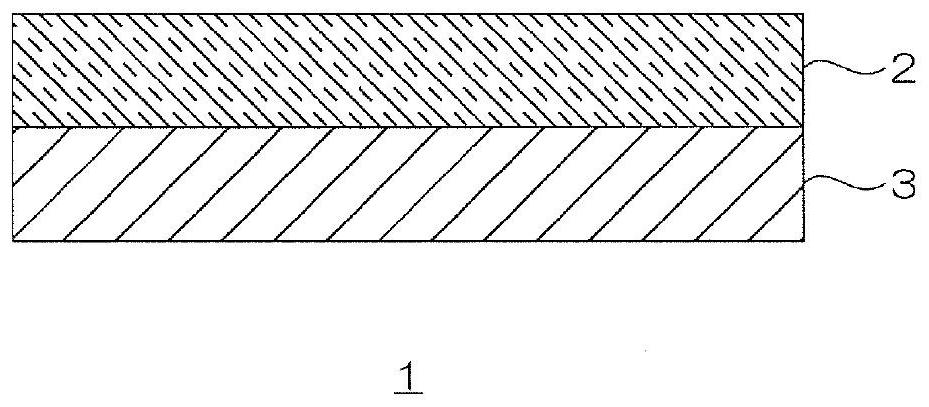

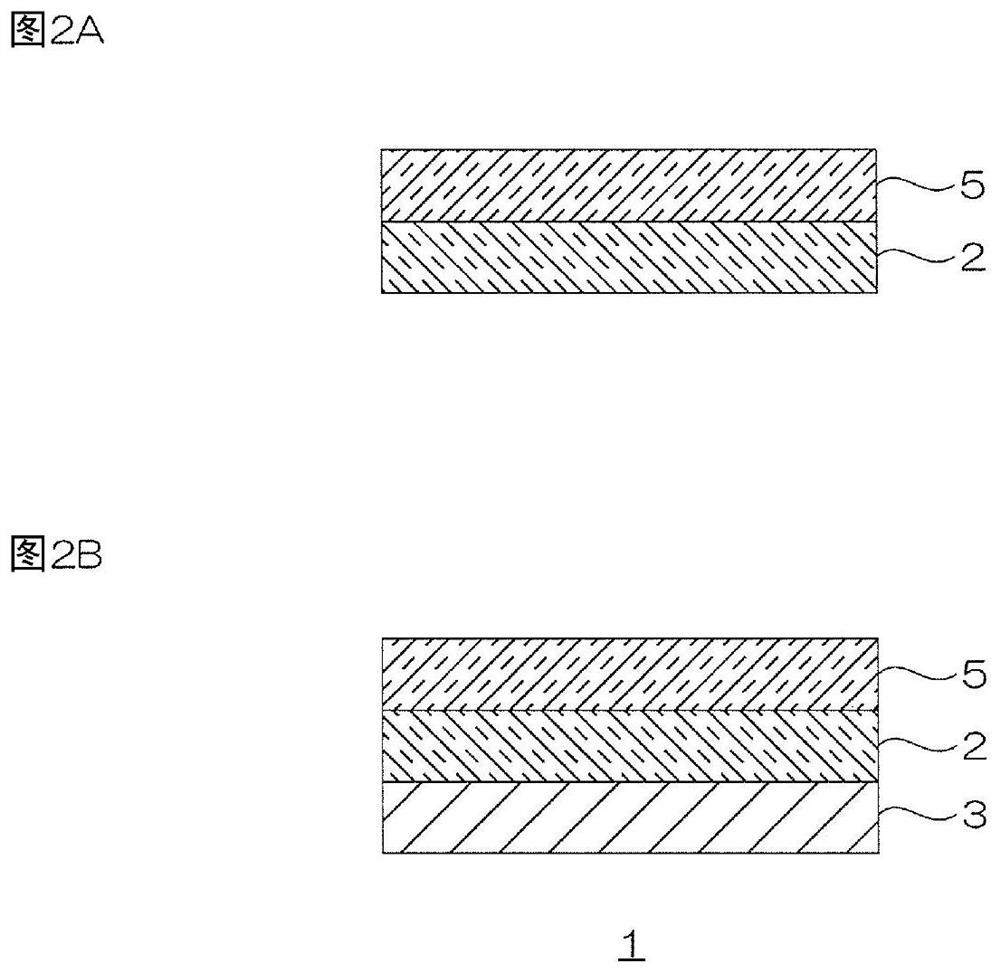

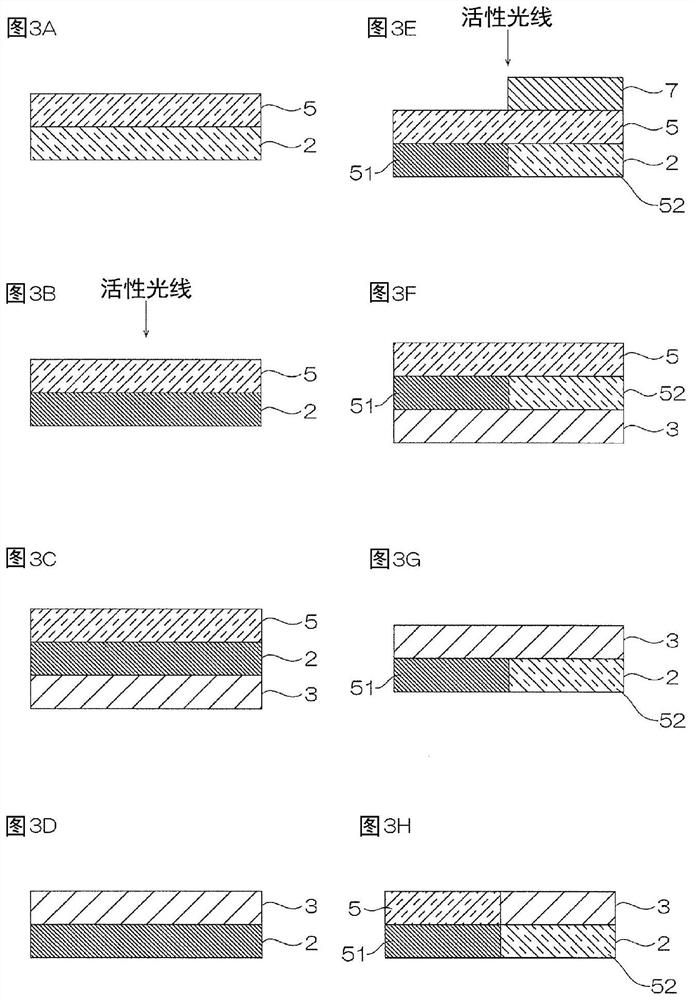

Adhesive sheet, production method for adhesive sheet, production method for intermediate laminate, and intermediate laminate

A manufacturing method and adhesive layer technology, applied in chemical instruments and methods, synthetic resin layered products, film/sheet adhesives, etc., and can solve the problems of external light reflection, reflective glare, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0436] Examples and comparative examples are shown below, and the present invention will be described in more detail. In addition, this invention is not limited to any Example and comparative example. In addition, specific numerical values such as compounding ratios (content ratios), physical properties, and parameters used in the following descriptions may be replaced with their corresponding compounding ratios (content ratios), The upper limit value (value defined in the form of "below" or "less than") or the lower limit value (value defined in the form of "above" or "exceed") of physical property values, parameters, etc.

[0437] In addition, "part" and "%" are mass standards unless otherwise indicated.

[0438] 1. Details of ingredients

[0439] Each component used in each Example and each comparative example is described below.

[0440] BA: butyl acrylate

[0441] AA: Acrylic

[0442] TETRAD C: Trade name: 1,3-bis(N,N-diglycidylaminomethyl)cyclohexane (epoxy crossl...

Synthetic example 1

[0455] 95 parts by mass of butyl acrylate, 5 parts by mass of acrylic acid, 0.2 parts by mass of azobisisobutyronitrile as a polymerization initiator, and 233 parts by mass of ethyl acetate as a solvent was passed through nitrogen gas, and nitrogen substitution was performed for about 1 hour while stirring. Then, it heated to 60 degreeC, and it was made to react for 7 hours, and the solution of the adhesive polymer whose weight average molecular weight (Mw) was 600000 was obtained.

[0456] 3. Manufacture of adhesive sheet

Embodiment 1

[0458] To the solution of the adhesive polymer of Synthesis Example 1, 0.075 parts by mass of TETRAD C as a crosslinking agent was added to 100 parts by mass of the adhesive polymer in the solution of the adhesive polymer. 100 parts by mass of the adhesive polymer in the solution of the adhesive polymer is 2 parts by mass of BLACK ND1 (leuco dye), which is a compound colored by acid, to the adhesiveness in the solution of the adhesive polymer. CP-310B (photoacid generator) as an acid generator was uniformly mixed with 100 parts by mass of a permanent polymer and 10 parts by mass to prepare an adhesive composition.

[0459] Next, on one side of a polyethylene terephthalate film with a thickness of 50 μm (hereinafter referred to as release film A) that has undergone surface release treatment, the thickness after drying is 25 μm. The adhesive composition of Synthesis Example 1 was clothed and dried at 130° C. for 1 minute to remove the solvent. Thereby, the pressure-sensitive ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com