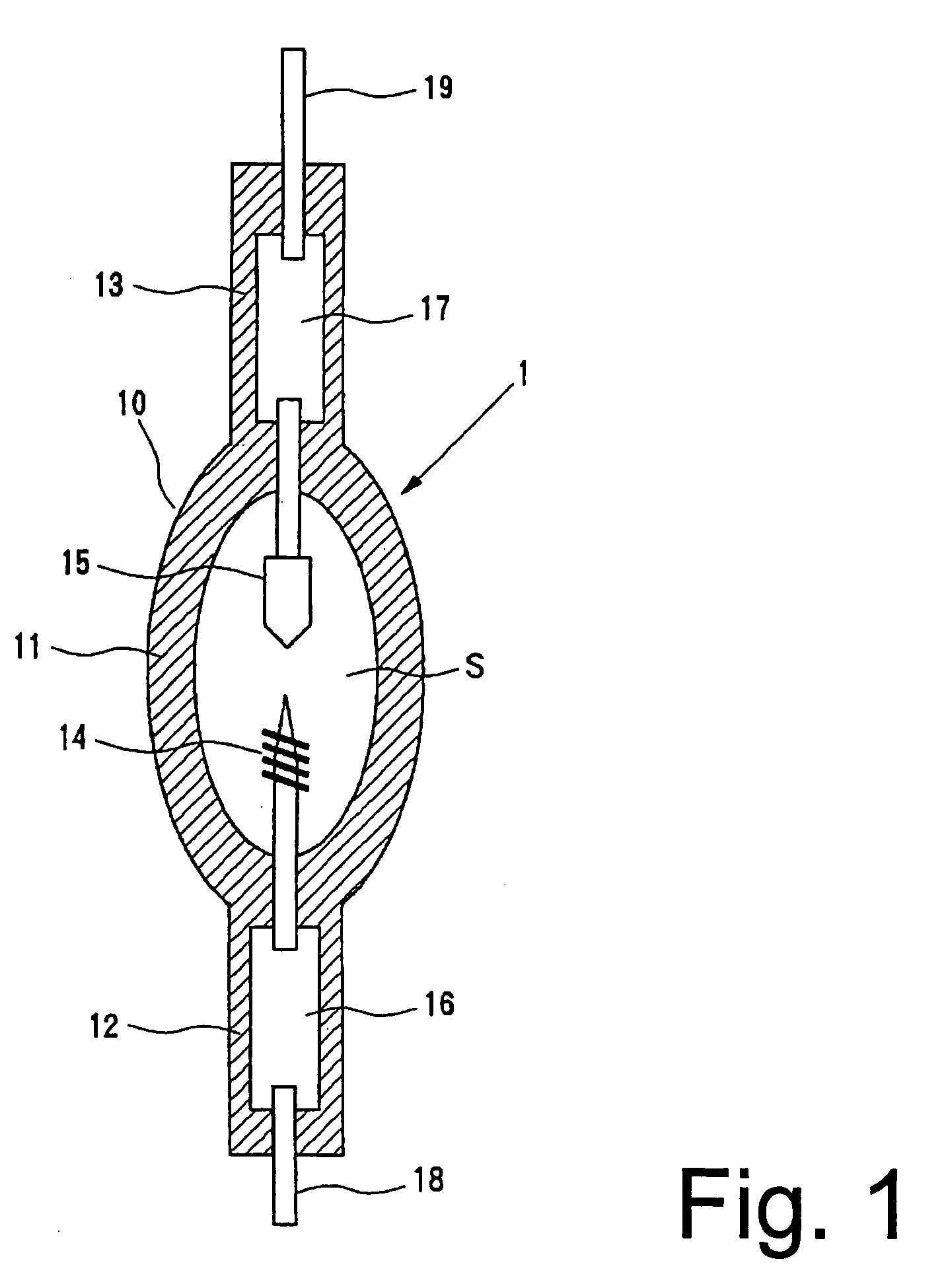

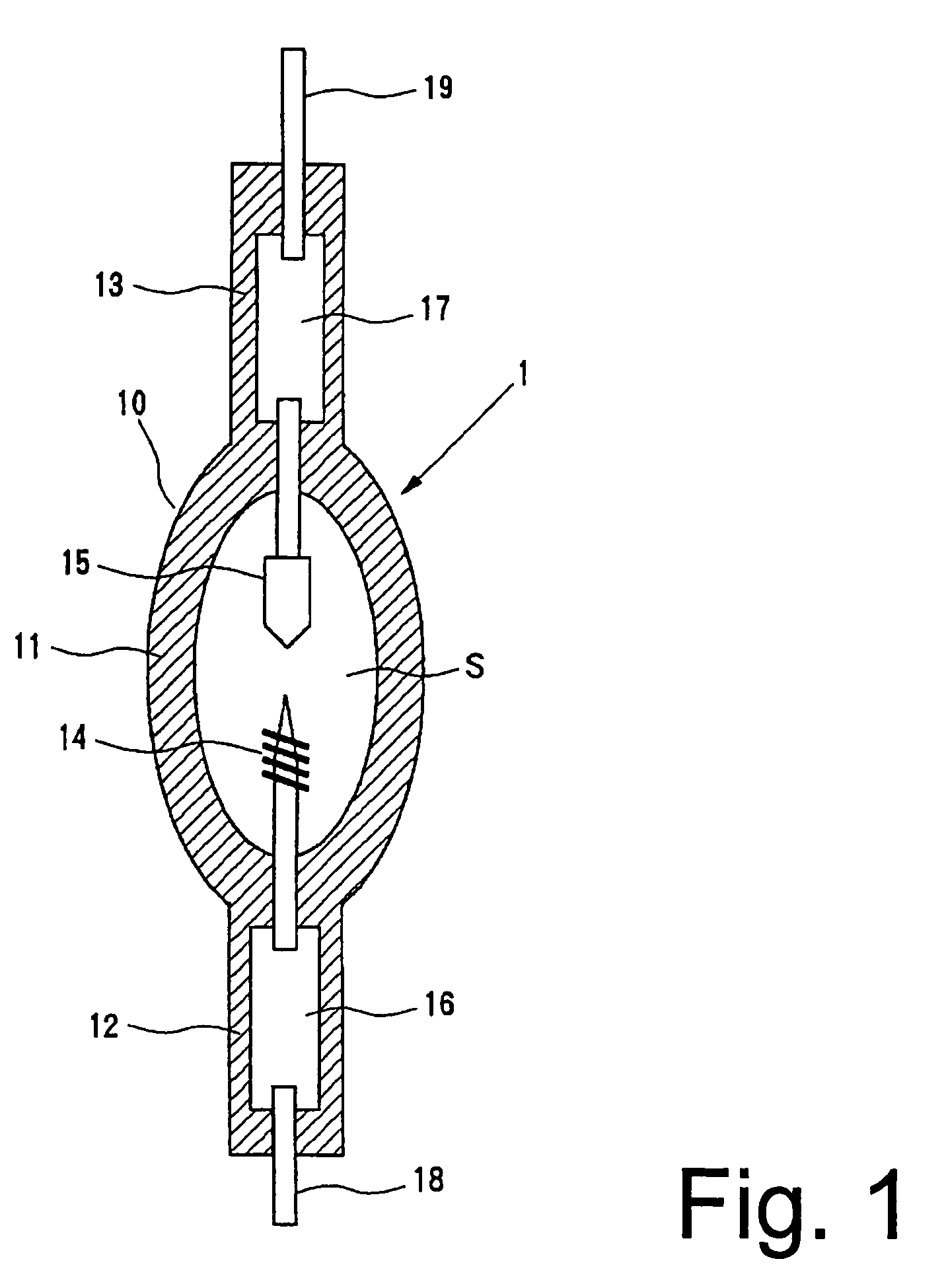

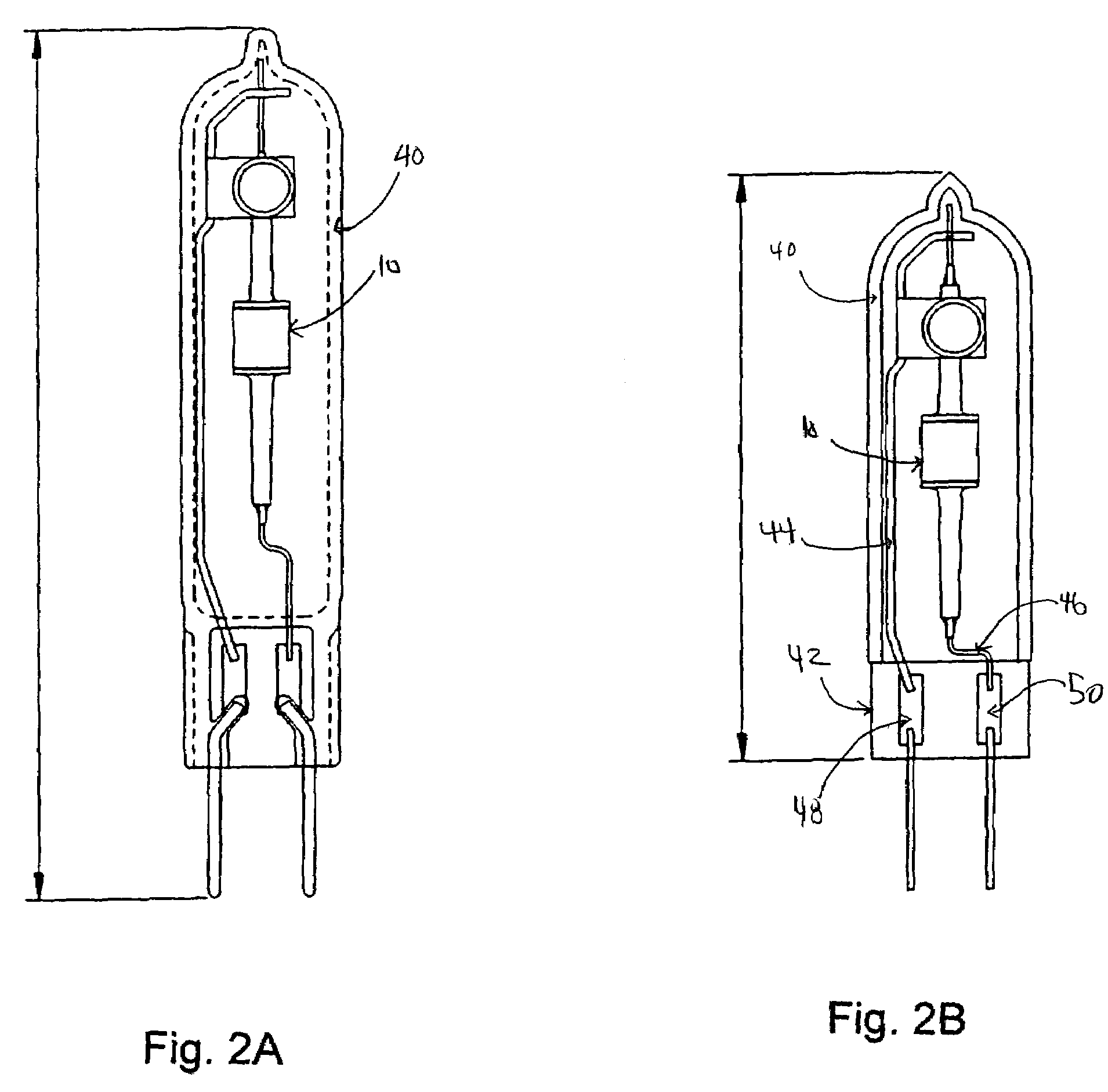

Coil antenna/protection for ceramic metal halide lamps

InactiveUS20050042967A1Good color consistencyImprove stabilityTube/lamp screens manufactureElectroluminescent light sourcesColor rendering indexLumen maintenance

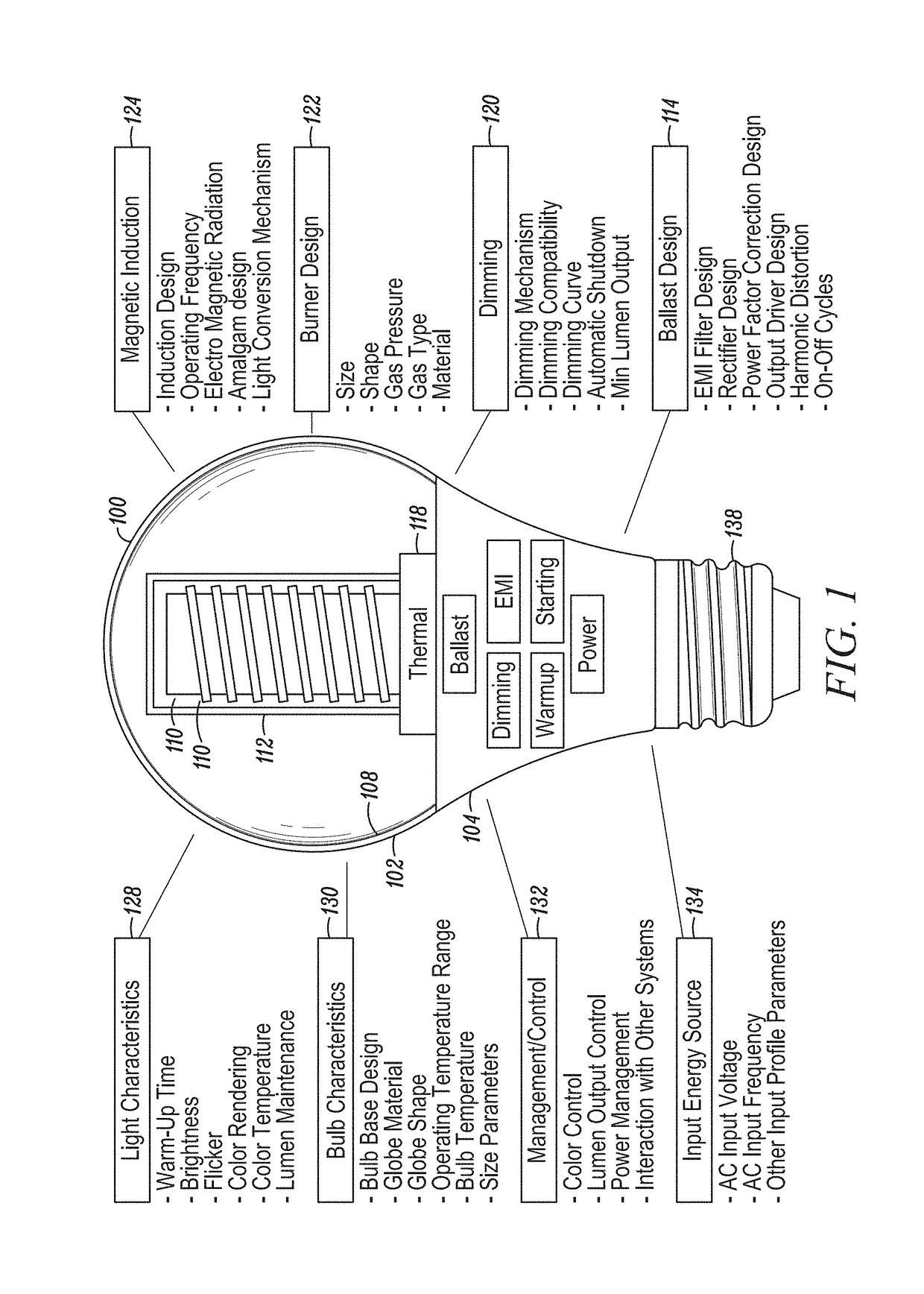

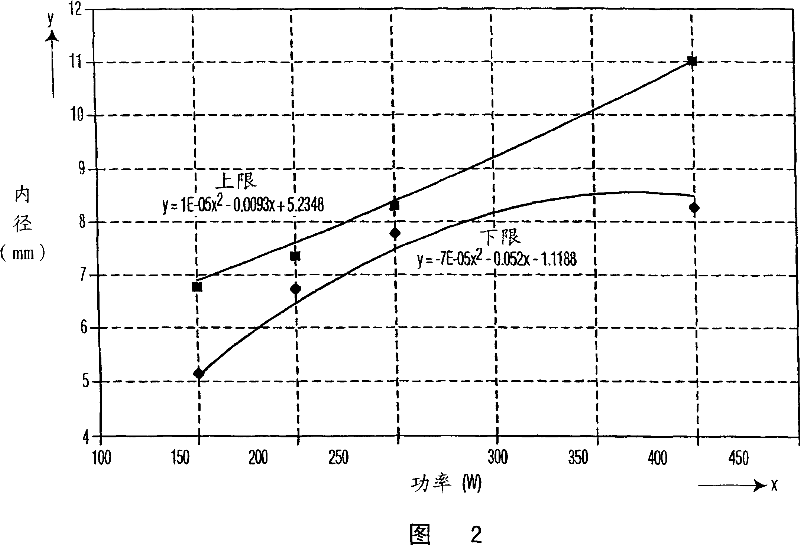

The invention relates to a high-pressure discharge lamp of the ceramic metal halide type of the Philips MasterColor series having a molybdenum coil wrapped around the discharge vessel and at least a portion of the electrode feed through means, and having power ranges of about 150 W to about 1000 W. Such lamps are provided with a discharge vessel which encloses a discharge space. The discharge vessel has a ceramic wall and is closed by a ceramic plug. An electrode which is located inside the discharge space is connected to an electric conductor by way of a leadthrough element. The leadthrough element projects through the ceramic plug with a close fit and is connected thereto in a gastight manner by way of a sealing ceramic. The leadthrough element has a first part which is formed by a cermet at the area of the gastight connection. In addition, the lamps display one or more and most preferably all of the following properties: a CCT (correlated color temperature) of about 3800 to about 4500K, a CRI (color rendering index) of about 70 to about 95, a MPCD (mean perceptible color difference) of about +10, and a luminous efficacy up to about 85-95 lumens / watt, a lumen maintenance of >80%, color temperature shift <200K from 100 to 8000, and lifetime of about 10,000 hours to about 25,000 hours. The invention also relates to design spaces for the design and construction of high power lamps and methods for construction of such lamps using the design spaces.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

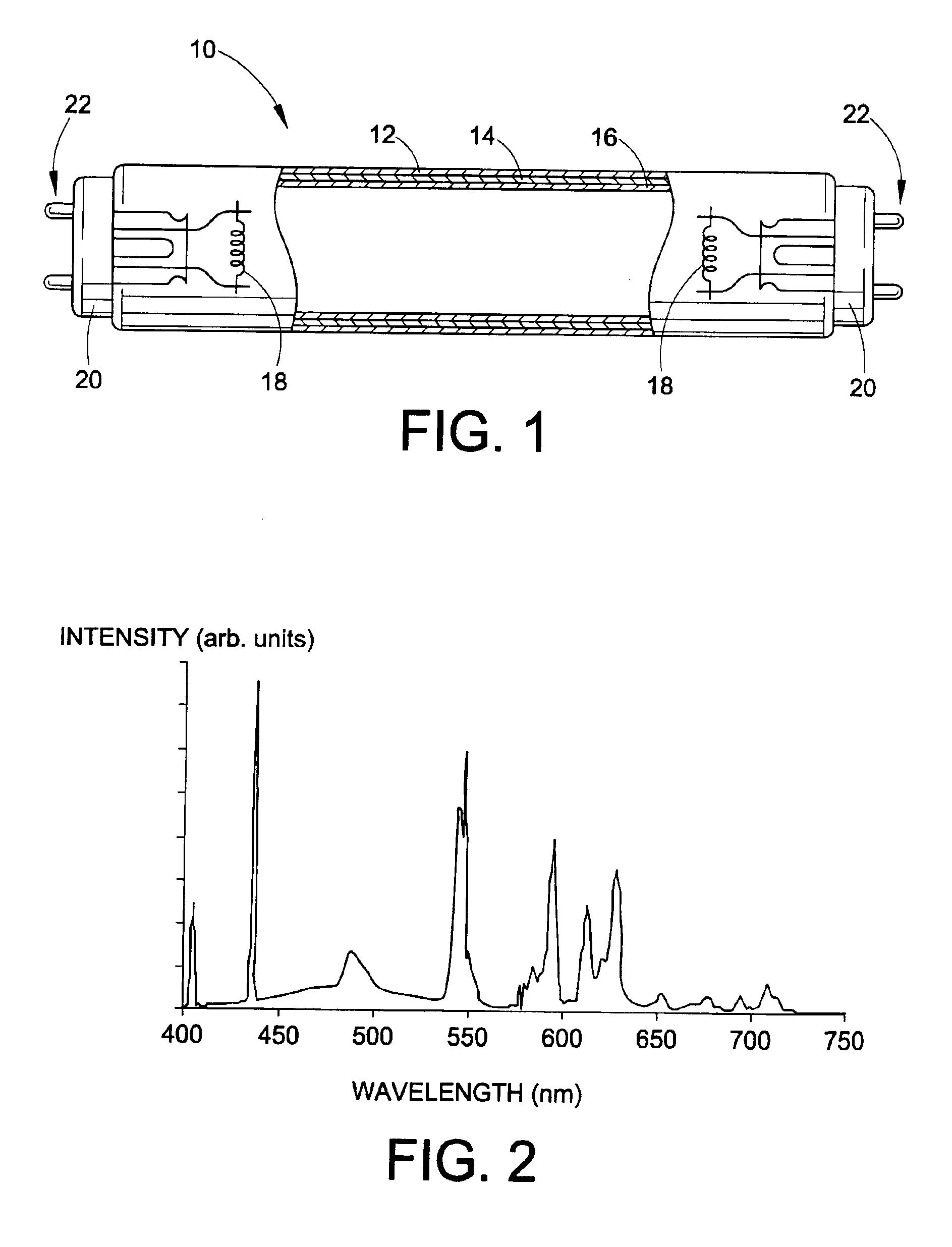

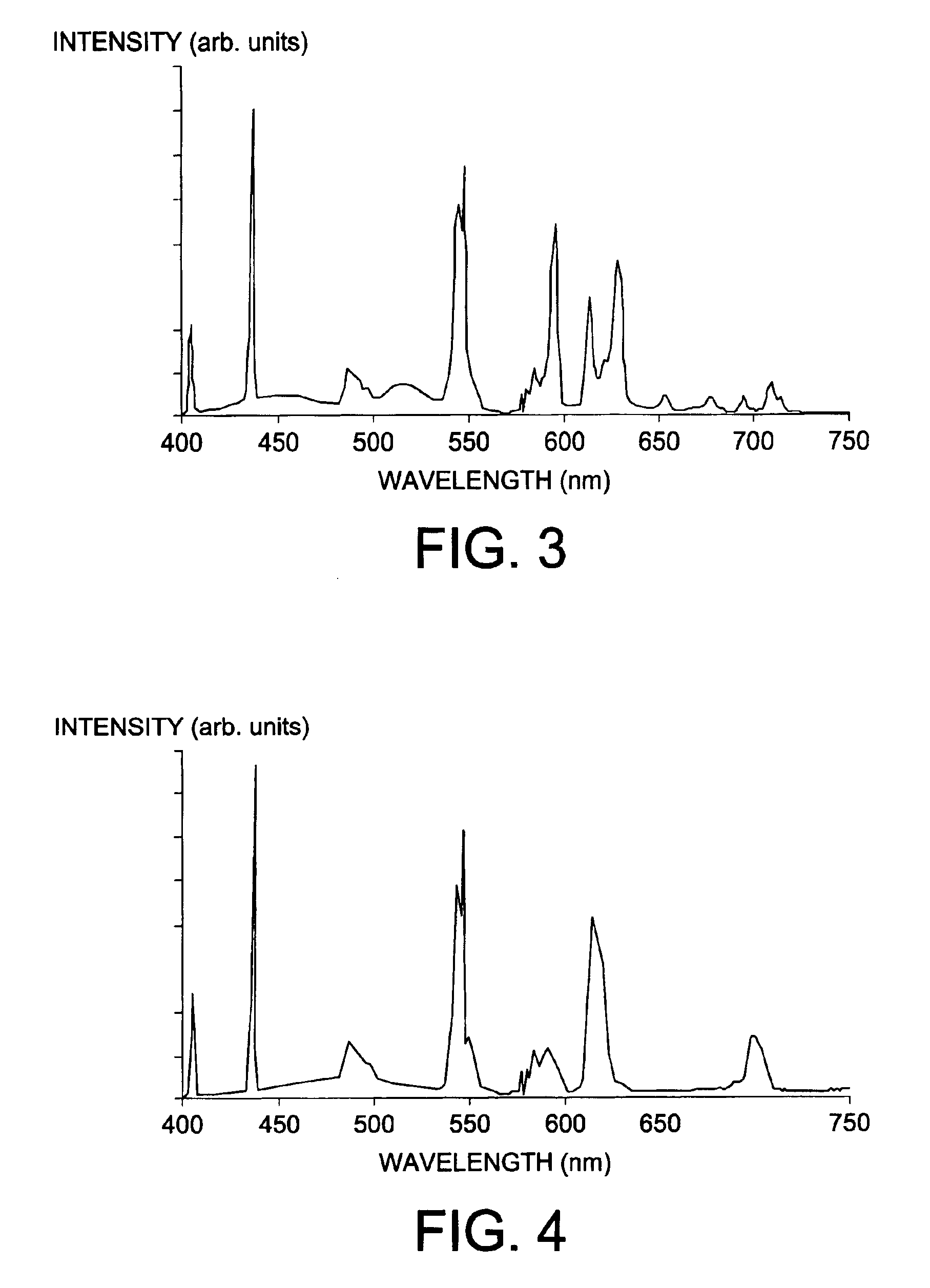

Red phosphors for use in high CRI fluorescent lamps

Novel red emitting phosphors for use in fluorescent lamps resulting in superior color rendering index values compared to conventional red phosphors. Also disclosed is a fluorescent lamp including a phosphor layer comprising blends of one or more of a blue phosphor, a blue-green phosphor, a green phosphor and a red a phosphor selected from the group consisting of SrY2O4:Eu3+, (Y,Gd)Al3B4O12:Eu3+, and [(Y1-x-y-mLay)Gdx]BO3:Eum wherein y<0.50 and m=0.001-0.3. The phosphor layer can optionally include an additional deep red phosphor and a yellow emitting phosphor. The resulting lamp will exhibit a white light having a color rendering index of 90 or higher with a correlated color temperature of from 2500 to 10000 Kelvin. The use of the disclosed red phosphors in phosphor blends of lamps results in high CRI light sources with increased stability and acceptable lumen maintenance over the course of the lamp life.

Owner:GENERAL ELECTRIC CO

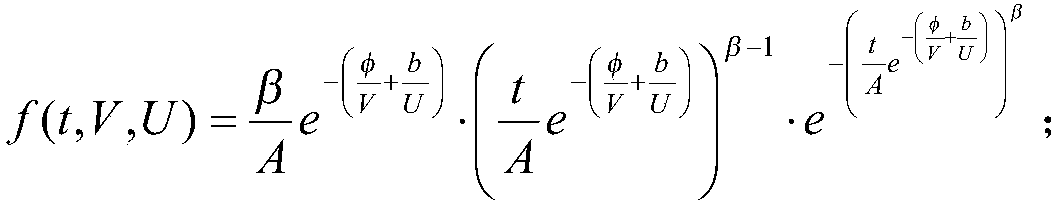

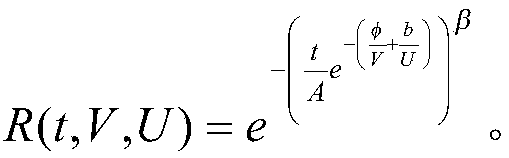

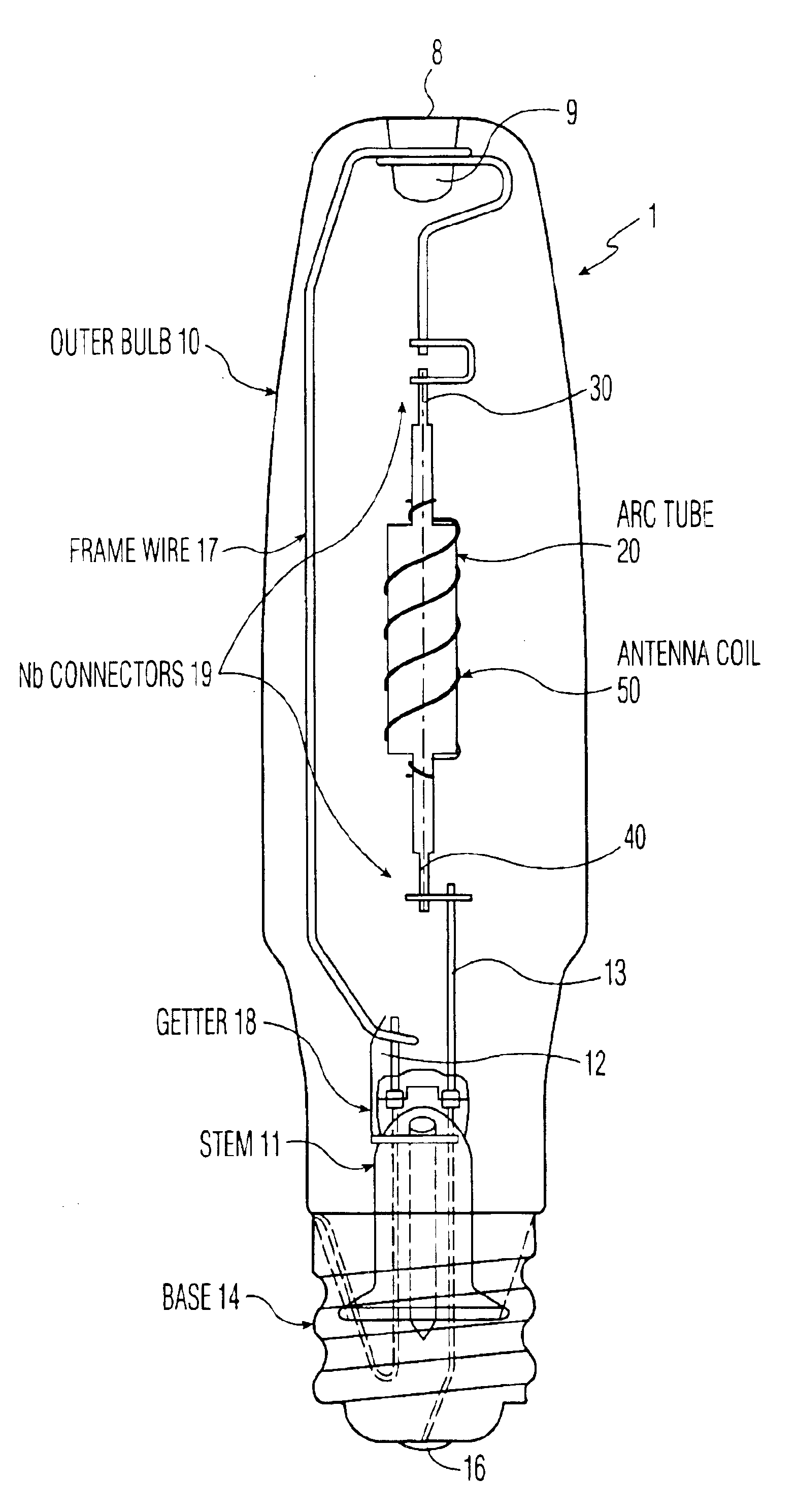

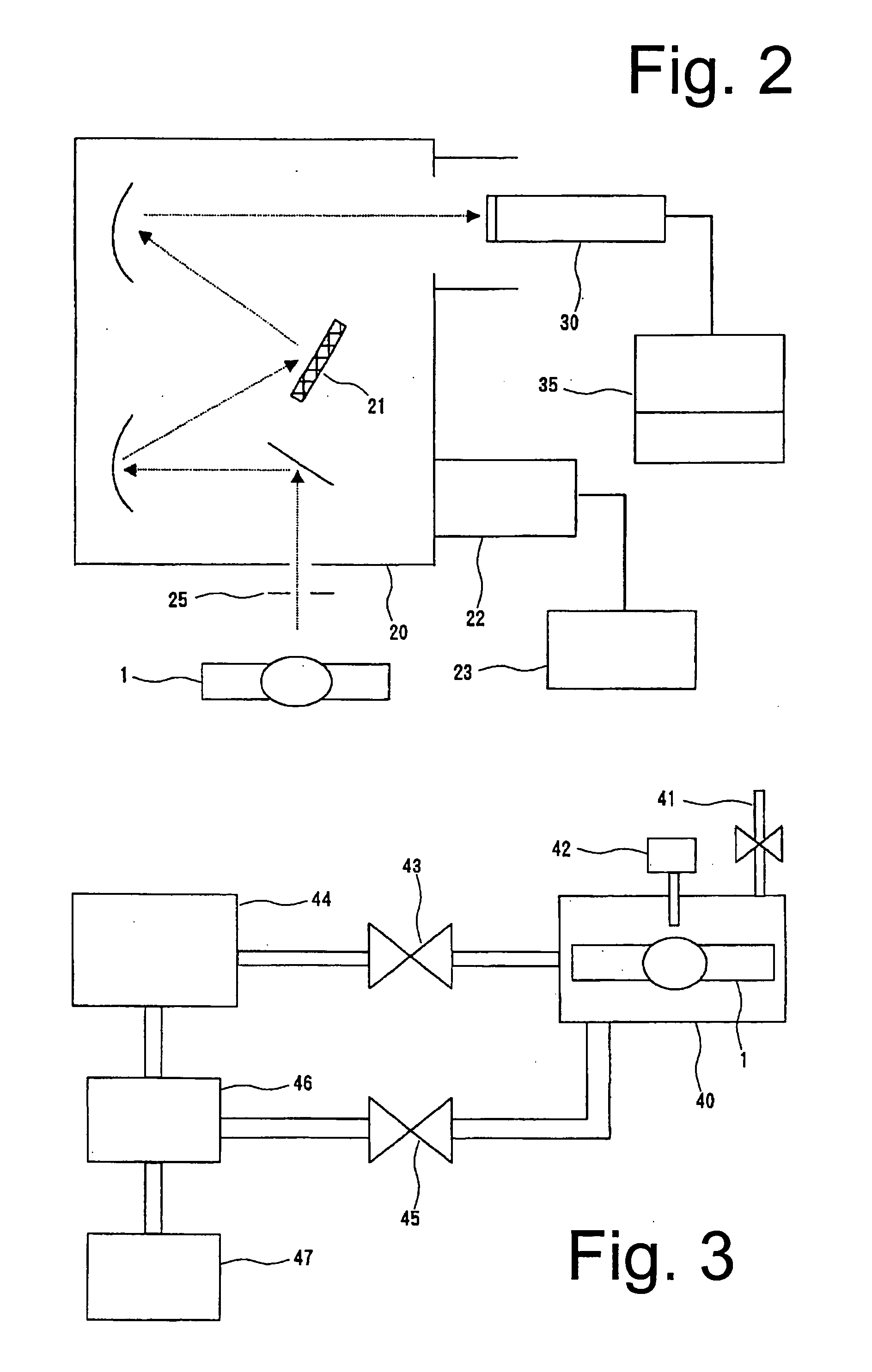

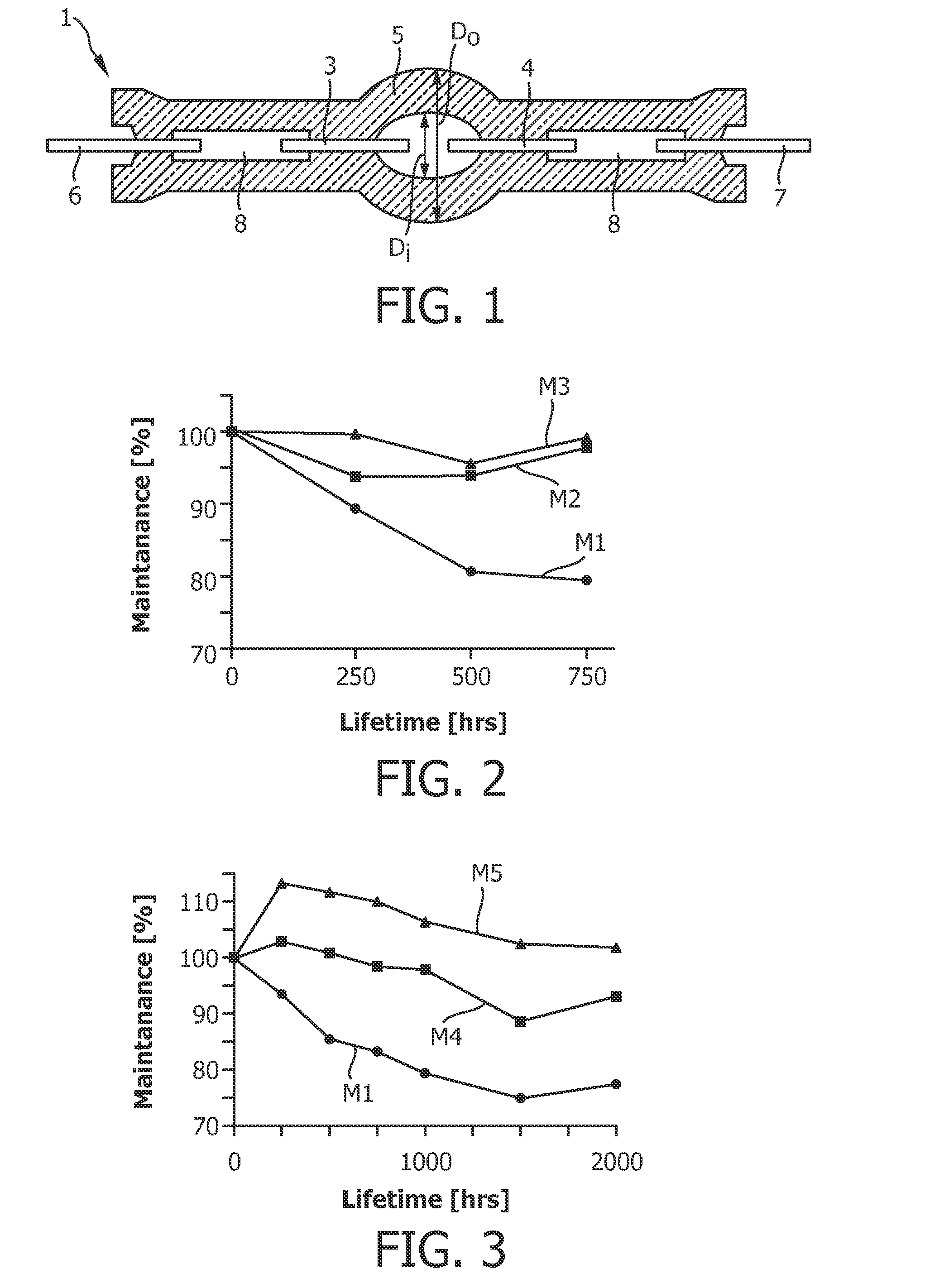

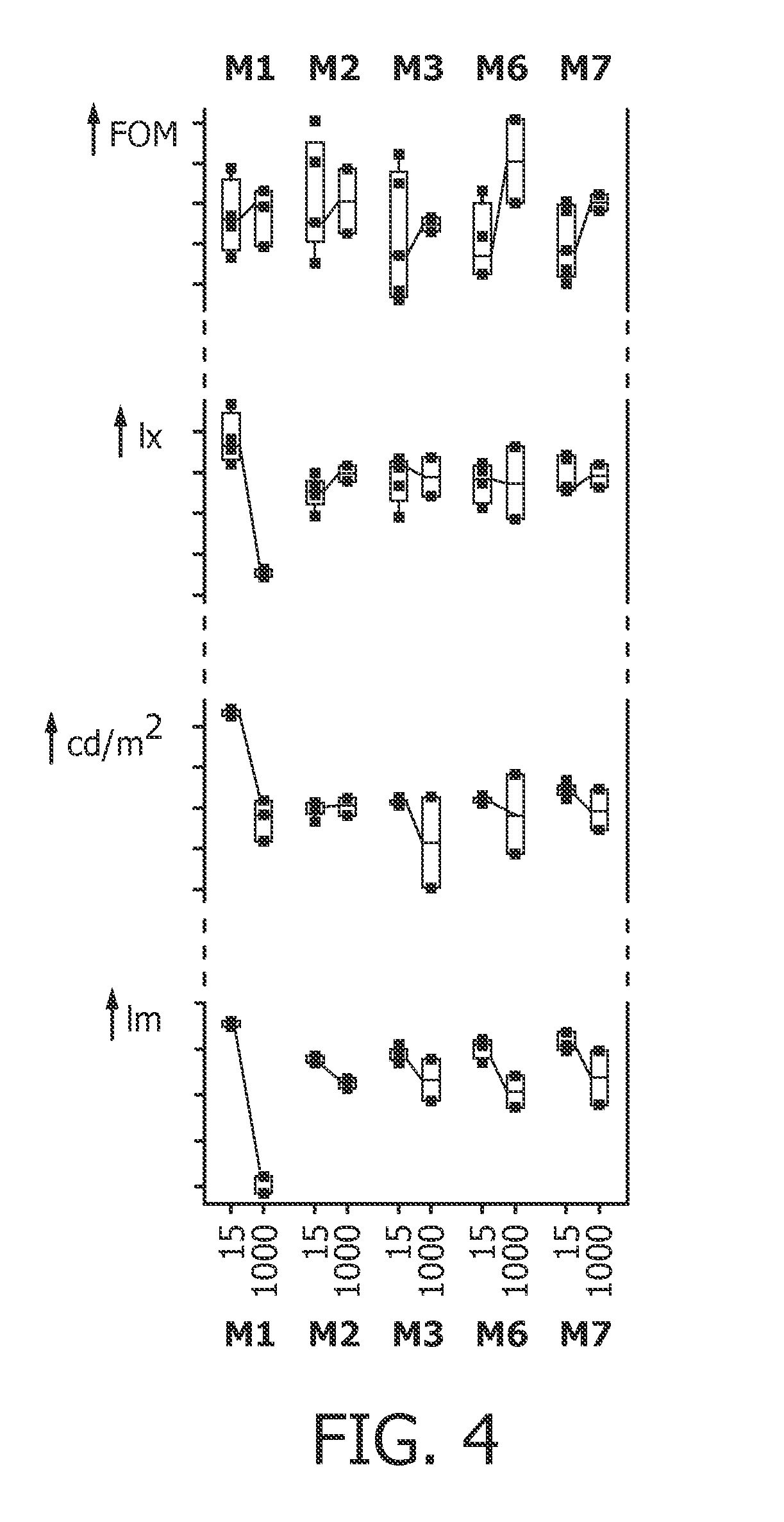

Rapid LED illumination product service life and reliability evaluation

InactiveCN107632275AShorten test timeEstimated confidence intervalLamps testingTesting optical propertiesLumen maintenanceLuminous flux

The invention relates to a rapid LED illumination product service life and reliability evaluation method. The method comprises steps that 1), a test sample is divided into multiple groups, and initialluminous fluxes and color coordinates of the samples are measured; 2), different temperature and humidity combination stresses are employed, and an acceleration experiment of each group of sample iscarried out; 3), a luminous flux and a color coordinate of each group of sample are respectively measured at multiple time segments, and lumen maintenance and color drift are calculated; 4), lumen maintenance degeneration data fitting and color drift data fitting are carried out to acquire a lumen maintenance degeneration locus equation and a color drift degeneration locus equation; 5) a lumen maintenance failure threshold and a color drift failure threshold are determined; and 6), lumen maintenance service life and color drift service life of LED illumination products under normal work conditions are respectively acquired according to the degeneration locus equations and a temperature-humidity Weibull model. The method is advantaged in that the test time is shortened to 1000 hours on thecondition that service life evaluation precision is not influenced, and product service life and reliability can be truly reflected.

Owner:厦门市产品质量监督检验院

Coil antenna/protection for ceramic metal halide lamps

InactiveUS6861805B2Good color consistencyImprove stabilitySolid cathode detailsStructural circuit elementsColor rendering indexLumen maintenance

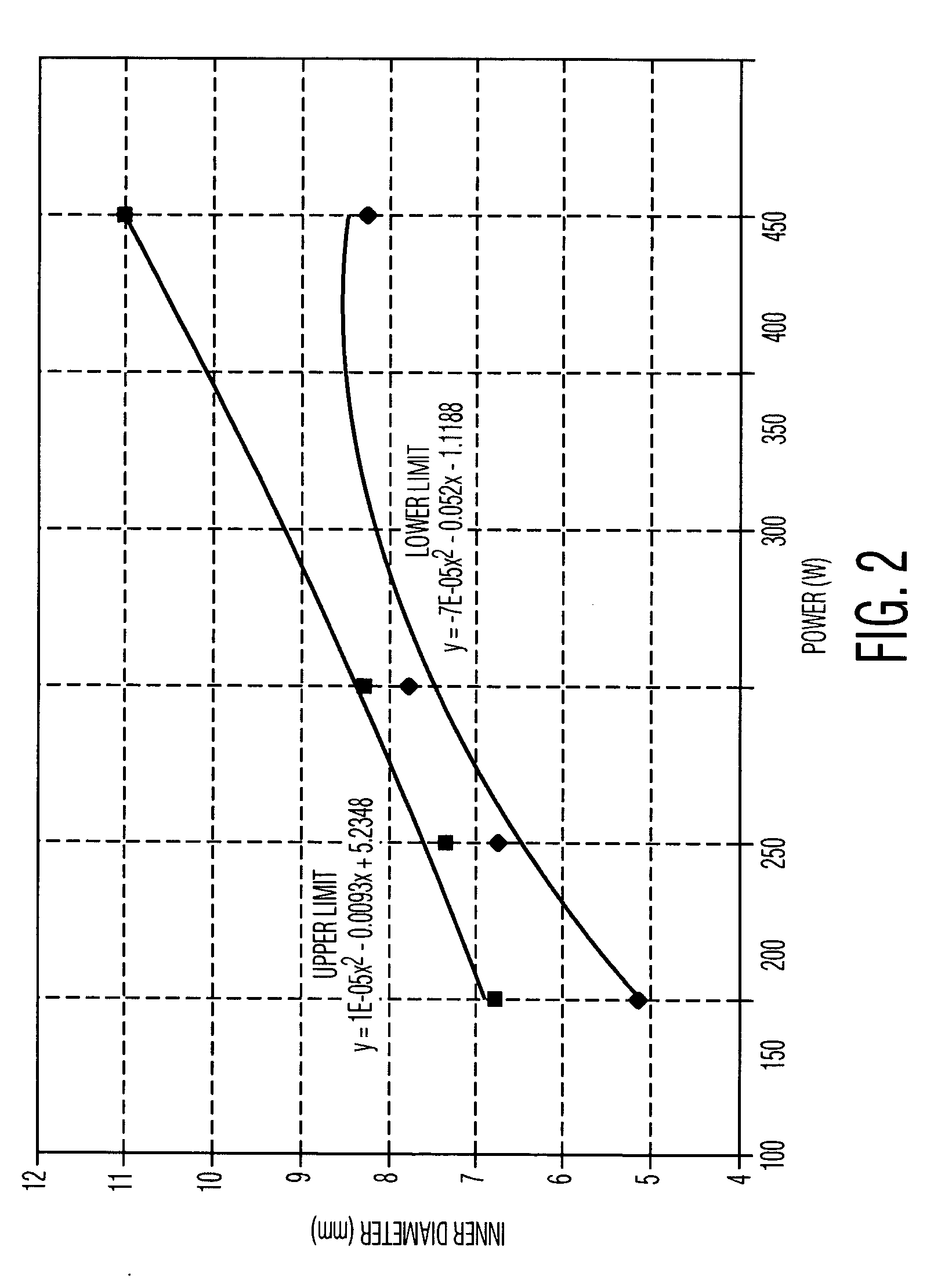

The invention relates to a high-pressure discharge lamp of the ceramic metal halide type of the Philips MasterColor series having a molybdenum coil wrapped around the discharge vessel and at least a portion of the electrode feed through means, and having power ranges of about 150 W to about 1000 W. Such lamps are provided with a discharge vessel which encloses a discharge space. The discharge vessel has a ceramic wall and is closed by a ceramic plug. An electrode which is located inside the discharge space is connected to an electric conductor by way of a leadthrough element. The leadthrough element projects through the ceramic plug with a close fit and is connected thereto in a gastight manner by way of a sealing ceramic. The leadthrough element has a first part which is formed by a cermet at the area of the gastight connection. In addition, the lamps display one or more and most preferably all of the following properties: a CCT (correlated color temperature) of about 3800 to about 4500K, a CRI (color rendering index) of about 70 to about 95, a MPCD (mean perceptible color difference) of about ±10, and a luminous efficacy up to about 85-95 lumens / watt, a lumen maintenance of >80%, color temperature shift <200K from 100 to 8000, and lifetime of about 10,000 hours to about 25,000 hours. The invention also relates to design spaces for the design and construction of high power lamps and methods for construction of such lamps using the design spaces.

Owner:KONINK PHILIPS ELECTRONICS NV

Ceramic metal halide lamp with oxygen content selected for high lumen maintenance

InactiveUS20100013417A1Improve lumen maintenanceEasy maintenanceSparking plugsAlternating current plasma display panelsLumen maintenanceOxygen content

A lamp includes a discharge vessel with electrodes extending into the discharge vessel and an ionizable fill scaled within the vessel. The fill includes a buffer gas, optionally mercury, and a halide component. The lamp includes available oxygen, sealed within the discharge vessel, at a concentration of at least 0.1 μmol O / cc.

Owner:TUNGSRAM OPERATIONS KFT

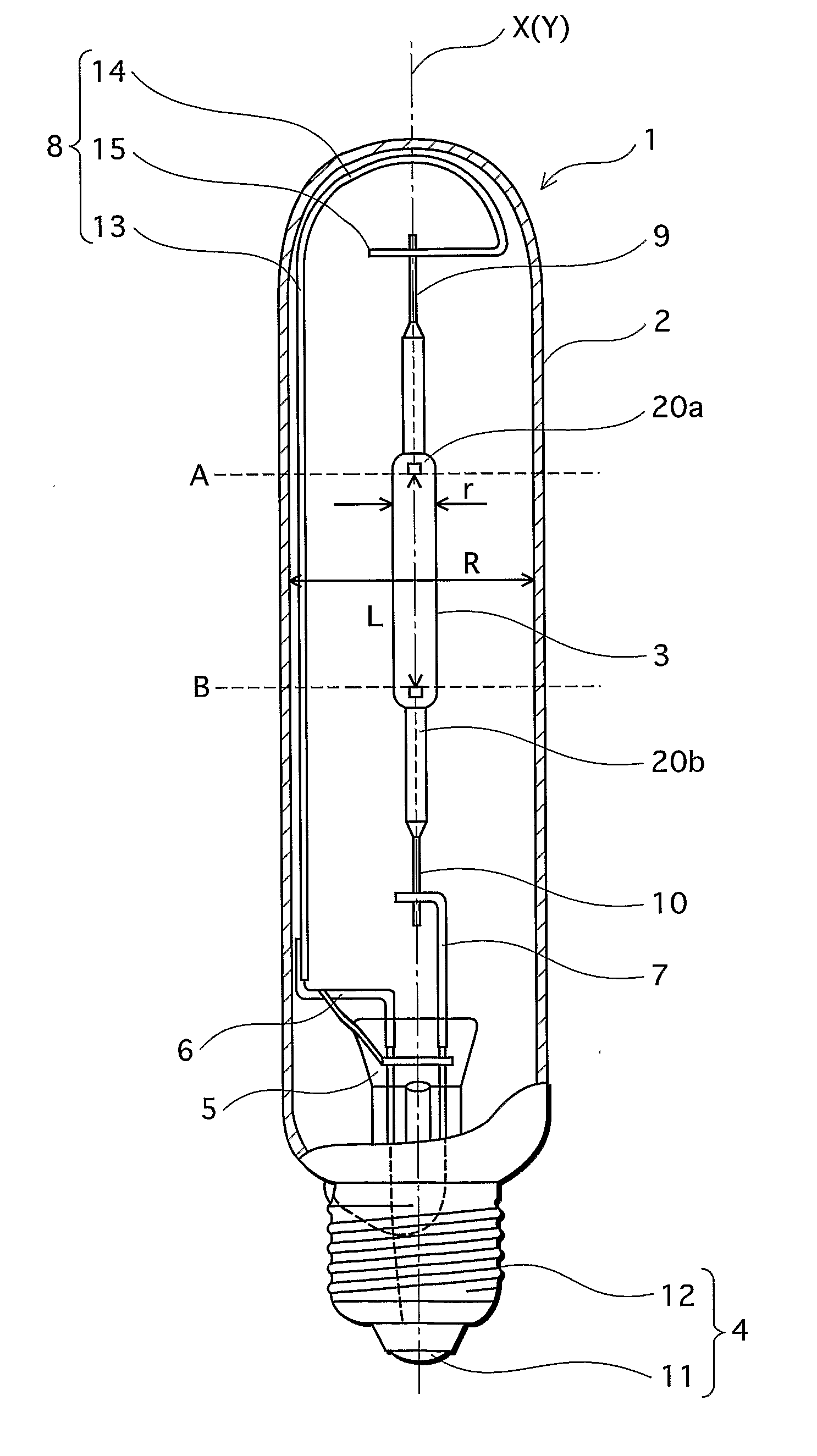

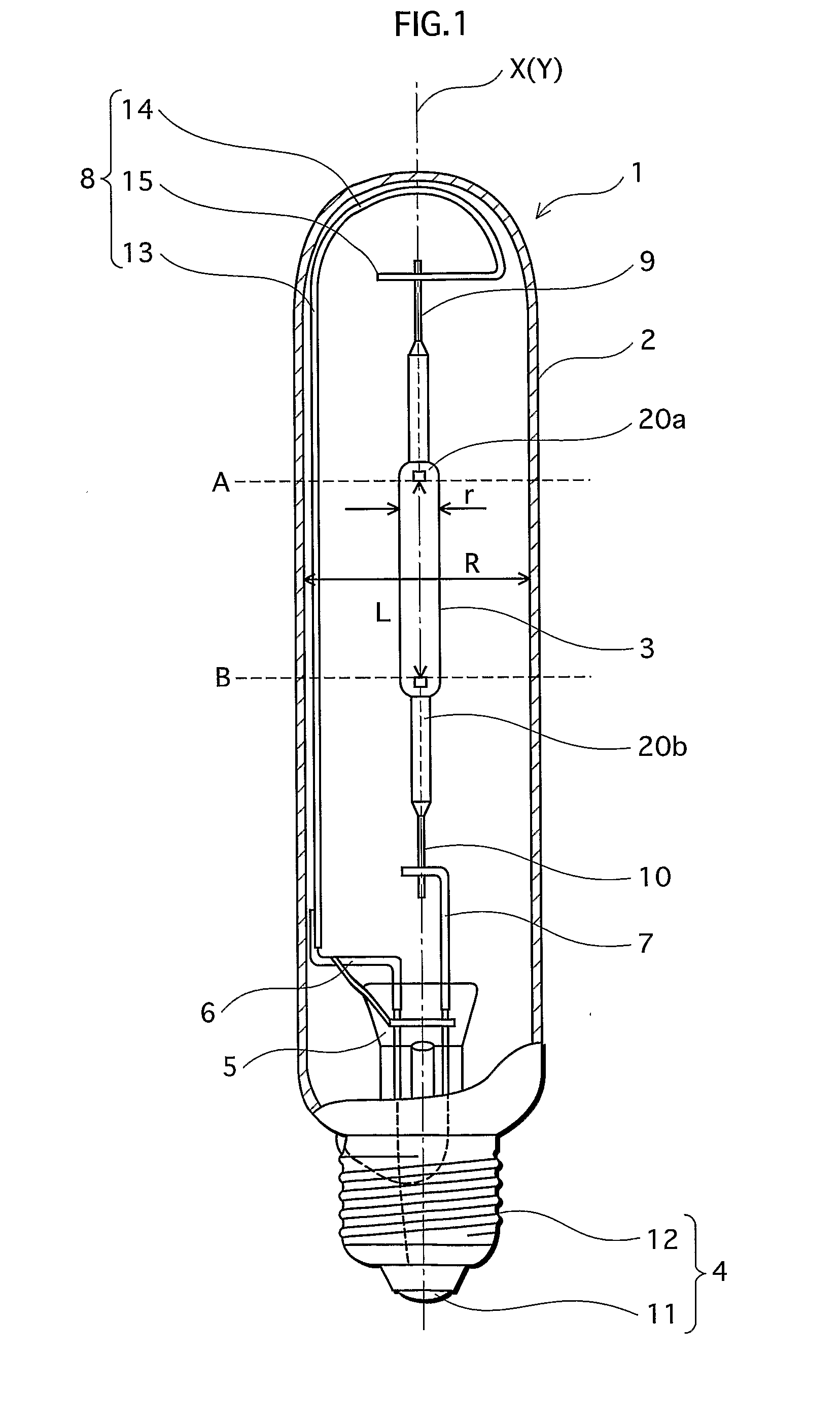

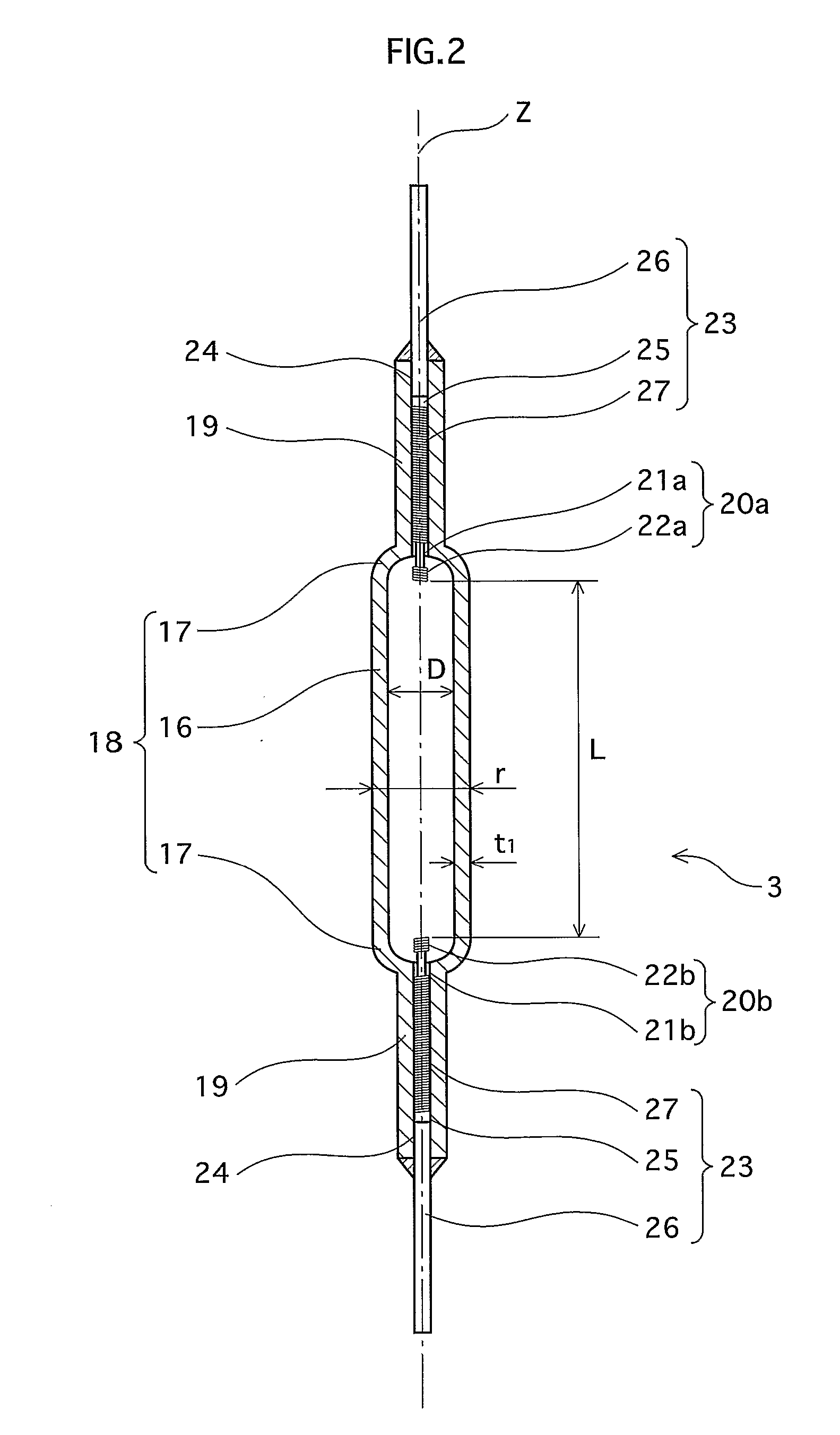

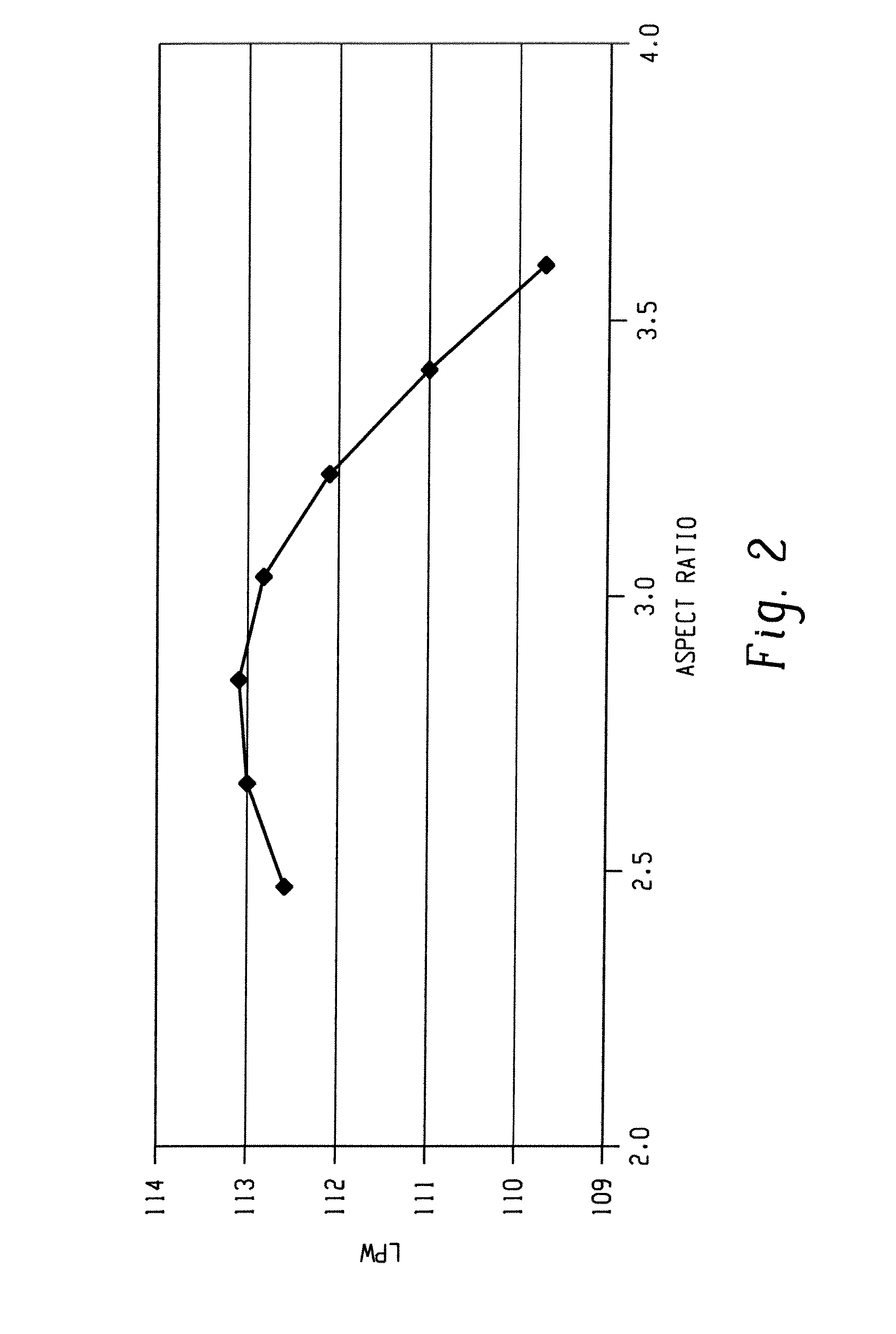

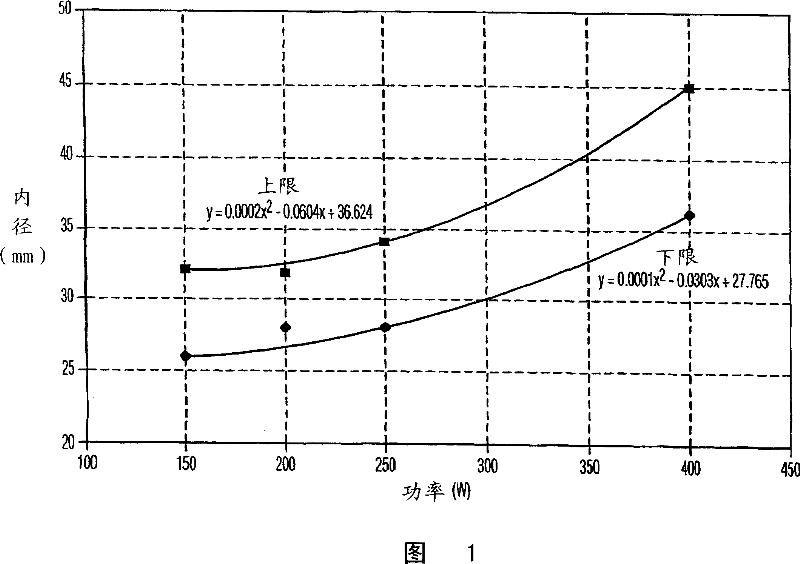

Metal halide lamp and luminaire using the same

InactiveUS20070159104A1Solve low luminous efficiencyDecline in maintenancePoint-like light sourceHigh-pressure discharge lampsMetal-halide lampLumen maintenance

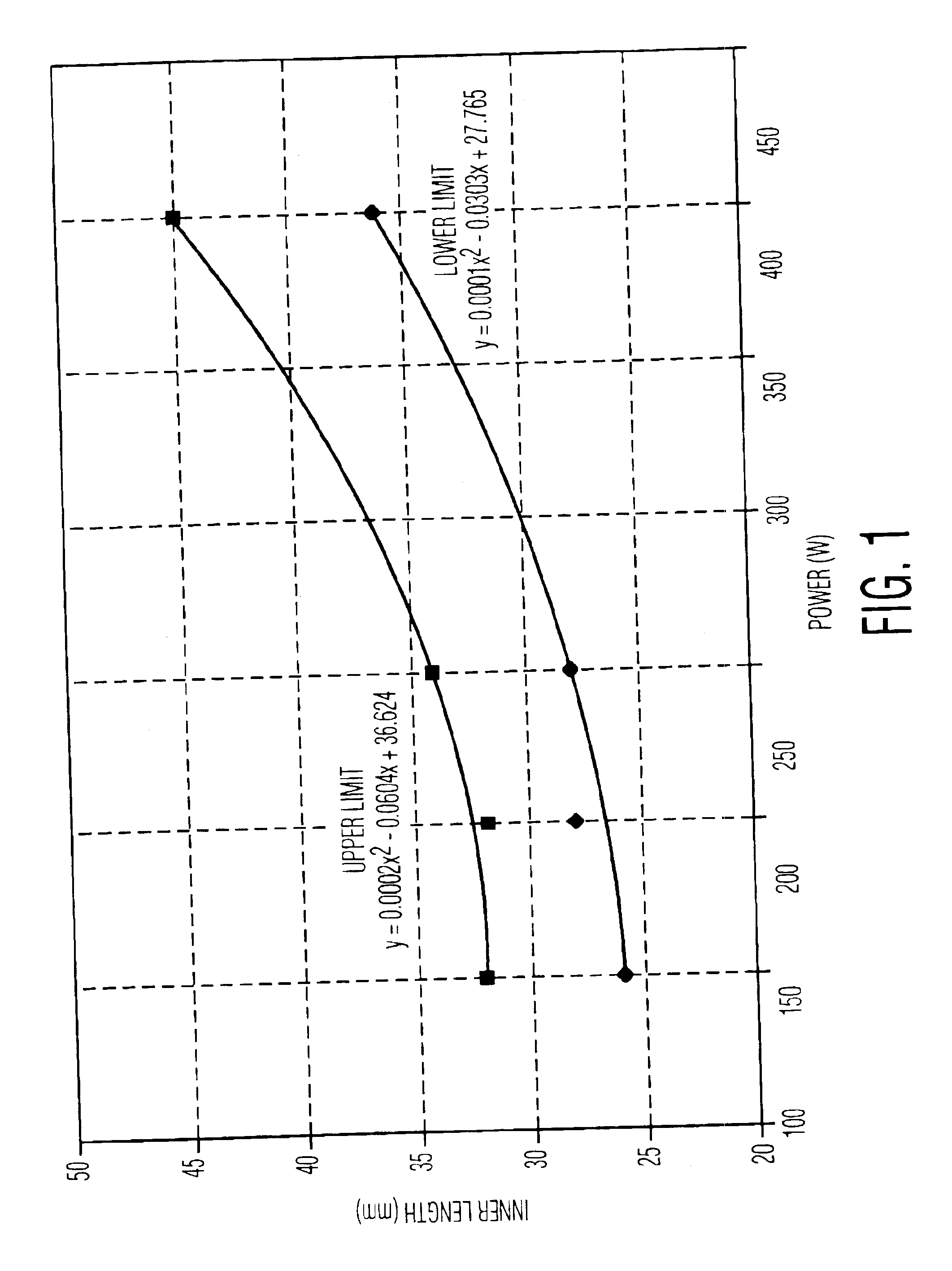

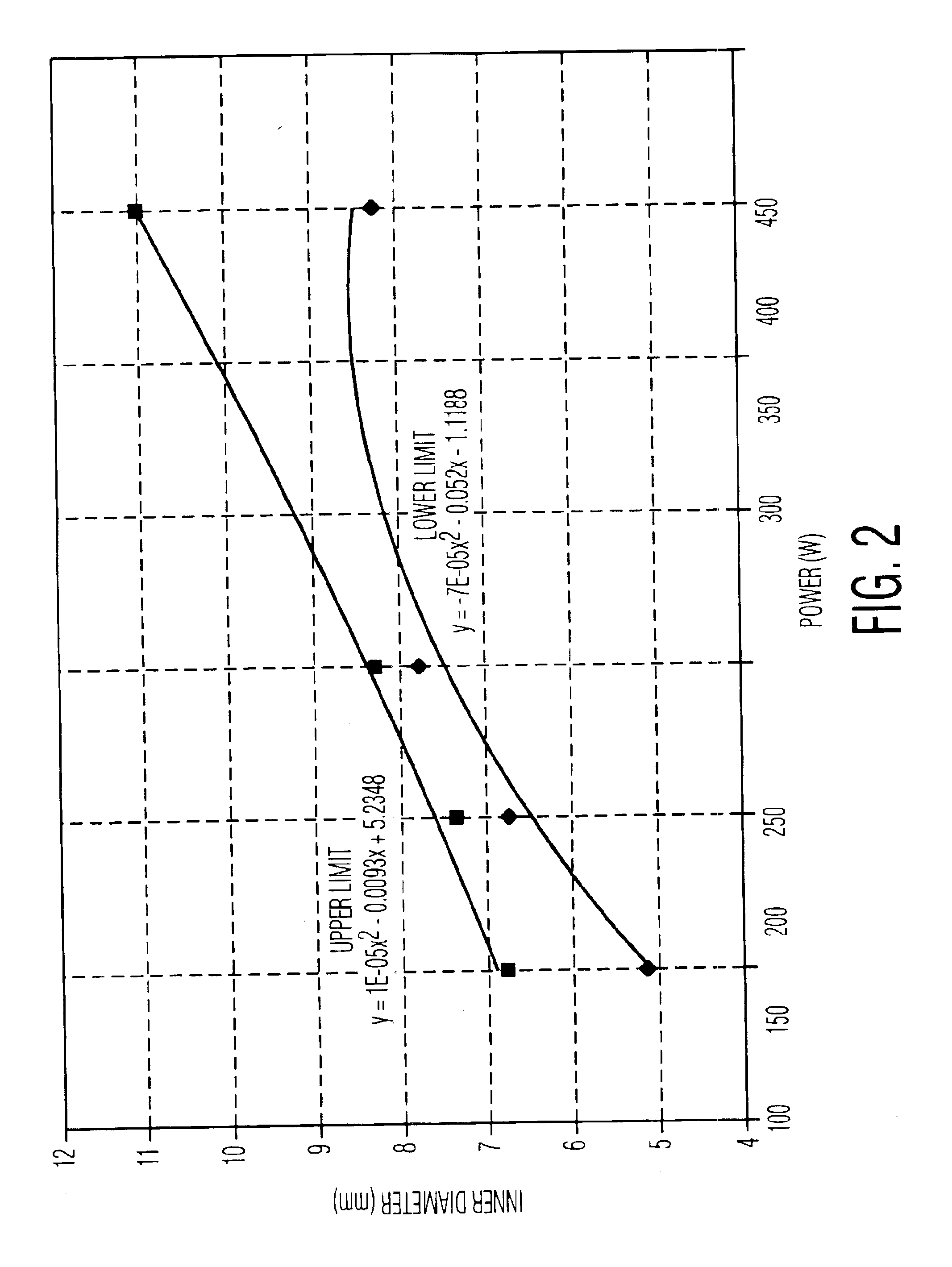

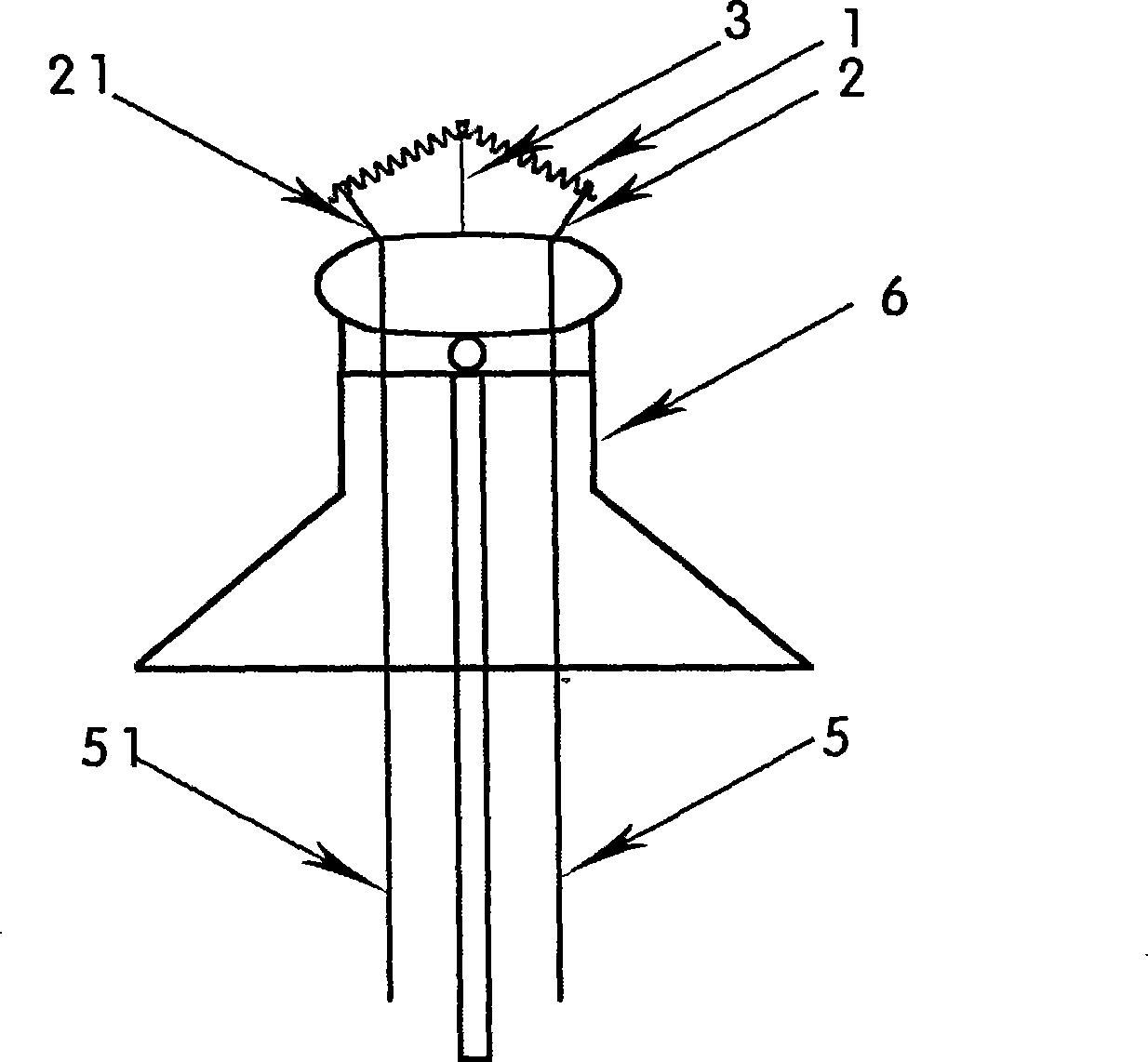

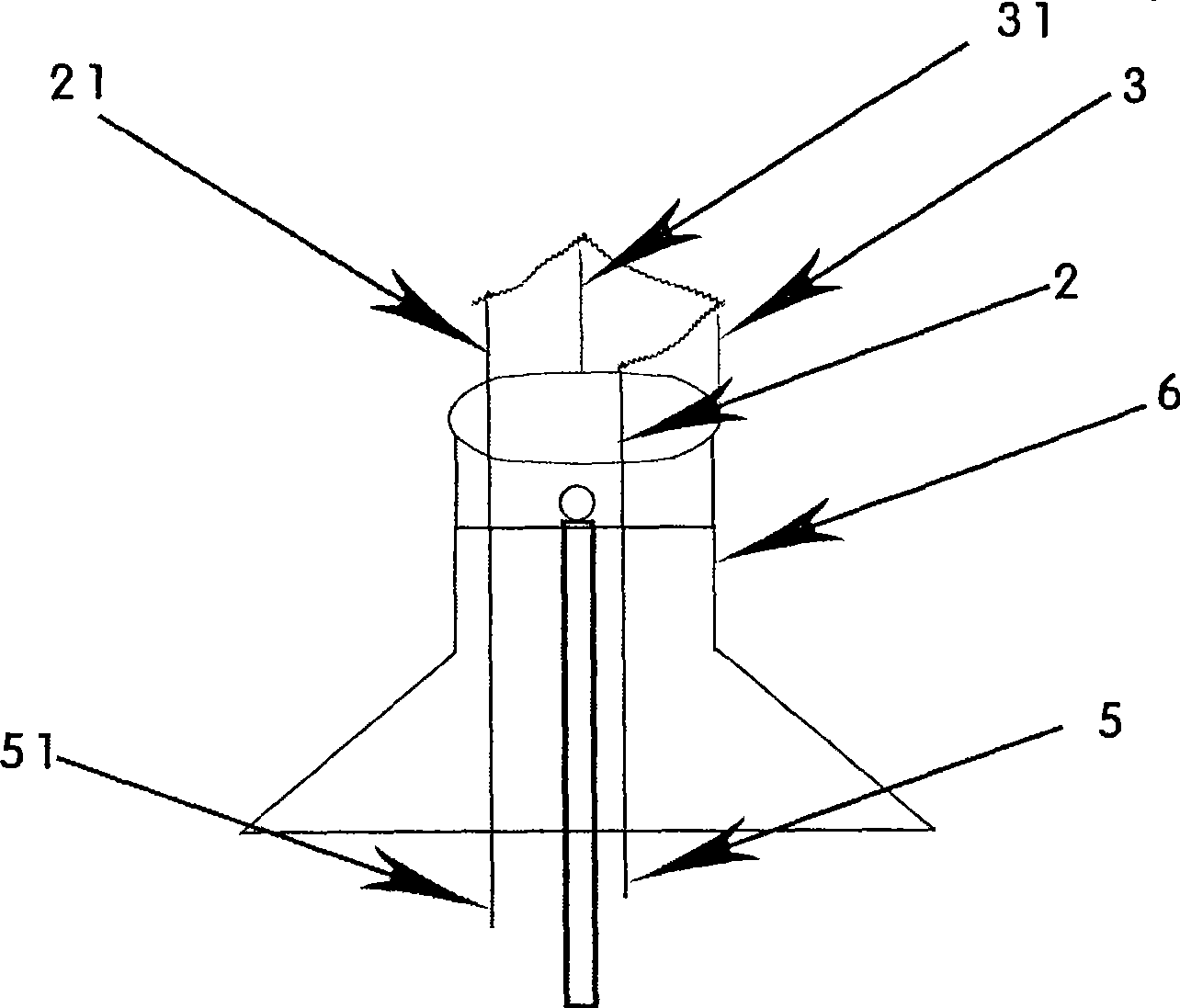

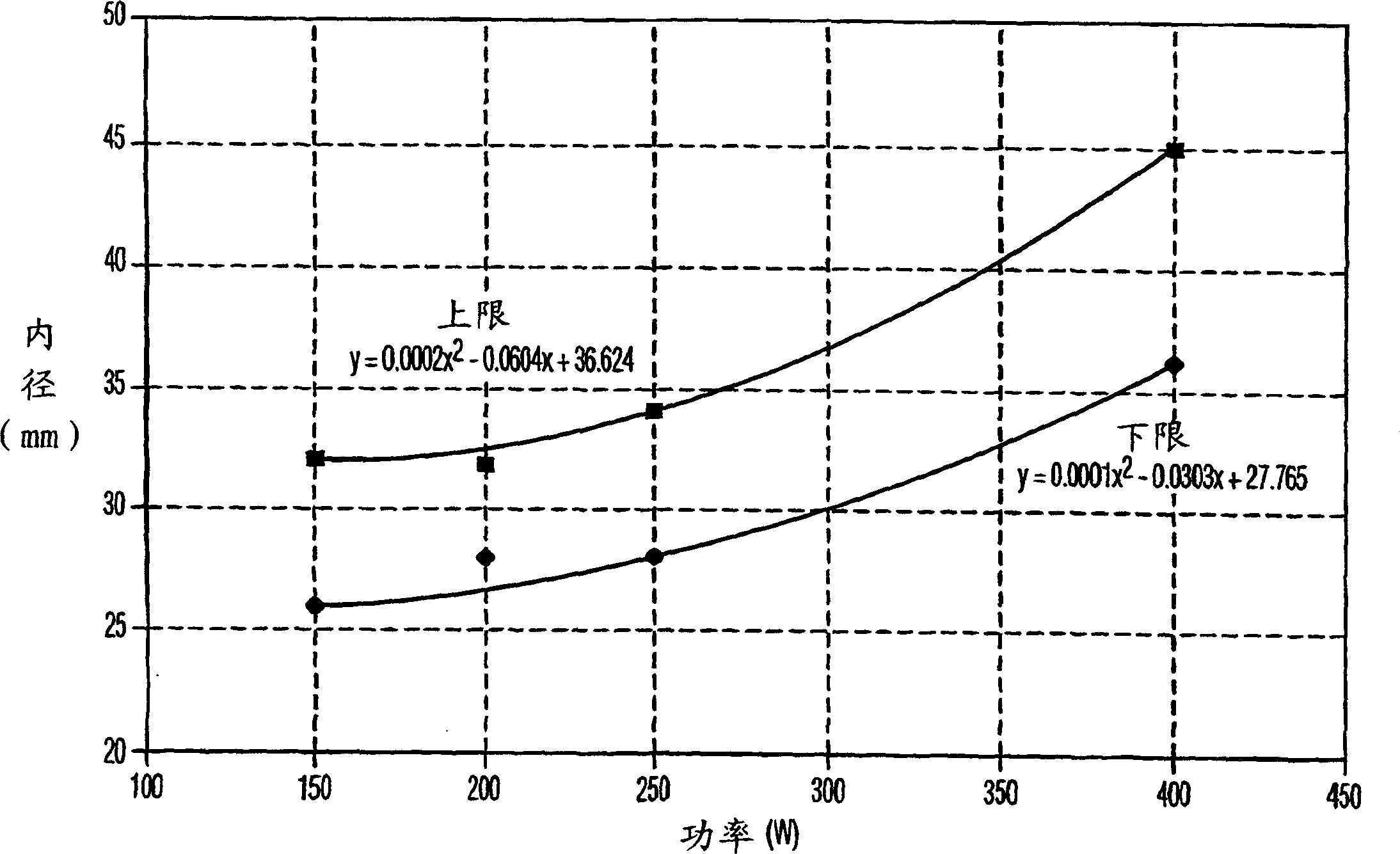

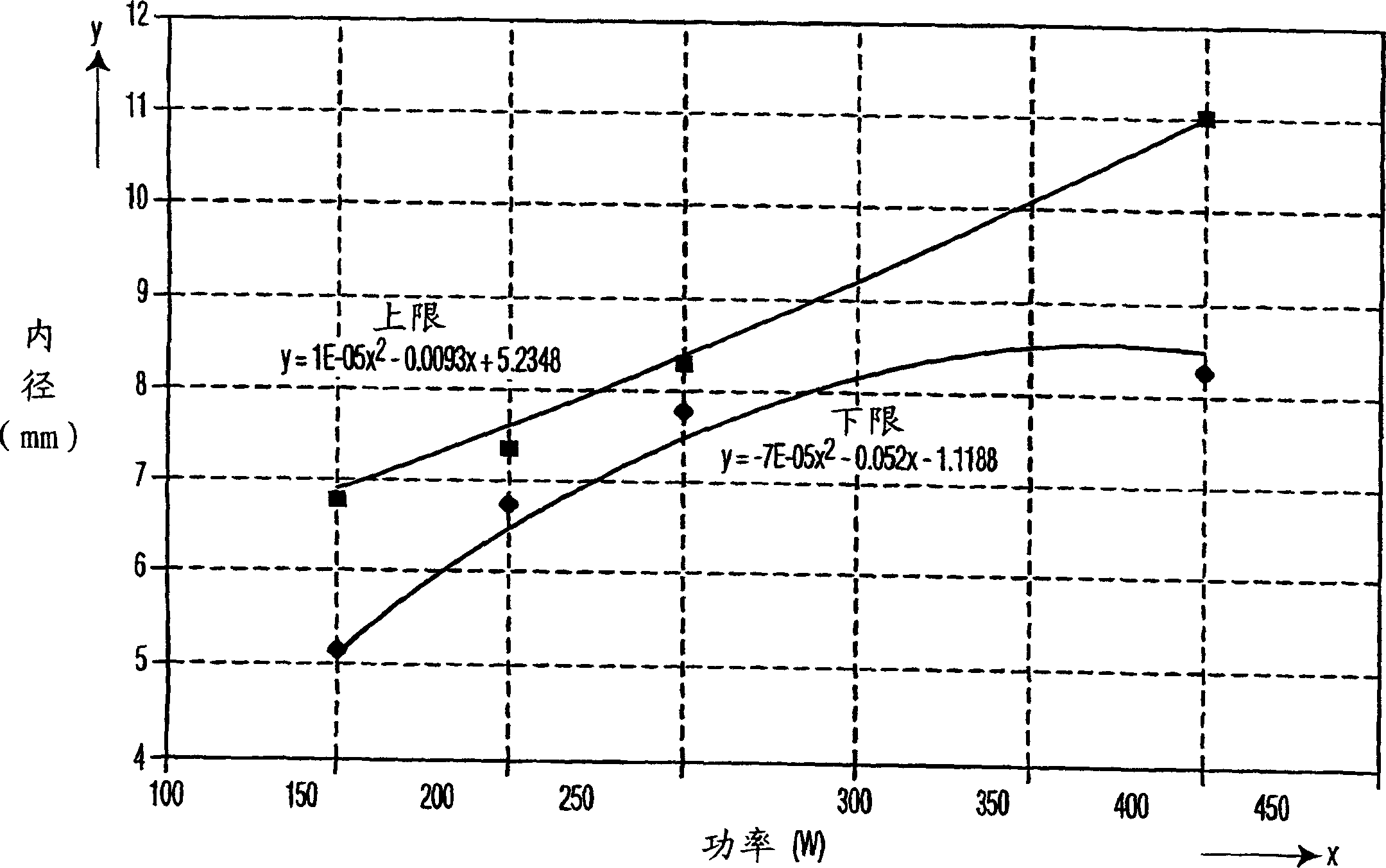

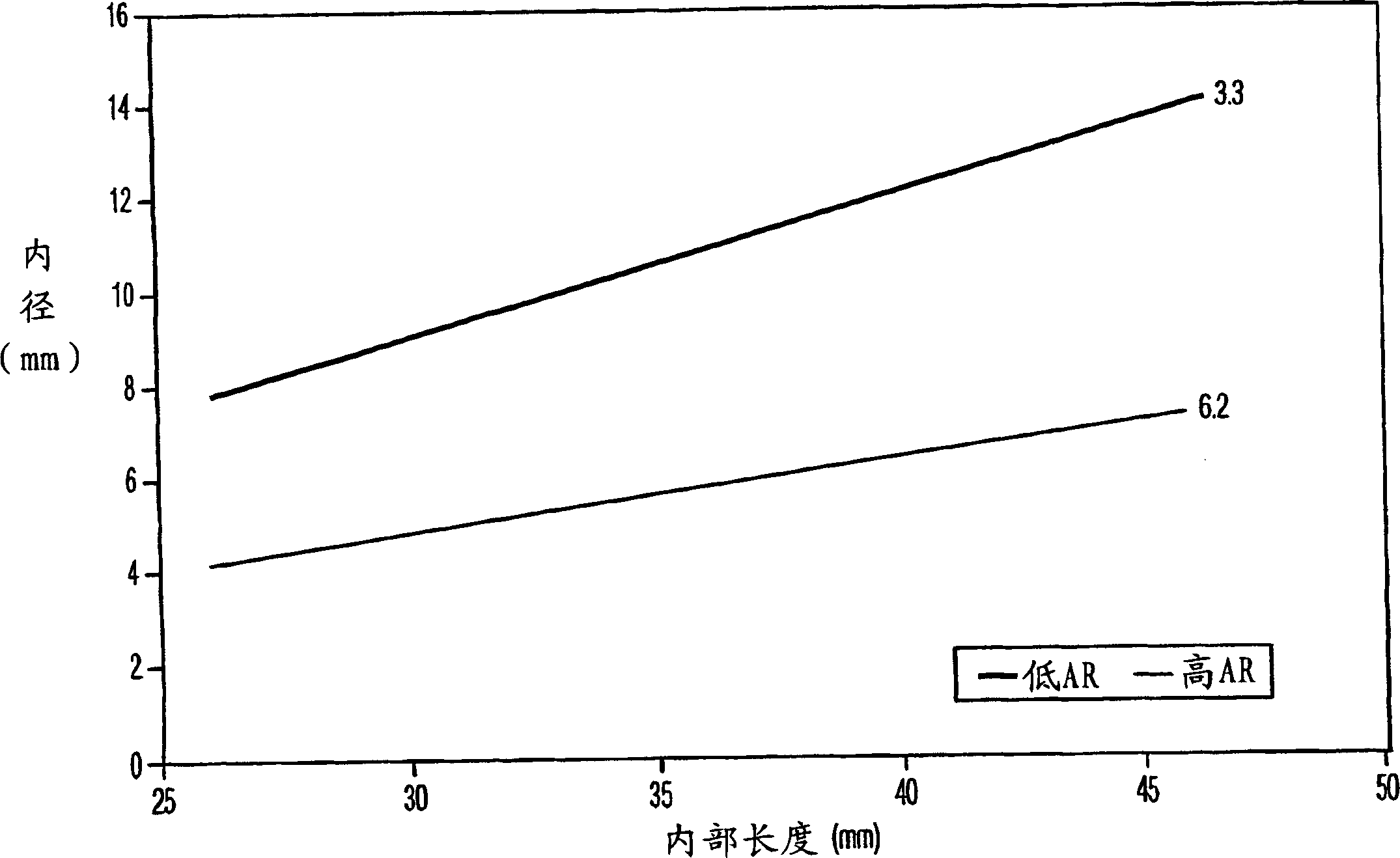

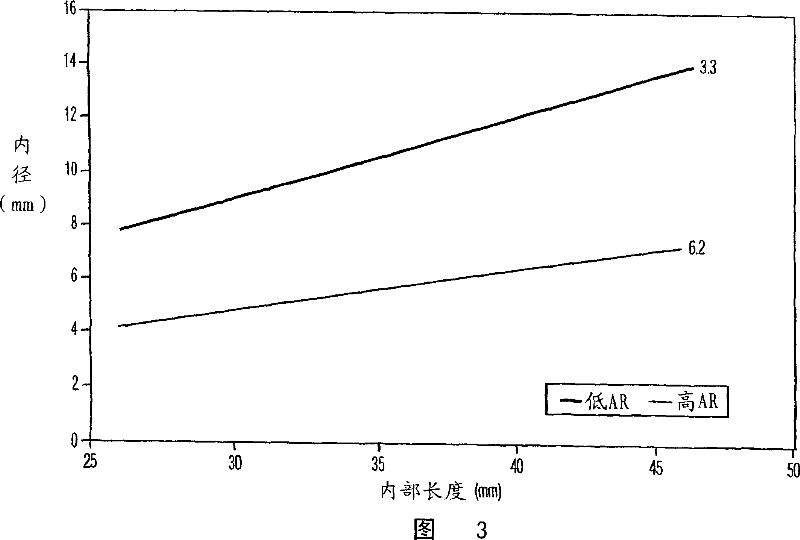

The present invention aims at providing a metal halide lamp that (i) prevents a decline in the lumen maintenance and a deterioration of quality in appearance due to the coloring of a casing tube surrounding the arc tube, and at the same time (ii) achieves high luminous efficiency. A metal halide lamp (1) has a pair of electrodes (20a&b) placed in an arc tube (3) made of translucent ceramic, and a sodium halide is enclosed therein. The metal halide lamp (1) satisfies L / D 4, where L (mm) is the length of the space between the electrodes (20a&b) and D (mm) is the internal diameter of the arc tube (3). The metal halide lamp (1) has a casing tube (2) surrounding the arc tube (3), at least around a portion between the electrodes (20a&b). Here, R / r 3.0 is satisfied, where R is the internal diameter of the casing tube (2) and r is the external diameter of the arc tube (3), within a region positionally corresponding to, in a radial direction of the arc tube, the space between the electrodes (20a&b), on a cross-sectional surface where an outer circumference of the arc tube (3) comes closest to the internal circumference of the casing tube (2).

Owner:PANASONIC CORP

Street lighting lamp with long life, high efficiency, and high lumen maintenance

InactiveUS20110031879A1Improve efficiencyHigh lumen maintenanceElectroluminescent light sourcesTube/lamp vessel fillingCeriumEffect light

A lamp includes a discharge vessel and electrodes extending into the discharge vessel. The lamp further includes an ionizable fill sealed within the vessel. The fill includes an inert gas and a halide component. The halide component includes a sodium halide, a thallium halide, at least one of a calcium halide and a strontium halide, and at least one of a rare earth halide. The rare earth halide is selected from the group consisting of lanthanum, cerium, praseodymium, samarium and neodymium, and combinations thereof.

Owner:GENERAL ELECTRIC CO

Discharge lamp

ActiveUS20040090183A1Blackening and devitrification of suppressedHigh lumen maintenanceElectroluminescent light sourcesTube/lamp vessel fillingGas-discharge lampNoble gas

A discharge lamp which maintains a high lumen maintenance factor even when operated for a long time is obtained in a discharge lamp which has a silica glass discharge vessel and a pair of opposed electrodes in the discharge vessel and in which the discharge vessel is filled with at least 0.15 mg / mm<3 >mercury, a rare gas with argon as the main component, and 2x10<-4 >mumole / mm<3 >to 7x10<-3 >mumole / mm<3 >bromine by meeting the following conditions when feeding a direct current of 5 mA between the electrodes and a glow discharge produced: 1.0x10<-4><=B / A<=1.2X10<-1 > Condition (1) c / a<=1.4X10<-1 > Condition (2) d / a<=1.2X10<-2 > Condition (3) e / a<=1.4X10<-2 > Condition (4) where a is the emission intensity of the argon with a wavelength of 668 nm, b is the emission intensity of OH with a wavelength of 309 nm, c is the emission intensity of hydrogen (H) with a wavelength of 656 mm, d is the emission intensity of C2 with a wavelength of 517 nm, and e is the emission intensity of CH with a wavelength of 431 nm

Owner:USHIO DENKI KK

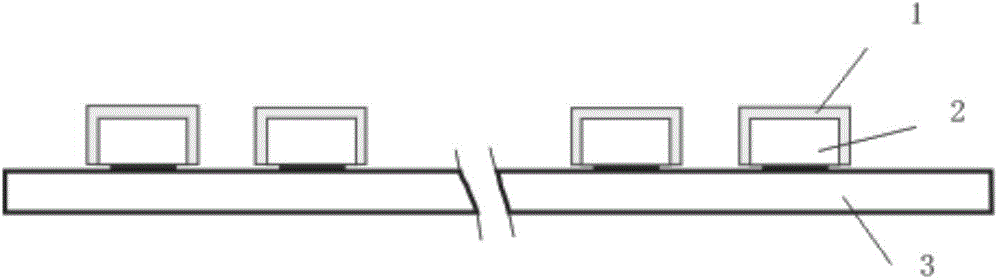

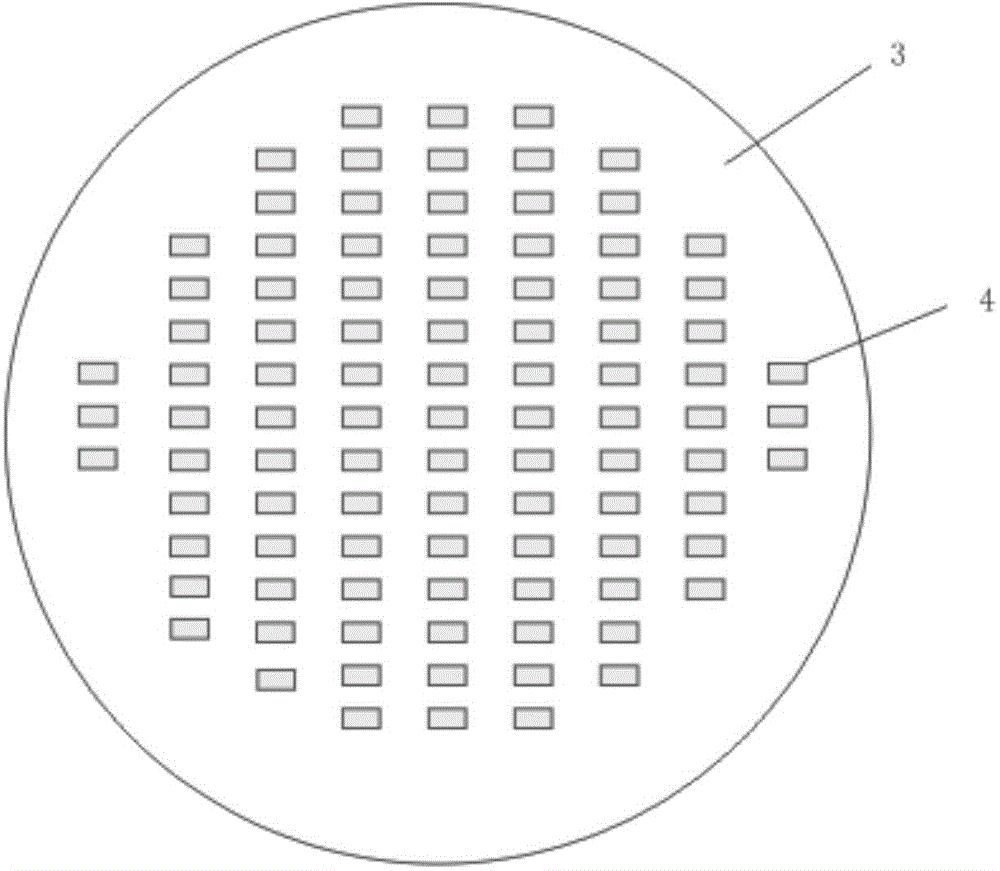

Preparation method of LED light source and preparation method of LED light-emitting module

ActiveCN104485327AShorten the timeImprove light distribution designPoint-like light sourceSolid-state devicesFluorescenceAdhesive

The invention discloses a preparation method of an LED light source and a preparation method of an LED light-emitting module. The preparation method of the LED light source comprises the following steps: bonding an LED chip on a PET film or a PTFE film with UV adhesive on the surface, and carrying out ultraviolet irradiation for initial curing; preparing an insulation rubber layer on the LED chip; then preparing a fluorescent colloid layer; using UV light to irradiate the PET film or the PTFE film to enable the UV adhesive on the surface to lose viscidity, and taking down the LED chip after encapsulation to obtain the LED light source. The LED light sources are arranged in a series-parallel connection mode, and are welded on a base plate, so that the LED light-emitting module is obtained. According to the preparation methods, in the aspect of material composition, supports and money are saved, the reliability is improved while the cost is reduced, the material cost can be reduced, the light-emitting angle is increased, the processing convenience is increased, and the production link is simplified. The position of fluorescent powder is far away from the chip through the insulation rubber layer, so that the thermal quenching and thermal efficiency of the fluorescent powder are reduced, and the lighting effect and long-term lumen maintenance are improved.

Owner:HANGZHOU HANGKE OPTOELECTRONICS

LED Lamp With A High Color Rendering Index

InactiveUS20140035455A1Discharge tube luminescnet screensElectroluminescent light sourcesPhosphorHigh color

LED lamps having a high color rendering index are disclosed. In some embodiments, such lamps also exhibit high lumen maintenance and low color drift during lamp warm-up. The lamps may include, for example, a light emitting diode (LED) kernel having a mixture of red and blue LEDs, and a converter including a red phosphor in an amount ranging from greater than 0 to about 10 weight % of a total phosphor content of the converter.

Owner:OSRAM SYLVANIA INC

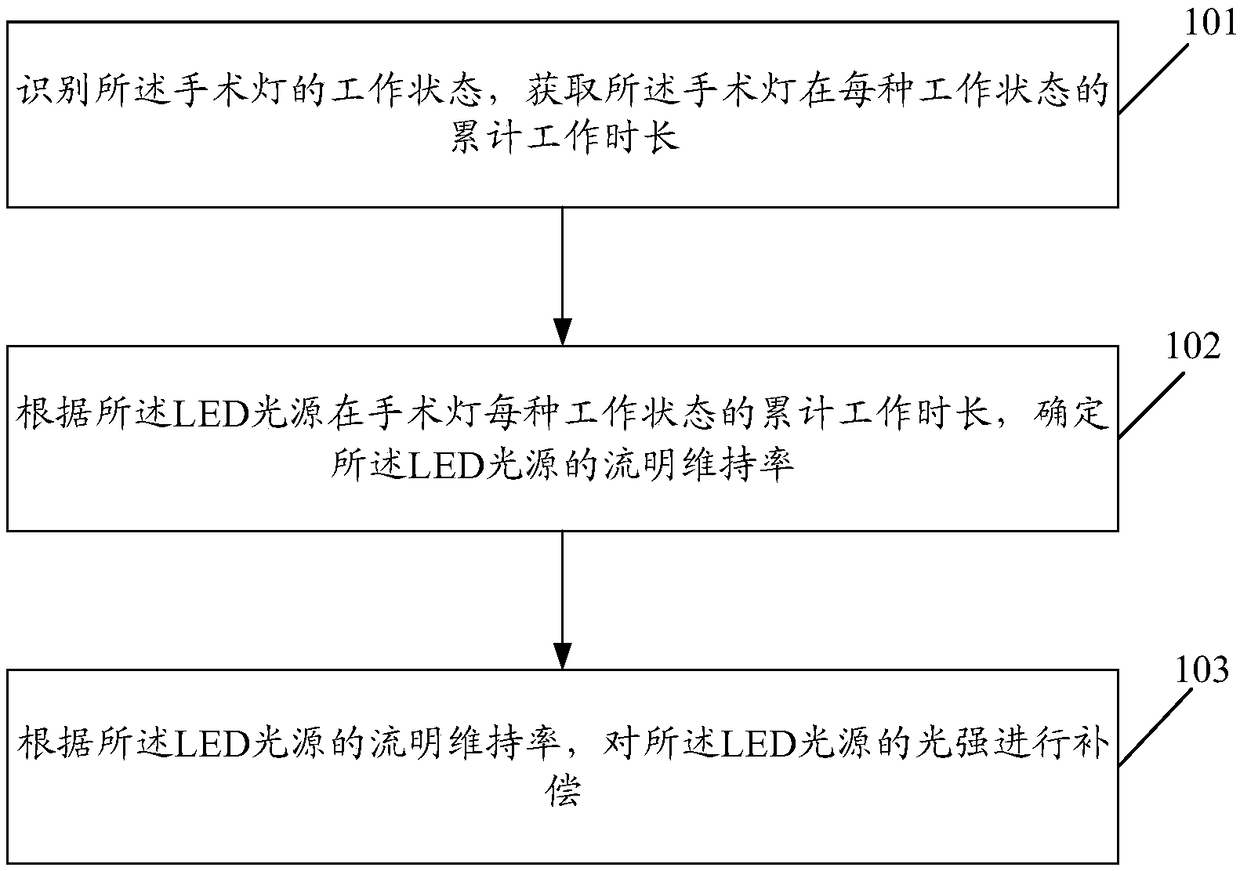

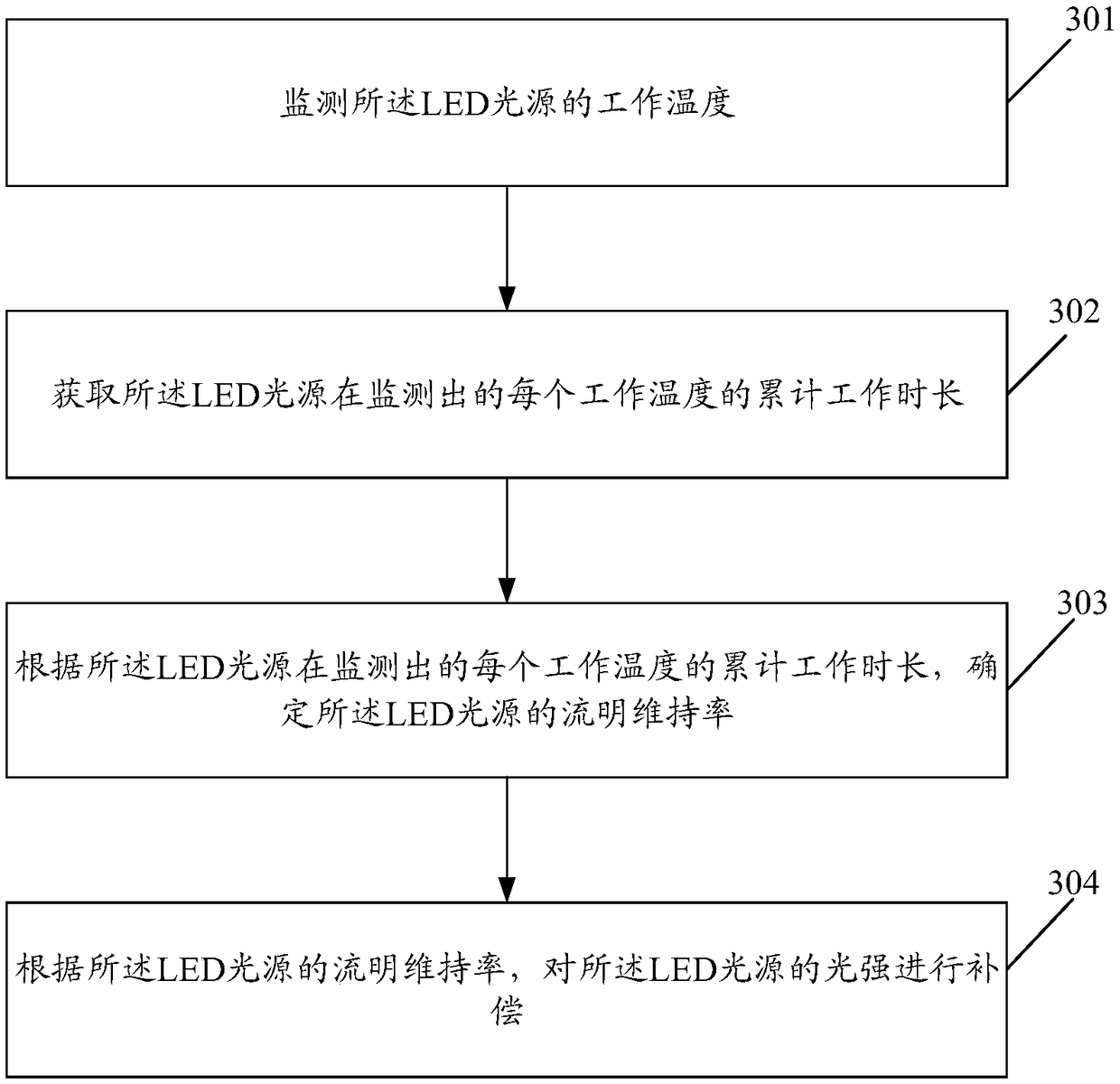

Light intensity compensation method, device and apparatus for operating lamps and computer storage medium

ActiveCN109104784AImprove luminous flux attenuationElectrical apparatusElectroluminescent light sourcesEngineeringLumen maintenance

The embodiments of the invention disclose a light intensity compensation method and device for operating lamps, a terminal and a computer storage medium. The method comprises the following steps: identifying the working state of the operating lamp, and acquiring the accumulated working time of the operating lamp in each working state; determining the lumen maintenance rate of the LED light sourceaccording to the cumulative working time of the LED light source in each working state of the operating lamp; according to the lumen maintenance rate of the LED light source, compensating for the light intensity of the LED light source. Thus, the lumen maintenance rate of the LED light source can be determined according to the accumulated working time of the LED light source in different working states of the operating lamp; according to the lumen maintenance rate of the LED light source, the intensity of the LED light source in the operation lamp can be compensated for, and the luminous fluxattenuation of the LED light source in the operation lamp can be improved.

Owner:NANJING MINDRAY BIO MEDICAL ELECTRONICS

Method for coating inner wall of fluorescent tube with nano titanium dioxide

InactiveCN101515526AMeet market requirementsEasy to operateTube/lamp screens manufactureGas discharge lamp detailsFluorescenceLuminous flux

The invention discloses a method for coating an inner wall of a fluorescent tube with nano titanium dioxide and belongs to the field of fluorescent tube manufacturing. A 2 to 2.5 percent thin aqueous solution of nano titanium dioxide is used to be coated on the inner wall of the fluorescent tube, and preferably the grain diameter of the nano titanium dioxide is less than 60 nanometers. Thus, the initial luminous flux of the inner wall coating is no less than that of the common aluminium oxide inner wall coating, but the black sodium amalgam is reduced to a required degree, the 2,000 hour lumen constantly increases by 5 percent, so the fluorescent tube meets market requirements.

Owner:SHANGHAI ZHENXIN ELECTRIC ENG CO LTD

Novel cathode of fluorescent lamp

InactiveCN101369512ASolve the problem of poor sealing assemblyGas discharge lamp detailsCold cathode manufactureElectrophoresisCold cathode

A novel cathode of a fluorescent lamp is composed of superfine flat filaments of T1-T2 tube diameter, V type filaments of 1.5 times of T3-T4 tube diameter, U type filaments of 2.5 times of T5 tube diameter or S type filaments of 3 times of tube diameter, the filaments are made into double spirals, three spirals or main and auxiliary type three spirals by tungsten filaments, are dip coated or electrophoresised with ternary carbonate electric powder on the surface, are exhausted to electrically decompose into oxide electrodes, under the condition that the lamp tube is used for driving an electronic ballast, a hot cathode wiring method without filaments can be adopted. The invention not only solves the problem that the tube diameter below T3 is not easy to seal and assemble, but also solves the key problem of making the T1 hot cathode fluorescent lamp without the method, and solves the problem that the electric powder storage is not enough after thinning the tube diameter of the fluorescent lamp. The invention is useful for improving switching characteristic of the fluorescent lamp, increasing lumen maintenance rate and prolonging light decline. The test proves that fifty present to one time of life service of the one lamp tube can be extended.

Owner:陈宗烈

Ceramic metal helide lamp

The invention relates to a high-pressure discharge lamp of the ceramic metal halide type having a molybdenum coil wrapped around the ceramic discharge vessel and at least a portion of the electrode feed through means, and having power ranges of about 150W to about 1000W. The discharge vessel has a ceramic wall and is closed by a ceramic plug. An electrode which is located inside the discharge space is connected to an electric conductor by way of a leadthrough element. The leadthrough element projects through the ceramic plug with a close fit and is connected thereto in a gastight manner by way of a sealing ceramic. The leadthrough element has a first part which is formed by a cermet at the area of the gastight connection. In addition, the lamps display one or more and most preferably all of the following properties: a CCT (correlated color temperature) of about 3800 to about 4500K, a CRI (color rendering index) of about 70 to about 95, a MPCD (mean perceptible color difference) of about + / -10, and a luminous efficacy up to about 85-95 lumens / watt, a lumen maintenance of >80%, color temperature shift <200K from 100 to 8000, and lifetime of about 10,000 hours to about 25,000 hours. The invention also relates to design spaces for the design and construction of high power lamps.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

High-lumen maintenance organosilicon material for LED packaging

ActiveCN108300408ANot yellowingIncrease luminous fluxNon-macromolecular adhesive additivesMacromolecular adhesive additivesLumen maintenanceLuminous flux

The invention discloses a high-lumen maintenance organosilicon material for LED packaging. The organosilicon material comprises a silicone component A, a silicone component B, nanometer magnesium oxide, a phosphor and an acrylic polymer, wherein the silicone component A comprises 60-85 parts of vinyl-terminated polymethylphenylsiloxane, 5-15 parts of vinyl-terminated polydimethylsiloxane, 3-8 parts of an active organic borosilicate tackifier, 10-25 parts of vinyl-terminated hyperbranched silicone resin and 0.05-0.5 part of a platinum catalyst; the silicone component B comprises 35-45 parts ofvinyl-terminated polymethylphenylvinylsiloxane, 45-55 parts of polymethylhydrosiloxane, 5-15 parts of MQ resin and 3-8 parts of a silane coupling agent A-172; and a mass part ratio of the silicone component A to the silicone component B to the nanometer magnesium oxide to the phosphor to the acrylic polymer in the organosilicon material is 100:100:(2.5-18):(3-8):(1-3). The organosilicon material has advantages of resistance to environmental hot and cold alternation, non-yellowing and high luminous flux.

Owner:NINGBO KLITE ELECTRIC MFG

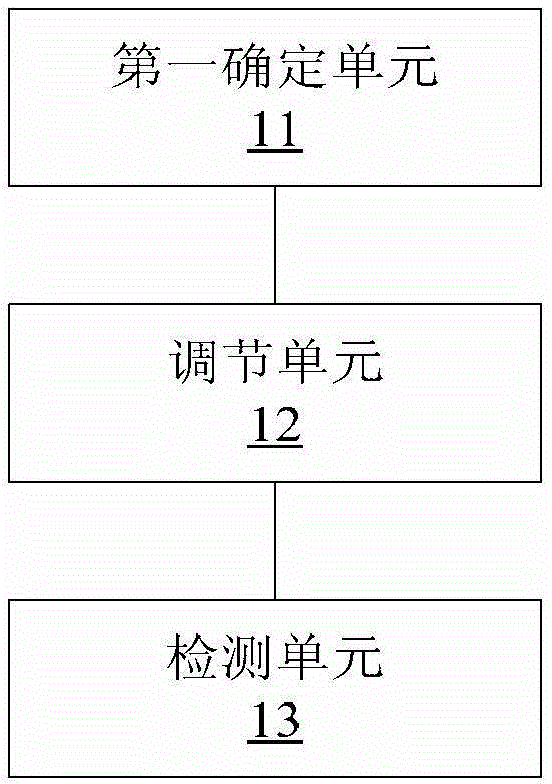

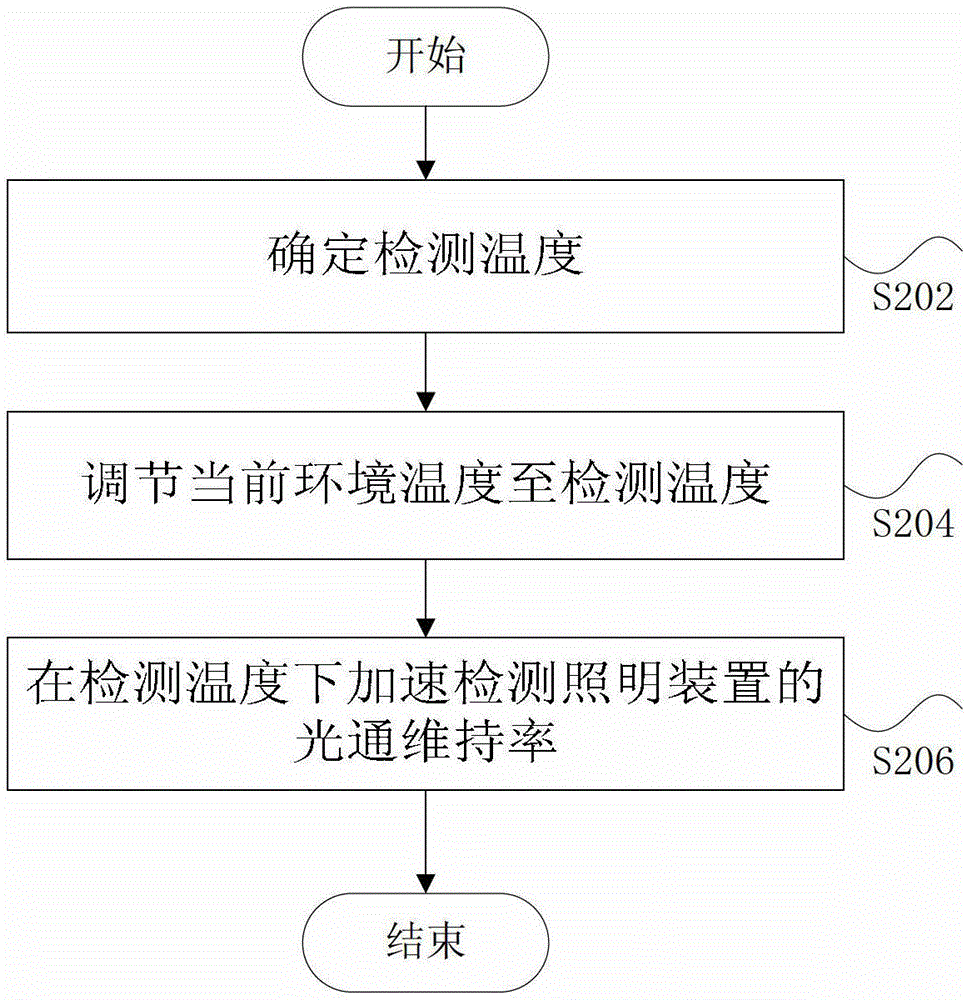

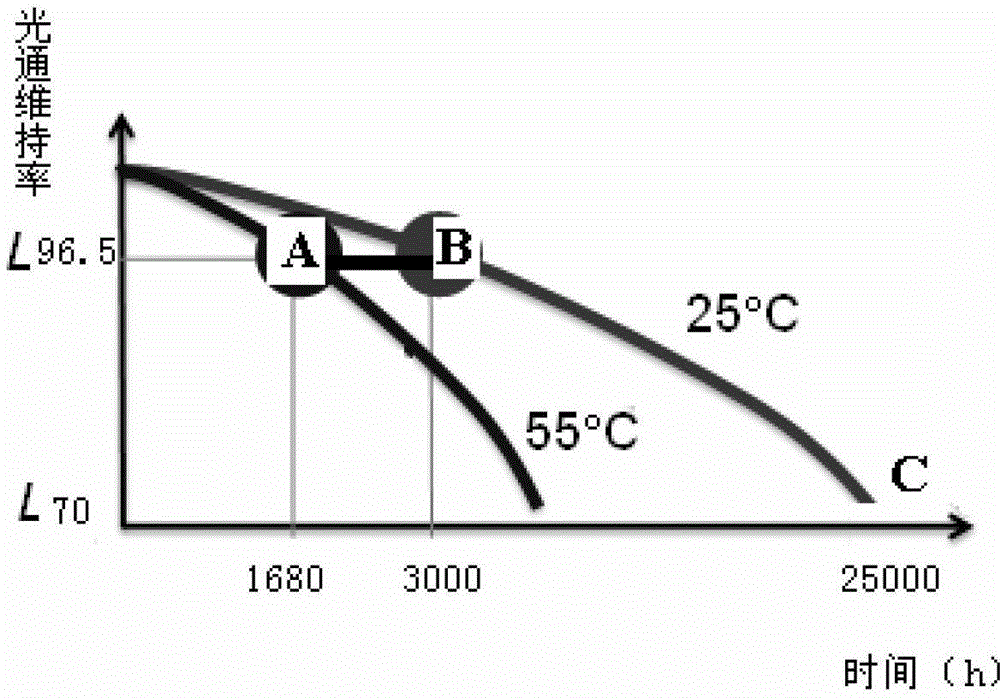

Method and device for accelerated detection of lumen maintenance of lighting device

ActiveCN102980747AShort detection cycleSolve the problem that accelerated detection takes too longTesting optical propertiesLumen maintenanceEngineering

The invention discloses a method and a device for accelerated detection of lumen maintenance of a lighting device. The method for accelerated detection of the lumen maintenance of the lighting device comprises the steps of determining a detection temperature, wherein the detection temperature is the environmental temperature at which the accelerated detection is conducted on the lighting device, and the detection temperature is higher than the normal temperature; adjusting the current environmental temperature to the detection temperature; and conducting accelerated detection on the lumen maintenance of the lighting device at the detection temperature. By the aid of the method and the device, the fact that the detection temperature is higher than the normal temperature is confirmed before the lumen maintenance of the lighting device is detected, so that the detection temperature guarantees that the detection period of the lighting device is shortened on the condition that a failure mechanism is not changed, and the life of the lighting device can be detected quickly.

Owner:北京半导体照明科技促进中心

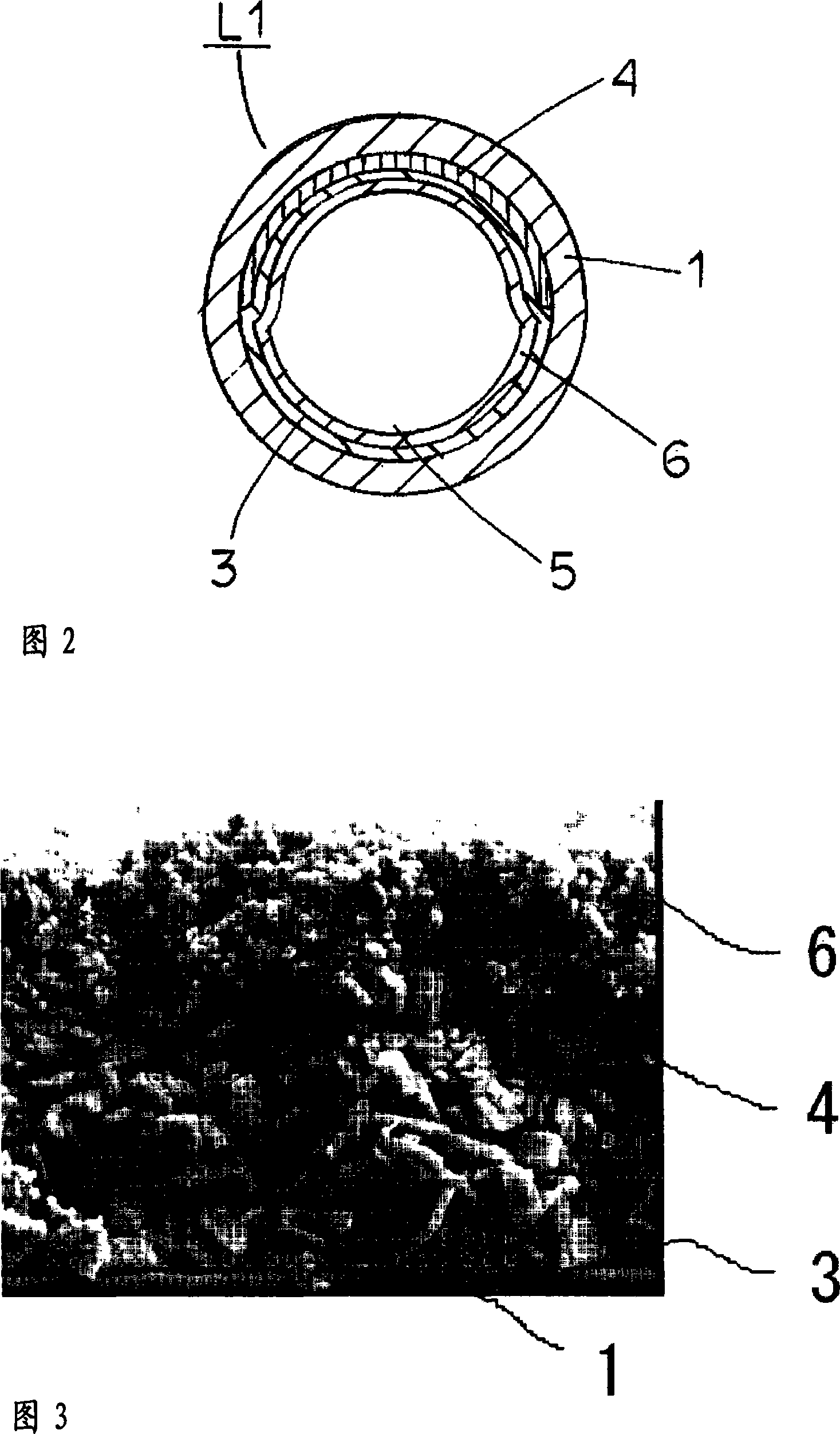

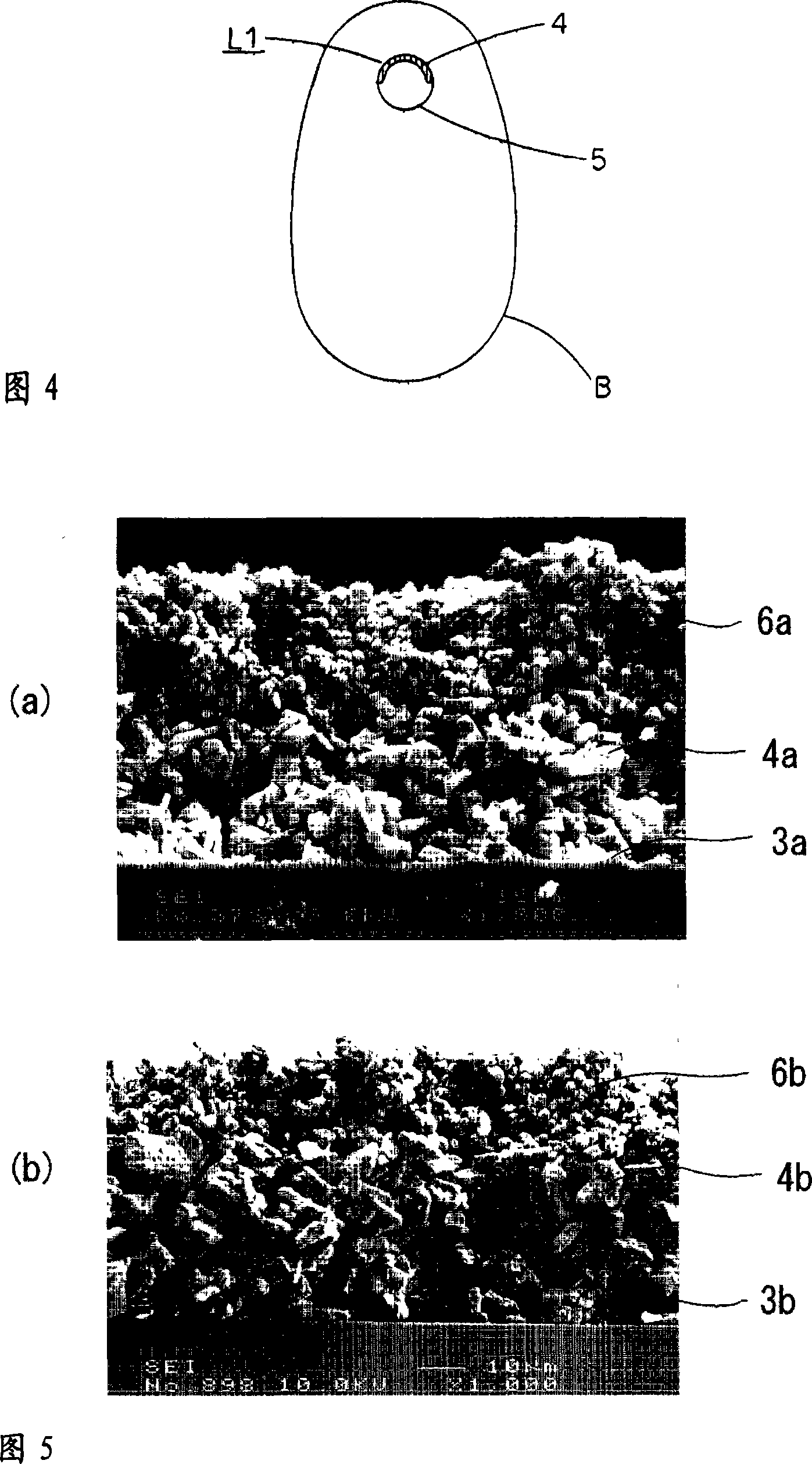

Lumen maintenance in fluorescent lamps

InactiveUS10236174B1Maintain stabilityTurn fasterElectric lighting sourcesGas discharge lamp detailsPhosphorEngineering

A fluorescent lamp, including a vitreous portion of the fluorescent lamp comprising a vitreous envelope filled with a working gas mixture, the vitreous envelope having an inner surface facing the working gas mixture side of the vitreous portion; a first coating deposited on the inner surface, the first coating comprising a first metal oxide; a second coating deposited on top of the first coating, the second coating comprising a phosphor; and a third coating deposited on top of the second coating, the third coating comprising a second metal oxide.

Owner:LUCIDITY LIGHTS

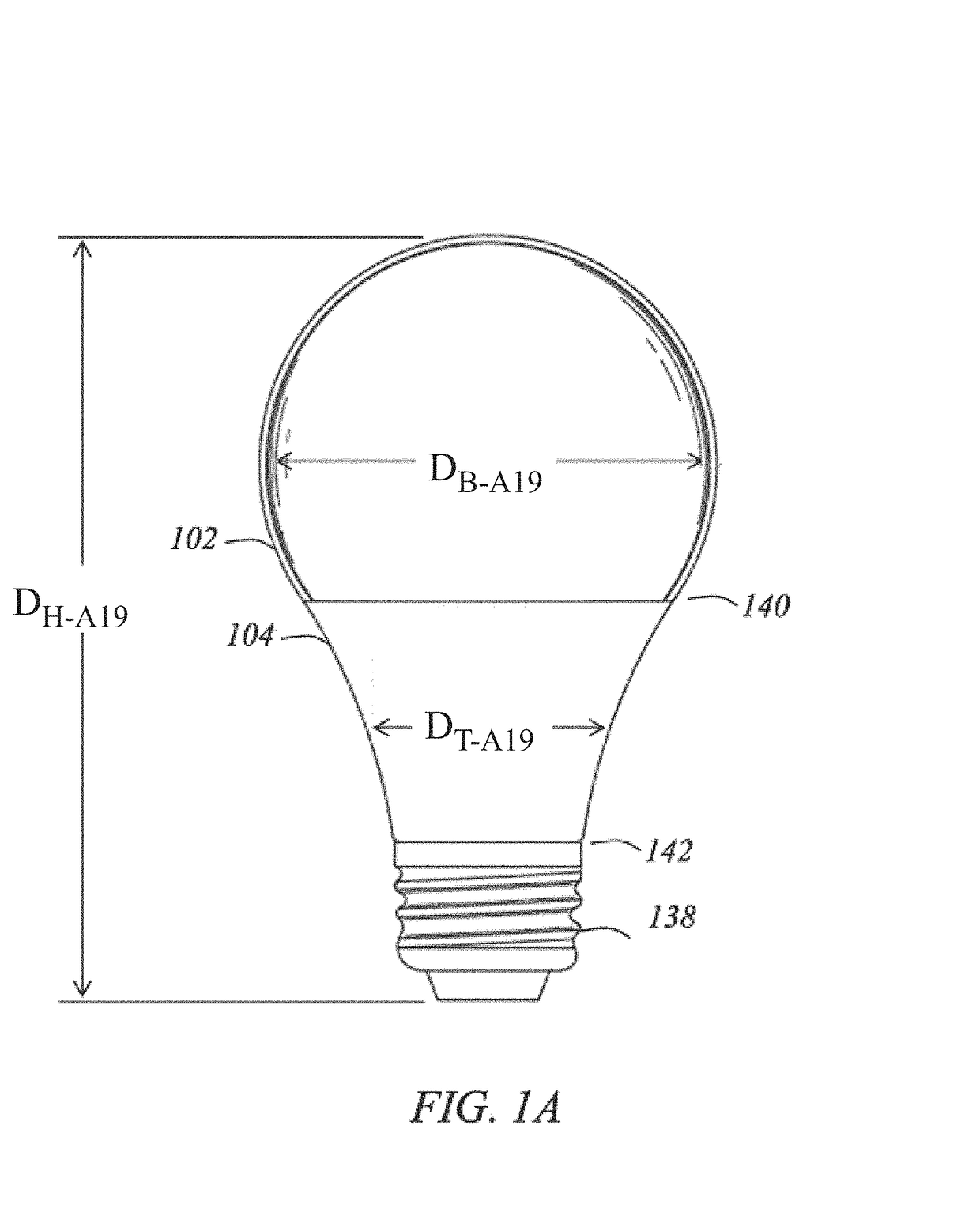

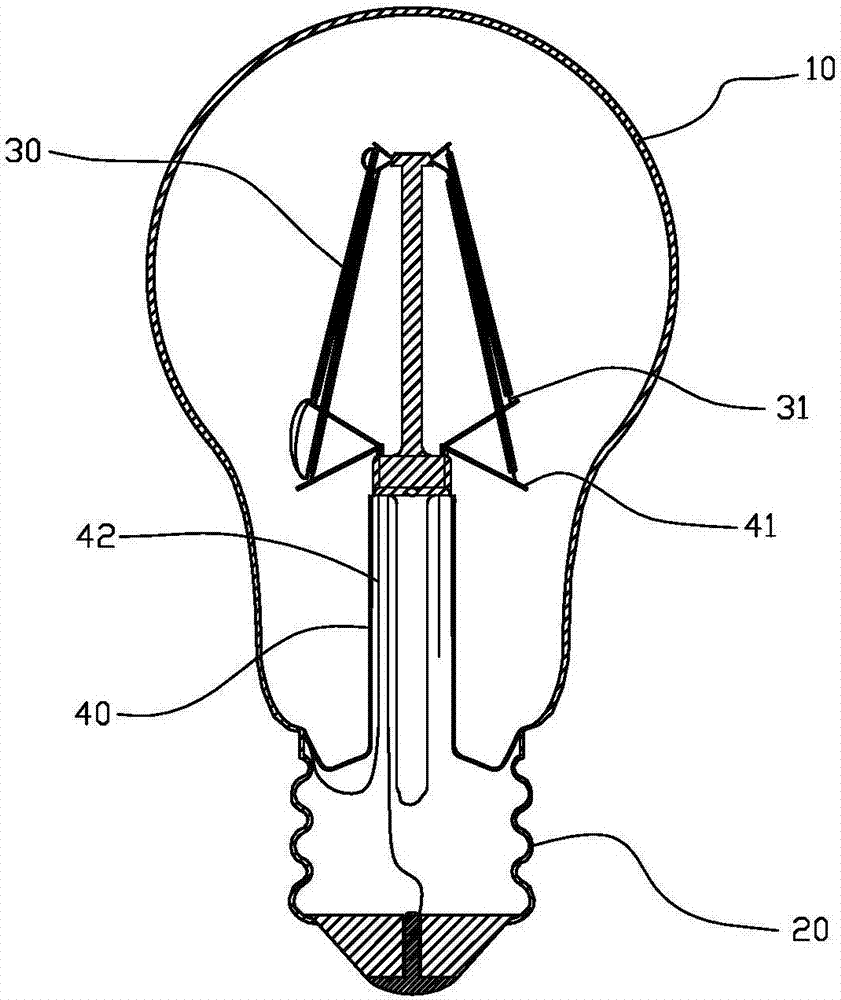

LED filament ball steep light with high lumen maintenance

PendingCN107062014APrevent restoreHigh lumen maintenanceElectrical apparatusElectroluminescent light sourcesTransmittanceLumen maintenance

The invention relates to a LED filament ball steep light with high lumen maintenance. The LED filament bulb light comprises an inclosed bulb shell and a bulb holder, wherein the bulb holder and the bulb shell are connected mutually and fixedly, a light staff, located inside the bulb shell, is fixedly connected on the bulb holder, and an LED light source is arranged on the light staff. The LED filament ball steep light is characterized in that the LED light source and the bulb holder form electrical connection, the bulb shell is filled with mixed gas, and the mixed gas comprises oxygen and high thermal conductivity gases, wherein the volume ratio of oxygen is 0.1% to 30%. The oxygen added into the gas can prevent reducing of the transmittance of ITO due to the fact that an ITO layer in an LED chip is reduced in gas in an oxygen-free environment in the aging process, therefore the lumen maintenance of filament aging is enhanced, and brightness decay is reduced. 1000H aged light of a filament with a good performance is kept at about 97% at present, 1000H lumen maintenance of a bulb with conventional gas is kept at about 96%, and the 1000H lumen maintenance of a bulb with gas added with oxygen in the scheme is kept at about 98.5%.

Owner:ZHEJIANG INTELED OPTOELECTRONICS TECH

Knowledge-based driver apparatus for high lumen maintenance and end-of-life adaptation

ActiveUS8072163B2Easy to operateAccuracyElectrical apparatusStatic indicating devicesDriving currentOperation mode

A knowledge-based driver is provided for powering a solid-state light source with a constant current, including a memory that stores lumens per amp and volts per amp performance characterizations of the light source over time, and a controller that operates in a test mode to estimate the light source degradation based on voltage feedback obtained at a predetermined test current value, and to adjust the drive current in normal operating mode according to the estimated device degradation to implement constant lumens control without external optical feedback components.

Owner:GE LIGHTING SOLUTIONS LLC

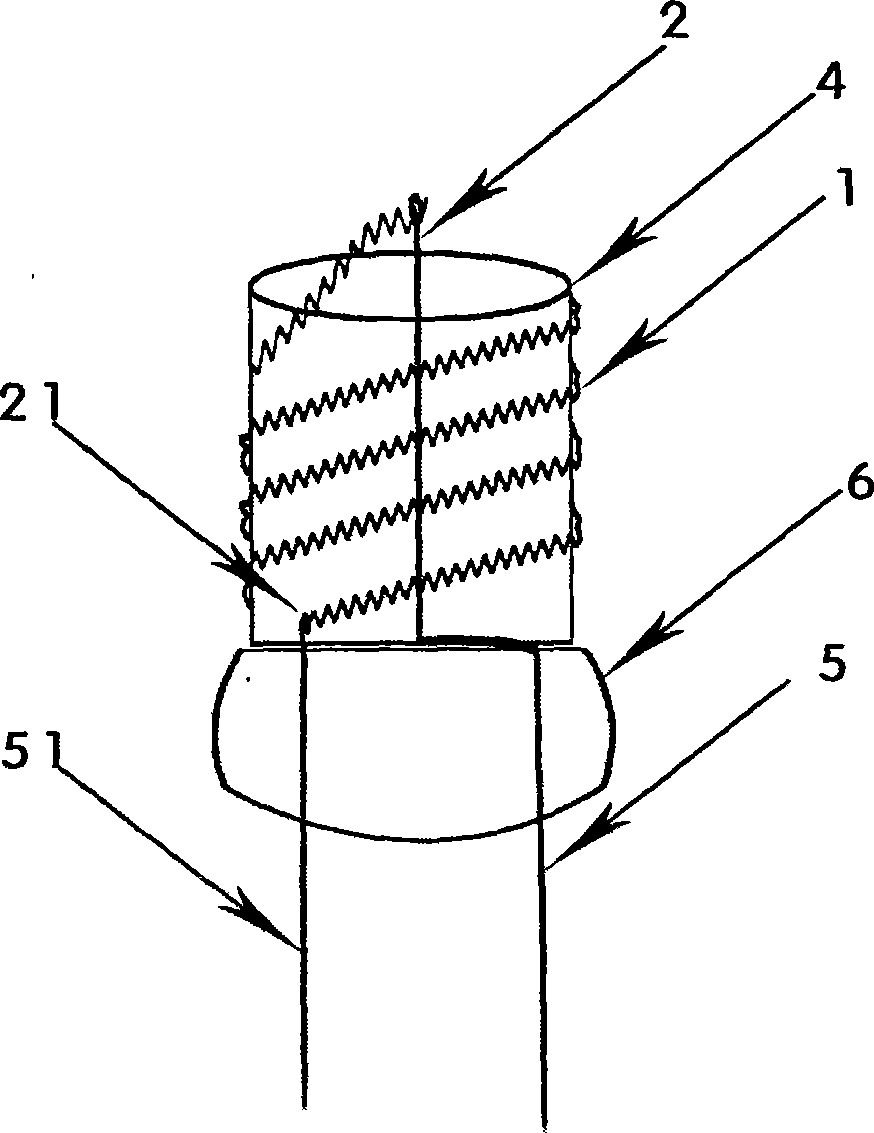

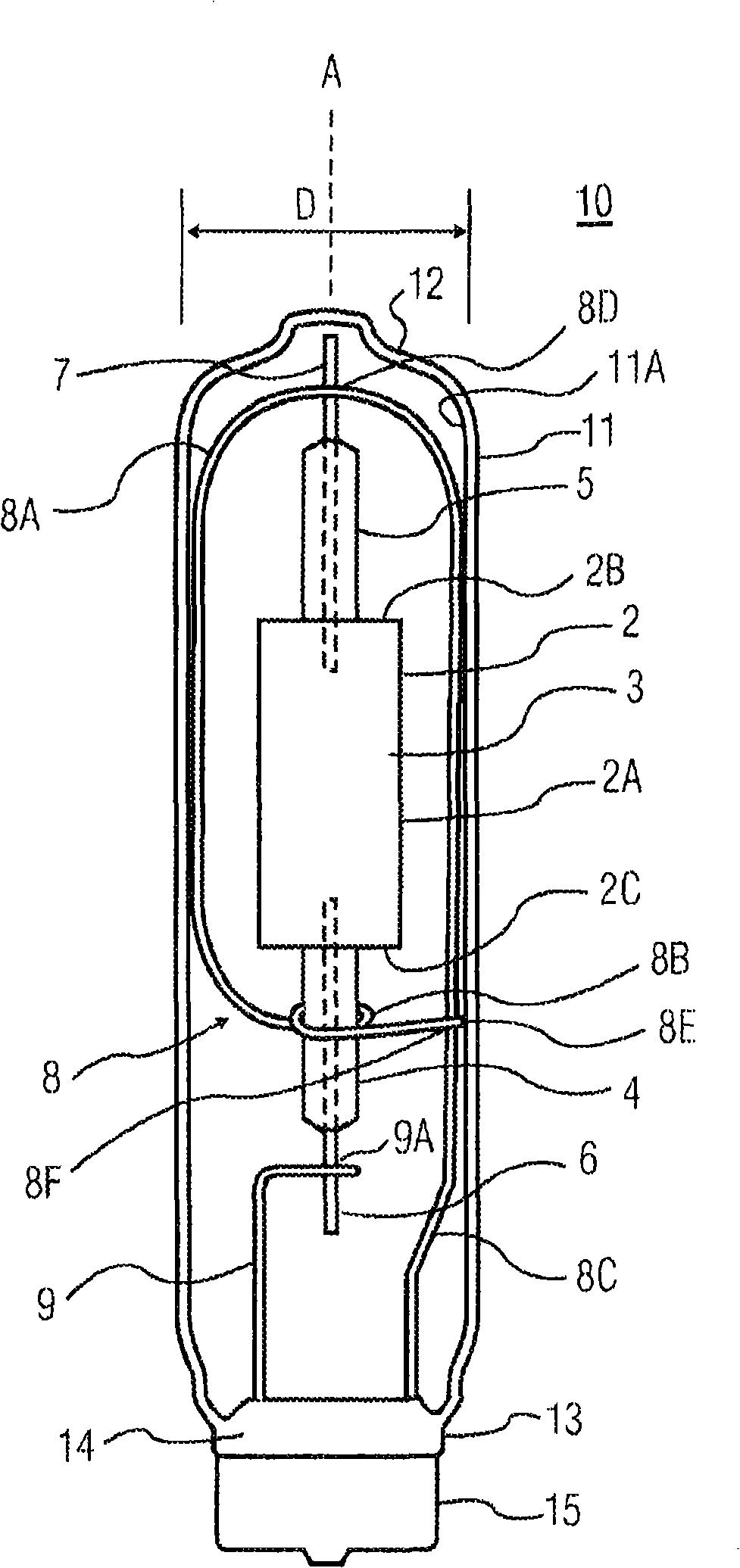

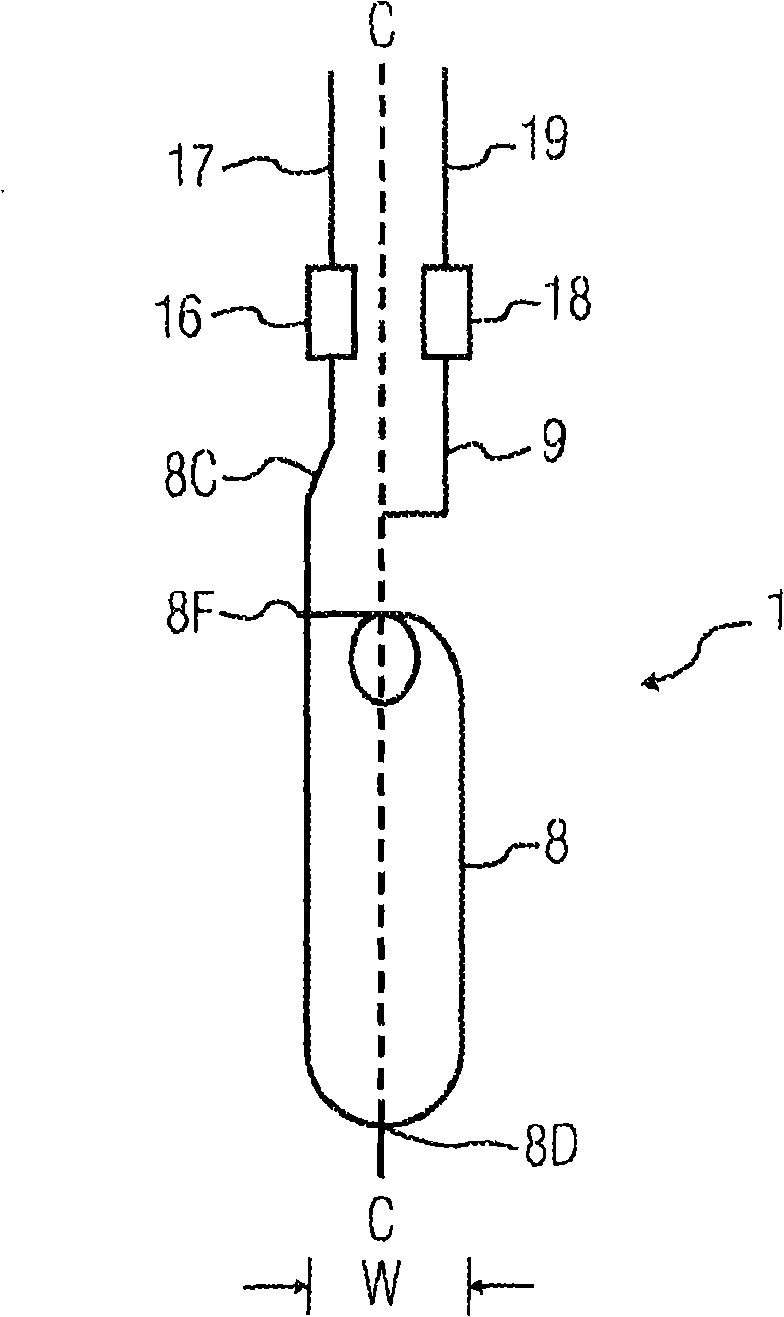

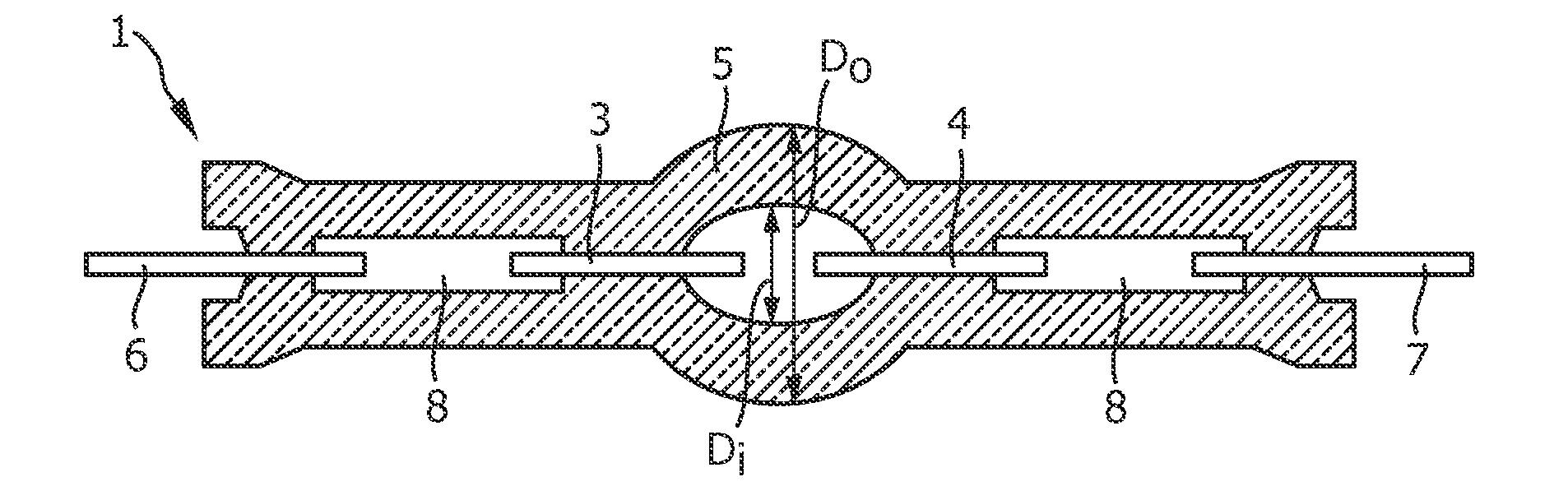

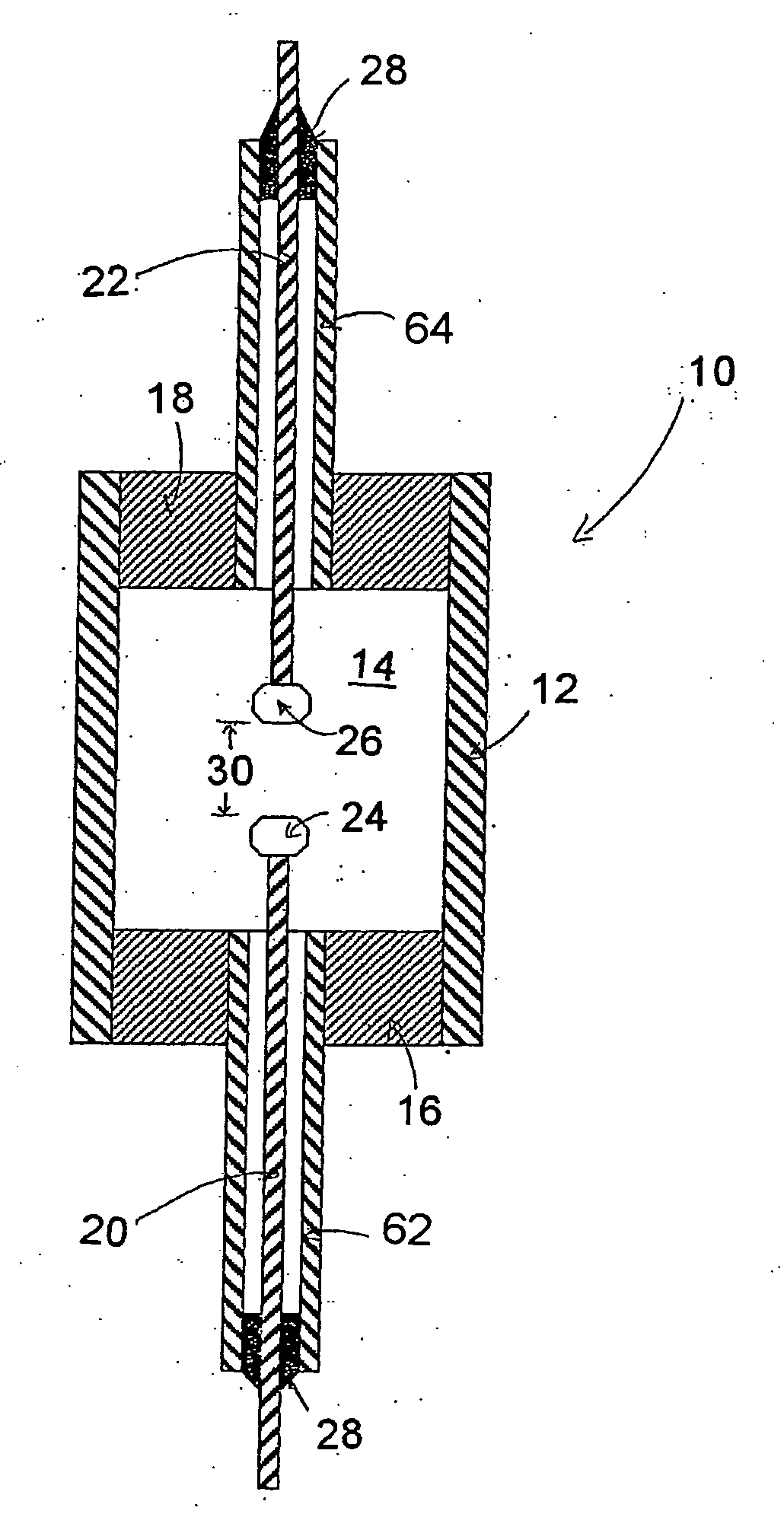

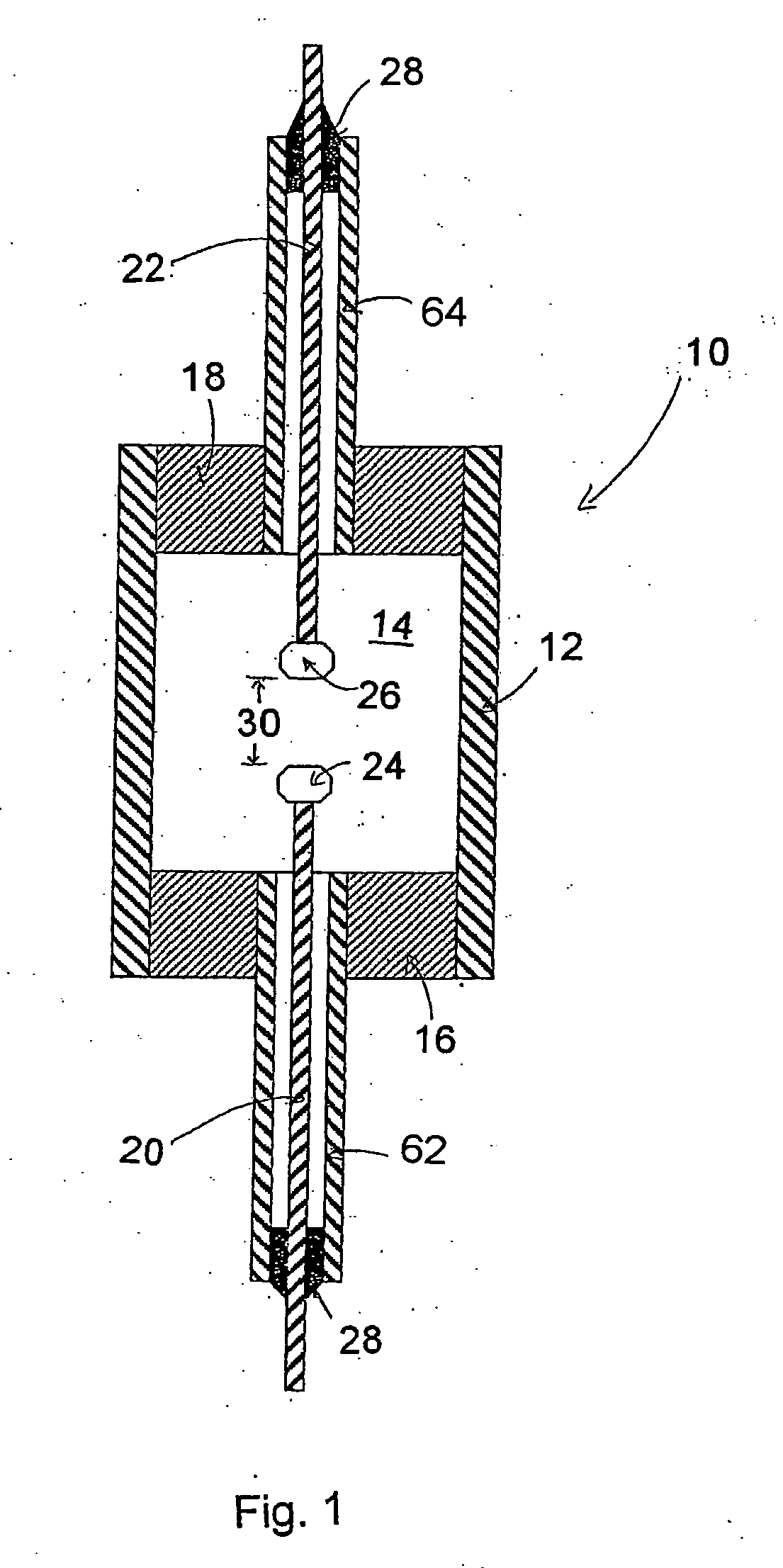

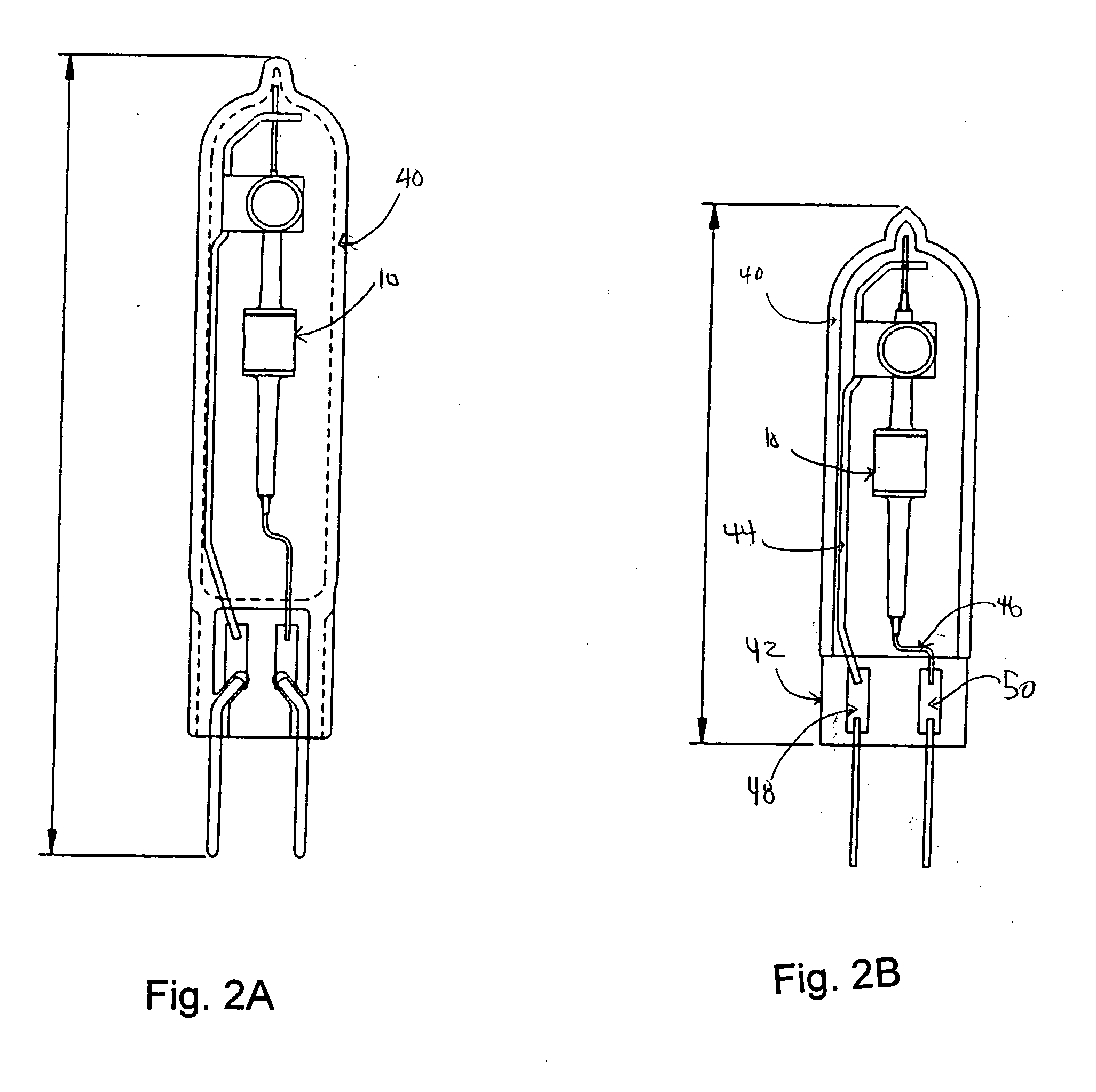

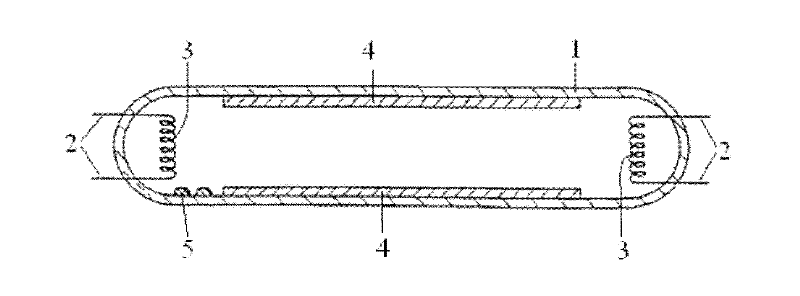

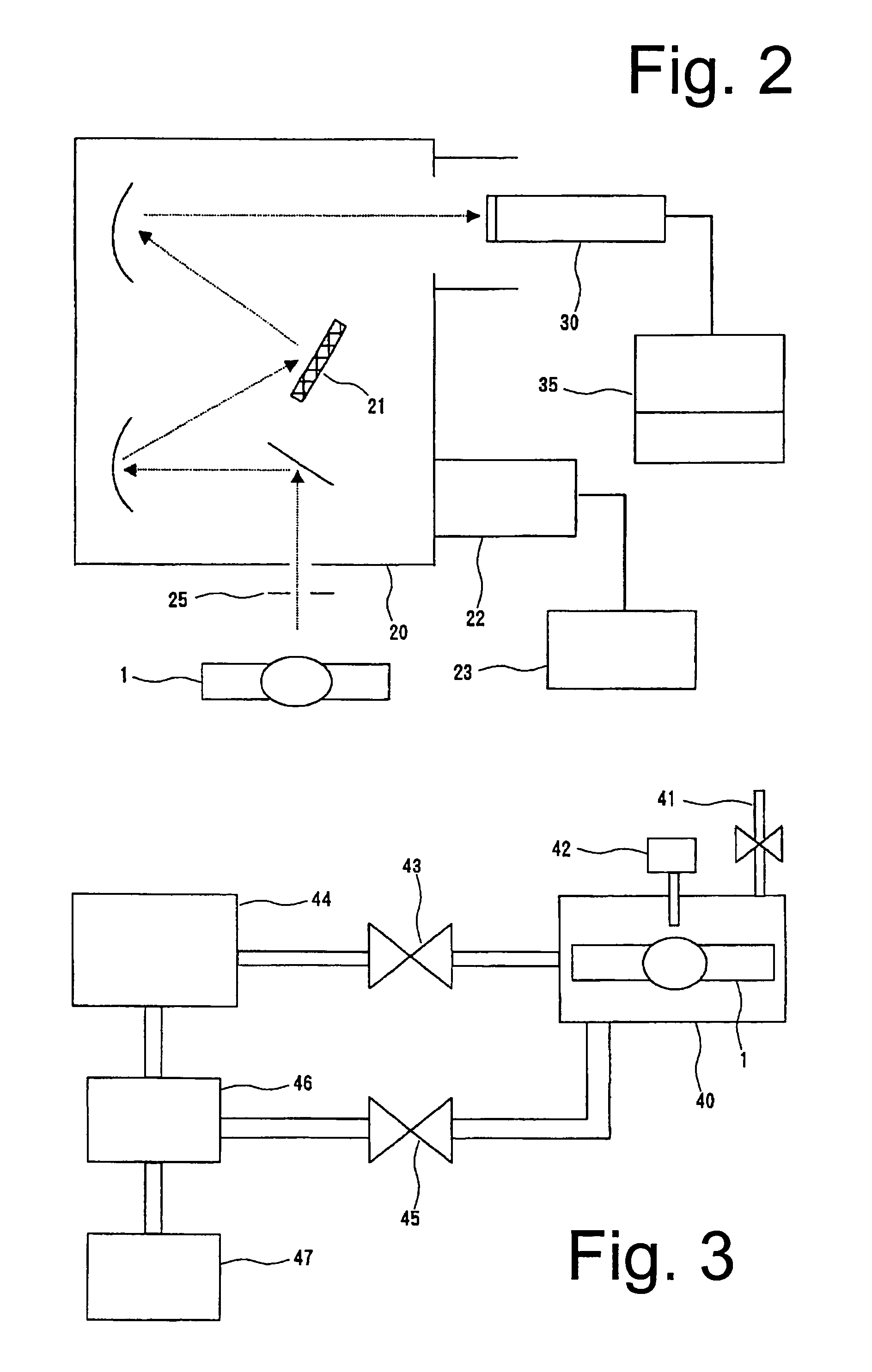

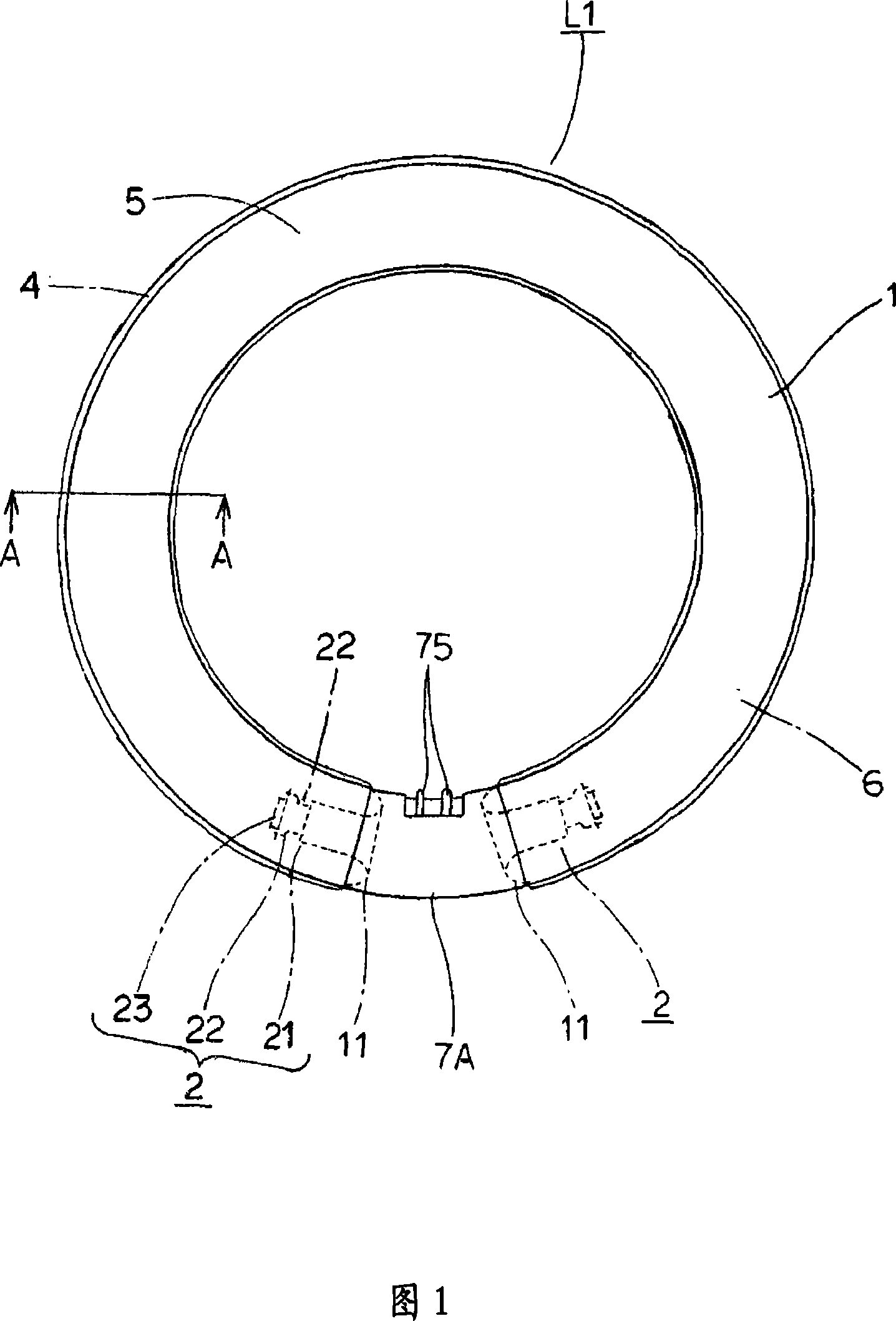

Looped frame arc tube mounting assembly for metal halide lamp

InactiveCN101310361AOffset magnetic forceImproved lumen maintenanceElectric discharge tubesGas discharge lamp detailsMagnetic tension forceMetal-halide lamp

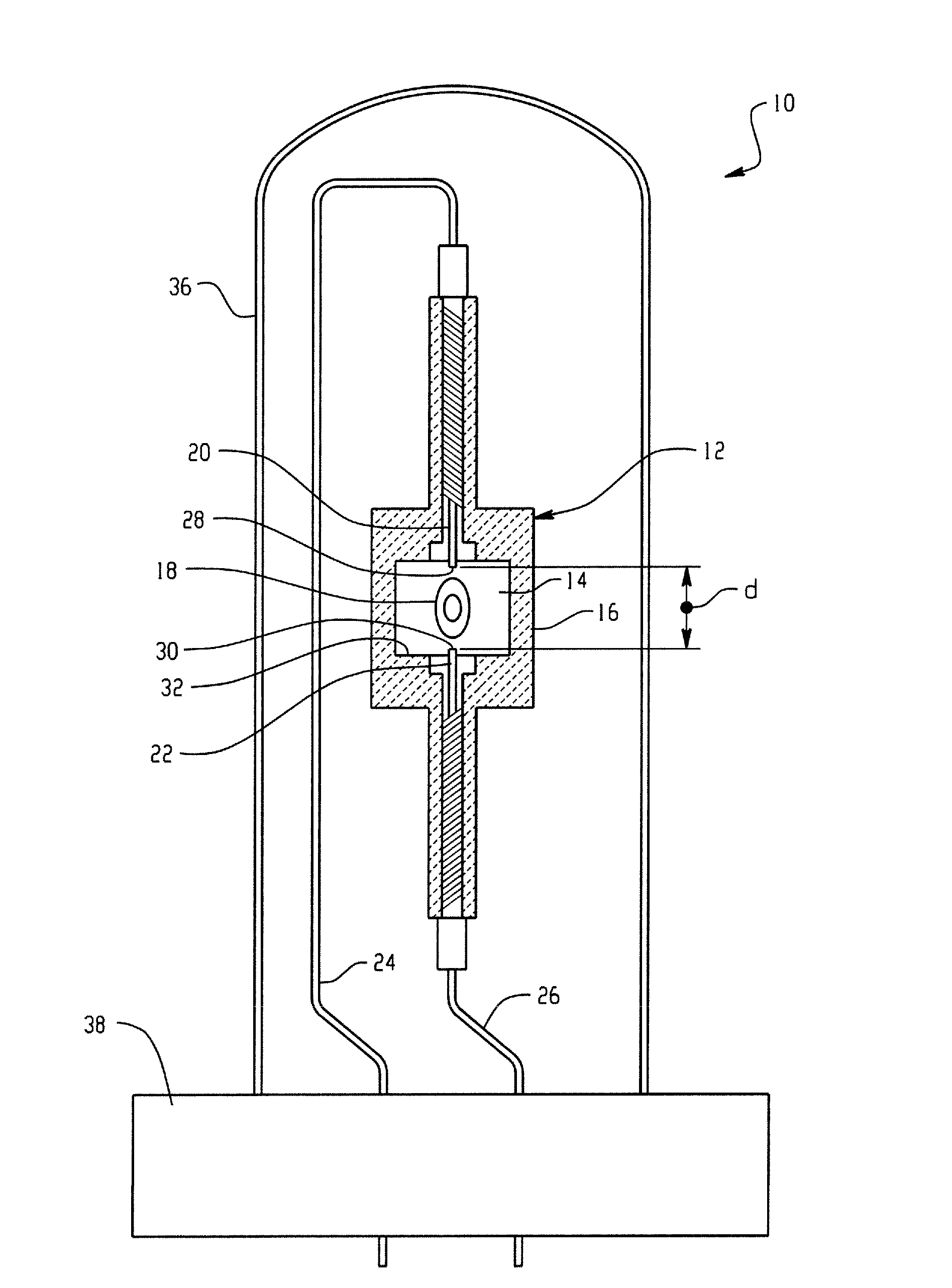

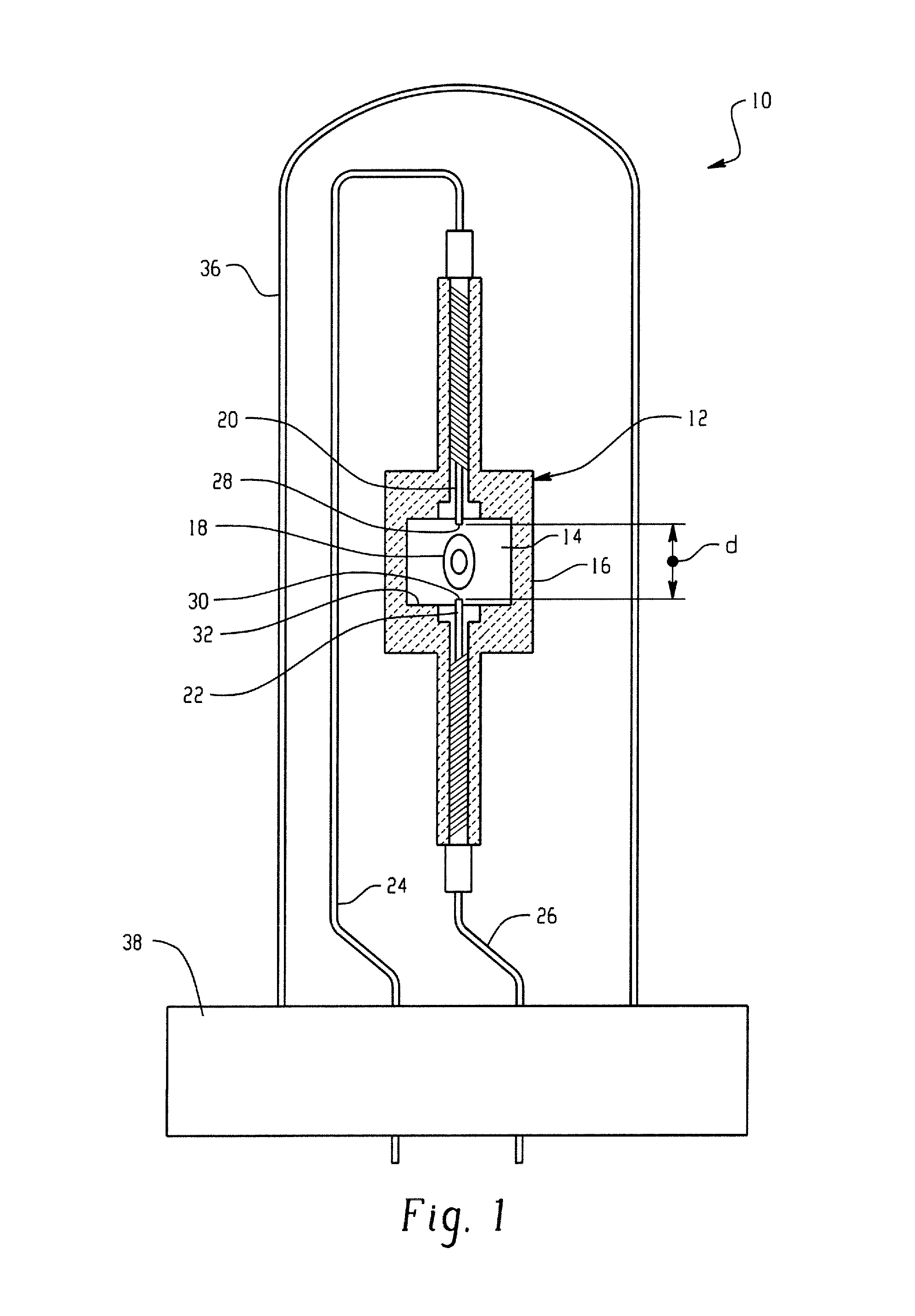

An arc tube mounting assembly (1) for a metal halide arc lamp (10) includes frame members (8, 9) for supporting an arc tube (2). The arc tube (2) is supported from above by a looped frame member (8) having a loop (8A) which extends along opposing sides, and across top and base ends (2A, 2B) of the arc tube (2), thus evenly distributing the current to discharge electrode 7, thereby cancelling magnetic forces which could displace the arc from the center of the arc tube (2), resulting in improved lumen maintenance and extended life. A centering circle (8B) of the frame member (8) wraps around the lower ceramic end plug (4), providing coaxial alignment of the arc tube (2) and the tubular outer envelope (11).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

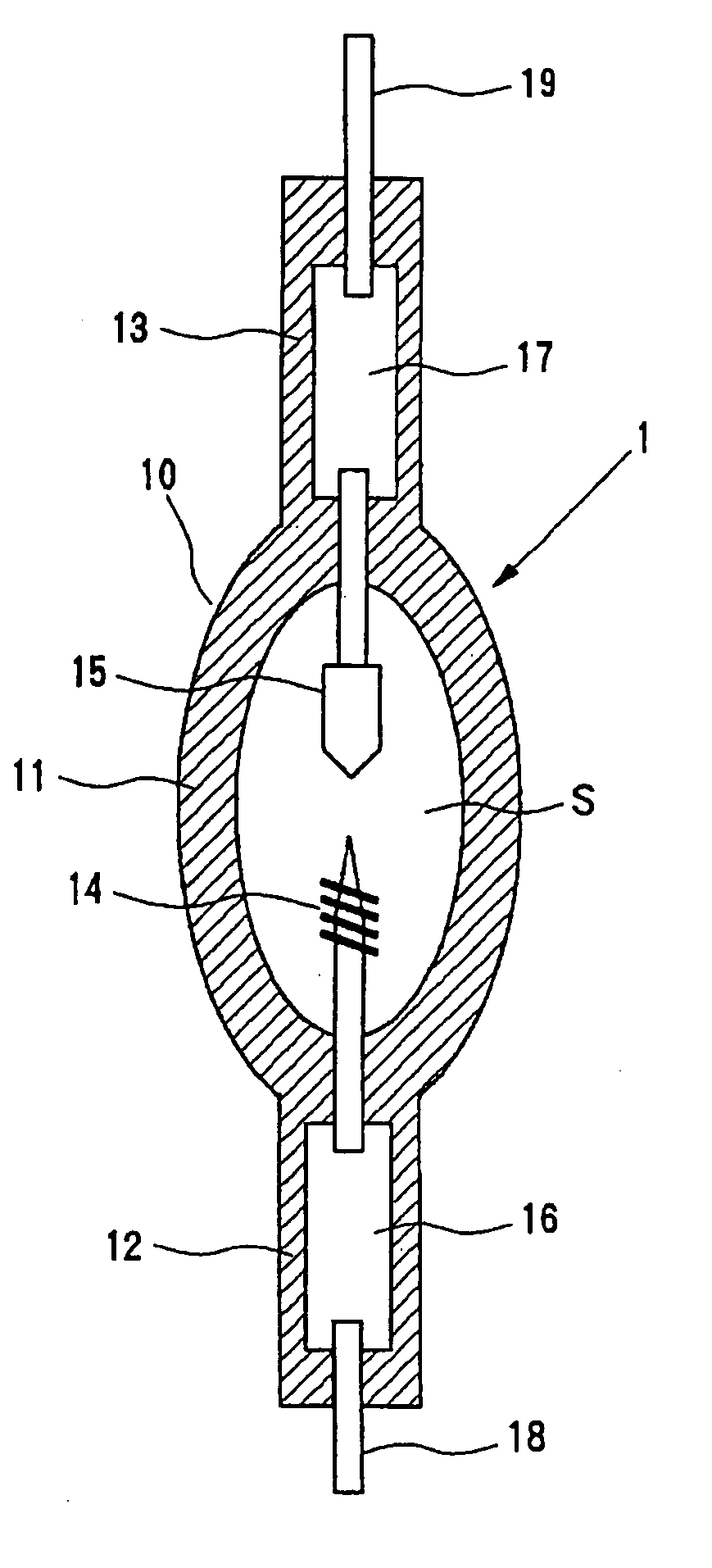

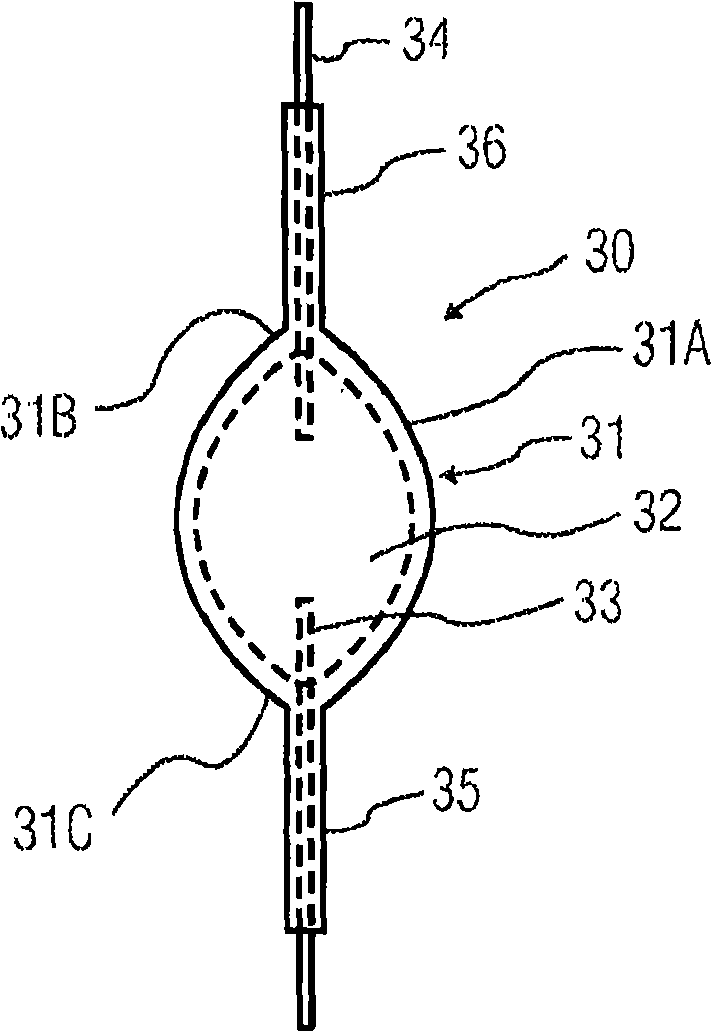

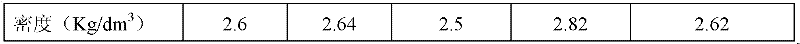

Mercury-free high intensity gas-discharge lamp

InactiveUS20130038207A1Improved emitter functionGood curative effectSolid cathode detailsGas discharge lamp detailsGas-discharge lampThallium

The invention describes a mercury-free high-intensity gas-discharge lamp (1) comprising a discharge vessel (5) enclosing a fill gas in a discharge chamber (2) and comprising a pair of electrodes (3, 4) extending into the discharge chamber (2), for which lamp (1) the fill gas is derived from a salt fill introduced into the discharge chamber (2) prior to sealing, which salt fill is free of scandium and includes a halide composition comprising a sodium halide to a proportion of at least 65 wt % and at most 97.2 wt %,a thallium halide to a proportion of at least 2 wt % and at most 25 wt %, and an indium halide to a proportion of at least 0.5 wt % and at most 25 wt %. Eliminating the highly reactive scandium from the fill gas significantly improves lumen maintenance.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Ceramic metal helide lamp

InactiveCN100336162CExcellent original color stabilityGas discharge lamp detailsElectrical conductorColor rendering index

The invention relates to a high-pressure discharge lamp of the ceramic metal halide type having a molybdenum coil wrapped around the ceramic discharge vessel and at least a portion of the electrode feed through means, and having power ranges of about 150W to about 1000W. The discharge vessel has a ceramic wall and is closed by a ceramic plug. An electrode which is located inside the discharge space is connected to an electric conductor by way of a leadthrough element. The leadthrough element projects through the ceramic plug with a close fit and is connected thereto in a gastight manner by way of a sealing ceramic. The leadthrough element has a first part which is formed by a cermet at the area of the gastight connection. In addition, the lamps display one or more and most preferably all of the following properties: a CCT (correlated color temperature) of about 3800 to about 4500K, a CRI (color rendering index) of about 70 to about 95, a MPCD (mean perceptible color difference) of about + / -10, and a luminous efficacy up to about 85-95 lumens / watt, a lumen maintenance of >80%, color temperature shift <200K from 100 to 8000, and lifetime of about 10,000 hours to about 25,000 hours. The invention also relates to design spaces for the design and construction of high power lamps.

Owner:KONINK PHILIPS ELECTRONICS NV

Preparation method of high strength gas discharge electrode

InactiveCN101840824AReduce sputteringCompact structureThermionic cathode manufactureSputteringHigh intensity

The invention discloses a preparation method of a high strength gas discharge electrode. By instantaneously fusing the discharge end part of the electrode with high temperature, oxygen content and purities of fusion part are eliminated, the metallographic structure of the discharge end part of the high strength gas discharge electrode is improved, the metallographic structure is densified, the sputtering of the discharge electrode in the high strength gas discharge light source igniting process is reduced and consequently, the service life of the high strength gas discharge light source is prolonged and the lumen maintenance therefore is improved.

Owner:周义华 +3

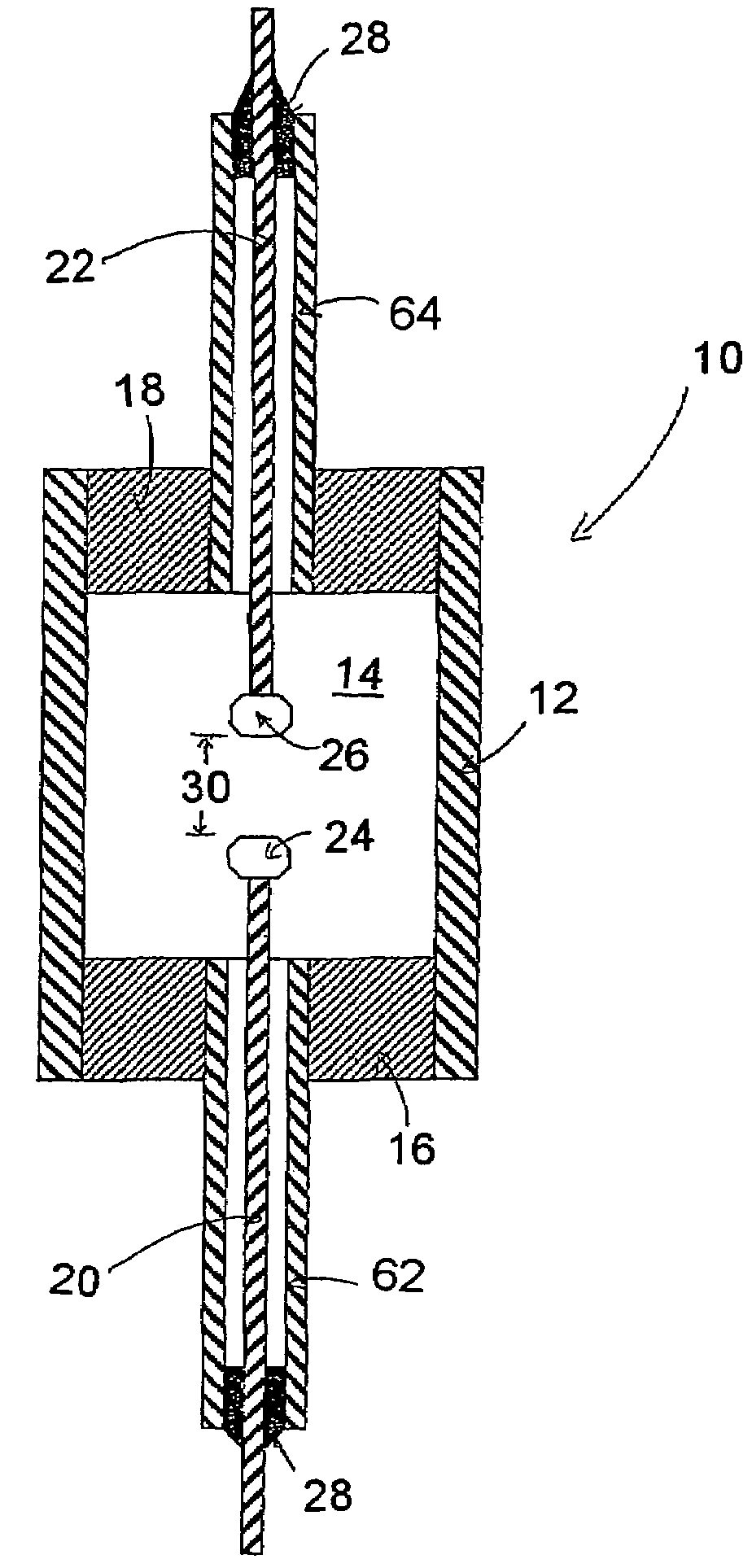

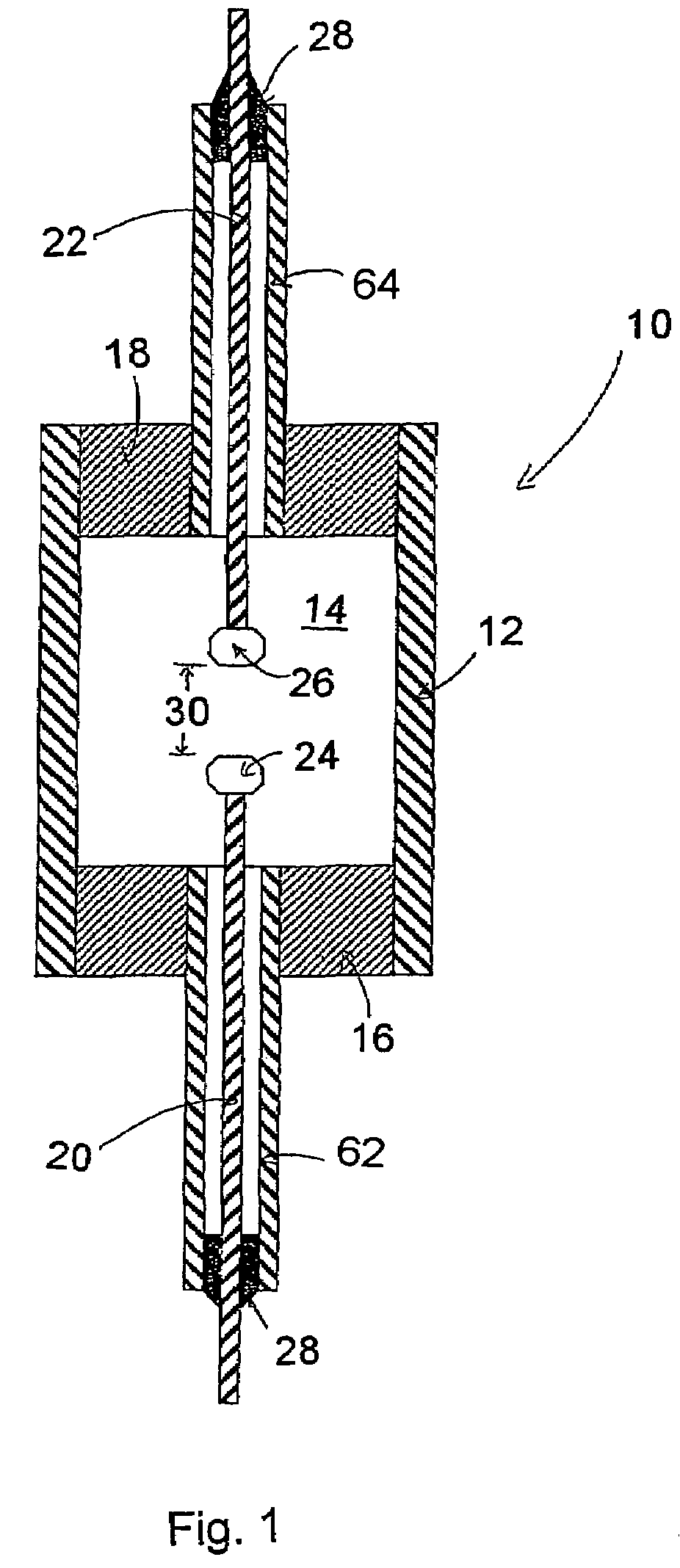

High mercury density ceramic metal halide lamp

InactiveUS20070120493A1Good lumen maintenanceImprove efficiencySolid cathode detailsGas discharge lamp detailsColor shiftFilling materials

A low wattage mercury vapor lamp comprises a discharge vessel (10) including a tubular body (12), first and second electrodes (20, 22) and two end walls (16, 18), which close opposite ends of the tubular body. The discharge vessel contains an ionizable fill material having a concentration of mercury of from 0.10 to 0.20 mg / mm3. The discharge vessel operates at elevated pressures of from 80 to 170 atmospheres at power of 20 watts resulting in improved lumen maintenance and reduced through-life color shift.

Owner:GENERAL ELECTRIC CO

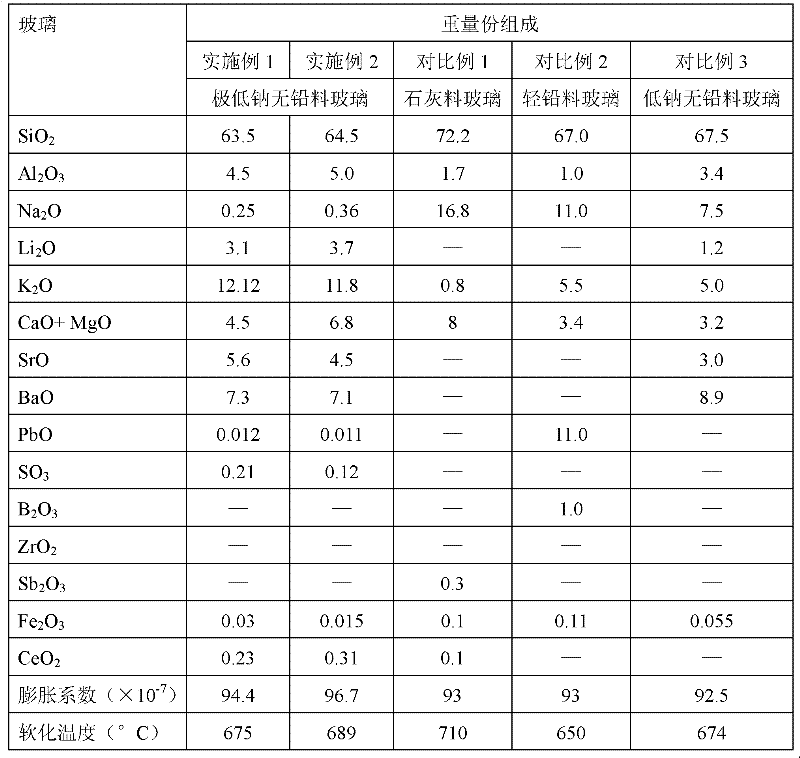

Ultra-low-sodium lead-free glass and applications thereof

InactiveCN102503124ARadiation suppressionMeet environmental protection requirementsGas discharge lamp detailsLumen maintenanceFluorescent lamp

The invention belongs to the technical field of the energy-saving light source material and relates to ultra-low-sodium lead-free glass and applications thereof. The sodium content of the ultra-low-sodium lead-free glass is below 0.5% and above 0.23%, thus the lumen maintenance of the lamp tube is extremely improved in the use process, the luminous decay of the lamp tube is minimized, the effect of extremely high lumen maintenance is realized without adopting protective film coating, the cost is saved and the coating difficulty of the fluorescent powder is reduced. The ultra-low-sodium lead-free glass does not contain As2O3 and Sb2O3; the content of PbO is extremely low, which is below 0.012%, thus the product belongs to lead-free glass; and the weight percent of CeO2 is not zero and the glass material meets the Rohs environmental protection standard. The ultra-low-sodium lead-free glass can be widely used to prepare various electronic luminous bodies such as fluorescent lamp tubes or energy saving lamp tubes.

Owner:SHANGHAI YAMING LIGHTING

Discharge lamp with specific amounts of halogen, oxygen, hydrogen and carbon

ActiveUS7002299B2High lumen maintenanceEliminate disadvantagesElectroluminescent light sourcesTube/lamp vessel fillingNoble gasLumen maintenance

A discharge lamp which maintains a high lumen maintenance factor even when operated for a long time is obtained in a discharge lamp which has a silica glass discharge vessel and a pair of opposed electrodes in the discharge vessel and in which the discharge vessel is filled with at least 0.15 mg / mm3 mercury, a rare gas with argon as the main component, and 2×10−4 μmole / mm3 to 7×10−3 μmole / mm3 bromine by meeting the following conditions when feeding a direct current of 5 mA between the electrodes and a glow discharge produced:1.0×10−4≦b / a≦1.2×10−1 Condition (1)c / a≦1.4×10−1 Condition (2)d / a≦1.2×10−2 Condition (3)e / a≦1.4×10−2 Condition (4)where a is the emission intensity of the argon with a wavelength of 668 nm, b is the emission intensity of OH with a wavelength of 309 nm, c is the emission intensity of hydrogen (H) with a wavelength of 656 nm, d is the emission intensity of C2 with a wavelength of 517 nm, and e is the emission intensity of CH with a wavelength of 431 nm.

Owner:USHIO DENKI KK

High mercury density ceramic metal halide lamp

InactiveUS7474057B2Easy maintenanceImprove efficiencySolid cathode detailsGas discharge lamp detailsEngineeringLumen maintenance

A low wattage mercury vapor lamp comprises a discharge vessel (10) including a tubular body (12), first and second electrodes (20, 22) and two end walls (16, 18), which close opposite ends of the tubular body. The discharge vessel contains an ionizable fill material having a concentration of mercury of from 0.10 to 0.20 mg / mm3. The discharge vessel operates at elevated pressures of from 80 to 170 atmospheres at power of 20 watts resulting in improved lumen maintenance and reduced through-life color shift.

Owner:GENERAL ELECTRIC CO

Fluorescent lamp and lighting fixture

InactiveCN101131912AReduced visible light transmissionPrevent intrusionGas discharge lamp detailsReflectorsTectorial membraneEffect light

The present invention aims to realize a fluorescent lamp and a lighting instrument installed the fluorescent lamp, the fluorescent lamp restrains the light reflection membrane from membrane stripping, and makes lumen maintenance rate and exterior quality promote. The fluorescent lamp of the present invention has: a sealed tubular glass bulb; an electrode generating unit making the bulb generate discharge; a discharge medium enveloped into the bulb; a protective membrane formed at the internal surface of the bulb and the membrane thickness is 0.2 to 0.9 micrometer; a light refection membrane formed at the regulated position of the protective membrane, and containing more than or equal to 25wt percent strontium pyrophosphate phosphor particulate; and a fluorophor membrane formed at more nearby to the internal side part than the light reflection membrane. According to the present invention, it can promote the lumen maintenance rate through thickening the protective membrane and restrain the light reflection membrane from membrane stripping.

Owner:TOSHIBA LIGHTING & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com