Method for preparing grapheme platinum nanocomposite material by using argon plasma

A composite material and plasma technology, which is applied in the field of preparing graphene-platinum nano-composite materials by ions, can solve the problems of time and energy consumption, introduction of impurities, complicated process, etc., and achieve shortened preparation time, simplified process, and good electrocatalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing graphene-platinum nanocomposites with argon plasma, comprising the following steps:

[0027] A. Put 50mg of graphene oxide into a beaker, then add 2ml of 1 mol.L -1 The chloroplatinic acid, the mixture of gained is placed in oven and dried at 60 DEG C to obtain the powder of drying;

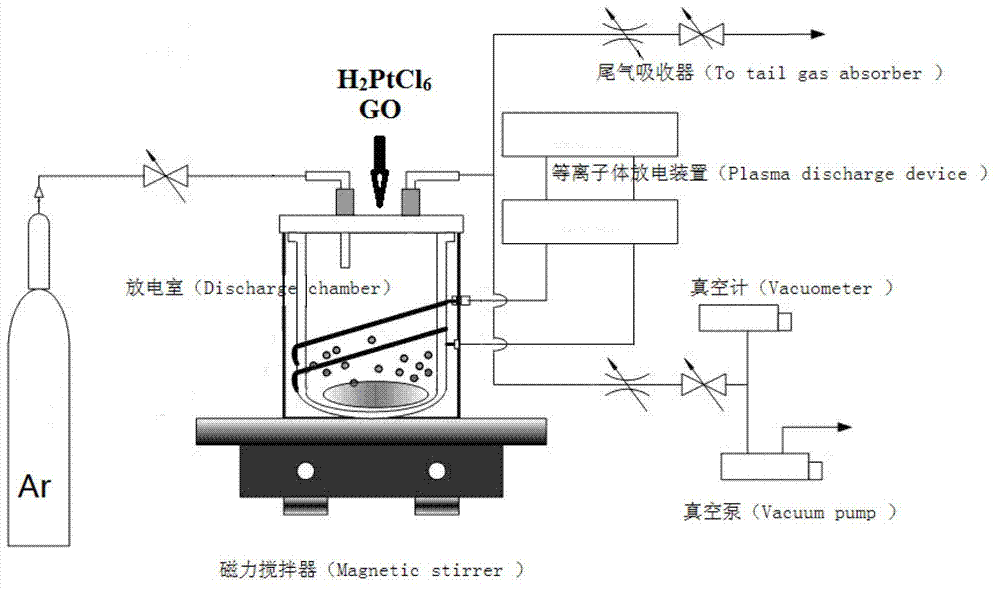

[0028] B. Place the dried powder in an airtight container (see figure 1 ), the container is connected with a graphite electrode, and the electrode is connected to an AC power supply, which can generate an inductively coupled plasma source, and then first pass argon gas into the container to drive away the air, and then turn on the vacuum pump to evacuate to 3Pa, and then turn on the AC The power supply generates argon plasma, and the plasma flow is directly applied to the surface of the dried powder for 30 minutes. After the discharge is completed, the reaction product is fully washed with deionized water or an appropriate organic solvent, filtered, and dried at 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com