Preparation method for monatomic ion dispersed oxygen reduction electro-catalyst

An electrocatalyst and dispersion technology, applied in the field of electrocatalysis, can solve problems such as instability and weak performance, and achieve the effects of convenient operation, excellent electrical conductivity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

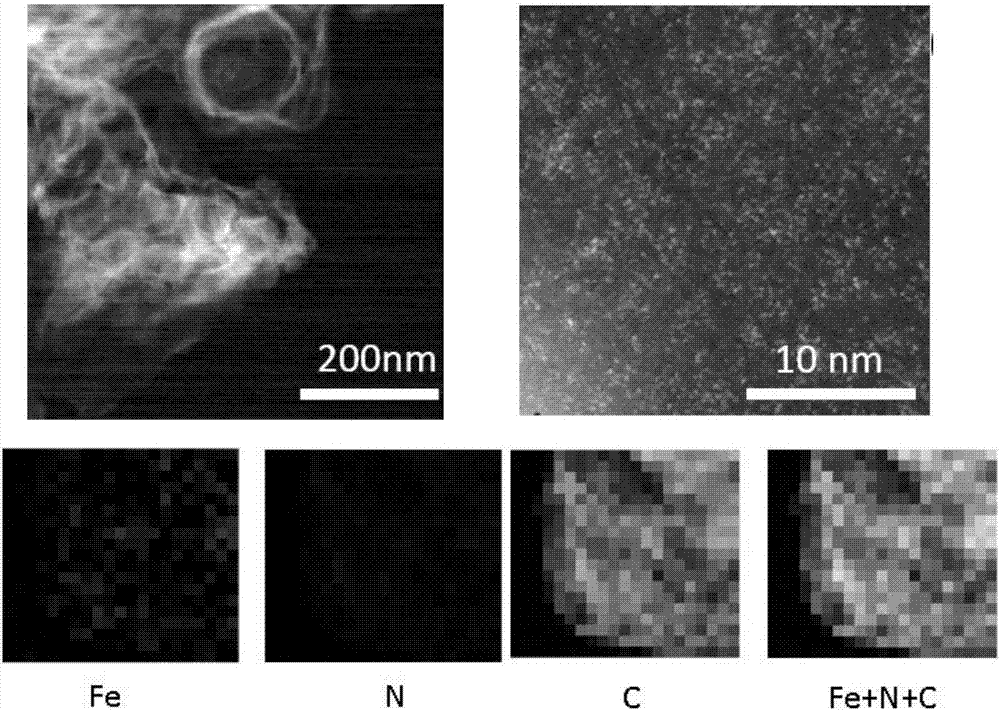

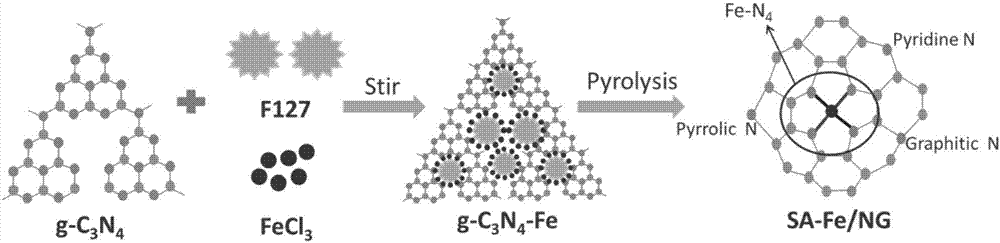

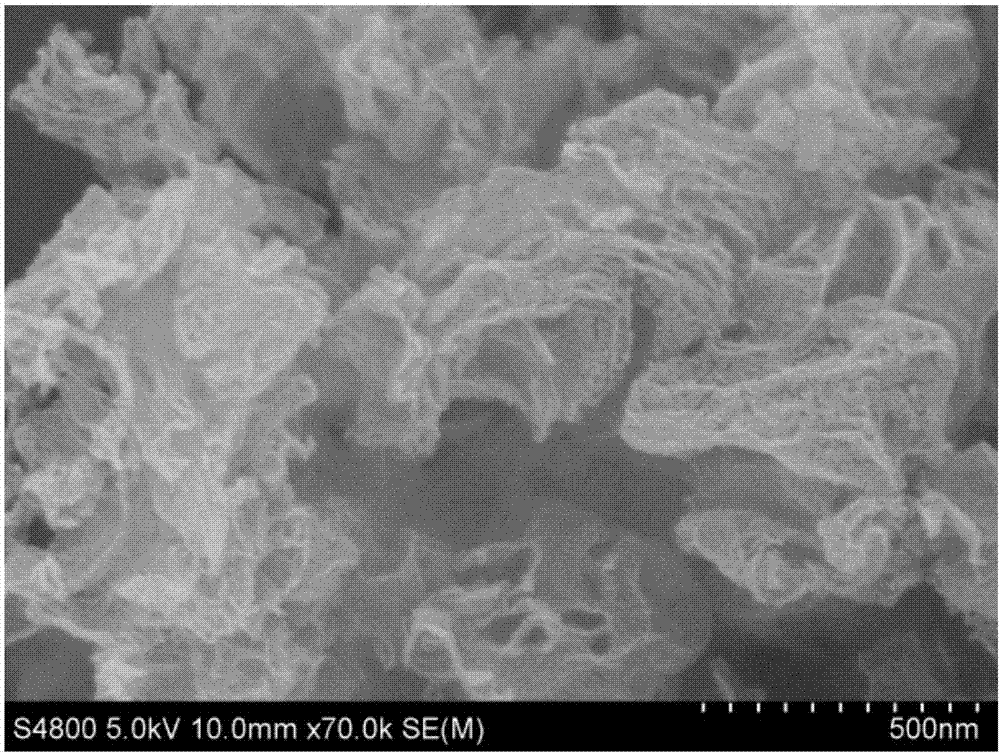

[0041] Example 1: with g-C 3 N 4 Method for preparing monoatomic iron-dispersed electrocatalysts as starting materials

[0042] 1) Weigh 3g of urea, put it into a tube furnace, raise the temperature at a rate of 3°C per minute, keep it at 550°C for 2 hours, and then cool down automatically.

[0043] 2) Weigh the product g-C synthesized in 0.3g step (1) 3 N 4 , add 30ml of deionized water, ultrasonic for half an hour, and stir for 1.5 hours.

[0044] 3) Add 0.3 g of polyether F127 to the product of step (2), and stir for 2 hours.

[0045] 4) Add 1ml of 0.298M FeCl to the solution of step (3) 3 The solution was stirred for 8 hours, and the temperature was raised to 100°C in a heated stirrer to naturally stir and air-dry.

[0046] 5) Put the above-mentioned dried powder into a tube furnace for carbonization, and the temperature rises to 800°C (increase at a rate of 2°C per minute, and keep at 800°C for 2 hours), take out the carbonized product, and soak it in 5ml of 1M HCl ...

Embodiment 3

[0052] Example 3: with g-C 3 N 4 Method for preparing nanoparticle iron, nitrogen co-doped carbon electrocatalyst as raw material

[0053] 1) Weigh 3g of urea, put it into a tube furnace, raise the temperature at a rate of 3°C per minute, keep it at 550°C for 2 hours, and then cool down automatically.

[0054] 2) Weigh the product g-C synthesized in 0.3g step (1) 3 N 4 , add 30ml of deionized water, ultrasonic for half an hour, and stir for 1.5 hours.

[0055] 3) Add 0.3 g of polyether F127 to the product of step (2), and stir for 2 hours.

[0056] 4) Add 5ml, 0.298M FeCl to the solution of step (3) 3 The solution was stirred for 8 hours, and the temperature was raised to 100°C in a heated stirrer to naturally stir and air-dry.

[0057] 5) Put the above-mentioned dried powder into a tube furnace for carbonization, and the temperature rises to 800°C (increase at a rate of 2°C per minute, and keep at 800°C for 2 hours), take out the carbonized product, and soak it in 5ml o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com