Titanium nitride carrier of catalyst of fuel batter with proton exchange film or titanium nitride and carbon carrier mixing carrier

A proton exchange membrane and fuel cell technology, applied in the direction of catalyst carrier, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of electronic state change on the metal surface and catalyst activity reduction, etc. Achieve high catalytic performance and excellent electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

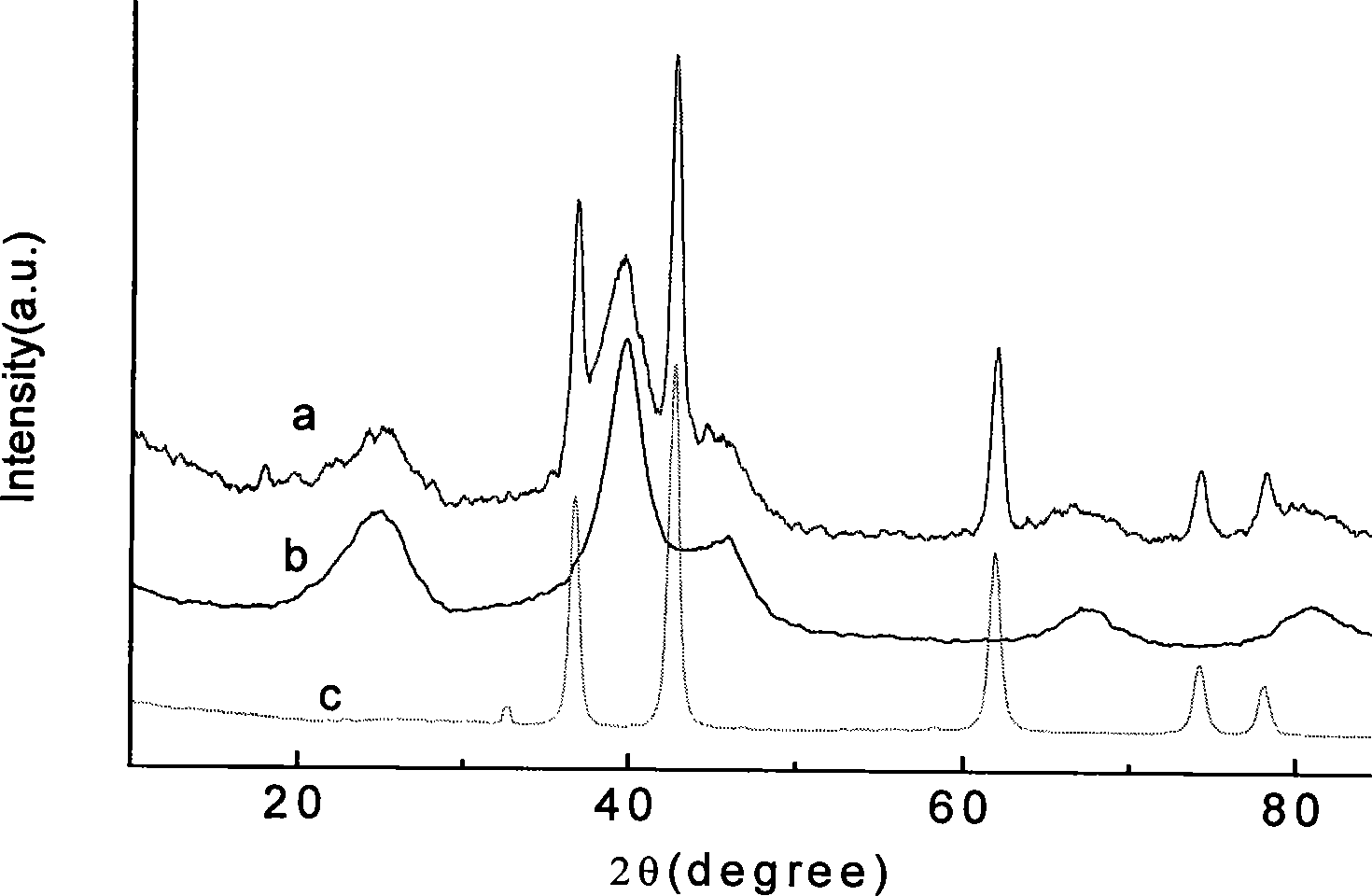

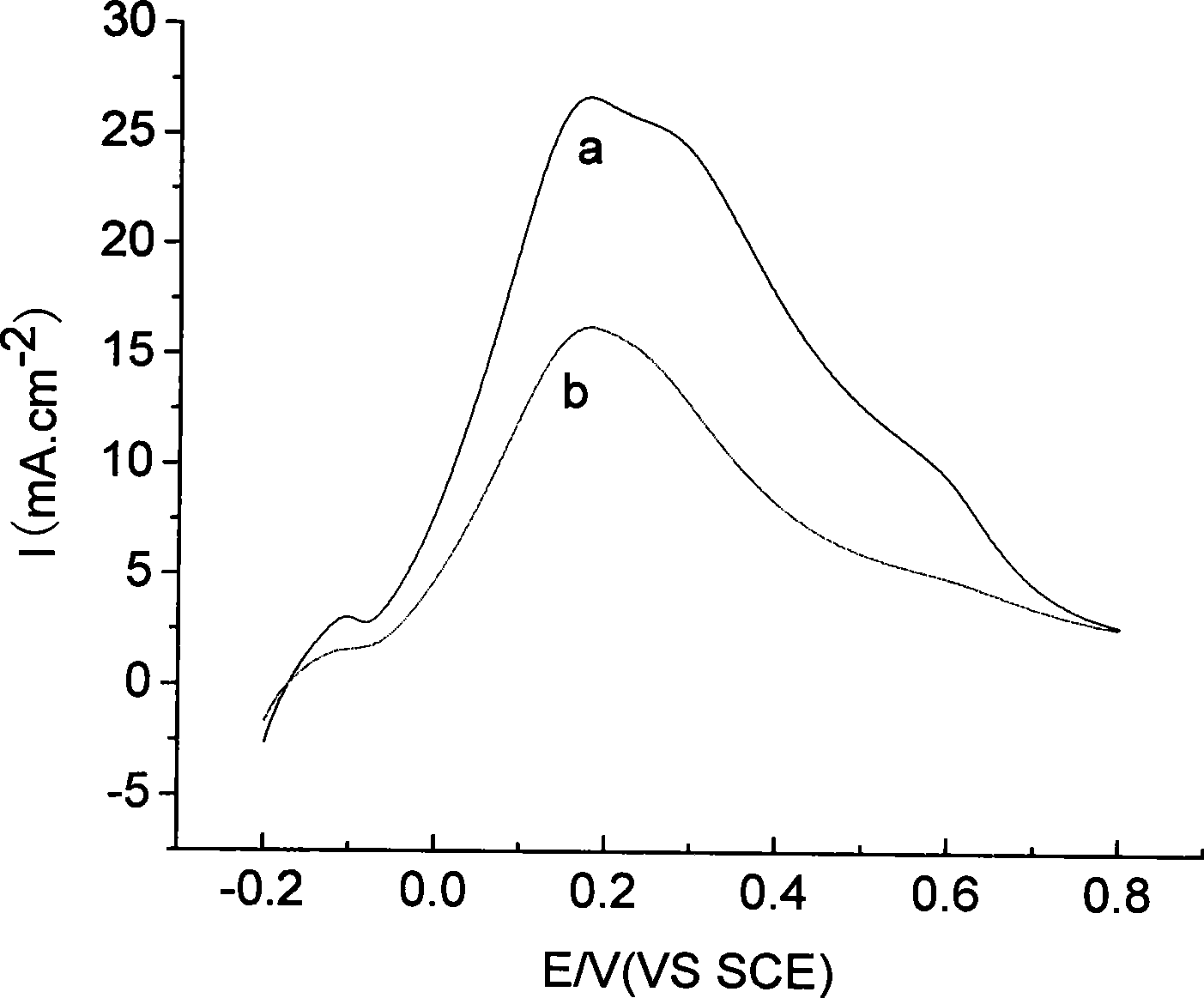

Embodiment 1

[0027] Weigh 60 mg of titanium nitride, add 112.68 mL of 0.04504 mol / L PdCl 2 solution, stir to make a homogeneous mixture.

[0028] (2) At 100°C, slowly add excess reducing agent solution (polyoxymethylene) and stir to completely react the metal salt and reducing agent.

[0029] (3), filter and wash until there is no chloride ion in the eluate. After drying, the Pd / TiN catalyst is obtained.

[0030] The titanium nitride accounts for 100% of the total mass of the carrier, the noble metal load is 90% of the total mass of the catalyst, and the reduction temperature is 100°C.

Embodiment 2

[0032] Weigh 1 mg of titanium nitride and 99 mg of activated carbon. Add 0.115mL 0.04504mol / L H 2 PtCl 6 solution, stir to make a homogeneous mixture.

[0033] (2), at 0°C, slowly add excess reducing agent solution (NaBH4 ), stirring to completely react the metal salt with the reducing agent.

[0034] (3), filter and wash until there is no chloride ion in the eluate. After drying, a Pt / TiN-C catalyst is obtained, wherein the loading of Pt metal is 1%.

[0035] The titanium nitride accounts for 1% of the total mass of the carrier, the loading of the noble metal is 1% of the total mass of the catalyst, and the reduction temperature is 0°C.

Embodiment 3

[0037] Weigh 20 mg of carbon nanotubes and 40 mg of titanium nitride. Add 1.32ml 0.0386mol / L H 2 PtCl 6 solution and 1.06ml0.04504mol / L PdCl 2 , and stir to combine evenly.

[0038] (2), at 25°C, slowly add excess reducing agent solution (NaBH 4 ), stirring to completely react the metal salt with the reducing agent.

[0039] (3), filter and wash until there is no chloride ion in the eluate. After drying, a PtPd / TiN-CNTs catalyst is obtained, wherein the loading of Pt metal is 13%, and the loading of Pd metal is 7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com