Reduced graphene supported molybdenum or tungsten carbide catalyst and preparation method and application thereof

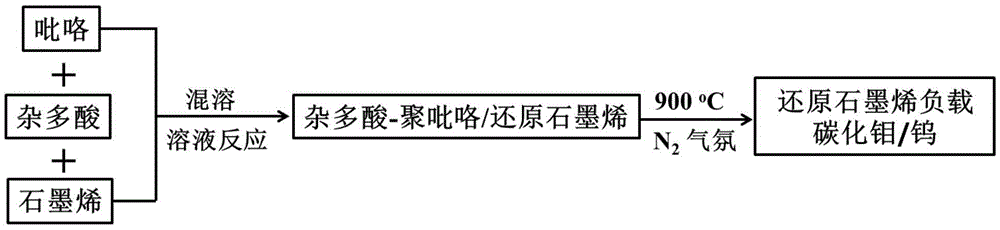

A technology of graphene and molybdenum carbide, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of complex production process, troubled synthesis, high cost, etc., and achieve simple process and enhanced dispersion , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of phosphomolybdic acid-polypyrrole / reduced graphene: first 25mL graphene aqueous solution (1mg / mL) is mixed with 300mL (7.3g / L) phosphomolybdic acid aqueous solution; Add the aqueous solution of 25mL pyrrole ( 17mg / mL). Then, it was continuously stirred at 60° C. for 24 h, and the product was obtained by suction filtration, washed several times with distilled water, and dried.

[0027] The preparation method of reduced graphene-supported molybdenum carbide or tungsten catalyst: 2g of phosphomolybdic acid-polypyrrole / reduced graphene was heat-treated at 900°C for 5h under the protection of high-purity nitrogen, cooled and pickled to obtain the final required sample.

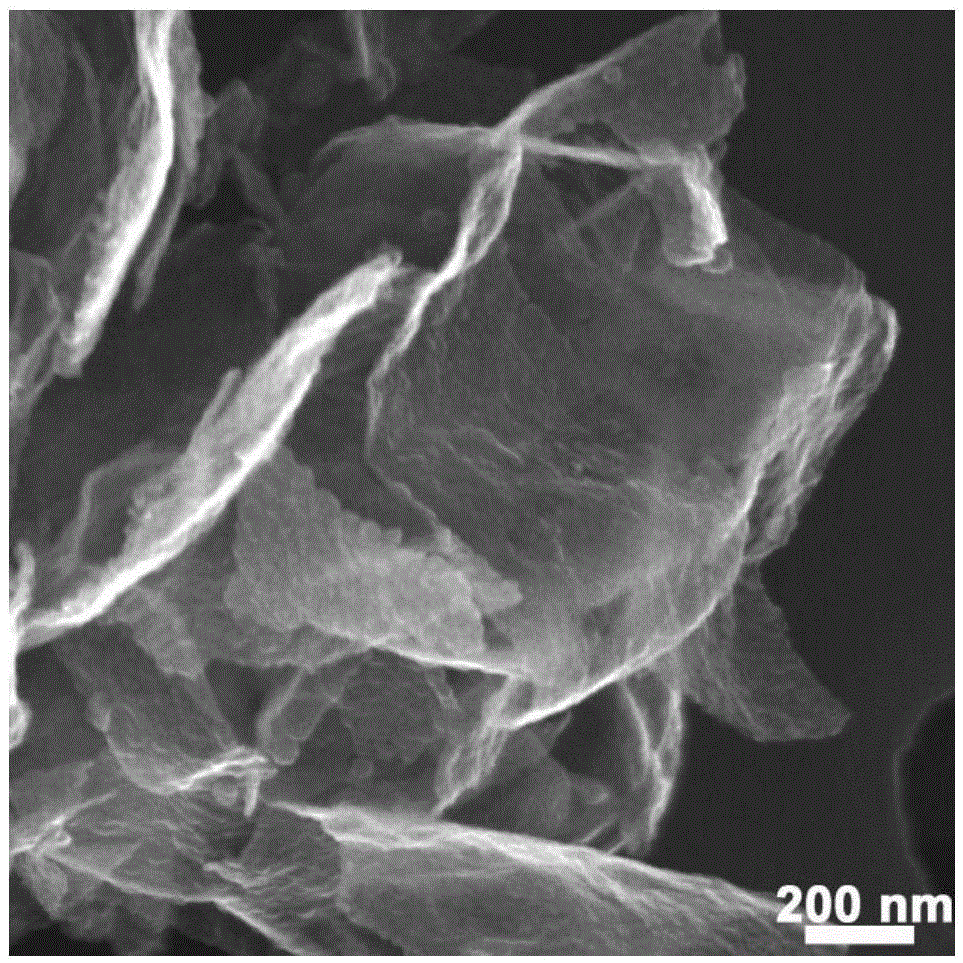

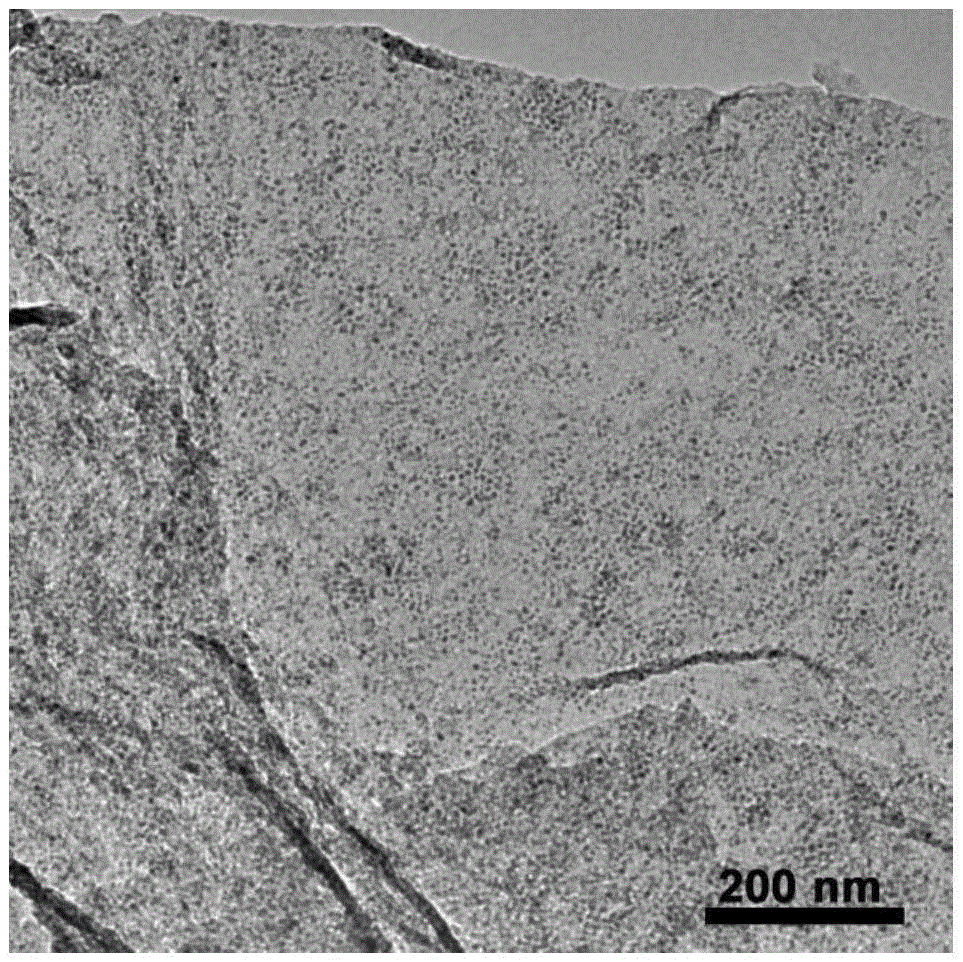

[0028] The SEM photographs of the obtained samples are shown in figure 2 , it can be seen from the figure that the surface of the wrinkled reduced graphene is relatively rough; the TEM photos are shown in Figure 3(a)-(b), and it can be seen from the figure that the prepared nanoparticles ...

Embodiment 2

[0030] The preparation process and steps in this example are basically the same as those in Example 1 above, except that the calcination temperature is adjusted from 900°C to 1100°C. The SEM and TEM photos of the obtained samples are shown in Figure 4(a)-(b). Its electrolytic water hydrogen production (hydrogen evolution) performance is: the initial potential is 27mV (relative to the standard hydrogen electrode), and the Tafel slope is 70.1mVdec -1 , Continuous operation 10h still maintains good stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com