Moisture-resistant phosphor and associated method

A technology of phosphor and phosphor layer, applied in the field of phosphor material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

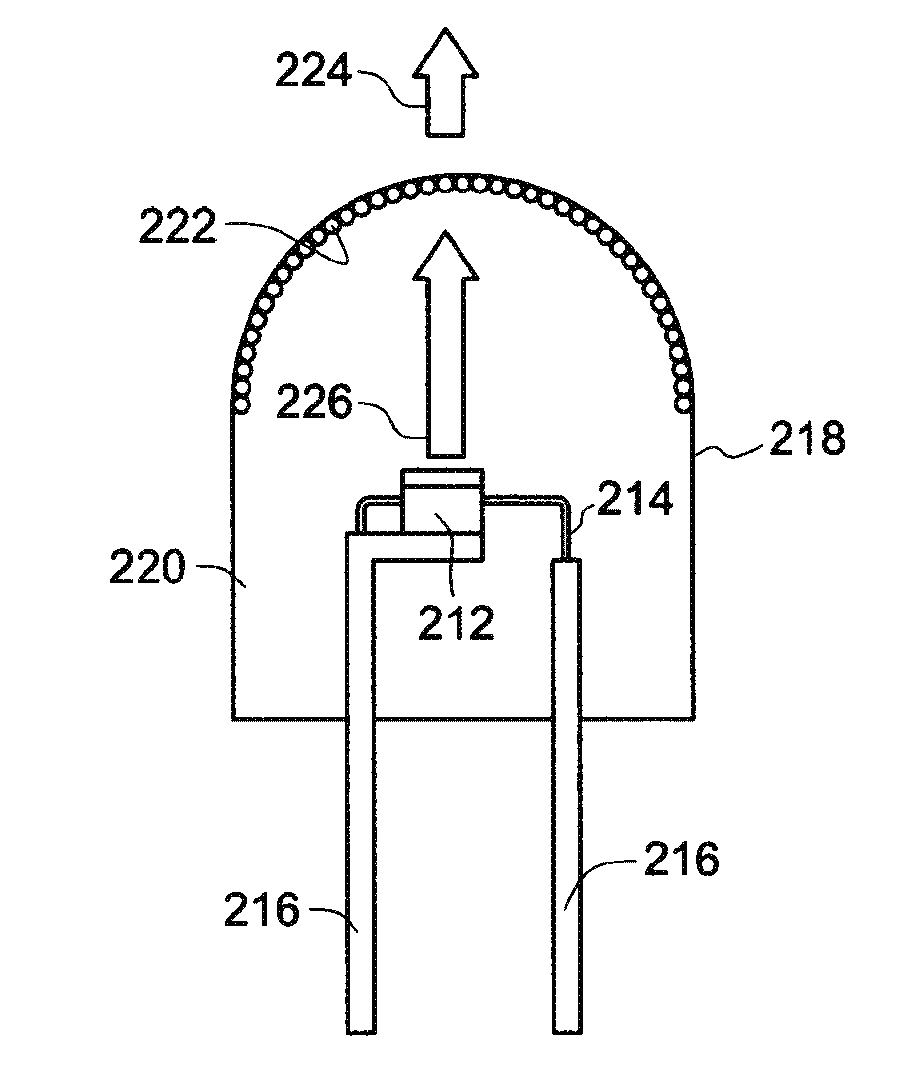

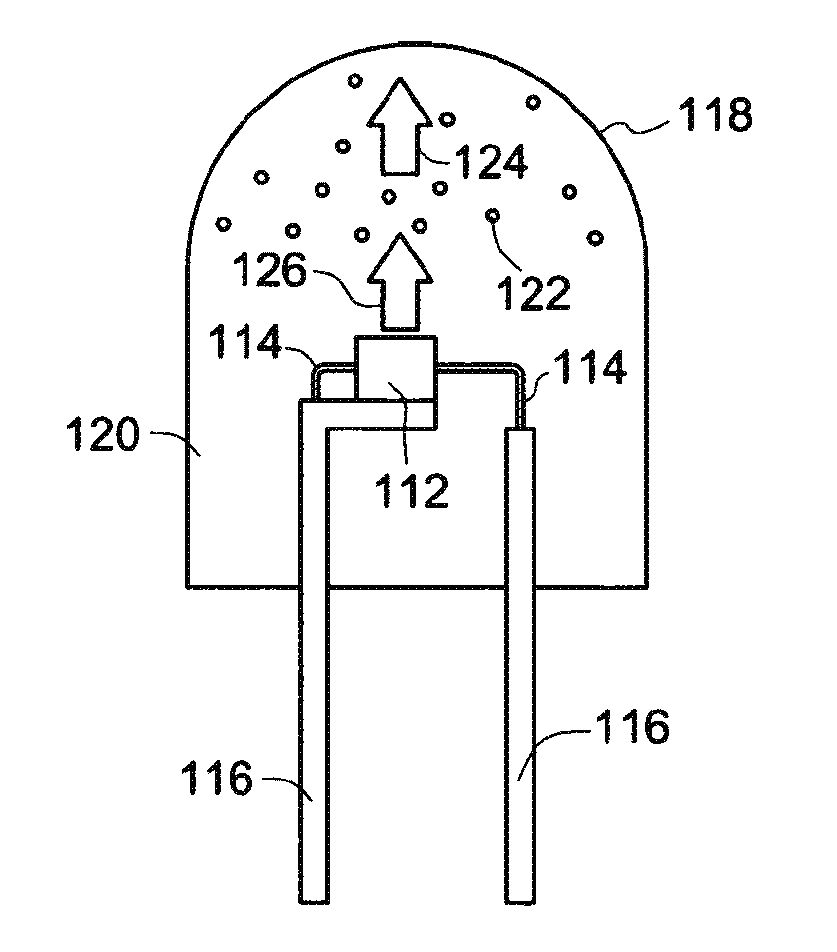

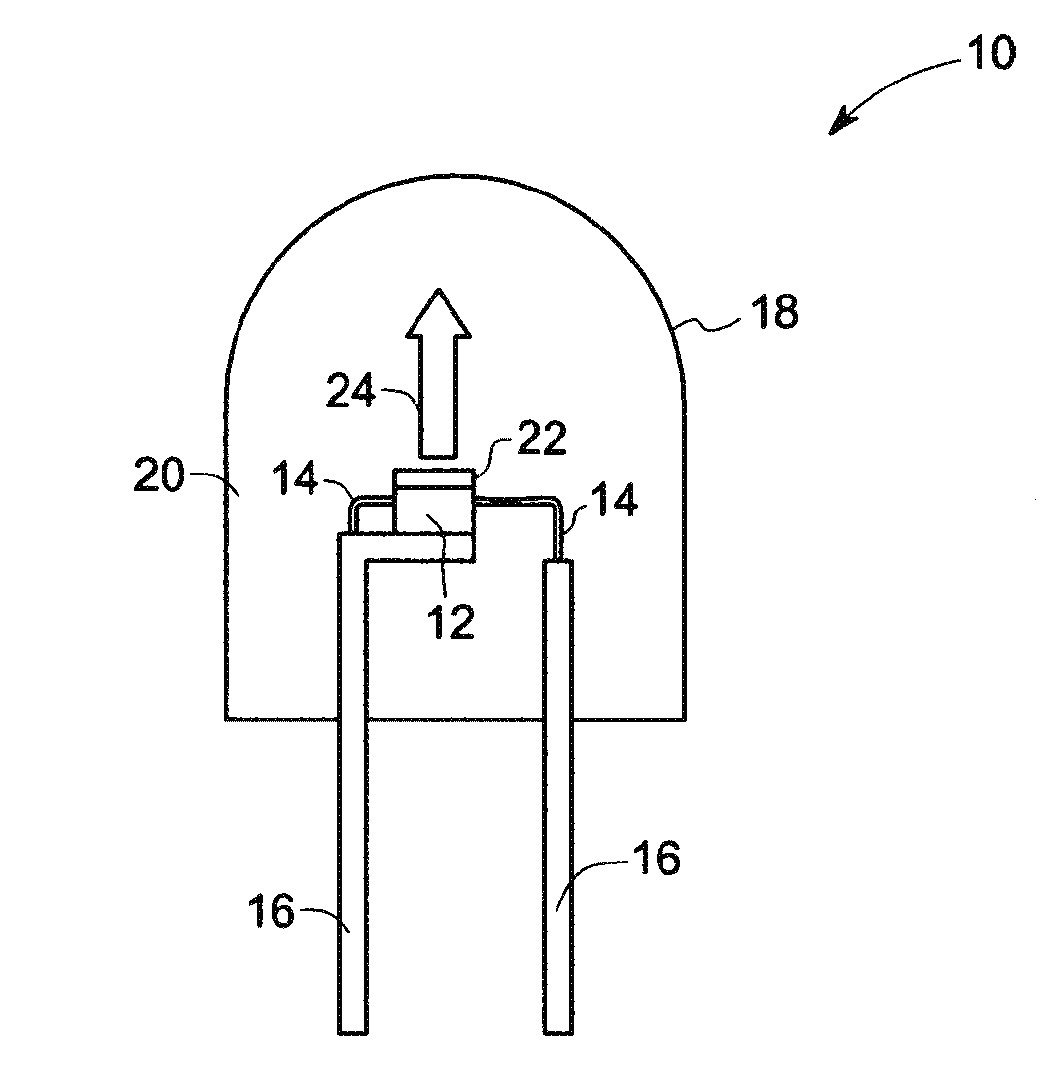

Image

Examples

Embodiment 1

[0056] prepared with K 2 TiF 6 coating (shell) with K 2 TiF 6 :Mn 4+ core complex fluoride phosphor.

[0057] Mn-free K 2 TiF 6 Commercially available from Fluka, manganese-doped K 2 TiF 6 Prepared in 70% HF solution with a drying temperature of 70°C according to the procedure described in cited US Patent 7,497,973.

[0058] 3 g K 2 TiF 6 Mix in 5 mL of 70% HF in a 70-90 °C water bath to prepare a saturated solution. This saturated solution was then poured over 3 g of K in a beaker 2 TiF 6 :Mn 4+ For the powder, the beaker was placed in a water bath, and in some cases, an oil bath. While pouring, the solution was stirred continuously at about 70°C. The suspension was recovered after stirring for about 15 minutes, then evaporated to a thick paste at about 70°C. The thick paste was then poured out on filter paper to dry. Drying was carried out in a dry box atmosphere at about 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com