Novel cathode of fluorescent lamp

A fluorescent lamp and filament cathode technology, applied in the field of electricity, can solve problems such as poor sealing, insufficient storage of assembled electronic powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

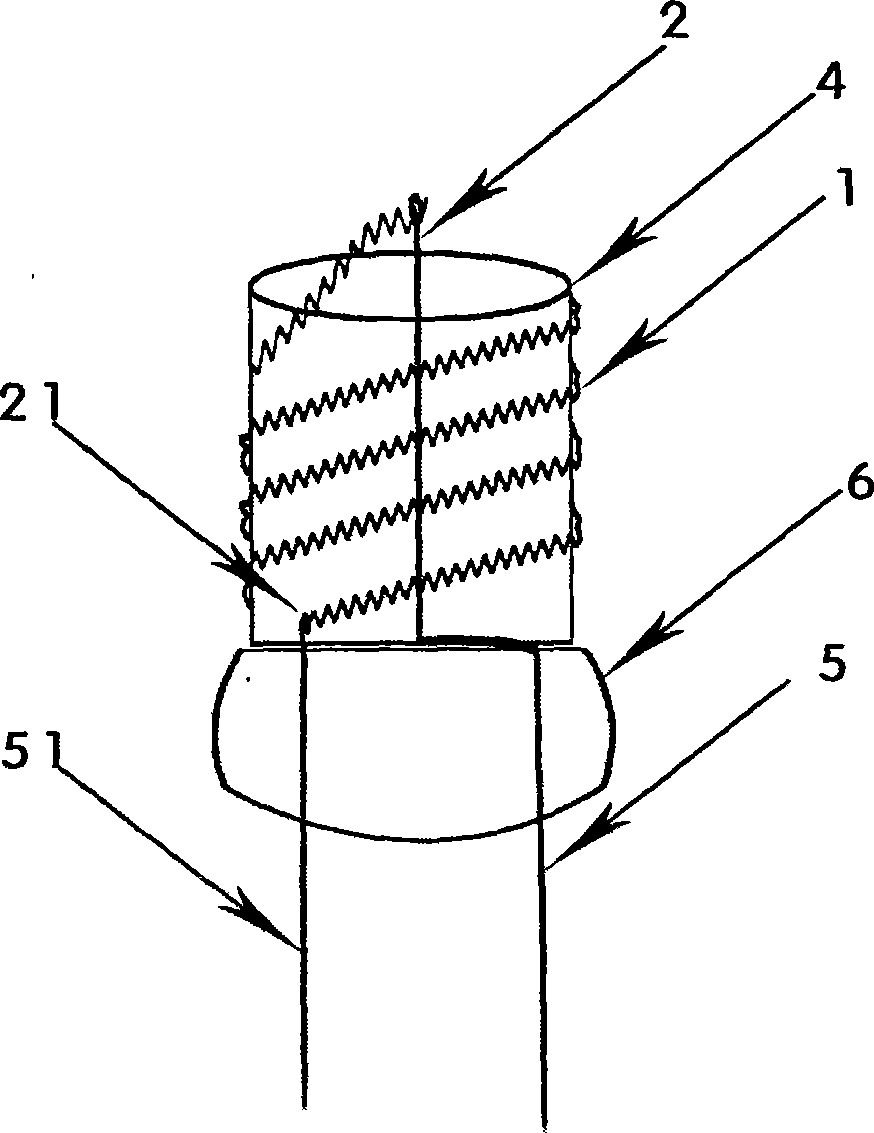

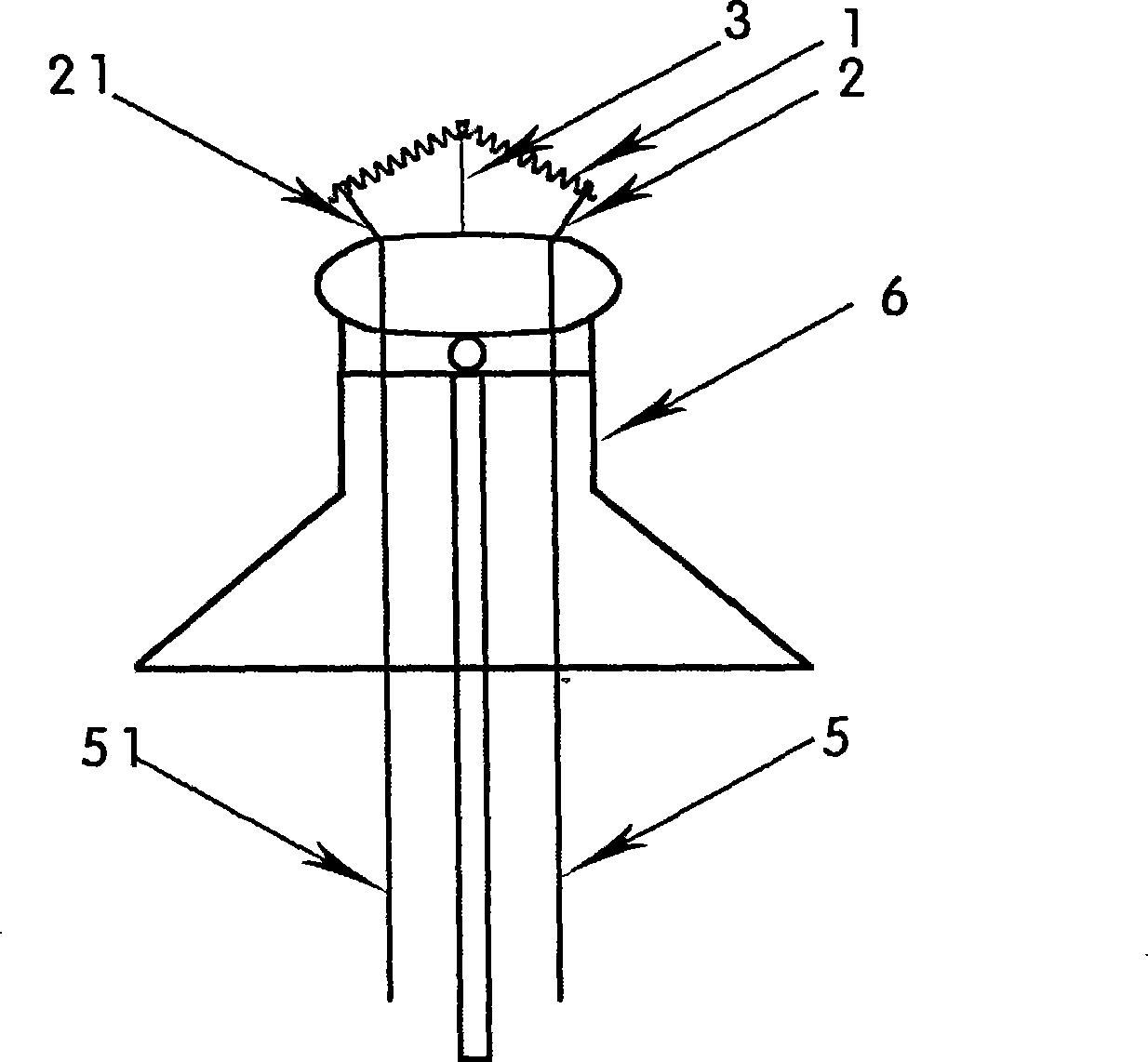

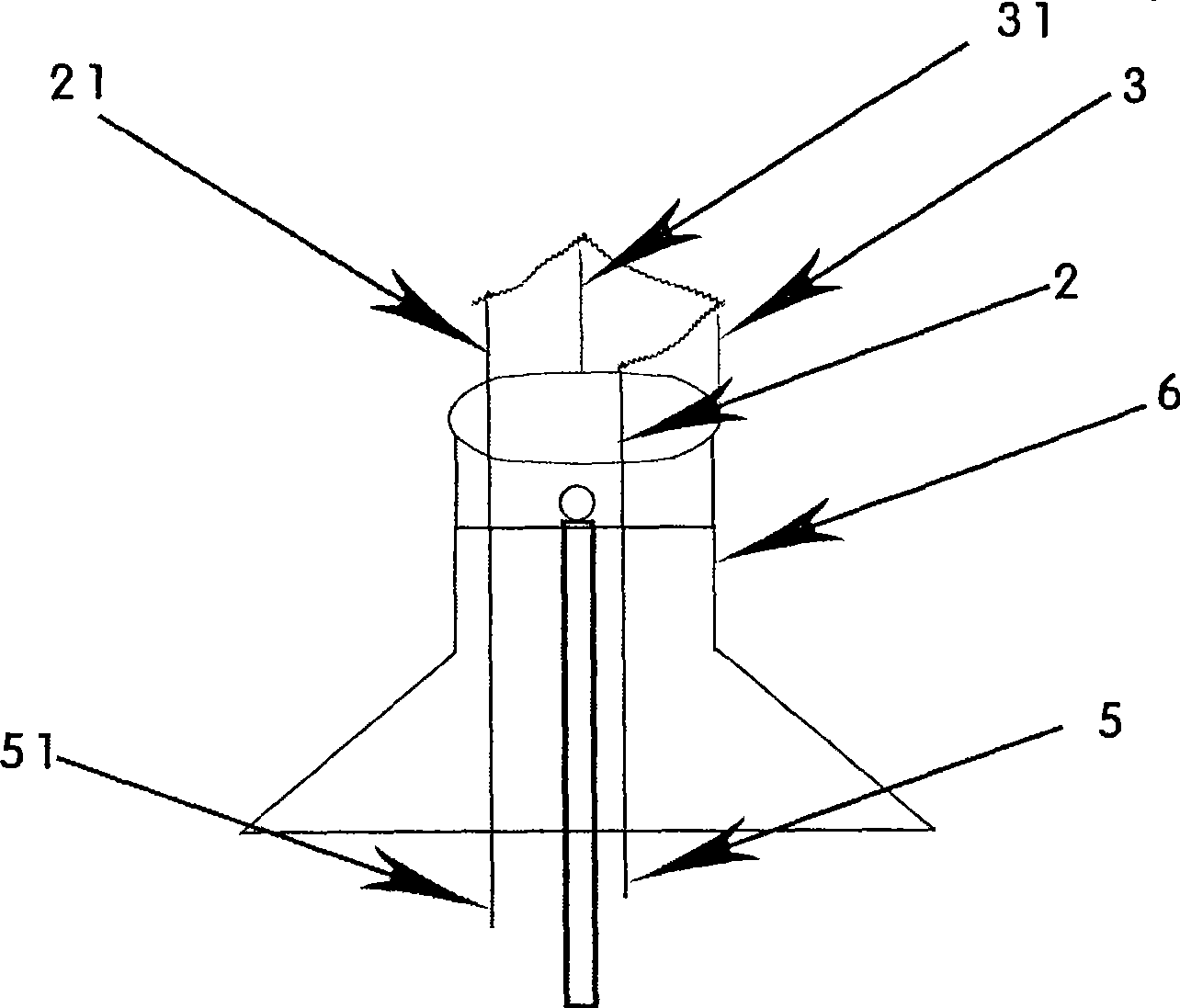

[0016] As shown in the accompanying drawings, the novel cathode of the fluorescent lamp of the present invention consists of figure 1 : T1 ~ T2 ultra-fine straight wire diameter, figure 2 : 1.5 times the diameter of T3 ~ T4 "V" type wire, image 3 : 2.5 times the diameter of T5 "U" type wire or Figure 4 : 3 times the tube diameter above T8, composed of "S" filament, the filament is wound by tungsten wire into double helix, triple helix or main and auxiliary triple helix, and the surface is dip-coated or electrophoretic ternary carbonate composed of electrons powder, the exhaust gas is energized and heated to decompose into high-efficiency oxide electrodes. figure 1 The ultra-fine straight wires of T1-T2 diameters shown are installed vertically. The vertical installation method is to put a section of ultra-fine quartz glass tube or aluminum dioxide tube 4 on an inner guide wire 2, and insert the The filament 1 dipped and coated with electronic powder is set on the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com