Fluorescent lamp and lighting fixture

A technology for fluorescent lamps and light bulbs, applied in the field of fluorescent lamps and lighting appliances, can solve problems such as film peeling, reflective film cracking, disadvantages, etc., to achieve the effect of ensuring the film strength, high suppression effect, and suppression of mercury intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

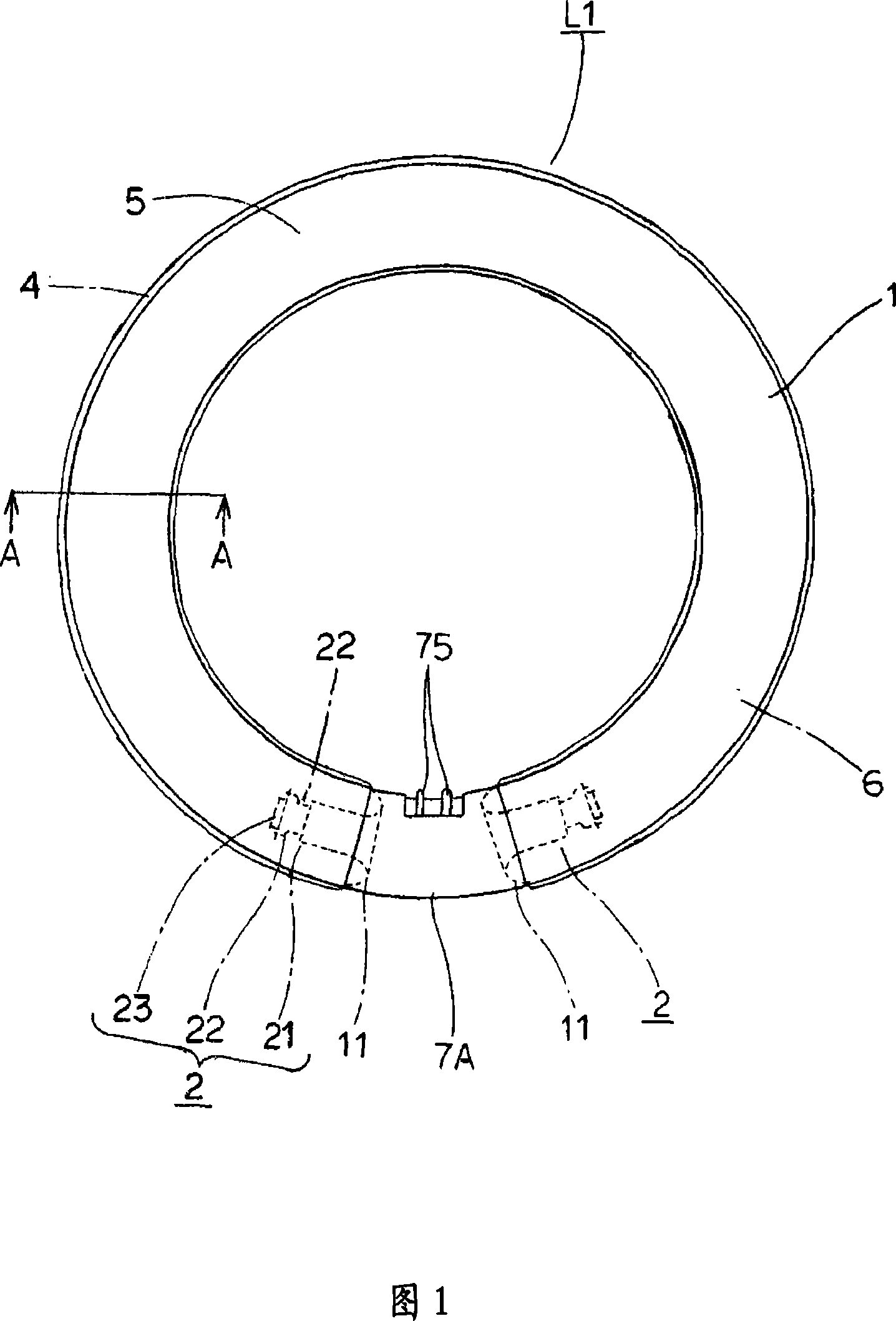

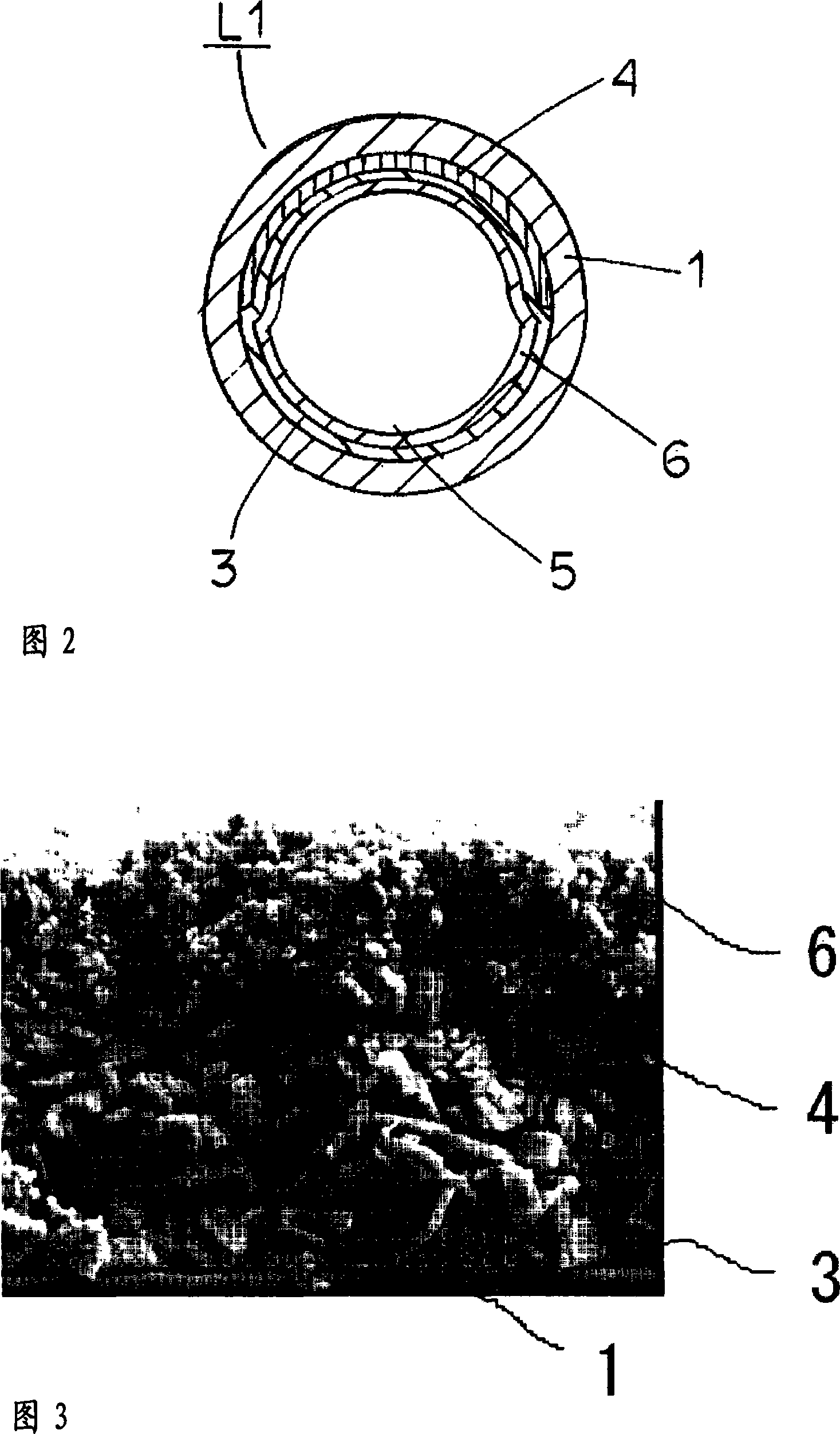

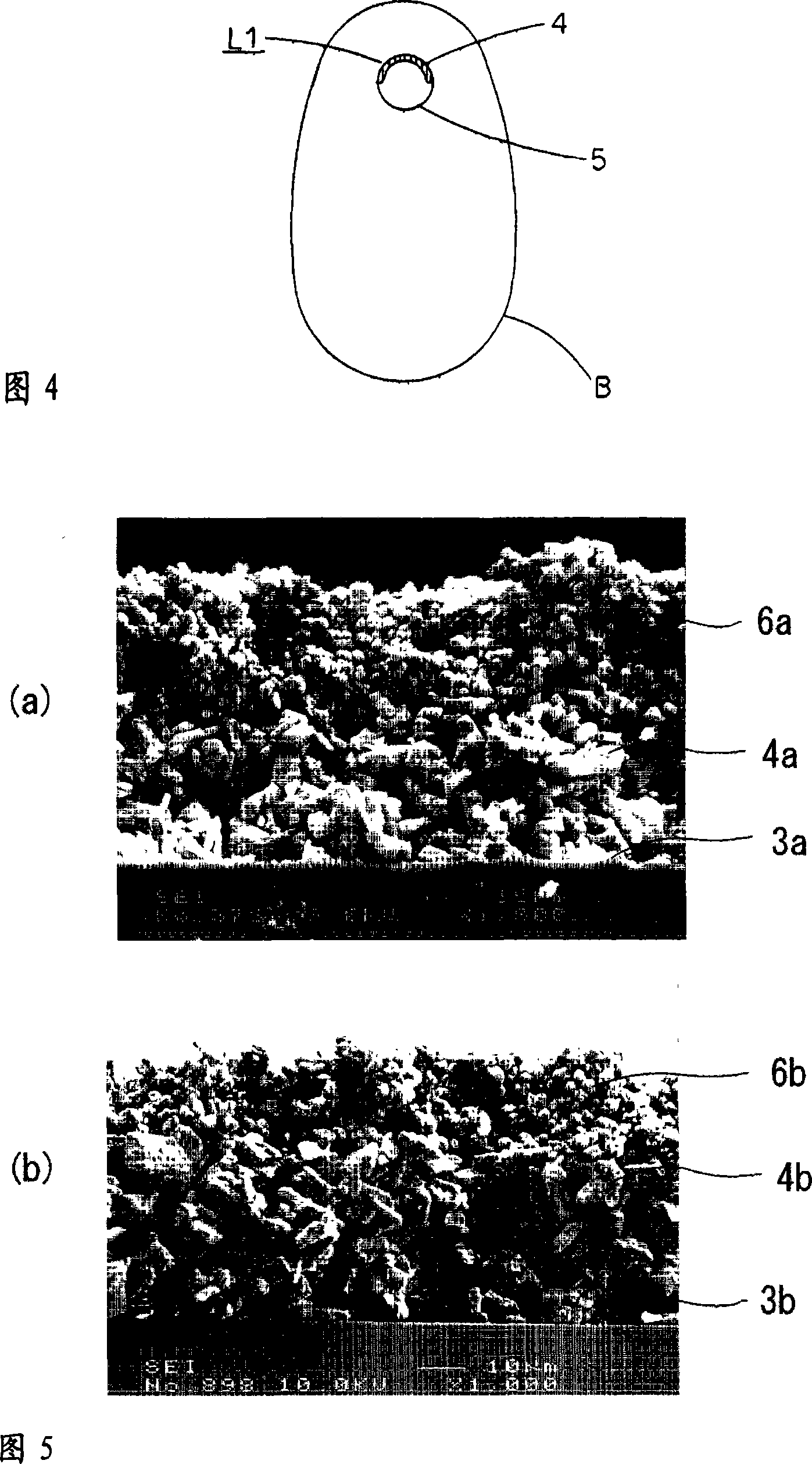

[0052] Hereinafter, an embodiment of the present invention will be described with reference to FIGS. 1 to 4 . Fig. 1 is a front view (opening part side) of the annular fluorescent lamp L1, Fig. 2 is an enlarged cross-sectional view showing an end face obtained by cutting along the line A-A of the arrow in Fig. Part of the electron micrographs, FIG. 4 is an iso-illuminance curve (iso-illuminance curve) when the ring fluorescent lamp L1 in FIG. 1 is turned on.

[0053] In addition, in the drawings, the film thickness and coating form of each film etc. are partially exaggerated for the convenience of explanation, and the dimensional ratio and the like of other constituent members are not the same as the actual ones.

[0054] In the illustrated annular fluorescent lamp L1, 1 is an annular glass bulb formed by bending a cylindrical glass tube such as soda lime glass or lead glass, 2 and 2 are mounts, and 11 11 is a sealing portion for sealing the socket 2 formed on the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com