Looped frame arc tube mounting assembly for metal halide lamp

A technology for metal halide lamps and mounting components, which is applied in the field of component lamps and arc tube mounting components, can solve problems such as rising wall temperature, catastrophic failure of discharge vessels, and shortened lamp life, so as to prolong life and improve lumen maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

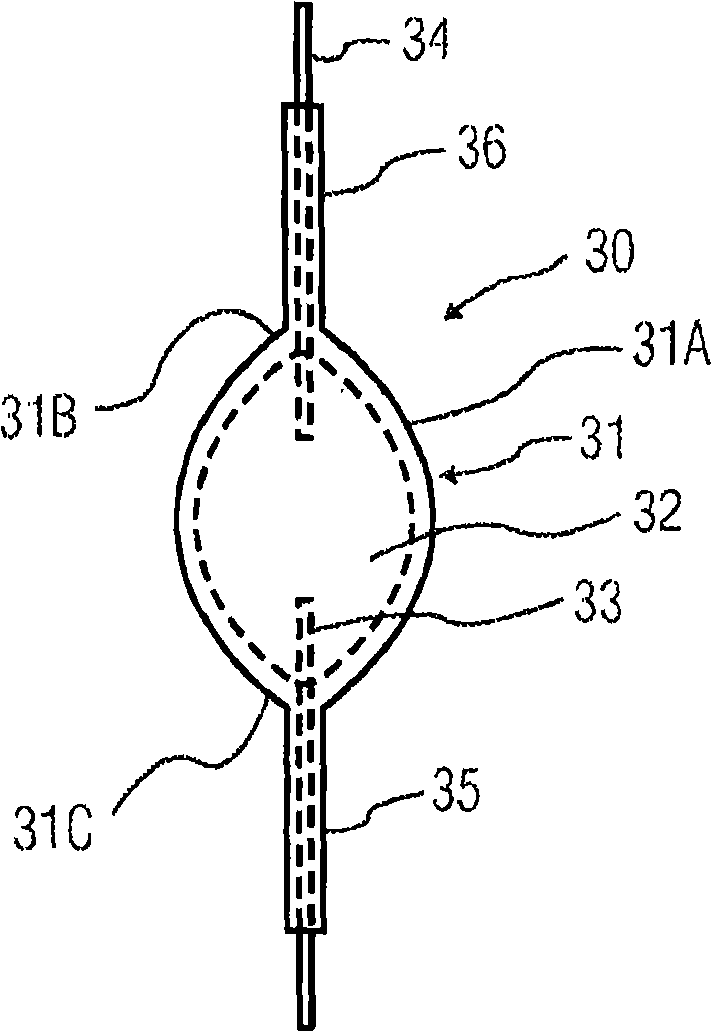

[0034] The figures are diagrammatic and not drawn to scale. The same reference numerals refer to the same components in different figures.

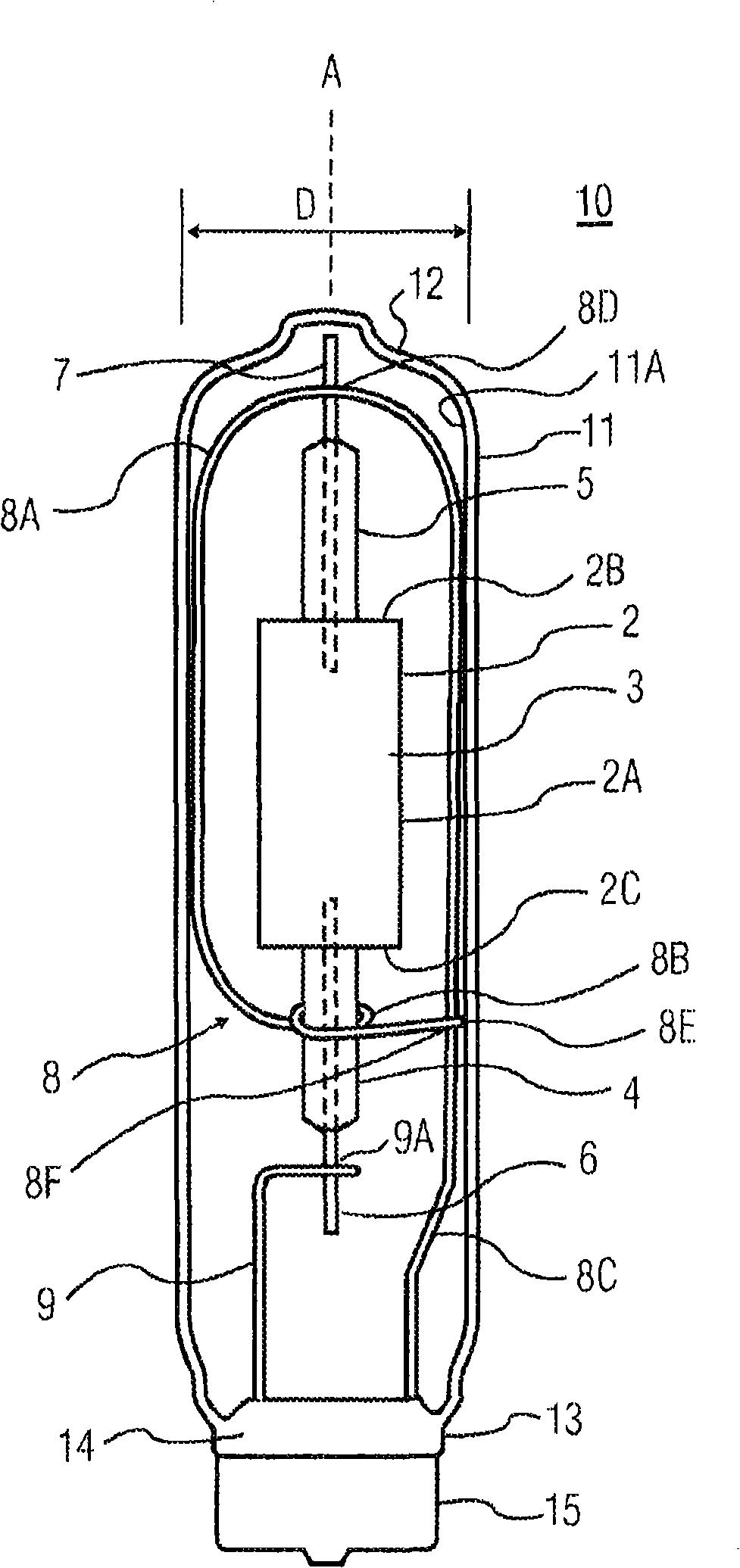

[0035] see now figure 1 , which shows a front view of one embodiment of a ceramic metal halide lamp 10 of the present invention, shown in partial cutaway, having a tubular outer shell 11, typically made of fused silica, the tubular outer shell Body 11 has sealed top 12 and bottom 13 ends, and a pinch seal 14 . A ceramic base 15 is attached to the bottom end 13 of the outer shell 11 .

[0036] An arc tube installation assembly 1 is arranged inside the outer shell 11, the arc tube installation assembly 1 includes a sealed ceramic arc tube 2, the ceramic arc tube 2 is generally made of polycrystalline alumina (PCA), and the ceramic arc tube 2 seals the discharge space 3 , the discharge space 3 has a filling, usually mercury and a rare gas such as argon, which can support the arc discharge. Extending from the bottom end 2B and top end 2C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com