Titanium-based composite anode as well as preparation method and application thereof

A composite anode and titanium-based technology, applied in the field of electrochemistry, can solve the problems of insufficient density of the intermediate layer and active layer, unsatisfactory effect, and lower oxygen evolution potential, so as to inhibit passivation, prolong life, and increase specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

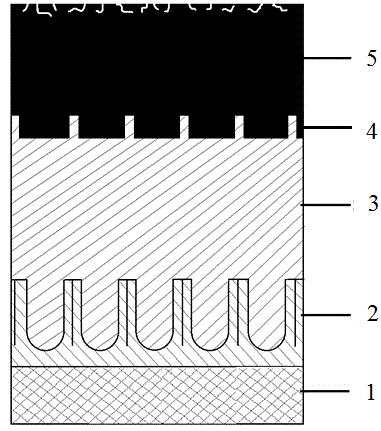

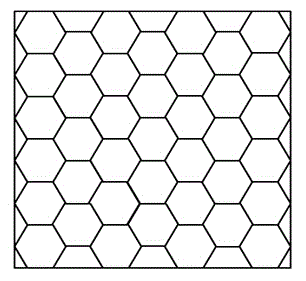

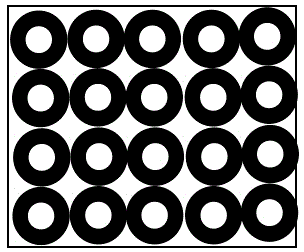

[0037] A long-life titanium-based composite anode of the present invention, such as figure 1 As shown, the titanium-based composite anode includes a titanium substrate 1 (in this embodiment, a metal titanium plate), a double-dense protective intermediate layer, and an active surface layer 5; wherein the double-dense protective intermediate layer is divided into two layers, the first layer is titanium dioxide The nanotube 2, the second layer is a tin-antimony oxide dense layer 3; the above-mentioned tin-antimony oxide dense layer 3 is covered with a honeycomb tin-antimony oxide layer 4; the active surface layer 5 is MnO 2 Metal oxide. figure 2 It is a cross-sectional view of the honeycomb tin-antimony oxide layer 4 of the titanium-based composite anode of the present invention; image 3 It is a cross-sectional view of the titanium dioxide nanotube 2 of the titanium-based composite anode of the present invention.

[0038] The preparation method of the titanium-based composite...

Embodiment 2

[0049] A long-life titanium-based composite anode of the present invention, such as figure 1 As shown, the titanium-based composite anode includes a titanium substrate 1 (in this embodiment, a metal titanium plate), a double-dense protective intermediate layer, and an active surface layer 5; wherein the double-dense protective intermediate layer is divided into two layers, the first layer is titanium dioxide The nanotube 2, the second layer is a tin-antimony oxide dense layer 3; the above-mentioned tin-antimony oxide dense layer 3 is covered with a honeycomb tin-antimony oxide layer 4; the active surface layer 5 is MnO 2 Metal oxide.

[0050] The preparation method of the titanium-based composite anode of this embodiment comprises the following steps:

[0051] (1) Cut a titanium plate with a thickness of 1.2mm into a size of 2×2cm, then polish it with sandpaper, wash and remove oil with alkali in a boiling 5w% NaOH solution for 1h and etch in a boiling 10w% oxalic acid soluti...

Embodiment 3

[0061] A long-life titanium-based composite anode of the present invention, such as figure 1 As shown, the titanium-based composite anode includes a titanium substrate 1 (in this embodiment, a metal titanium plate), a double-dense protective intermediate layer, and an active surface layer 5; wherein the double-dense protective intermediate layer is divided into two layers, the first layer is titanium dioxide The nanotube 2, the second layer is a tin-antimony oxide dense layer 3; the above-mentioned tin-antimony oxide dense layer 3 is covered with a honeycomb tin-antimony oxide layer 4; the active surface layer 5 is MnO 2 Metal oxide.

[0062] The preparation method of the titanium-based composite anode of this embodiment comprises the following steps:

[0063] (1) Cut a titanium plate with a thickness of 1.2mm into a size of 2×2cm, then polish it with sandpaper, wash and remove oil with alkali in a boiling 5w% NaOH solution for 1h and etch in a boiling 10w% oxalic acid solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com