Patents

Literature

368results about "Tube/lamp vessels exhaustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

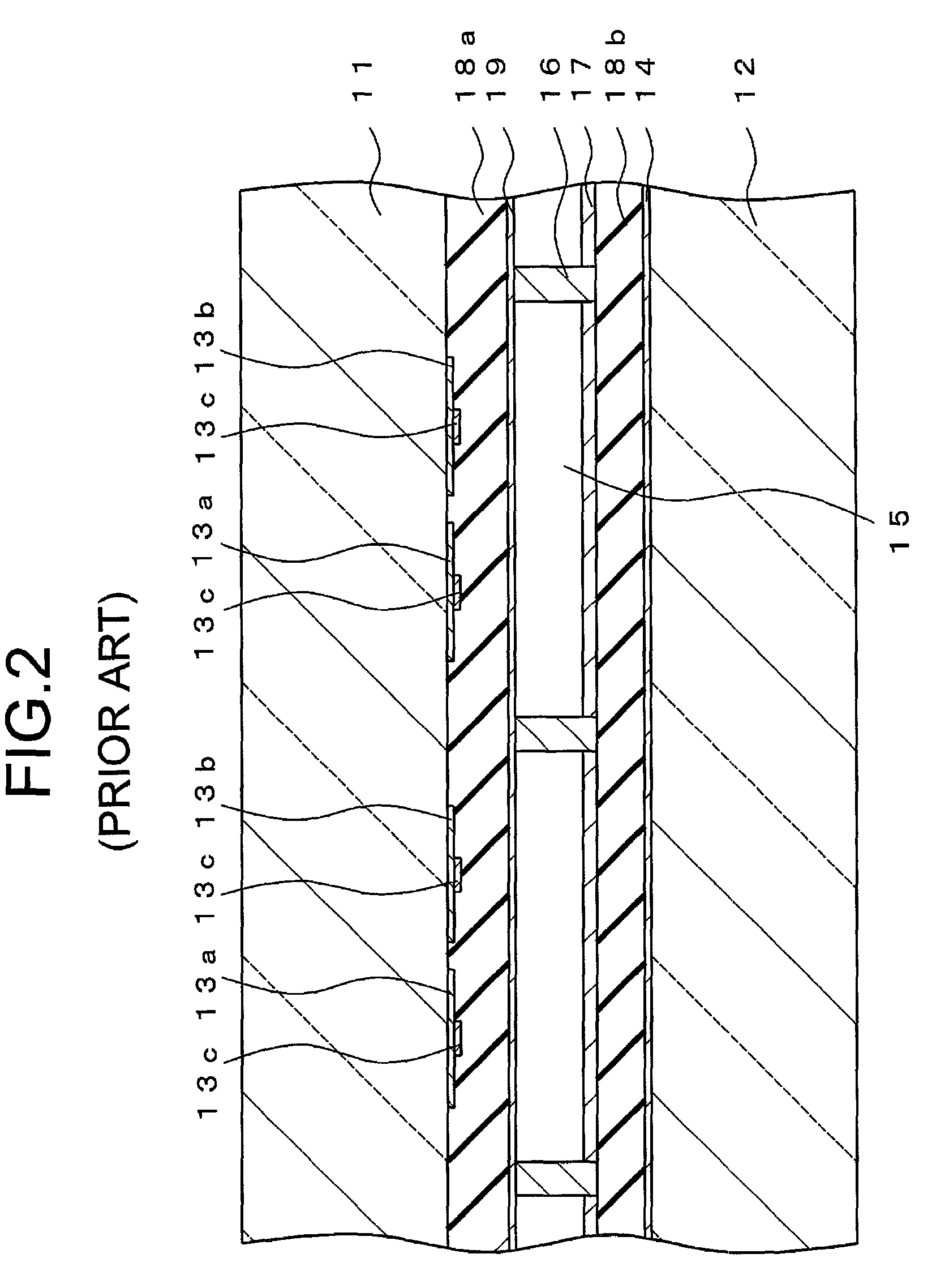

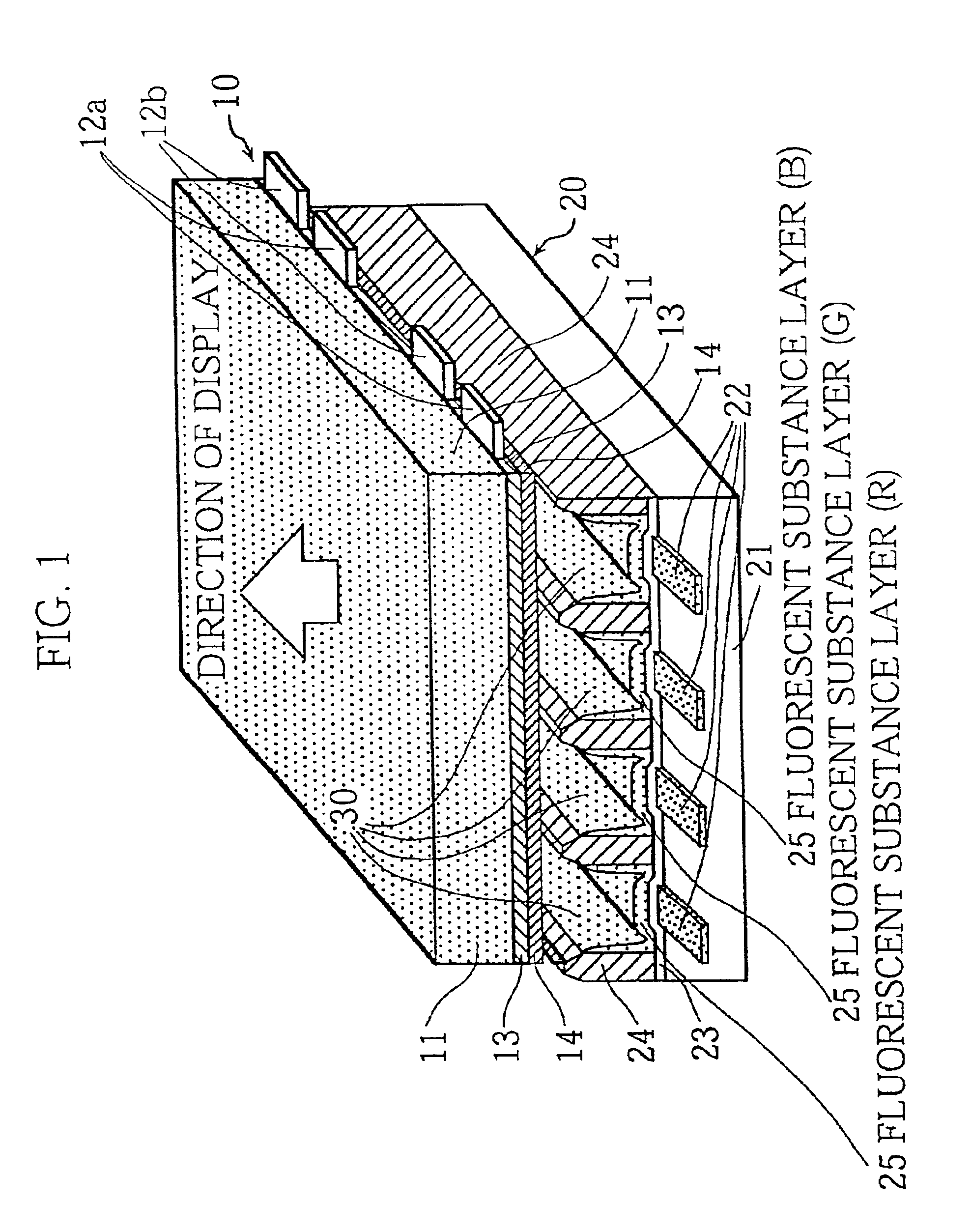

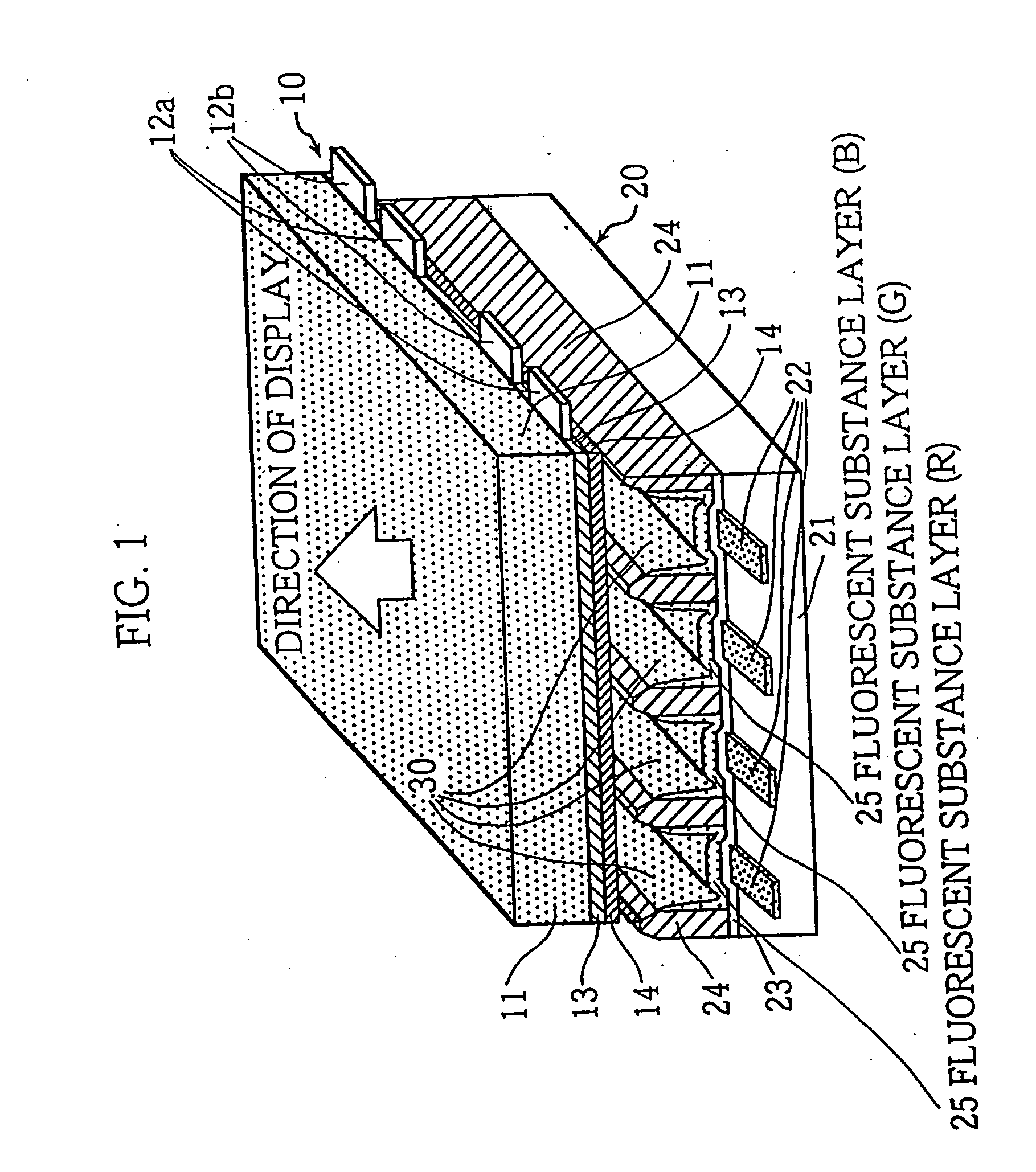

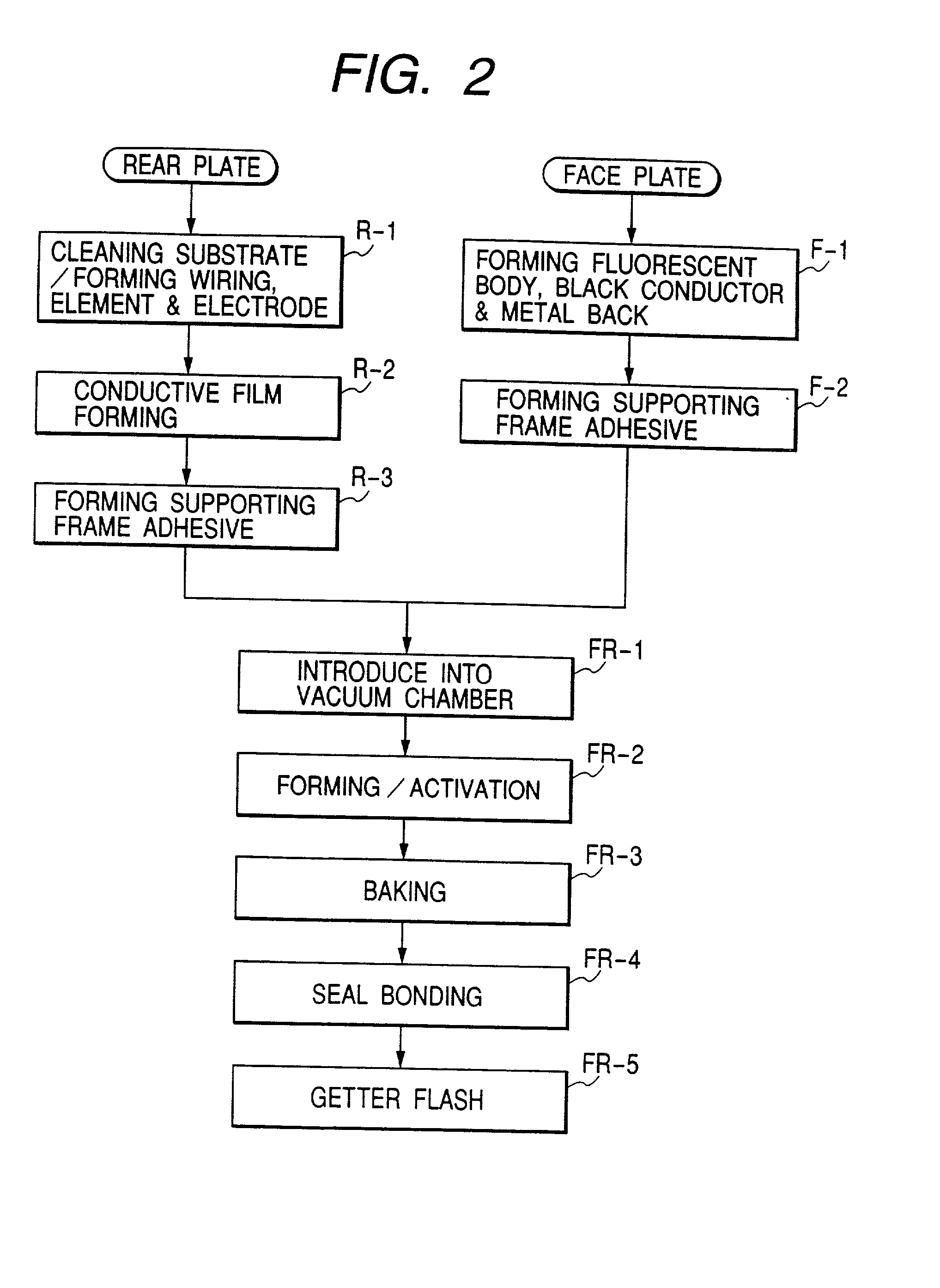

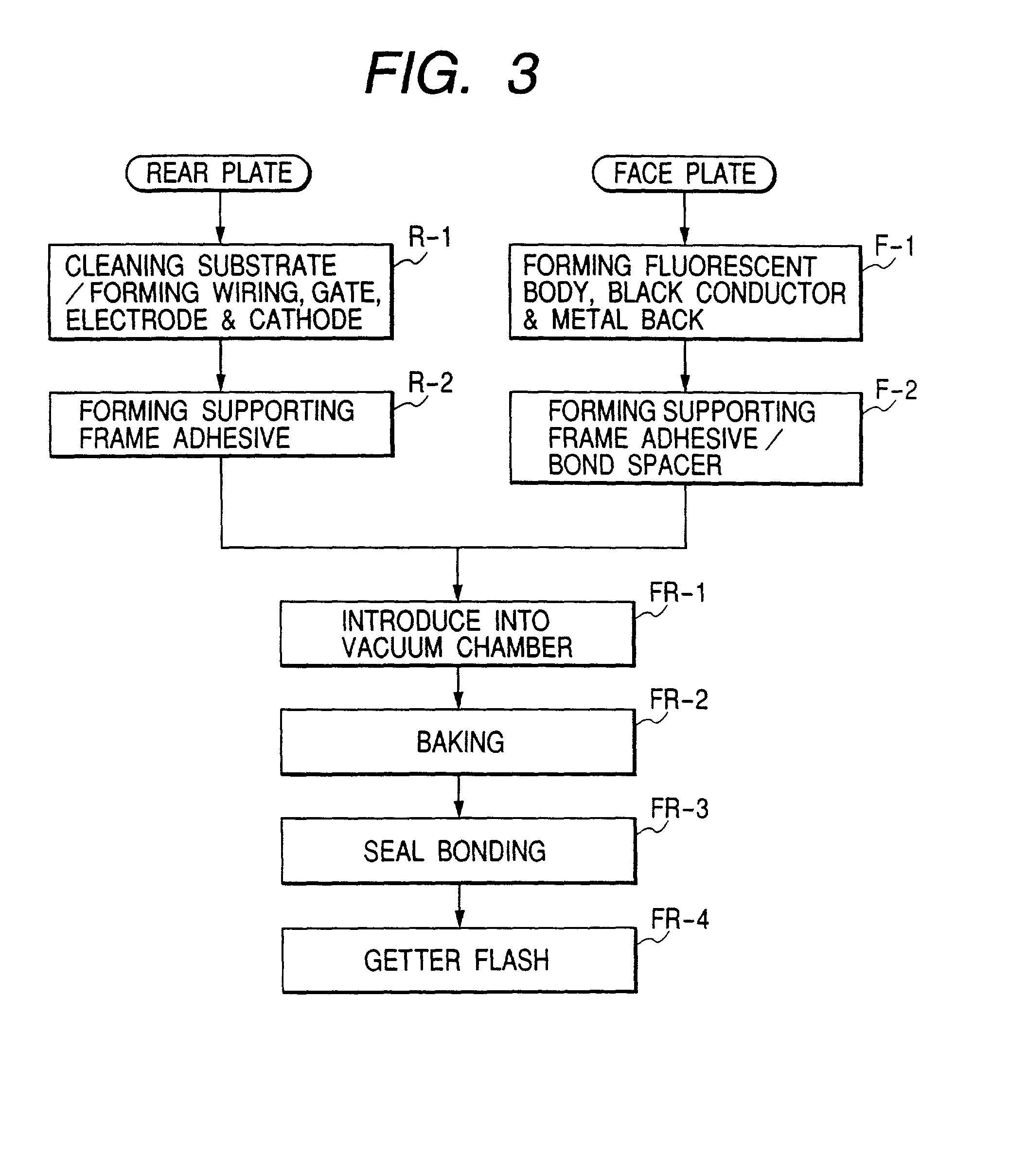

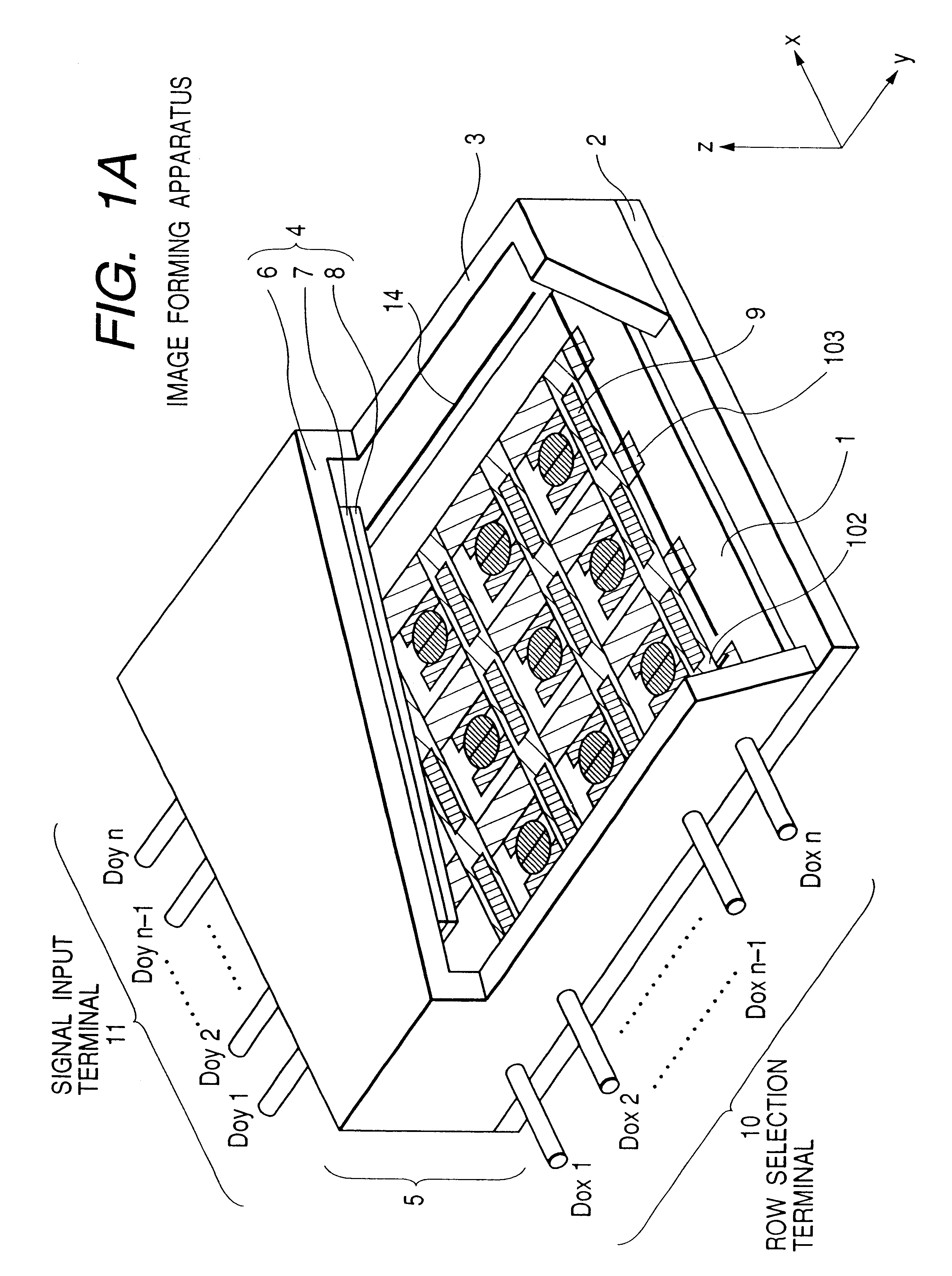

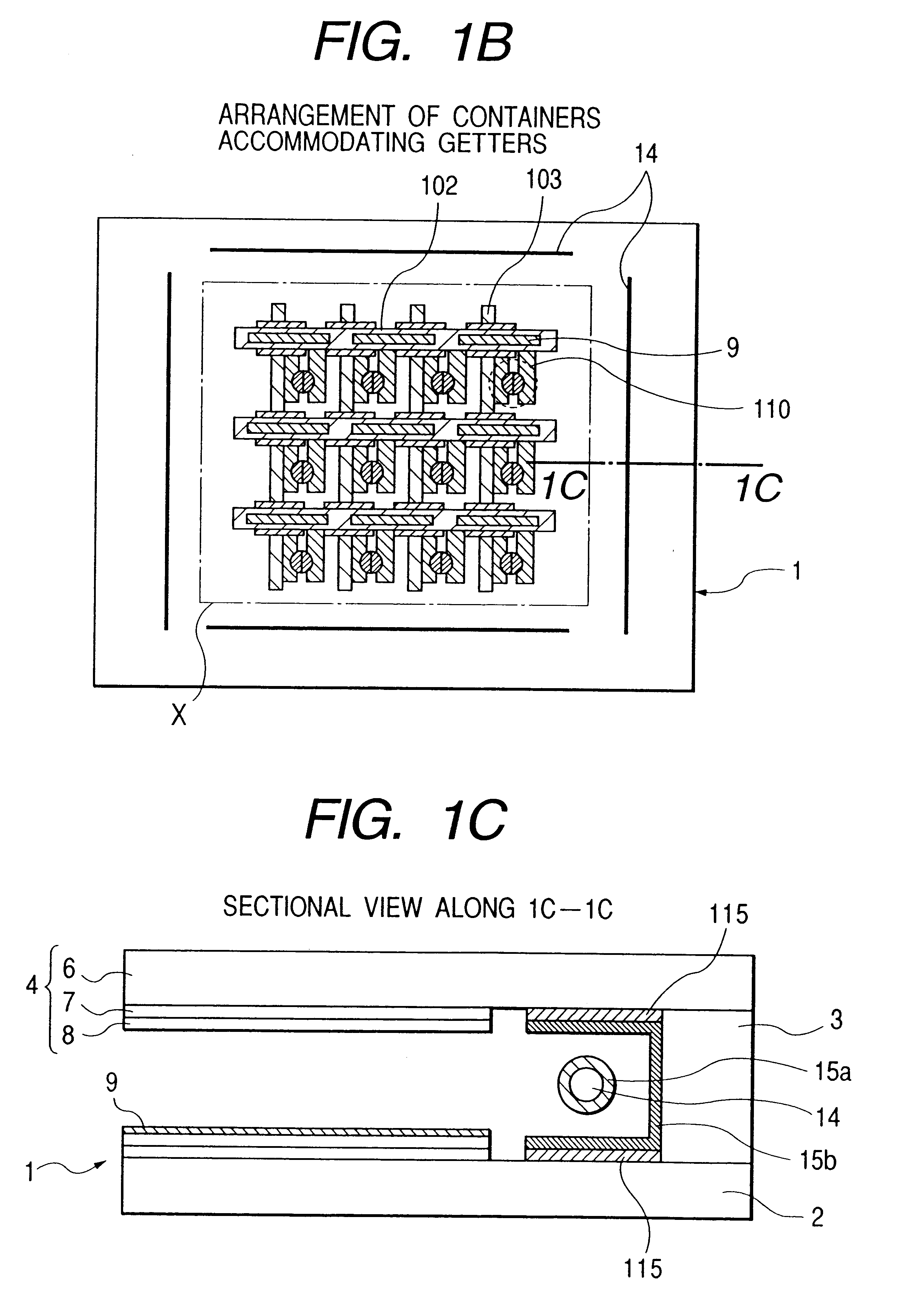

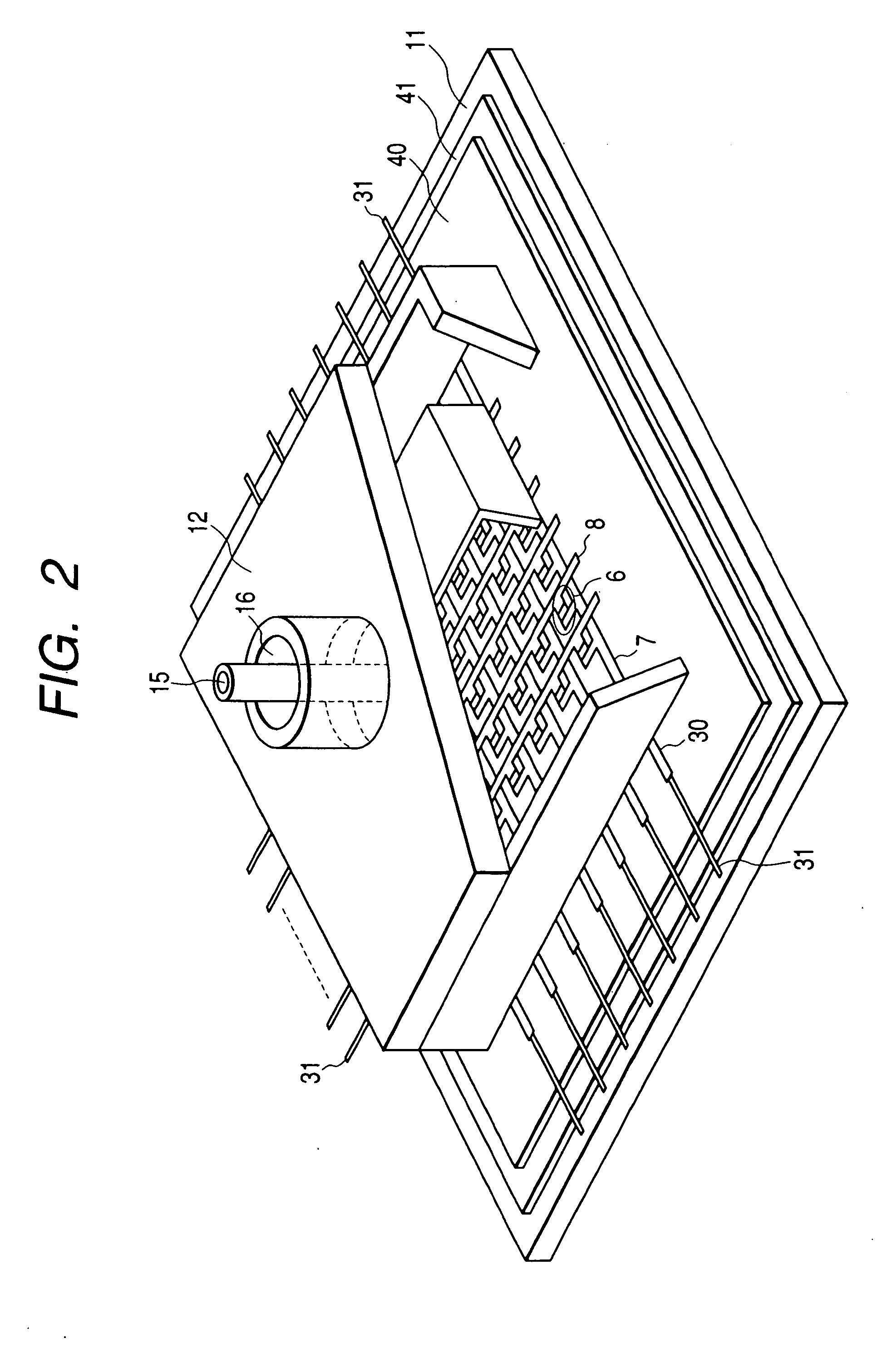

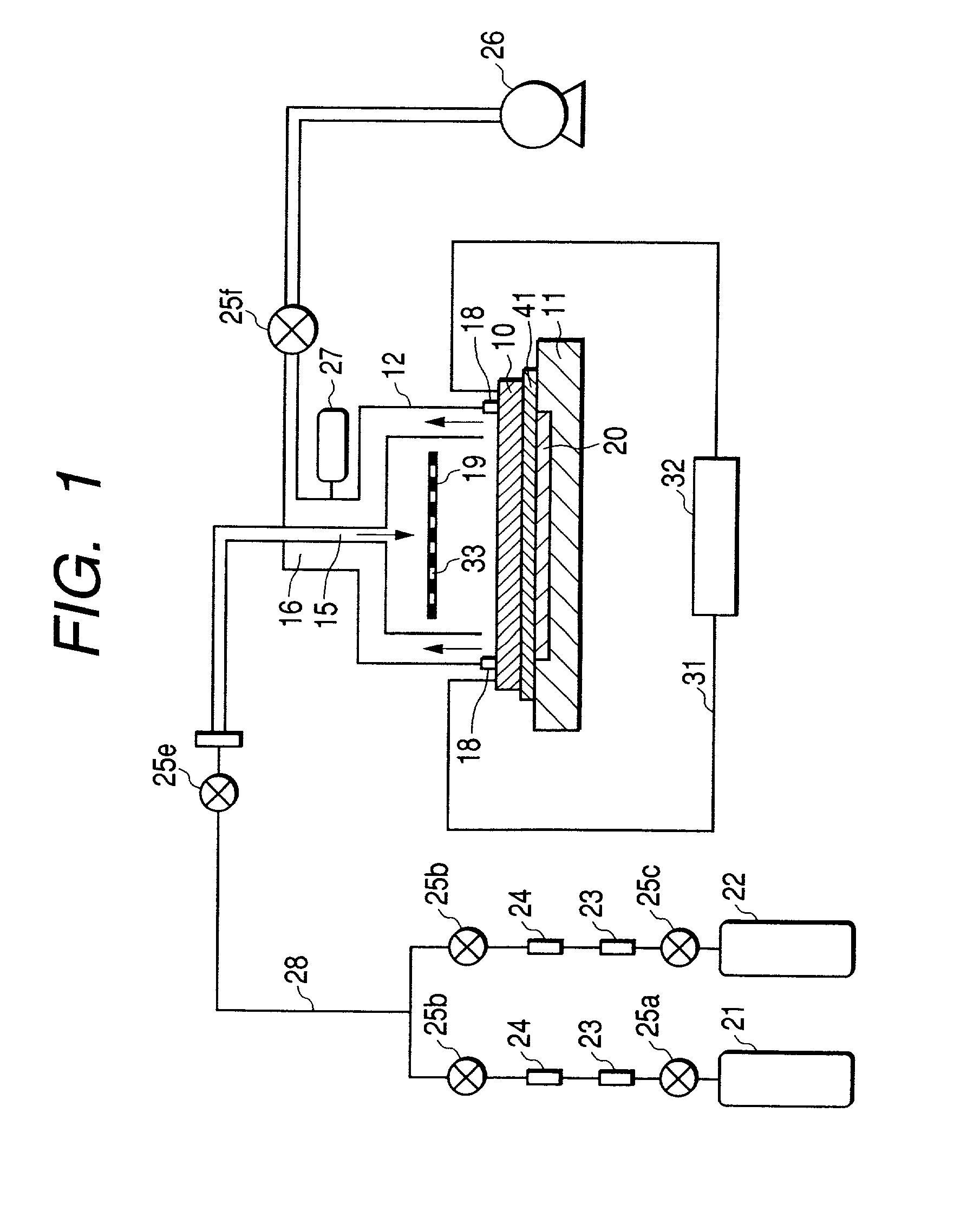

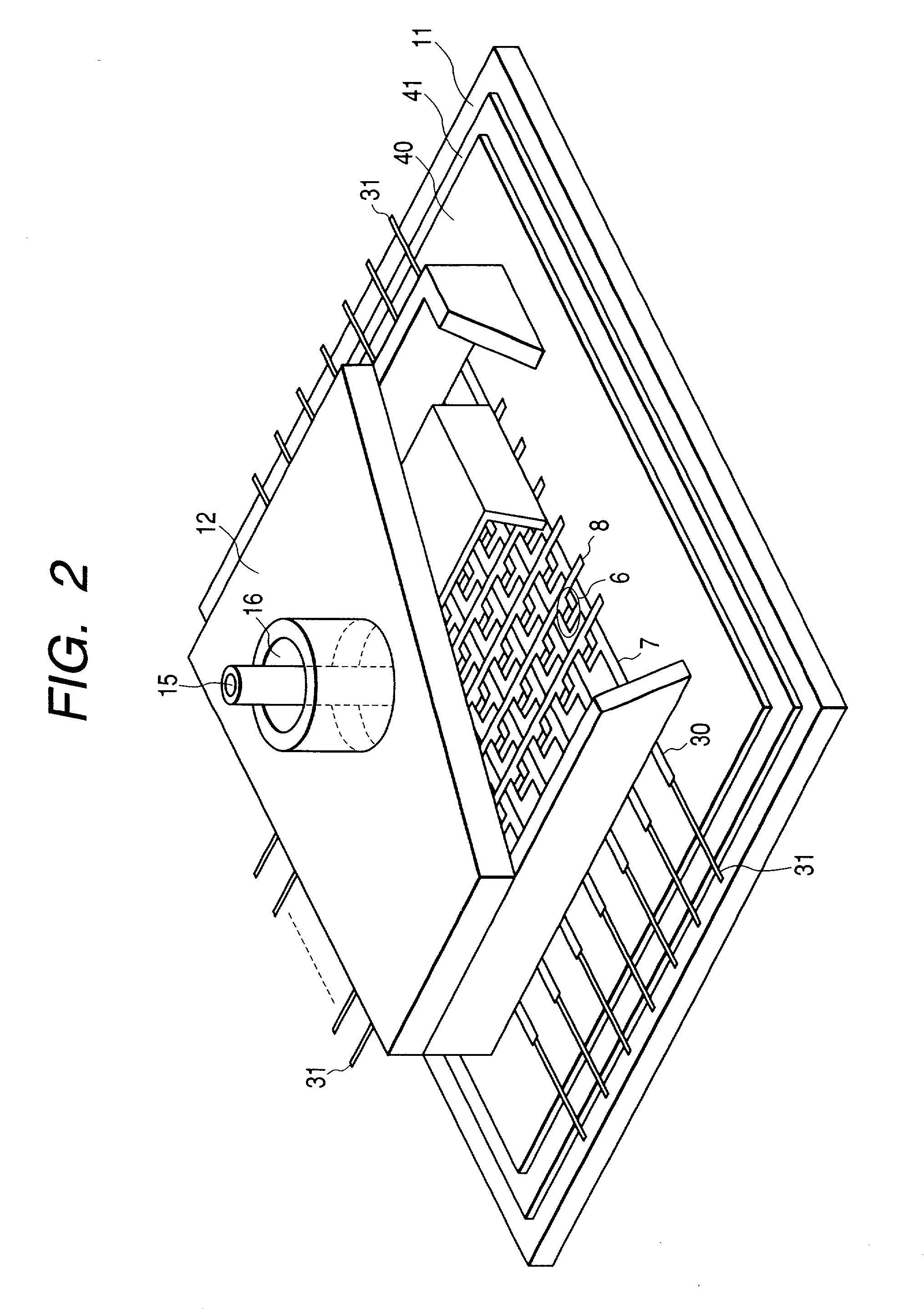

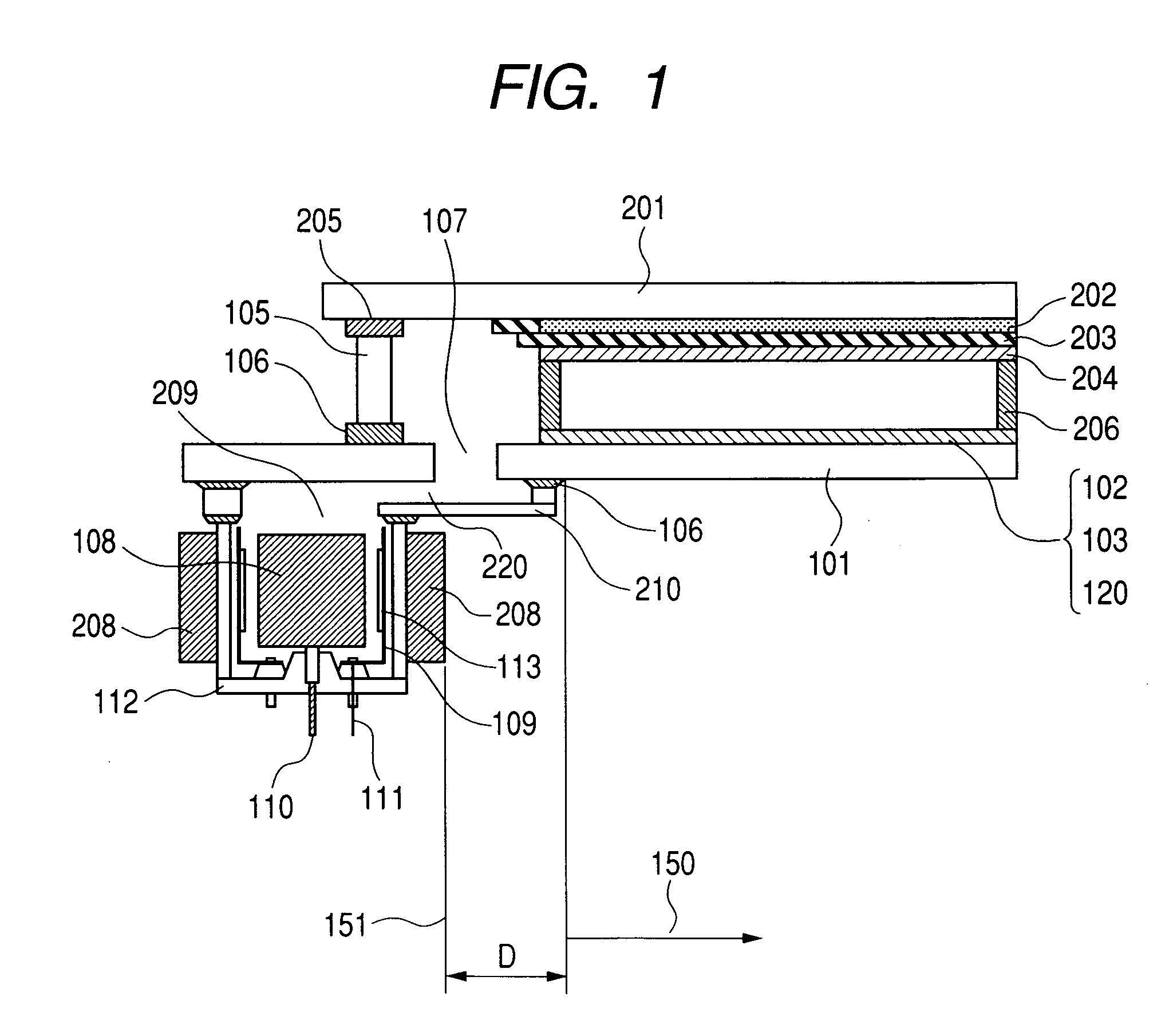

Manufacturing method of image forming apparatus, manufacturing apparatus of image forming apparatus, image forming apparatus, manufacturing method of panel apparatus, and manufacturing apparatus of panel apparatus

InactiveUS6254449B1Tube/lamp vessels exhaustionTube/lamp vessels closingManufactured apparatusImage formation

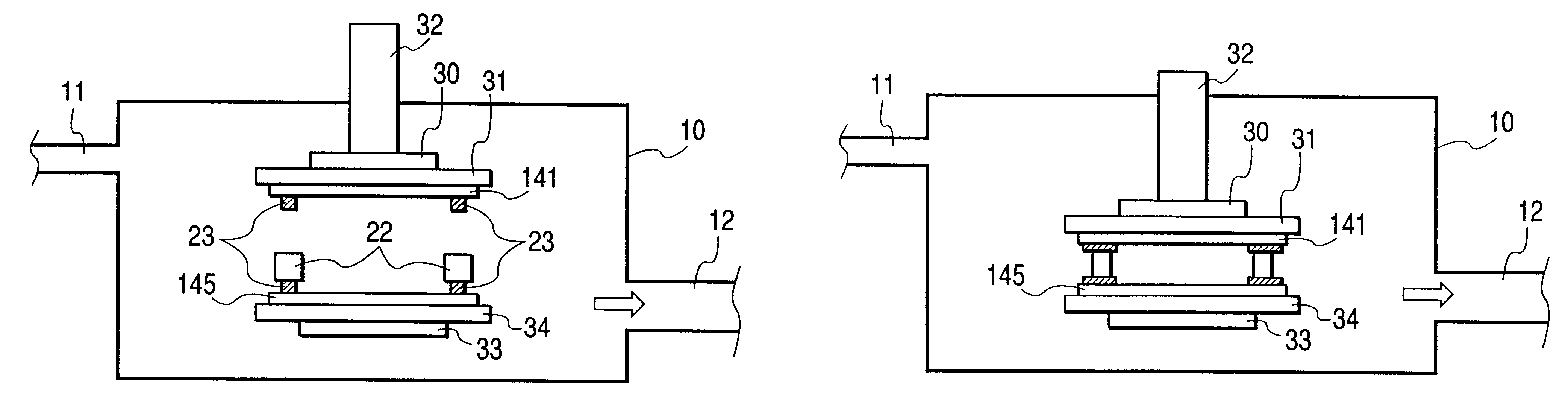

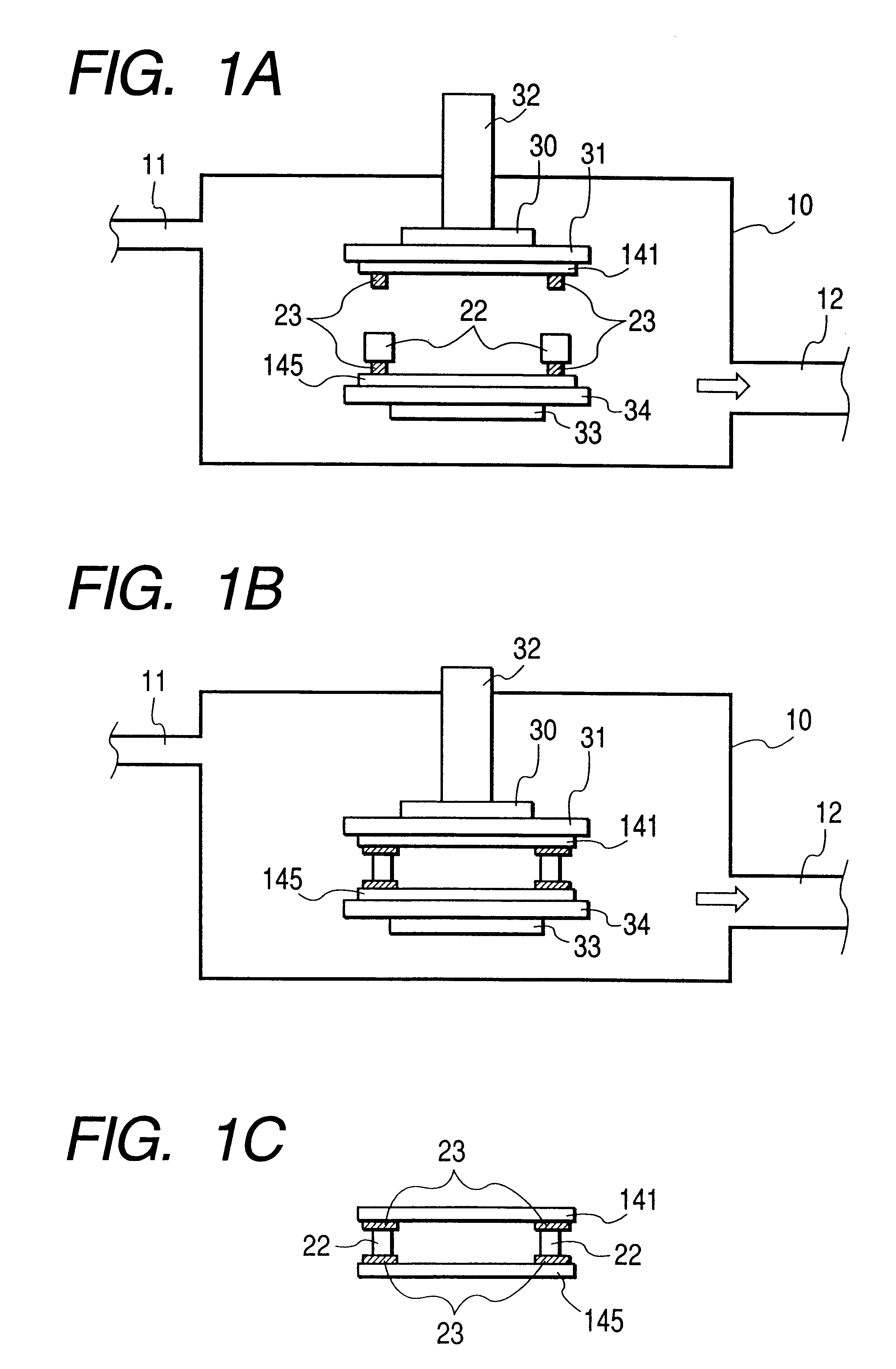

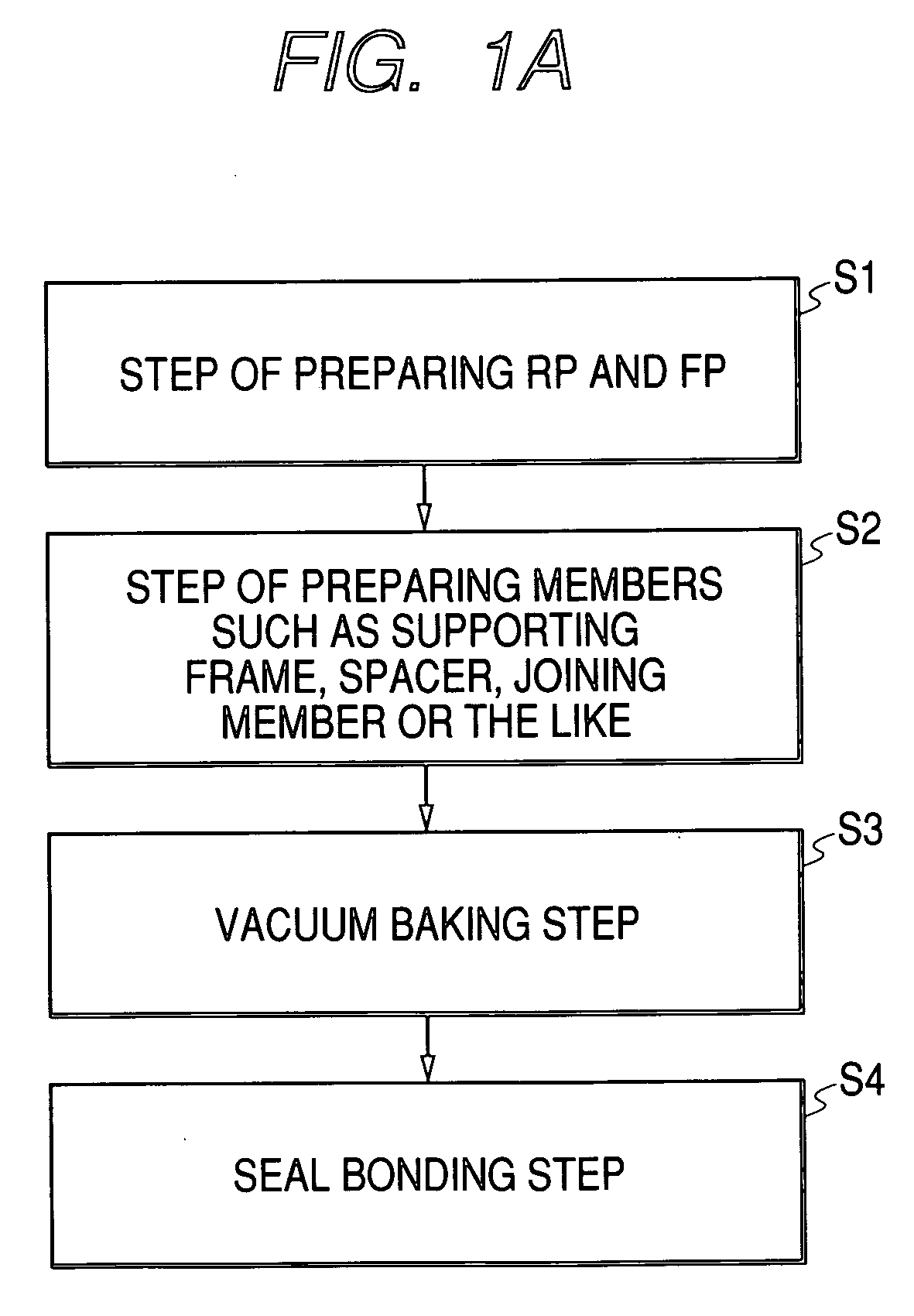

To obtain a stable image forming apparatus of a high quality without a luminance fluctuation and a color mixture due to a positional deviation, the following construction is disclosed. A method of manufacturing an image display apparatus in which a first substrate on which fluorescent body exciting means is arranged and a second substrate on which a fluorescent body that emits light by the fluorescent body exciting means is arranged are arranged so as to face each other and are adhered through joining members at their peripheries, wherein a seal bonding step of adhering the first and second substrates through a joining members and a step of performing a position matching of the first and second substrates are executed in a vacuum.

Owner:CANON KK

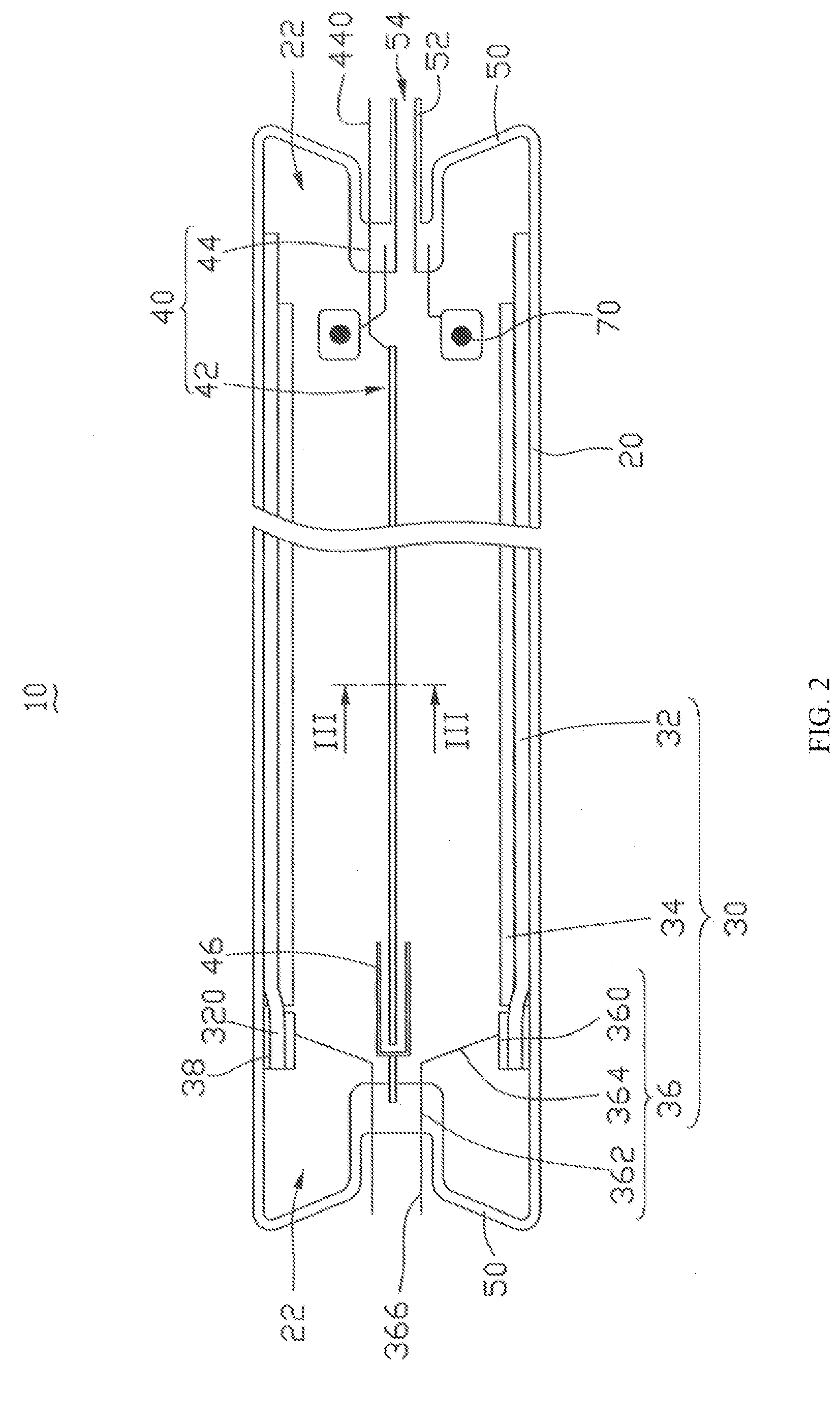

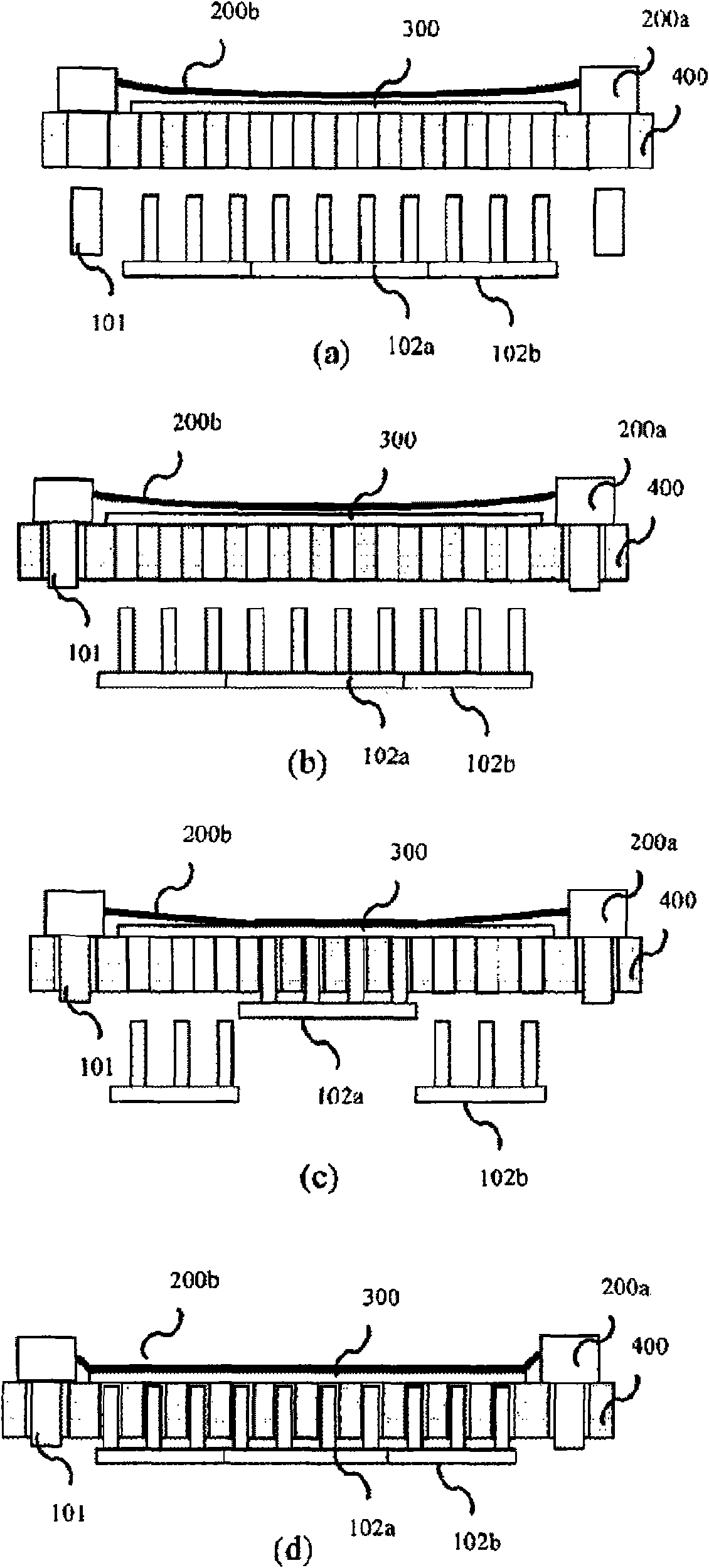

Manufacturing method and manufacturing apparatus of envelope

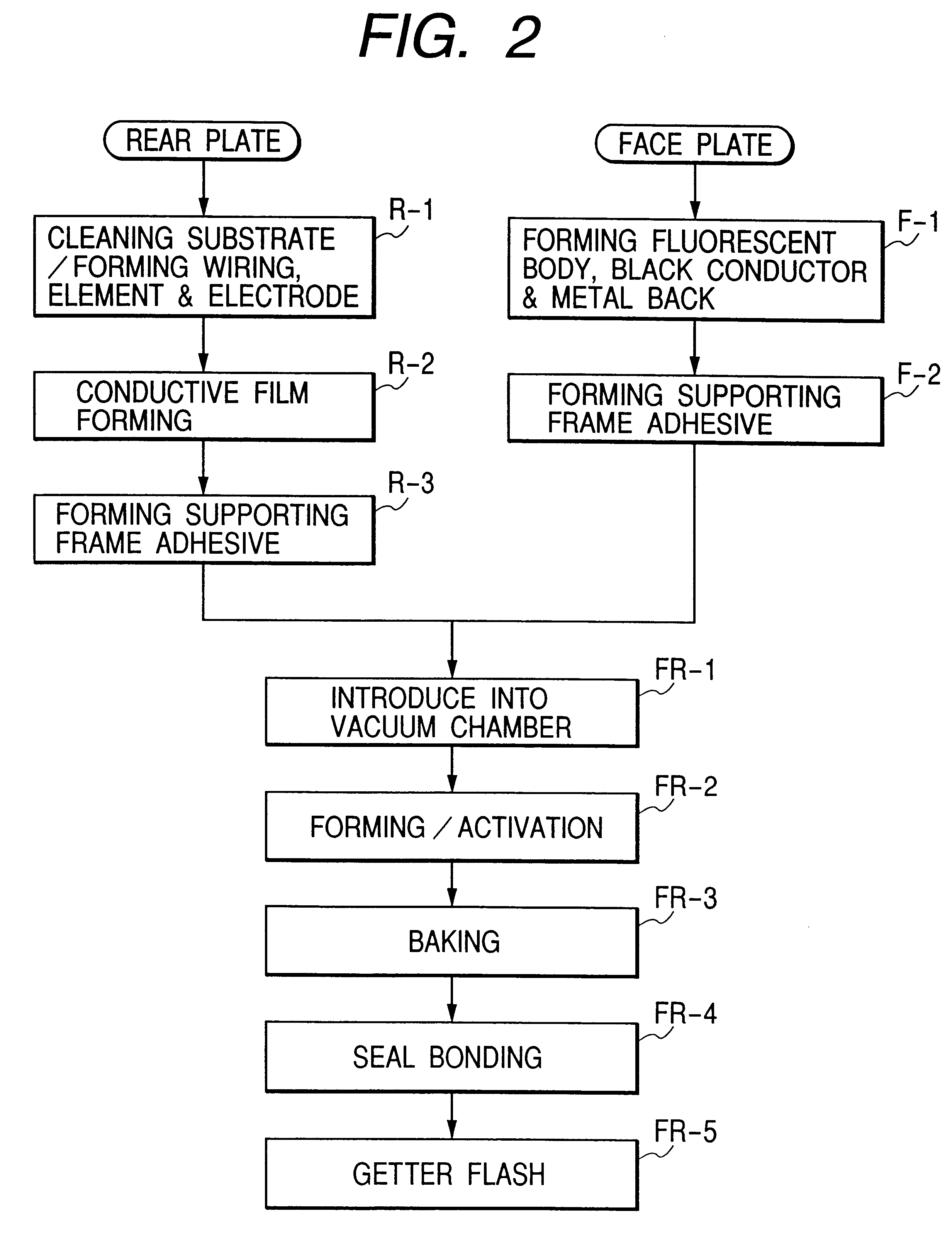

In a manufacturing method of forming a hermetically sealed container by bringing a pair of substrates into intimate contact via a supporting frame between them, one of the substrates is warped in a depressurized atmosphere before getting into intimate contact and is thereby separated from the other substrate so as to evacuate inside of the hermetically sealed container by releasing the depressurized atmosphere therein. Relative positions of the substrates are restored by having the warp undone thereafter. Therefore, it is possible to achieve evacuation inside the hermetically sealed container without causing the relative positions of the substrates to deviate.

Owner:CANON KK

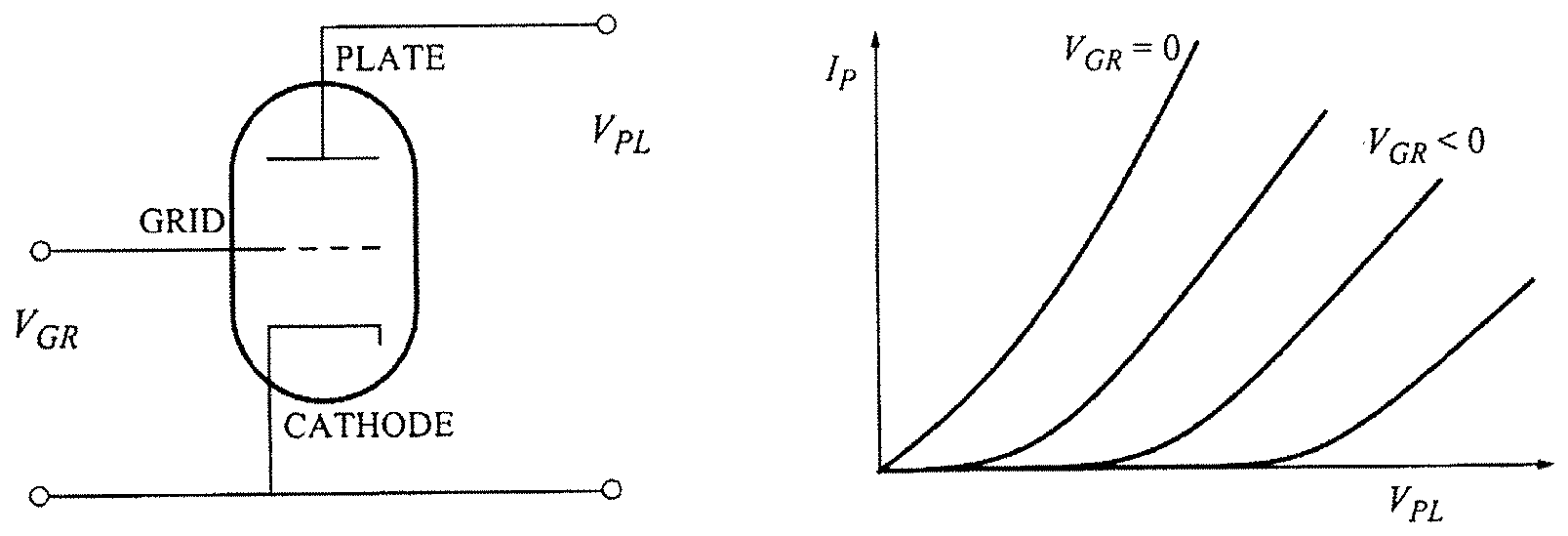

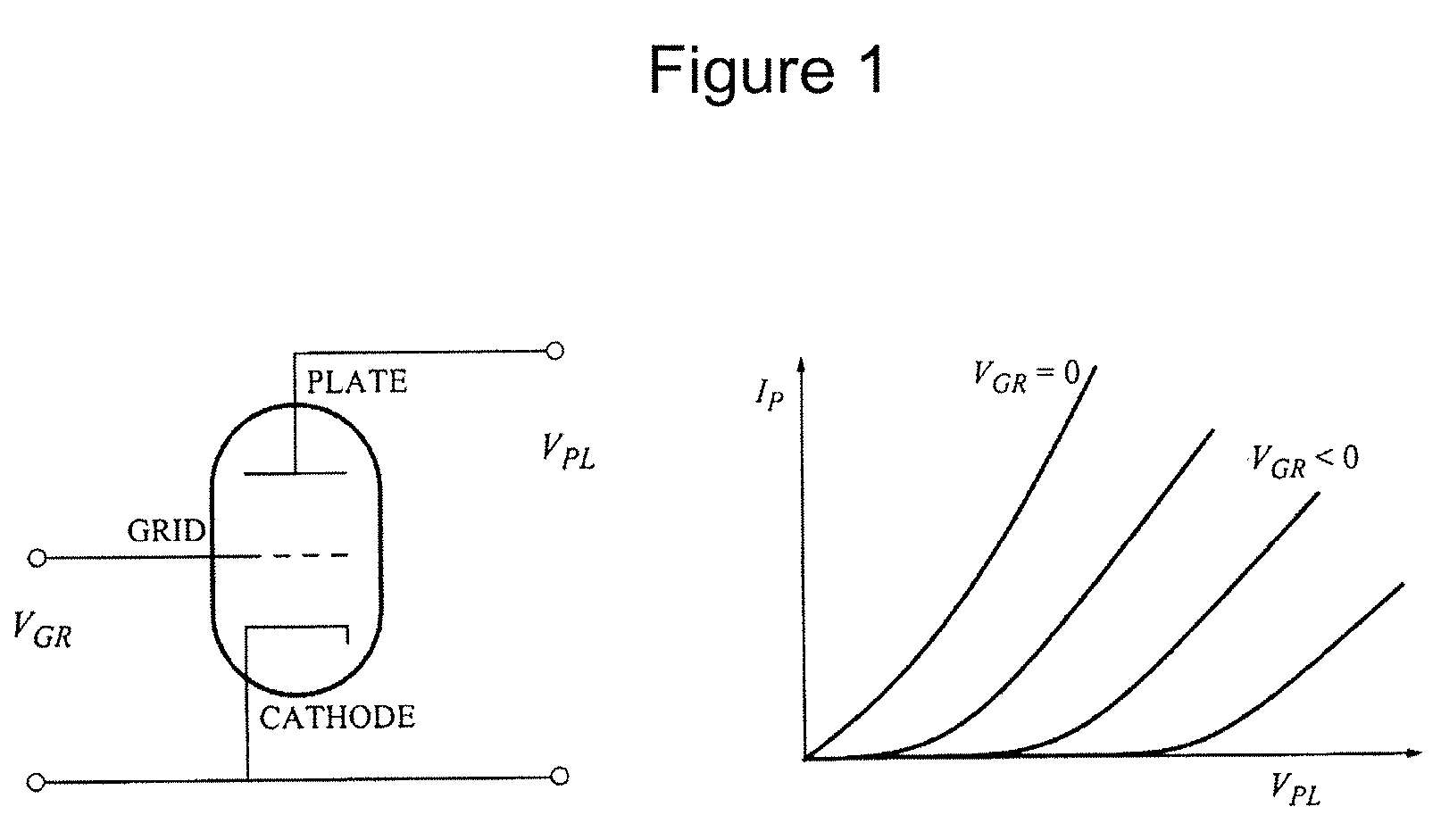

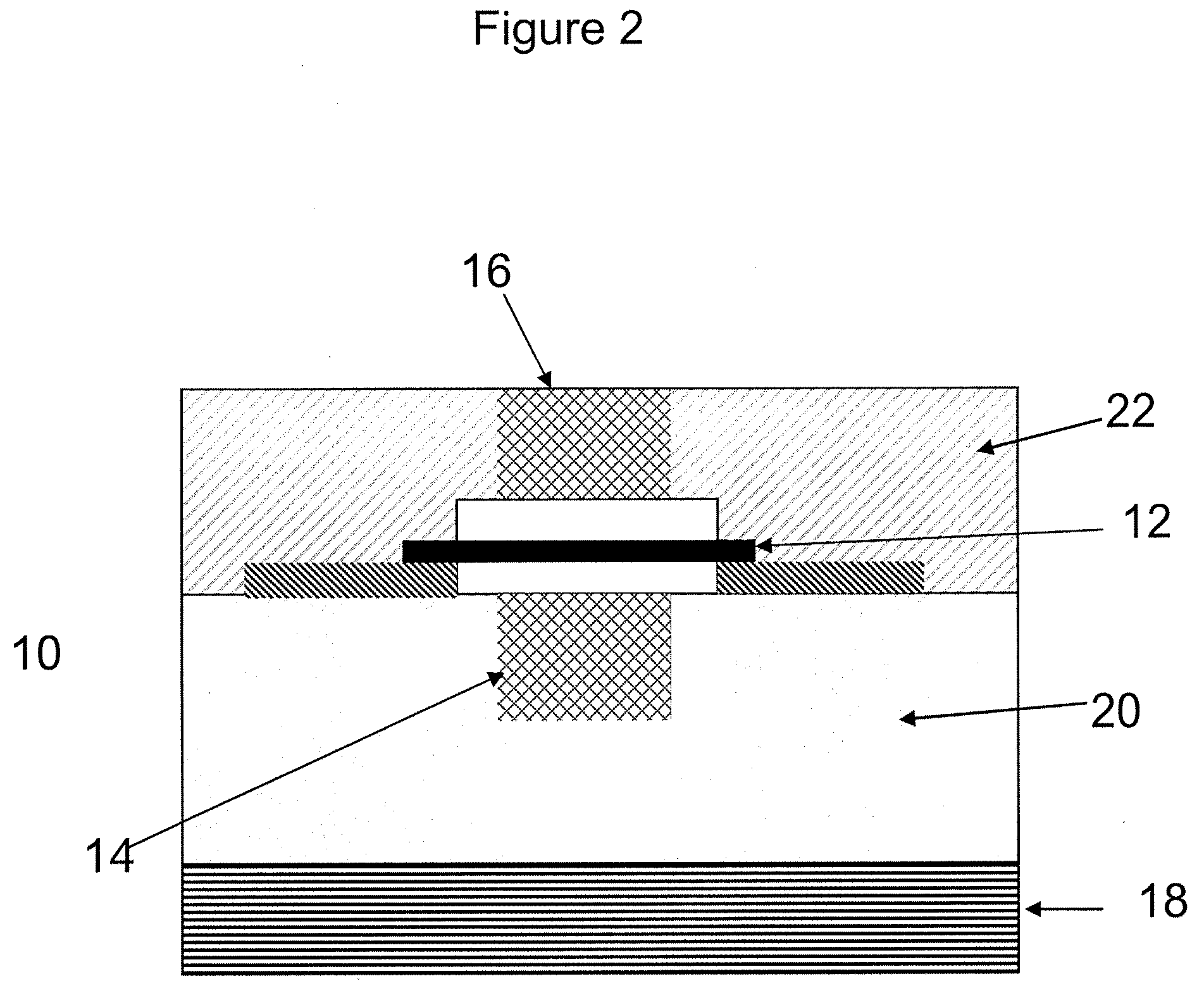

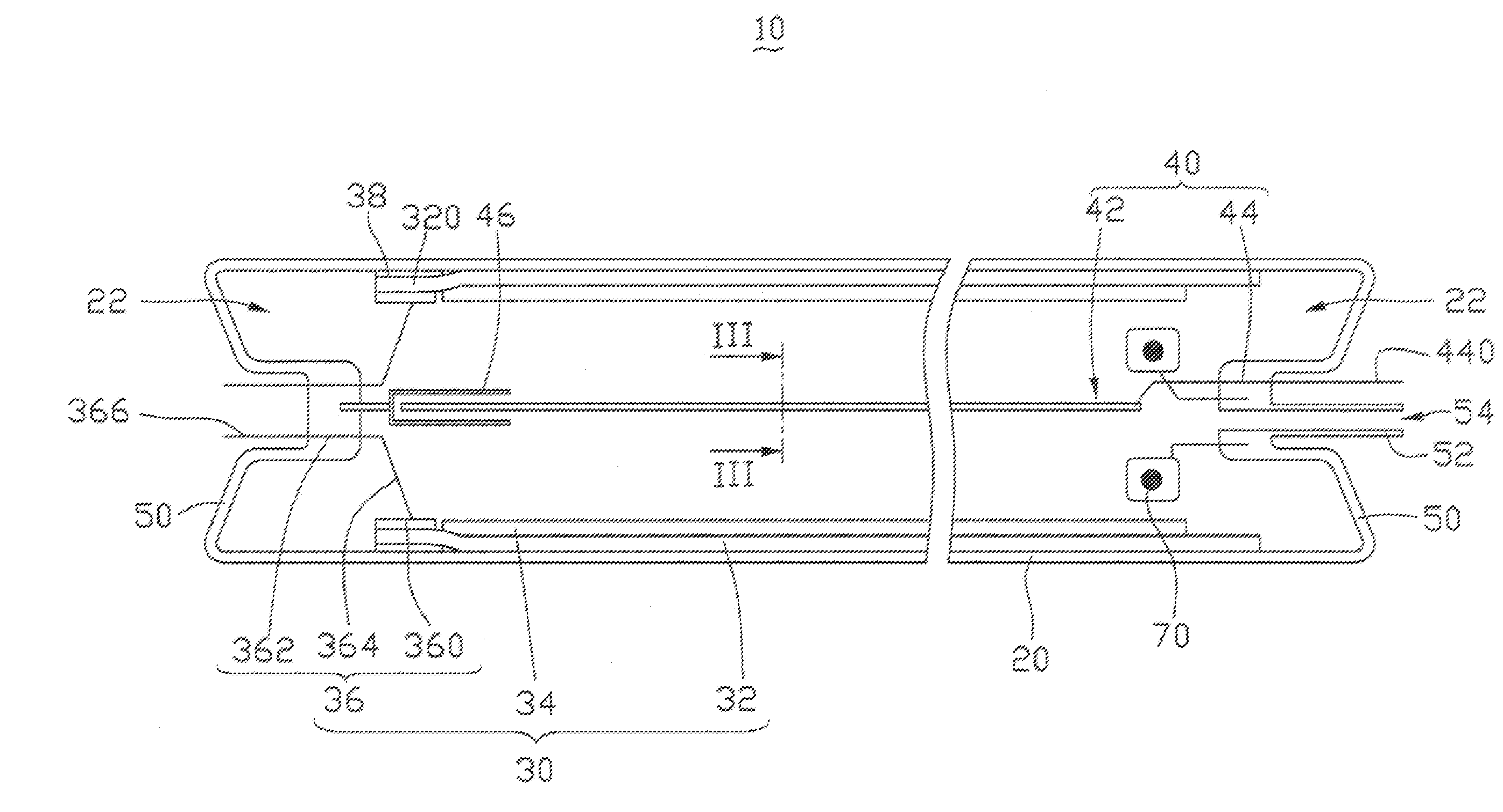

Triodes using nanofabric articles and methods of making the same

Vacuum microelectronic devices with carbon nanotube films, layers, ribbons and fabrics are provided. The present invention discloses microelectronic vacuum devices including triode structures that include three-terminals (an emitter, a grid and an anode), and also higher-order devices such as tetrodes and pentodes, all of which use carbon nanotubes to form various components of the devices. In certain embodiments, patterned portions of nanotube fabric may be used as grid / gate components, conductive traces, etc. Nanotube fabrics may be suspended or conformally disposed. In certain embodiments, methods for stiffening a nanotube fabric layer are used. Various methods for applying, selectively removing (e.g. etching), suspending, and stiffening vertically- and horizontally-disposed nanotube fabrics are disclosed, as are CMOS-compatible fabrication methods. In certain embodiments, nanotube fabric triodes provide high-speed, small-scale, low-power devices that can be employed in radiation-intensive applications.

Owner:NANTERO

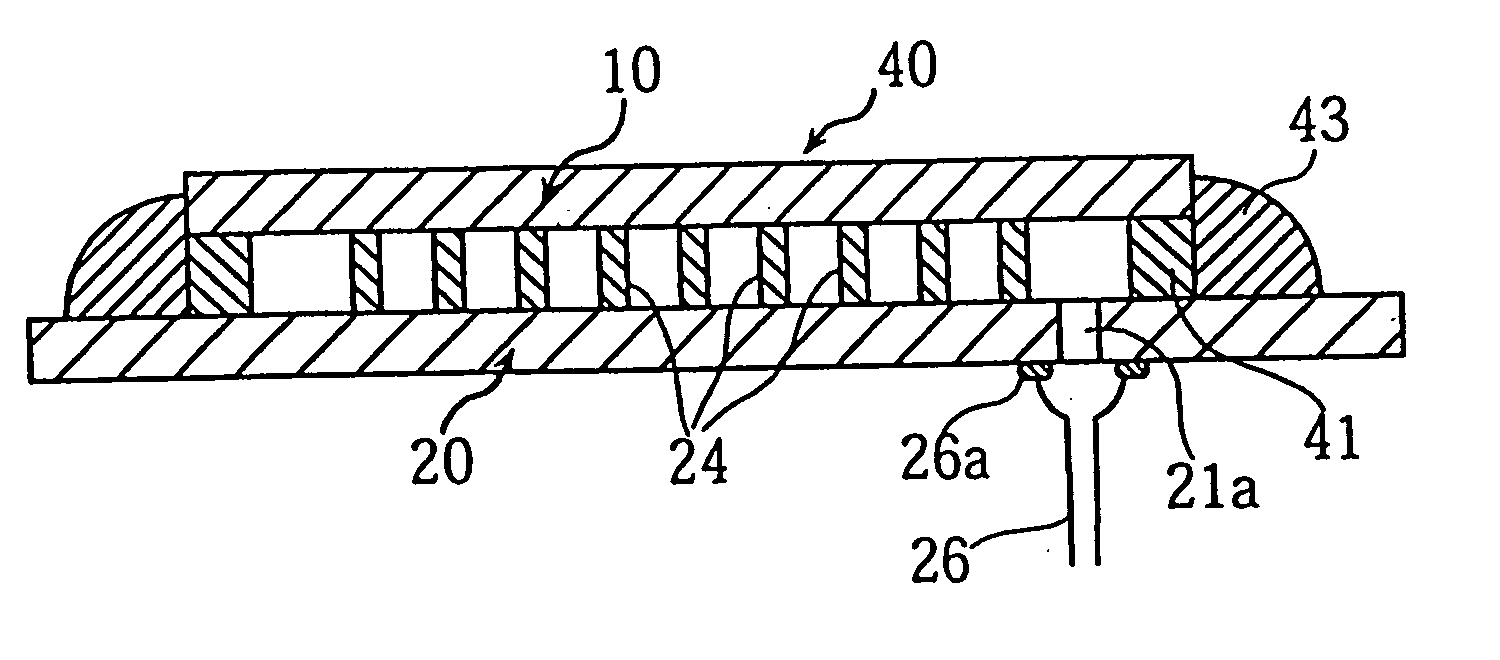

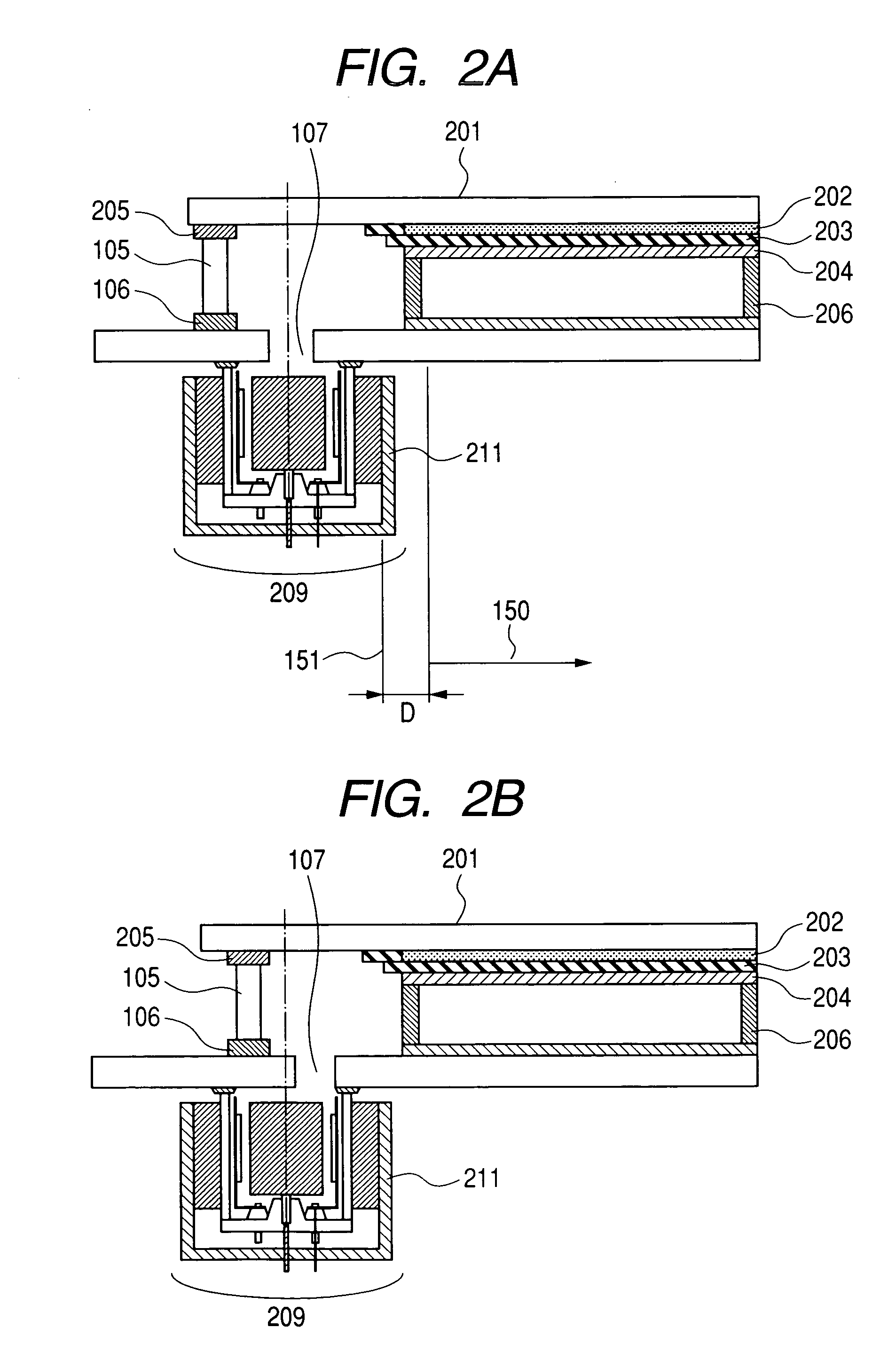

Image-forming apparatus and method of manufacture therefor

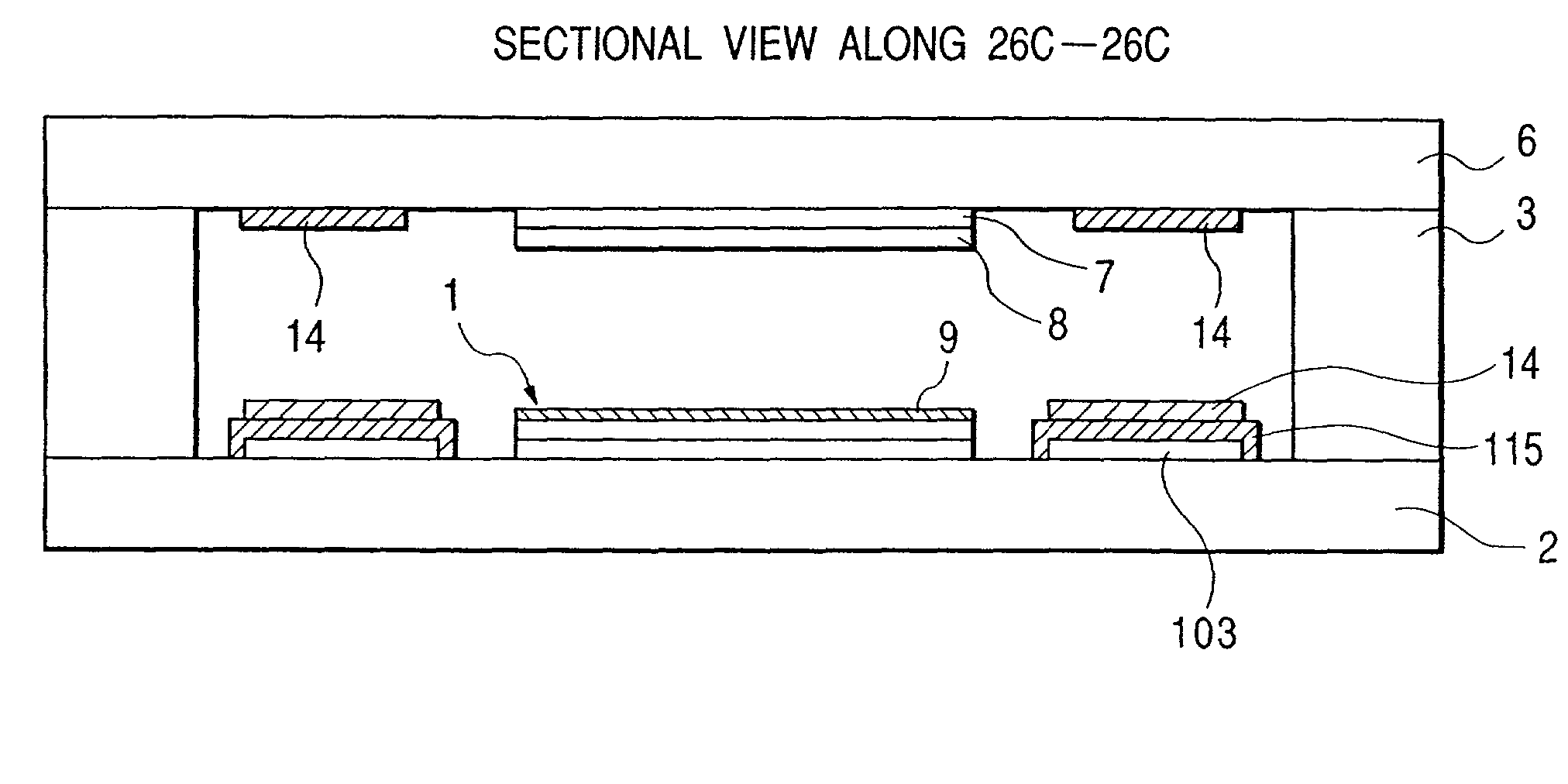

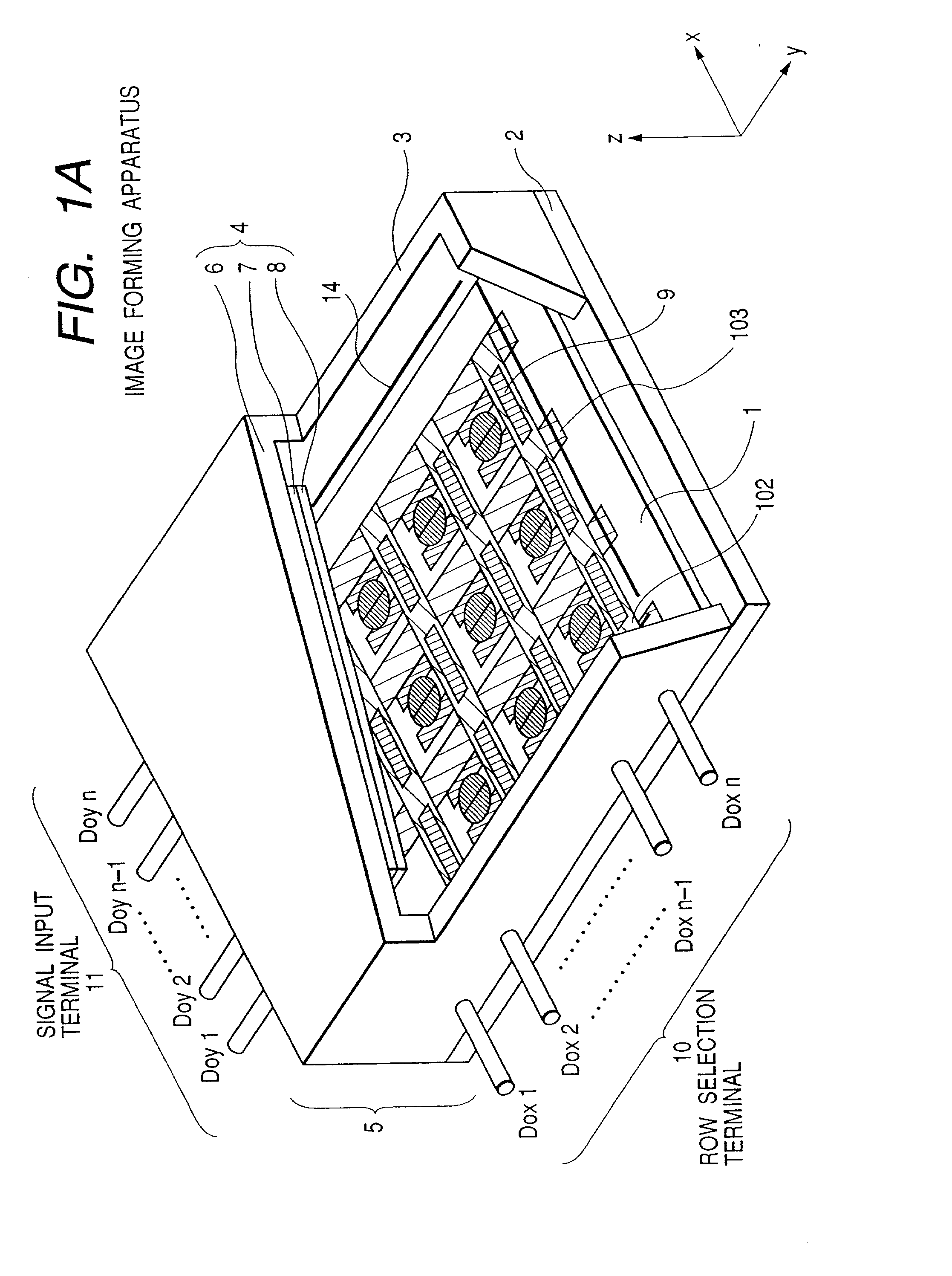

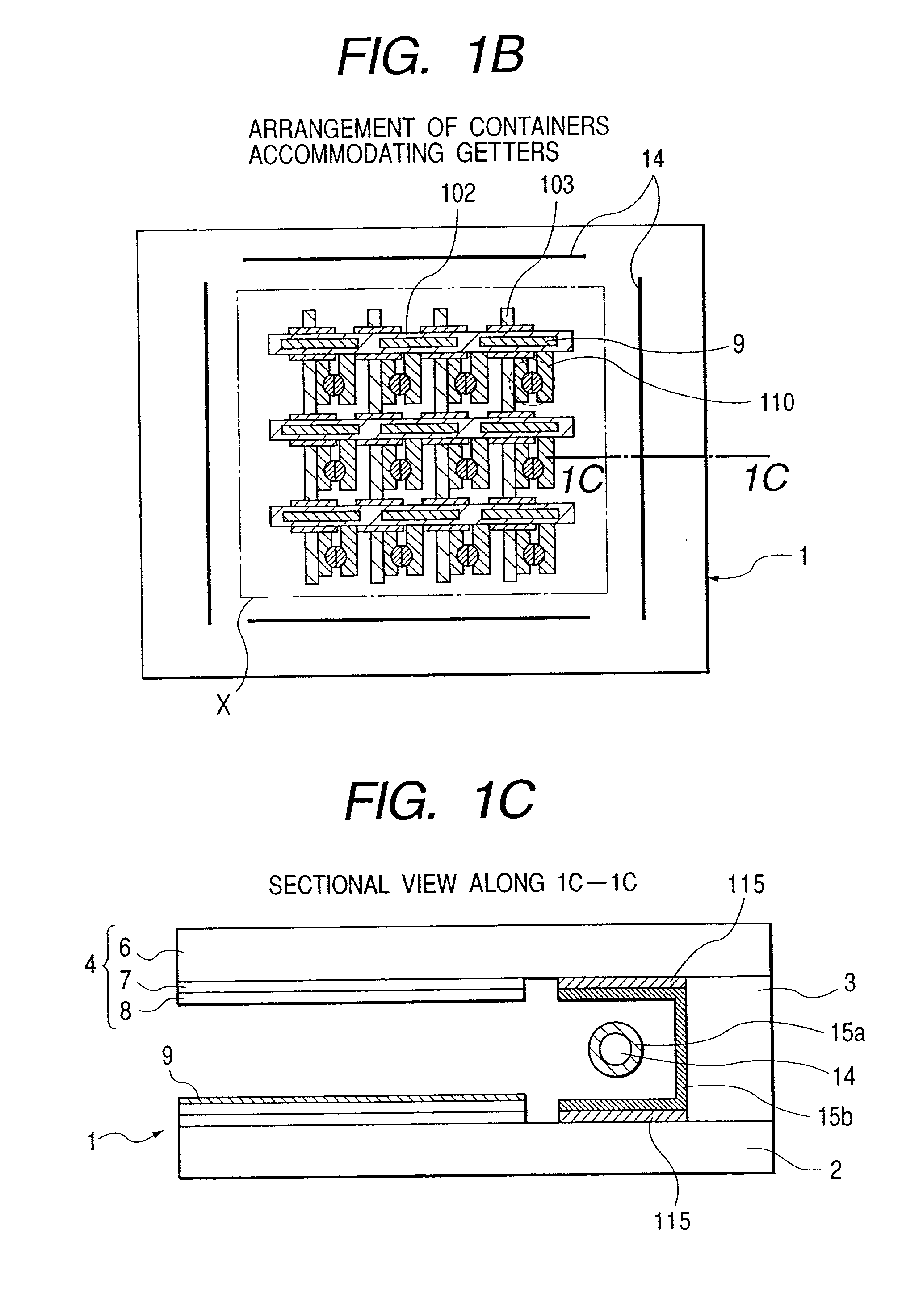

InactiveUS6528939B1Cathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube leading-in arrangementsElectron sourceImage formation

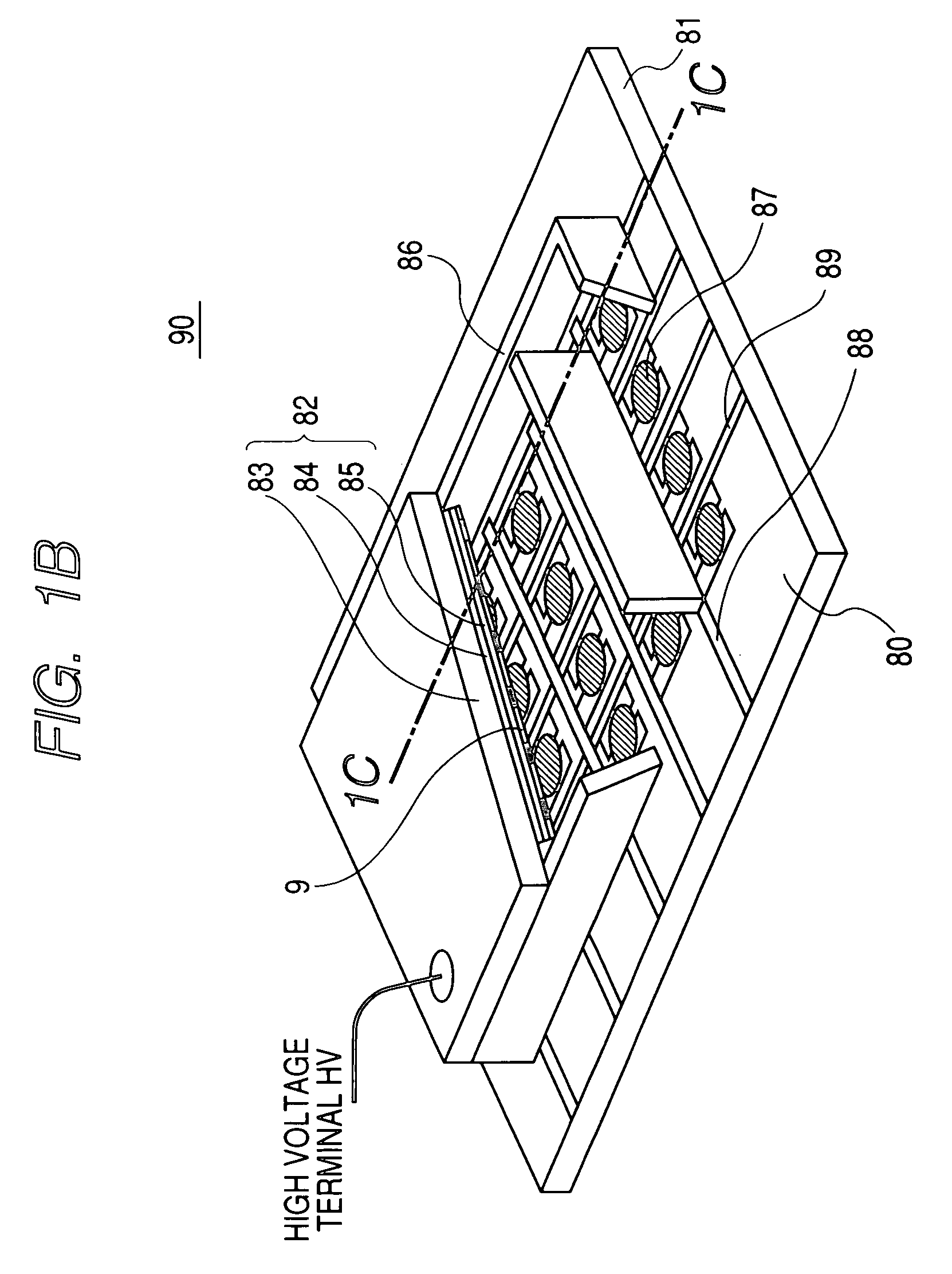

An image-forming apparatus includes a vacuum container having a first plate and a second plate arranged opposite to the first plate, an electron source disposed on the first plate and provided within the vacuum container, and an image-forming member disposed on the second plate within the vacuum container and irradiated with an electron emitted from the electron source. An airtight lead-in terminal has a first end in electrical contact with the image-forming member and a second end leading outside of the vacuum container through a hole in the first plate. The second end leading outside of the vacuum container is held and fixed so as not to protrude from an outer surface of the first plate.

Owner:CANON KK

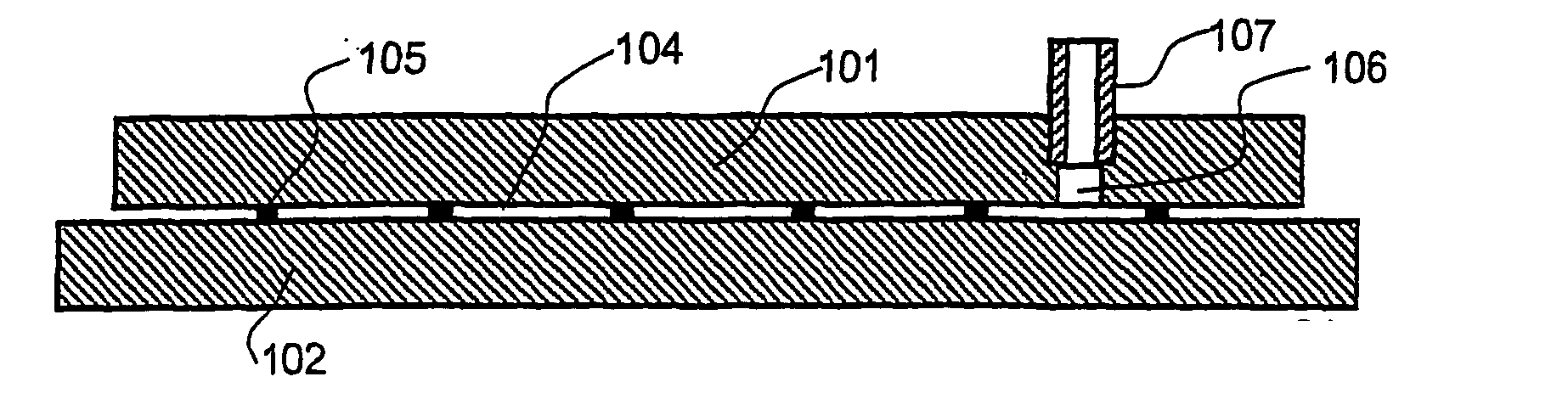

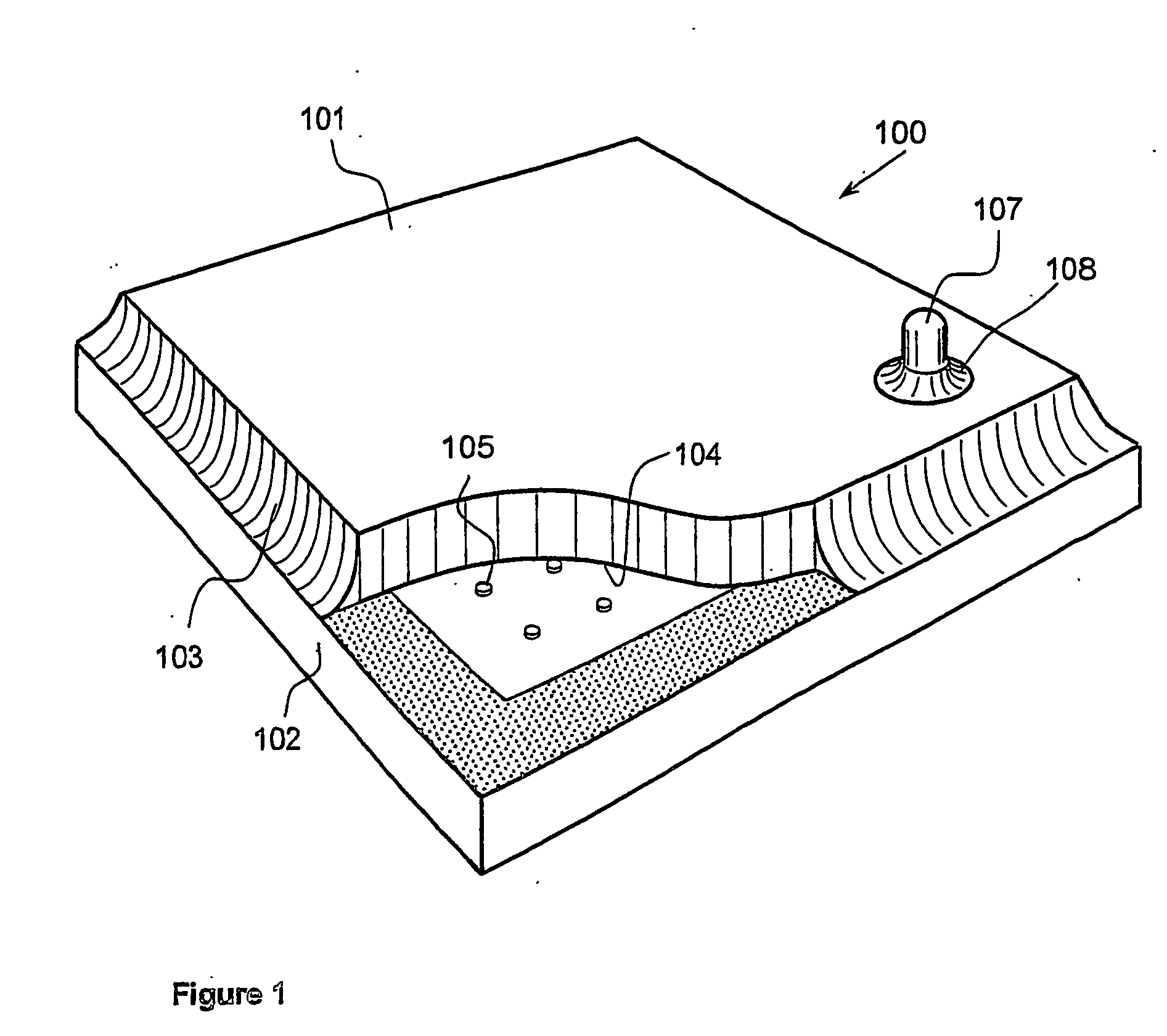

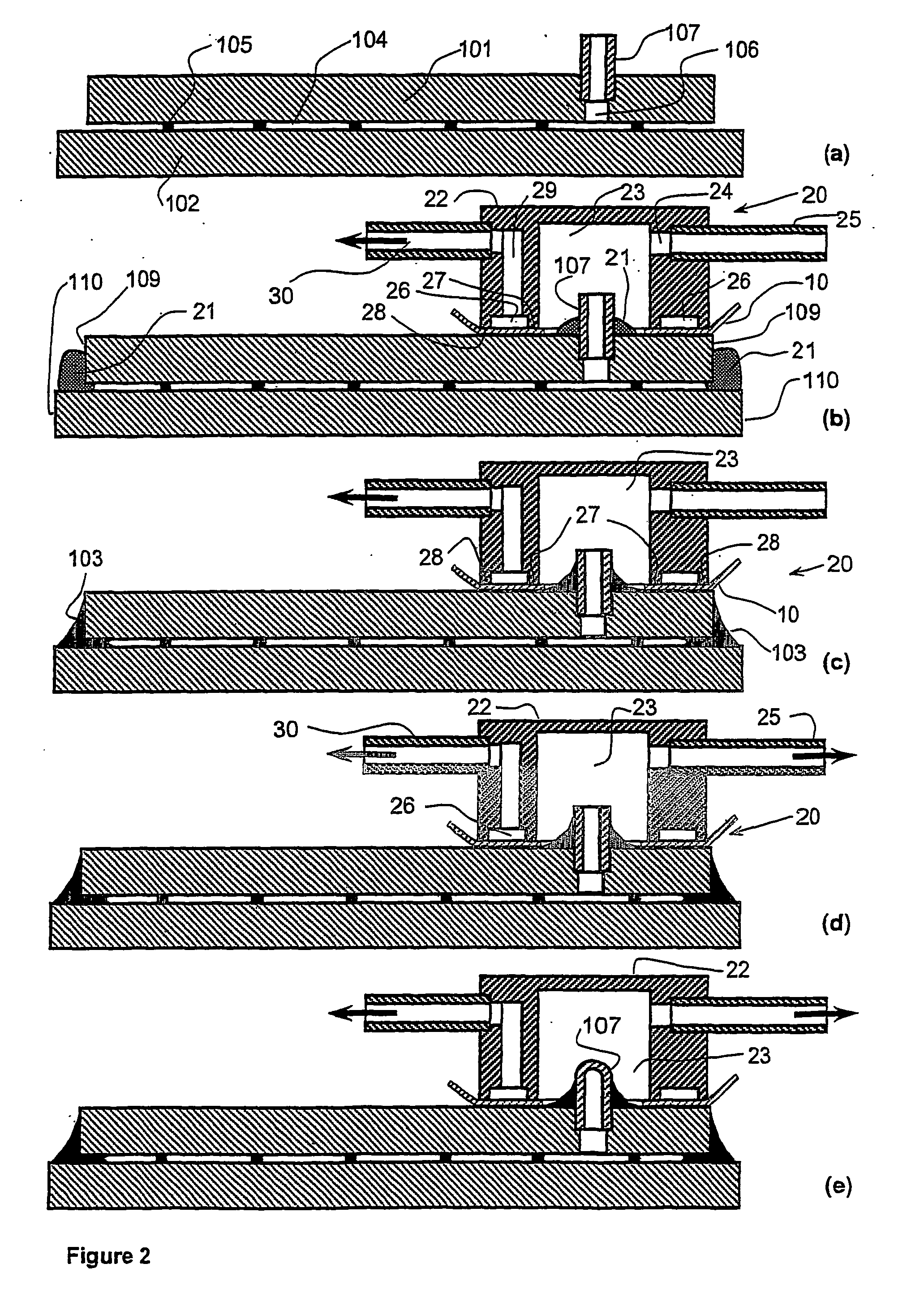

Sealing arrangement for use in evacuating a glass chamber

InactiveUS20060175767A1Degrade quality of vacuumSuppress mutationEngine sealsElectric discharge tubesEngineeringGlass sheet

A gasket (10) is provided for an evacuation head assembly (20) to evacuate a chamber (104) defined by two glass sheets (101, 102). The gasket (10) may be made from a metal foil such as aluminium and has opposite sealing surfaces (14, 15, 19) that are profiled with a series of fine grooves (17) and wherein the variation in thickness between the sealing surfaces is less than 1 μm.

Owner:THE UNIV OF SYDNEY

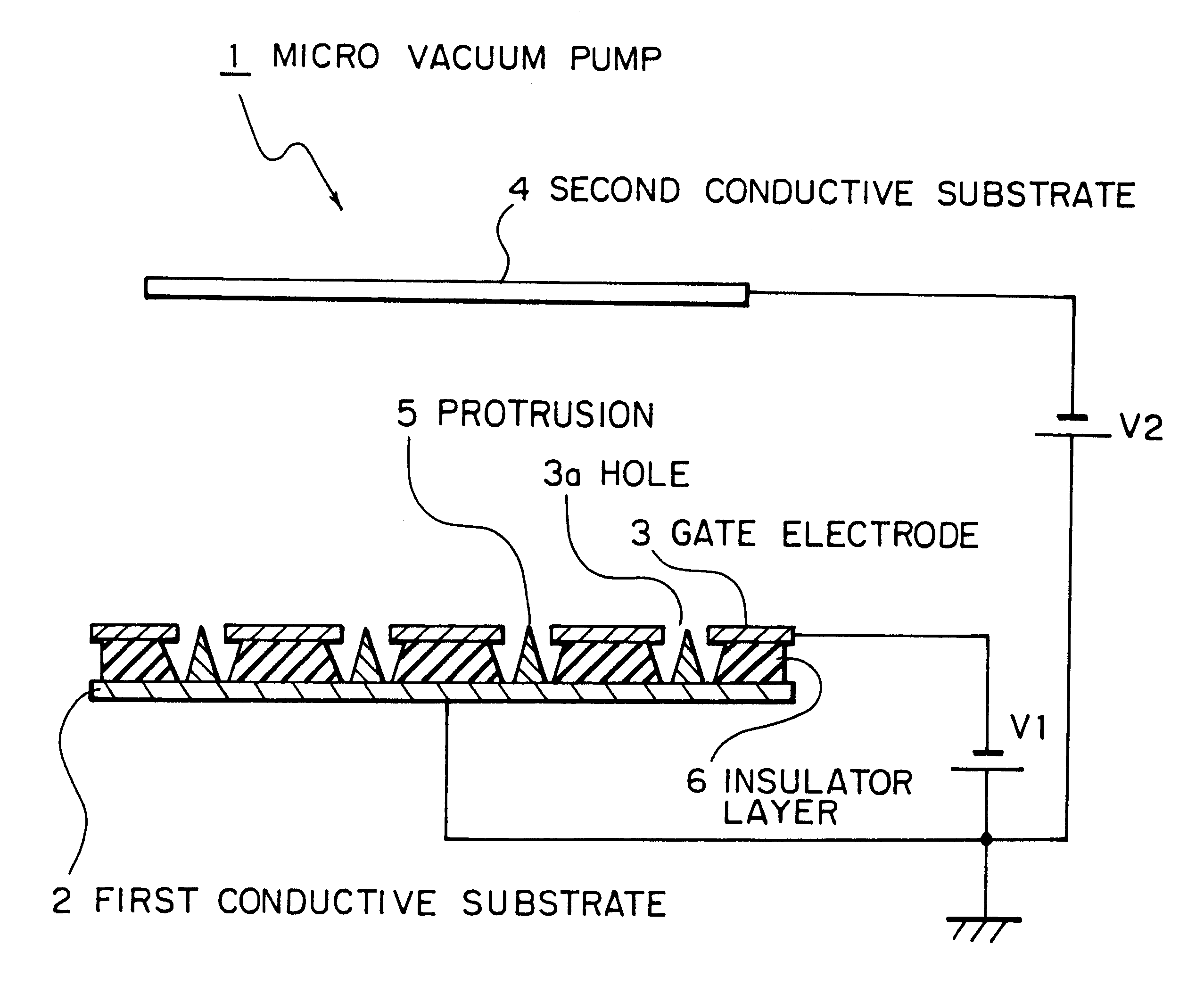

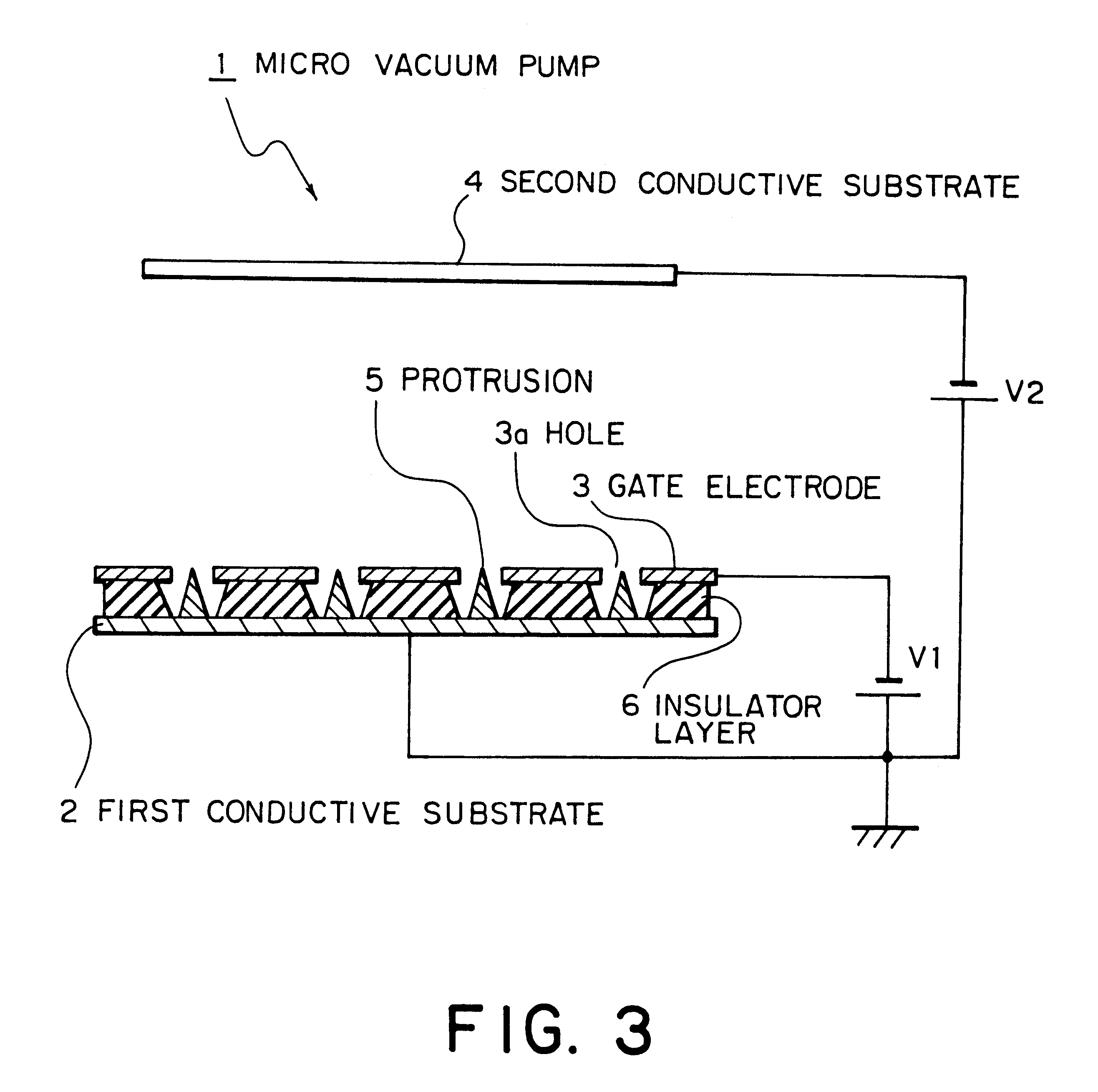

Micro vacuum pump for maintaining high degree of vacuum and apparatus including the same

InactiveUS6236156B1Gas filling substance selectionDischarge tube luminescnet screensNoble gasEngineering

The present invention provides a micro vacuum pump capable of enhancing the performance of exhausting rare gases as well as active gases thereby to ensure quality, good repeatability and stable getter action of the micro vacuum pump over a long time. The invention also provides an apparatus assembling the micro vacuum pump. The micro vacuum pump capable of maintaining a high degree of vacuum includes a first conductive substrate having many protrusions and mounting a second conductive substrate disposed with a predetermined interval provided with respect to the first conductive substrate so that it faces the protrusions. A gate electrode is disposed in the vicinity of the apexes of the protrusions on the first conductive substrate via an insulator layer, and is positioned to face the second conductive substrate. Relative to the first conductive substrate, a negative potential is supplied to the second conductive substrate, and, a same negative potential difference is also applied to the gate electrode relative to the cones.

Owner:NEC CORP

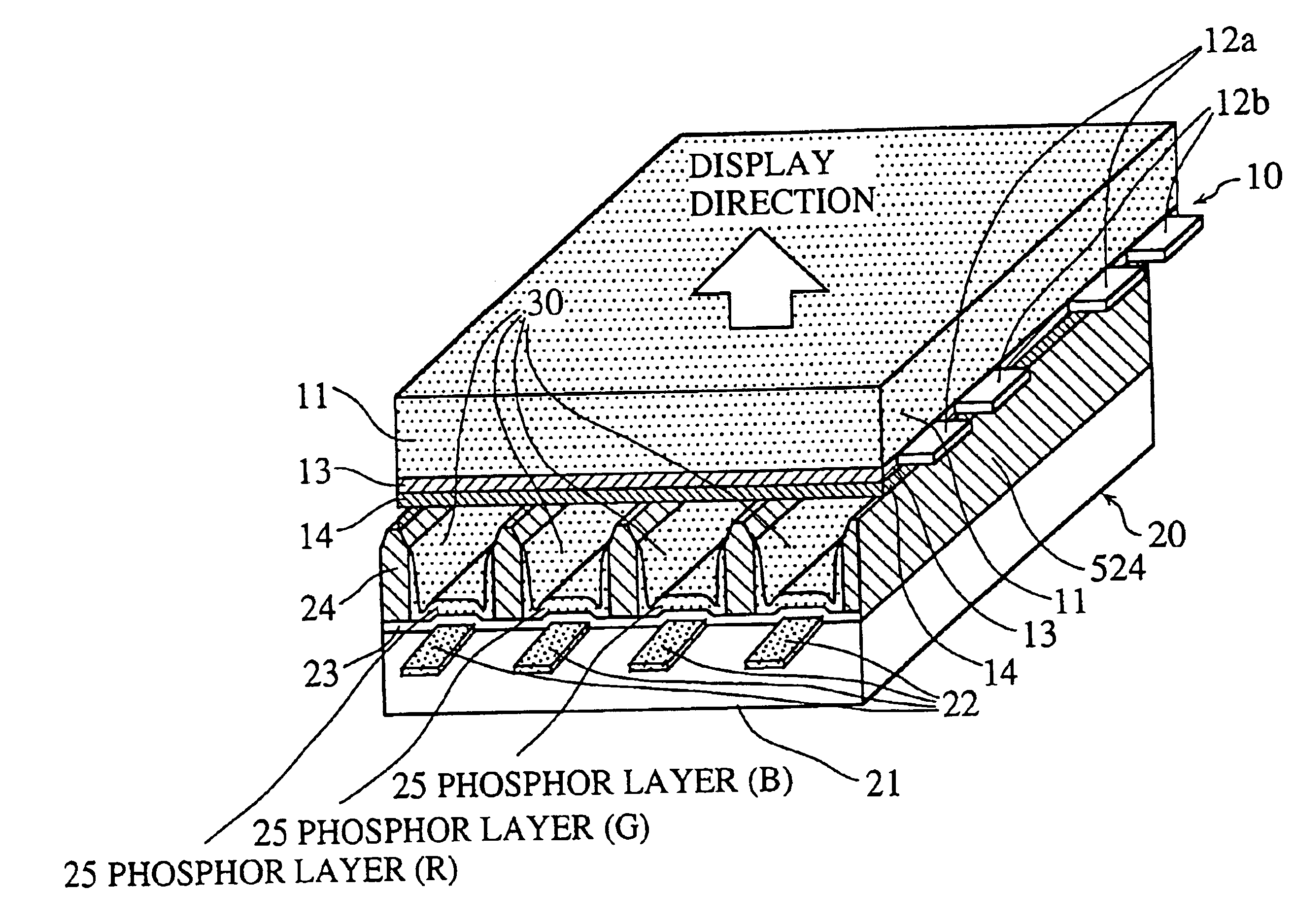

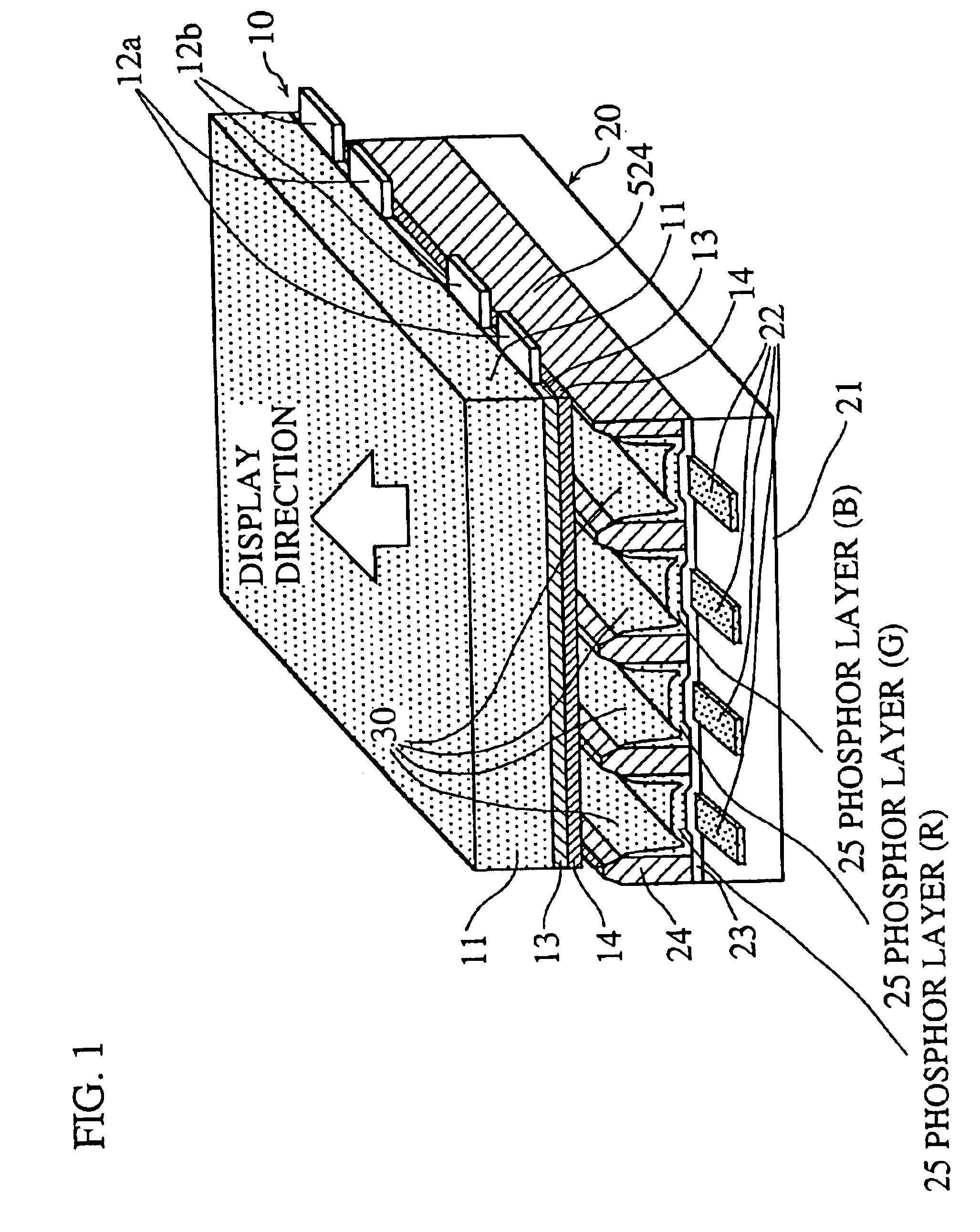

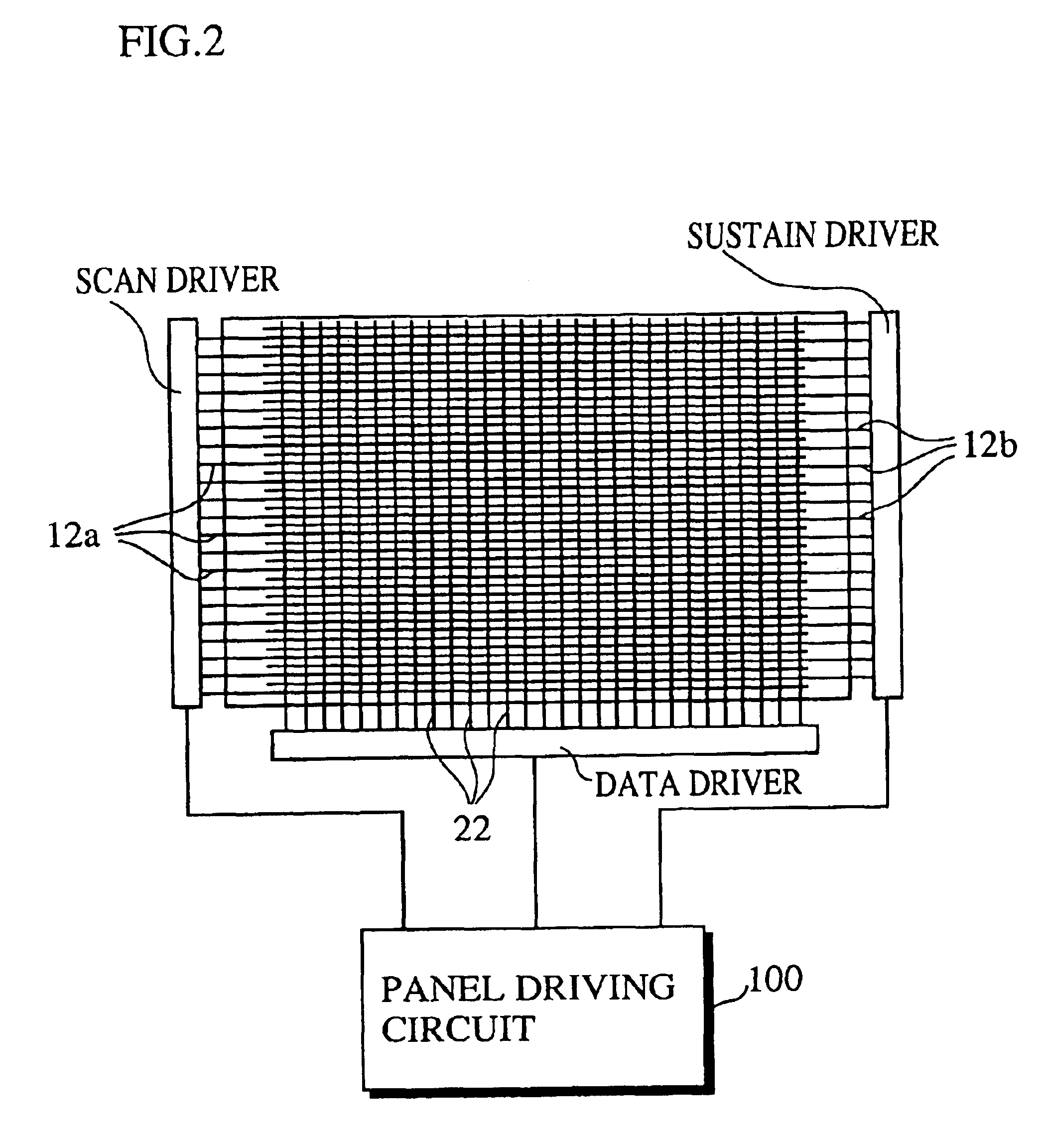

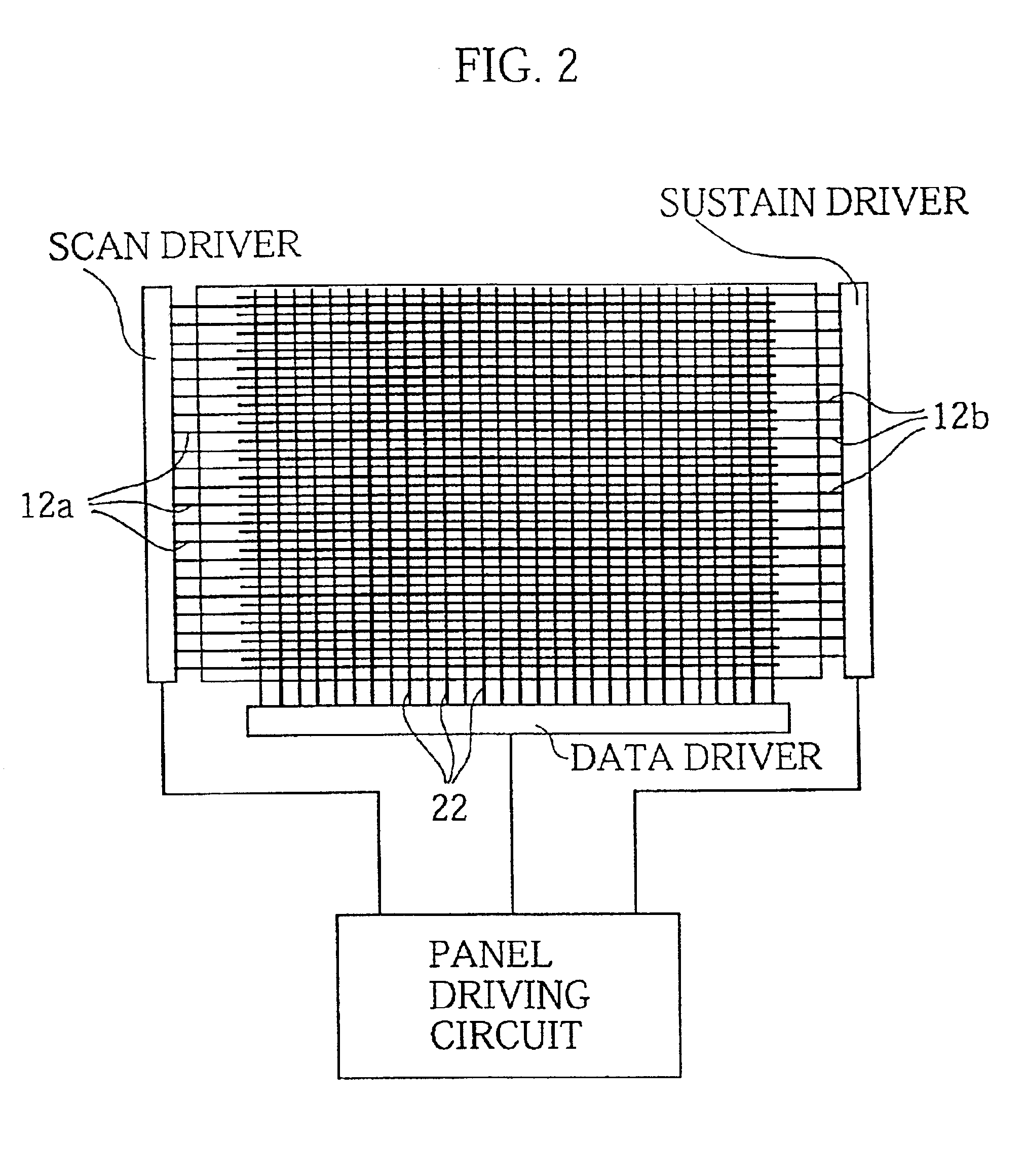

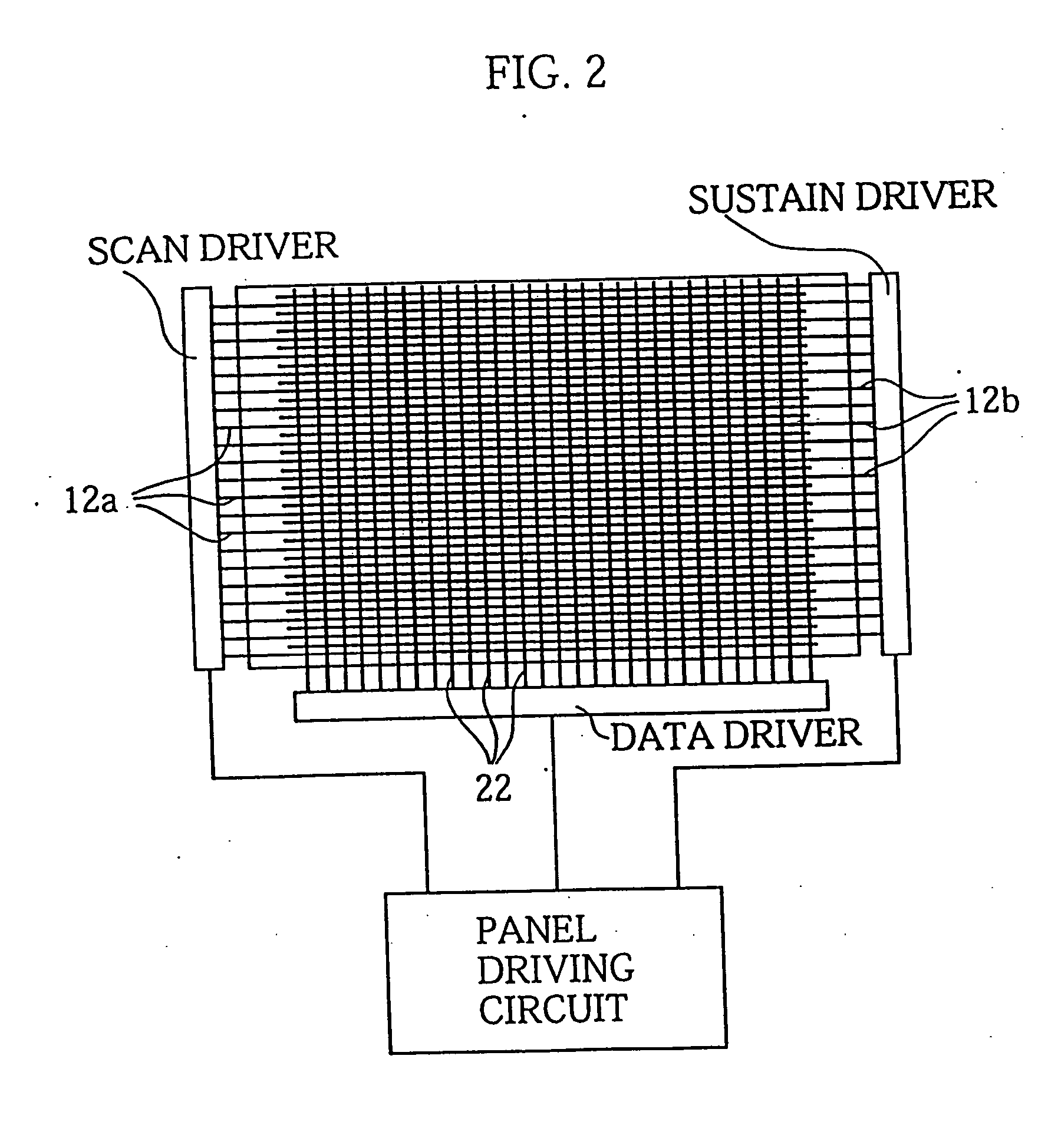

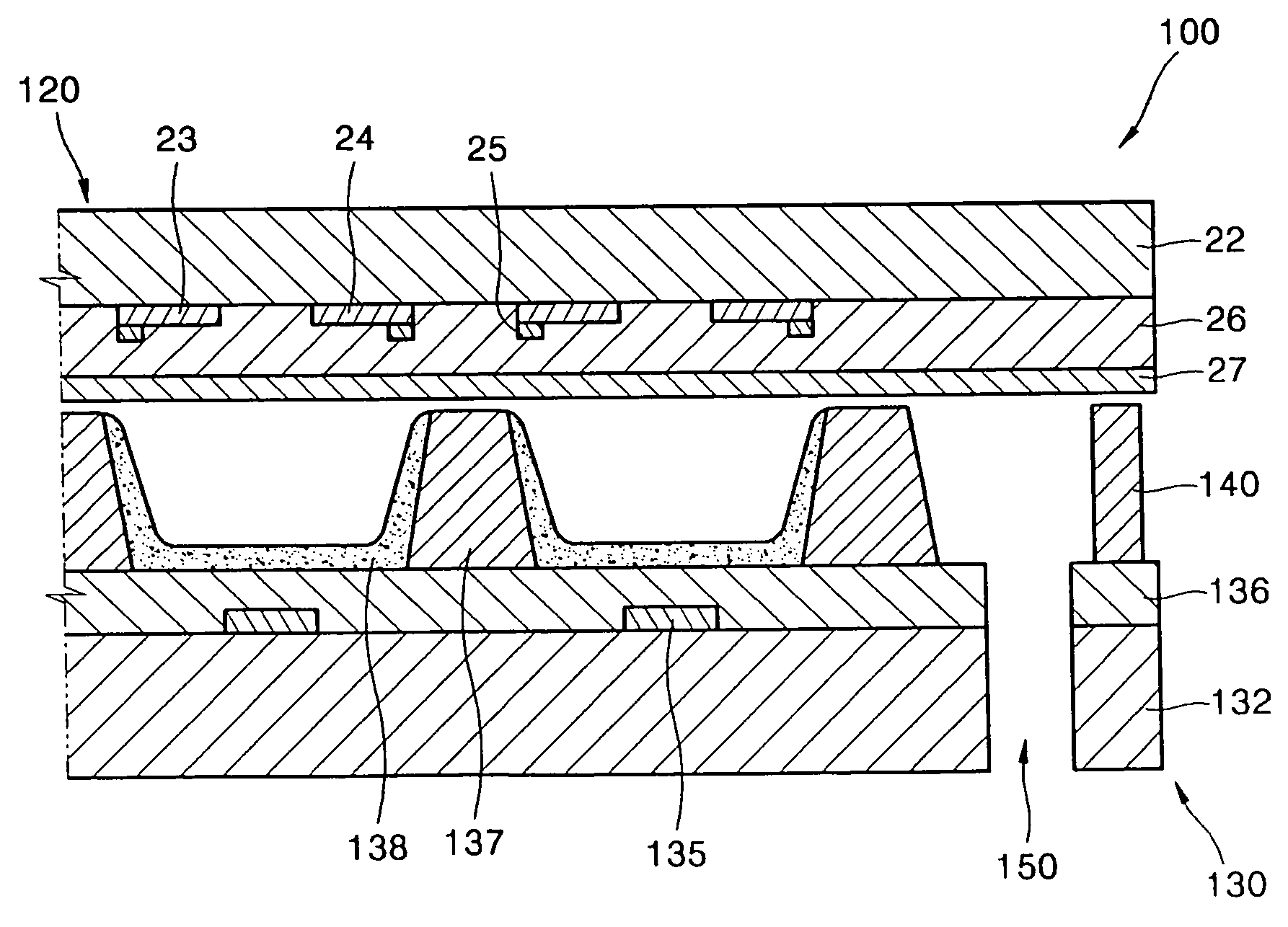

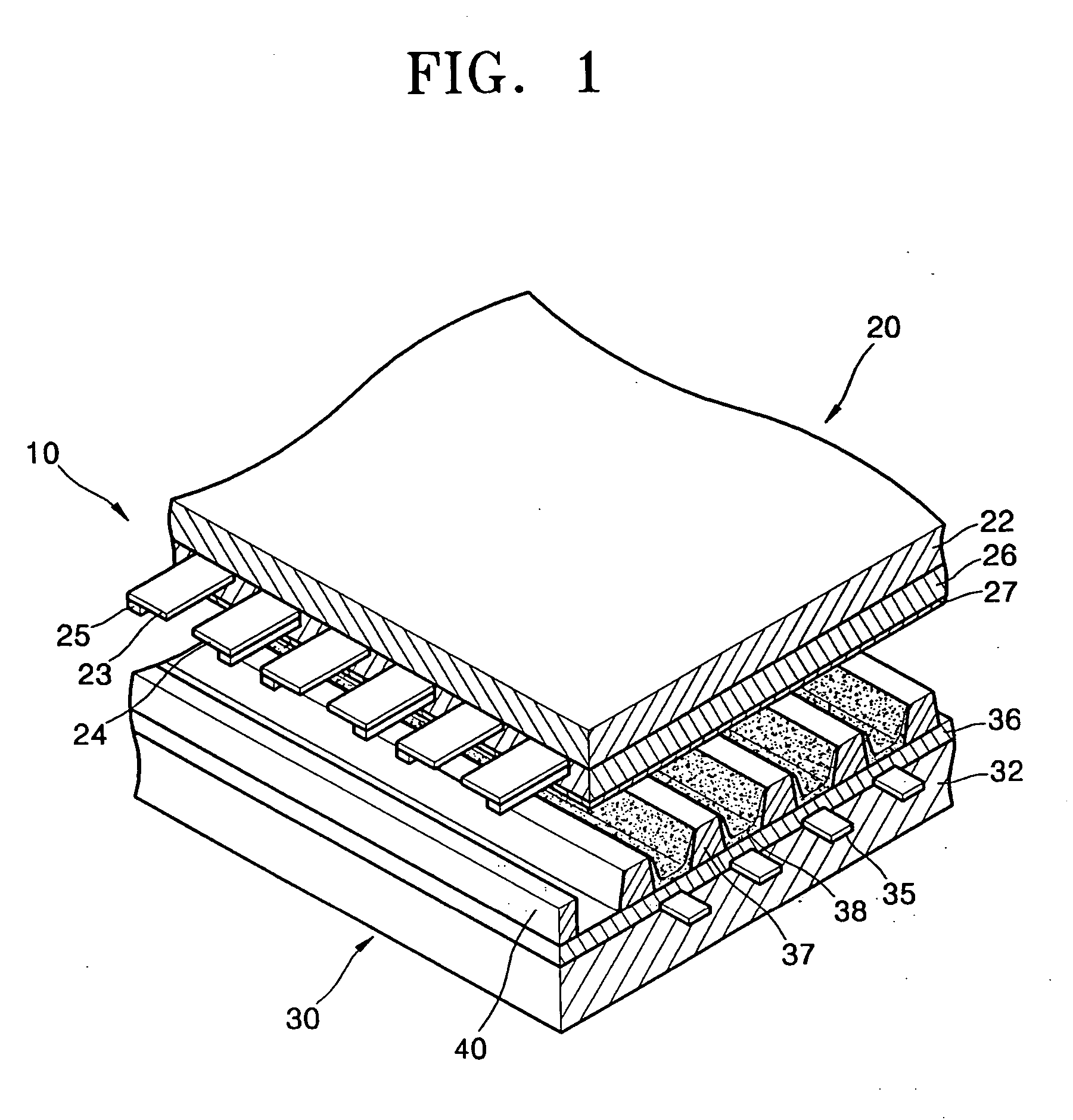

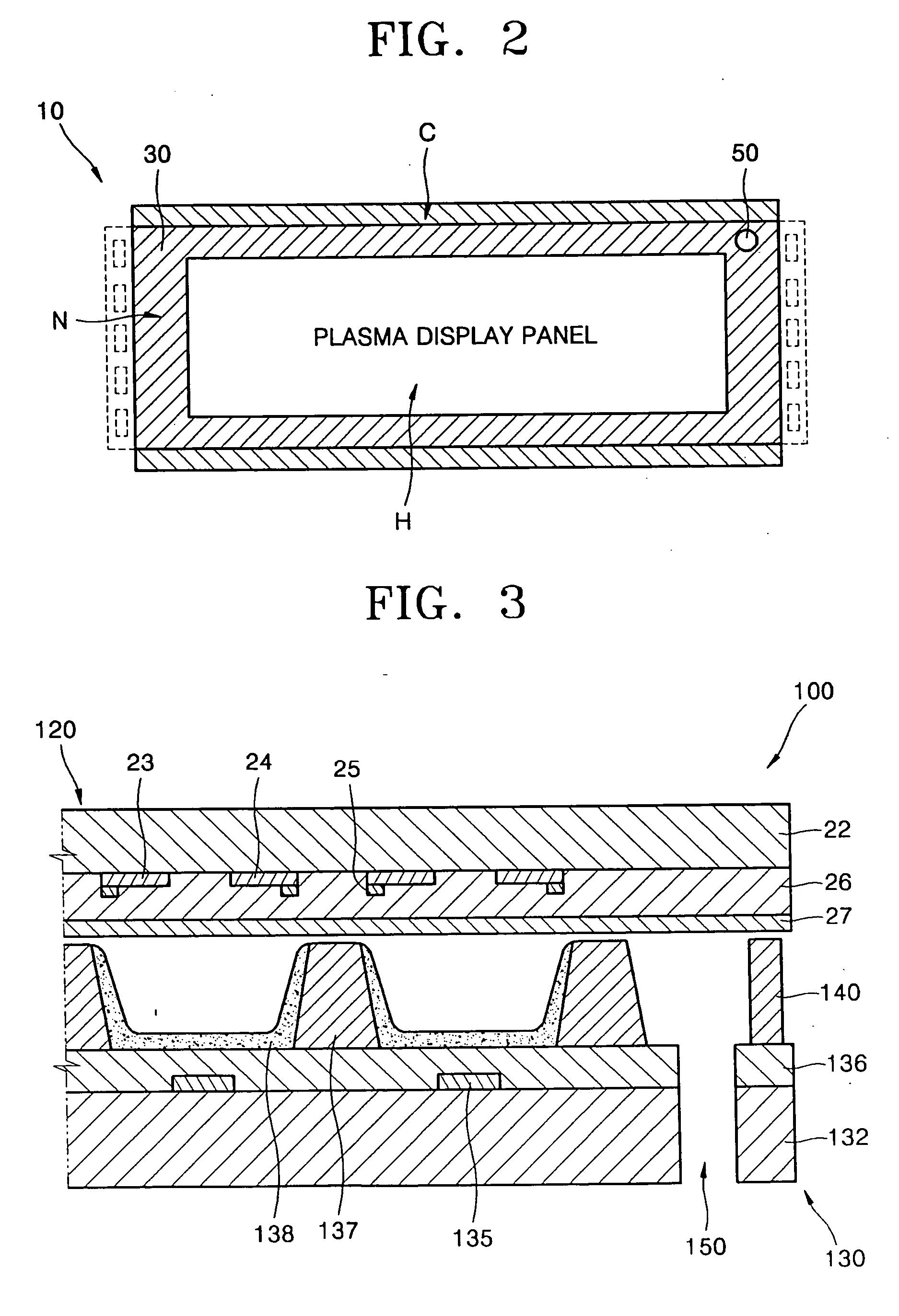

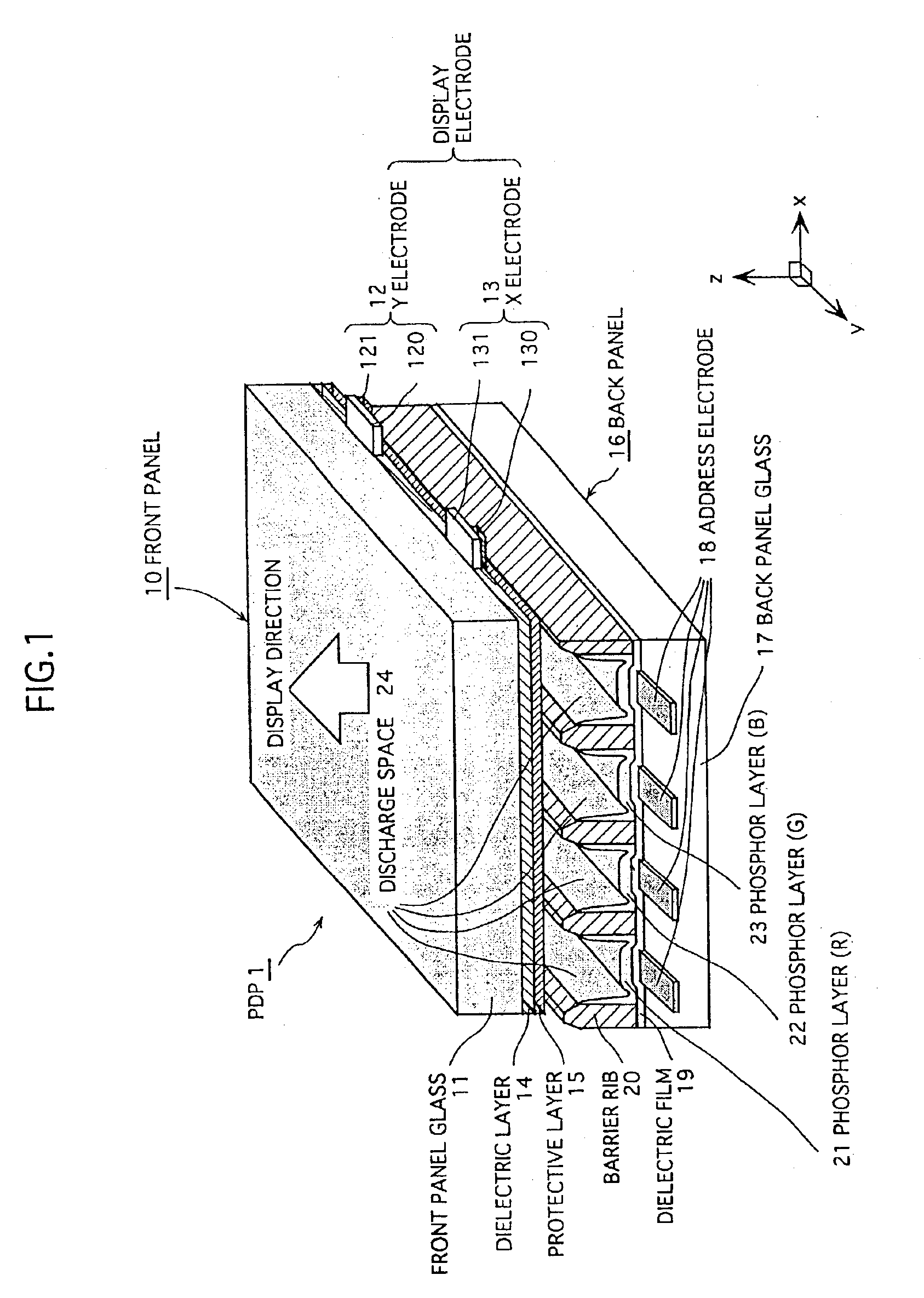

Plasma display panel and method for fabricating the same

InactiveUS7002296B2Improve efficiencyLess power consumptionAddress electrodesSustain/scan electrodesEngineeringPlasma display

Ribs for defining pixel cells are formed in the shape of a lattice, and sustain electrodes and scan electrodes are disposed near the ribs. The electrodes are spaced apart in each pixel cell, and the sustain electrode and the scan electrode are each cut away between pixel cells arranged in the row direction to provide each pixel cell with individually separated electrodes. In addition, between pixel cells adjacent to each other in the row direction, the sustain electrodes and the scan electrodes are connected to each other by means of a sustain-side bus electrode and a scan-side bus electrode, respectively. This makes it possible to provide a high luminous efficiency.

Owner:PANASONIC CORP

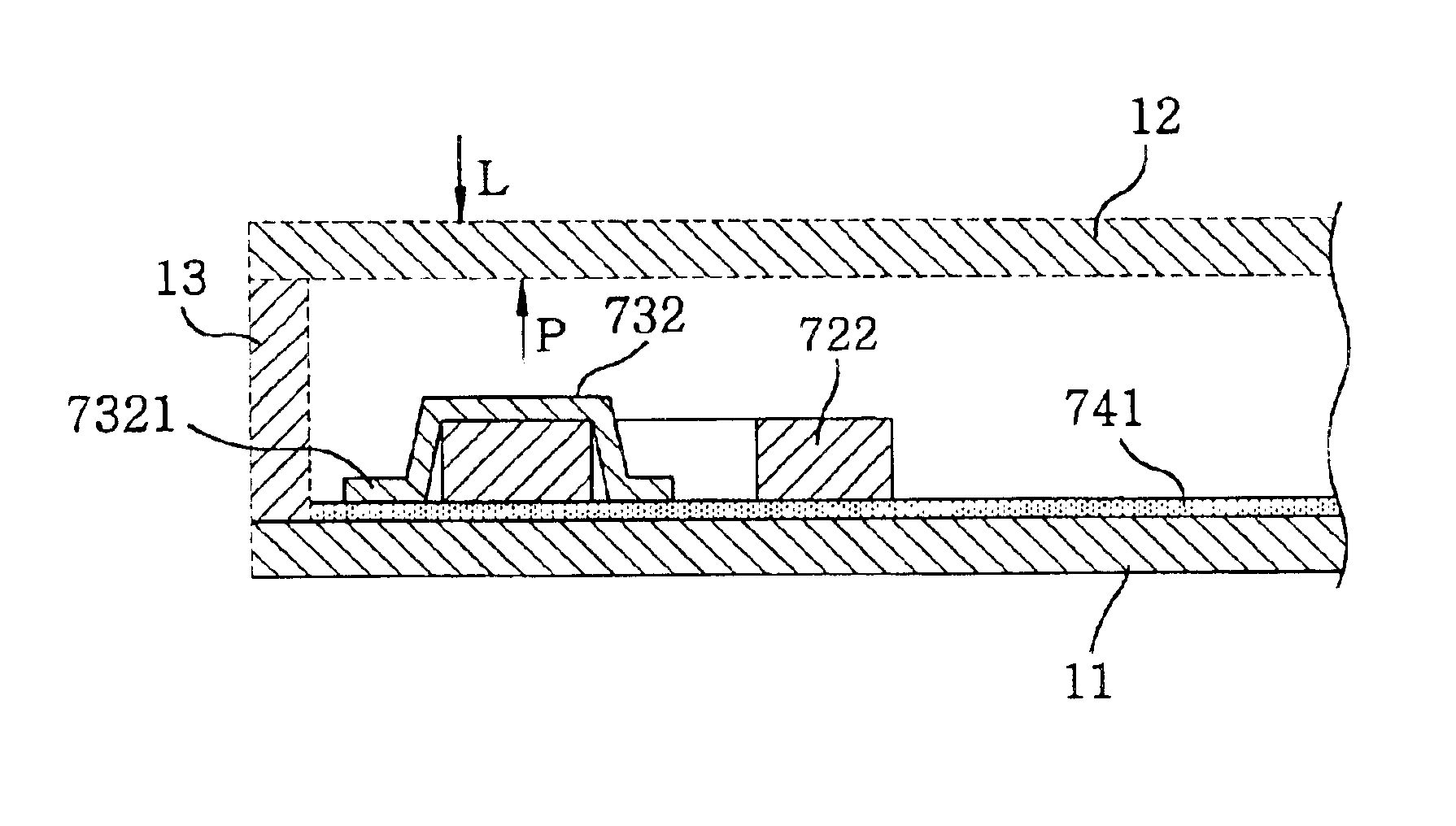

Visual display

InactiveUS6517403B1Cathode-ray/electron-beam tube electrical connectionGas filling substance selectionRadiant heaterIrradiation

The apparatus for sealing face plates (753) and cathodes (754) has three stations (701, 702, 703). The first (701) is a preheater, the second (702) is an alignment and irradiation station and the third (703) is a controlled cooling station. Beneath each station, a vacuum pump (710) capable of drawing ultralow pressures is provided. The preheater is equipped with upper and lower banks of radiant heaters and reflectors (712). The upper heaters are Provided above a quartz: window (713) of a chamber (714) constituting the station. The pressure in the preheater is pumped down to that in the alignment and irradiation station prior to opening of the gate valve between them and transfer of the face plate and cathode. At the alignment and irradiation station, further heaters (716) are provided. Those above the face plate and cathode, the face plate being uppermost, are mounted on frames (717) about hinges (718), whereby they can be swung up to clear this station's top quartz window, exposing the face plate to the view of an optical system (719) and a laser (720). Manipulation controls (722) are provided for manipulating the position of the face plate to be pixel alignment, as measured by the optical system (719), with the cathode. The laser is traversed around further. The cooling station (703) has meanwhile been pumped down and the sealed device is transferred to it. The temperature of the device is allowed to rise very slowly, in order to reduce the risk of thermal cracking to as great an extent as possible. As the temperature slowly falls, air is slowly introduced, so that the finished device can be removed to the ambient surroundings.

Owner:COMPLETE MULTILAYER SOLUTIONS +1

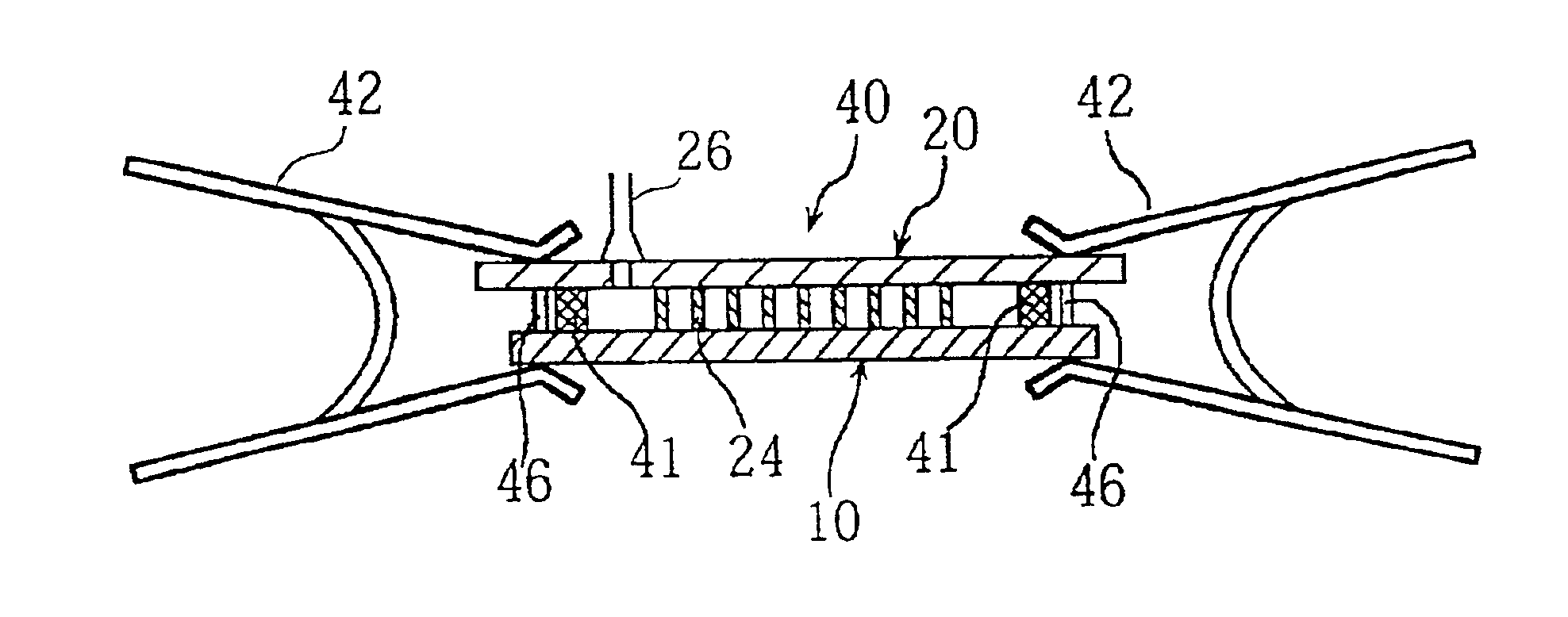

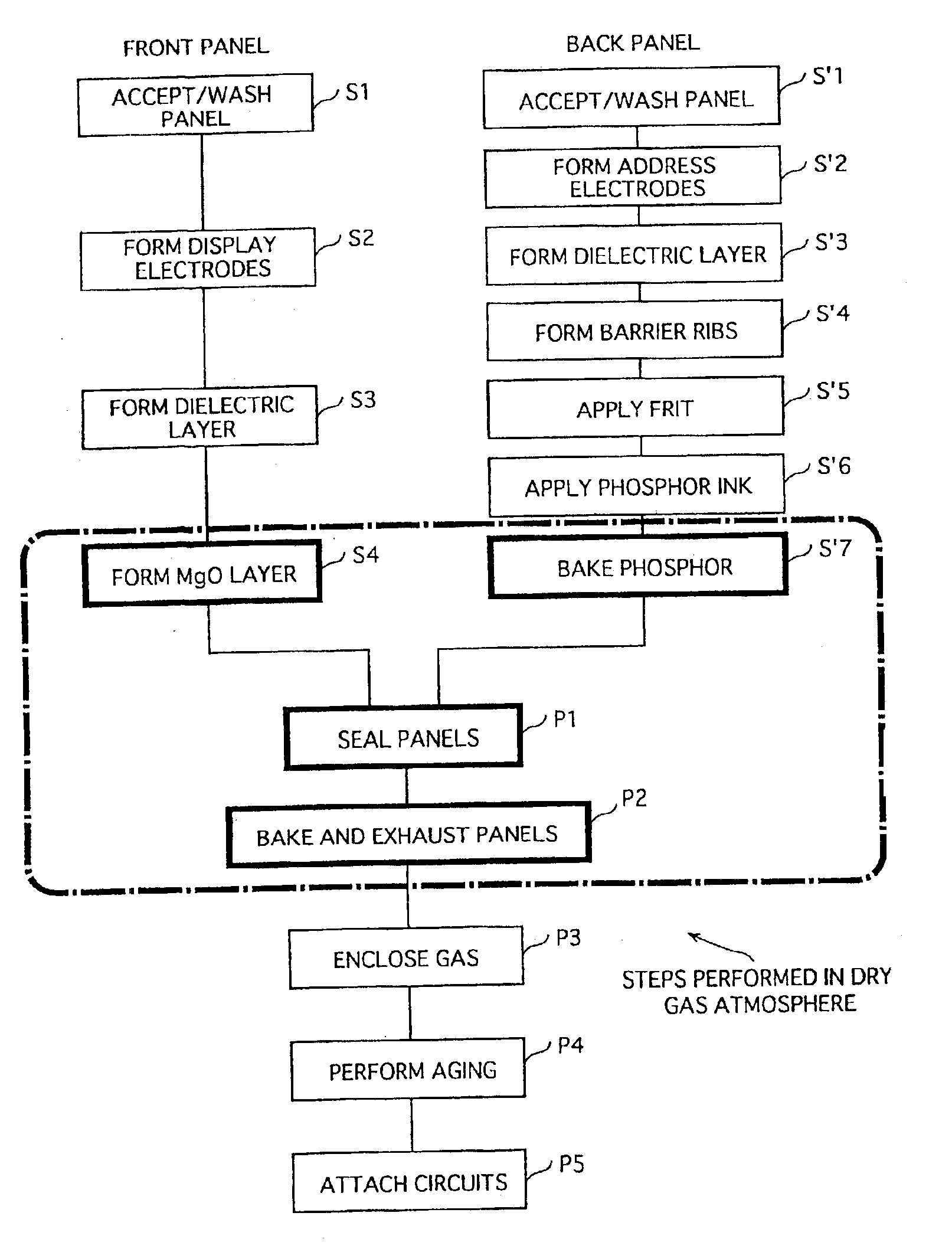

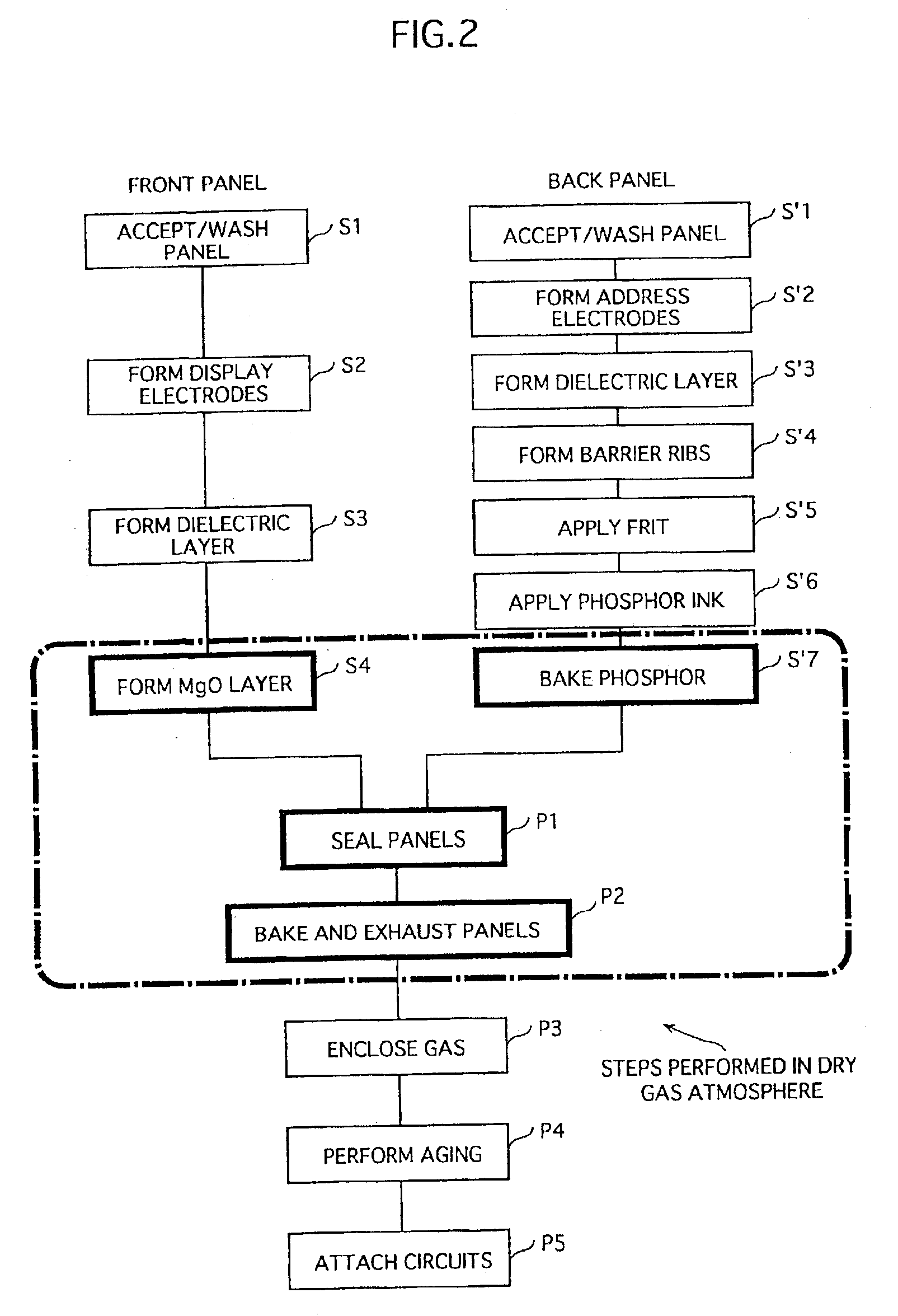

Highly productive method of producing plasma display panel

InactiveUS6860780B2Inhibit deteriorationHigh light-emitting efficiency and color purityAddress electrodesSustain/scan electrodesPhosphorEngineering

A method for producing a plasma display panel that has a front substrate and a back substrate disposed to face each other. A pre-baking phosphor layer containing a phosphor and an organic binder is formed on at least one of surfaces of the front substrate and the back substrate that are to face each other. A sealing material that softens with heat is applied to the peripheral region of at least one of the surfaces of the front and back substrates that are to face each other. The front and back substrates are disposed to face each other in a stack. The front and back substrates are heated to burn out the organic binder while supplying a dry gas containing oxygen to an internal space that is formed between the front and back substrates.

Owner:PANASONIC CORP

Sealing method and apparatus for manufacturing high-performance gas discharge panel

InactiveUS6848964B1Reduce pressureEnsure processTube/lamp vessel fillingAlternating current plasma display panelsEngineeringLaser beams

A method is provided to steadily produce a gas discharge panel, such as a PDP, in which a panel and the top of the barrier ribs are in intimate contact in entirety. First a surrounding unit for the gas discharge panel is formed, then a process for sealing the surrounding unit with a sealing material inserted between two panels at the rim is performed while pressure is adjusted so that pressure inside the surrounding unit is lower than pressure outside. With this construction, the panels constituting the surrounding unit are bonded together while they are pressurized from outside. As a result, a panel and the top of the barrier ribs on the other panel are bonded together while they are in intimate contact in entirety. To fully acquire these effects, it is preferable that the adjustment of pressure starts before the sealing material hardens. During, before, or after the sealing step, an energy such as laser beams or ultrasonic waves may be radiated onto the top of the barrier ribs to bond a panel and the top of the barrier ribs in entirety almost without a gap between them.

Owner:PANASONIC CORP

Electron tube with a ring-less getter

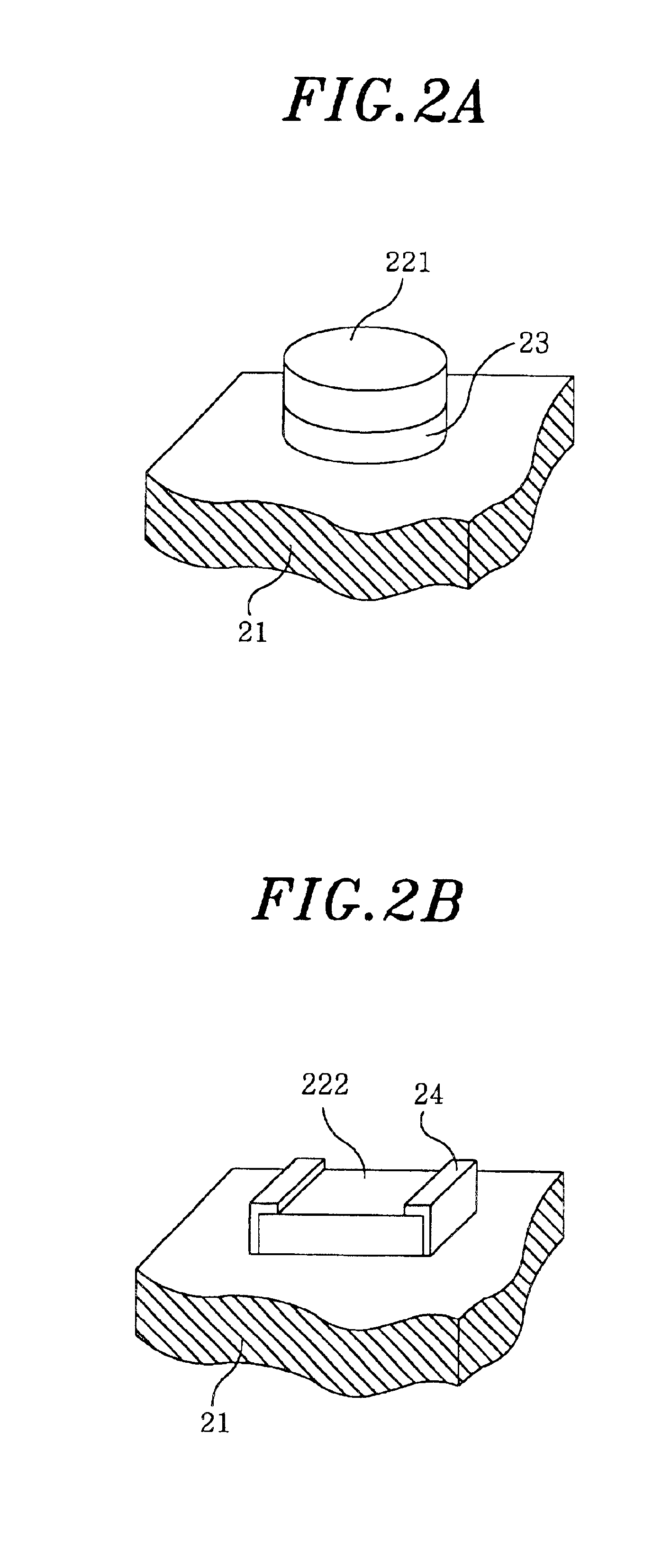

InactiveUS6838822B2Reduced space required for installationSimple handlingGetteringGas filling substance selectionEngineeringElectron

In a method for manufacturing an electron tube including a front substrate and a back substrate, a wiring and an electrode are formed on the front substrate and / or the back substrate. A component is mounted on the front substrate and / or the back substrate. A ring-less getter is mounted on at least one of the front substrate, the back substrate and the component. A vessel is assembled and sealed so that the front substrate faces the back substrate. A light is irradiated on the ring-less getter from outside of the sealed vessel, thereby activating the ring-less getter.

Owner:FUTABA CORPORATION

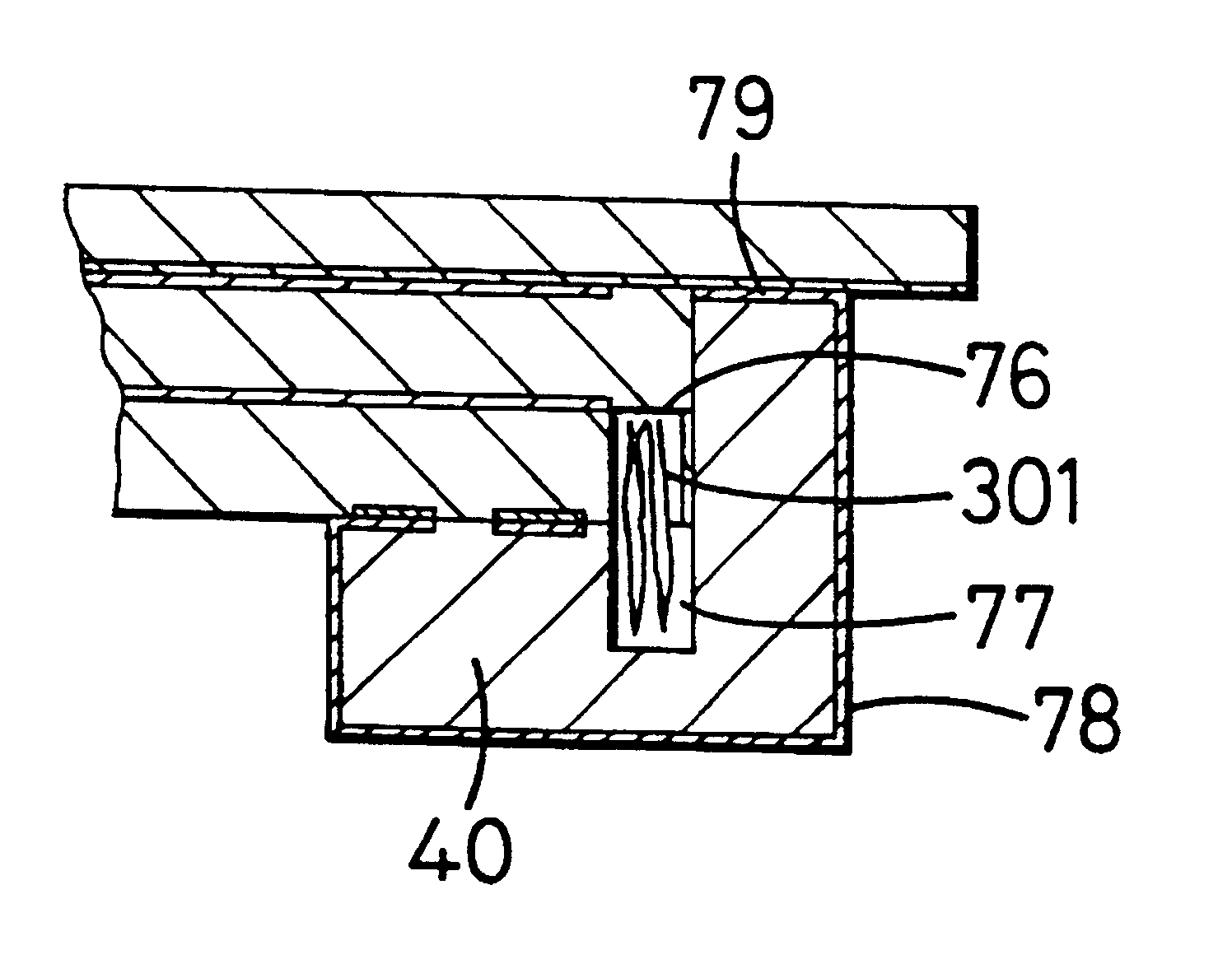

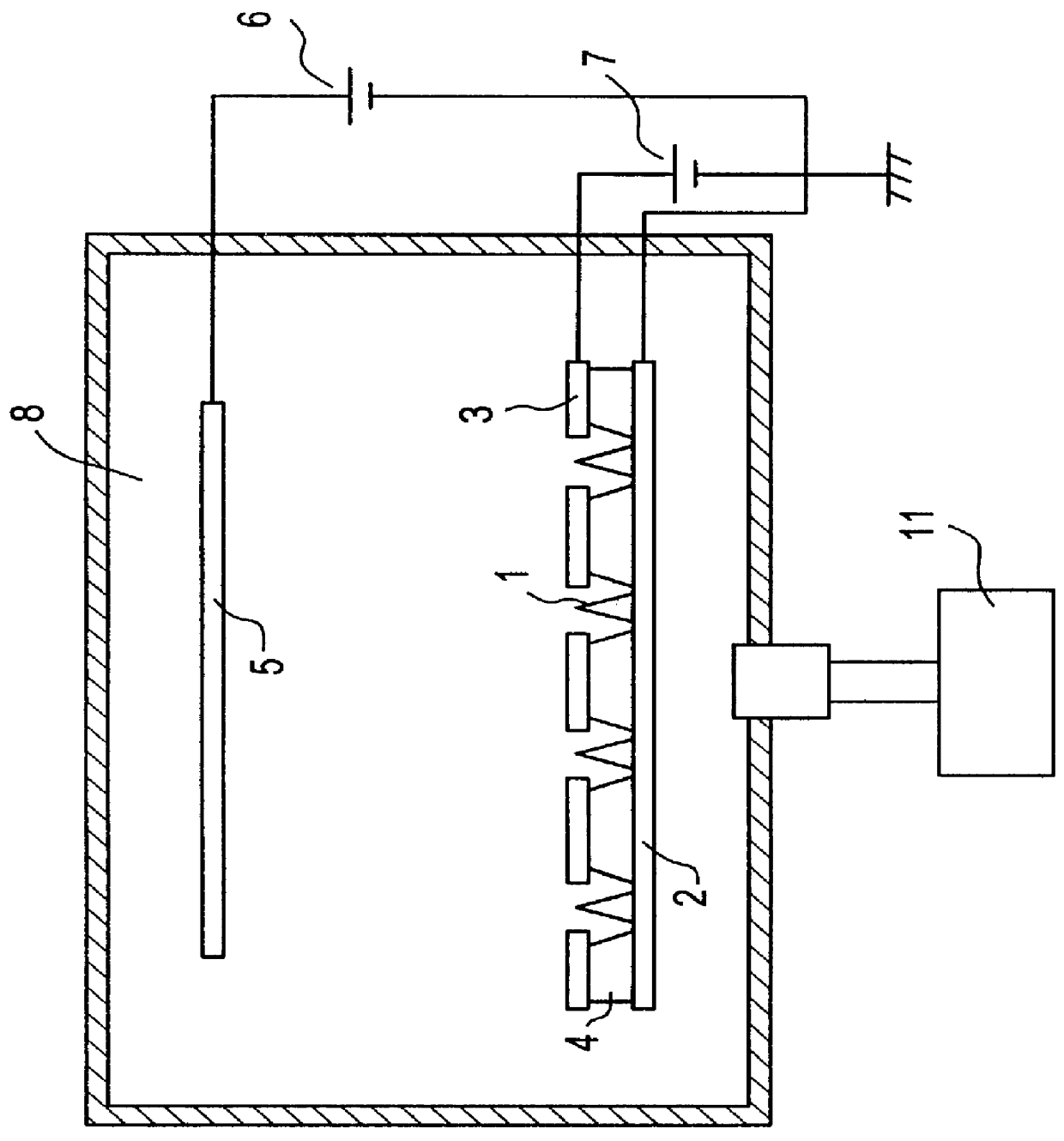

Image display apparatus

InactiveUS20060043871A1Reduce leakageHigh display gradeGas filling substance selectionPump componentsElectron sourceVacuum chamber

An image display apparatus is provided with a vacuum chamber consisting of an electron source substrate and an image display substrate, and an ion pump which is attached to an electron-emitting substrate or the image display substrate and exhausts air from the vacuum chamber by the action of a magnet, wherein the magnet is attached and fixed to the substrate to which the ion pump has been attached. Thereby, the image display apparatus prevents the magnet from applying an excessive force to the ion pump by its weight, and acquires a stable structure without causing a vacuum leak.

Owner:CANON KK

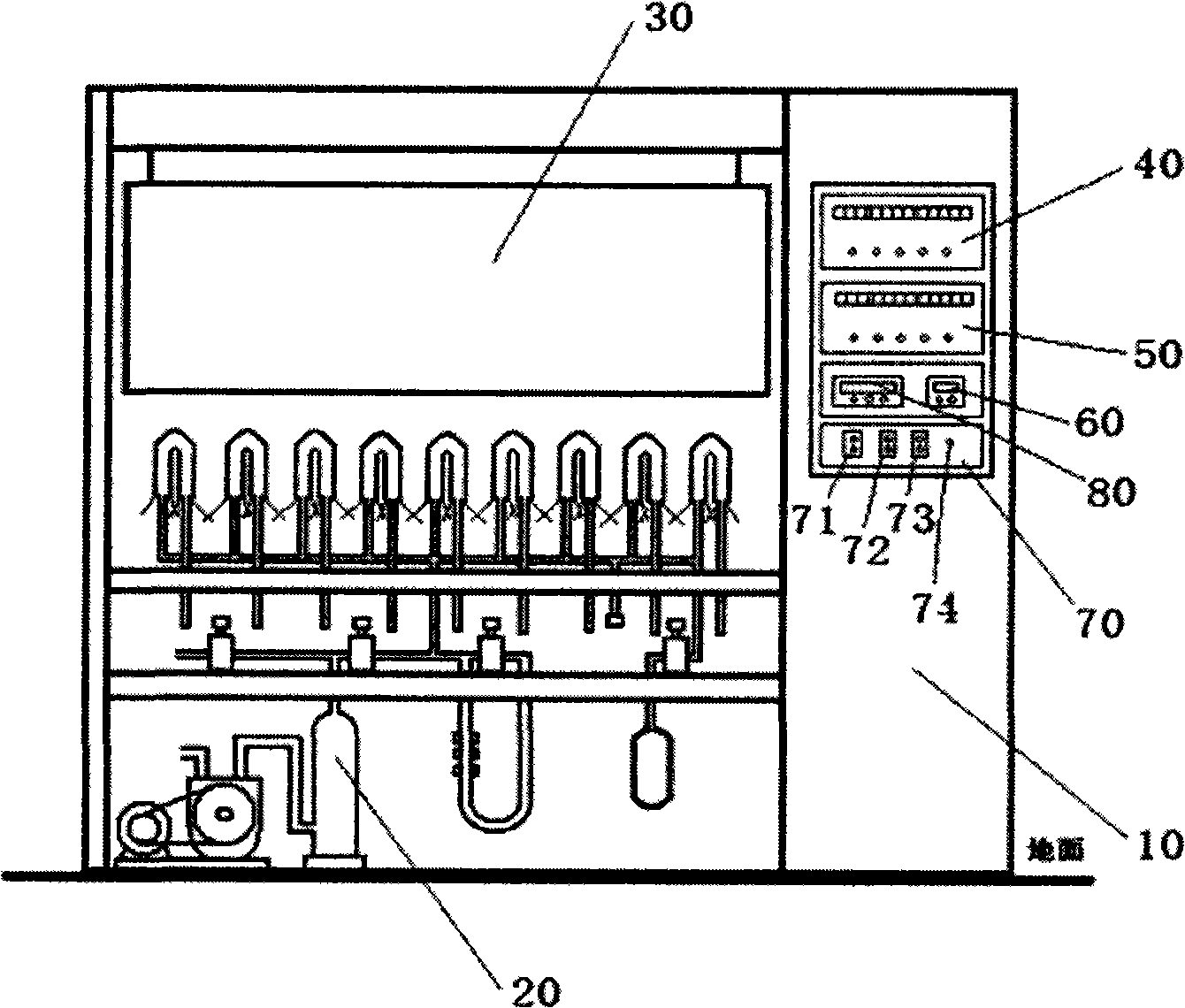

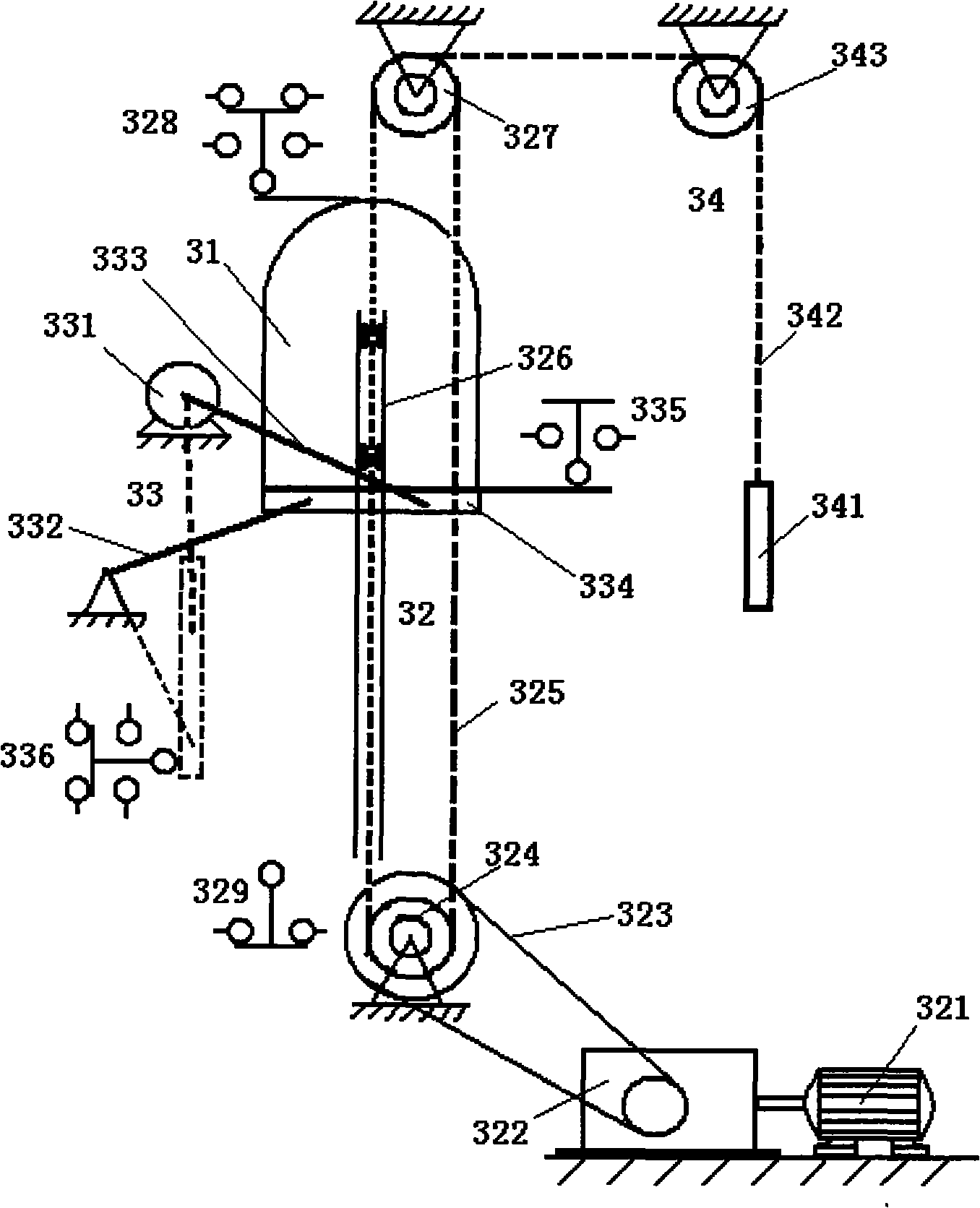

Exhaustion bench for full-automatic glass vacuum system

InactiveCN101276717ASimple structureLow priceTube/lamp vessel degassingTube/lamp vessels exhaustionAutomatic controlControl system

A full-automatic glass vacuum system exhausting table is disclosed, comprising a full glass vacuum pipeline, a glass target connected with a lamp to be exhausted, four electric control glass valves, a glass argon gas bottle and a photoelectric reading U-shaped glass pressure gauge. The vacuumization system is composed by a glass dispersing pump and a mechanical vacuum pump, and installed with an oven whose temperature is automatically controlled, an oven temperature preservation door and a control system for controlling the oven to automatic ascend and descend. The invention realize the automatization of the glass vacuum system by using above technical proposal. The full-automatic glass vacuum system exhausting table not only has good airproof performance and the advantage that preservation time of the glass vacuum system is far longer than that of common metal vacuum system, but also has low cost and convenient maintenance, thus completely eliminating the influence by human factors to the quality of products, reducing the waste product rate and enhancing production efficiency.

Owner:匡正芳

Sealing method and apparatus for manufacturing high-performance gas discharge panel

InactiveUS20050151475A1Reduce pressureAvoid deformationElectroluminescent light sourcesAlternating current plasma display panelsEngineeringLaser beams

A method is provided to steadily produce a gas discharge panel, such as a PDP, in which a panel and the top of the barrier ribs are in intimate contact in entirety. First a surrounding unit for the gas discharge panel is formed, then a process for sealing the surrounding unit with a sealing material inserted between two panels at the rim is performed while pressure is adjusted so that pressure inside the surrounding unit is lower than pressure outside. With this construction, the panels constituting the surrounding unit are bonded together while they are pressurized from outside. As a result, a panel and the top of the barrier ribs on the other panel are bonded together while they are in intimate contact in entirety. To fully acquire these effects, it is preferable that the adjustment of pressure starts before the sealing material hardens. During, before, or after the sealing step, an energy such as laser beams or ultrasonic waves may be radiated onto the top of the barrier ribs to bond a panel and the top of the barrier ribs in entirety almost without a gap between them.

Owner:PANASONIC CORP

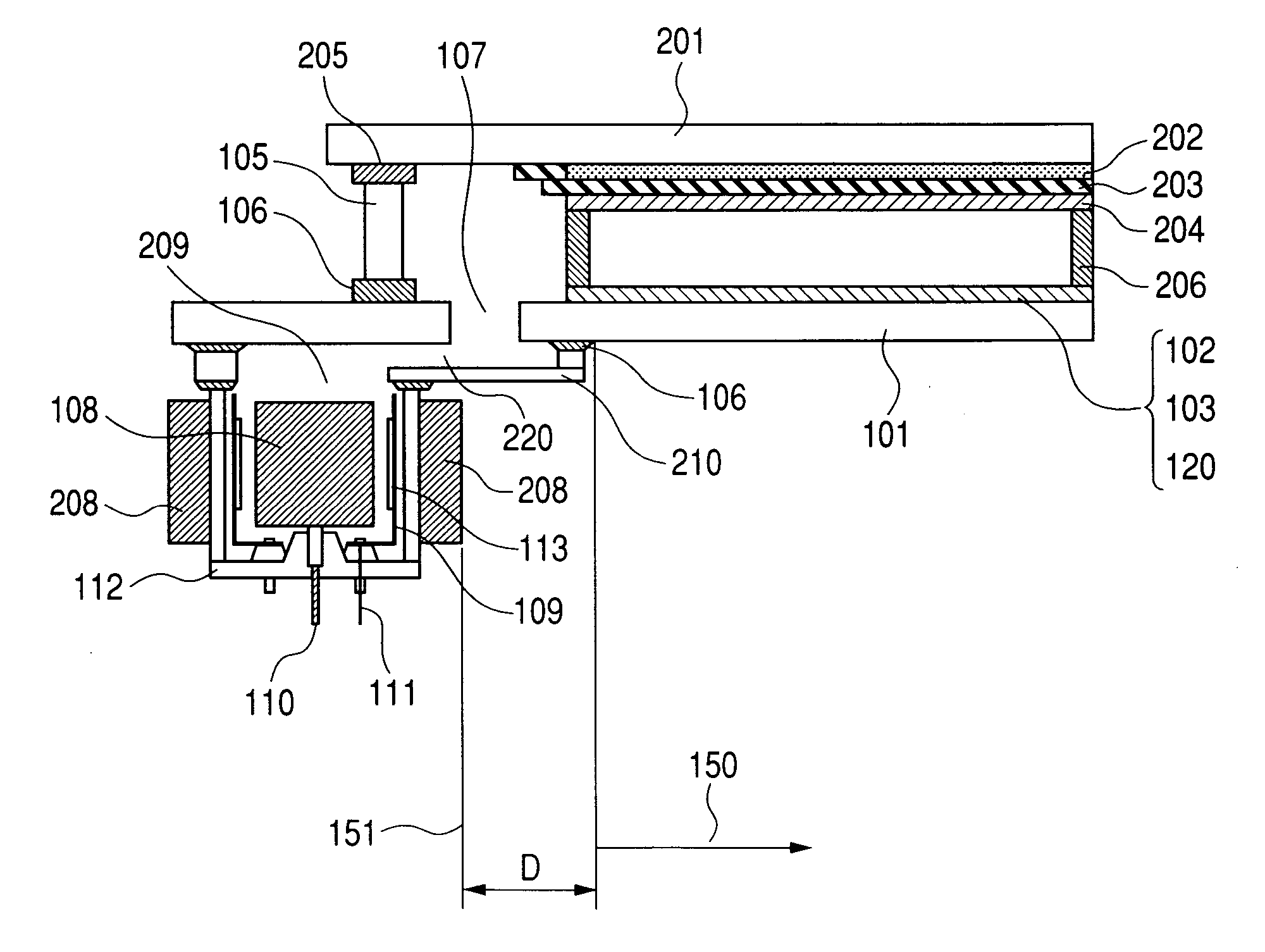

Manufacturing method of image forming apparatus, manufacturing apparatus of image forming apparatus, image forming apparatus, manufacturing method of panel apparatus, and manufacturing apparatus of panel apparatus

InactiveUS20010009836A1Electroluminescent light sourcesTube/lamp vessels exhaustionManufactured apparatusImage formation

To obtain a stable image forming apparatus of a high quality without a luminance fluctuation and a color mixture due to a positional deviation, the following construction is disclosed. A method of manufacturing an image display apparatus in which a first substrate on which fluorescent body exciting means is arranged and a second substrate on which a fluorescent body that emits light by the fluorescent body exciting means is arranged are arranged so as to face each other and are adhered through joining members at their peripheries, wherein a seal bonding step of adhering the first and second substrates through a joining members and a step of performing a position matching of the first and second substrates are executed in a vacuum.

Owner:CANON KK

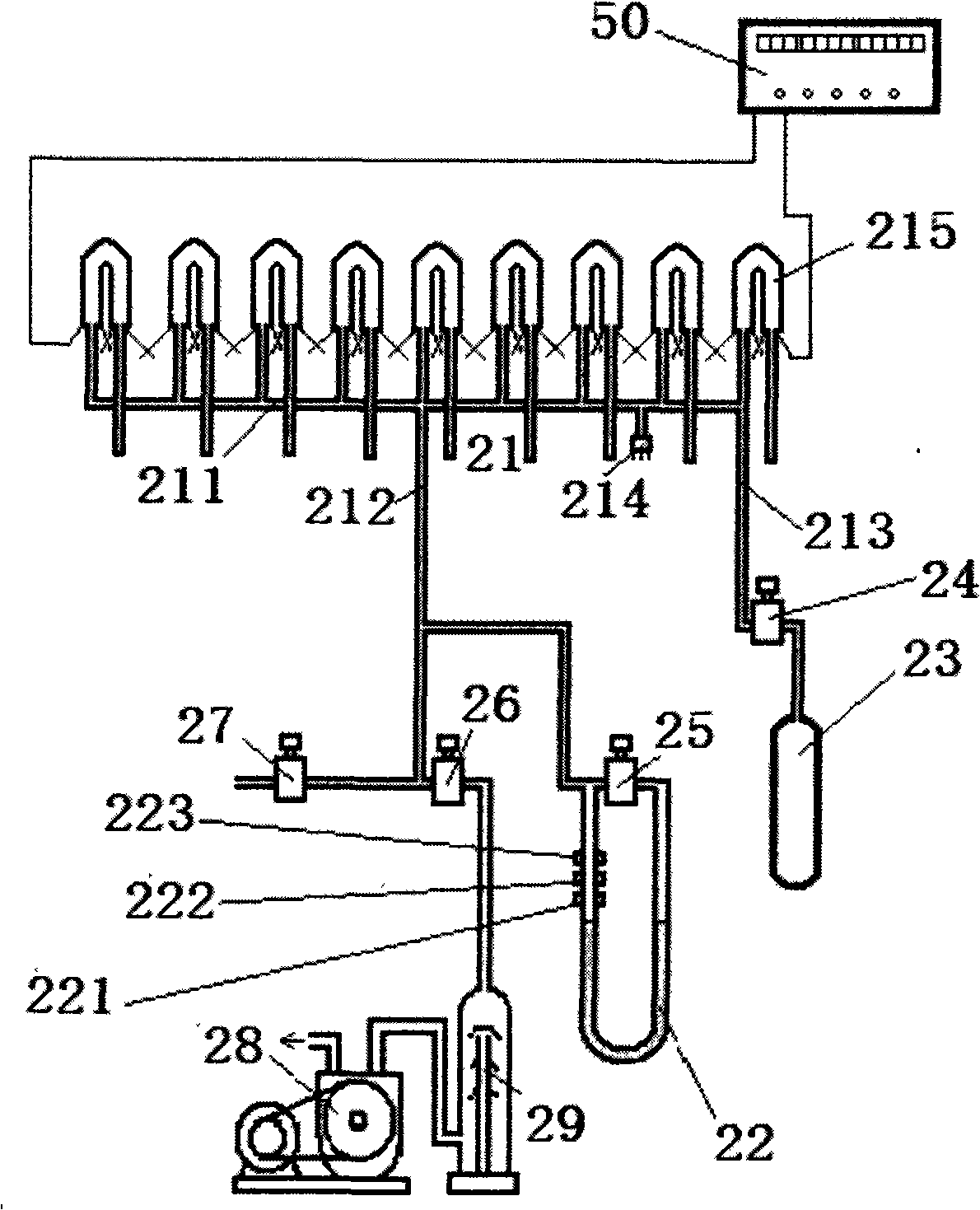

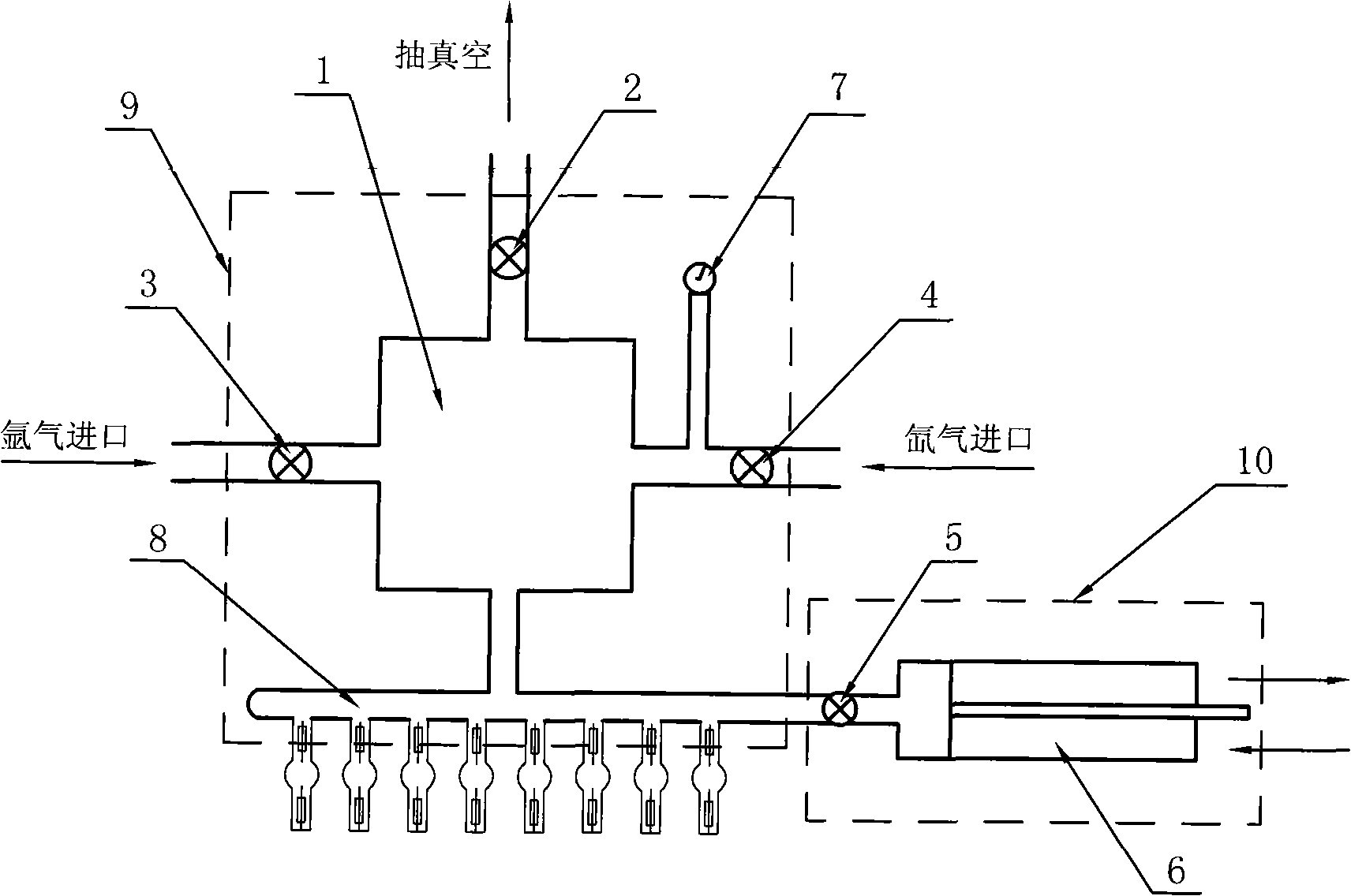

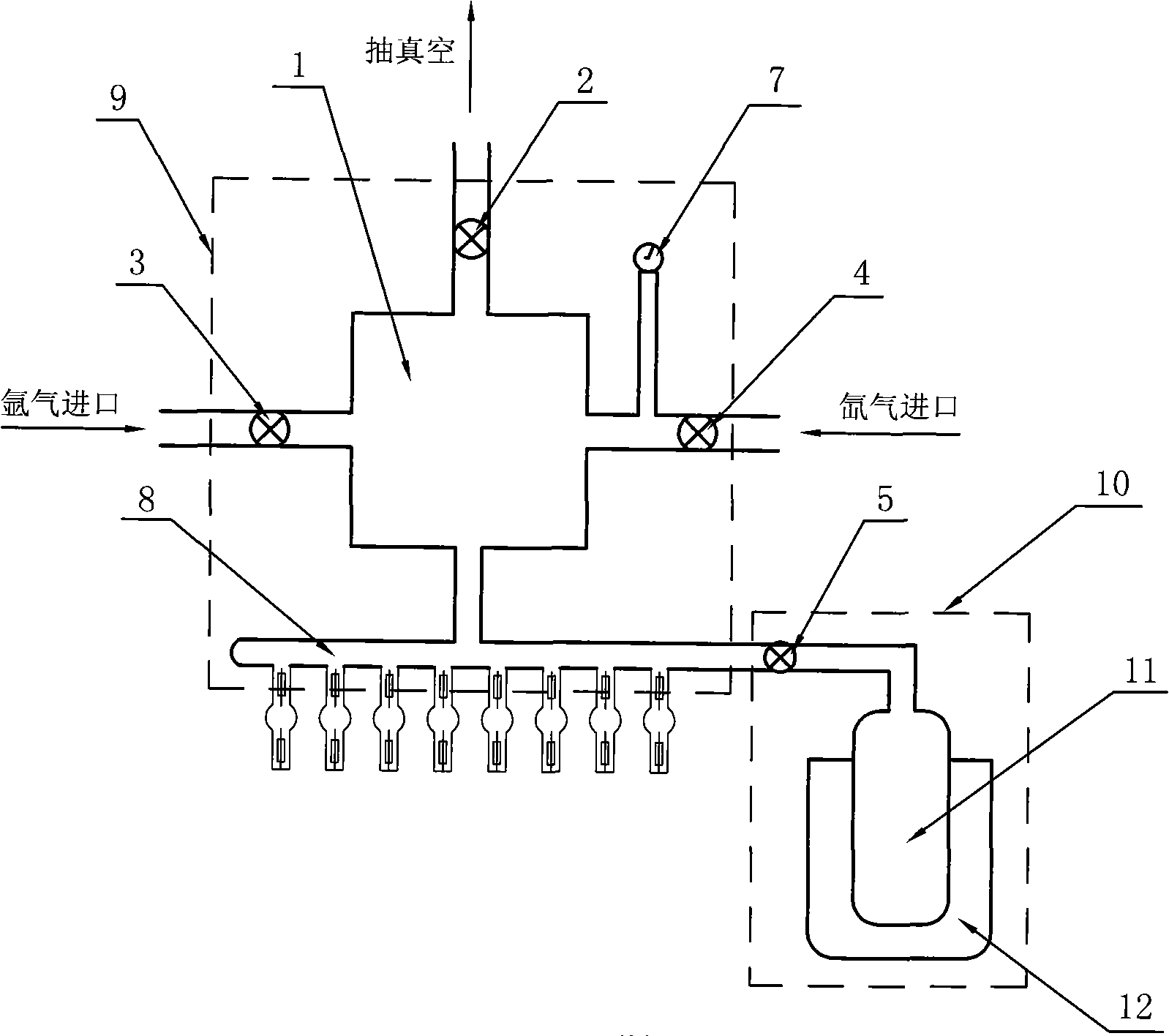

A charging and discharging method and device based on Xe gas

InactiveCN101266903AReduce wasteImprove recycling ratesTube/lamp vessel fillingTube/lamp vessels exhaustionVacuum pumpingCharge discharge

The invention discloses a gas charge-discharge method and device capable of adequately using xenon gas, comprising: using a recovery system connected with a charge-discharge system in parallel to collect and store the xenon gas remained in the charge-discharge system as charging gas for next batch of arc tubes. The device is composed of a charge-discharge system and a recovery system for collecting the xenon gas. The charge-discharge system comprises a four-way connector, three valves respectively connected with the four-way connector, and a arc tube arranging pipe; three valves are respectively connected with a vacuum pumping device, a flushing gas inlet and a working gas (xenon gas) inlet; a plurality of arc tubes to be charged can be disposed on the arc tube arranging pipe simultaneously; the recovery system is disposed on one end of the arc tube arranging pipe, composed by a recovery device and a valve, the valve is disposed between the arc tube arranging pipe and the recovery device. The invention can effectively enhance the utilization rate of xenon gas during xenon gas lamp manufacture, by increasing the utilization rate from under existing 30% up to over 95%.

Owner:浙江新光阳照明股份有限公司

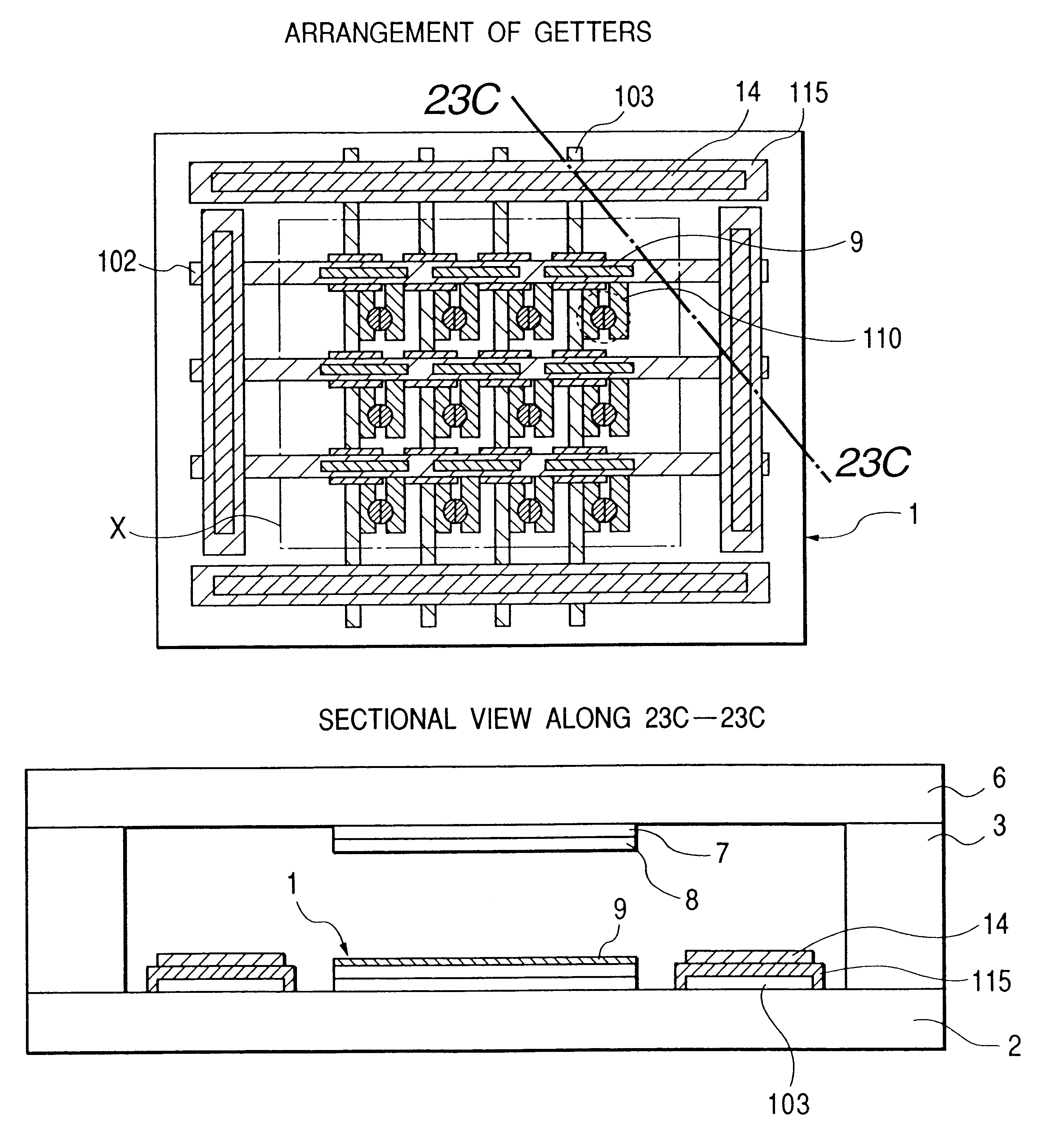

Method for gettering an image display apparatus

InactiveUS6652343B2Little changeLittle unevennessGas filling substance selectionDischarge tube luminescnet screensElectron sourceFluorescence

An image display apparatus is provided with an external housing constituted by members including first and second substrates positioned with a gap therebetween, an electron source positioned on the first substrate in the external housing, and a fluorescent film and an accelerating electrode provided on the second substrate. A first getter is positioned in the image display area in the external housing. A second getter is provided, so that it is insulated from the electron source and the accelerating electrode, which surrounds the first getter.

Owner:CANON KK

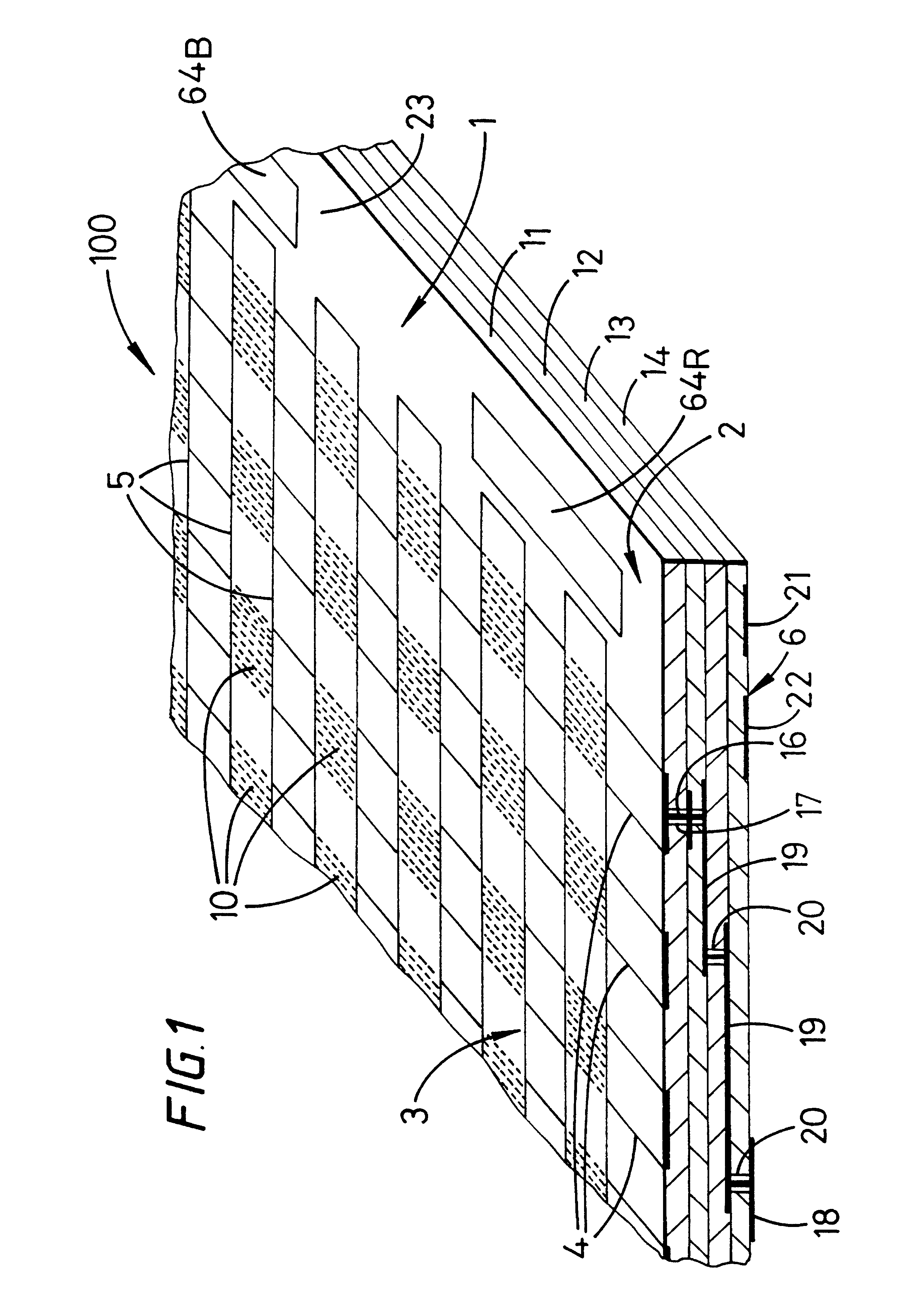

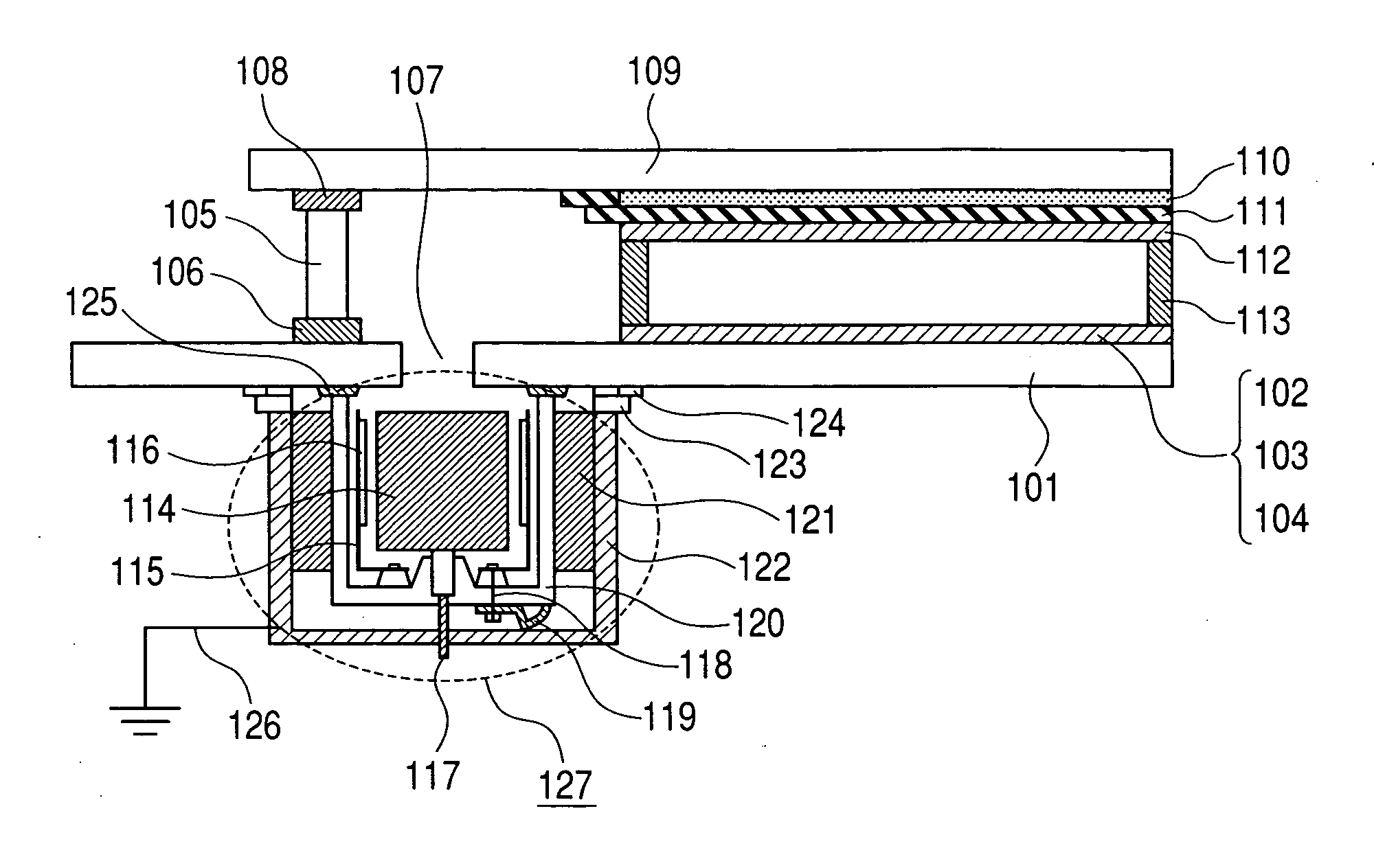

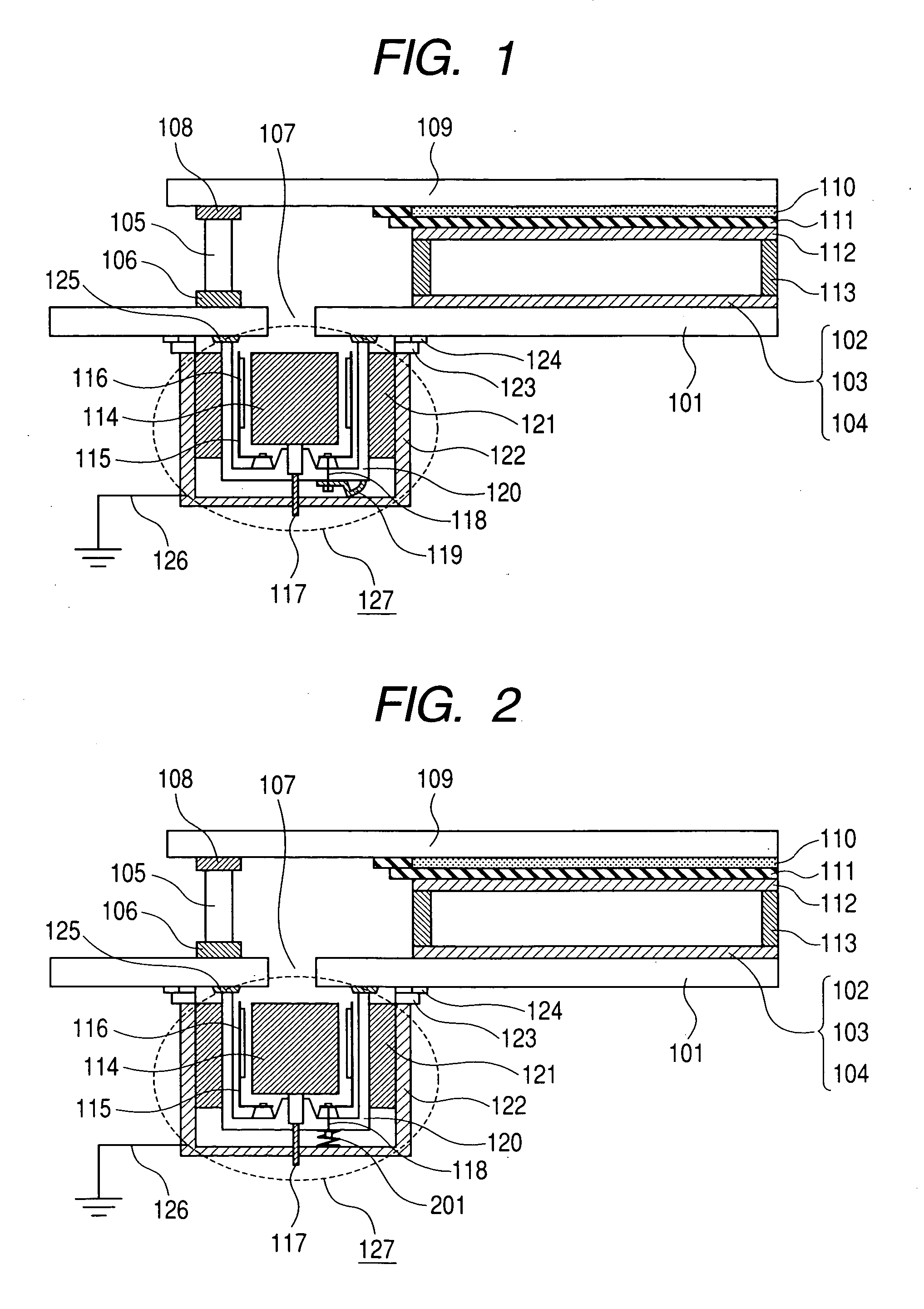

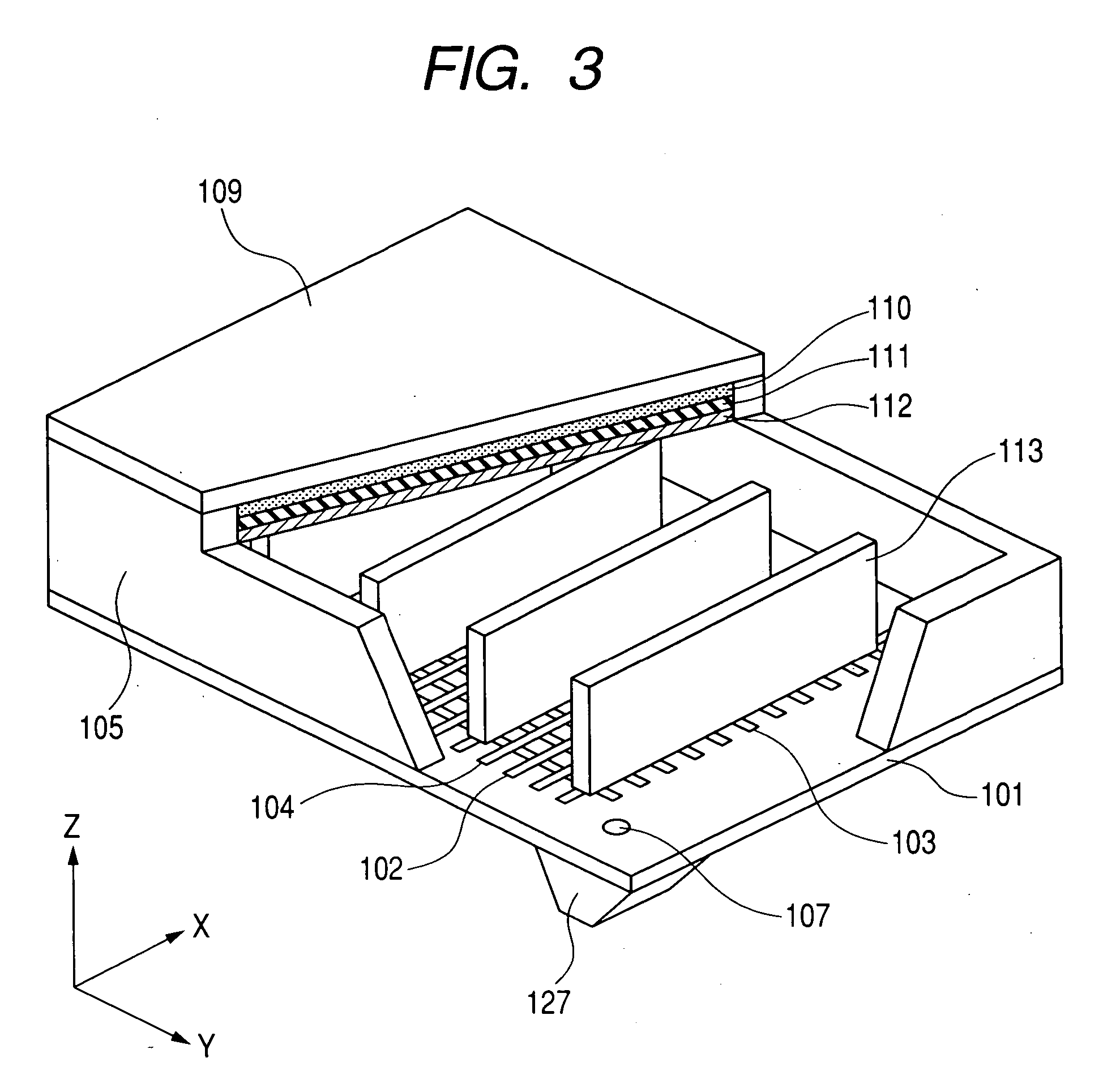

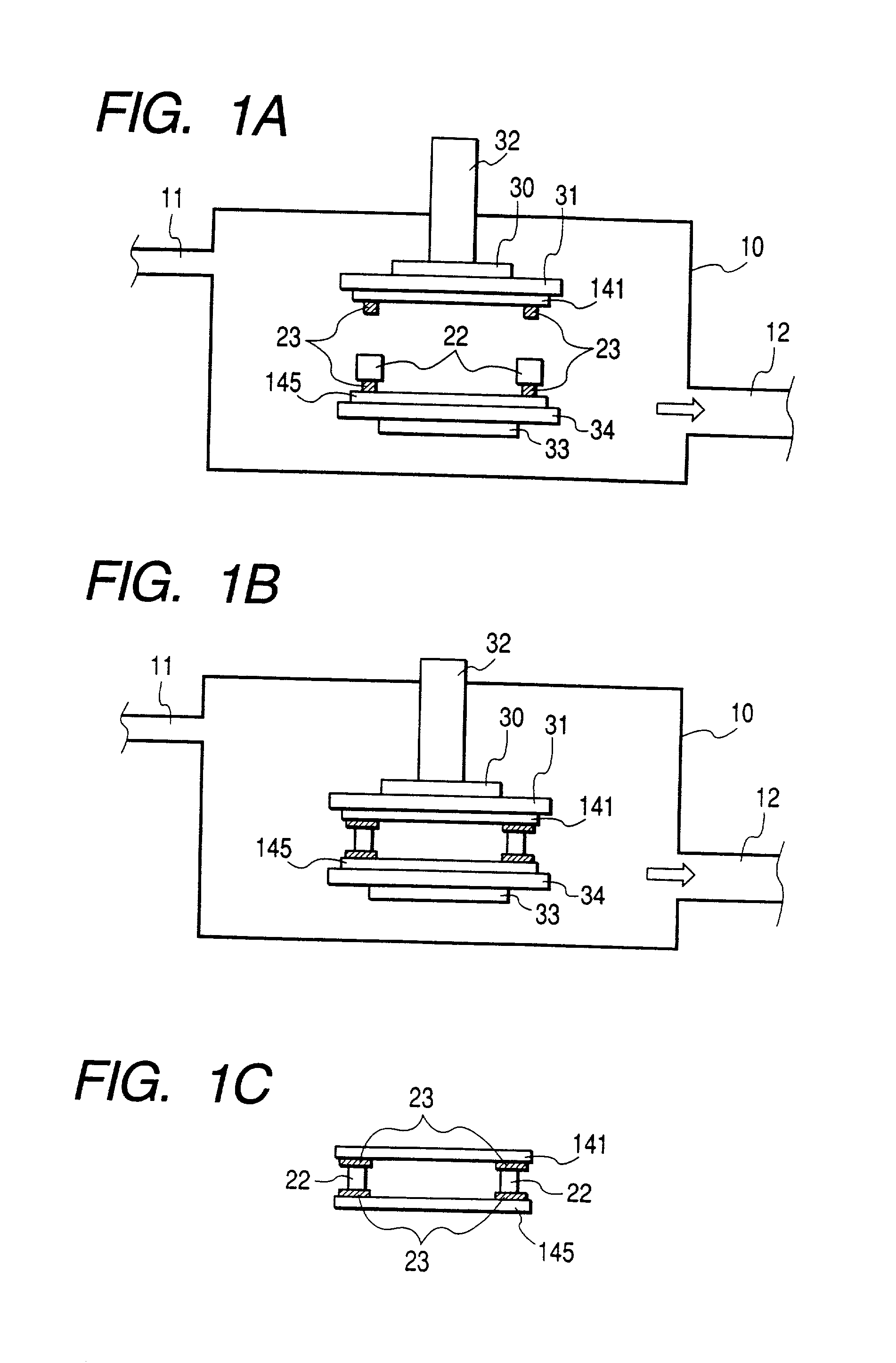

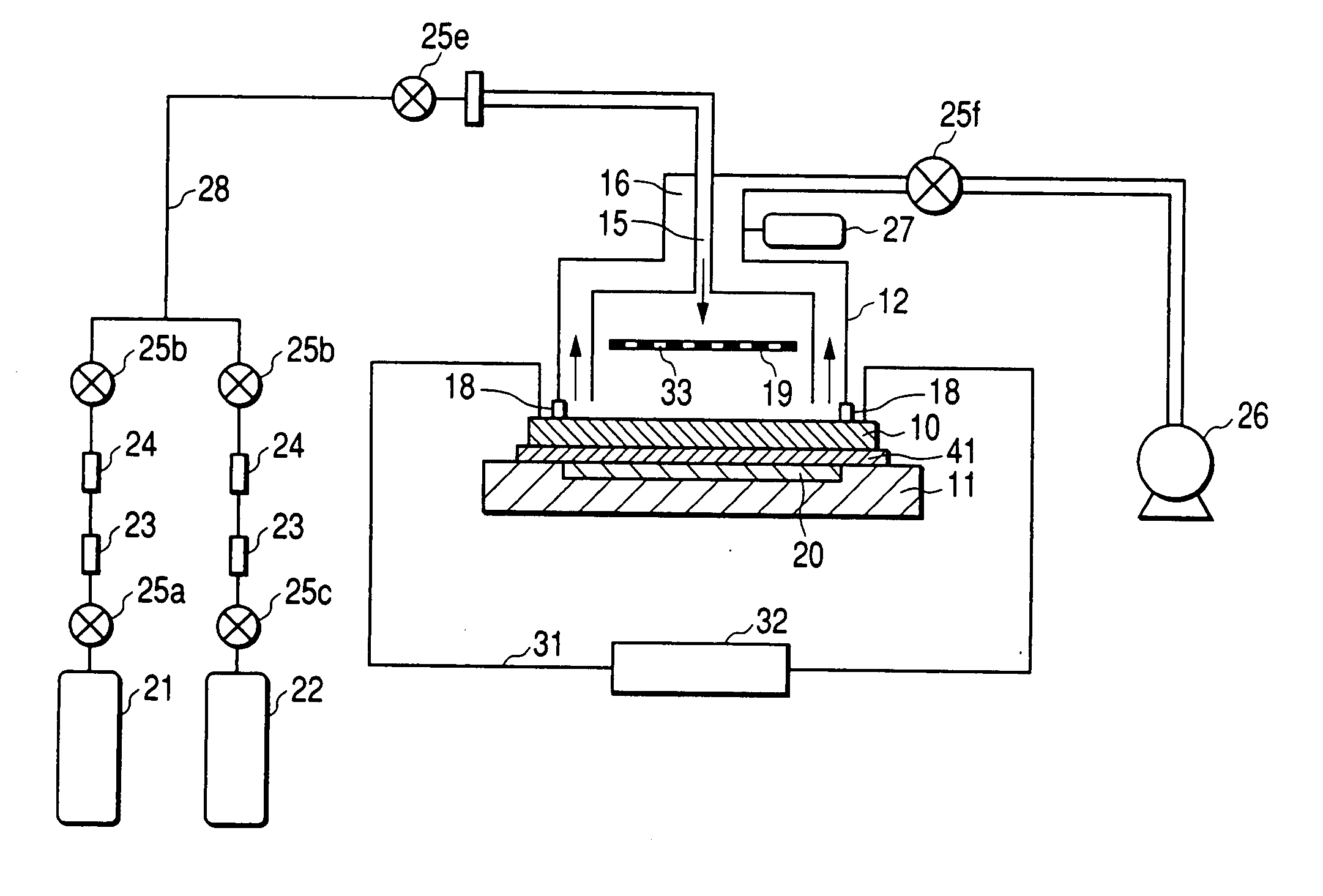

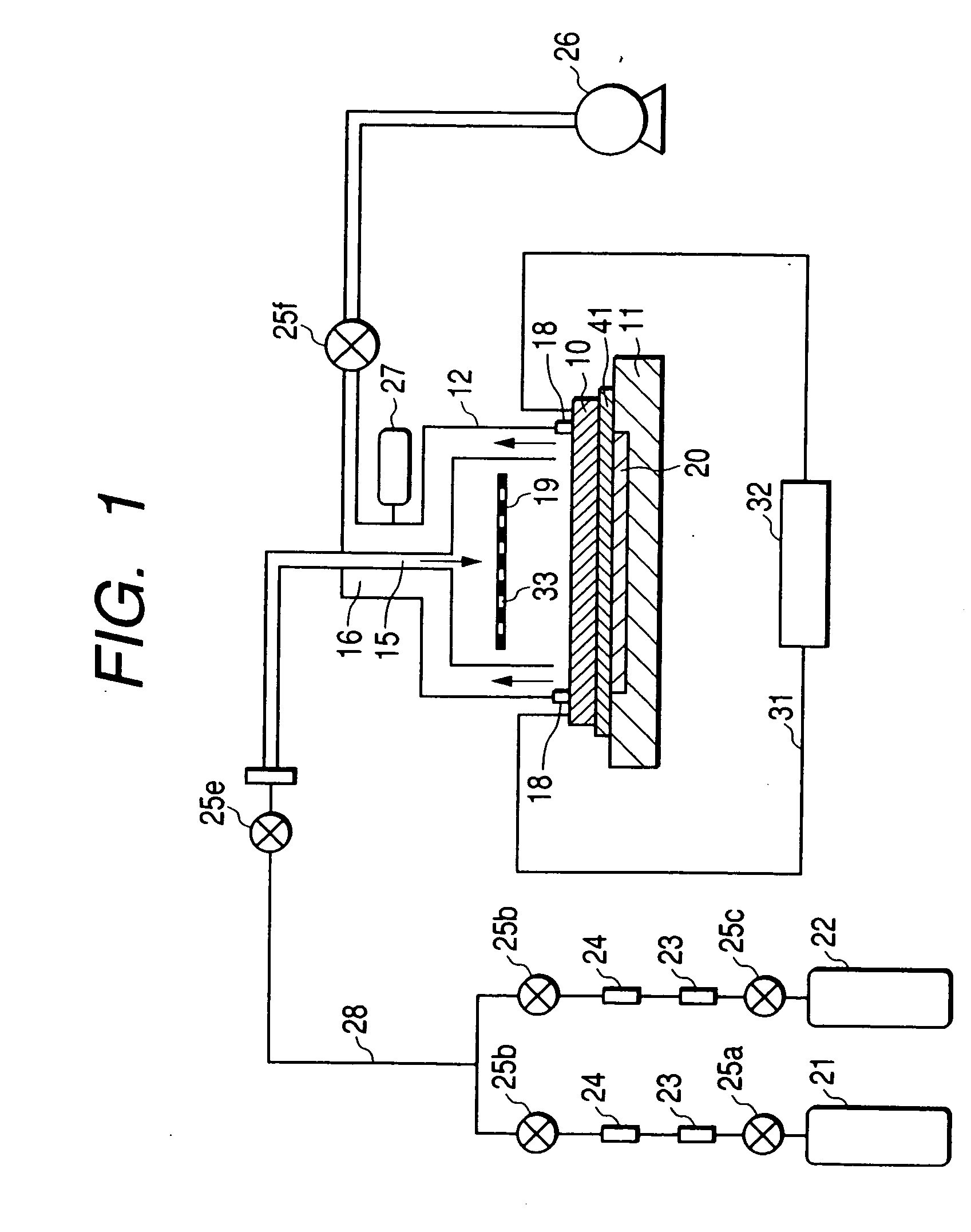

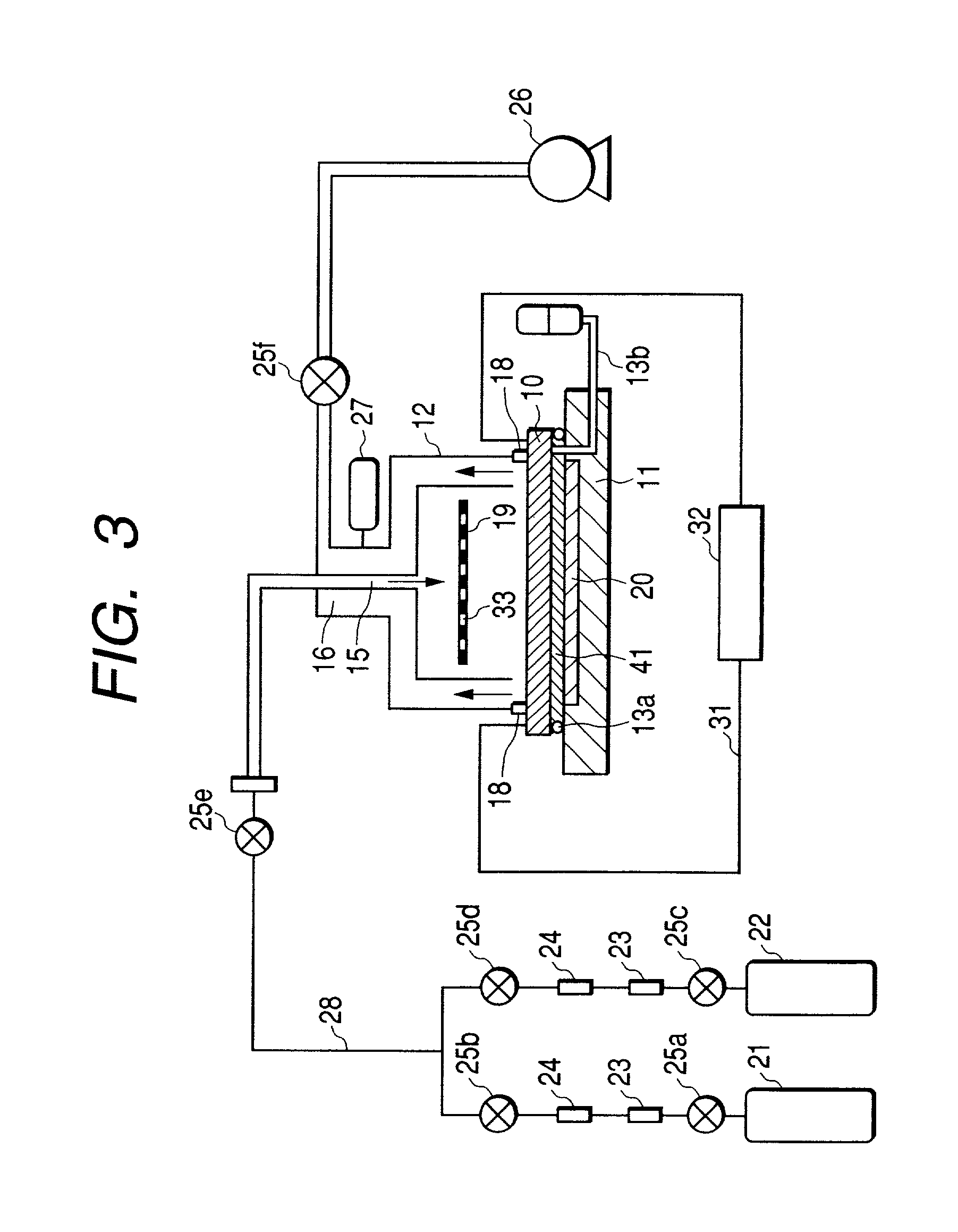

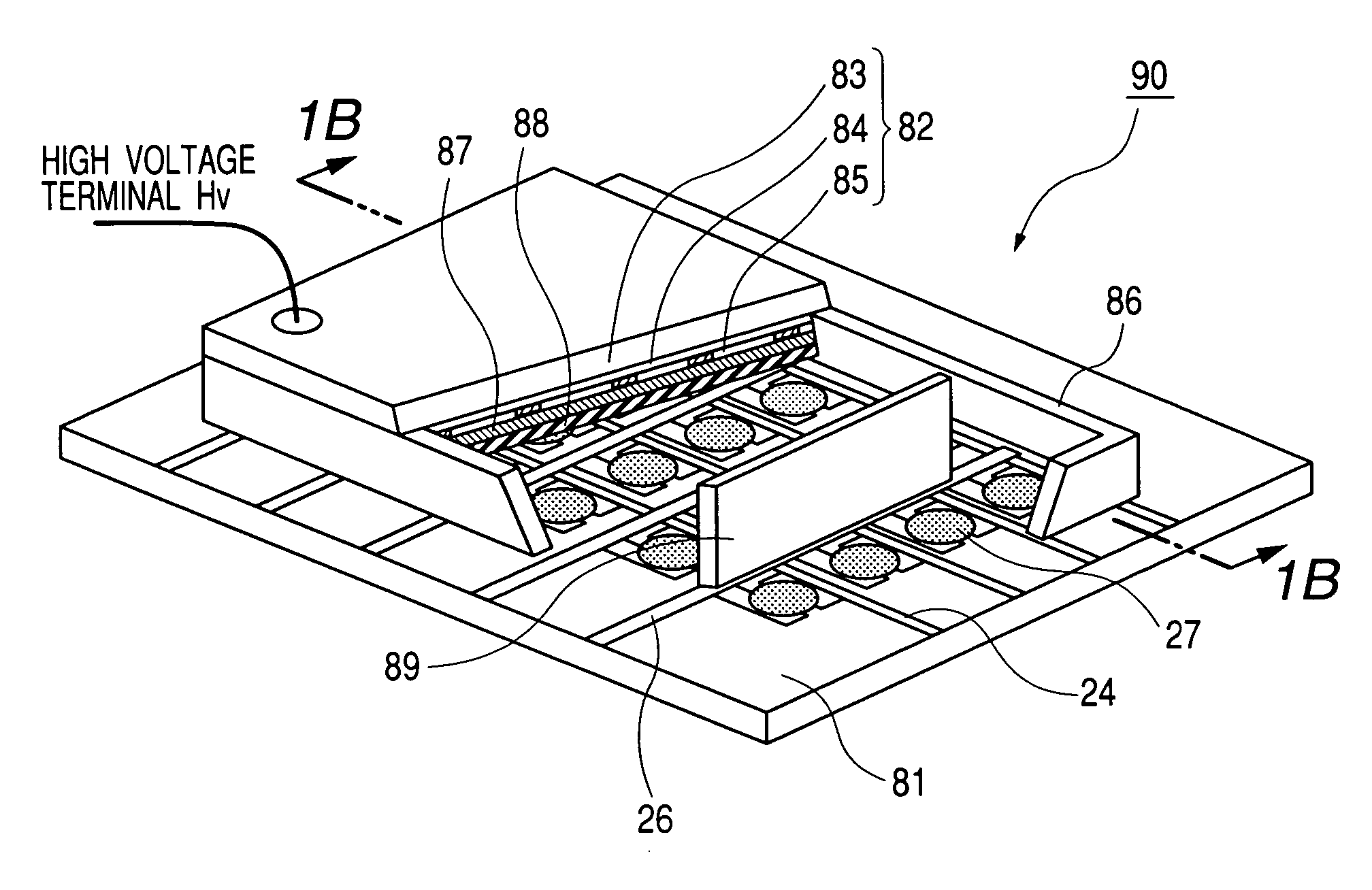

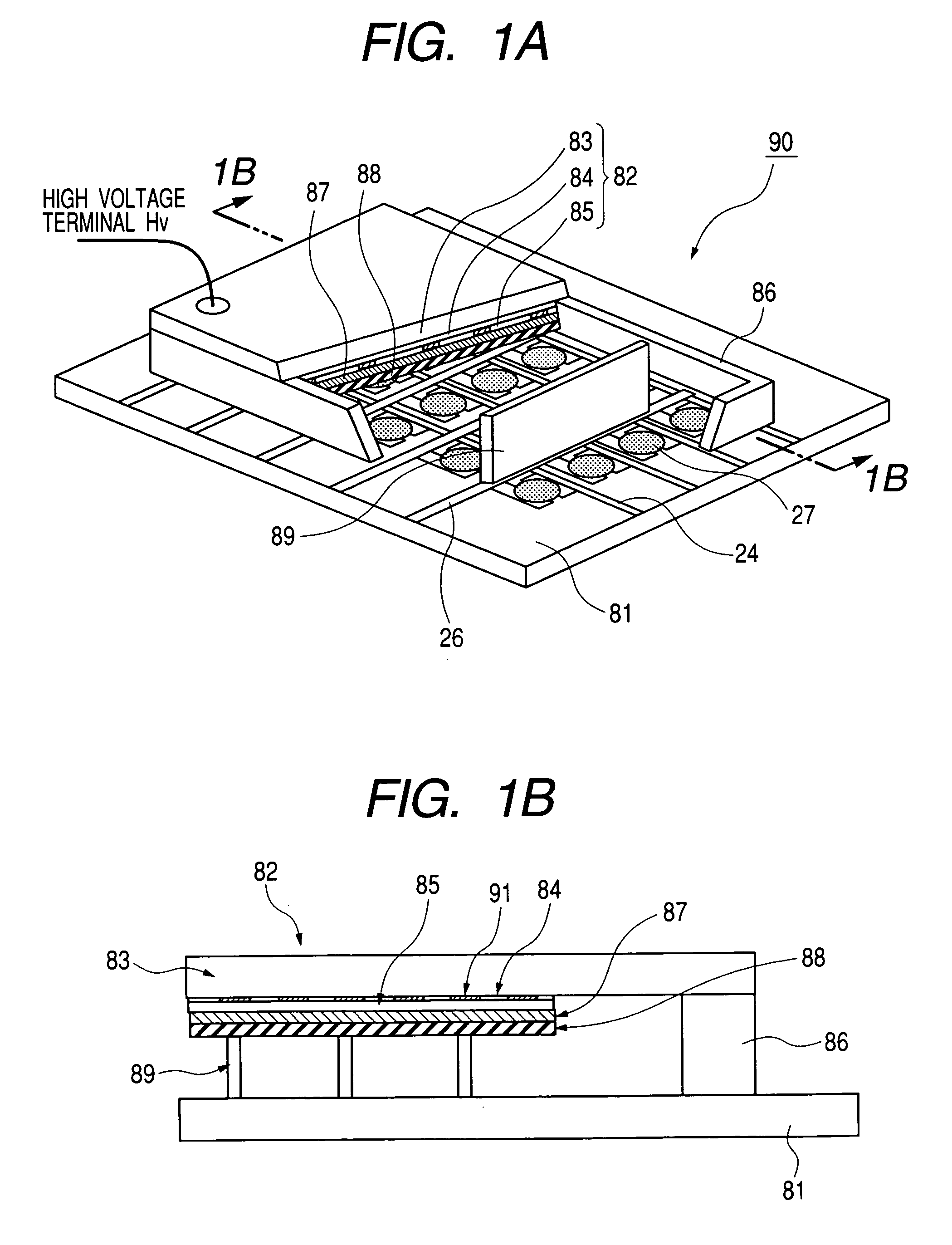

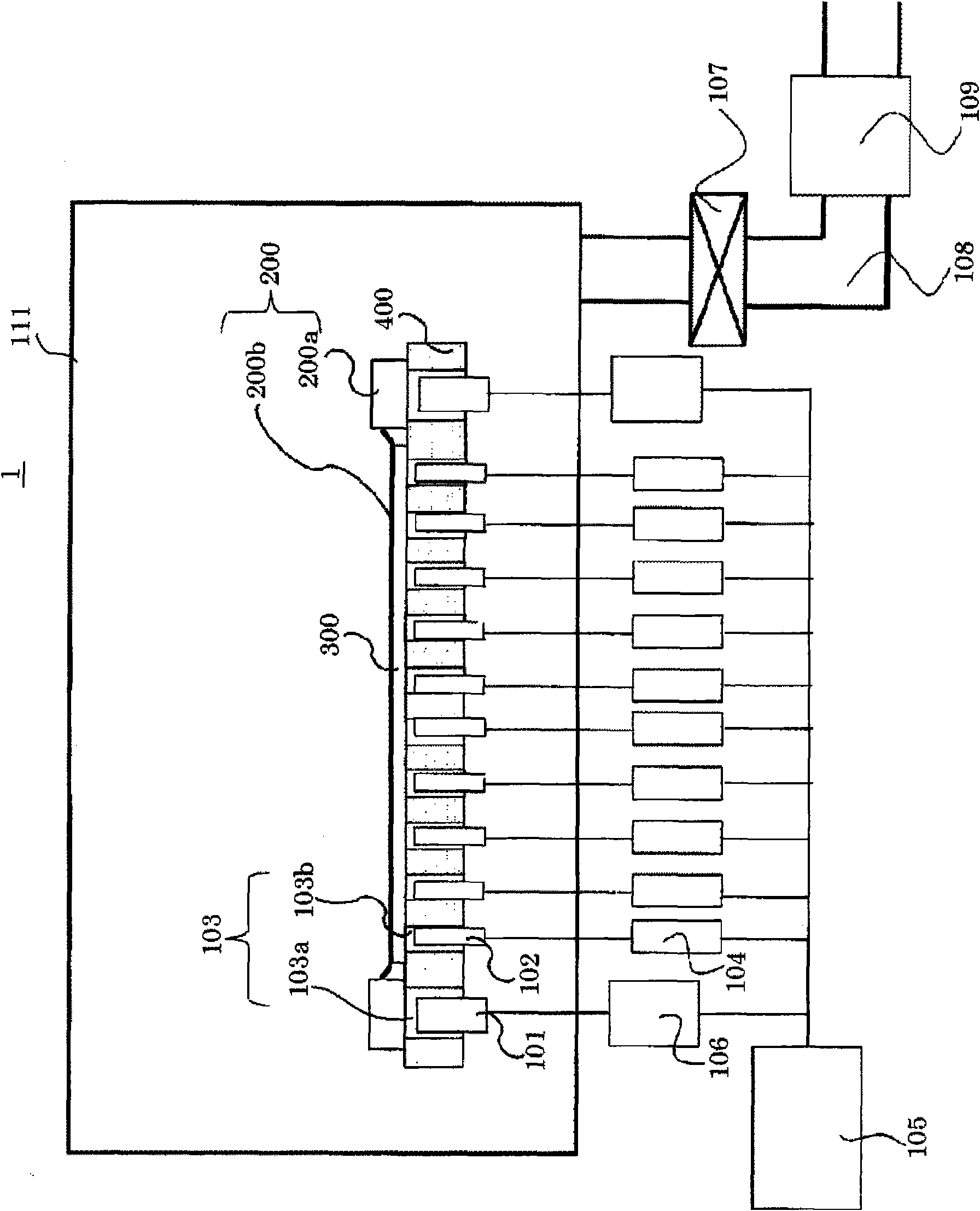

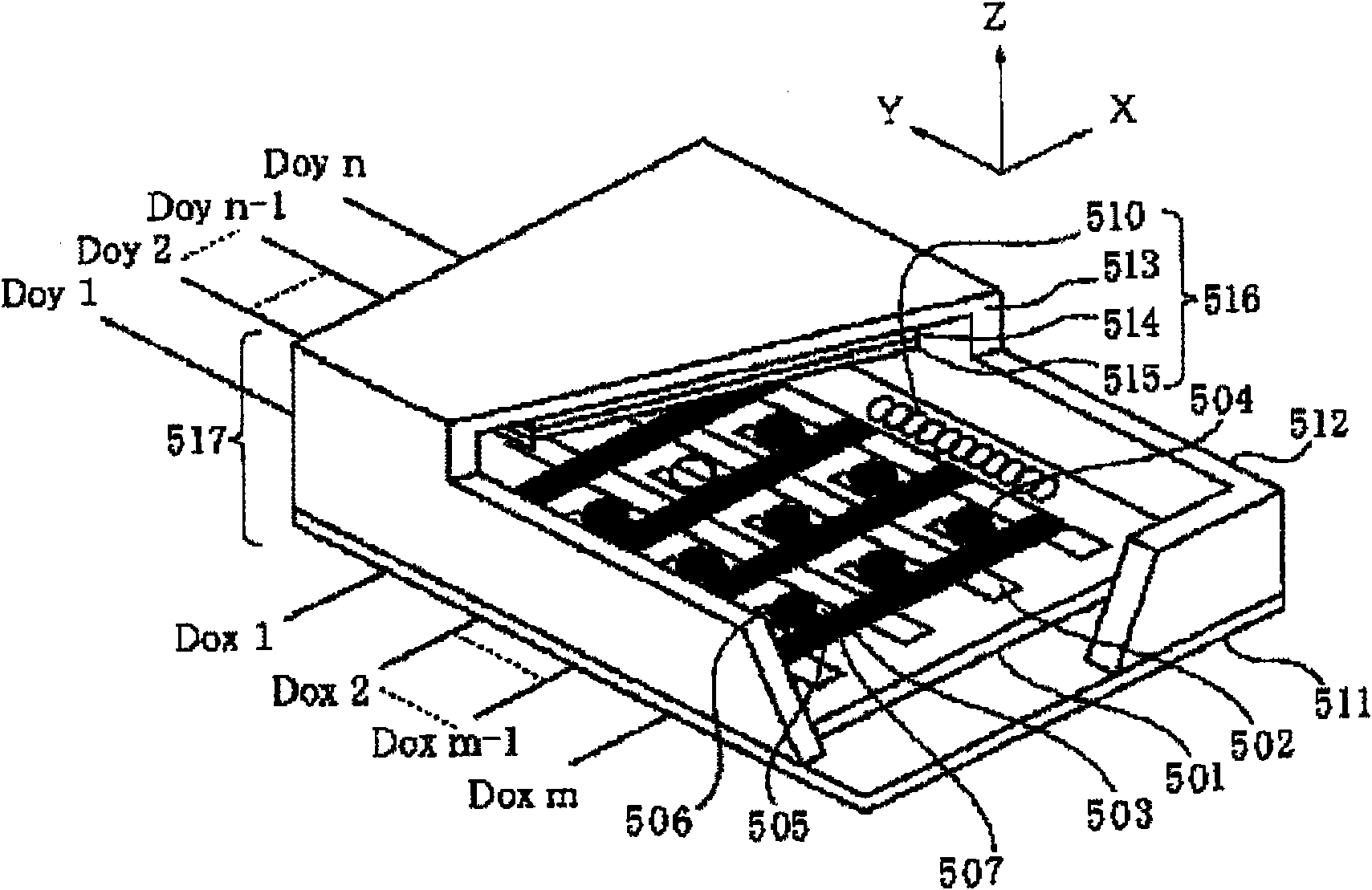

Method and apparatus for manufacturing image displaying apparatus

InactiveUS20050009433A1Excellent electron-emitting characteristicEasy to fallGetteringCathode ray tubes/electron beam tubesElectrical conductorElectron source

A method and an apparatus of manufacturing an image displaying apparatus having an electron source substrate and a phosphor substrate. The electron source substrate is provided with an electron emitting element formed by covering with a container and by applying a voltage to an electronic conductor on the substrate. While, the phosphor substrate is provided with a phosphor thereon. The substrates are subjected to a getter processing and to a seal bonding process under a vacuum condition through a processing chamber, to complete an image forming apparatus. An improvement resides in miniaturizing and simplifying operation, and in greater manufacture speed and mass production.

Owner:CANON KK

Method and apparatus for manufacturing image displaying apparatus

InactiveUS20010041490A1Reduce sizeEasy to operateGetteringCathode ray tubes/electron beam tubesElectrical conductorElectron source

A method and an apparatus of manufacturing an image displaying apparatus comprising an electron source substrate and a phosphor substrate. The electron source substrate is provided with an electron emitting element formed by covering with a container and by applying a voltage to an electronic conductor on the substrate. While, the phosphor substrate is provided with a phosphor thereon. The substrates are subjected to a getter processing and to a seal bonding process under a vacuum condition through a processing chamber, to complete an image forming apparatus. An improvement resides in miniaturizing and simplifying operation, and in greater manufacture speed and mass production.

Owner:CANON KK

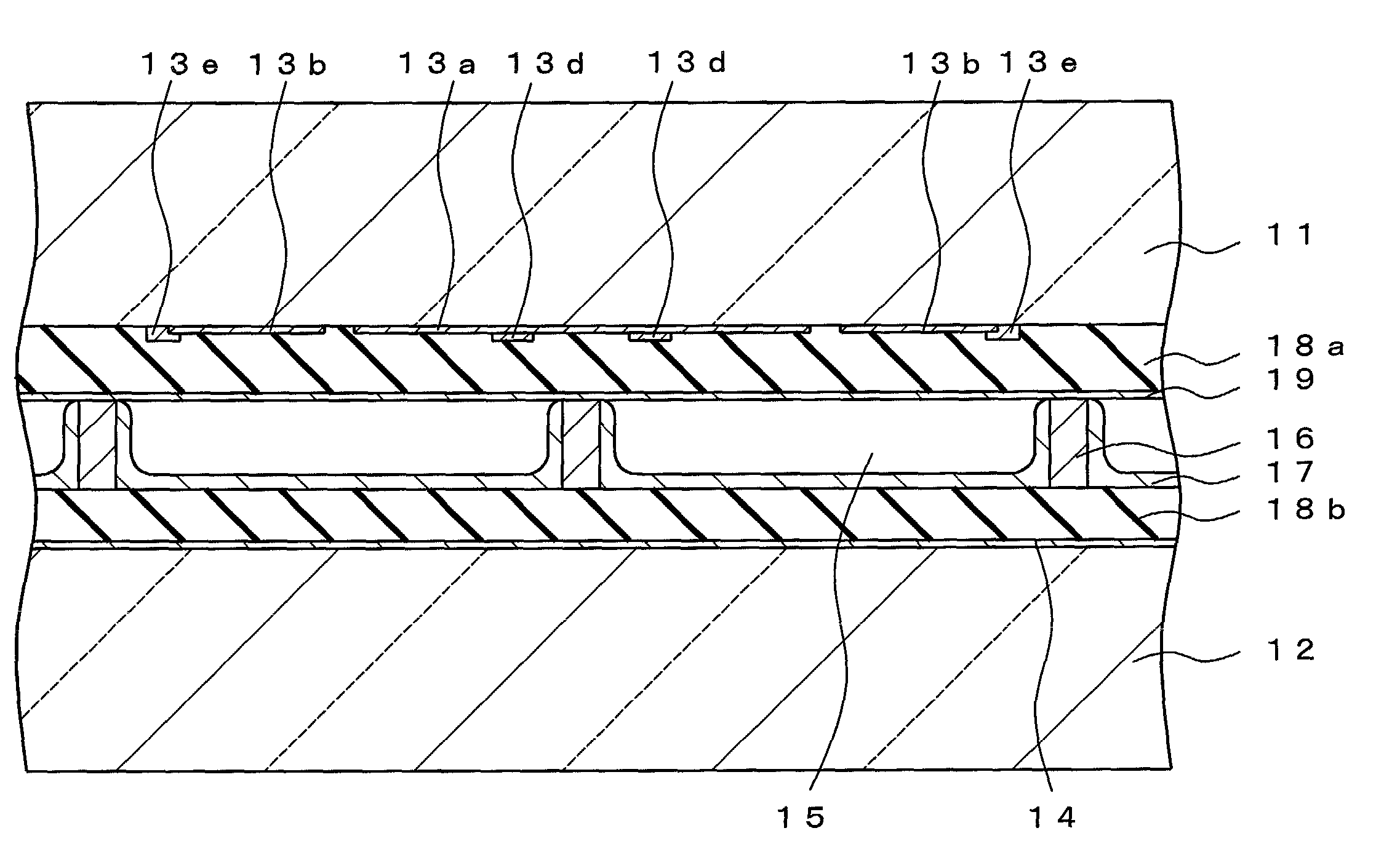

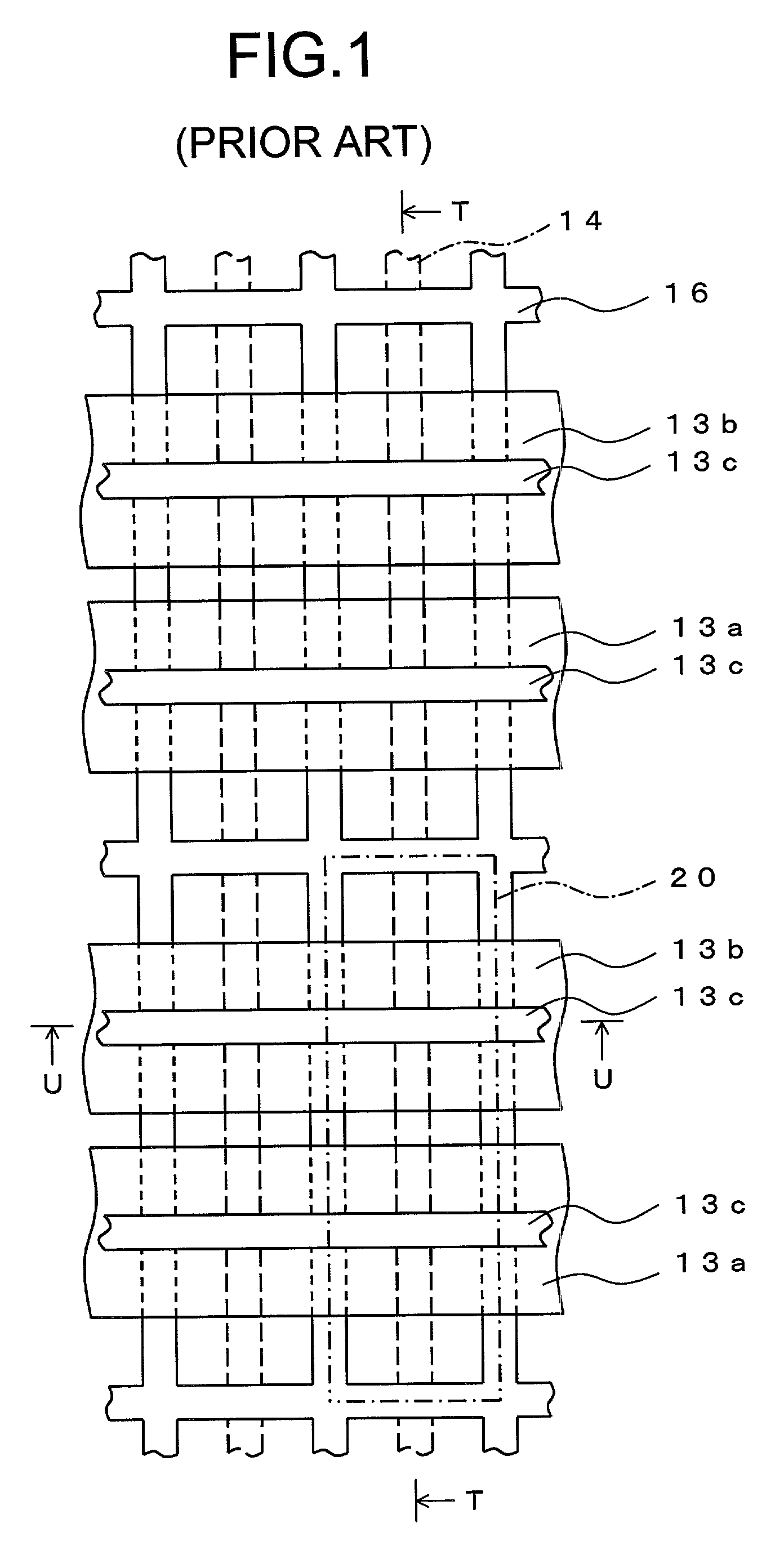

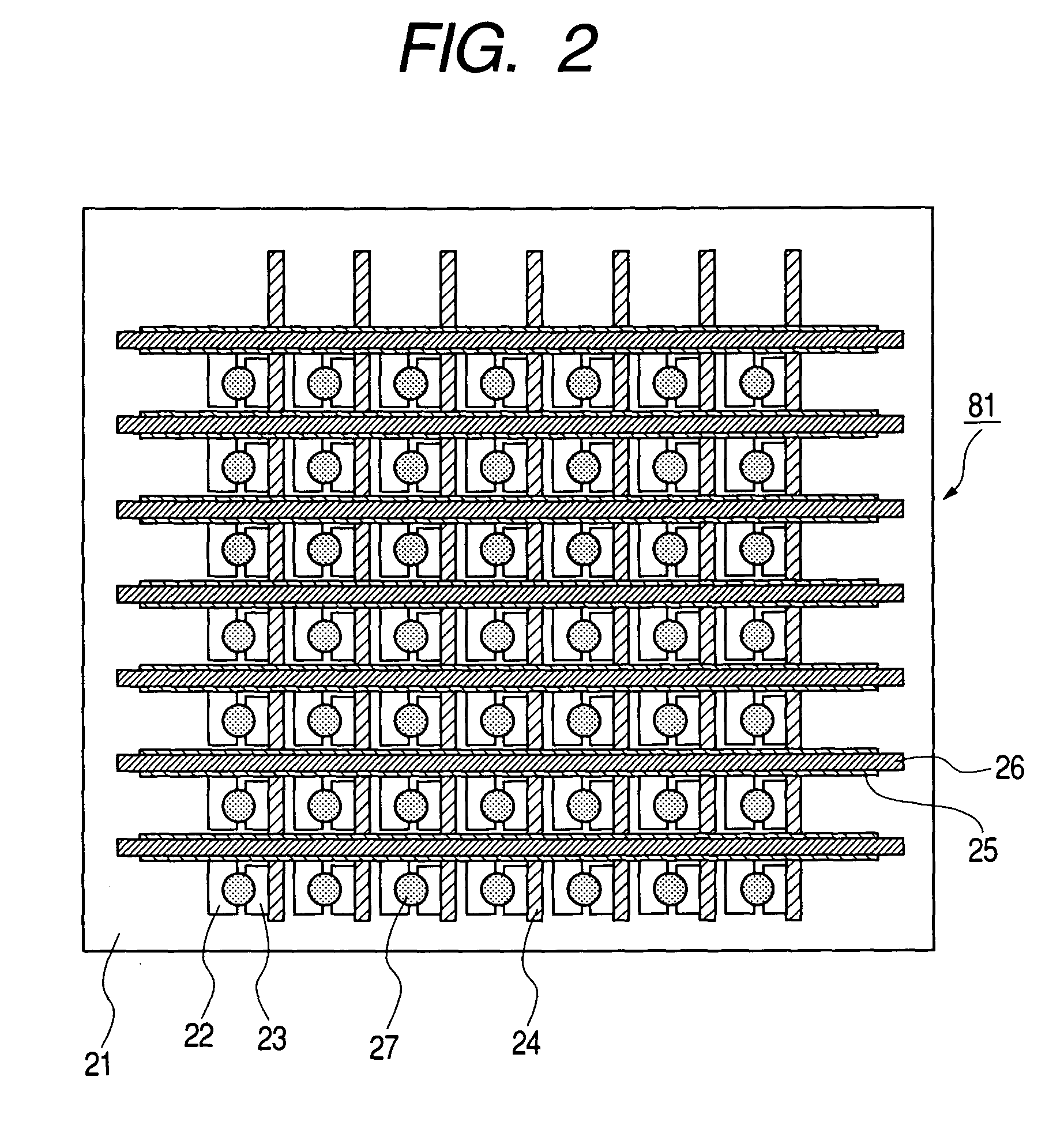

Plasma display panel and method of manufacturing back panel thereof

A Plasma Display Panel (PDP) includes: a front panel having a front plate and a plurality of electrodes arranged on a surface of the front plate in a predetermined pattern and a back panel having a back plate facing the front plate, a plurality of electrodes arranged on a surface of the back plate in a predetermined pattern to correspond to the plurality of electrodes of the front plate, and at least one ventilation hole. At least two back plates are formed by cutting one base plate on which at least two ventilation holes are formed. Each ventilation hole has a first width in a first edge direction of the back plate and a distance from the first edge to a center of the at least one ventilation hole is at least twice that of the first width.

Owner:SAMSUNG SDI CO LTD

Image display apparatus

InactiveUS20060043870A1Reduce magnetic influenceLittle nonuniformity in brightnessGas filling substance selectionElectrode and associated part arrangementsElectron sourceImage formation

An image display apparatus for forming an image in an image displaying region provided with a vacuum chamber having an electron source substrate and an image forming substrate has an ion pump for evacuating the vacuum chamber by an action of a magnet-filed-forming portion through an aperture portion formed in the electron source substrate or an image displaying substrate, wherein the magnet-filed-forming portion is arranged so that a shadow formed by perpendicularly projecting the magnet-filed-forming portion onto the electron source substrate or the image forming substrate can be located outside the image displaying region.

Owner:CANON KK

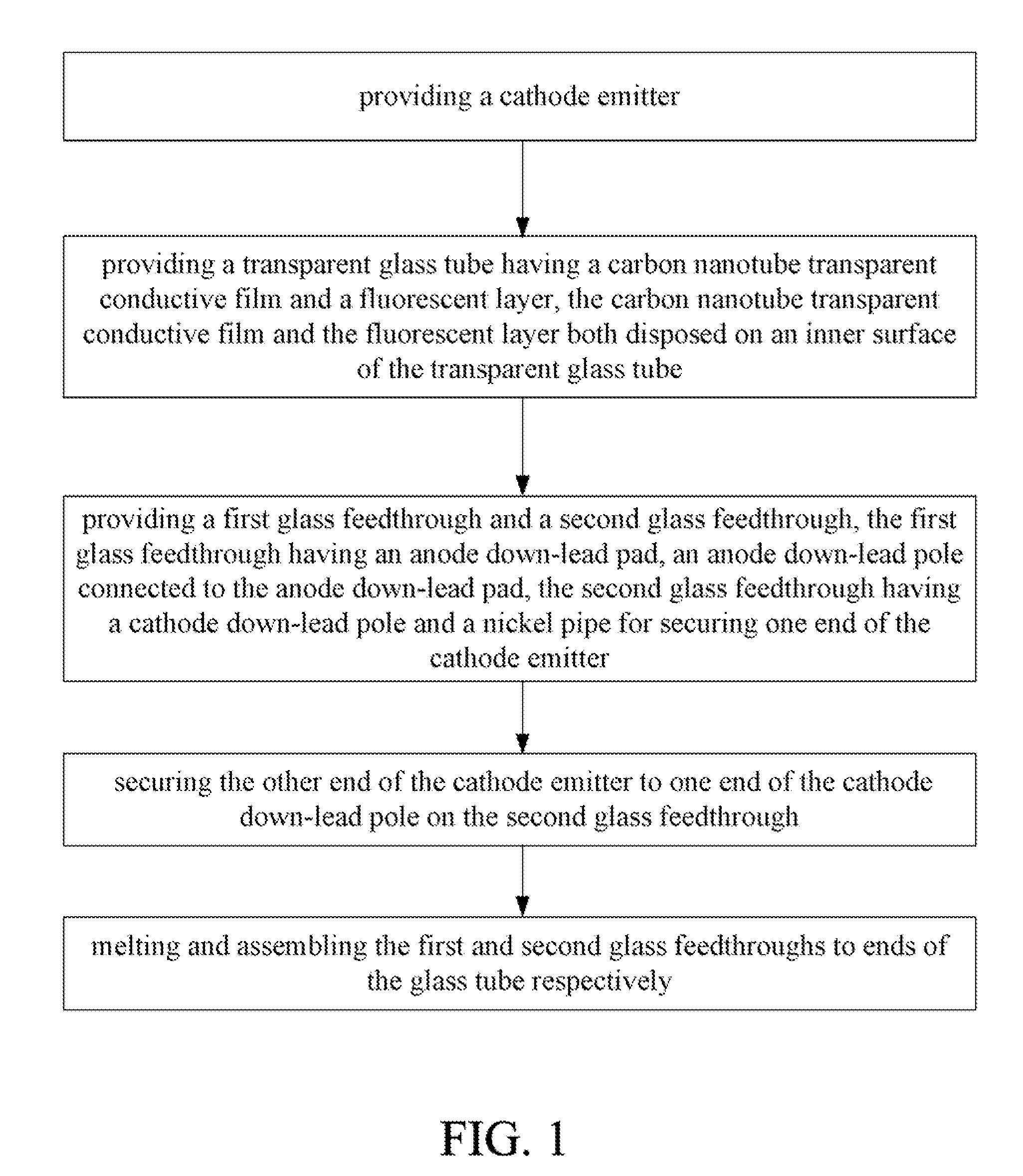

Method for making field emission lamp

ActiveUS20080160865A1Affects performance lifeLow costTube/lamp vessel degassingThermionic cathodesCarbon nanotubeNickel

A method for making a field emission lamp generally includes the steps of: (a) providing a cathode emitter; (b) providing a transparent glass tube having a carbon nanotube transparent conductive film and a fluorescent layer, the carbon nanotube transparent conductive film and the fluorescent layer both disposed on an inner surface of the transparent glass tube; (c) providing a first glass feedthrough and a second glass feedthrough, the first glass feedthrough having an anode down-lead pad, an anode down-lead pole connected to the anode down-lead pad, the second glass feedthrough having a cathode down-lead pole and a nickel pipe for securing one end of the cathode emitter; (d) securing the other end of the cathode emitter to one end of the cathode down-lead pole on the second glass feedthrough; (e) melting and assembling the first and second glass feedthroughs to ends of the glass tube respectively.

Owner:TSINGHUA UNIV +1

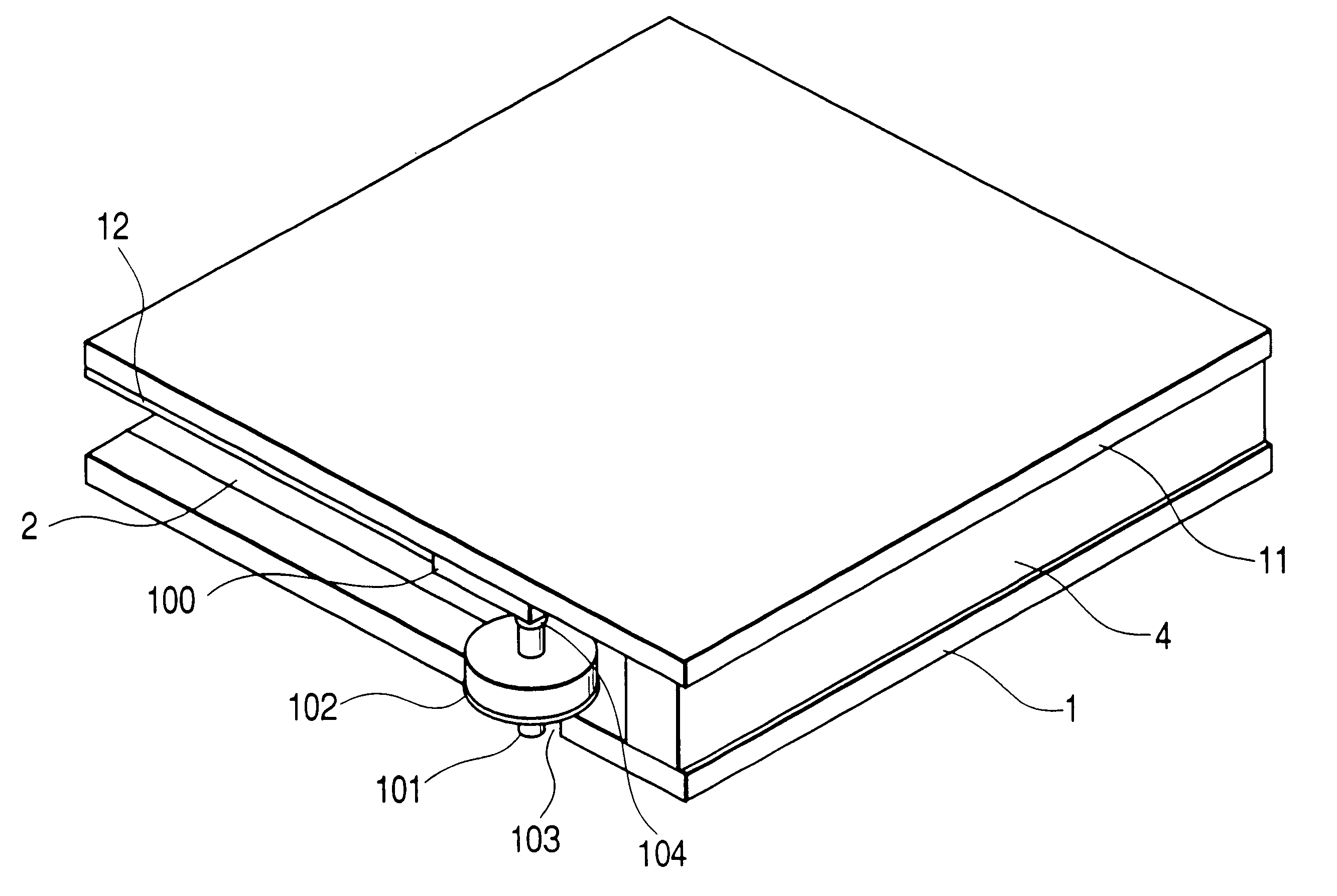

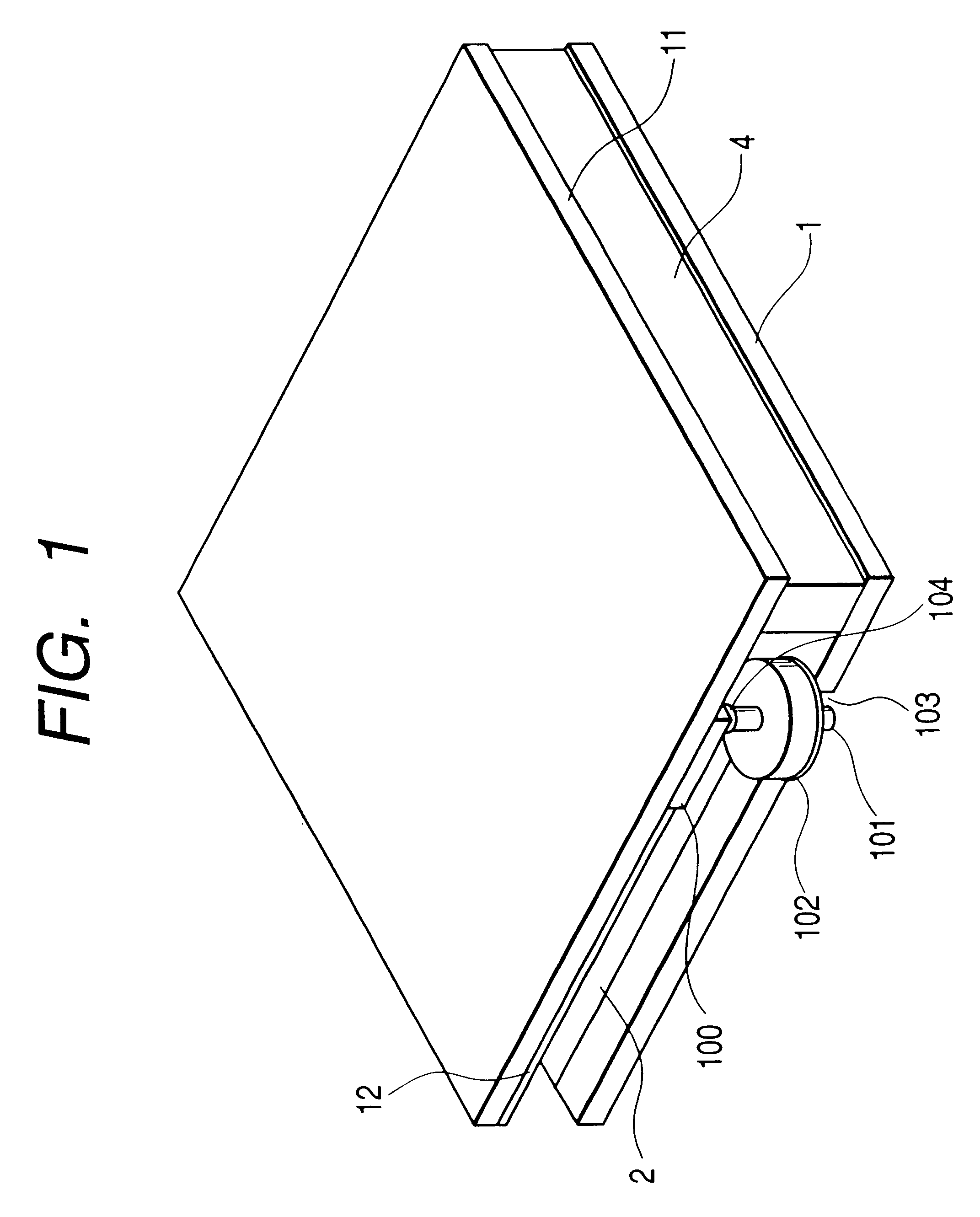

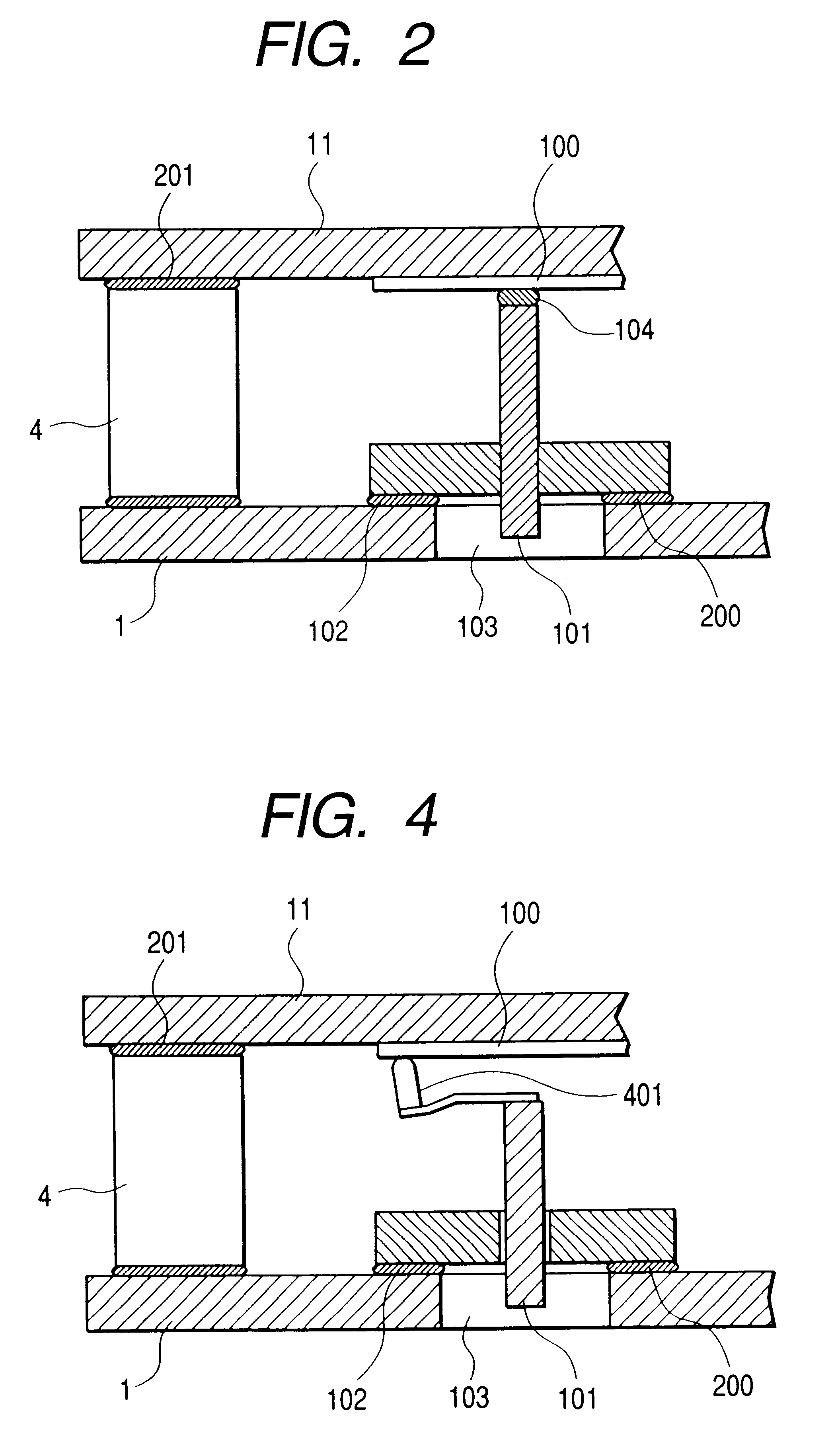

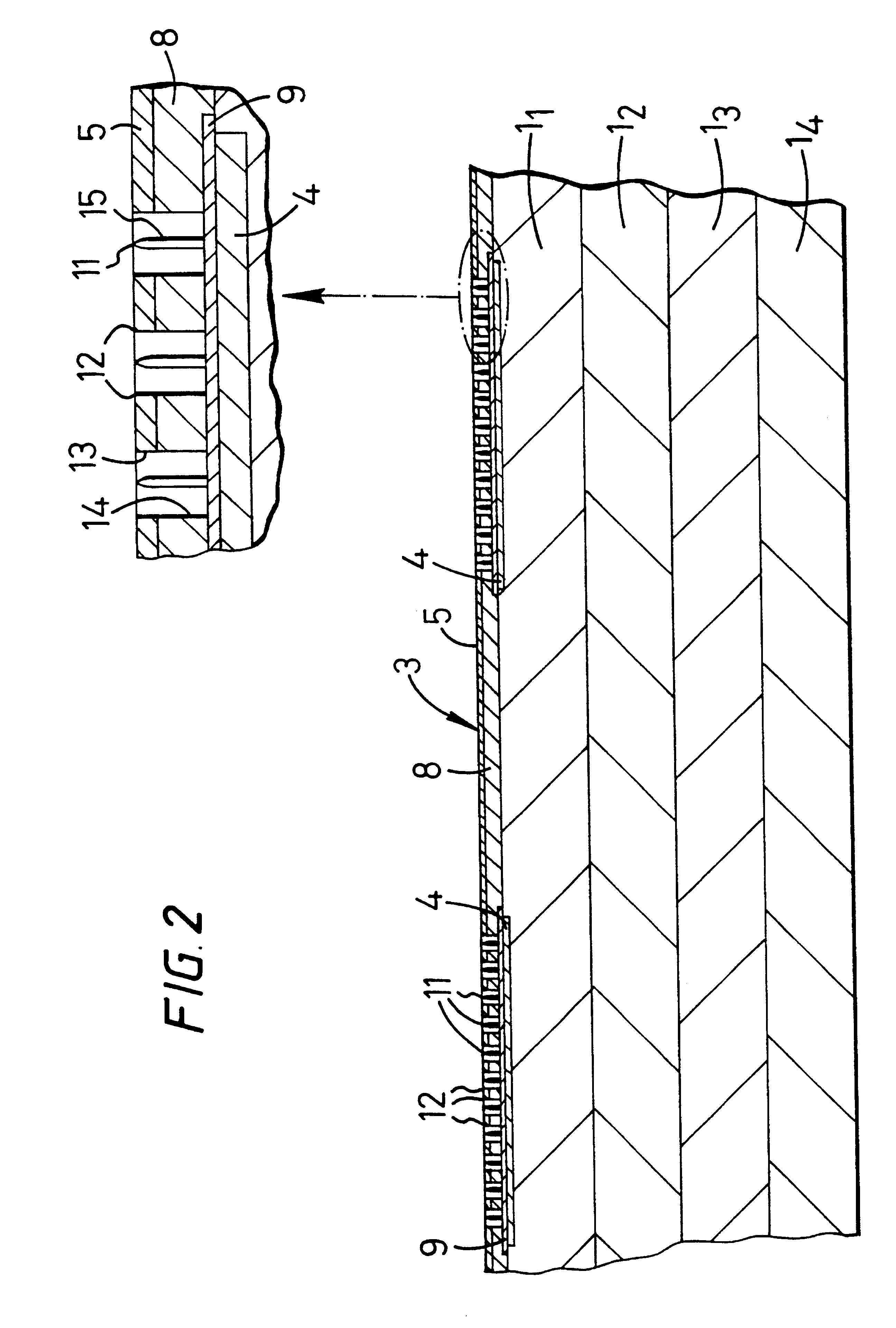

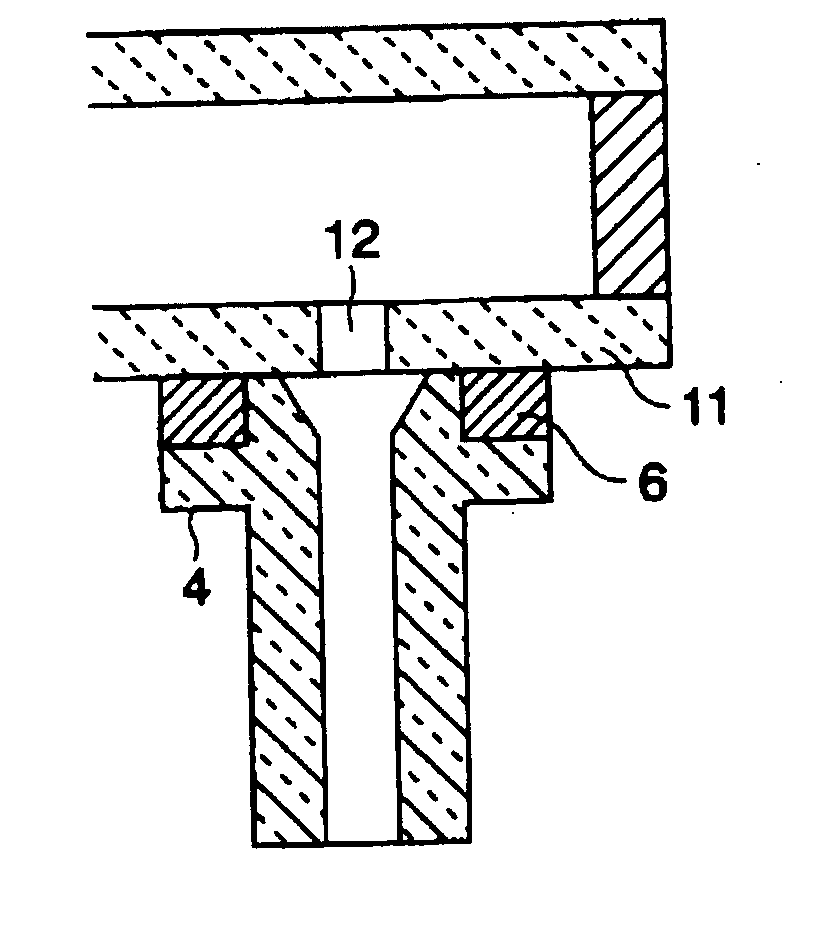

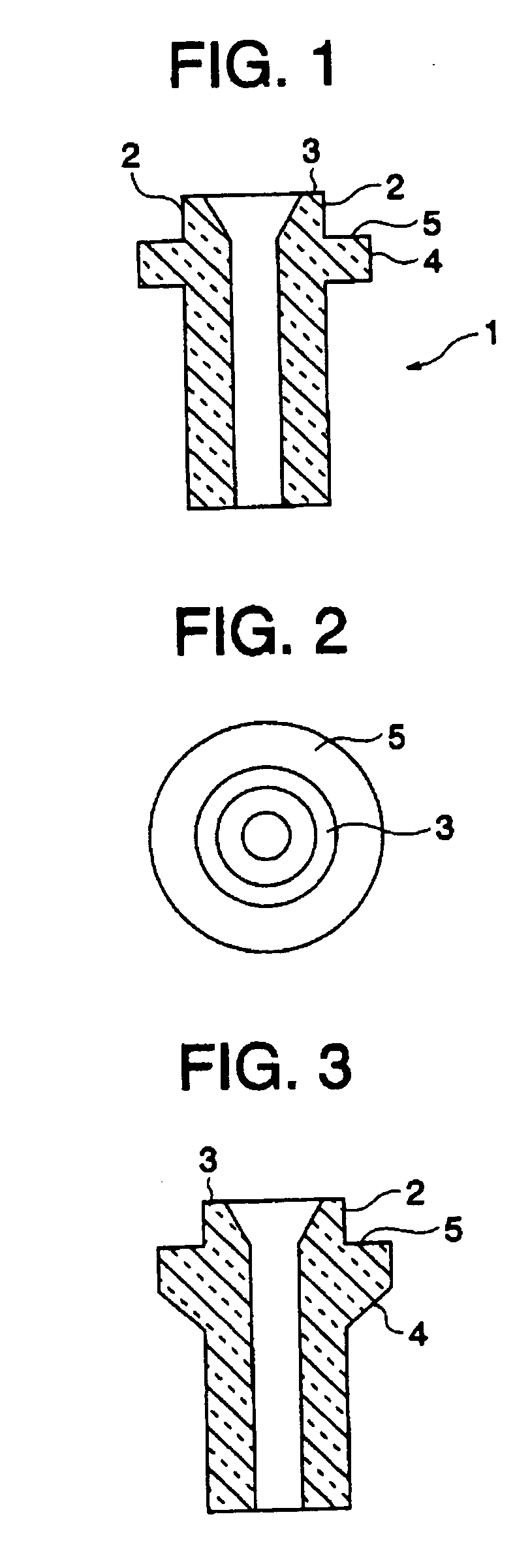

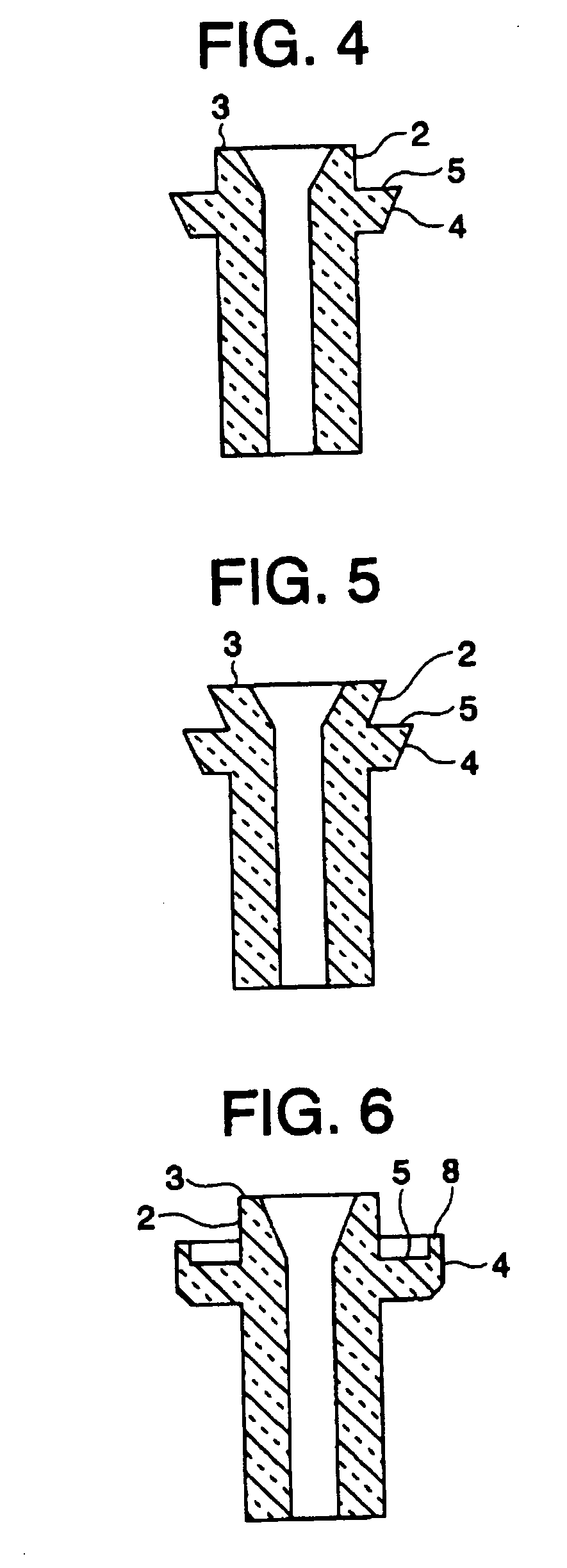

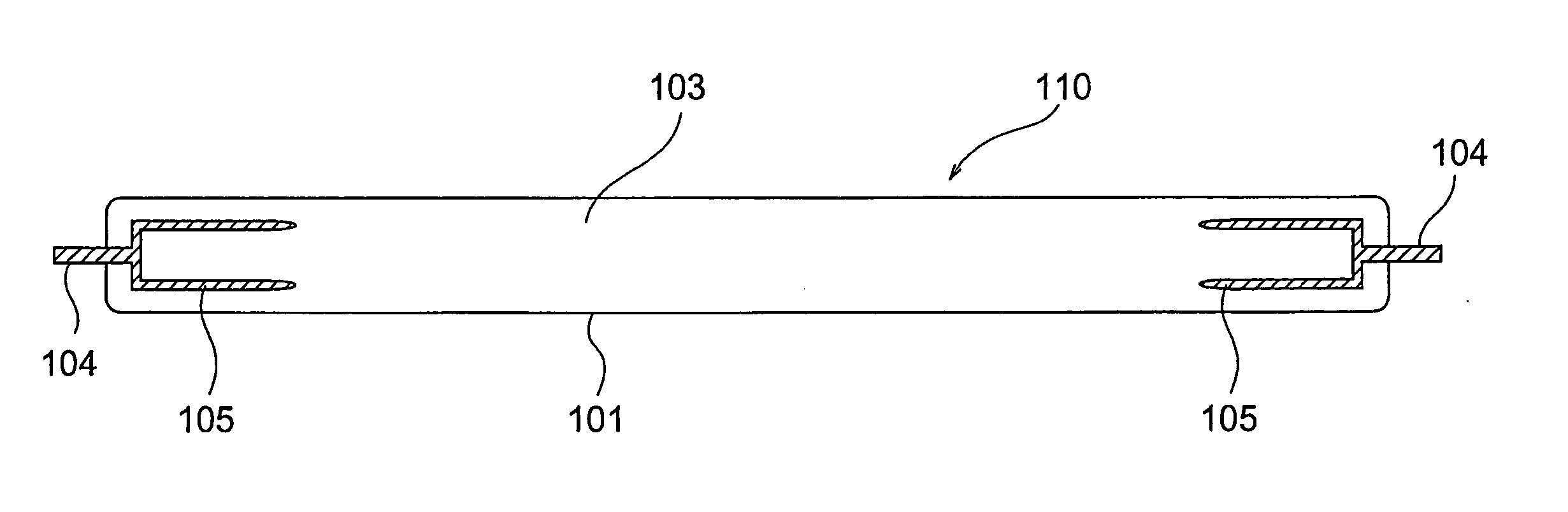

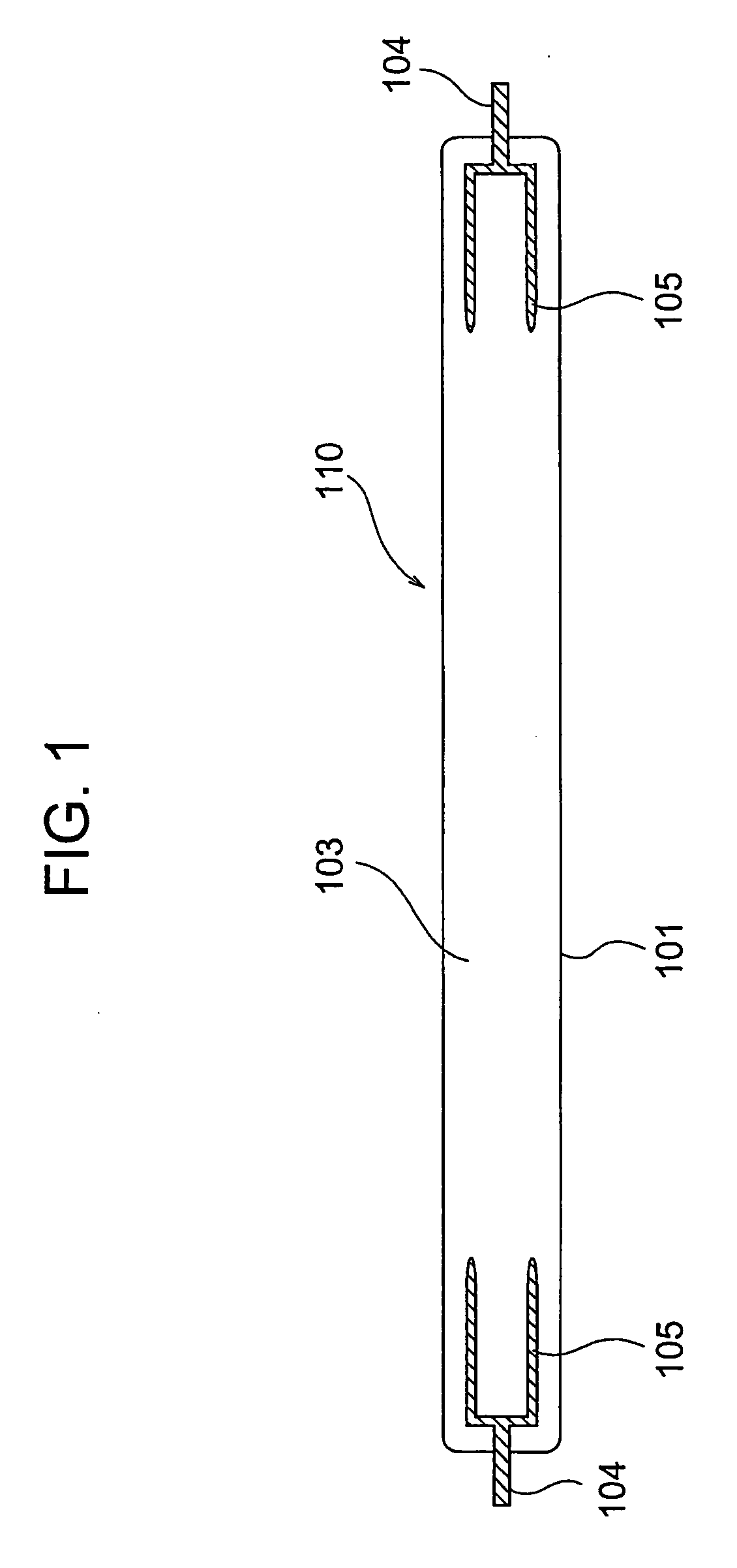

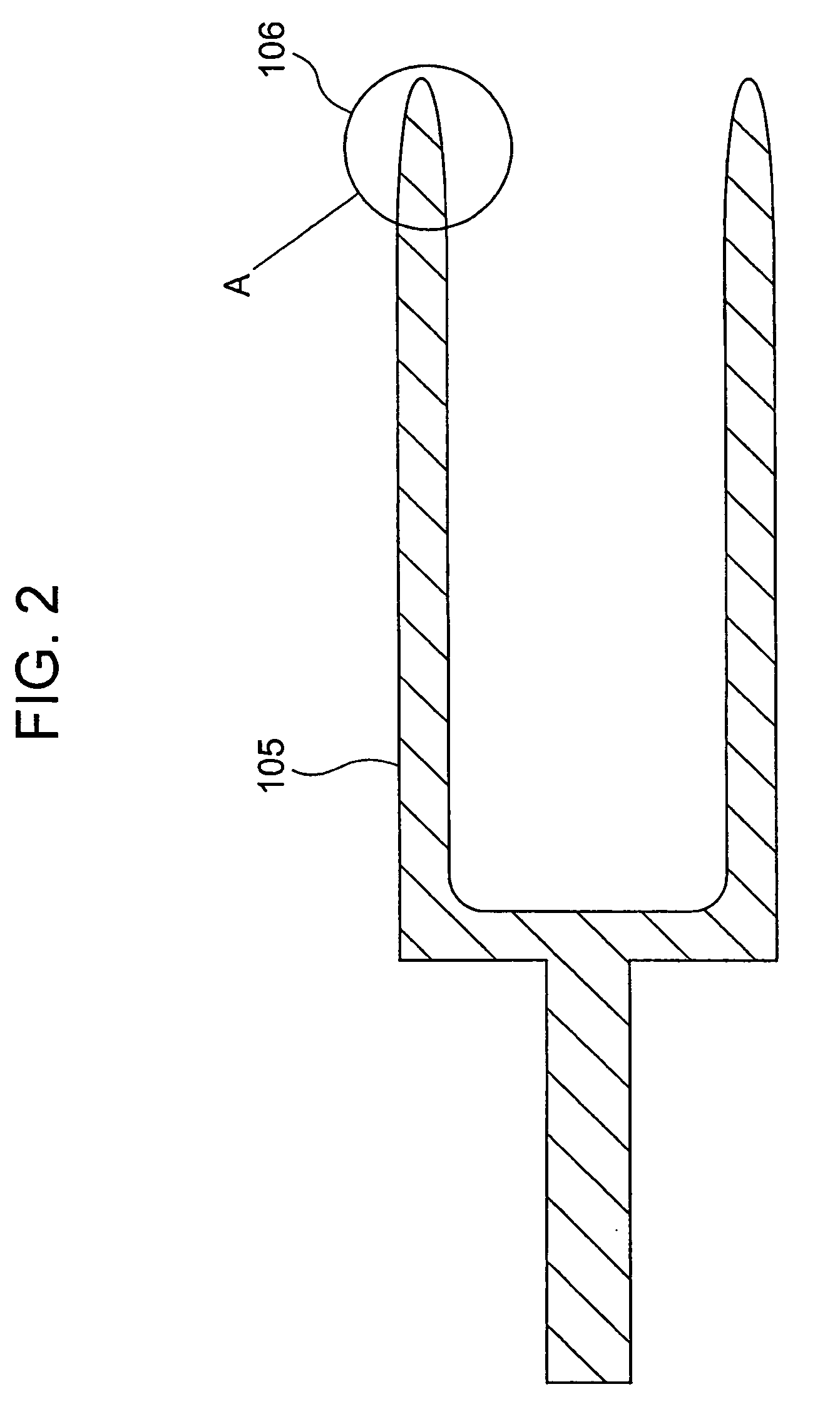

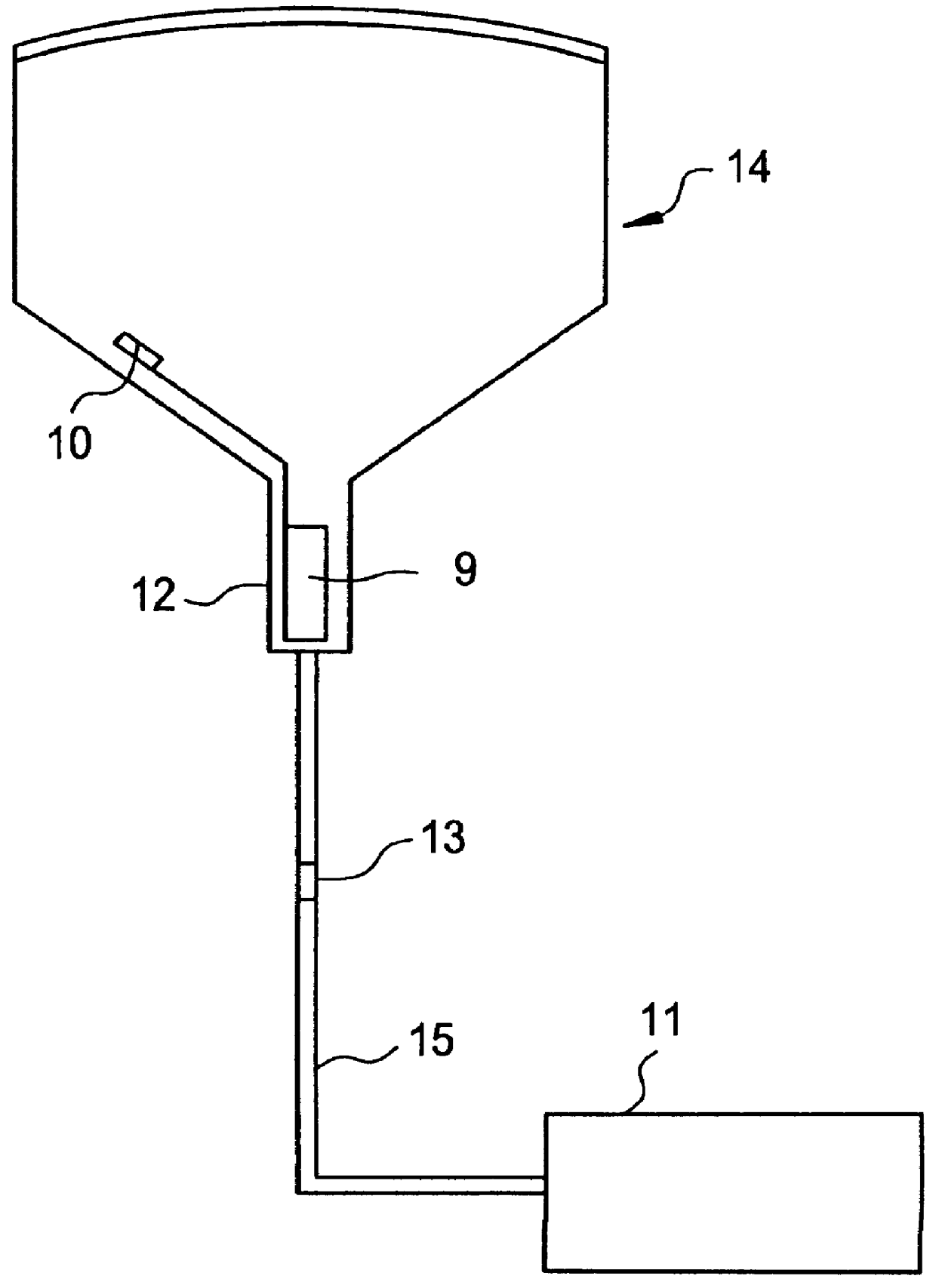

Glass tube, method of manufacturing the glass tube, and method of adhering the glass tube

InactiveUS20060154008A1Improve relationshipAvoid crackingElectric discharge tubesLayered productsFritEngineering

A glass tube (1) that is used in such a manner that an end face thereof is hermetically and firmly bonded to a surface of a panel (11) of a flat display tube so as to cover a ventilation hole (12) which is formed in the panel (11), the glass tube (1) including a flange portion (4) formed by heating work of the glass tube (1) and provided on an outer periphery near the end face on a side firmly bonded to the surface of the panel (11) of the flat display tube. When the flange portion (4) is formed, a tube end portion (2) protruding ahead of the flange portion (4) is left, so that a flange portion (4) face on a side facing the surface of the panel (11) of the flat display tube allows a frit glass (6) to be placed thereon, the frit glass (6) having a height equal to an interval (an outer peripheral face of the tube end portion) between the end face of the glass tube and the flange portion (4) face, which enables stable bonding of the glass tube (1) to the surface of the panel (11) of the flat display tube.

Owner:ASAHI TECHNO GLASS CORP

Method for producing an image display apparatus

InactiveUS20020109460A1Little change with timeTime is unevenGas filling substance selectionDischarge tube luminescnet screensElectron sourceFluorescence

An image display apparatus is provided with an external housing constituted by members including first and second substrates positioned with a gap therebetween, an electron source positioned on the first substrate in the external housing, and a fluorescent film and an accelerating electrode provided on the second substrate. A first getter is positioned in the image display area in the external housing. And a second getter is so provided as to be insulated from the electron source and the accelerating electrode and as to surround the first getter.

Owner:CANON KK

Production method for plasma display panel

InactiveUS7070471B2Quality improvementImprove the display effectAlternating current plasma display panelsTube contructional detailsPhosphorManufactured apparatus

A manufacturing apparatus for a PDP includes a unit for forming a protective layer protecting a dielectric layer on a first plate, a unit for baking a phosphor layer applied on a second plate, a unit for sealing the first and second plates arranged so that the protective layer faces the phosphor layer, and a unit for baking the first and second plates while exhausting a space between them. The four units are placed in one or more closed chamber. When the apparatus is driven, spaces in and between the closed chambers each contain a gas atmosphere with vapor partial pressure of 10 mPa or lower, or with a pressure of 1 Pa or lower, where the protective layer and the phosphor layer exhibit less water-absorbing property, preventing degradation of the PDP performances. The protective layer does not contact with atmospheric carbonic acid gas, preventing alteration thereof.

Owner:PANASONIC CORP

Image display device and method of manufacturing the same

InactiveUS7091662B2Less luminanceLess deteriorationGetteringGas filling substance selectionElectron sourceVacuum level

In an image display device having in an airtight container an electron source and an image display member that receives electrons from the electron source, an evaporating getter and a non-evaporating getter are stacked in the airtight container. This makes it possible to maintain the vacuum level in the airtight container. The image display device thus obtains a prolonged life and a stable display operation.

Owner:CANON KK

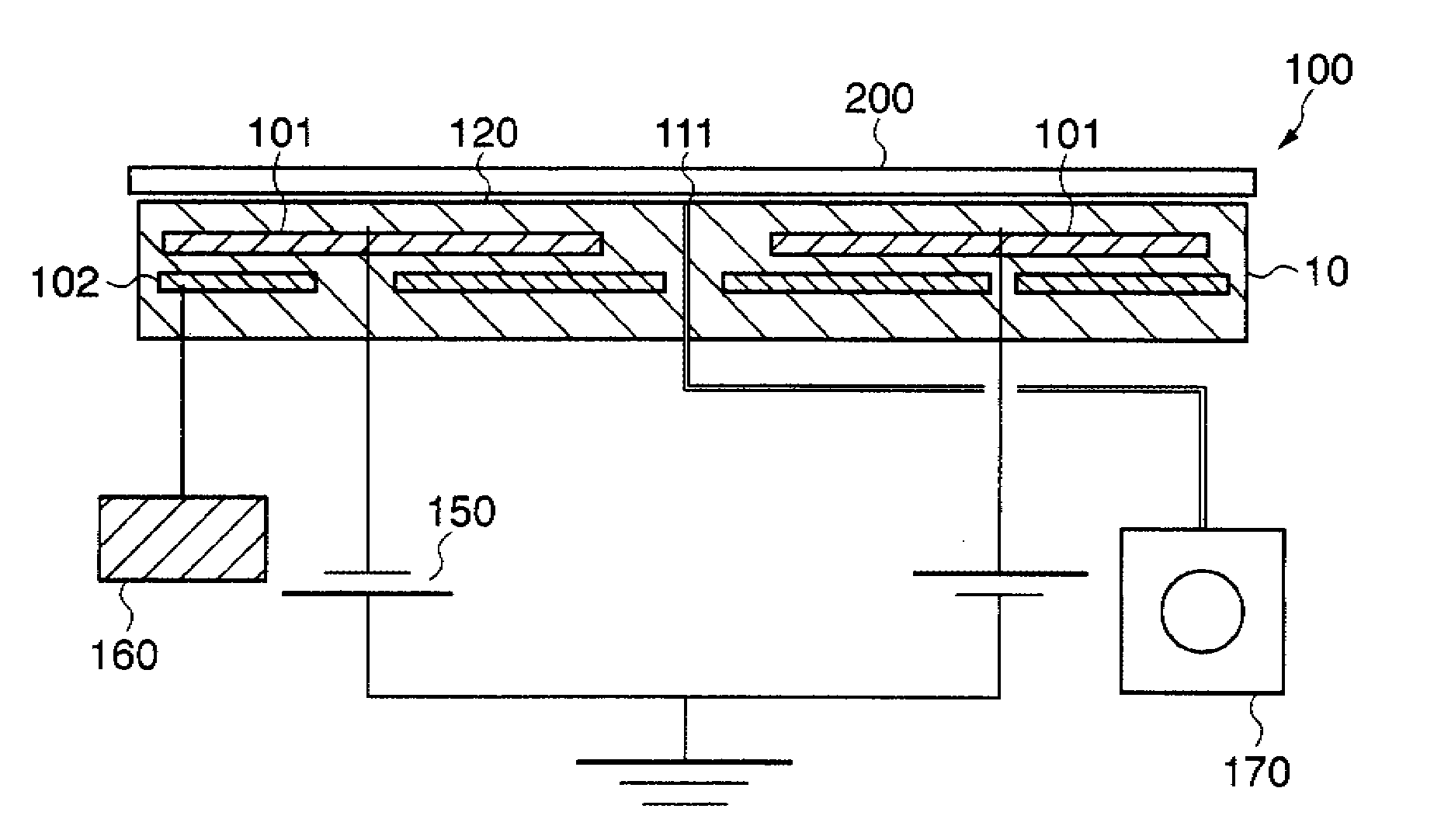

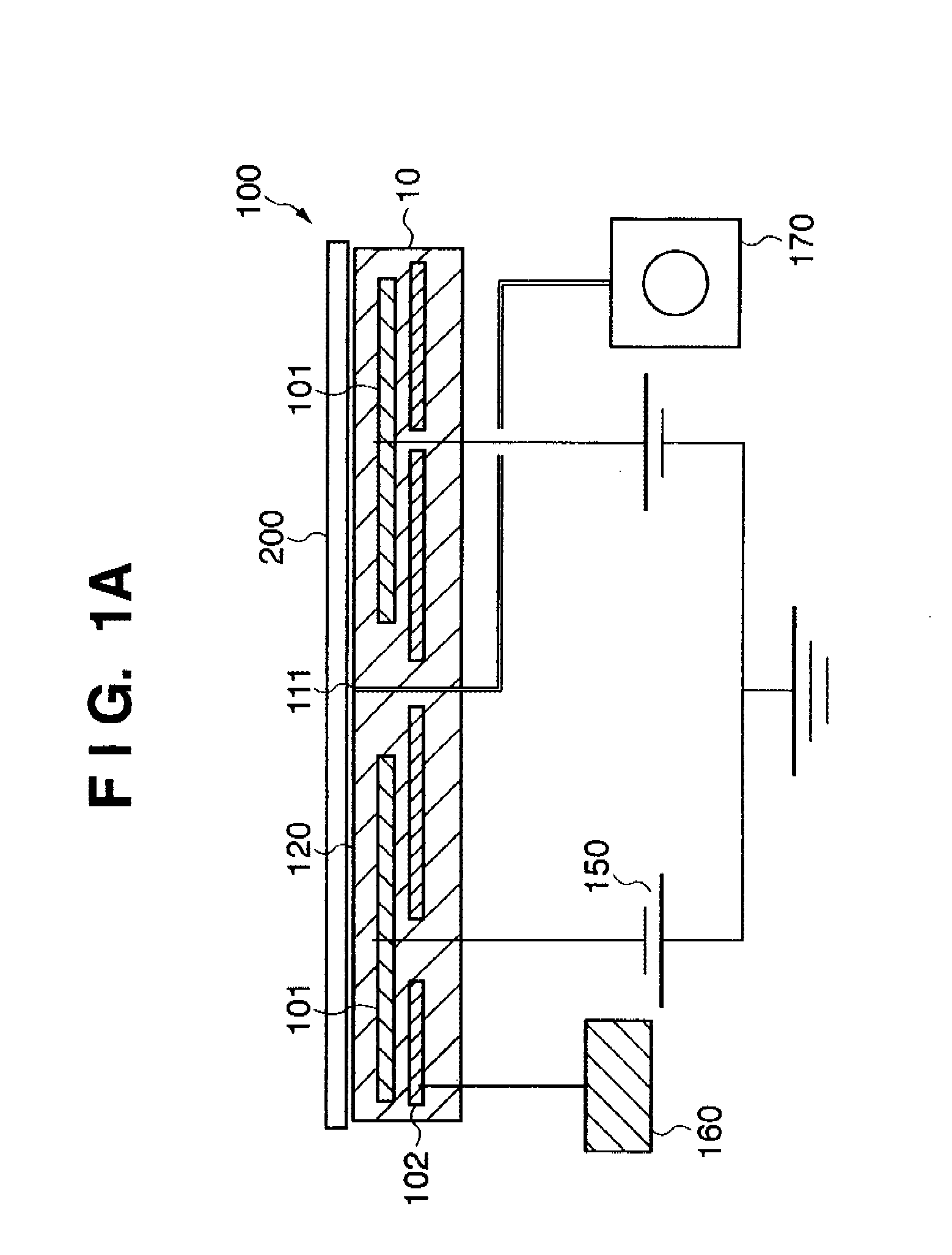

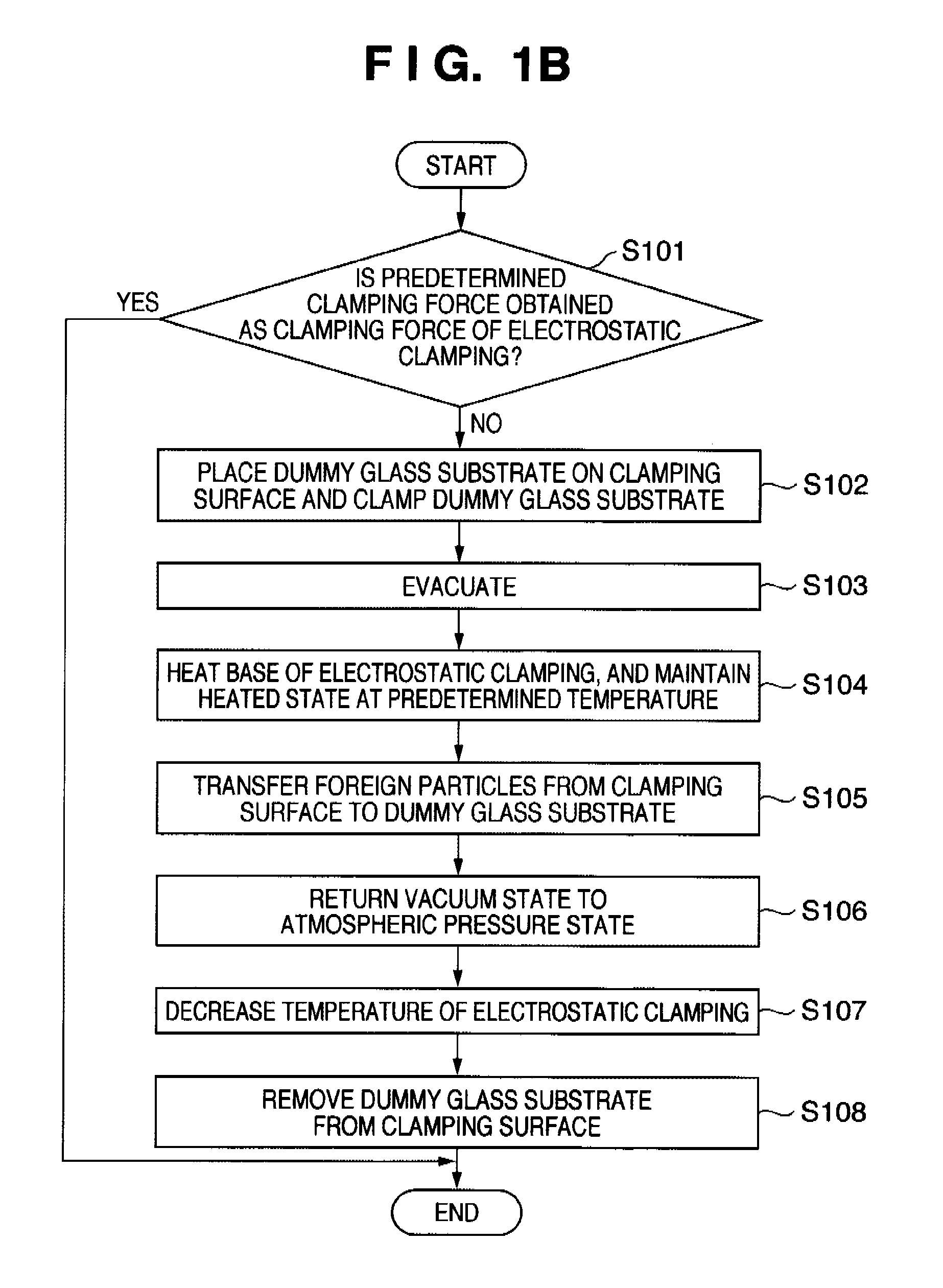

Display substrate manufacturing method and vacuum processing apparatus

InactiveUS20090088041A1Simple methodShort timeSemiconductor/solid-state device manufacturingTube/lamp vessels exhaustionForeign matterBiomedical engineering

Owner:CANON ANELVA CORP

Fluorescent lamp and method of manufacturing same

InactiveUS20060097641A1Lower resistanceHigh melting pointDischarge tube luminescnet screensTube/lamp vessel degassingCold cathodeHelium

A cold cathode fluorescent tube where an electron emitting electrode is sealed in shows much deterioration in the luminance with time, thereby being not adequate for a long time use. The electrode emitting electrode is formed in such a shape that an electric field is not locally concentrated. By mixing a material of high heat conductivity, such as tungsten, as the material for the electron emitting electrode or using helium of high heat conductivity as the sealing gas, a long life of the cold cathode fluorescent tube is achieved.

Owner:FOUND FOR ADVANCEMENT OF INT SCI

Processing apparatus and method of manufacturing electron emission element and organic el display

InactiveCN101970707AWidening requirements are easyResponding to widening requirementsGetteringElectroluminescent light sourcesSize increaseComputer science

Owner:CANON ANELVA CORP

Device having field emission type cold cathode and vacuum tank exhausting method and system in the same

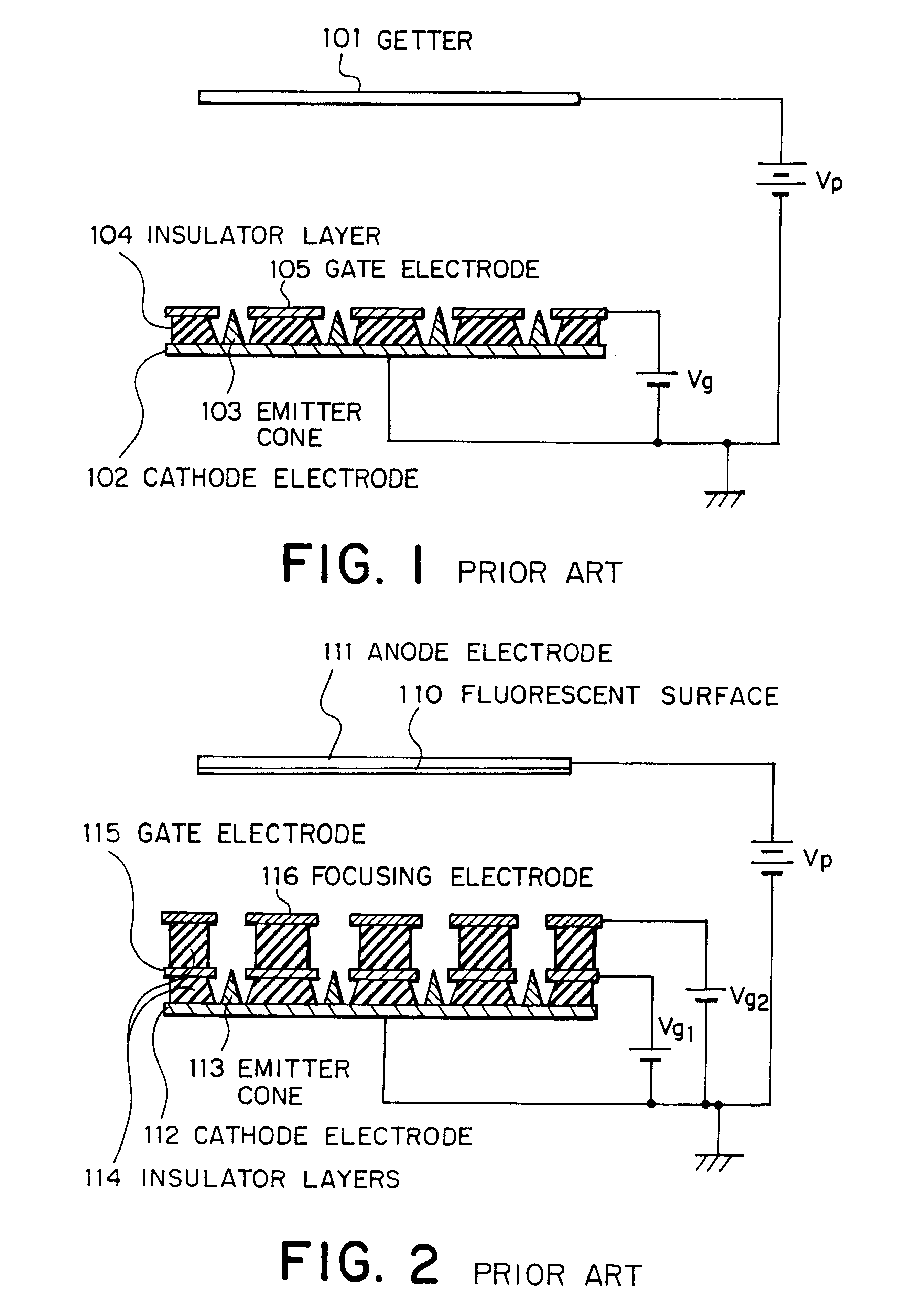

The present invention discloses a field emission type cold cathode incorporated device, which comprises a field emission type cold cathode having a number of electron emitting sections, said sections having sharp projections, and a vacuum tank for placing the field emission type cold cathode in a vacuum environment. In this device, a partial pressure of particular noble gas in residual gas contained in the vacuum tank is set equal to or lower than C / I (C is a constant and I is a maximum emission current value per one of the number of electron emitting sections during driving of the field emission type cold cathode). Also, in order to set a partial pressure of the particular noble gas in the residual gas contained in the vacuum tank equal to C / I (C: constant) or lower, a partial pressure of the particular residual gas in the vacuum tank is monitored by a mass analyzer during vacuum tank exhaustion.

Owner:NEC CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com