Coating titanium anode

A titanium anode and coating technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve problems such as unsatisfactory electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The preparation method of titanium anode of the present invention is:

[0013] (1) The treatment of the base material, that is, the cleaning agent degreasing, degreasing, pickling and etching;

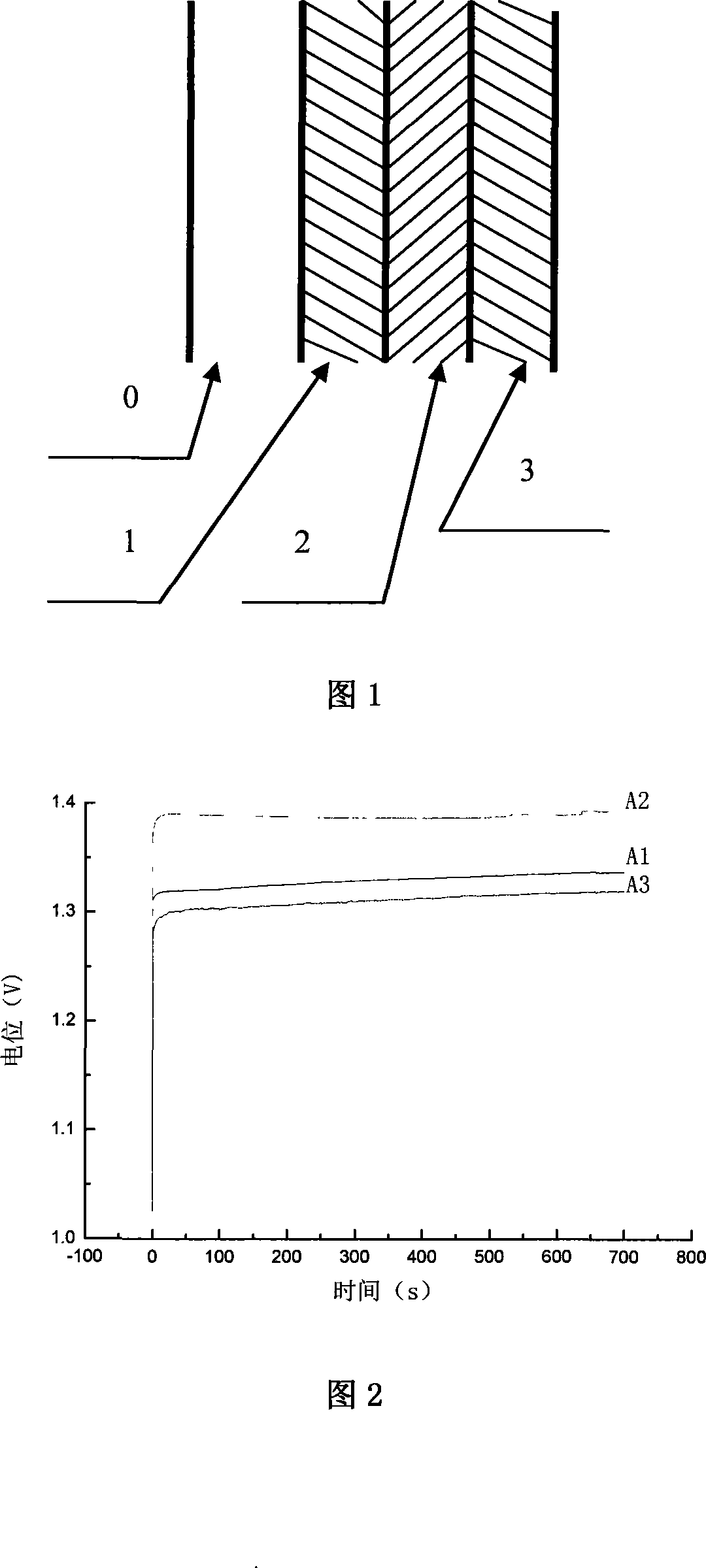

[0014] (2) preparation of active coating liquid;

[0015] (3) The coating of the inner layer coating, the core layer coating and the outer layer coating of the active coating;

[0016] (4) Coating and heat treatment of active coating.

[0017] The specific steps are:

[0018] (1) Taking titanium as the base material, washing it with washing powder solution, soaking it in 10% oxalic acid solution for 2 hours to make the surface of the titanium base form an uneven pockmarked layer, then washing it with distilled water and drying;

[0019] (2) preparation of ruthenium-titanium oxide binary coating solution: raw material is ruthenium trichloride, wherein contains Ru 37wt%, tetra-n-butyl titanate (99%, chemically pure), the coating of ruthenium on every titanium anode The surface...

Embodiment

[0025] An implementation example of the present invention is described in detail below:

[0026] Titanium anodes A1, A2 and A3 were prepared by thermal decomposition method. Among them, A1 is a ruthenium-titanium oxide binary titanium anode, A2 is an iridium-tantalum oxide binary titanium anode, and A3 is a titanium anode with a sandwich structure. The specific steps are:

[0027] (1) With titanium as the substrate, take TA1 with a thickness of 2mm and a specification of 20mm×50mm, wash it with washing powder solution, and soak it in 10% oxalic acid solution for 2 hours, so that the surface of the titanium substrate will form uneven pockmarks layers, washed with distilled water, and dried.

[0028] (2) prepare ruthenium-titanium oxide binary coating liquid, raw material is ruthenium trichloride (containing Ru 37wt%), tetra-n-butyl titanate, and the coating mass surface density of ruthenium on every titanium anode gets 1.5g / m 2 , weigh the source material according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com