Process for preparing molybdenum trioxide/polyaniline laminated composite material

A molybdenum trioxide and polyaniline layer technology is applied in the field of preparation of molybdenum trioxide/polyaniline layered composite materials, and can solve the problems of complex pollution, impurity of the complex, restriction of reaction conditions and the like, and achieves simple preparation process, Avoid contamination products, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one: raw material is MoO 3 / DDA powder, aniline of analytical grade and anhydrous acetic acid of analytical grade.

[0028] a. Weigh MoO 3 / DDA powder 0.5g and analytical pure aniline 10mL were added to 50mL anhydrous acetic acid at the same time, ultrasonically oscillated to form a uniform suspension;

[0029] b. Seal the above suspension and transfer it to a 70°C water bath, and react at a constant temperature for 7 days to obtain a pink precipitate;

[0030]c. Wash the above pink precipitate twice with absolute ethanol, transfer it to a muffle furnace at room temperature, gradually heat it to 150°C for 5 days, and then cool it slowly to obtain a dark green product with crystal luster, which is polyaniline intercalation Molybdenum trioxide complex.

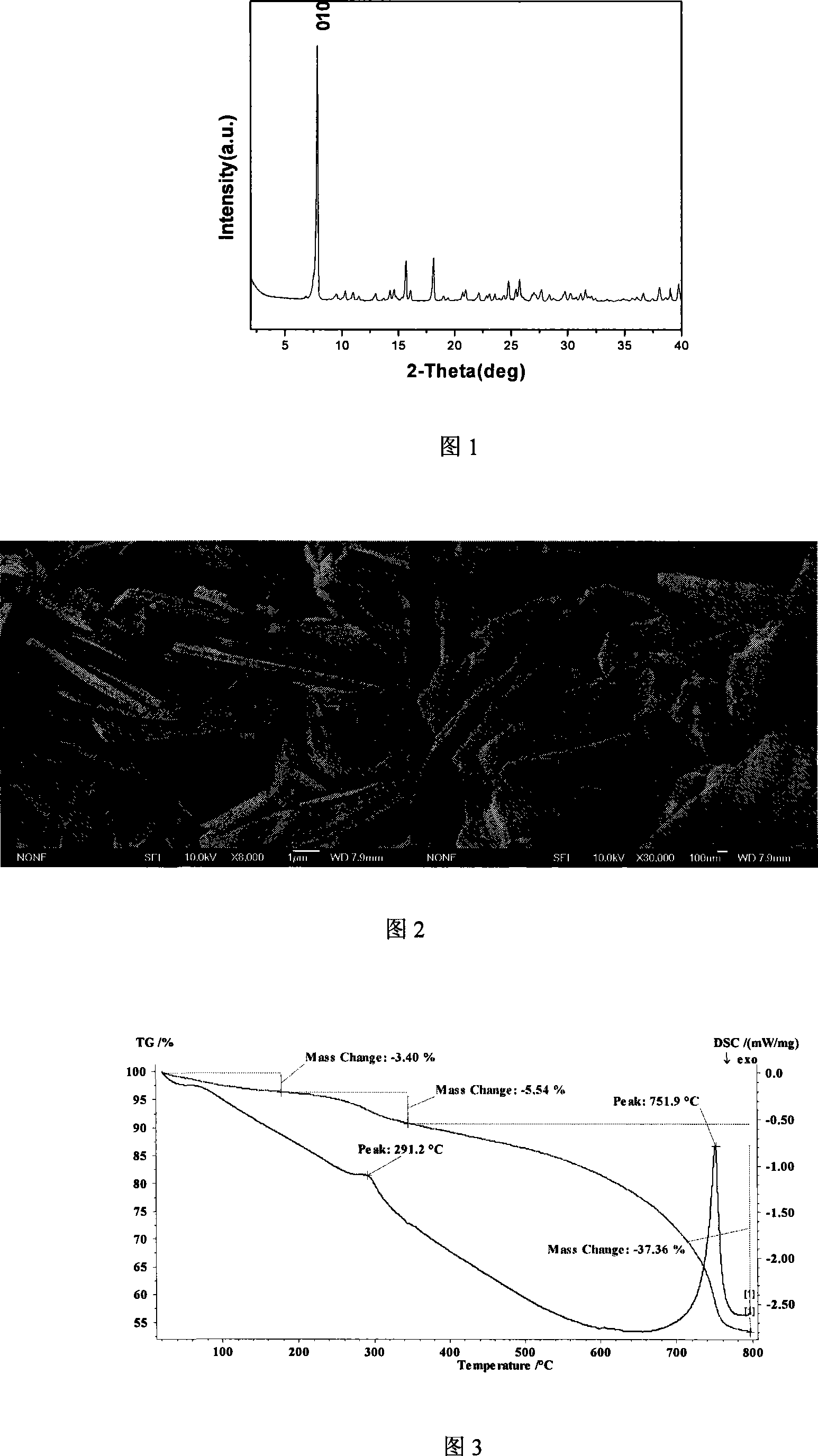

[0031] The obtained product is characterized by X-ray diffraction, differential thermal analysis, scanning electron microscope scanning and the like. Referring to Figure 1, the position of the 010 diffracti...

Embodiment 2

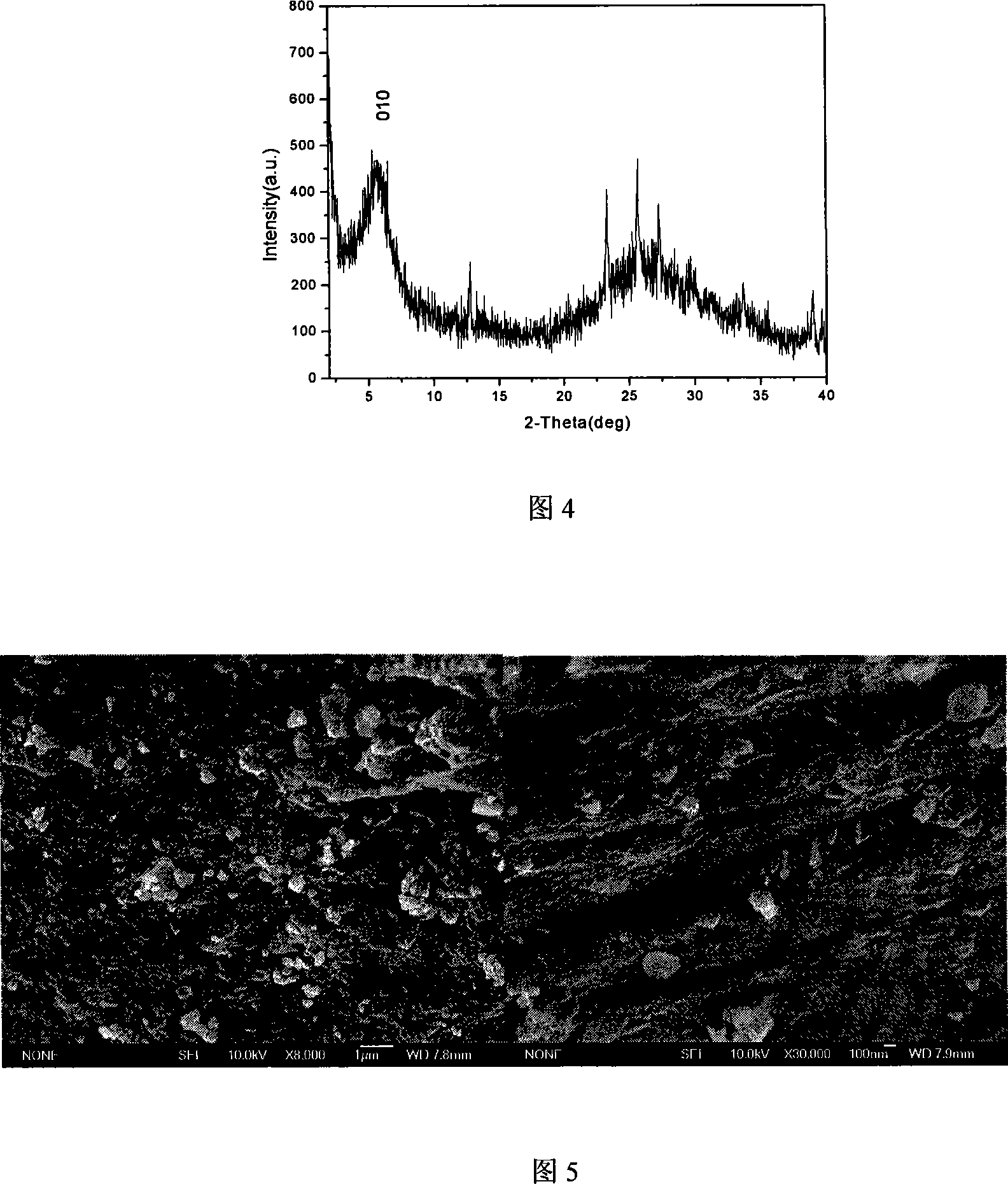

[0032] Embodiment 2: This embodiment is basically the same as Embodiment 1, except that in step c, the monomer intercalation product is directly placed in a muffle furnace heated to 150° C. for heat treatment, and then cooled rapidly. Please refer to FIG. 4 and FIG. 5 for the X-ray diffraction pattern and the scanning electron microscope image of the molybdenum trioxide / polyaniline layered composite obtained in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com