A charging and discharging method and device based on Xe gas

A technology of filling and exhausting xenon, applied in the field of electric light sources, can solve the problems that threaten xenon lamp manufacturers' production cost product market competitiveness, waste of xenon, and high price, so as to reduce product cost, improve recycling rate, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

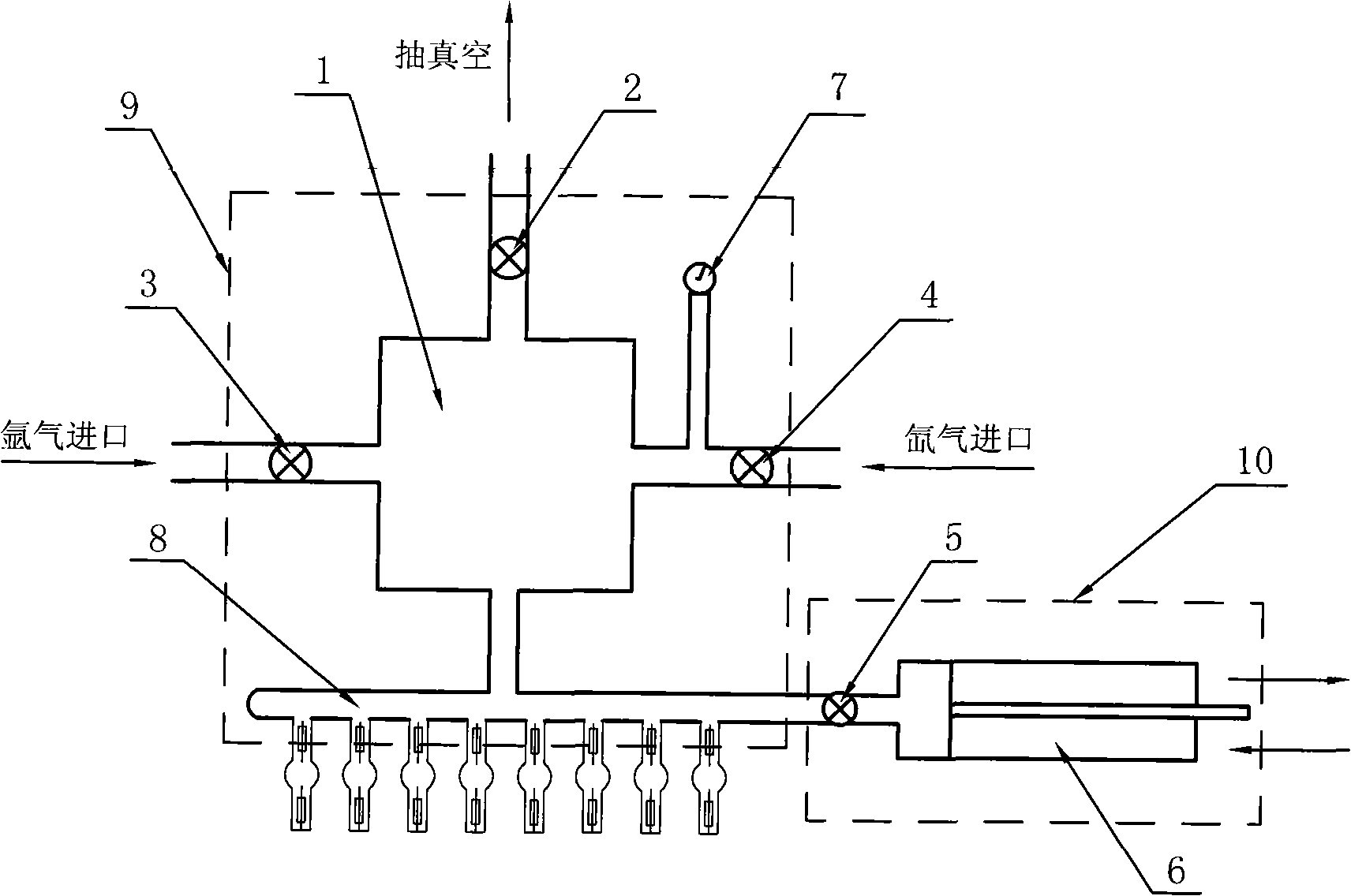

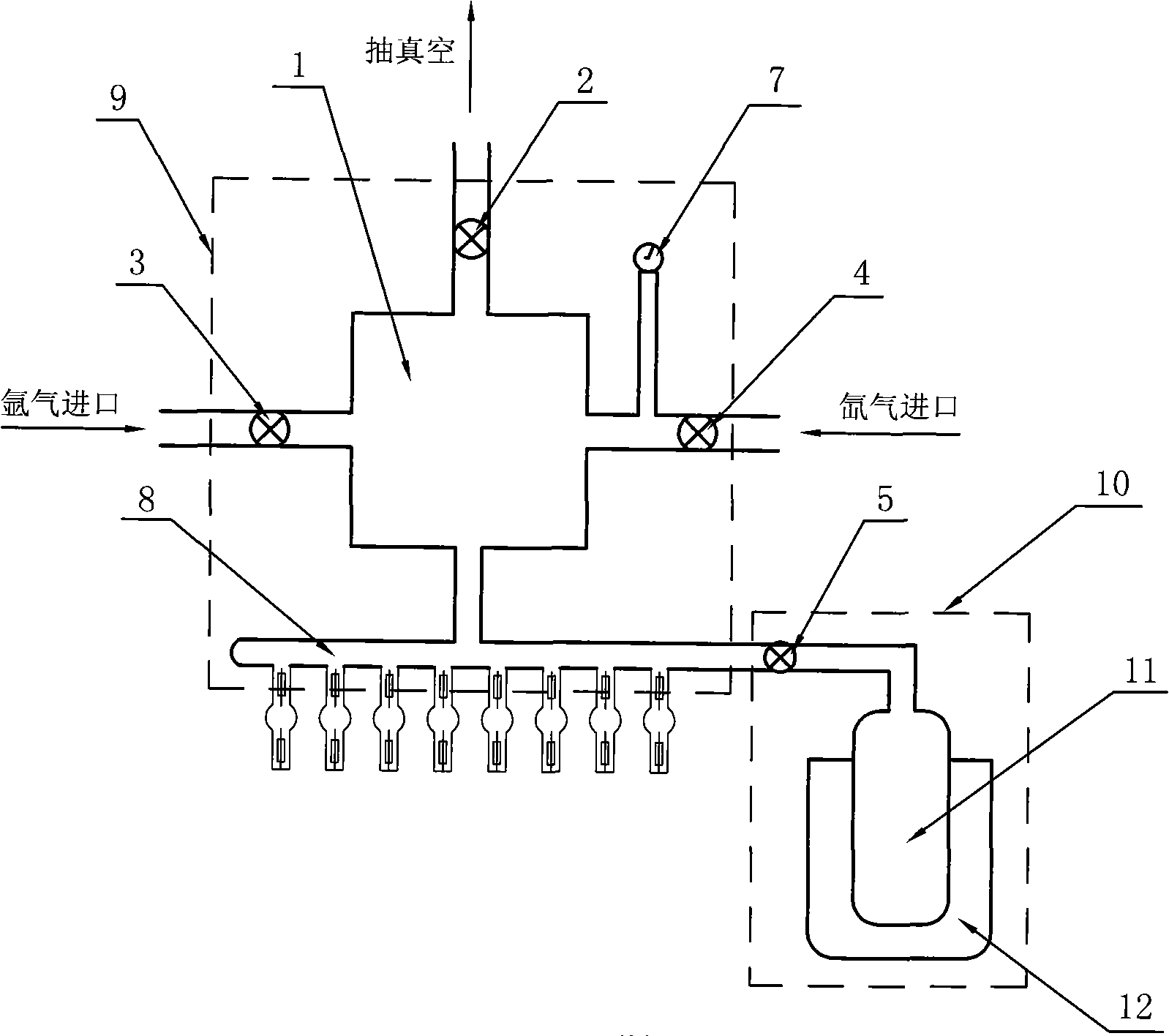

[0014] Such as figure 1 As shown, the device of the present invention is composed of an inflation and exhaust system 9 and a recovery system 10 that can collect residual xenon gas. The inflation and exhaust system 9 is composed of four-way connector 1, arc tube arrangement pipe 8, pressure gauge 7 and electromagnetic valves 2, 3, 4. The pressure gauge 7 can display the vacuum degree in the inflation and exhaust system and the pressure of the inflated gas . The electromagnetic valve 2 is connected with the vacuum pump, the electromagnetic valve 3 is connected with the argon gas inlet, the electromagnetic valve 4 is connected with the xenon gas inlet, and eight arc tubes to be inflated can be placed on the arc tube arrangement pipeline 8 at the same time. The recovery system 10 is arranged at the tail end of the arc tube arrangement pipeline 8 and is composed of a cylinder 6 and an electromagnetic valve 5 , and the electromagnetic valve 5 is arranged between the arc tube arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com