Nickel-iron double hydroxide/foamed nickel catalyst based on ferric chloride/urea eutectic solvent, and preparation method and application thereof

A technology of deep eutectic solvent and hydroxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., to achieve short preparation cycle, cheap and easy-to-obtain raw materials, The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

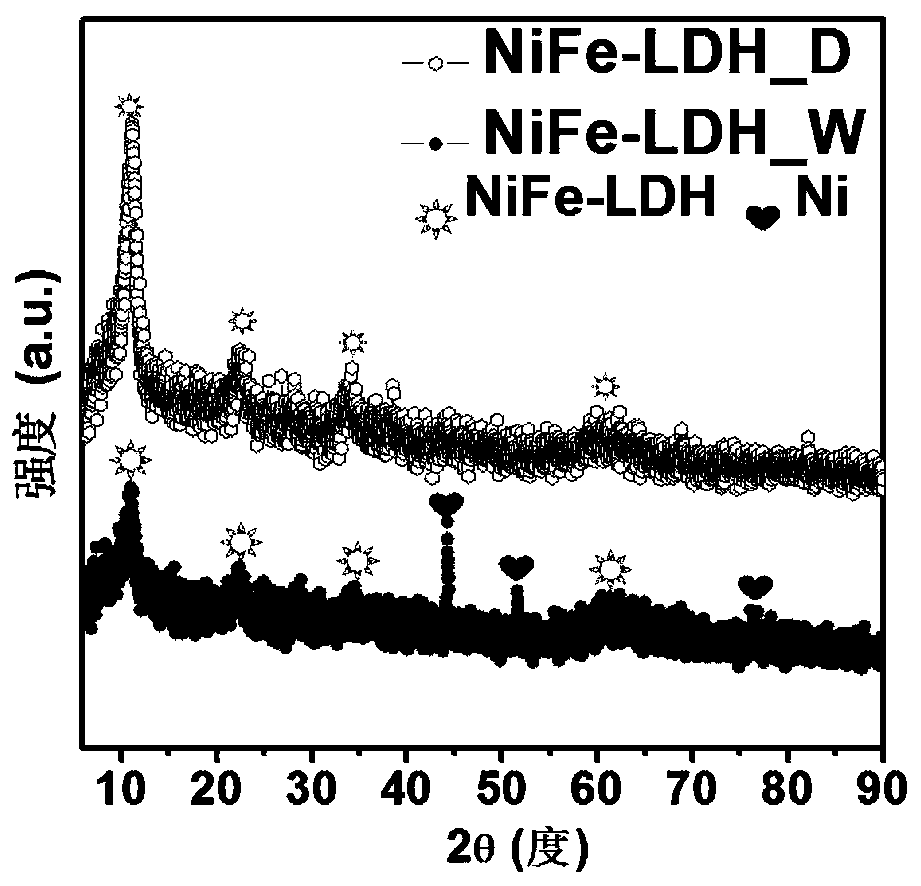

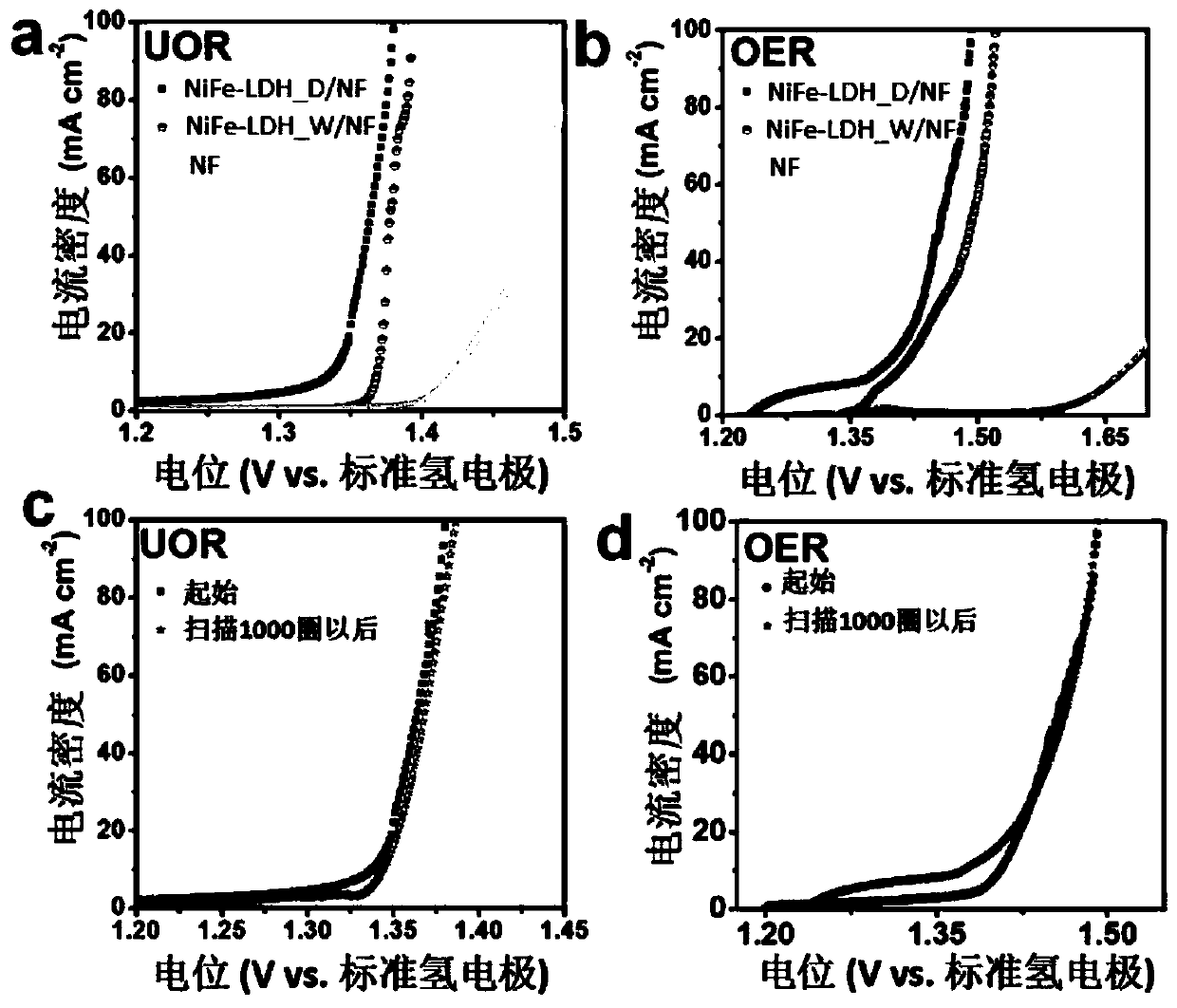

[0042] A kind of preparation method of the nickel-iron double metal hydroxide / foam nickel catalyst based on iron trichloride / urea deep eutectic solvent, comprises steps:

[0043] (1) Synthesis of deep eutectic solvent: Mix ferric chloride hexahydrate and urea at a molar ratio of 2:1, then heat in an oil bath at 60°C for 30 minutes to obtain a reddish-brown liquid with high viscosity, After cooling to room temperature, the ferric chloride hexahydrate / urea deep eutectic solvent was successfully synthesized.

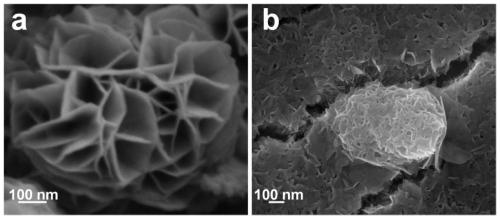

[0044] (2) Pretreatment of foamed nickel: cut the foamed nickel into a size of 1*1cm 2 The square was then ultrasonically treated with 1 mol / L hydrochloric acid for 10 minutes, and then ultrasonicated with water and ethanol for 10 minutes to remove oxides and impurities on the surface. Finally, vacuum-dry at room temperature for 12 hours to obtain pure foamed nickel.

[0045] (3) Preparation of NiFe-LDH / nickel foam catalyst: soak the pure nickel foam above in the deep eut...

Embodiment 2

[0061] A kind of preparation method of the nickel-iron double metal hydroxide / foam nickel catalyst based on iron trichloride / urea deep eutectic solvent, comprises steps:

[0062] (1) Synthesis of deep eutectic solvent: Mix ferric chloride hexahydrate and urea at a molar ratio of 1:1, then heat in an oil bath at 60°C for 30 minutes to obtain a reddish-brown liquid with high viscosity, After cooling to room temperature, the ferric chloride hexahydrate / urea deep eutectic solvent was successfully synthesized.

[0063] (2) Pretreatment of foamed nickel: cut the foamed nickel into 0.5*0.5cm 2 square, subsequent processing steps and conditions are as described in Example 1 to obtain pure foamed nickel.

[0064] (3) Preparation of NiFe-LDH / nickel foam catalyst: soak the pure nickel foam above in the deep eutectic solvent obtained in step (1), and react at 40° C. for 10 s. Then take out the foamed nickel (NiFe-LDH is supported on the surface of the foamed nickel), wash with ethanol a...

Embodiment 3

[0066] A kind of preparation method of the nickel-iron double metal hydroxide / foam nickel catalyst based on iron trichloride / urea deep eutectic solvent, comprises steps:

[0067] (1) Synthesis of deep eutectic solvent: Mix ferric chloride hexahydrate and urea at a molar ratio of 3:1, then heat in an oil bath at 60°C for 30 minutes to obtain a reddish-brown liquid with high viscosity, After cooling to room temperature, the ferric chloride hexahydrate / urea deep eutectic solvent was successfully synthesized.

[0068] (2) Pretreatment of foamed nickel: cut the foamed nickel into 2*2cm 2 square, subsequent processing steps and conditions are as described in Example 1 to obtain pure foamed nickel.

[0069] (3) Preparation of NiFe-LDH / nickel foam catalyst: soak the pure nickel foam above in the deep eutectic solvent obtained in step (1), and react at 80° C. for 40 s. Then take out the foamed nickel (NiFe-LDH is supported on the surface of the foamed nickel), wash with ethanol and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com