LED filament ball steep light with high lumen maintenance

A technology of LED filament and maintenance rate, which is applied in the field of LED lighting, can solve the problems of reduced luminous flux and aggravated aging light decay, and achieve the effect of reducing light decay, reducing double costs, and improving luminous flux maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

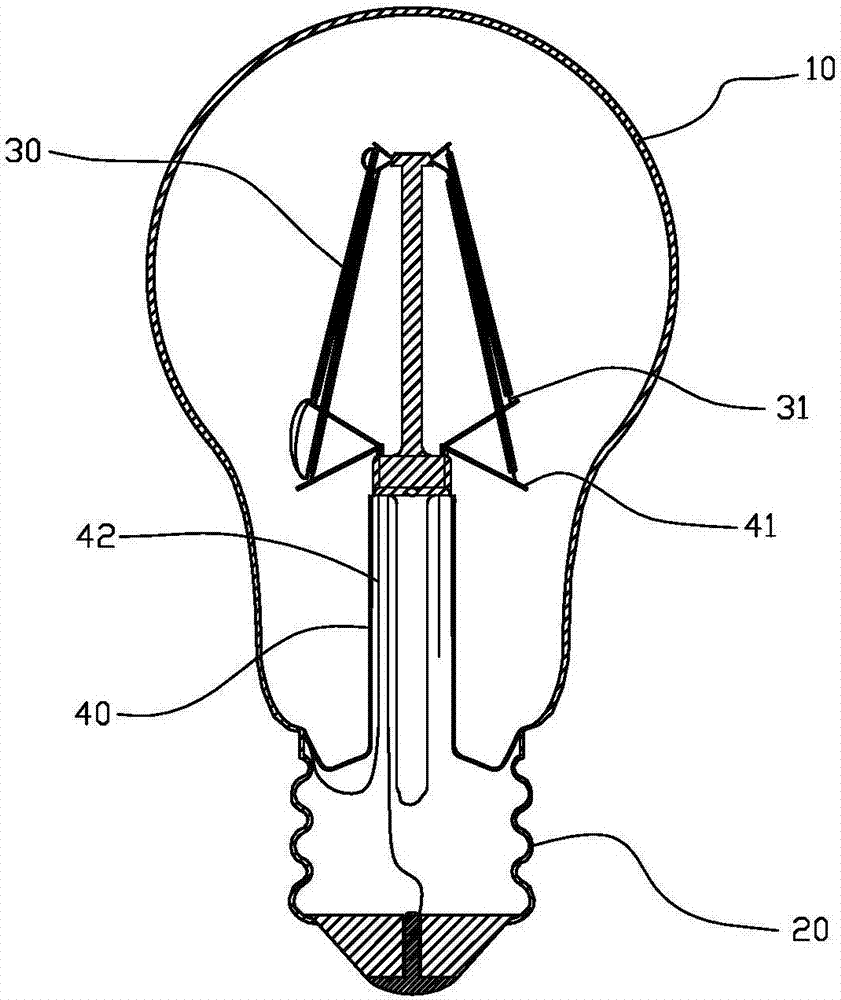

[0019] Example 1: see figure 1 , a LED filament bulb lamp with high luminous flux maintenance rate, including a closed bulb shell 10 and a lamp base 20 fixedly connected to the bulb shell 10, and a lamp post 40 fixedly connected to the lamp base 20 and inside the bulb shell 10 , the lamp post 40 is provided with an LED light source 30, the LED light source 30 forms a conductive connection with the lamp holder 20, the bulb shell 10 is filled with a mixed gas, the mixed gas contains oxygen and gas, and the volume ratio of oxygen is 0.1%-30% . The gas is an inert gas. In an oxygen-free environment, the ITO (indium tin oxide) layer in the LED chip undergoes the following chemical reactions, InO 2 ⇋InO+½O 2 SnO 2 ⇋SnO+½O 2 , adding oxygen to the gas can prevent the reduction of the ITO layer in the LED chip in the inert gas, thereby improving the luminous flux maintenance rate of the filament aging. At present, the 1000H aging light of the filament with better performance is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com