Patents

Literature

302results about "Tube/lamp vessels closing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

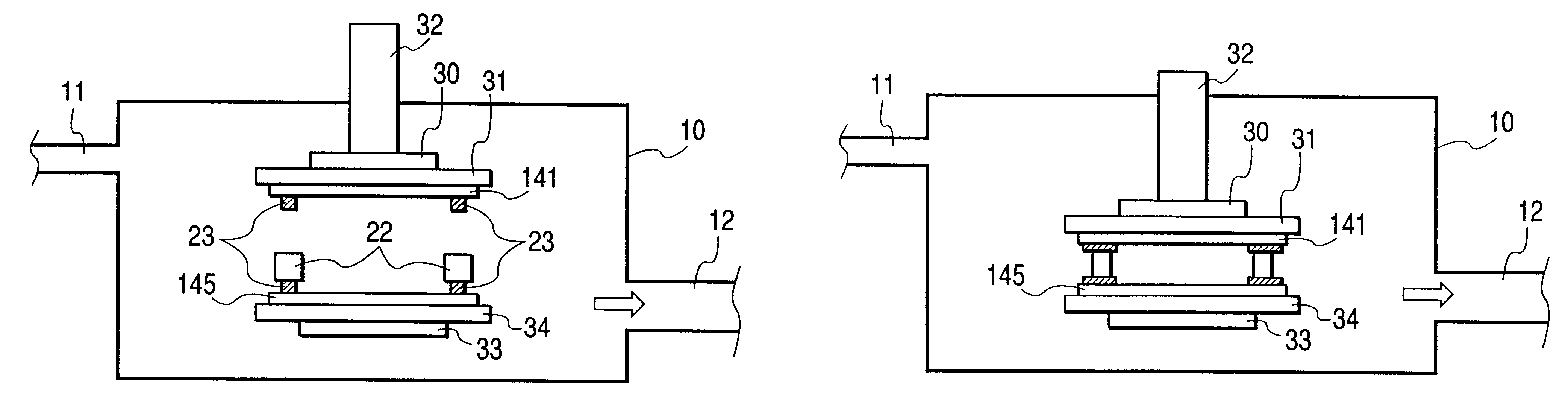

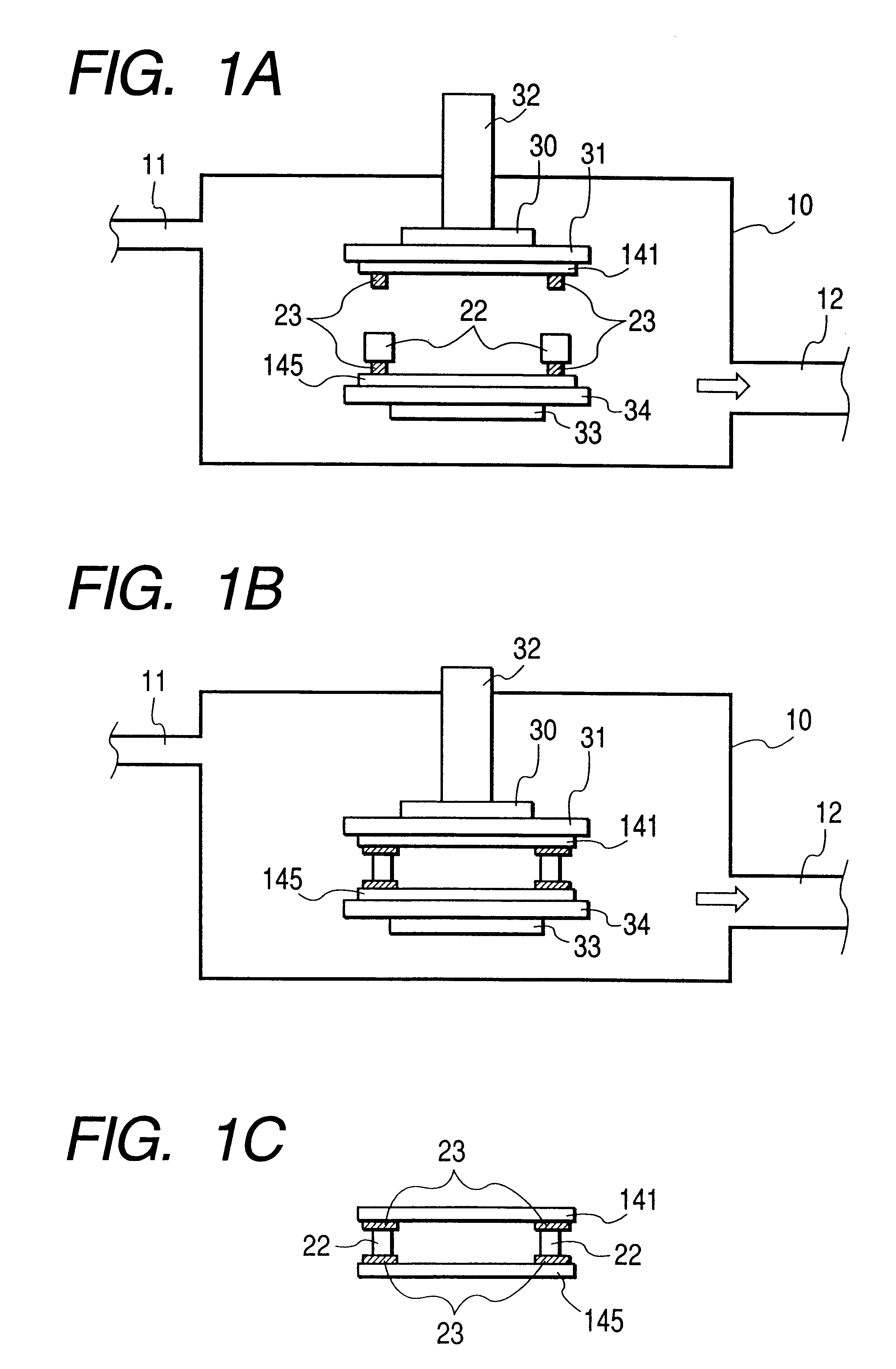

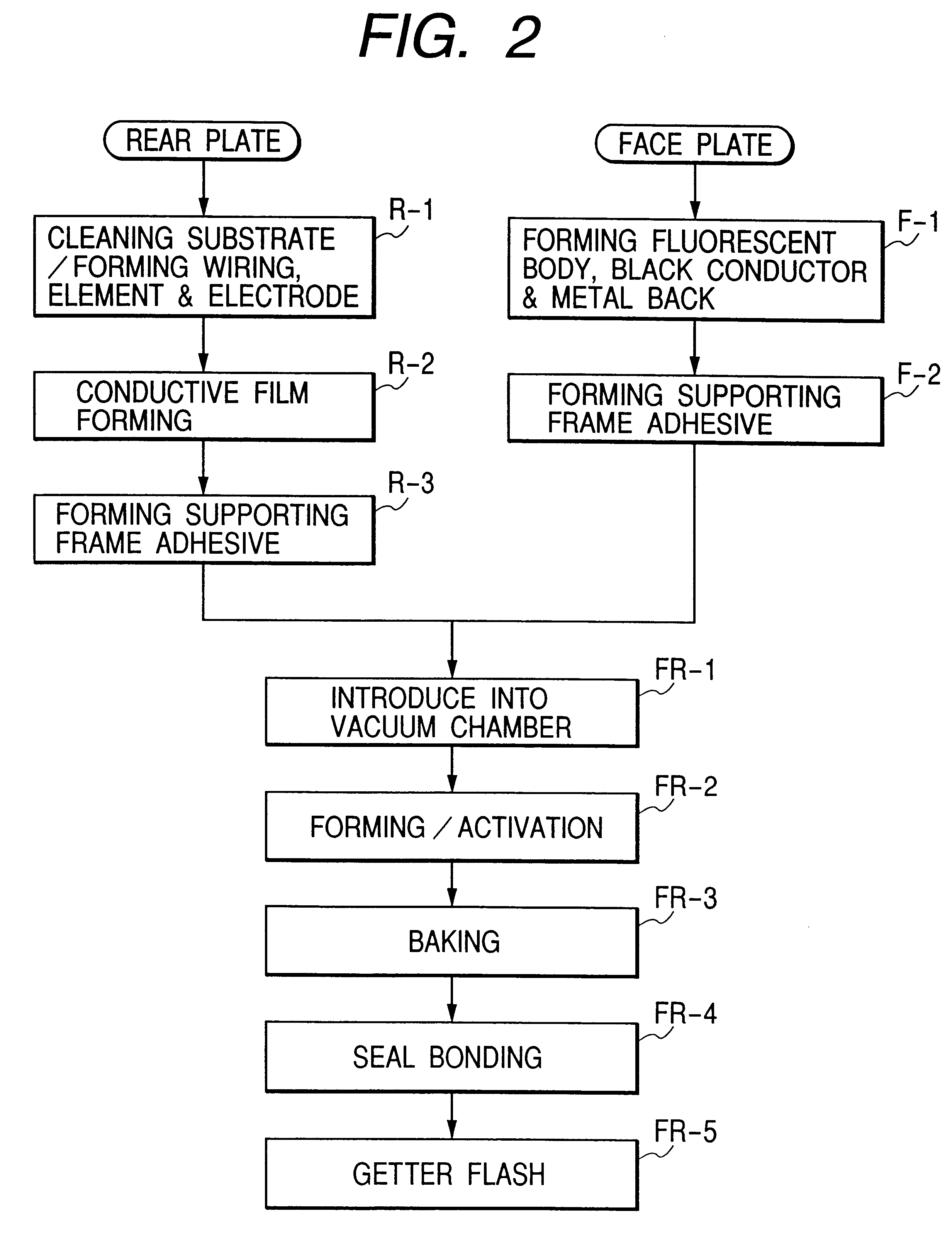

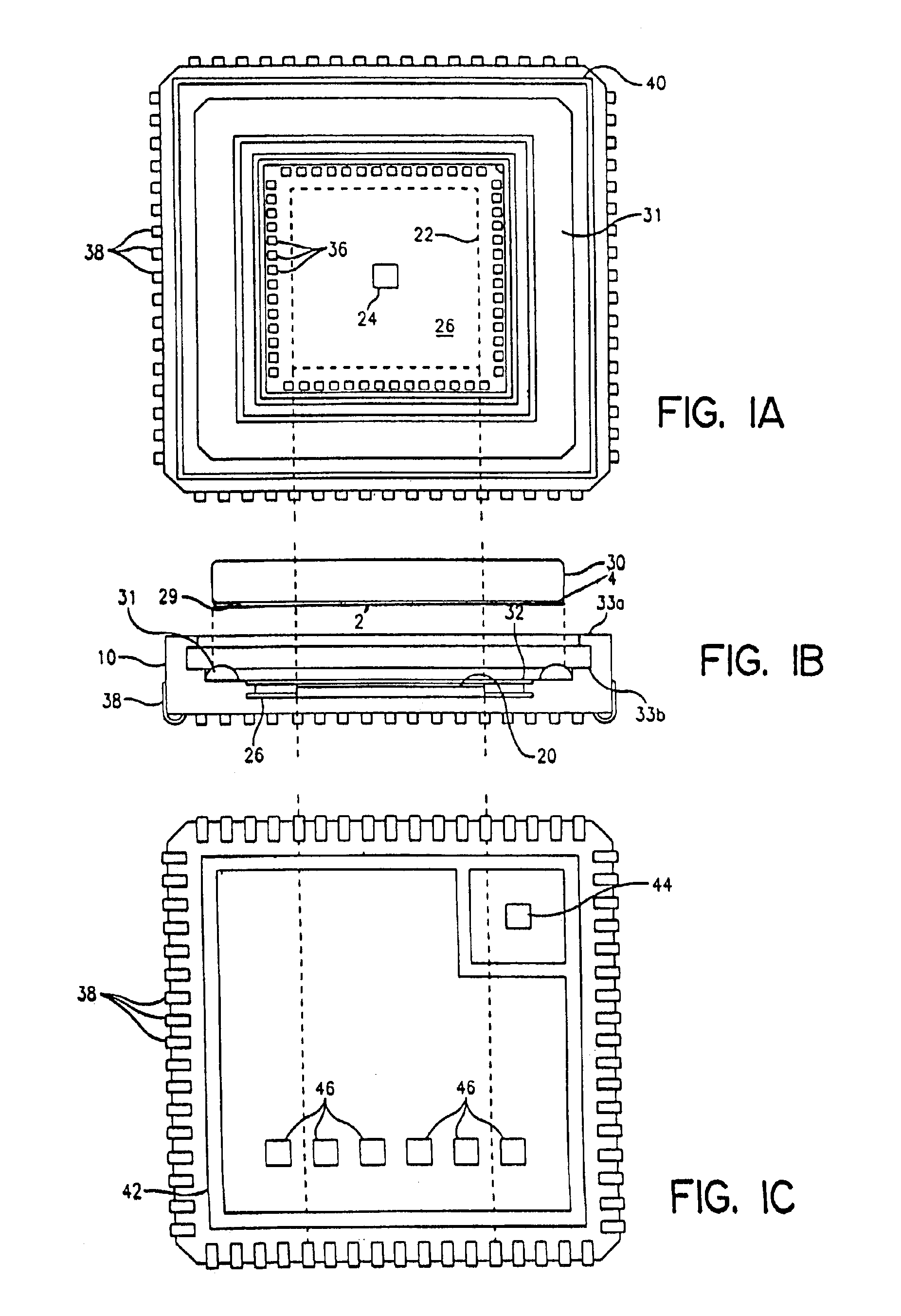

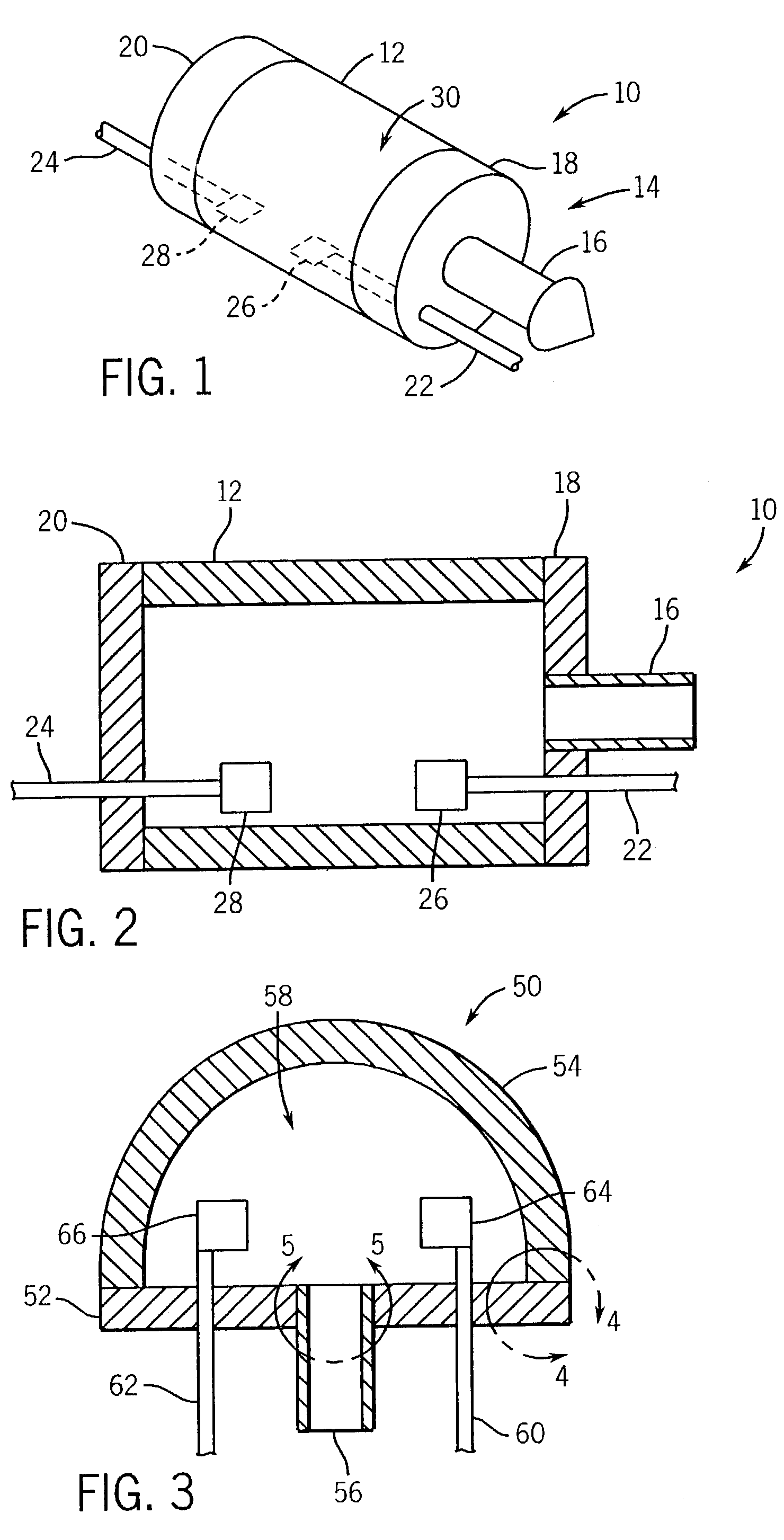

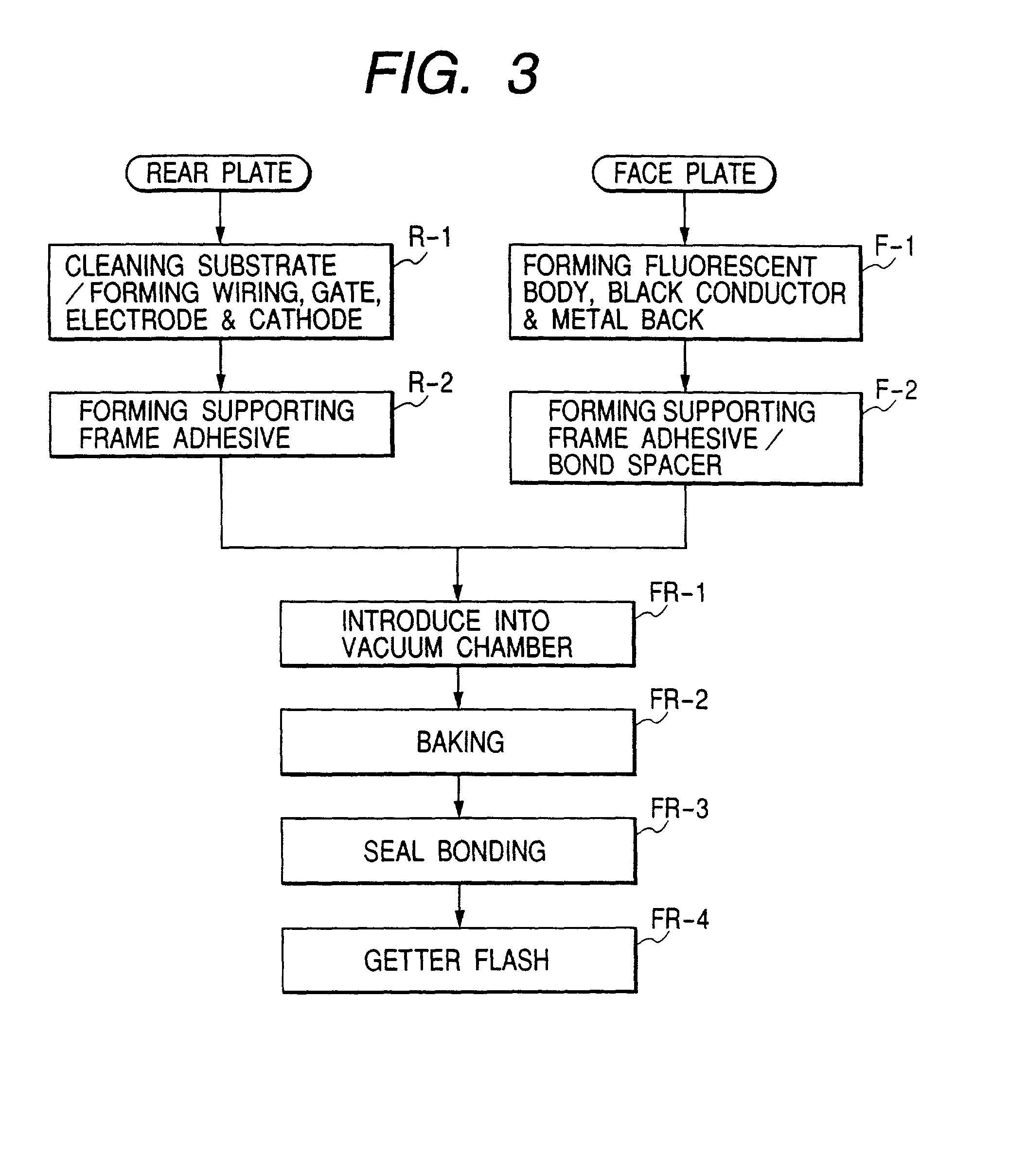

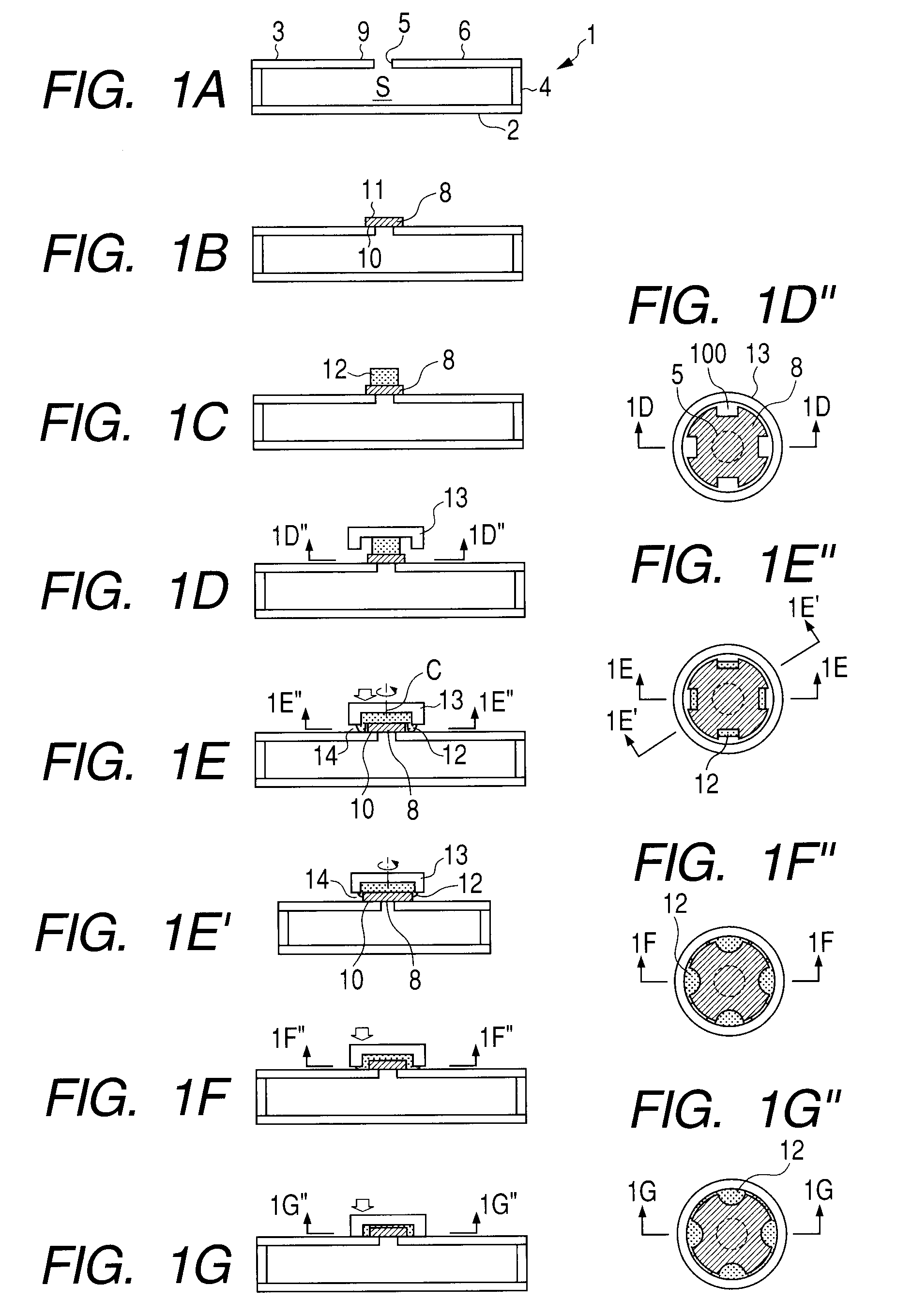

Manufacturing method of image forming apparatus, manufacturing apparatus of image forming apparatus, image forming apparatus, manufacturing method of panel apparatus, and manufacturing apparatus of panel apparatus

InactiveUS6254449B1Tube/lamp vessels exhaustionTube/lamp vessels closingManufactured apparatusImage formation

To obtain a stable image forming apparatus of a high quality without a luminance fluctuation and a color mixture due to a positional deviation, the following construction is disclosed. A method of manufacturing an image display apparatus in which a first substrate on which fluorescent body exciting means is arranged and a second substrate on which a fluorescent body that emits light by the fluorescent body exciting means is arranged are arranged so as to face each other and are adhered through joining members at their peripheries, wherein a seal bonding step of adhering the first and second substrates through a joining members and a step of performing a position matching of the first and second substrates are executed in a vacuum.

Owner:CANON KK

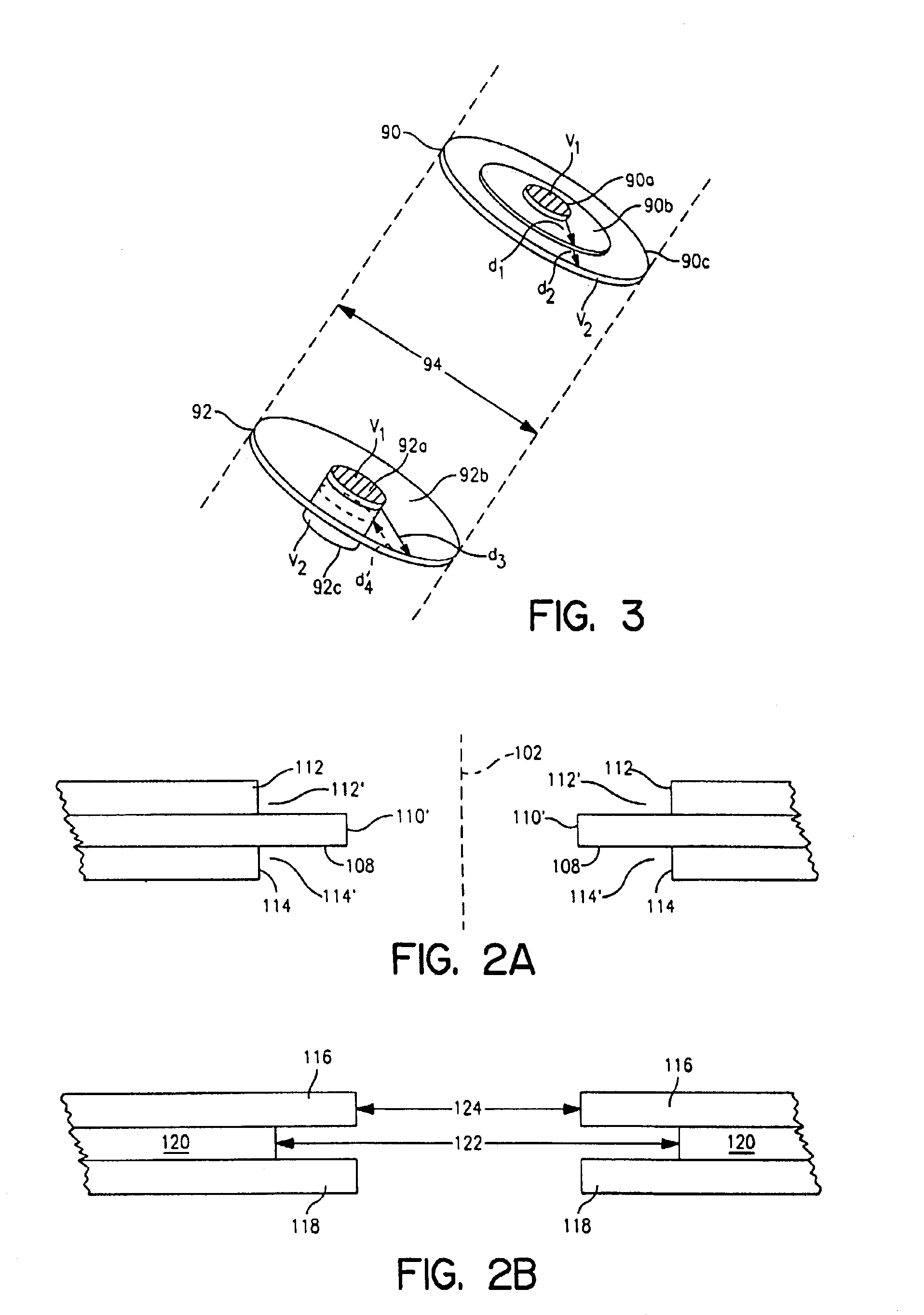

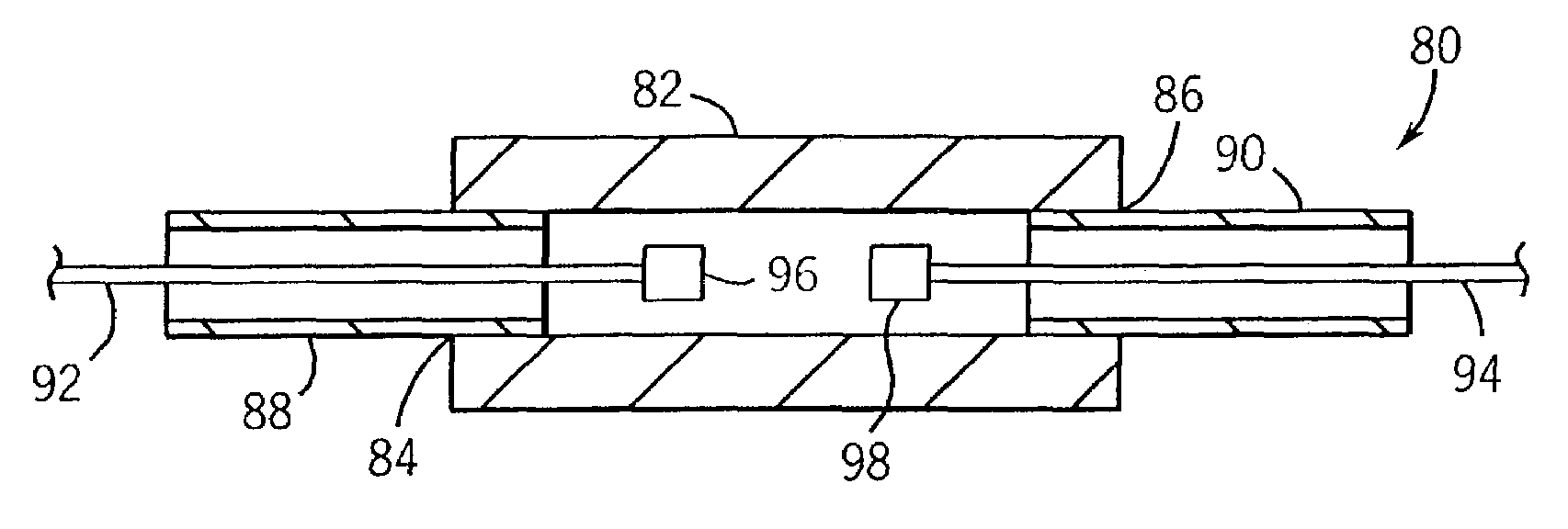

Unitary vacuum tube incorporating high voltage isolation

InactiveUS6837766B2Improve isolationLinear distance increasesGas filling substance selectionCathode-ray/electron-beam tube vessels/containersGreen tapeHigh pressure

A housing for microelectronic devices requiring an internal vacuum for operation, e.g., an image detector, is formed by tape casting and incorporates leads between interior and exterior of the housing where the leads are disposed on a facing surface of green tape layers. Adjacent green tape layers having corresponding apertures therein are stacked on a first closure member to form a resulting cavity and increased electrical isolation or channel sub-structures are achievable by forming adjacent layers with aperture dimension which vary non-monotonically. After assembly of the device within the cavity, a second closure member is sealed against an open face of the package in a vacuum environment to produce a vacuum sealed device.

Owner:EOTECH LLC

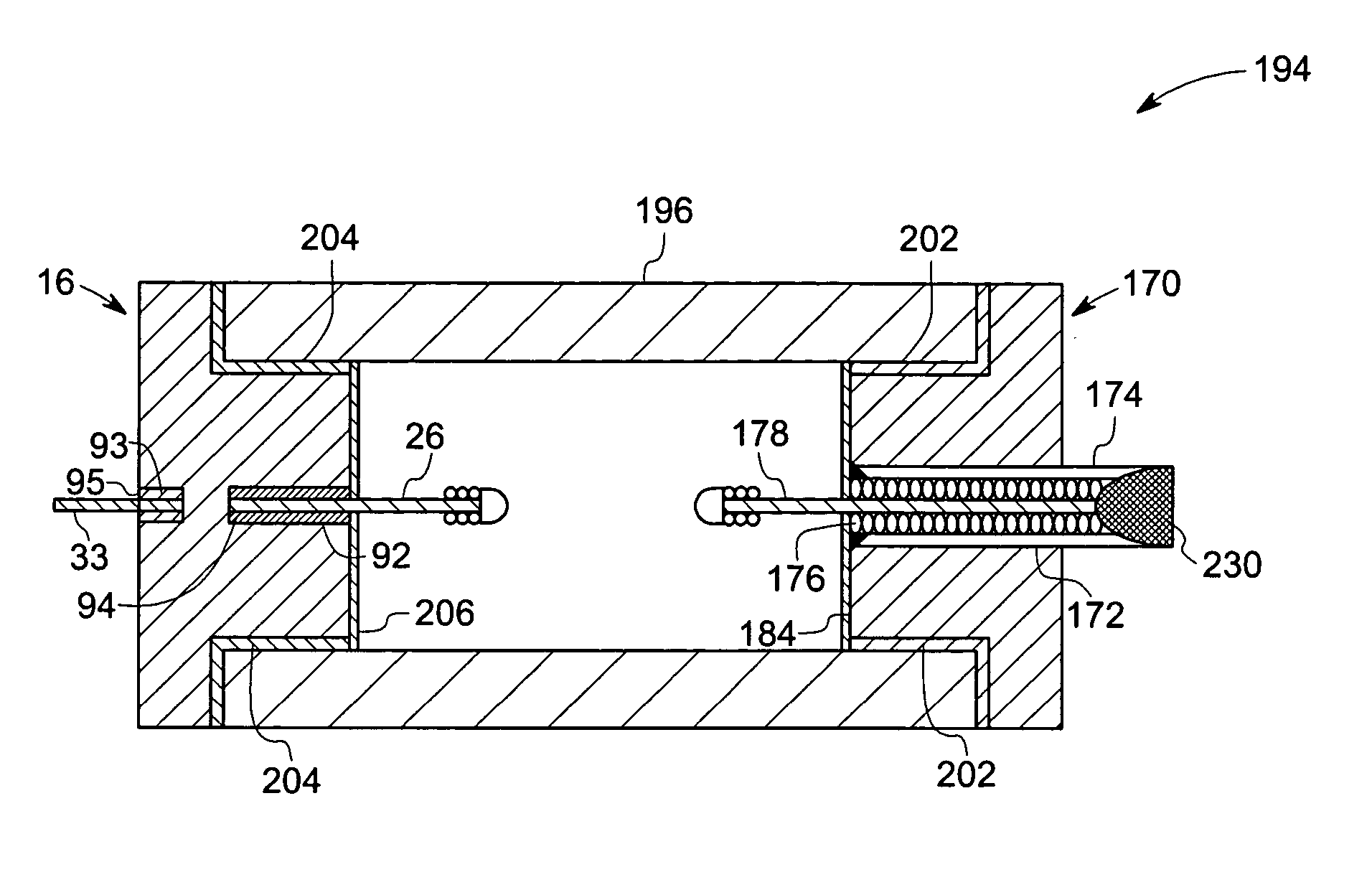

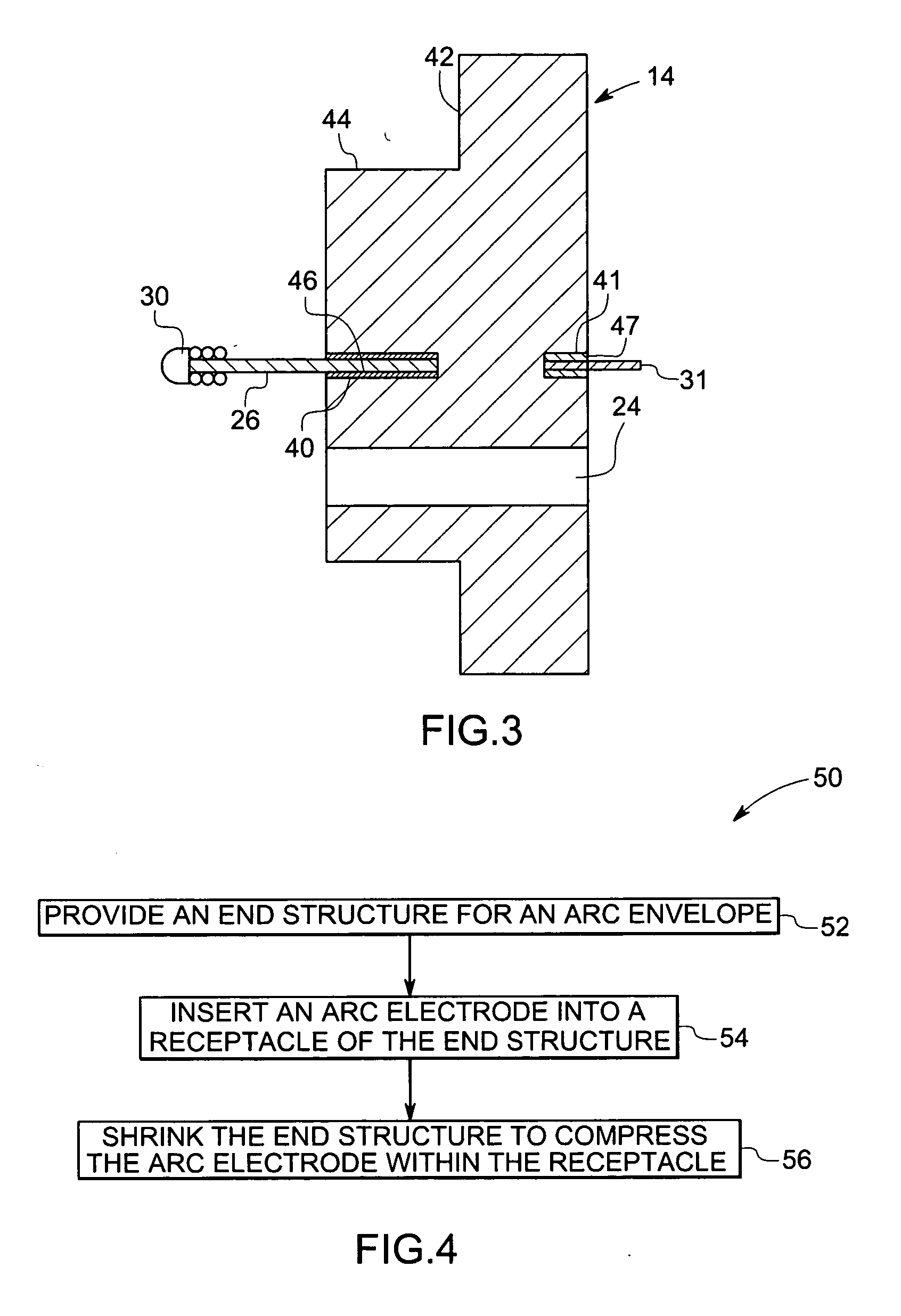

System and method for design of projector lamp

InactiveUS20060001346A1Electric discharge tubesElectroluminescent light sourcesBiomedical engineeringProjector

A lamp comprising an arc envelope and an end structure coupled to the arc envelope, and wherein the end structure comprises at least one opening adapted to support an arc electrode and to receive a dosing material into the arc envelope.

Owner:GENERAL ELECTRIC CO

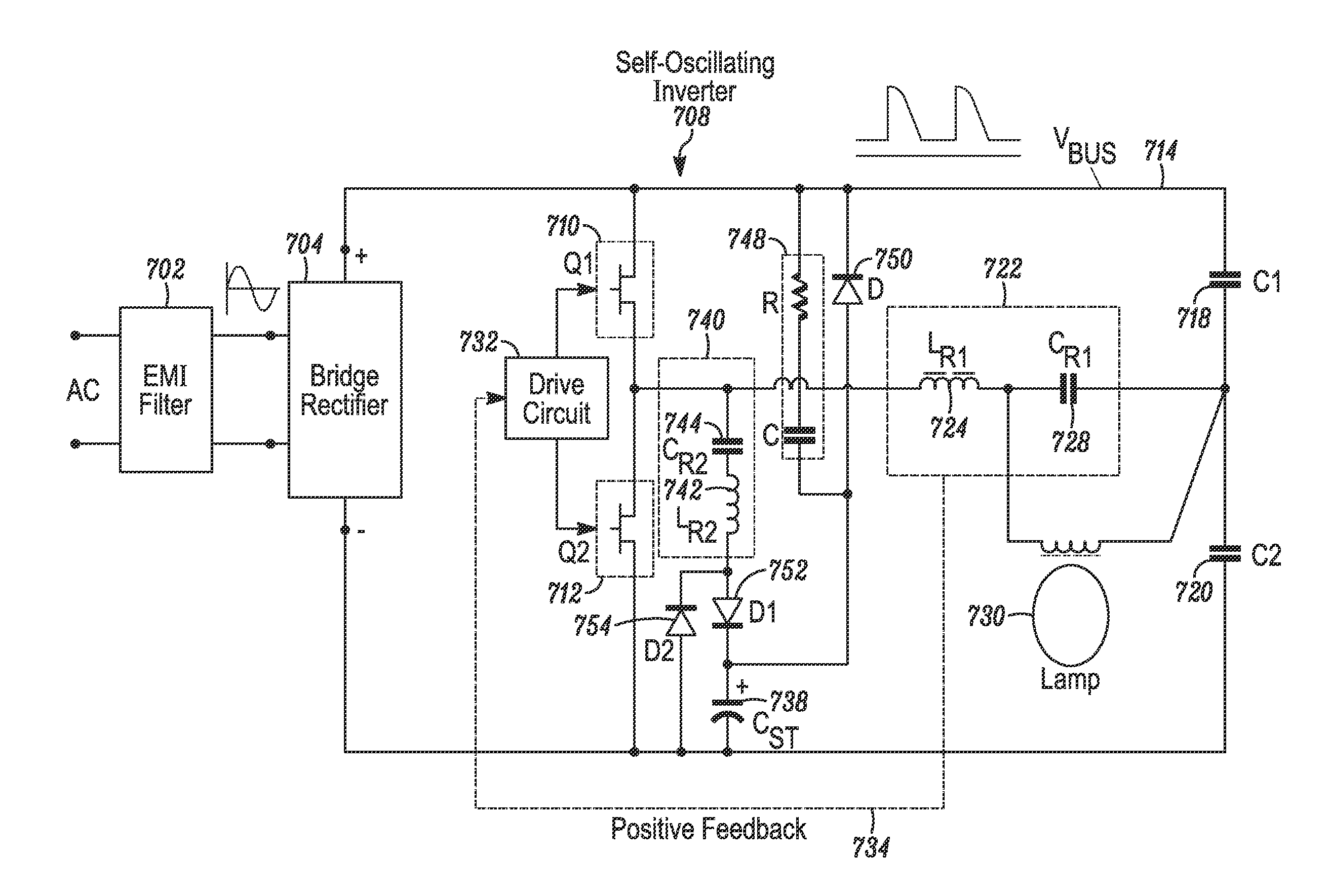

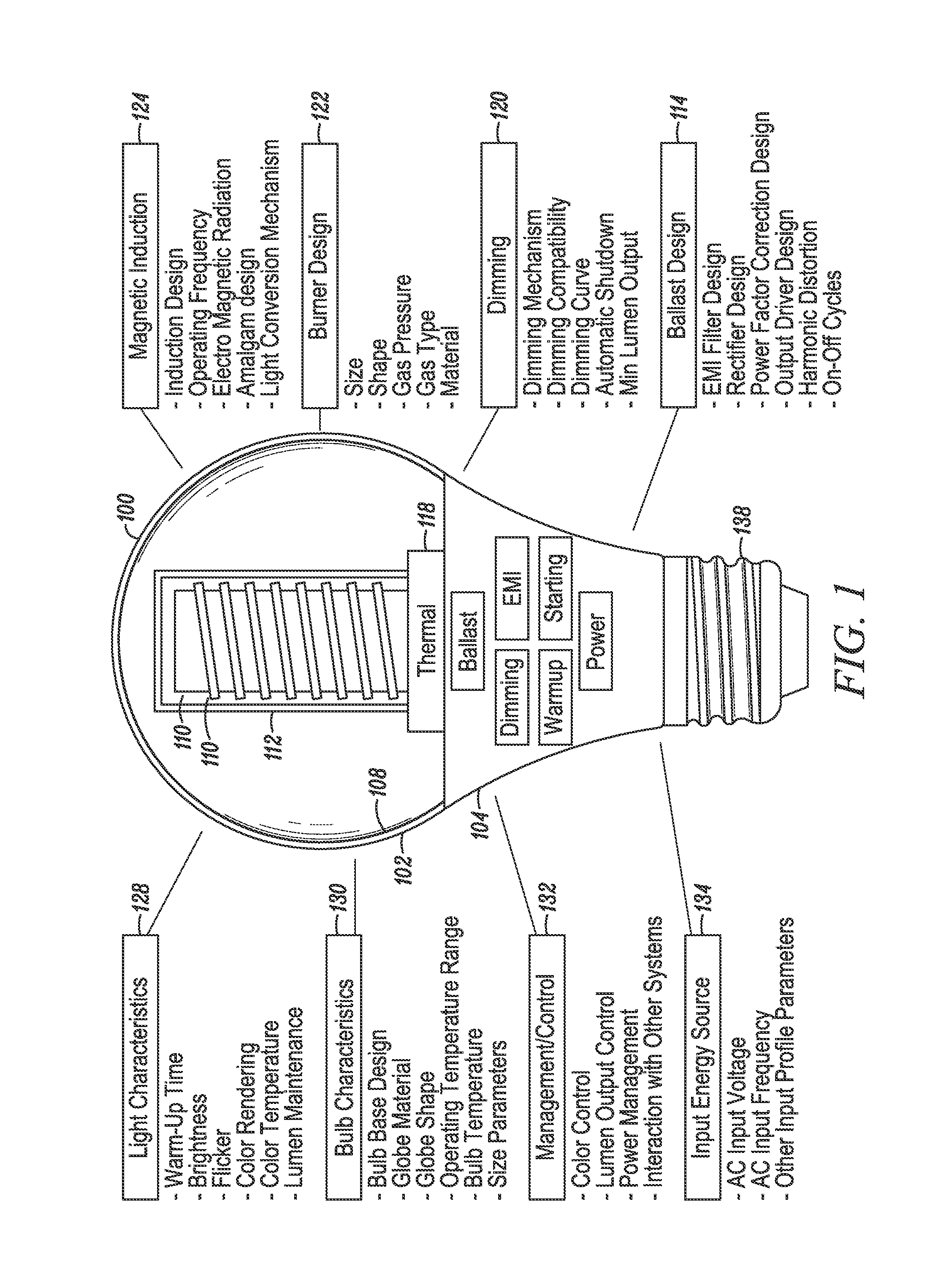

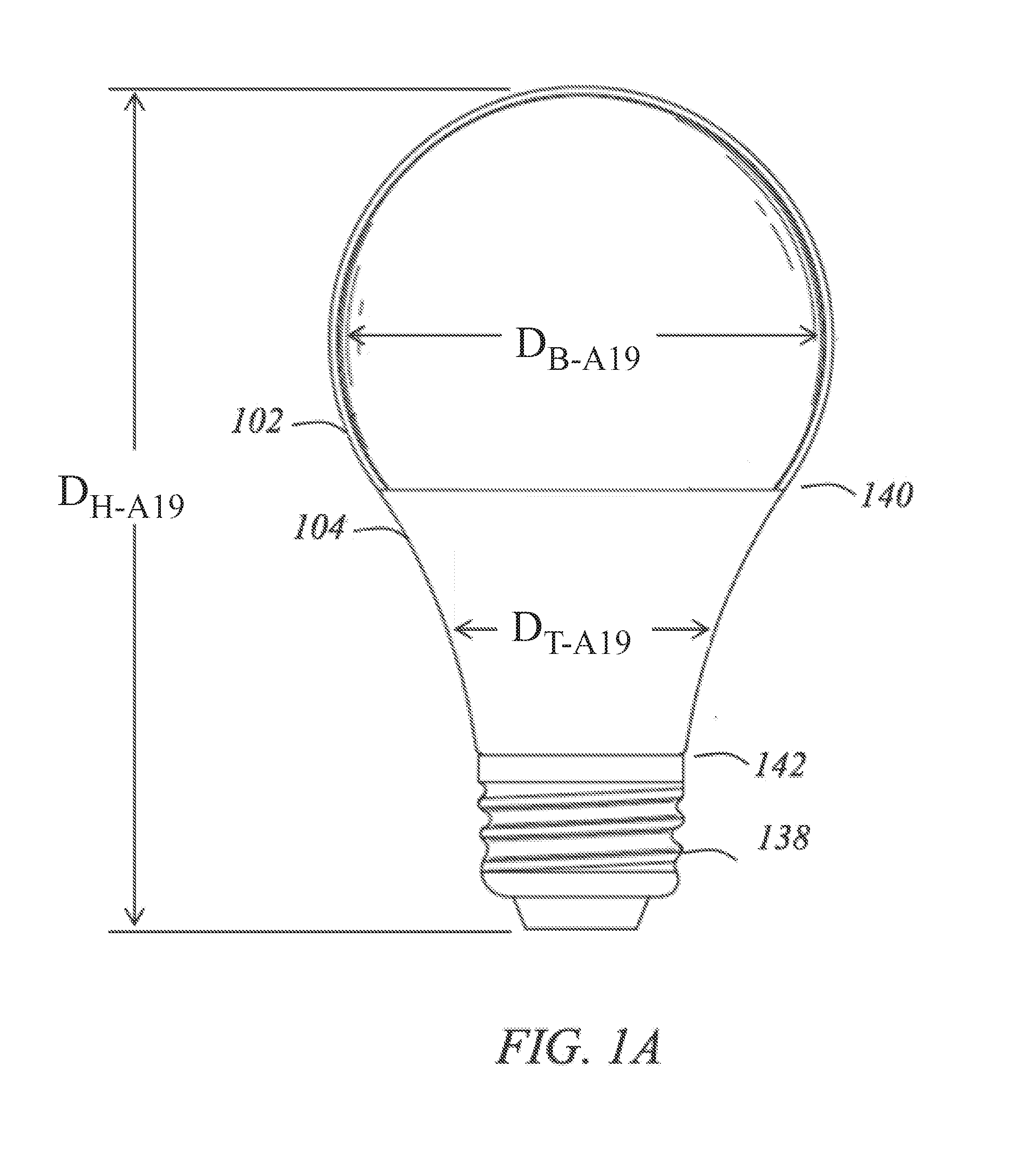

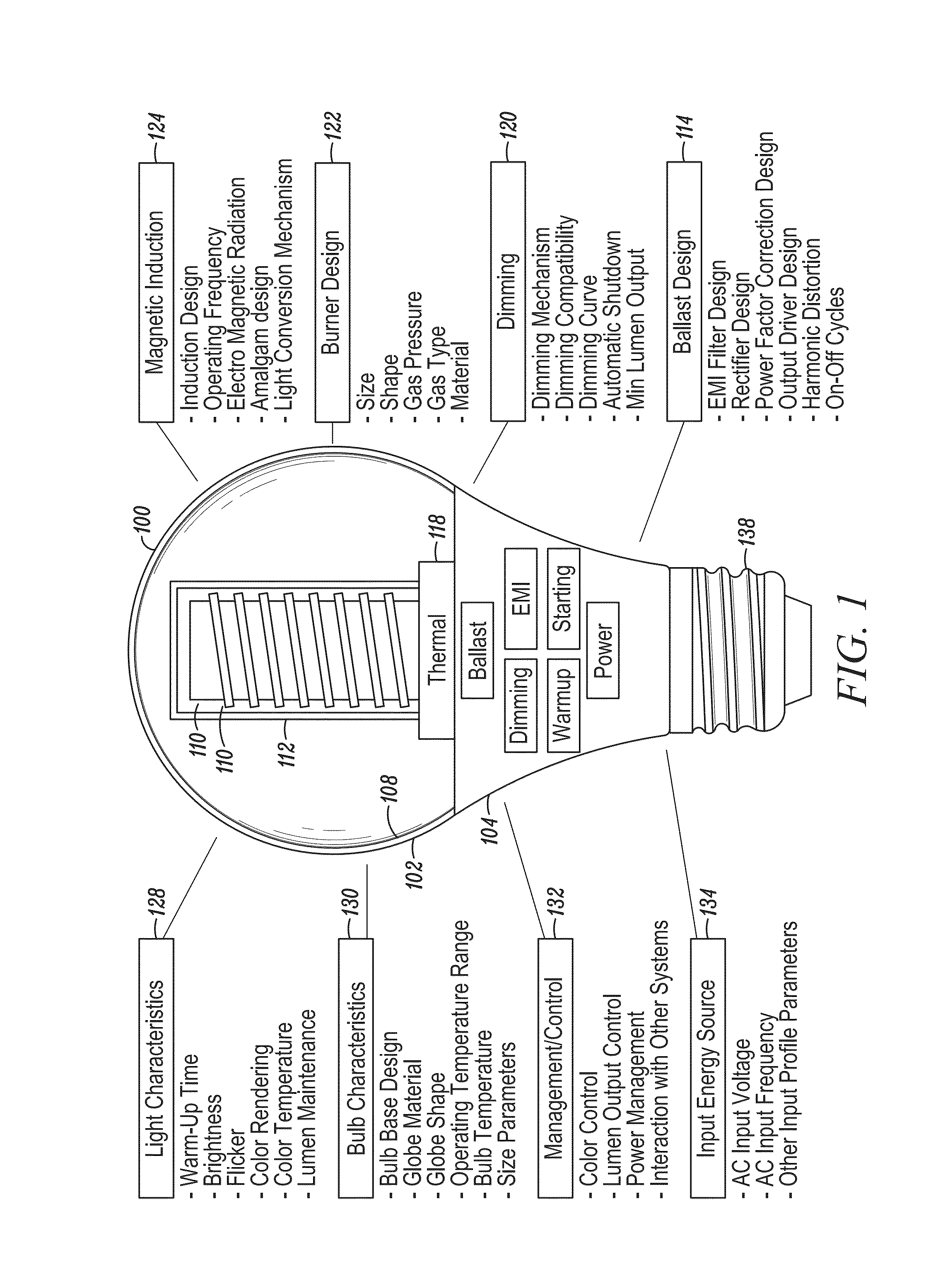

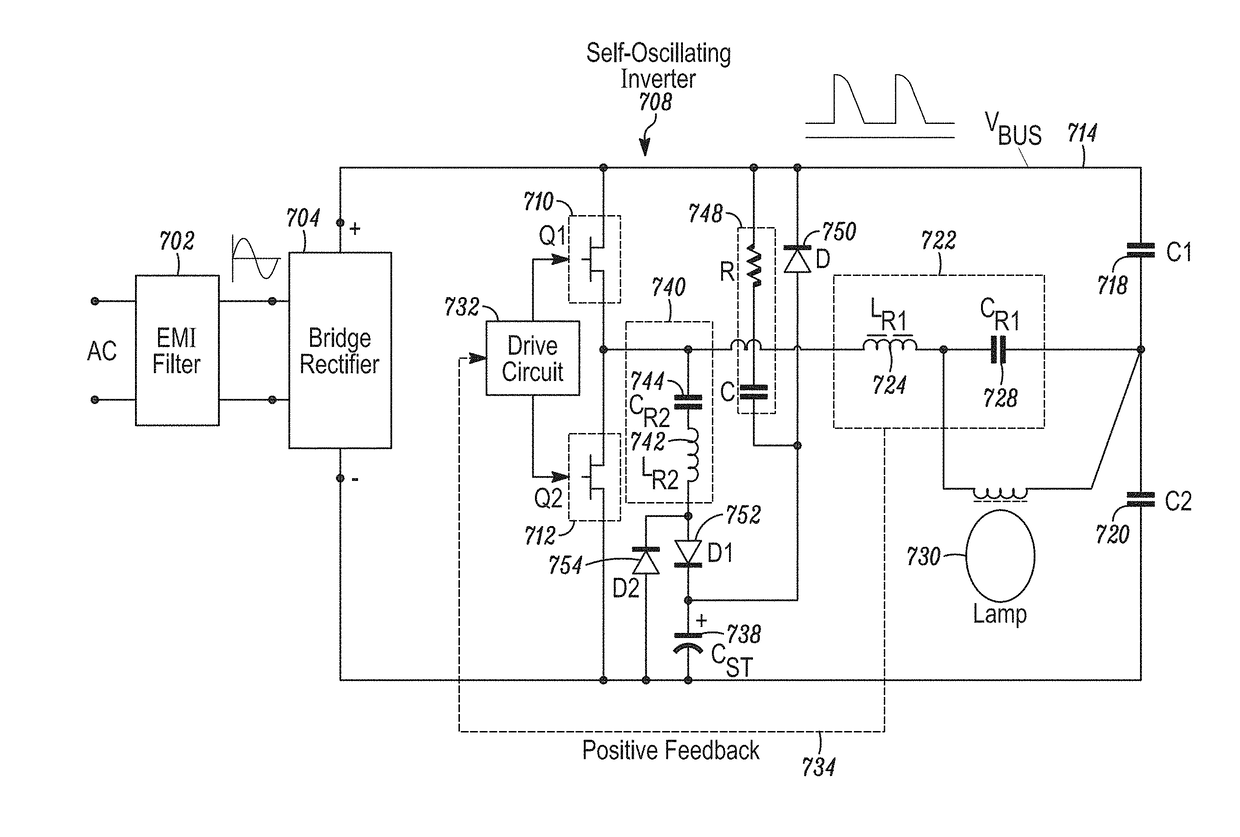

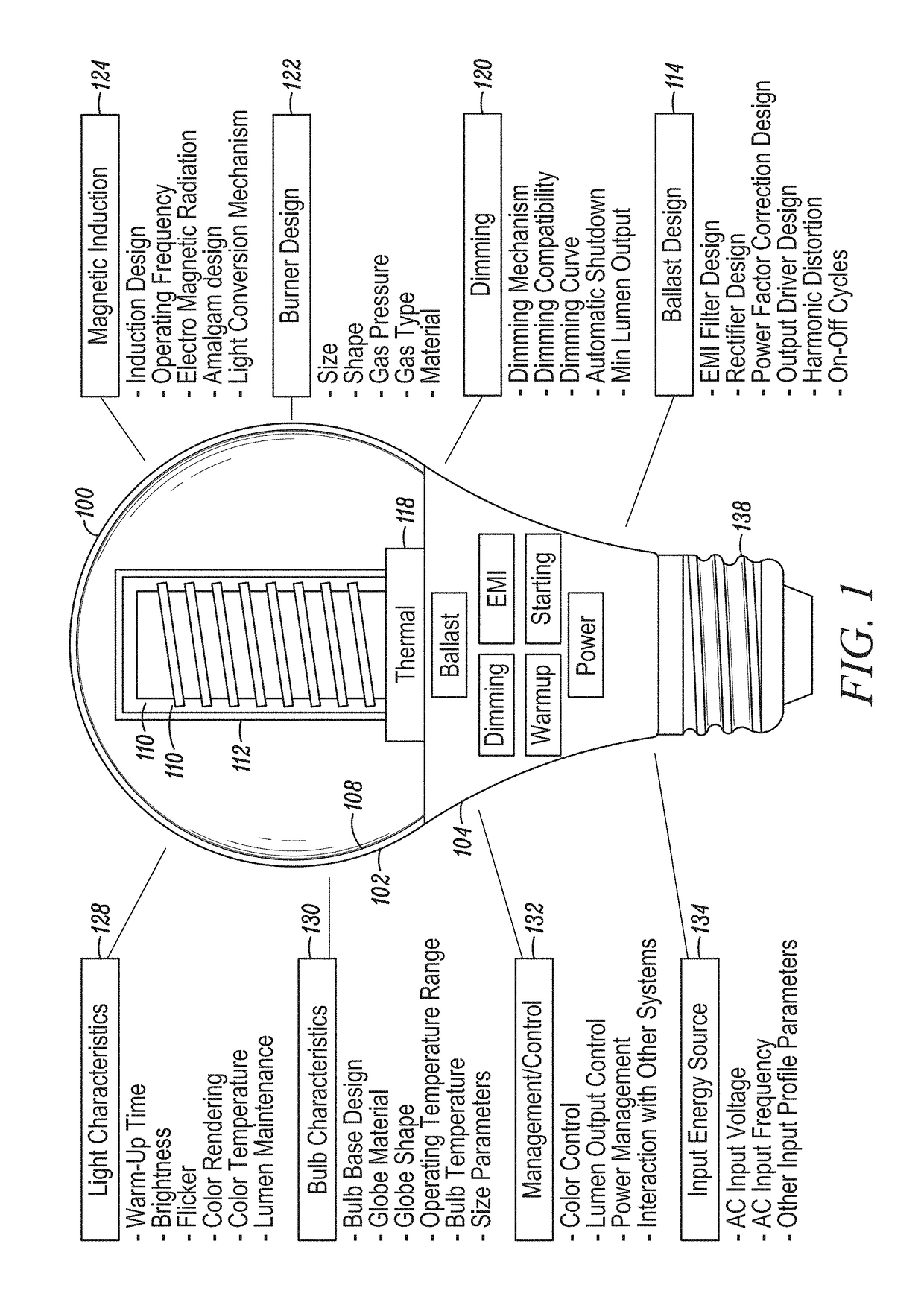

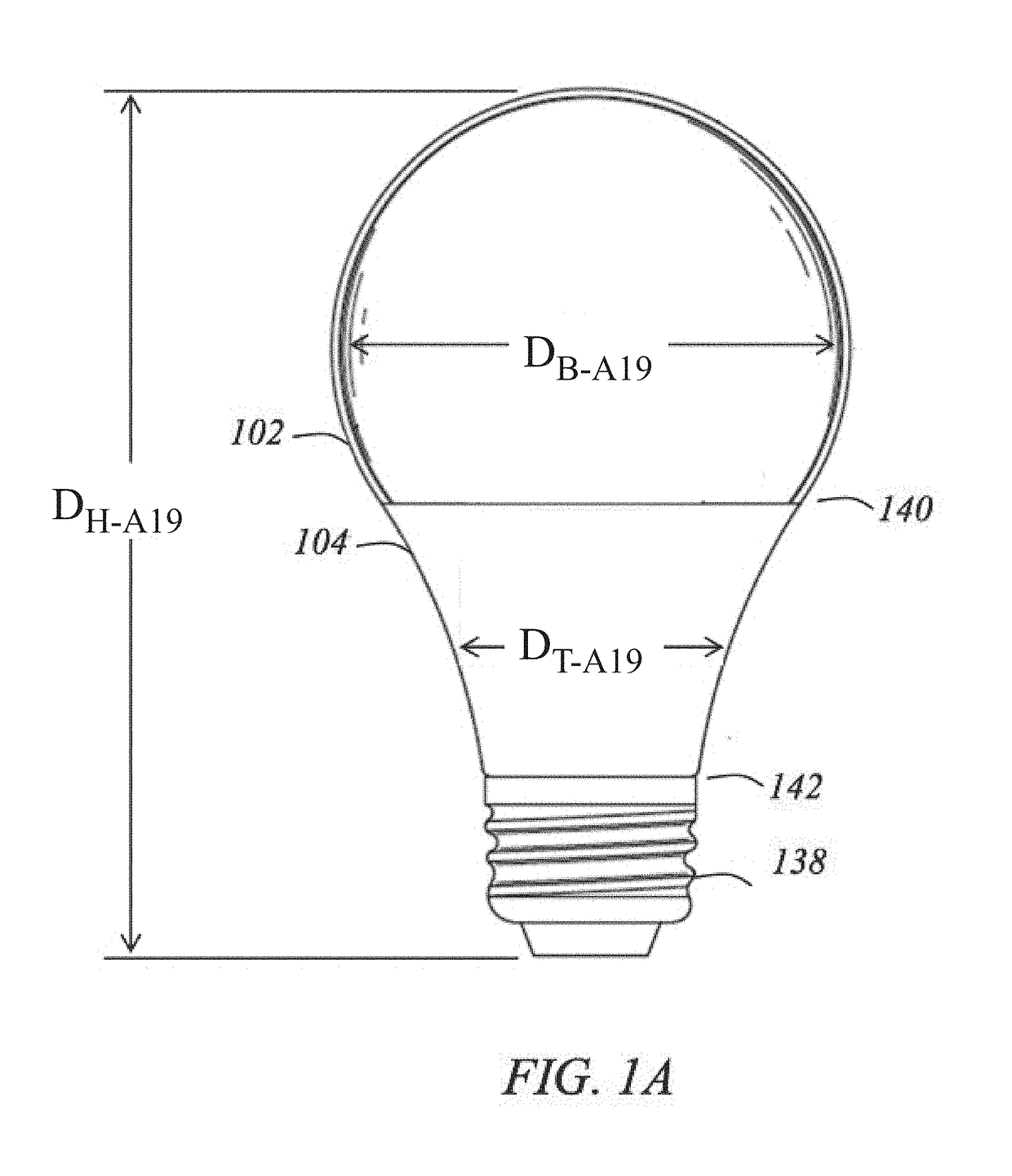

Induction RF fluorescent lamp with processor-based external dimmer load control

InactiveUS20140368109A1Operational flexibilitySmall sizeEfficient power electronics conversionElectric discharge tubesElectricityElectrical conductor

A processor controlled induction RF fluorescent lamp, where the control processor runs a load control algorithm at least for switching the electrical load for connection to an external dimming device, the lamp comprising a vitreous envelope filled with an ionizable gas mixture; a power coupler comprising at least one winding of an electrical conductor; and an electronic ballast providing appropriate voltage and current to the power coupler.

Owner:LUCIDITY LIGHTS

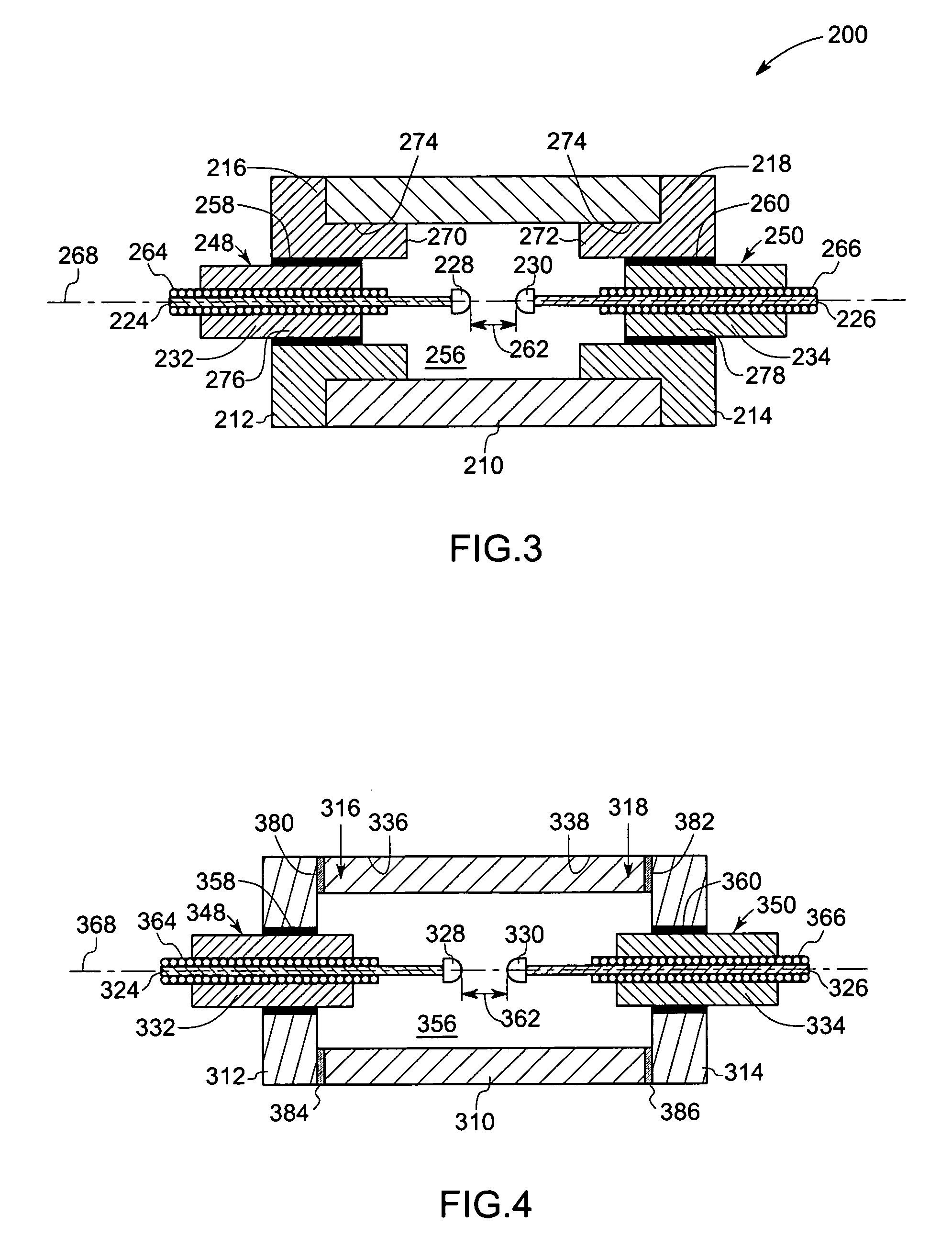

HID lamp having material free dosing tube seal

A hermetically sealed lamp having at least one seal-material-free bond. The seal material-free bond may be a material diffusion bond, a mechanically deformed bond such as a cold weld or crimp, a focused heat bond such as a laser bond, or any other such bond. For example, the hermetically sealed lamp may have one or more endcaps diffusion bonded to an arc envelope, such as a ceramic tube or bulb. The hermetically sealed lamp also may have one or more tubular structures, such as dosing tubes, which are mechanically closed via cold welding or crimping. Localized heating, such as the heat provided by an intense laser, also may be used to enhance any of the foregoing bonds.

Owner:GENERAL ELECTRIC CO

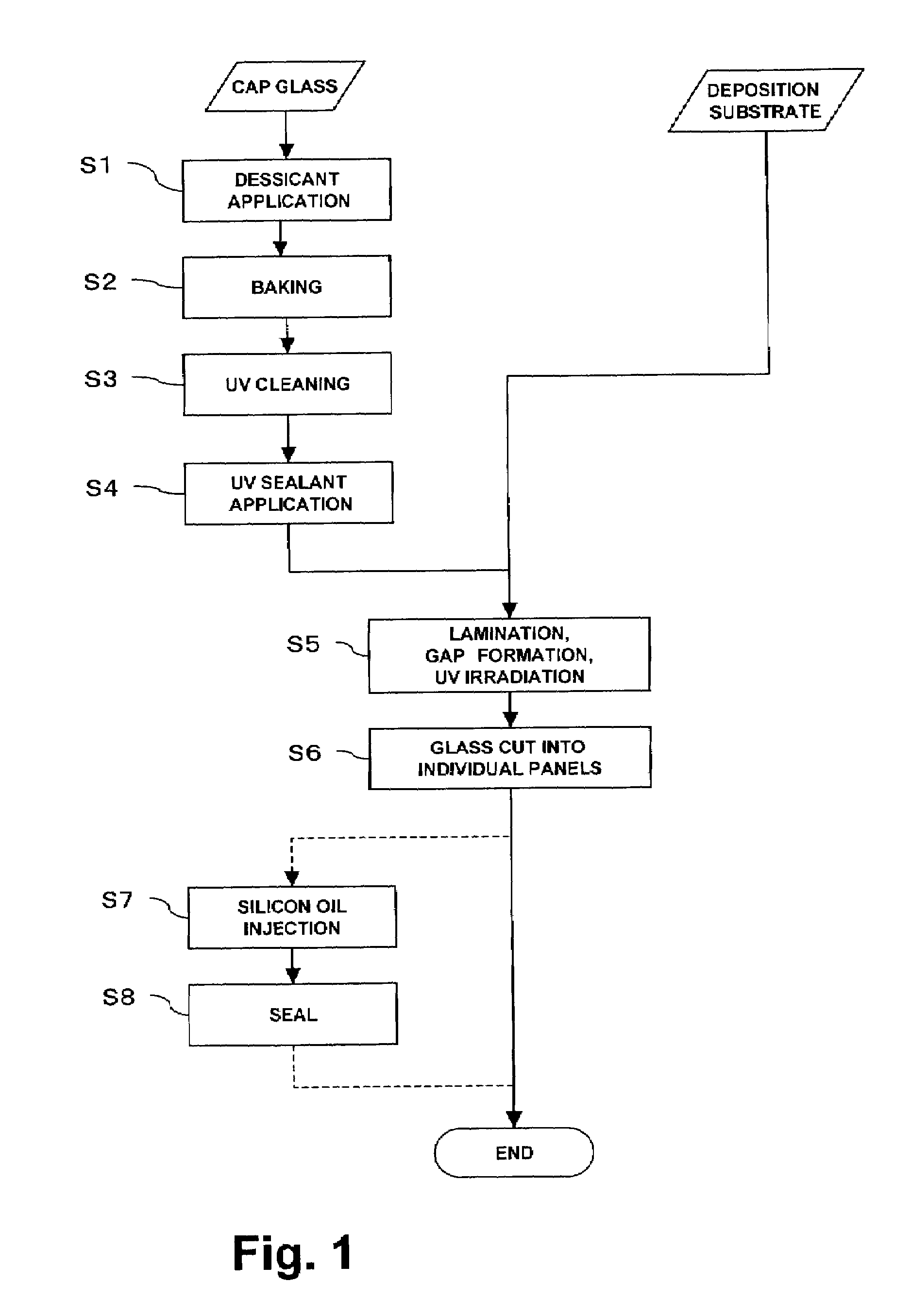

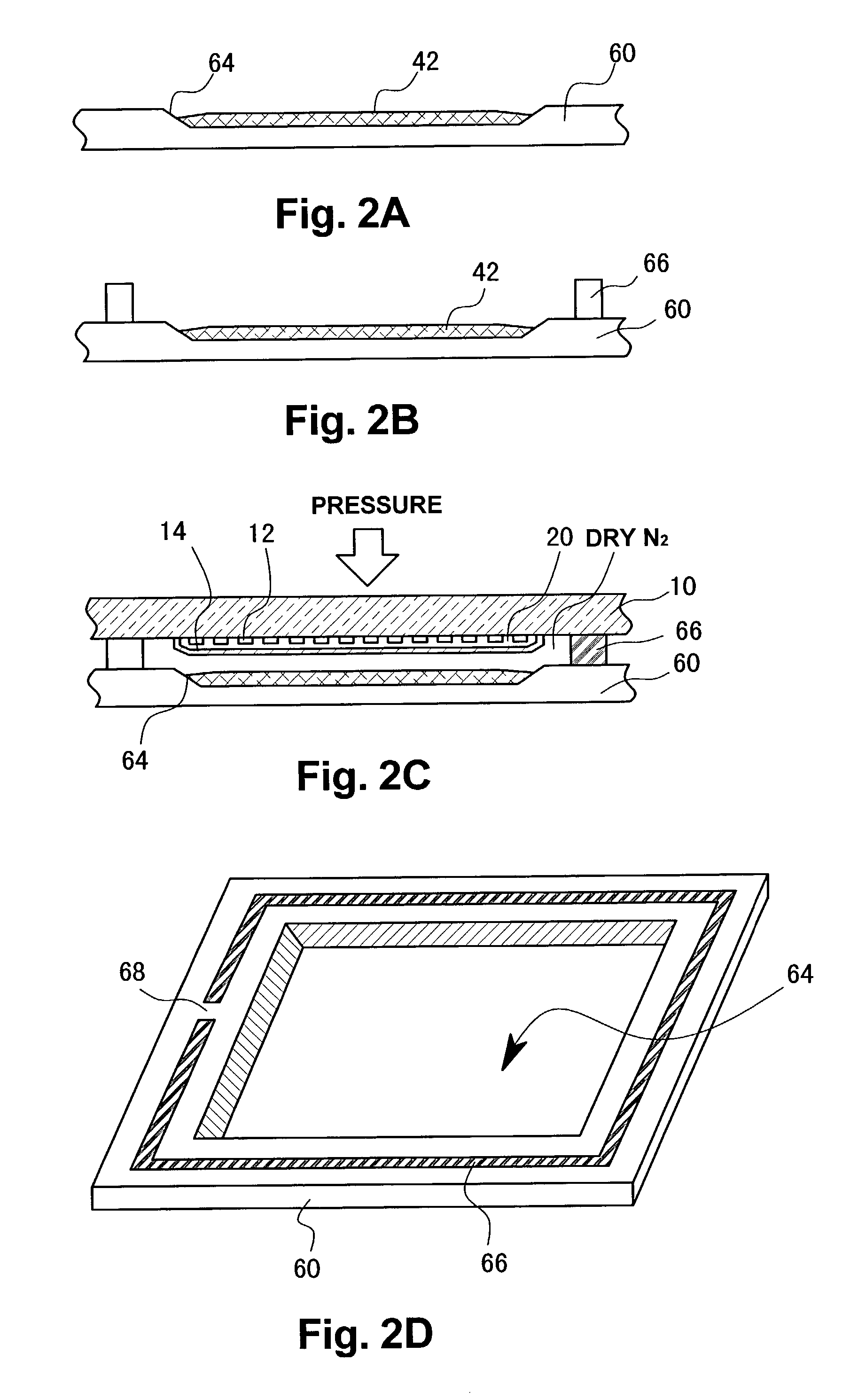

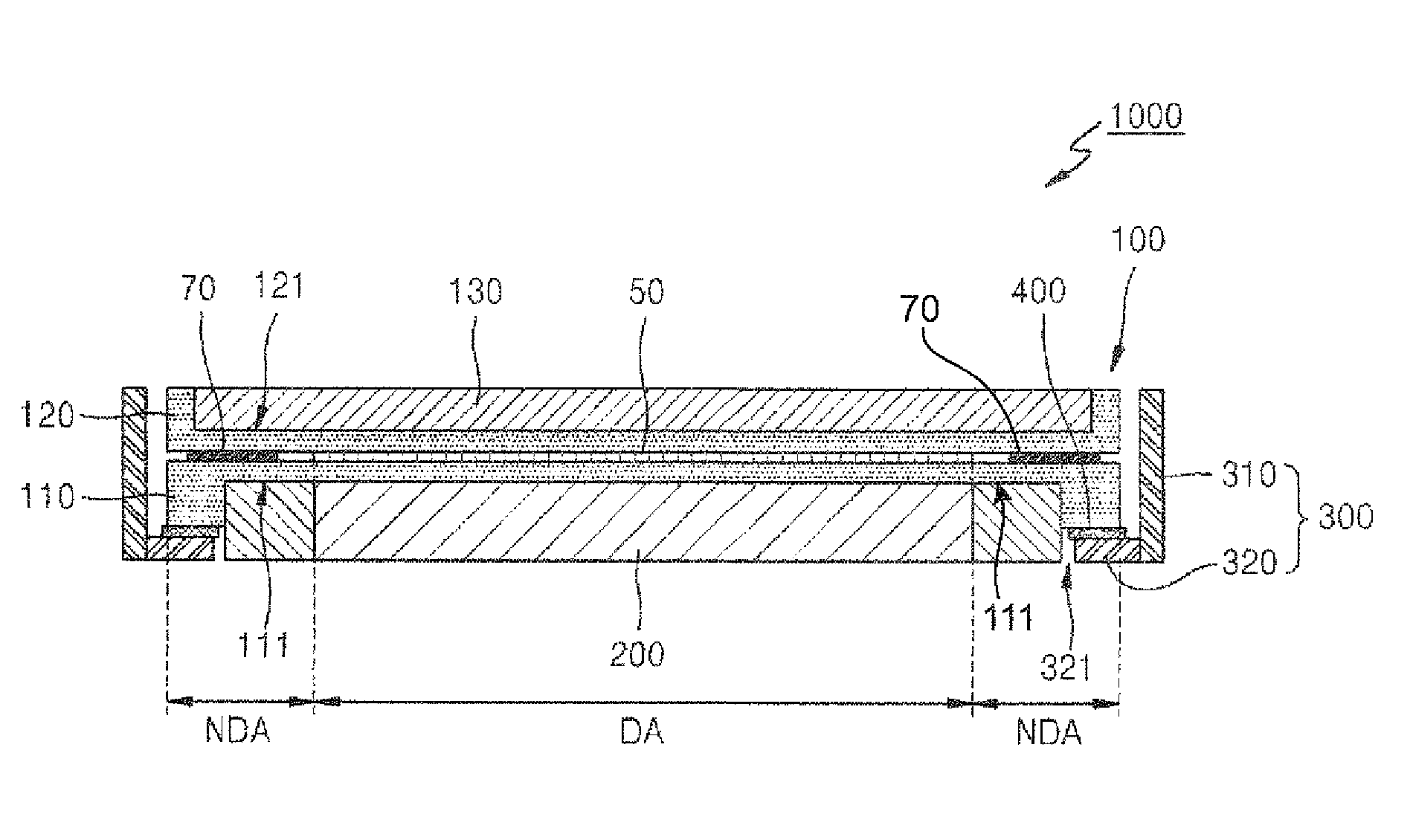

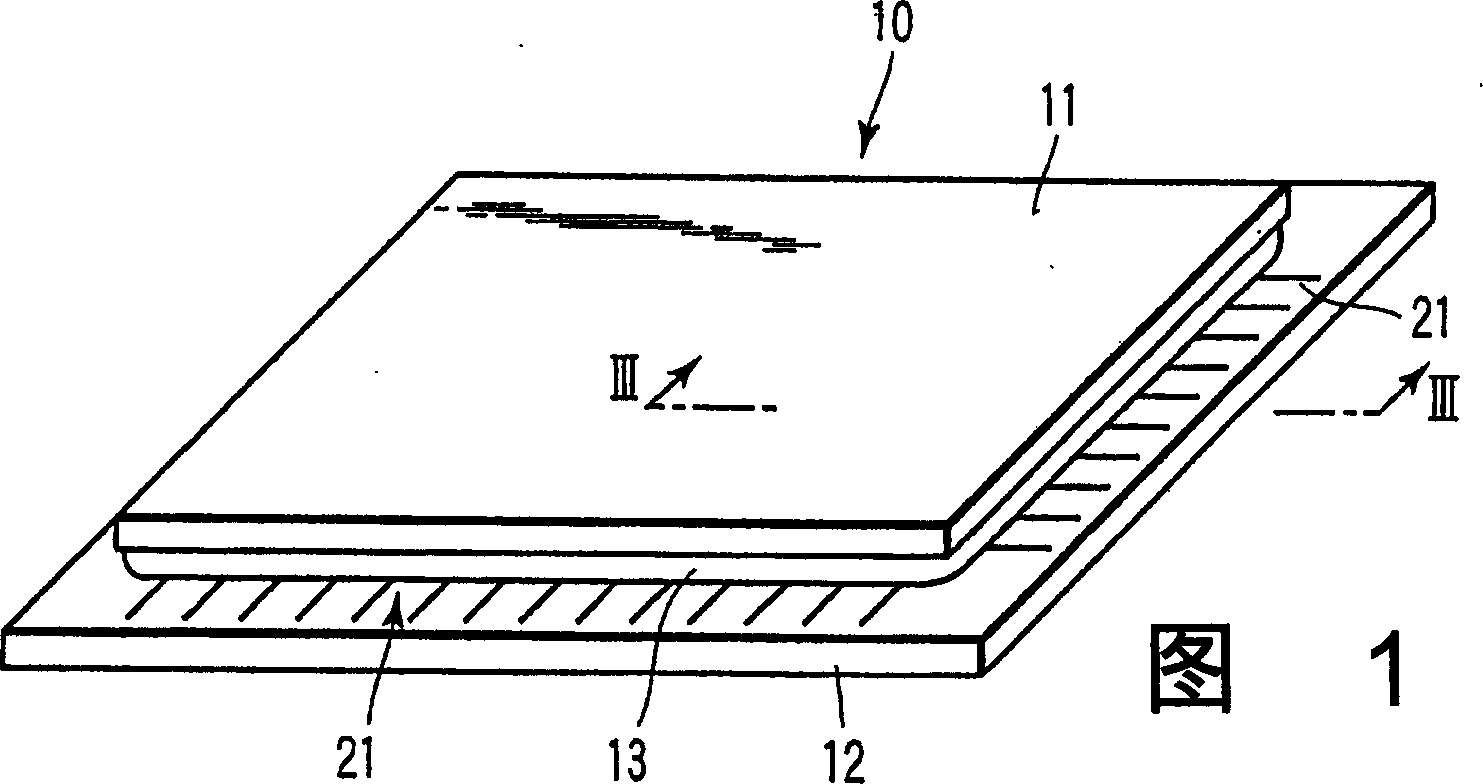

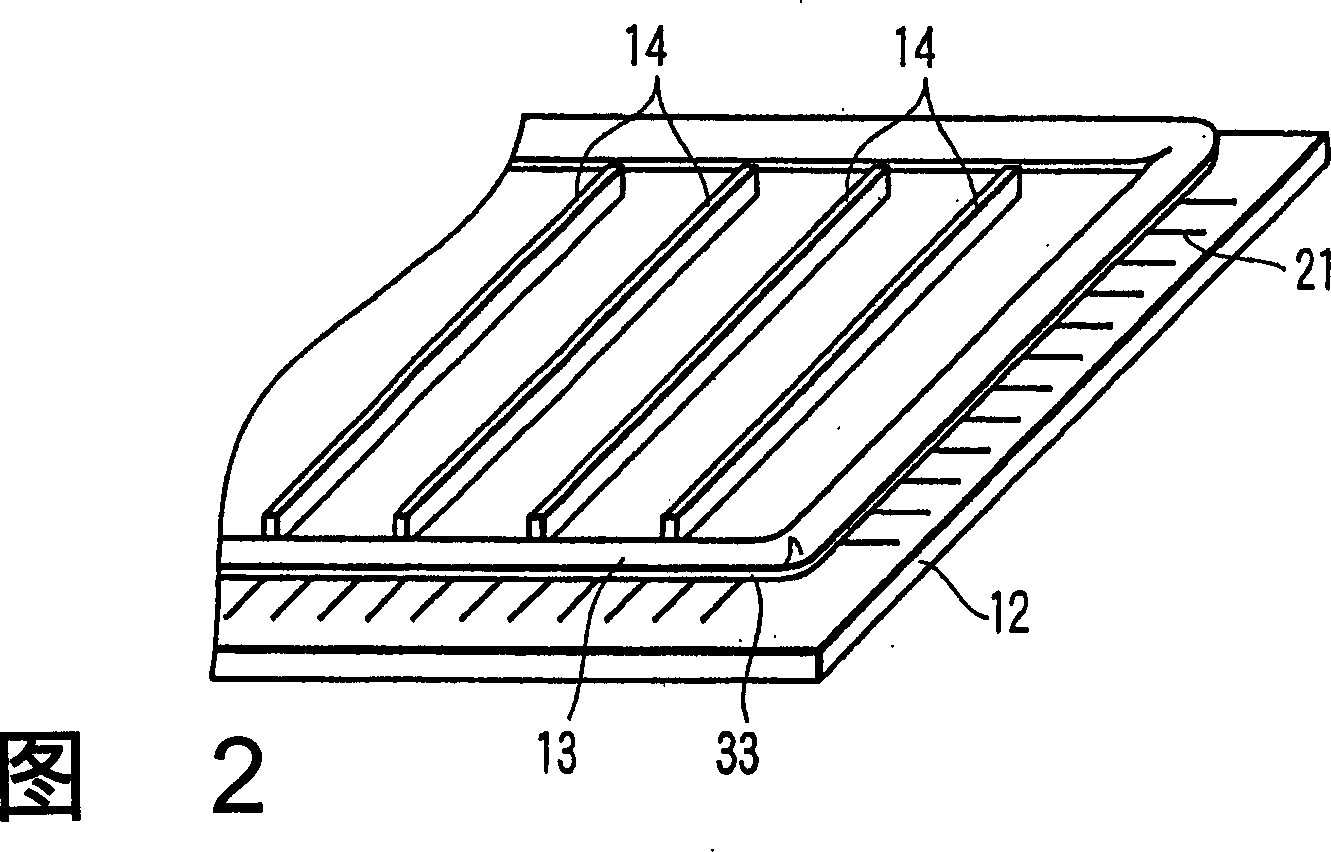

Method of manufacturing electroluminescence panel

InactiveUS7097527B2Improve protectionEasy to manufactureElectroluminescent light sourcesSolid-state devicesEngineeringSealant

An opposing substrate which is subjected to desiccant application, baking, UV cleaning, UV sealant application, or the like and an element substrate having EL elements formed thereon are affixed together by applying a sealing liquid such as silicon oil in a vacuum. Subsequently, when exposed to a normal atmosphere, the opposing substrate and the element substrate are adsorbed to each other while a predetermined gap is maintained in between. In this state, the UV sealant is cured with UV irradiation. It is thus possible to enclose the sealing liquid between the opposing substrate and the element substrate using a simple manufacturing method.

Owner:SANYO ELECTRIC CO LTD

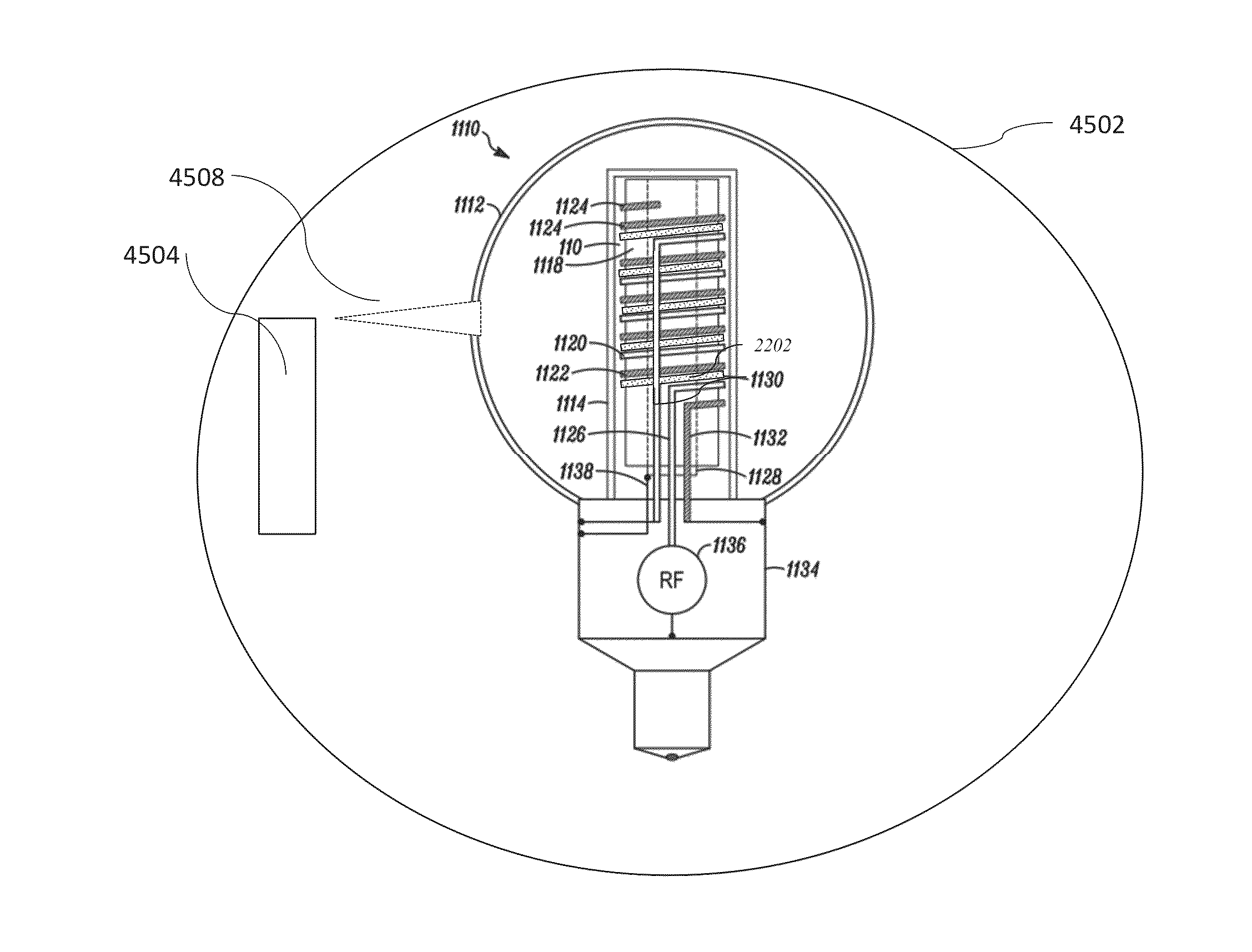

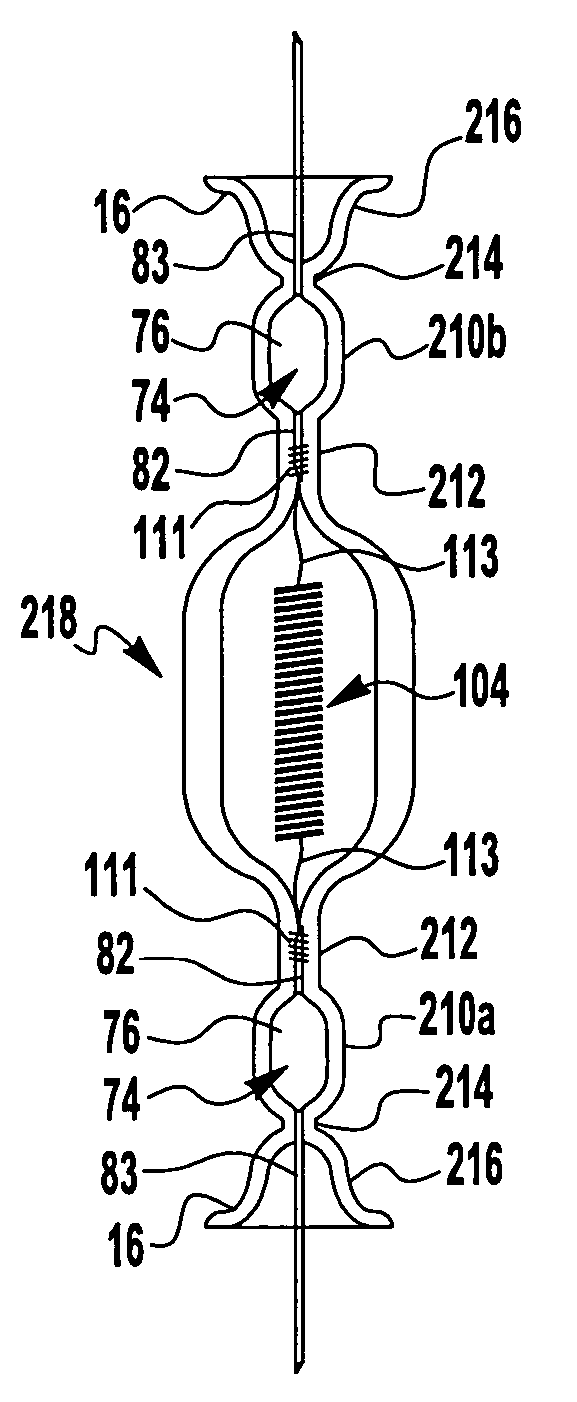

Induction RF fluorescent lamp with helix mount

InactiveUS20140375203A1Operational flexibilitySmall sizeEfficient power electronics conversionElectric discharge tubesRe entrantFluorescent lamp

An induction RF fluorescent lamp, comprising: a lamp envelope with a re-entrant cavity and evacuation tube; a power coupler, wherein the power coupler is located inside the re-entrant cavity; an electronic ballast, wherein the electronic ballast provides appropriate voltage and current to the power coupler; and an amalgam held within a capsule located above the power coupler within the lamp envelope, wherein the capsule is positioned with a mount comprising at least one wire attached to the capsule and having at least two wire ends extending from the capsule into the evacuation tube with contact made between the wire ends and the interior surface of the evacuation tube of the re-entrant cavity.

Owner:LUCIDITY LIGHTS

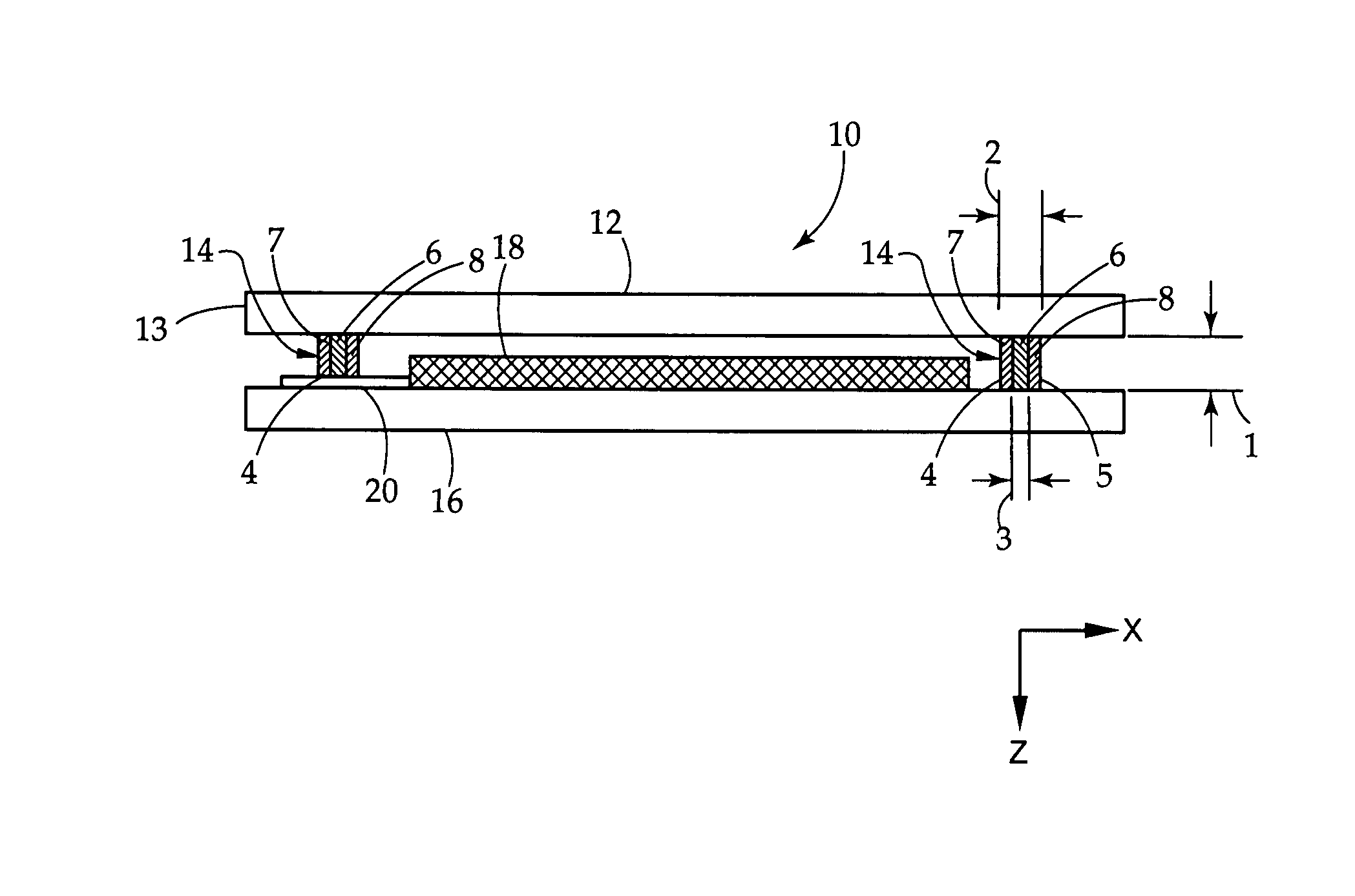

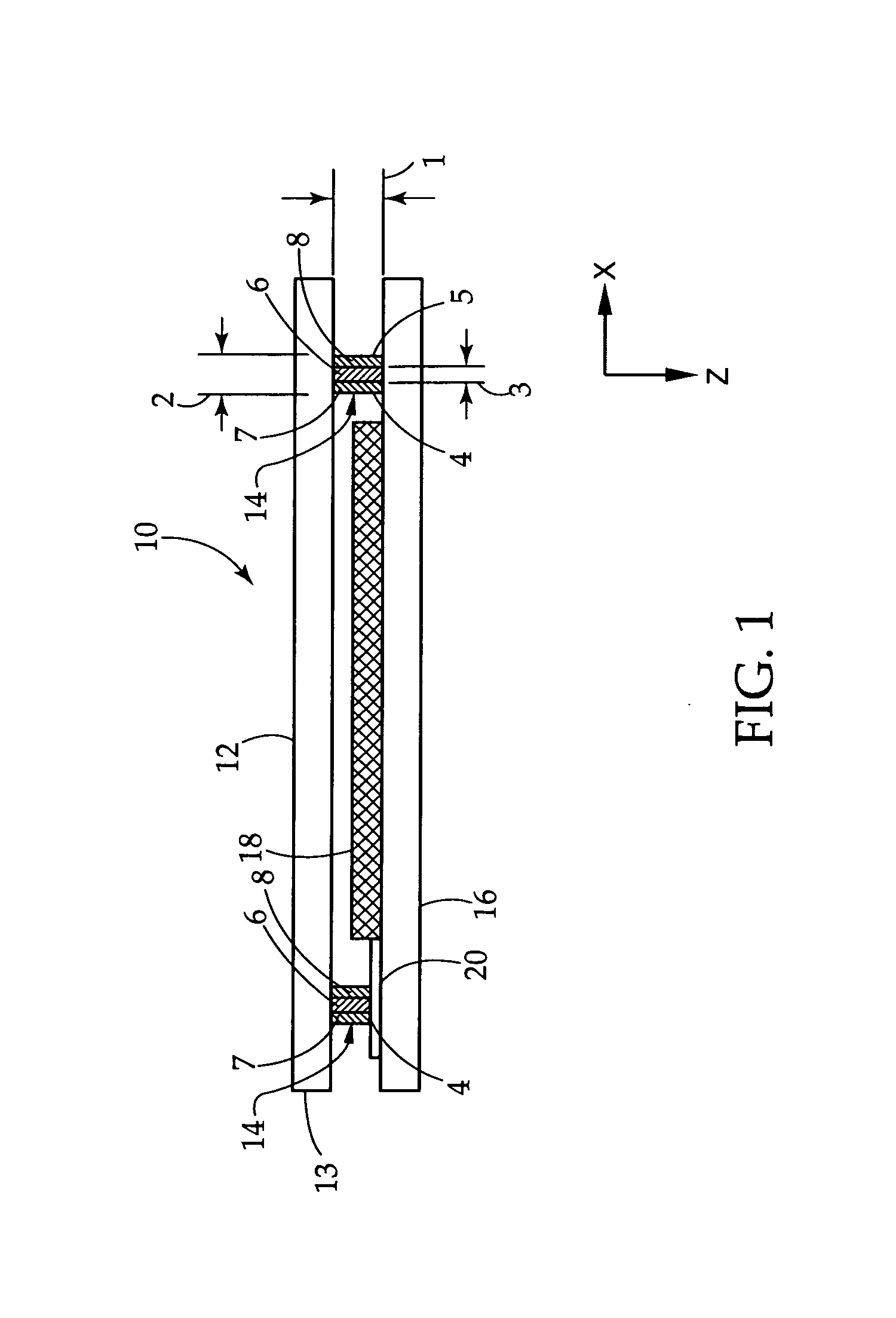

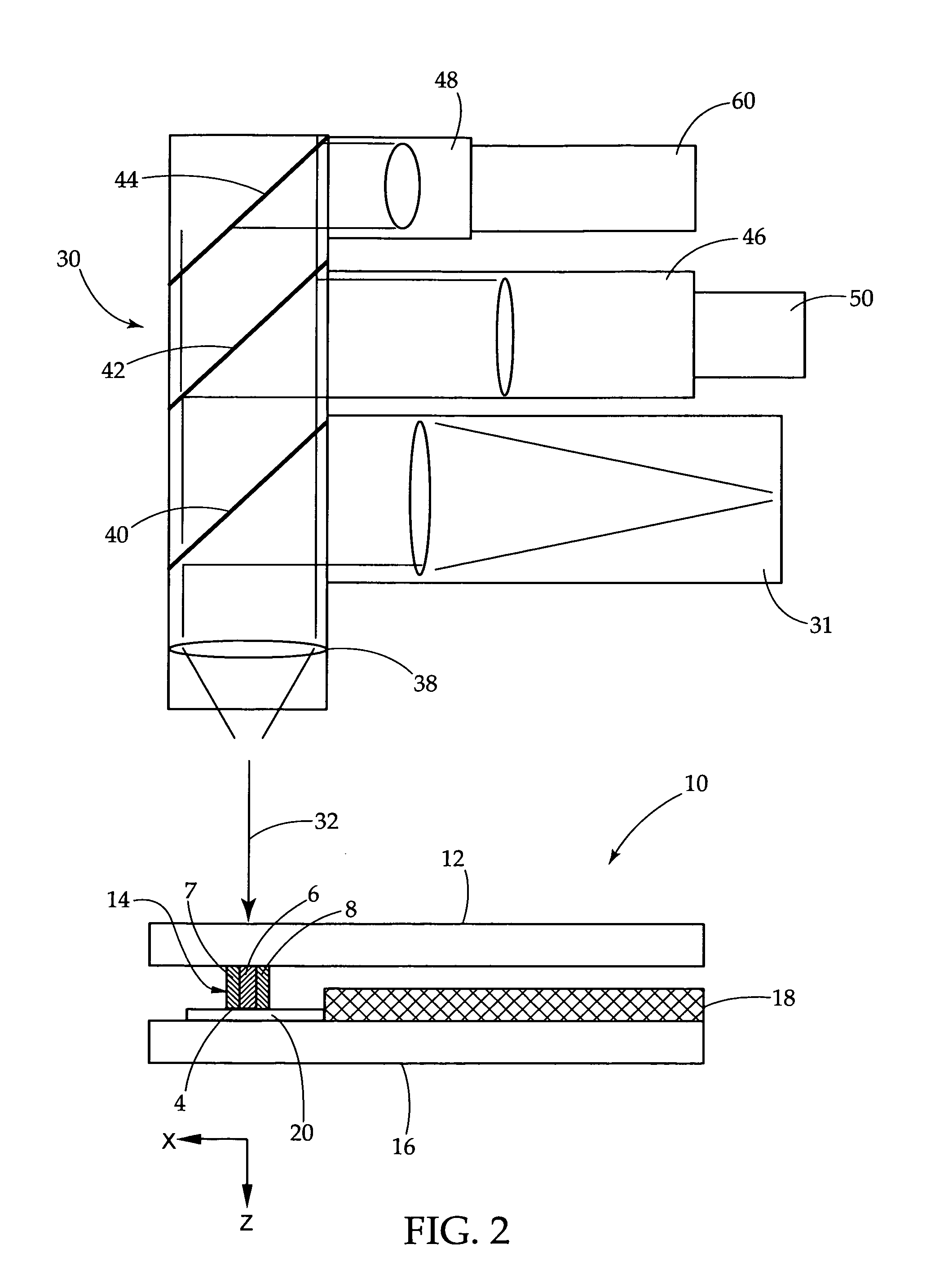

Glass packages and methods of controlling laser beam characteristics for sealing them

InactiveUS20090295277A1Less sensitiveAvoid excessive changesSparking plugsDischarge tube luminescnet screensHermetic sealDisplay device

A display device (10) including a first substrate (12), a second substrate (16), an OLED element (18), and a wall (14) that contains glass. A sealed portion (6) is formed in the wall and between the first substrate and the second substrate so as to produce a hermetic seal. The sealed portion is disposed in the wall so that unsealed portions (7,8) are disposed on opposite sides of the sealed portion. A width (3) of the sealed portion is from about 35% to about 77.3% of a width (2) of the wall. The sealed portion may be formed by heating the wall with a laser beam (32) so that a thickness (1) of the wall lies within the depth of focus (34) of the laser beam. Further, the width (36) of the laser beam can be less than or equal to the width of the wall.

Owner:CORNING INC

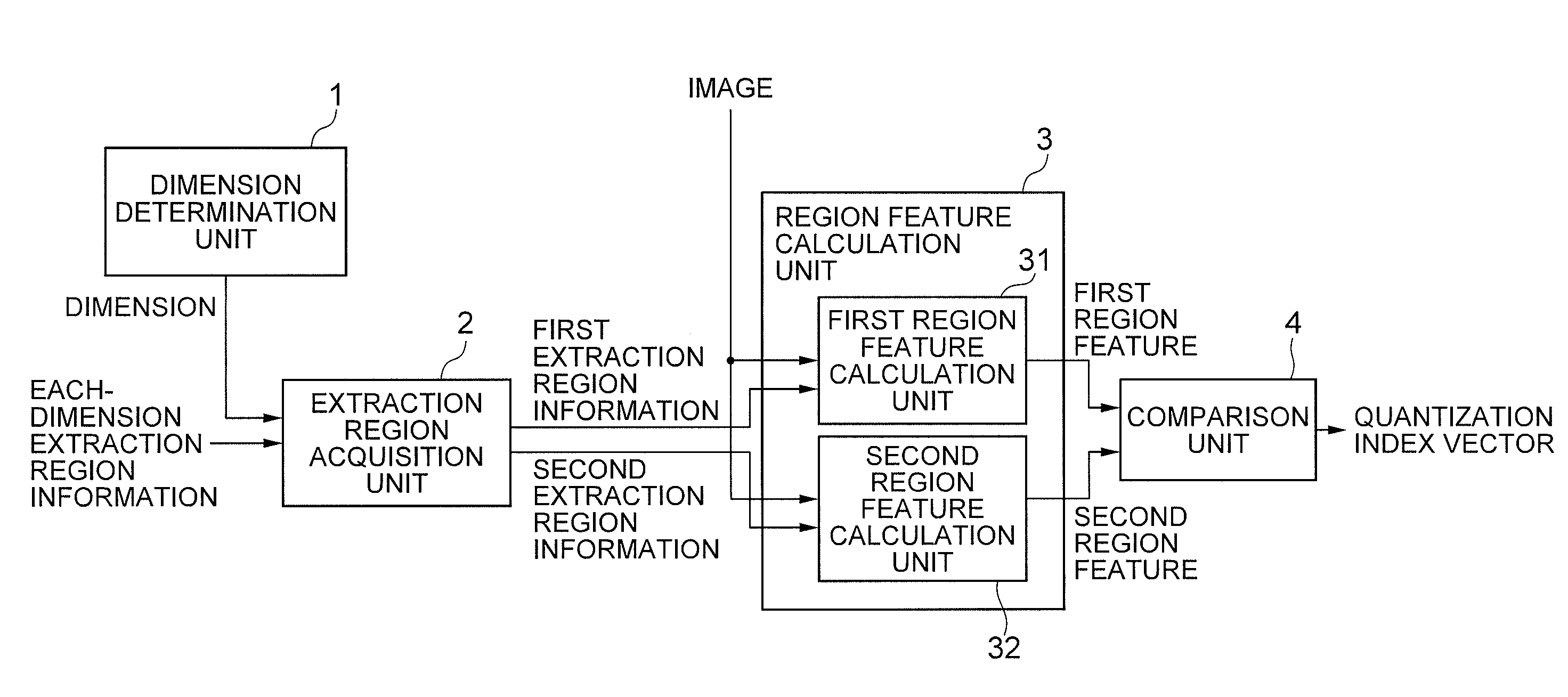

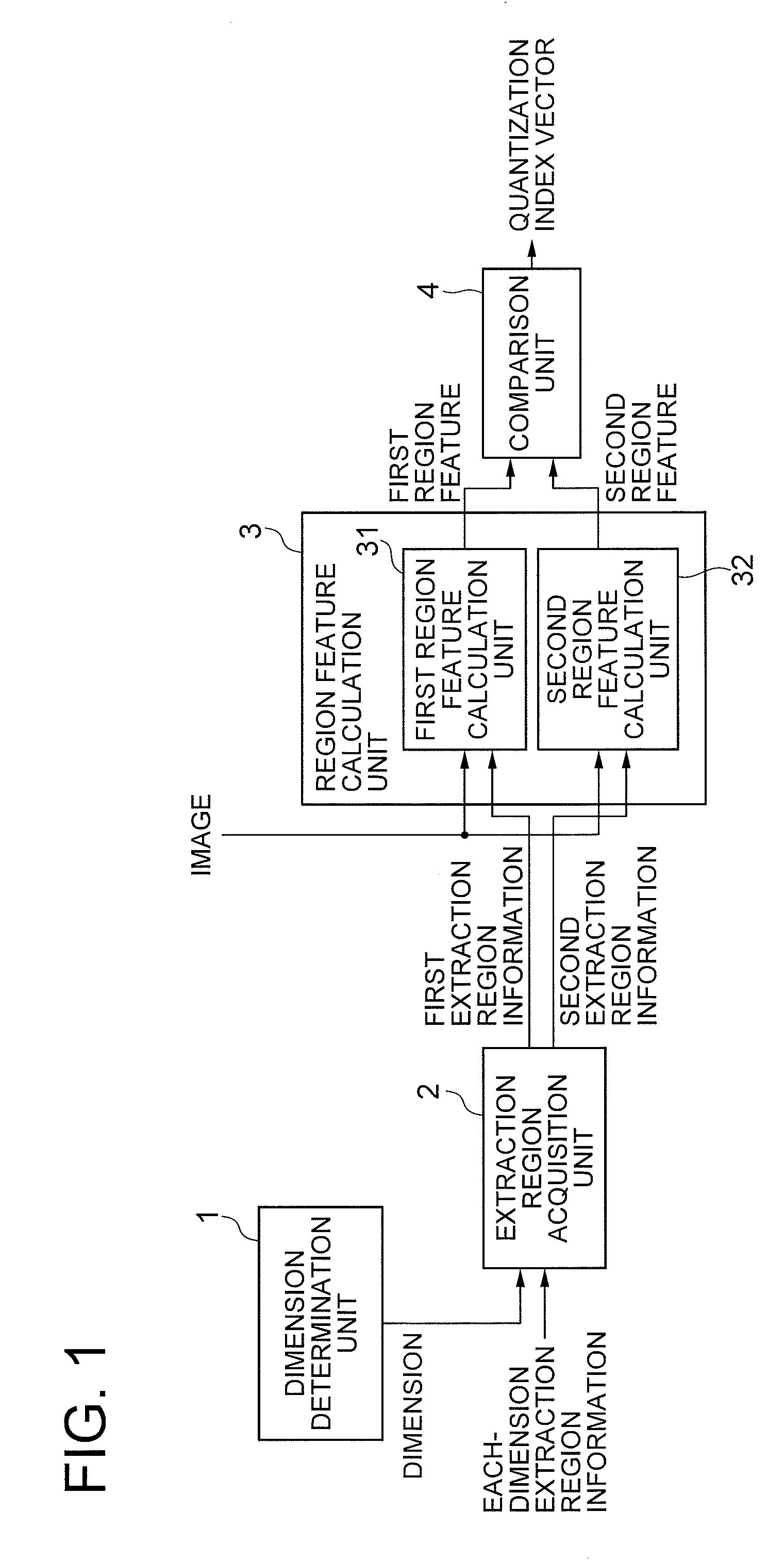

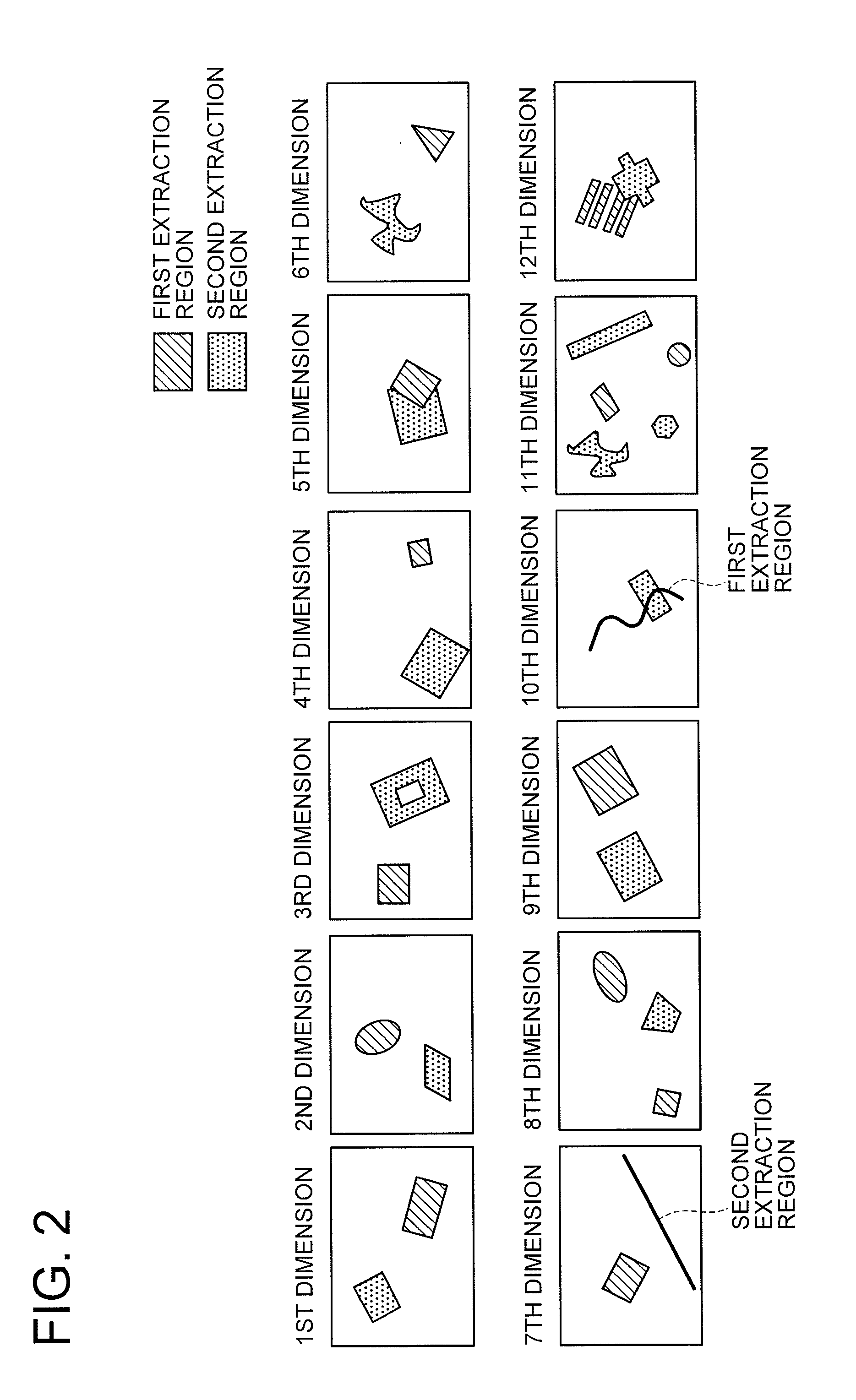

Image signature extraction device

ActiveUS20110274357A1Discrimination capability is not loweredHigh correlationImage analysisCathode-ray/electron-beam tube vessels/containersComputer visionPattern recognition

Owner:NEC CORP

Fast start fluorescent light bulb

ActiveUS20170358441A1Enriching the flag amalgam with mercuryShorten the timeEfficient power electronics conversionElectric discharge tubesIndiumAlloy

An RF fluorescent lamp, comprising a bulbous vitreous portion of the RF fluorescent lamp comprising a vitreous envelope filled with a working gas mixture, a power coupler to induce an alternating electric field within the vitreous envelope, an electronic ballast, and a mercury amalgam accommodating structure mounted within the lamp envelope and adapted to absorb power from the electric field to rapidly heat and vaporize an amalgam of mercury to rapidly illuminate the lamp envelope during a turn-on phase of the RF fluorescent lamp, wherein the structure is comprised of a substrate material coated with a mixture of indium and gold.

Owner:LUCIDITY LIGHTS

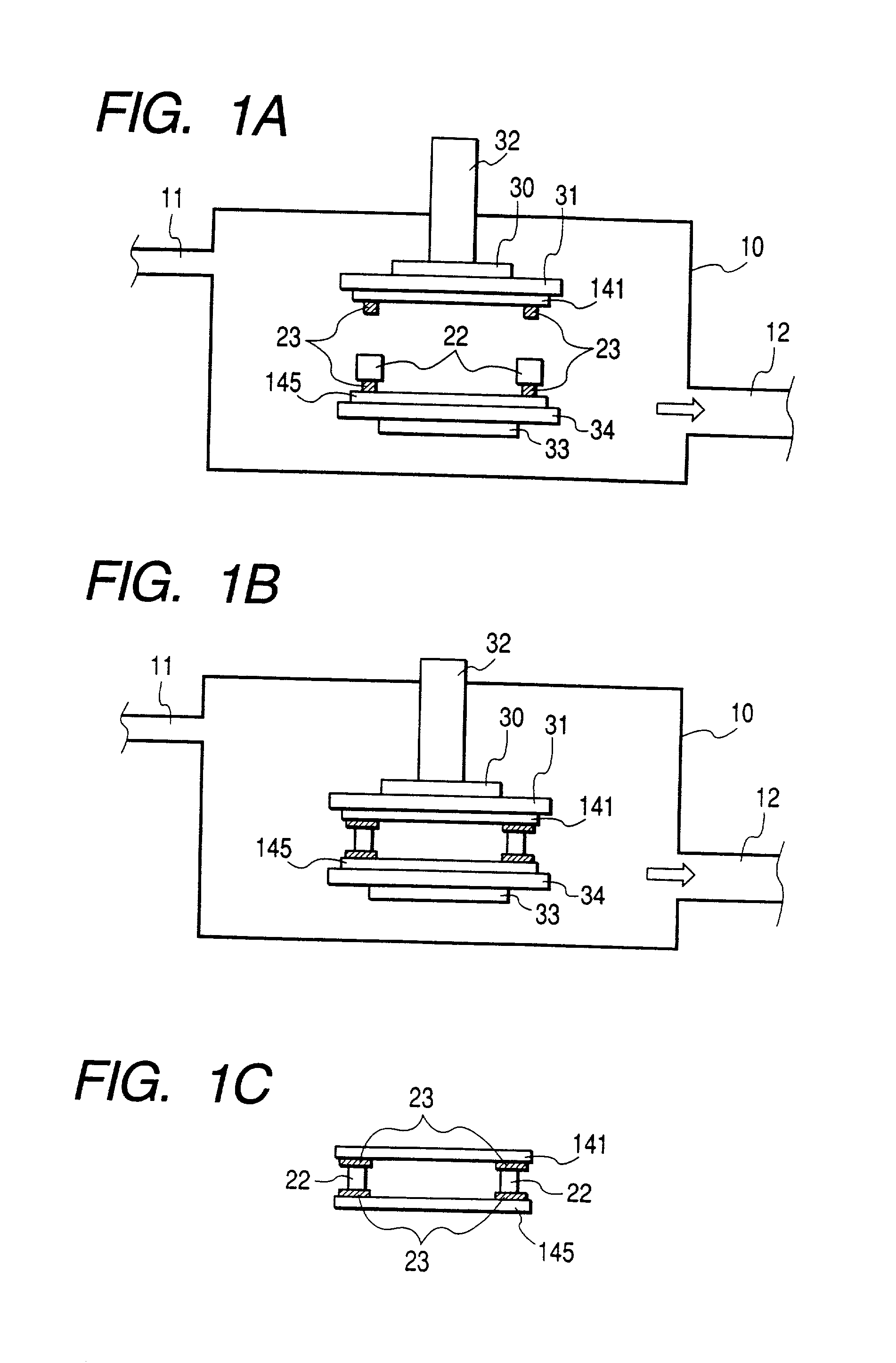

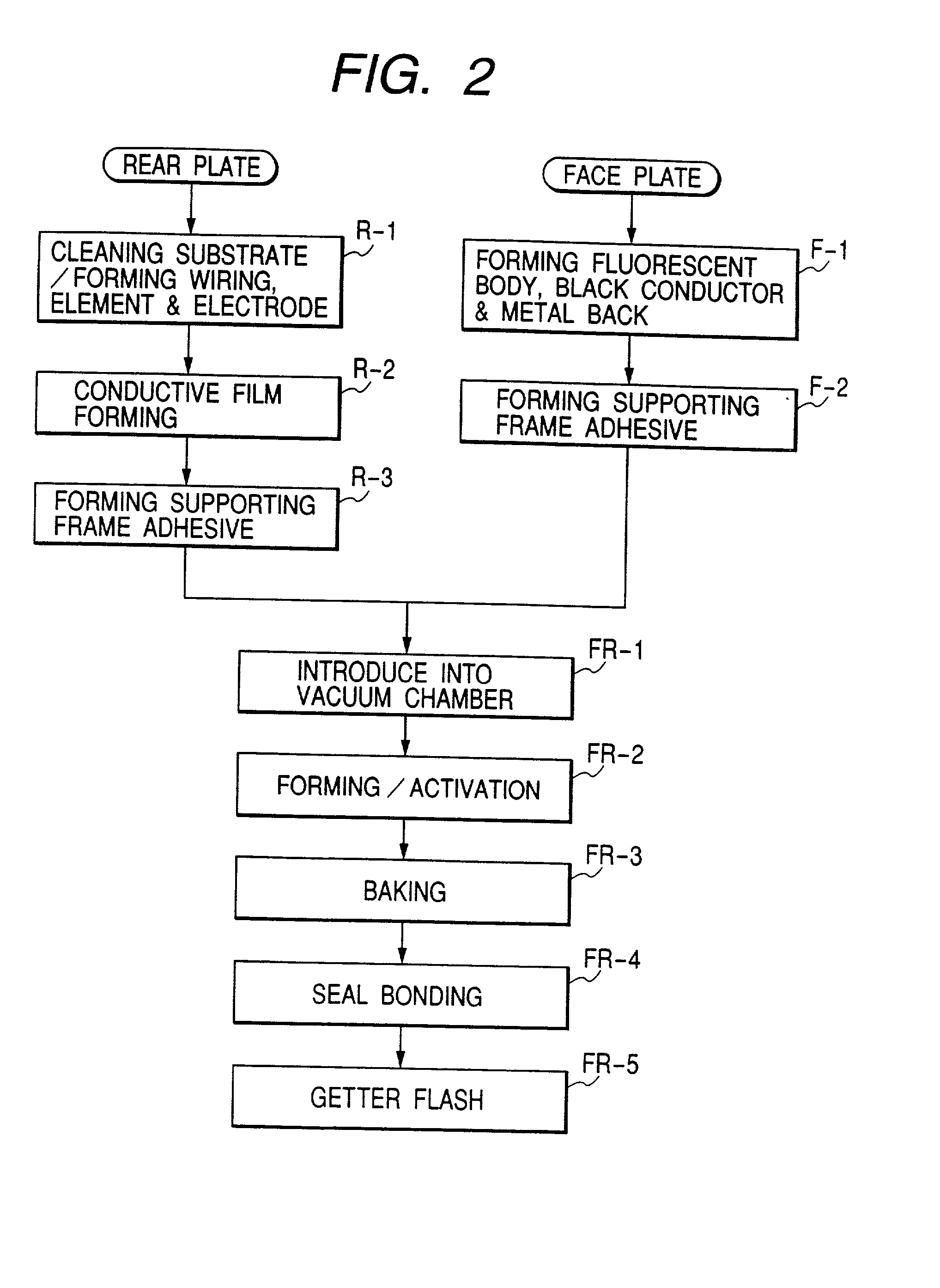

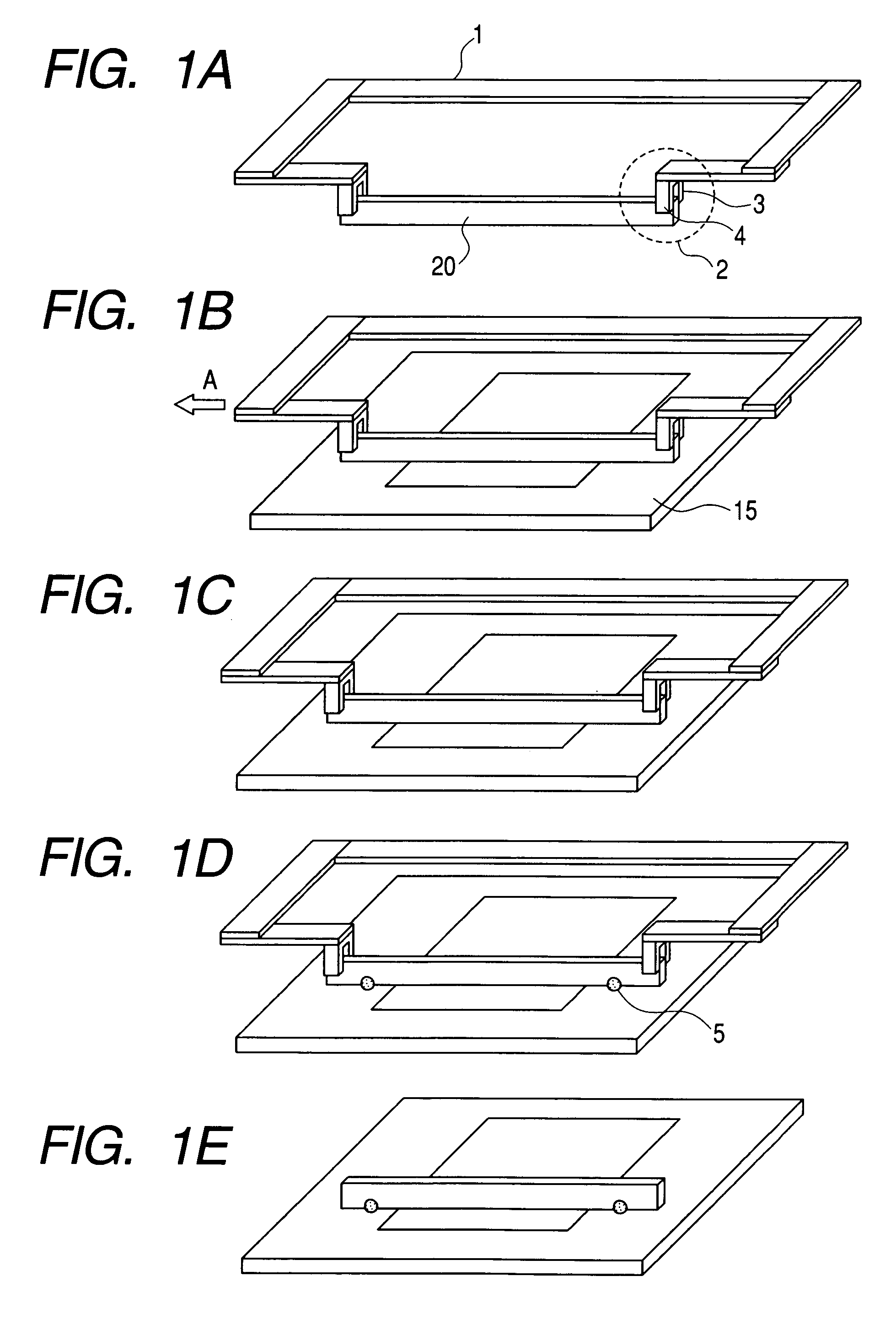

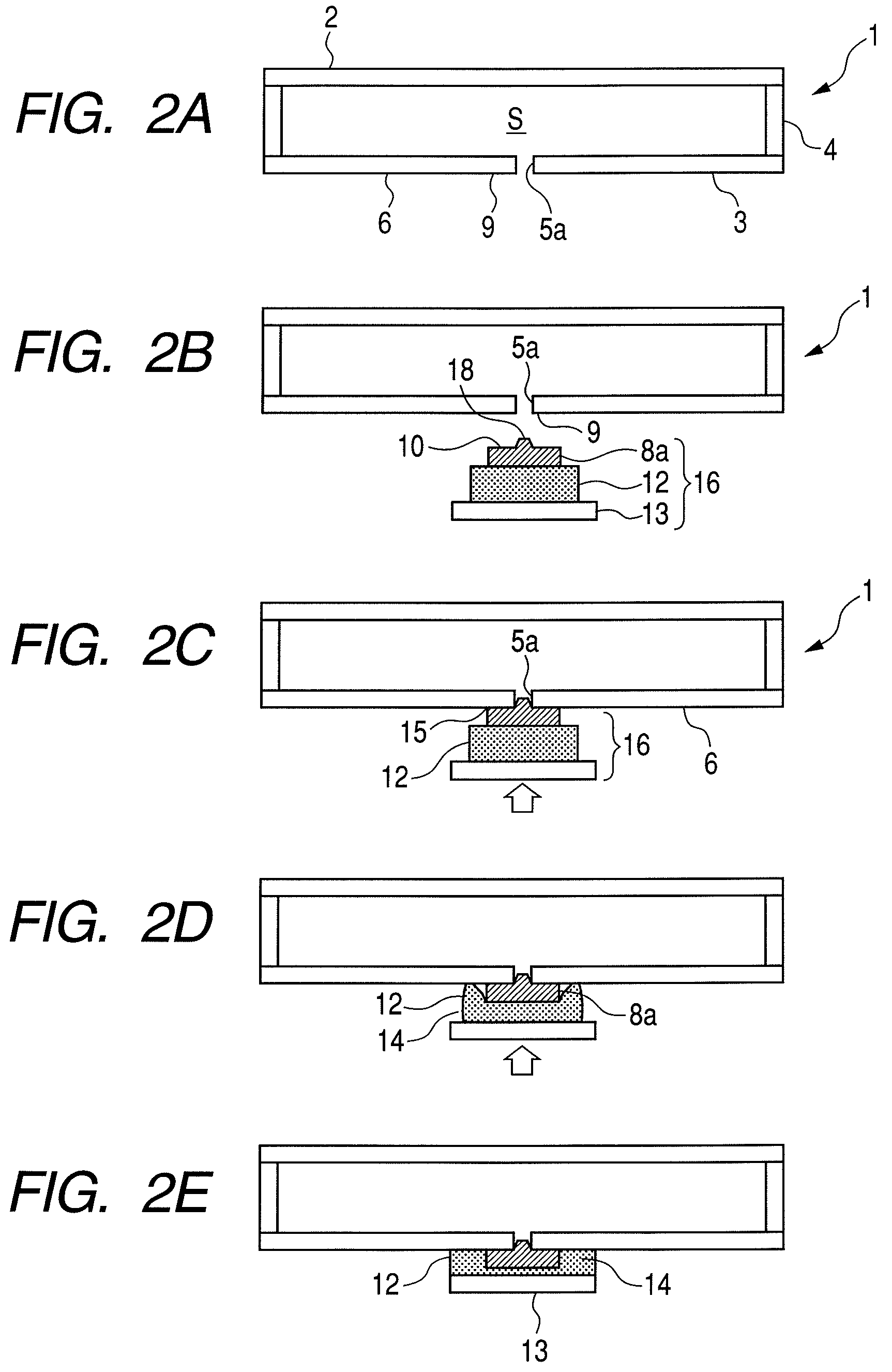

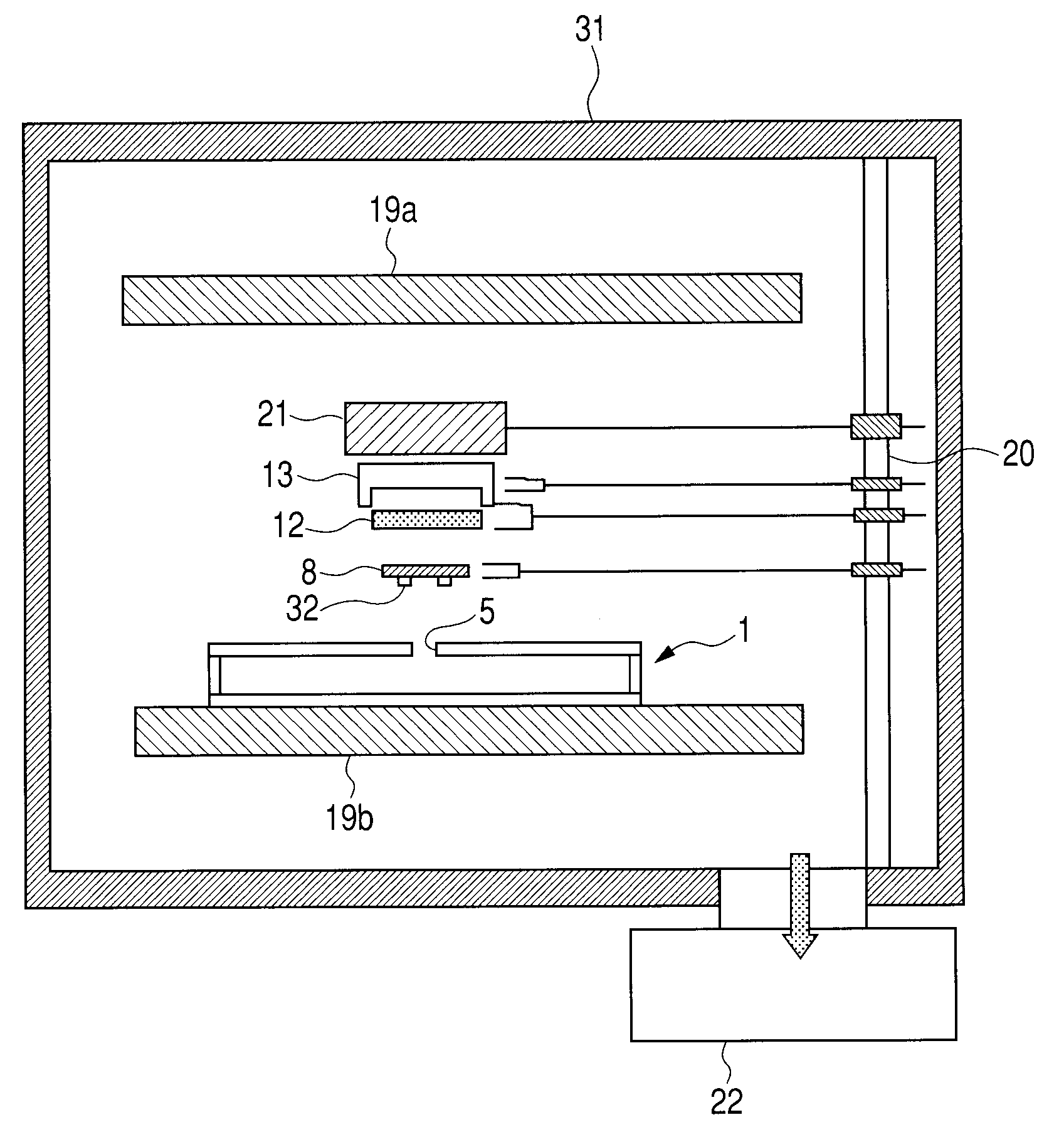

Manufacturing method of image forming apparatus, manufacturing apparatus of image forming apparatus, image forming apparatus, manufacturing method of panel apparatus, and manufacturing apparatus of panel apparatus

InactiveUS20010009836A1Electroluminescent light sourcesTube/lamp vessels exhaustionManufactured apparatusImage formation

To obtain a stable image forming apparatus of a high quality without a luminance fluctuation and a color mixture due to a positional deviation, the following construction is disclosed. A method of manufacturing an image display apparatus in which a first substrate on which fluorescent body exciting means is arranged and a second substrate on which a fluorescent body that emits light by the fluorescent body exciting means is arranged are arranged so as to face each other and are adhered through joining members at their peripheries, wherein a seal bonding step of adhering the first and second substrates through a joining members and a step of performing a position matching of the first and second substrates are executed in a vacuum.

Owner:CANON KK

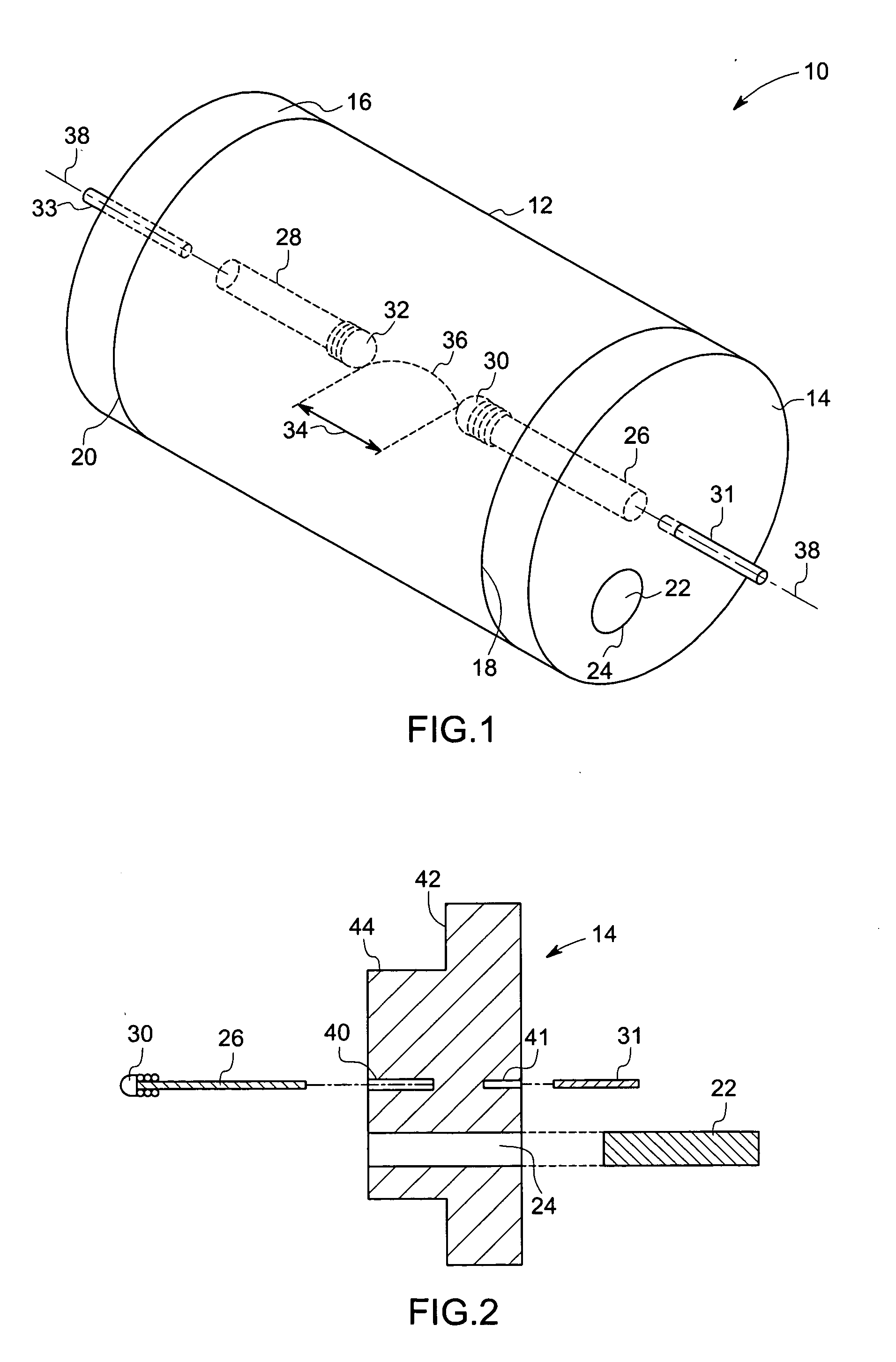

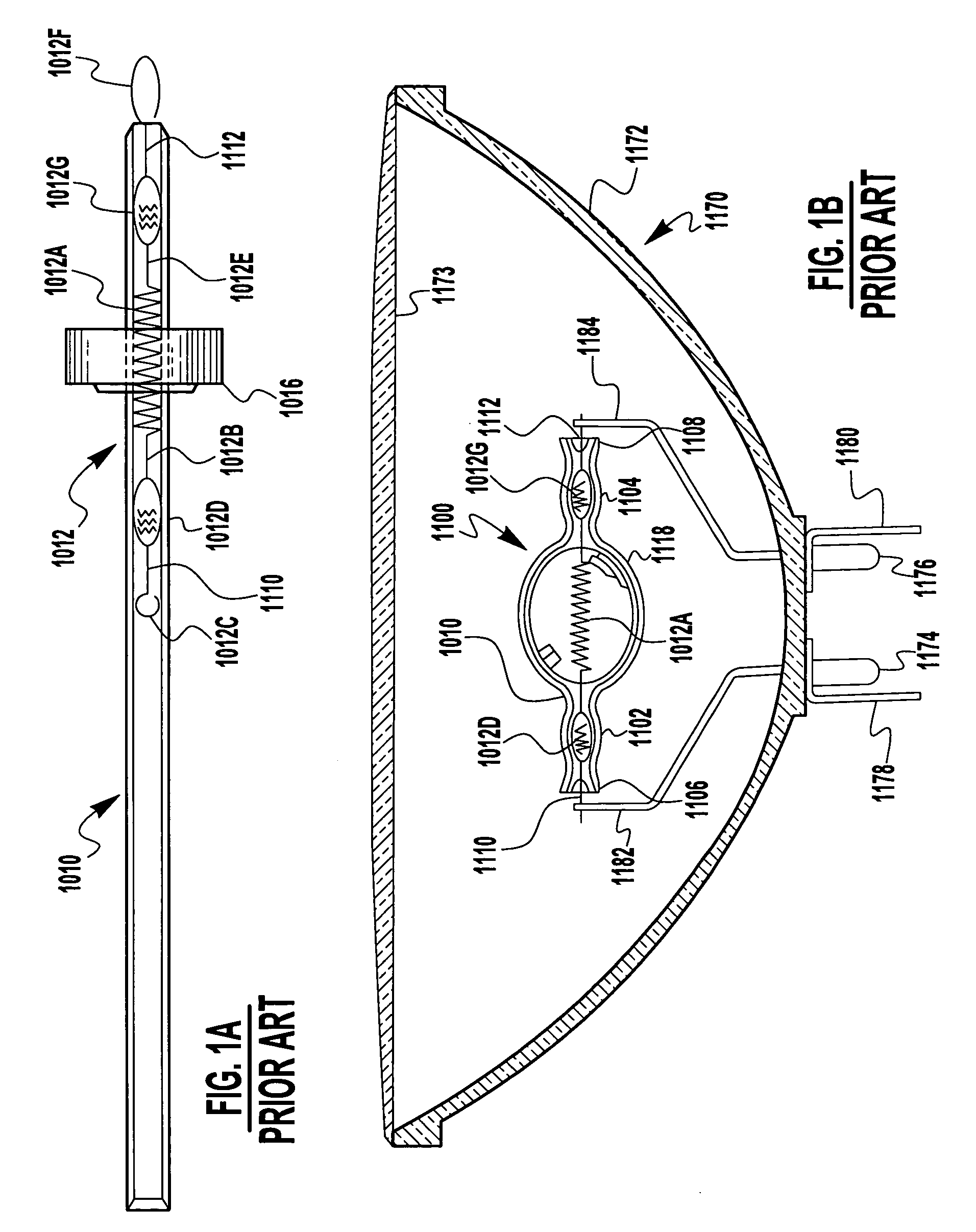

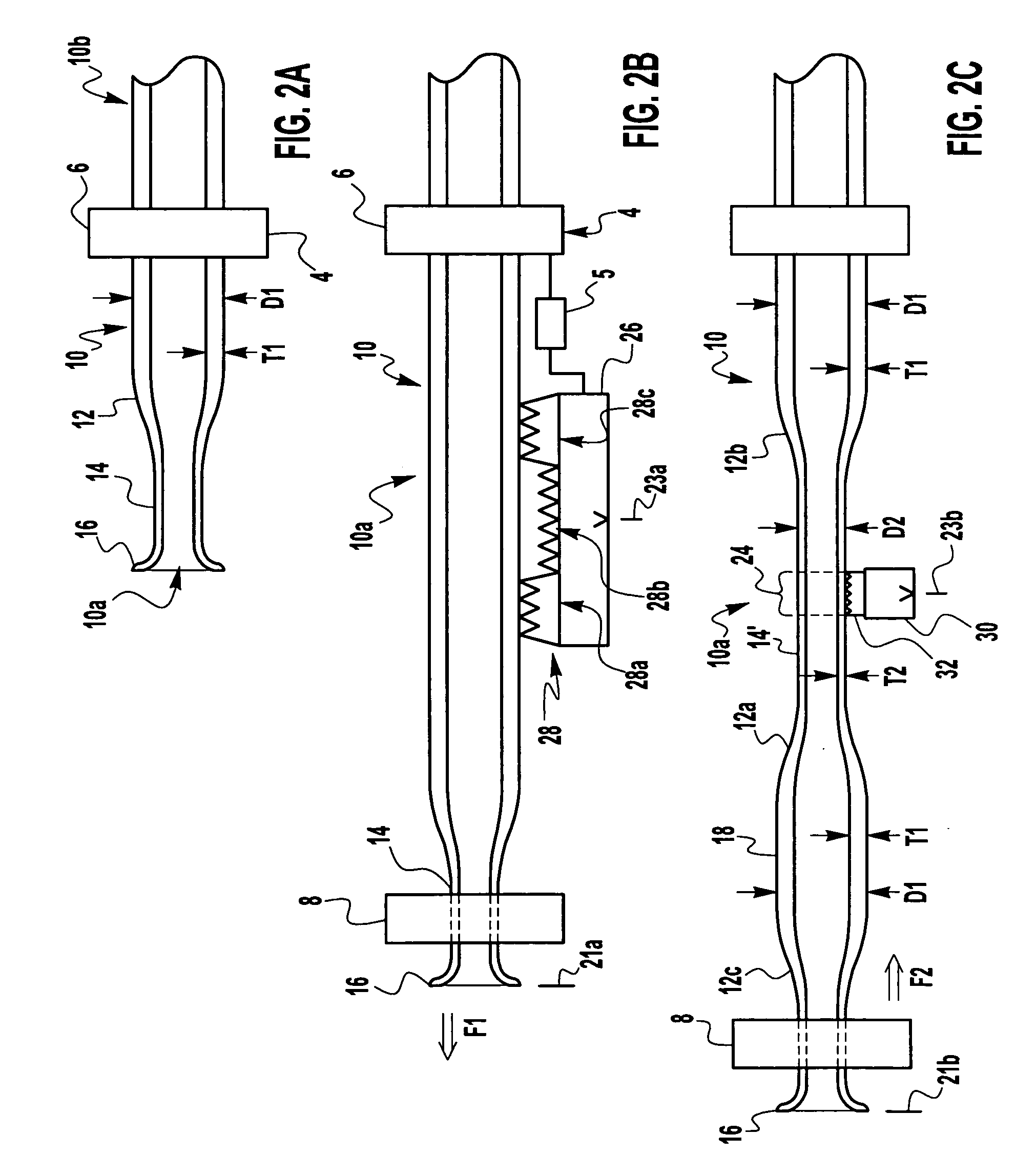

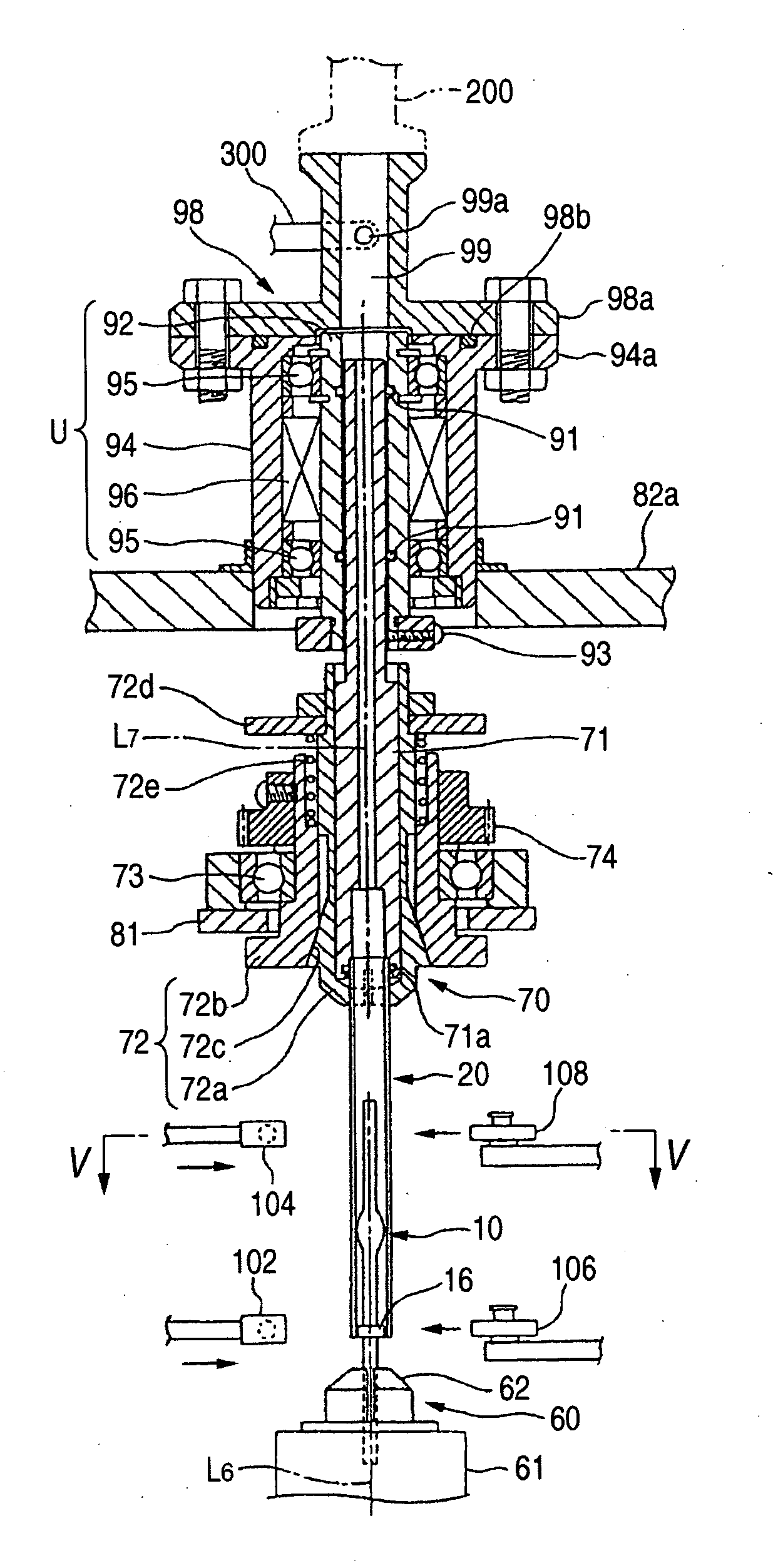

Apparatus and process for finishing light source filament tubes and arc tubes

InactiveUS20050092025A1Minor misalignmentAvoid pollutionTube/lamp screens manufactureElectroluminescent light sourcesManufacturing technologyEngineering

Manufacturing equipment and manufacturing process steps that improve upon prior art processes for the manufacturing of filament tube and arc tube light sources, their components and subassemblies, and lamps employing said light sources. A double ended, tipless filament tube or arc tube light source incorporates a drawn-down tubular body, and one piece foliated leads with spurs for process handling and for spudding into a filament with stretched-out legs. Bugled ends on the body provide a novel cutoff means, facilitate a flush-fill finishing process, and enhance mounting and support of the light sources in lamps. The foliated leads are made from a continuous length of wire in a process including foil hammering and two-bath AC electrochemical etching. Cost-reduced light source and lamp production enables affordable household consumer lamps, even when containing two series-connected halogen filament tubes. Safety benefits ensue from series connection, especially in combination with disclosed body and filament constructions.

Owner:THE FRIDRICH FAMILY TRUST

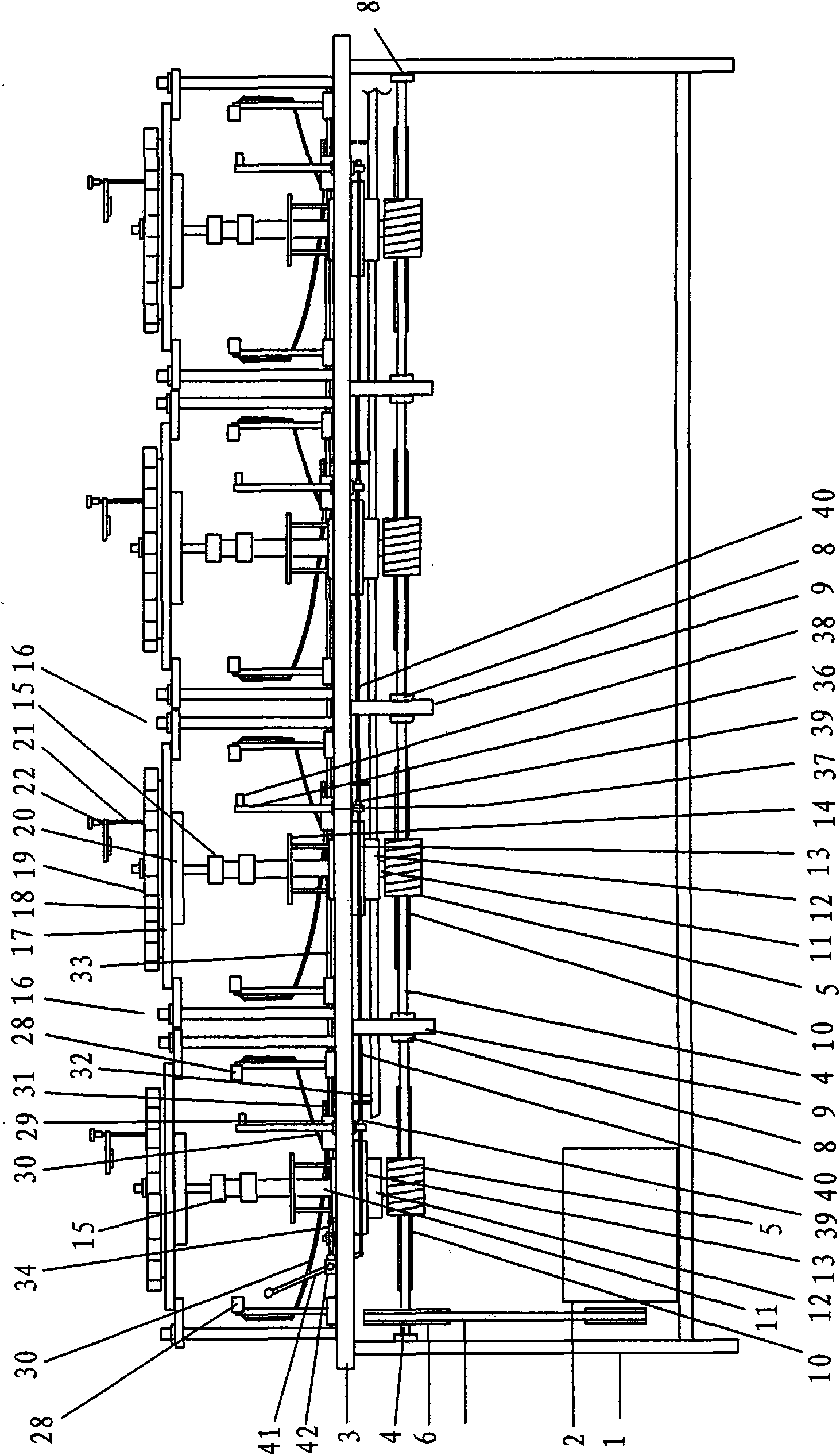

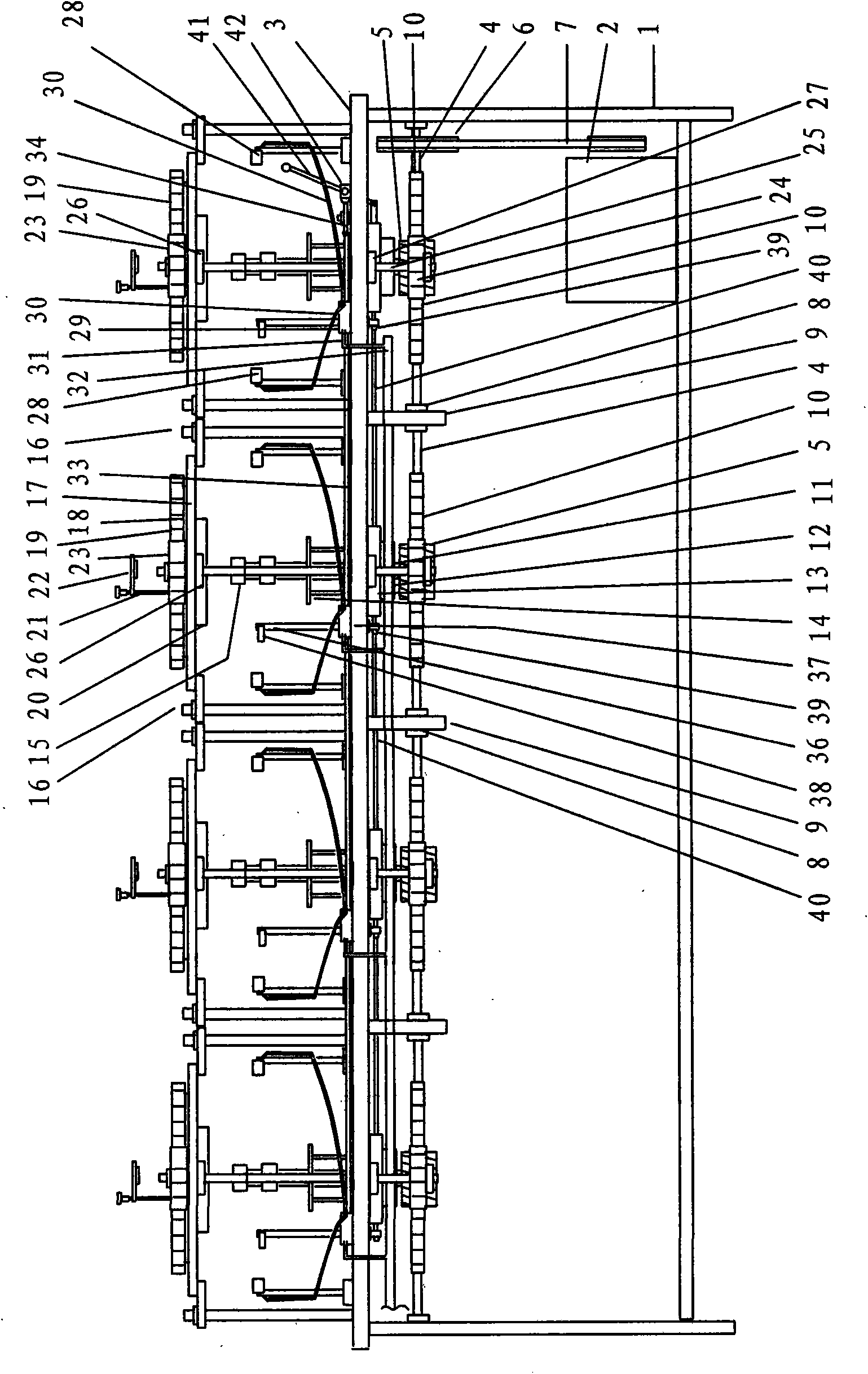

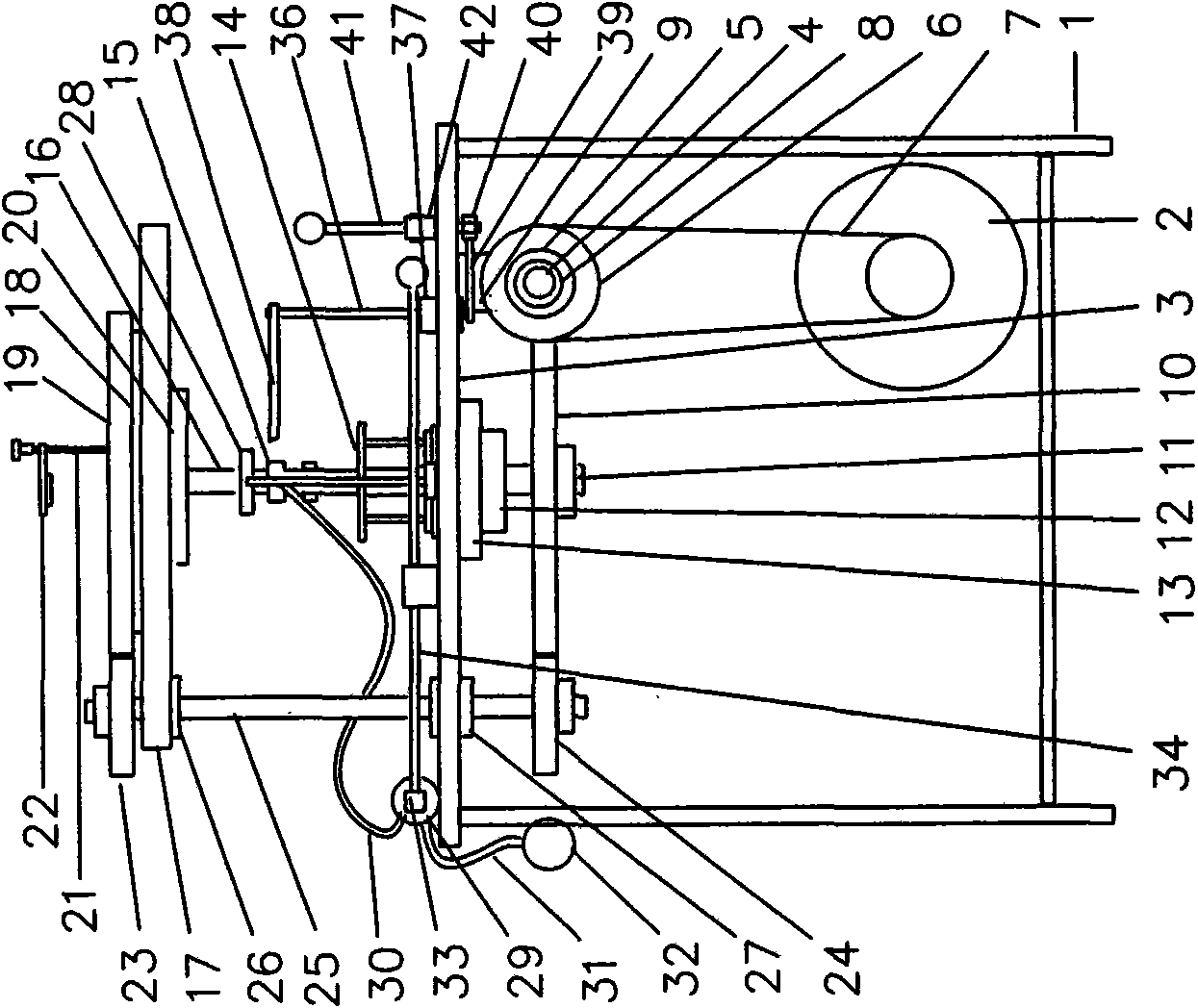

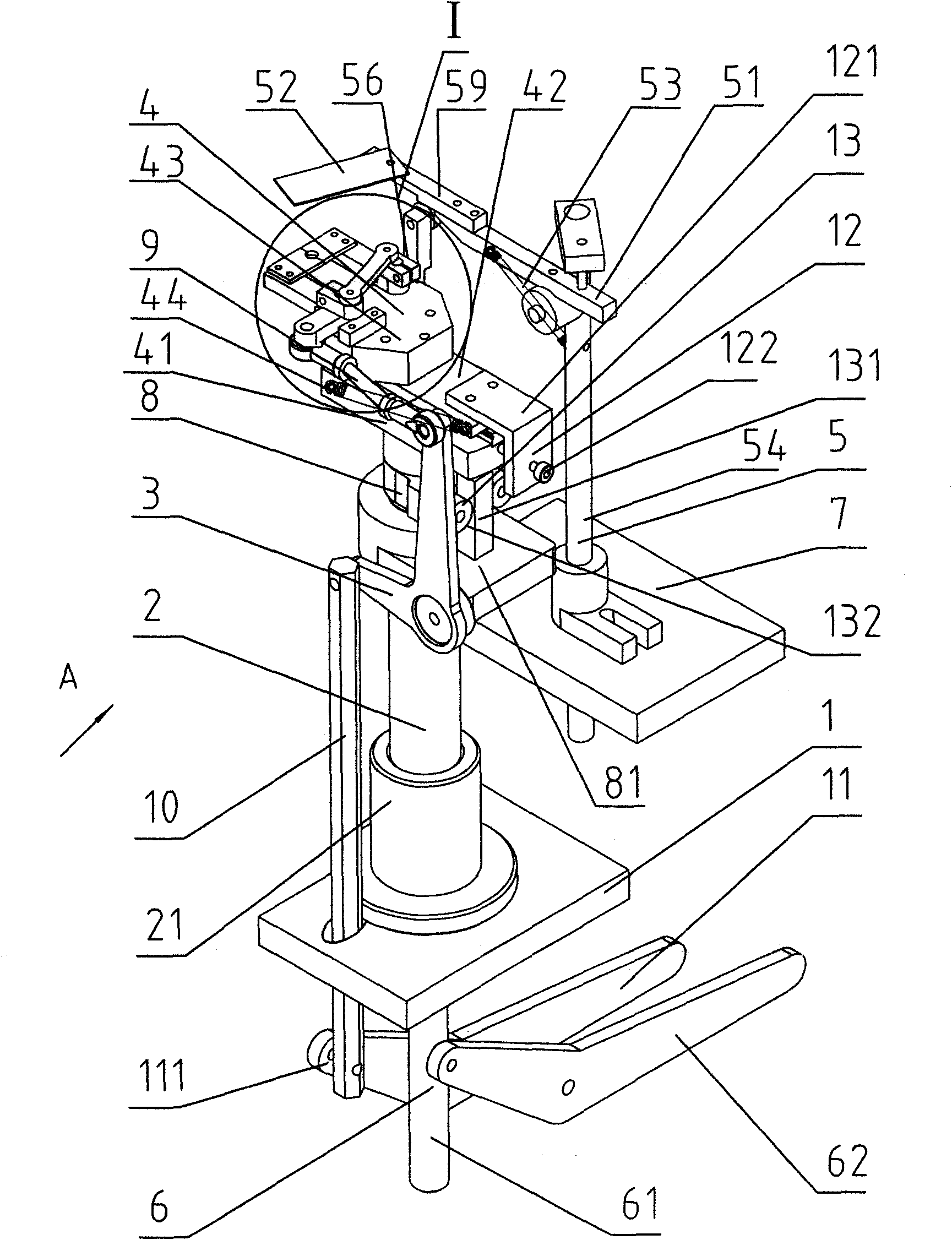

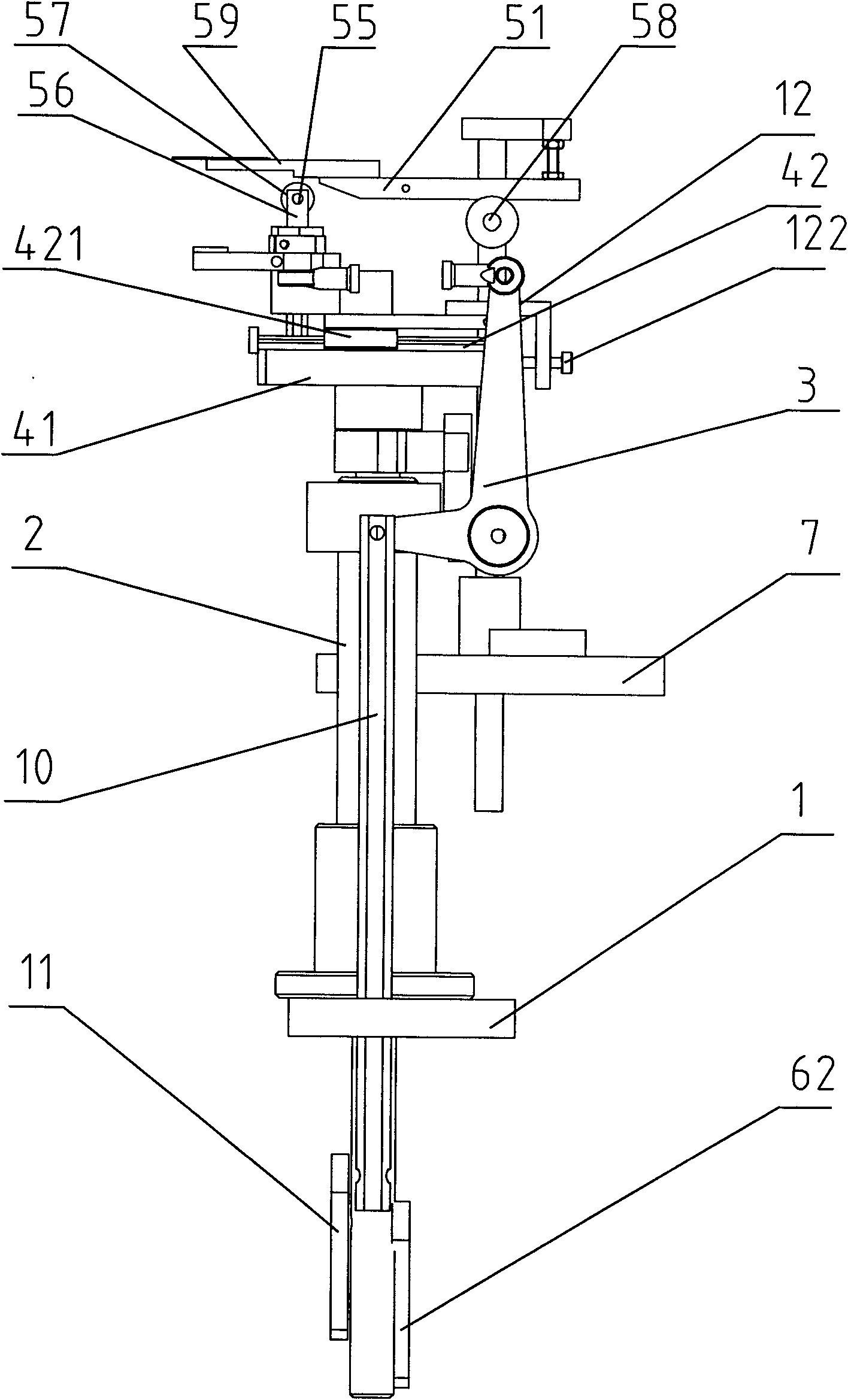

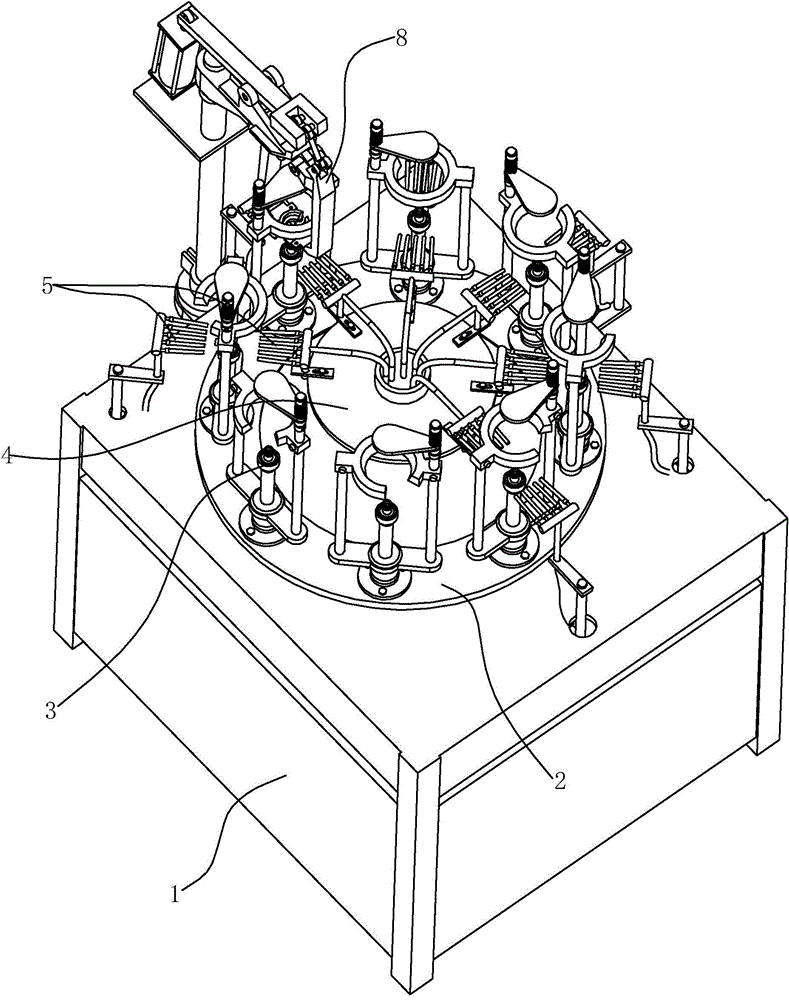

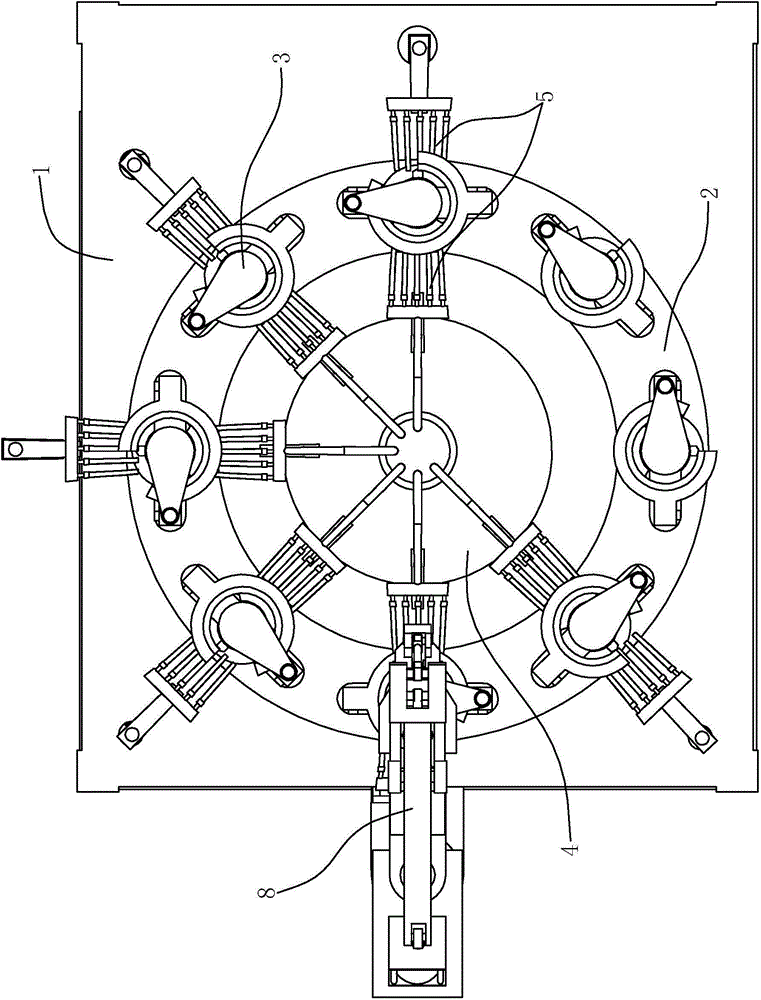

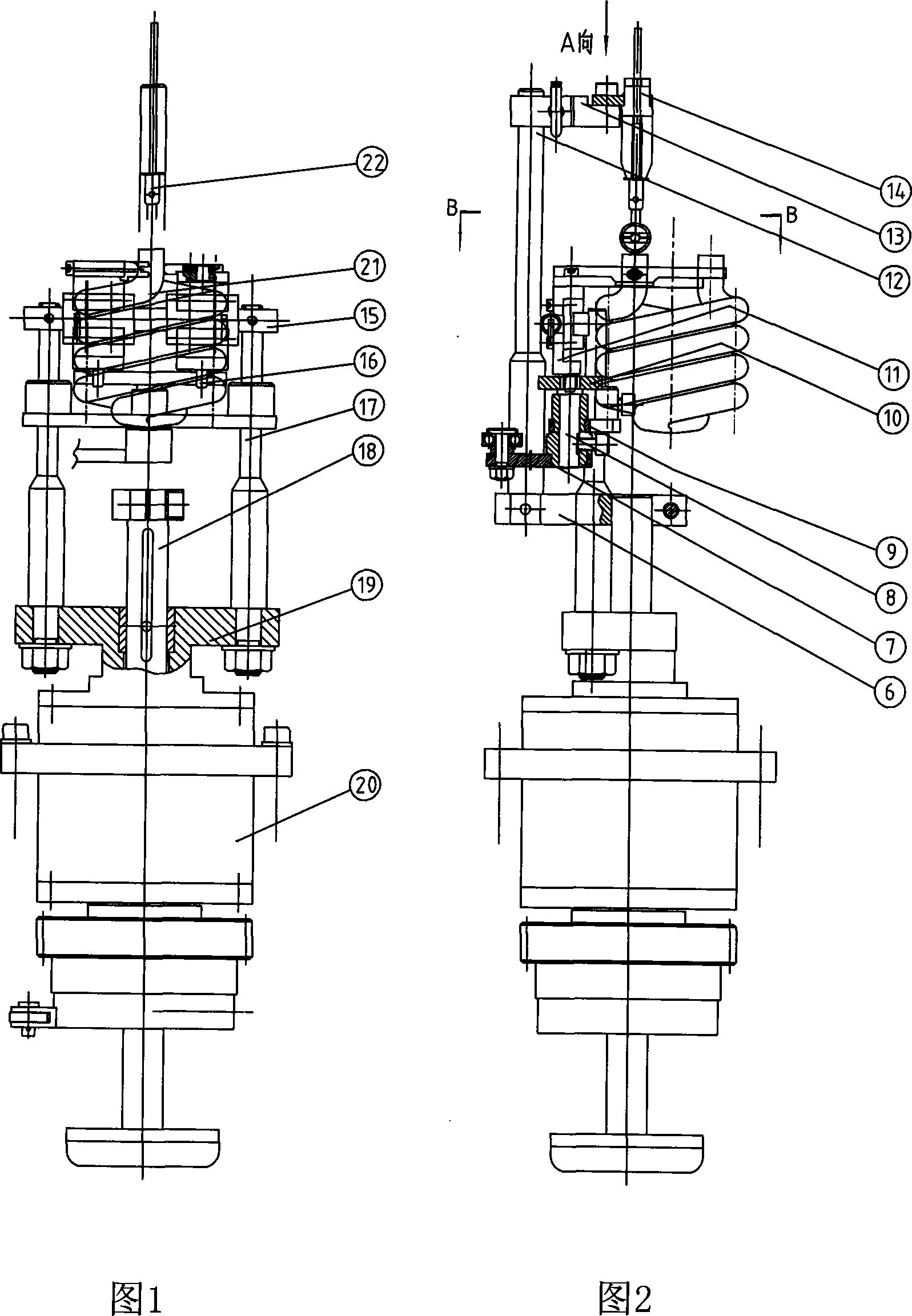

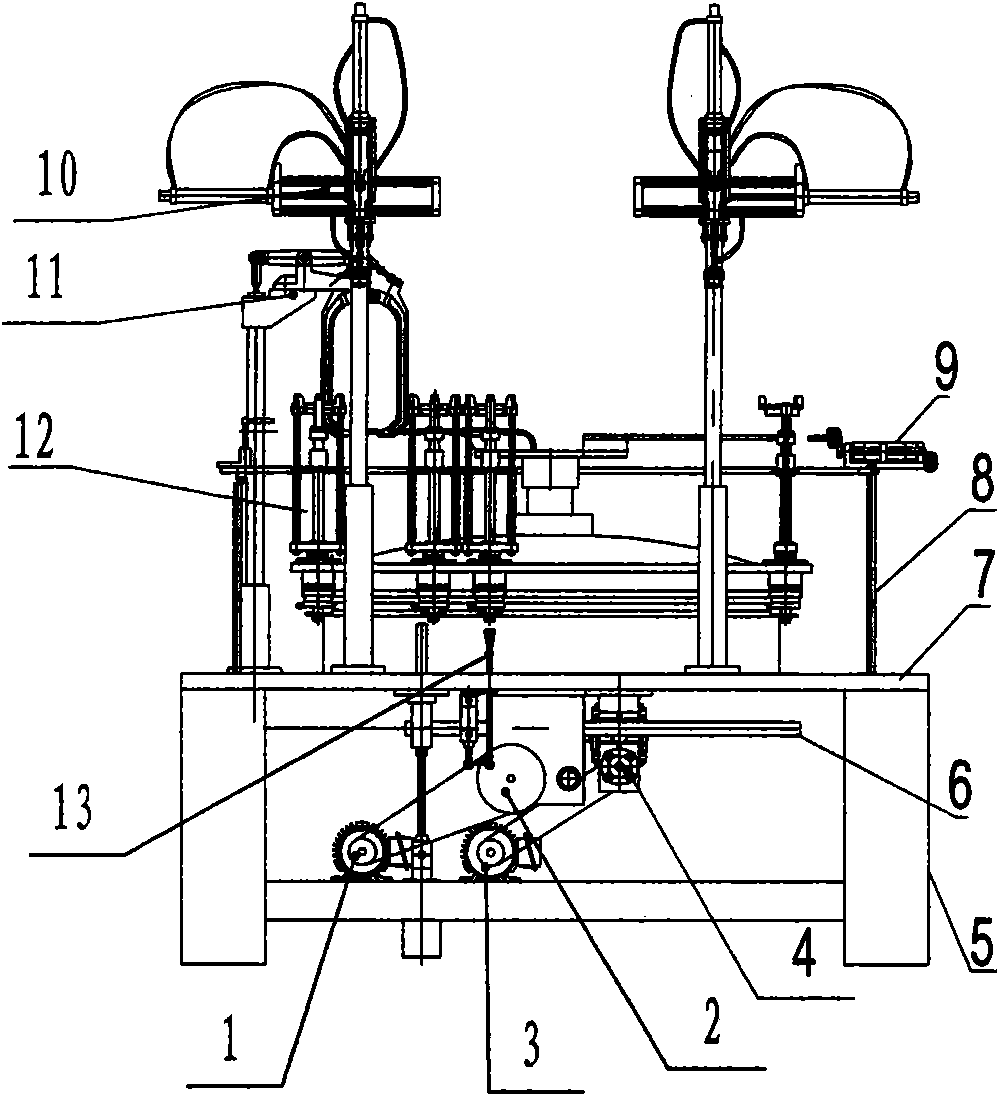

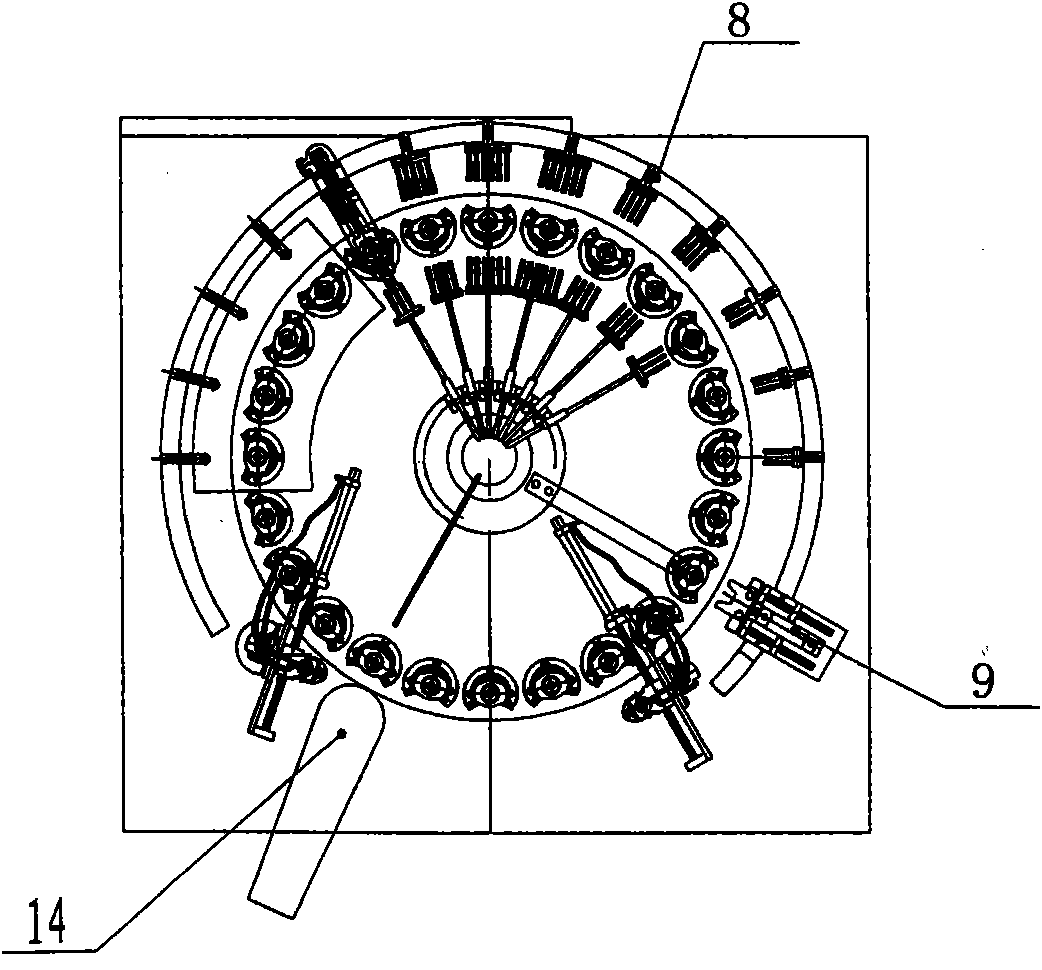

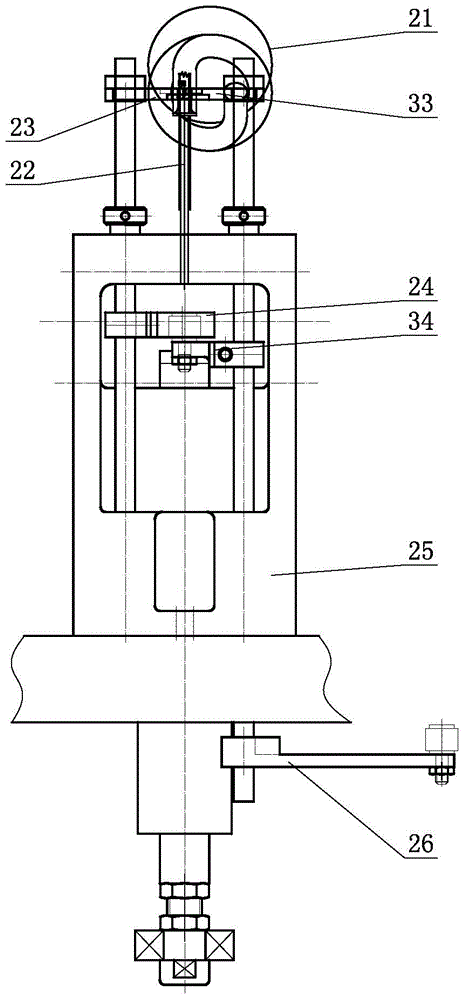

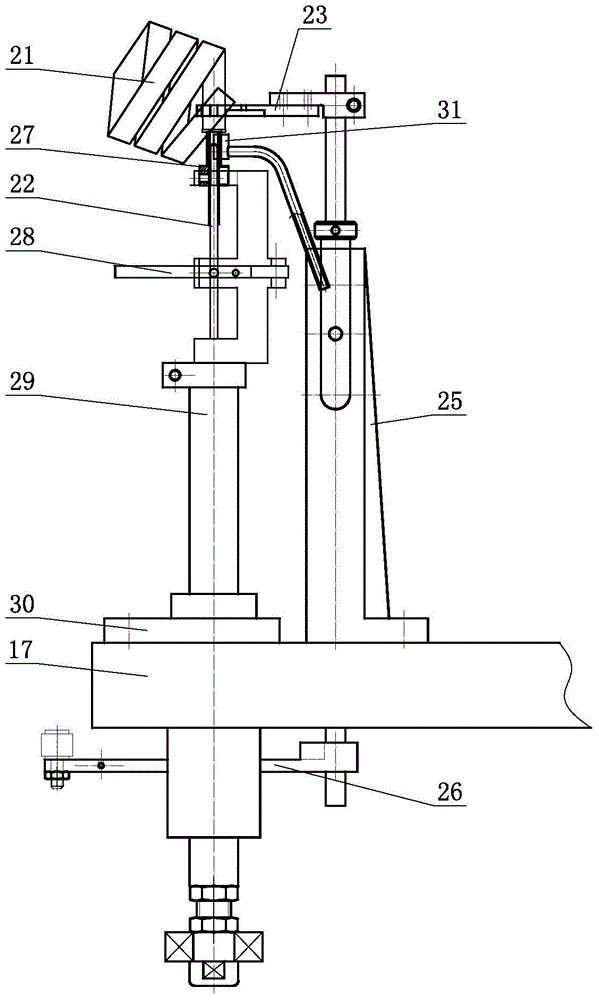

Automatic electrodeless bulb sealing machine

InactiveCN101673650AHigh degree of mechanizationImprove welding qualityTube/lamp vessels closingDrive shaftEngineering

The invention discloses an automatic electrodeless bulb sealing machine which is provided with a motor at the left lower side of a rack; a motor belt pulley is arranged on the motor; a worktable is arranged at the upper side of the rack; a worm-wheel shaft is installed at the front lower side of the worktable; a plurality of groups of active worm wheels are installed on the worm-wheel shaft; a plurality of groups of vertical shafts are arranged at the back side of the worm-wheel shaft; passive helical gears which are meshed with the active worm wheels are arranged at the lower end of the vertical shaft; a material-receiving frame is arranged at the upper end of the vertical shaft; a bulb inner wall bracket is arranged at the upper side of the material-receiving frame; supports are arrangedat two sides of the vertical shaft; the supporting plates provided with inner circular holes are installed on the supports; outer gear rings are installed in the circular holes of the supporting plate; a transmission shaft is arranged at the back side of the worktable; the lower end of the transmission shaft is provided a transmission lower gear and the upper end thereof is provide with a transmission upper gear; the two sides of the vertical shaft are provided with welding guns which are symmetrical; the front right side of the vertical shaft is provided with a plurality of groups of cutterbars, the upper ends of which are provided with cutters and the lower end ends of which are provided with a plurality of groups of rotating arms on which rotating arm linking rods are installed; and the left ends of the linking rods are provided with operating rods.

Owner:张誉耀

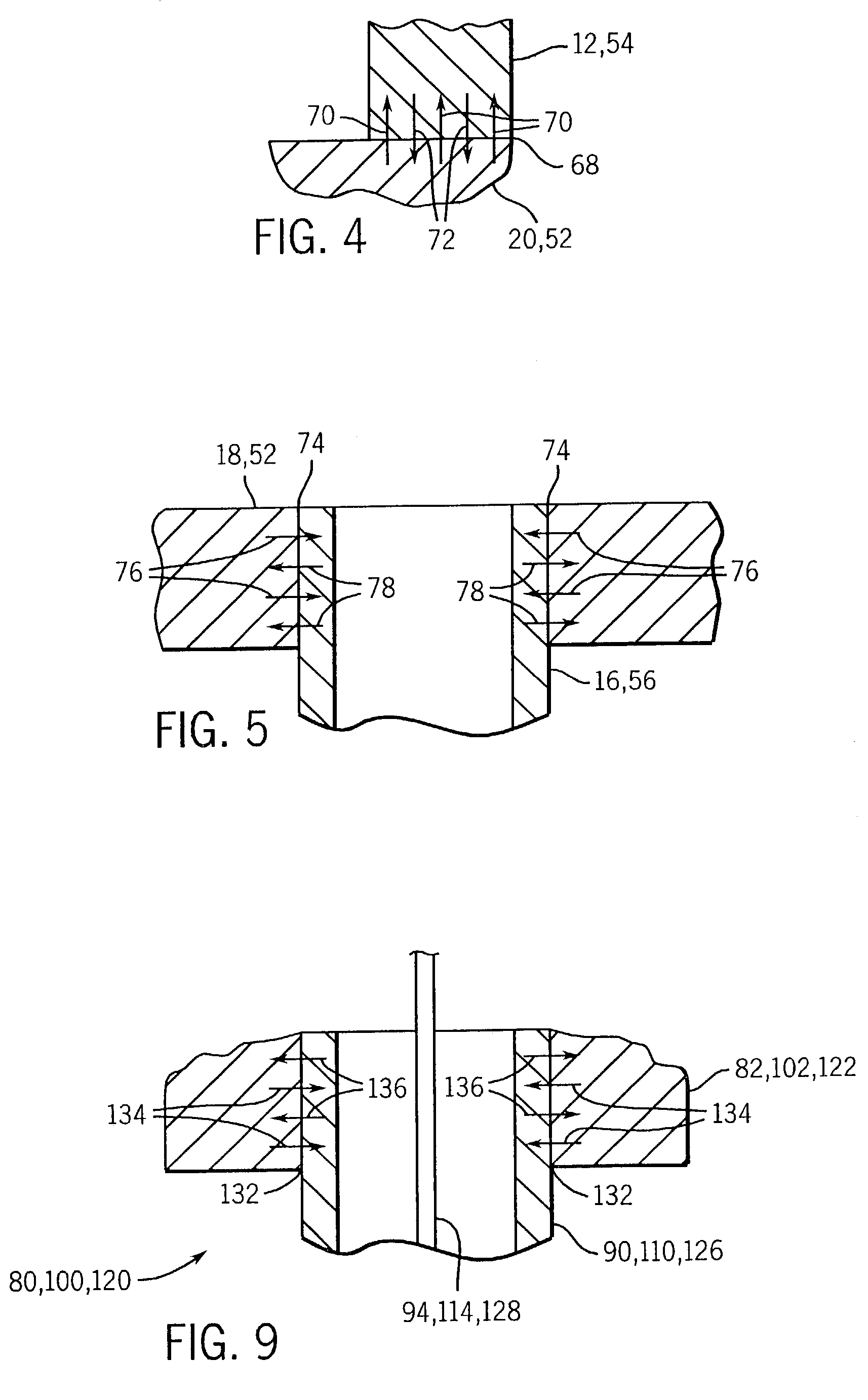

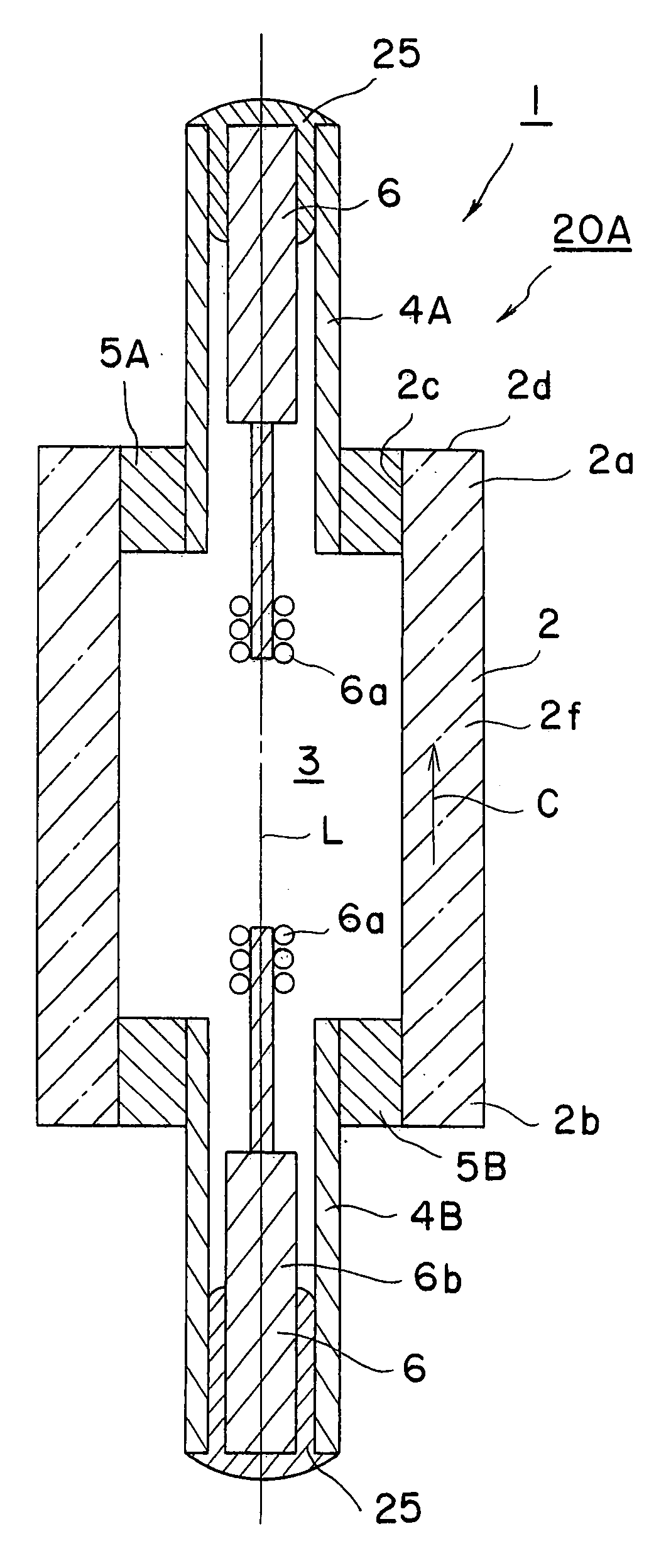

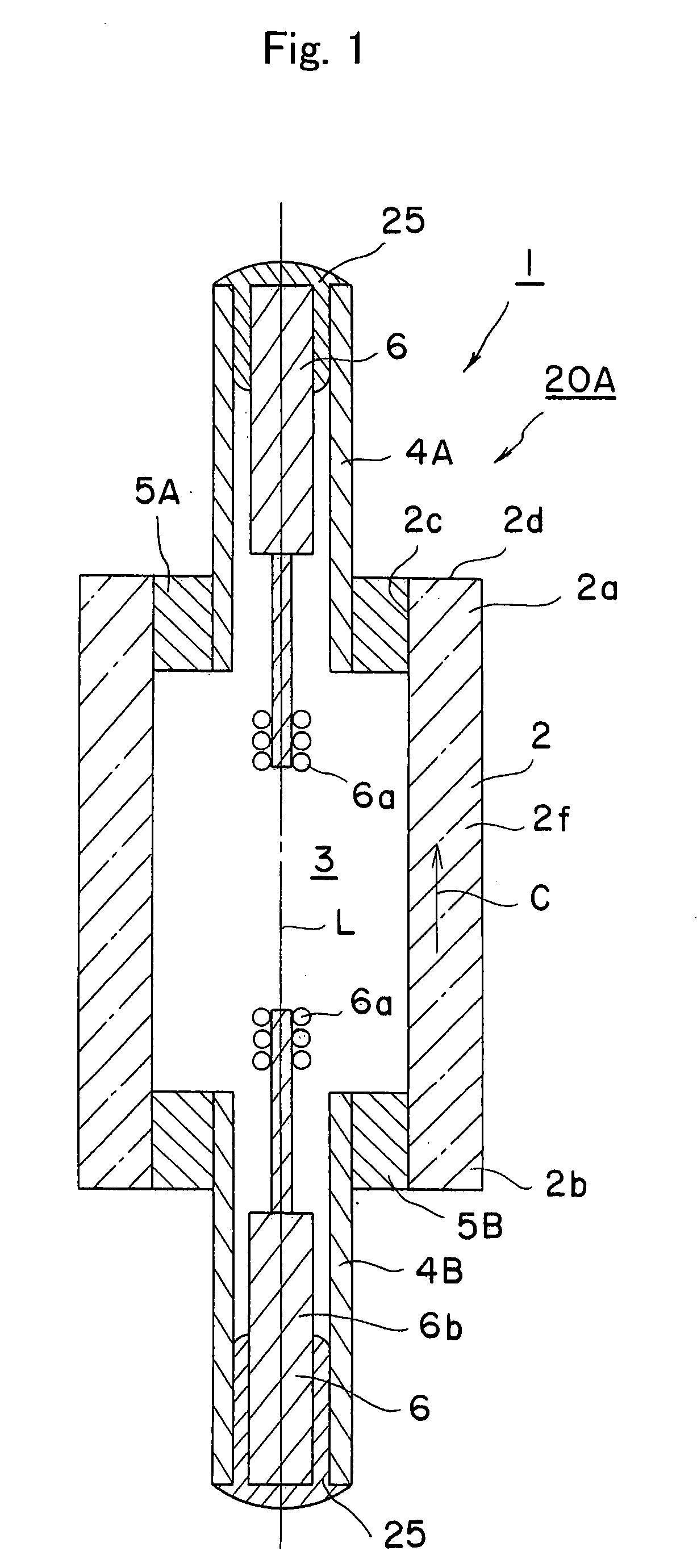

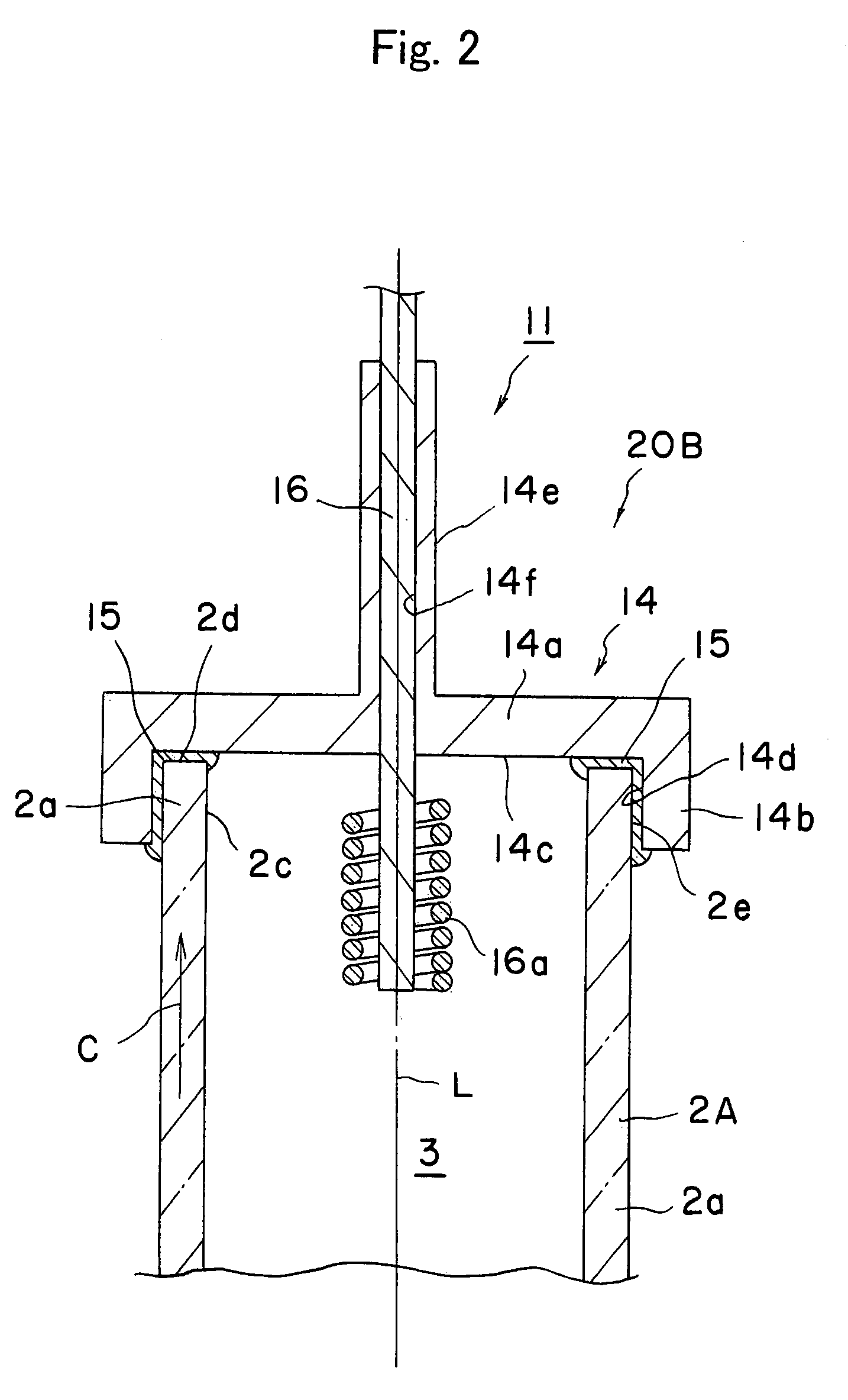

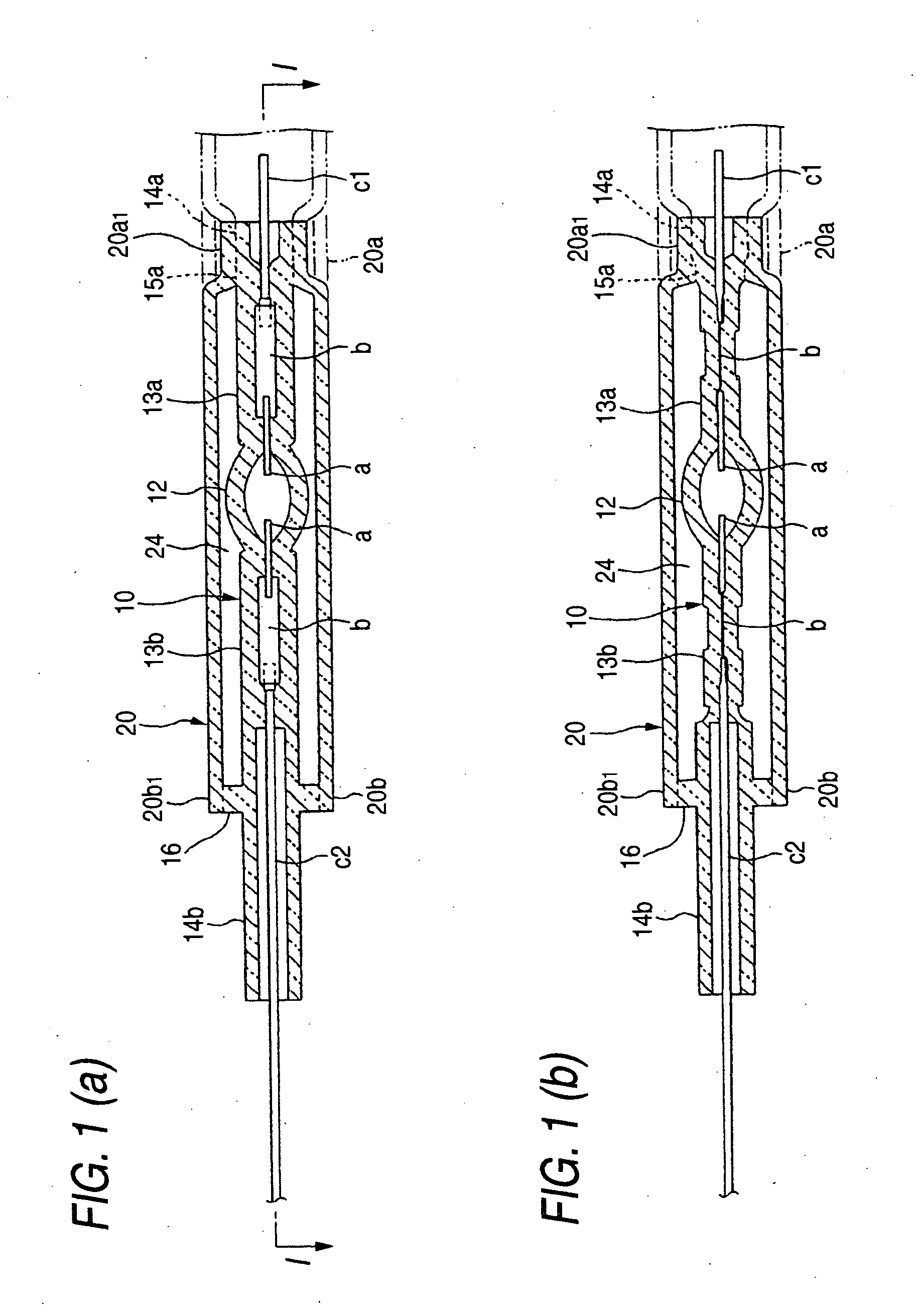

Method of fixing space defining members in an envelope of an electron beam apparatus

InactiveUS7063585B2Improve assembly accuracyAvoid displacementBoxes/cartons making machineryCathode-ray/electron-beam tube vessels/containersLinearityMechanical engineering

Each of spacers which defines an interval between substrates composing an envelope is fixed to the substrates while their linearity is kept by the tension exerted therein. In the fixation, it is set such that a fixing point of each of the spacers is located between points on which the tension is exerted. Thus, even when the tension is released, the linearity is maintained, so that a displacement of each of the spacers can be prevented to kept a high assembly accuracy.

Owner:CANON KK

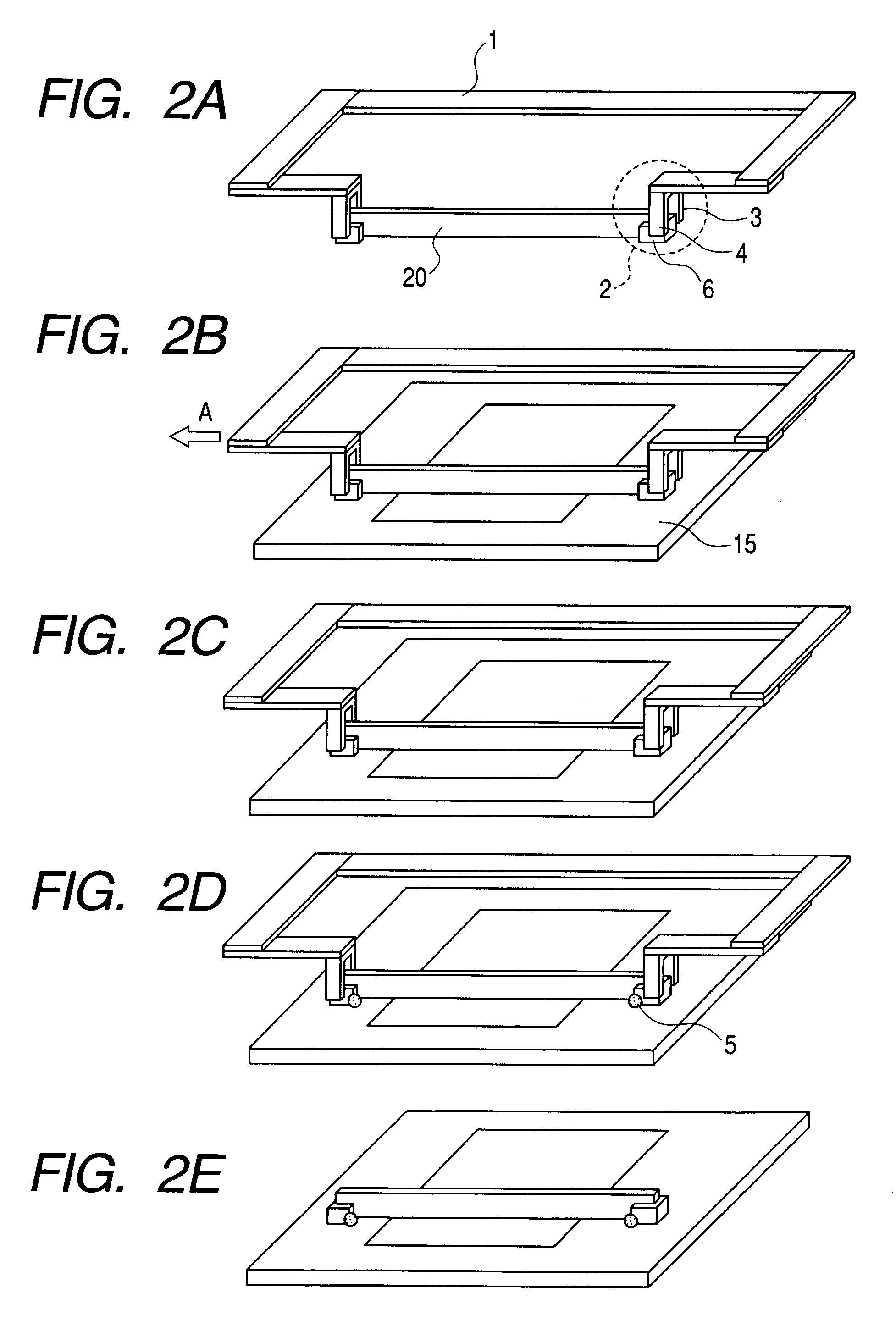

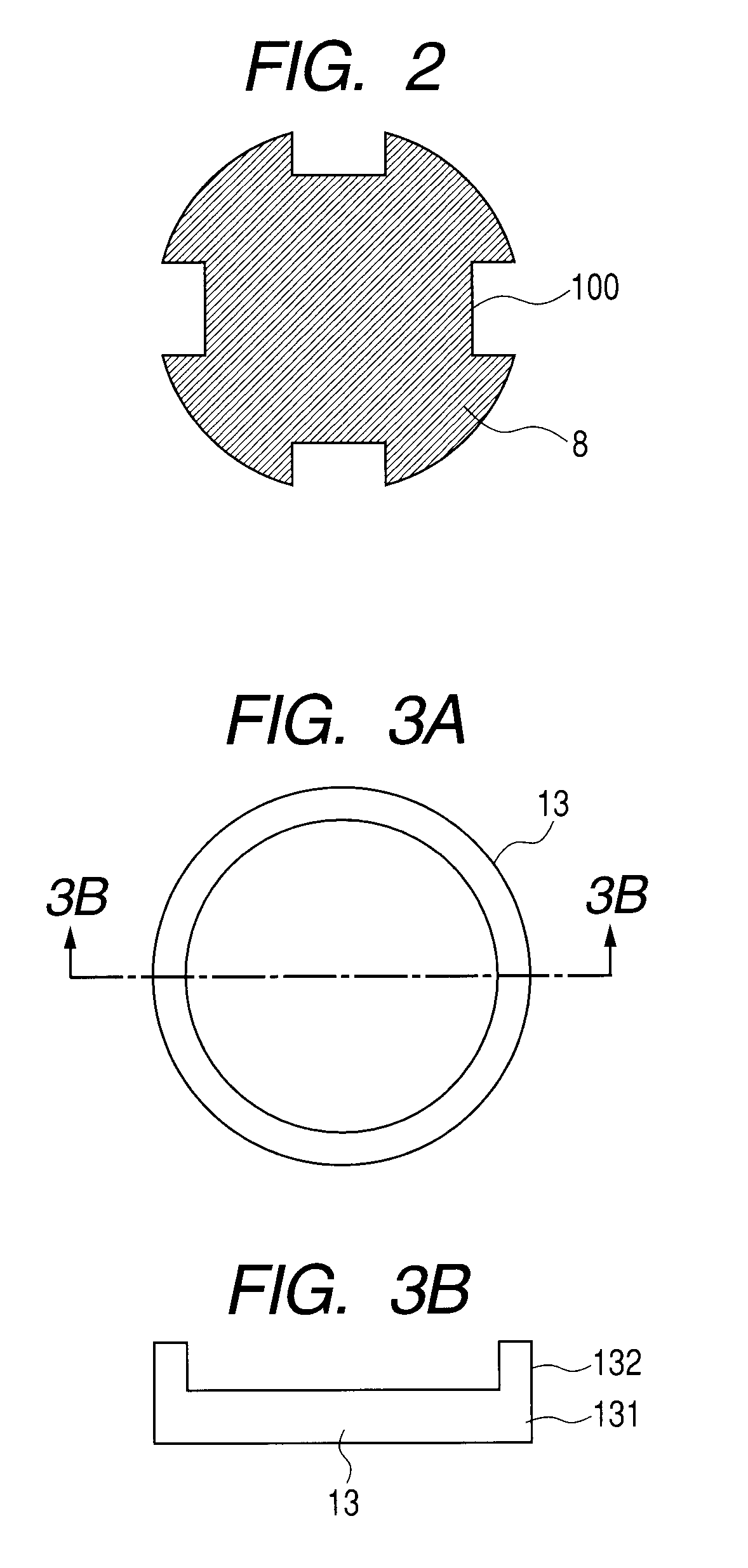

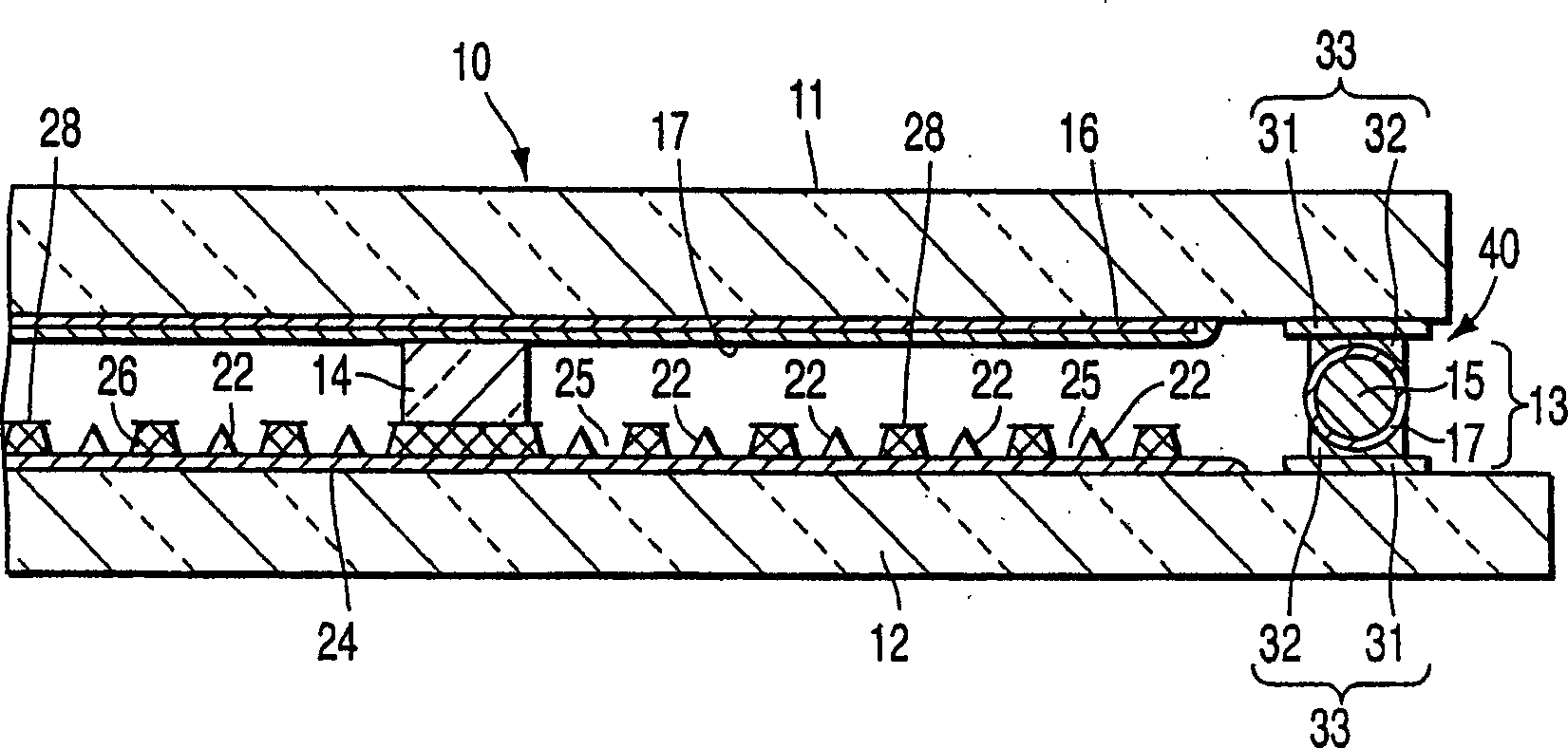

Airtight container and manufacturing method of image displaying apparatus using airtight container

InactiveUS7914357B2Secure sealing performanceAvoid flowVessels or leading-in conductors manufacturePhoto-emissive cathodes manufactureConductive materialsEngineering

A manufacturing method of an image displaying apparatus, having an airtight container with a vacuum interior, includes the steps of exhausting an inside of a container via a through-hole provided in the container, arranging a plate member on an outer surface of the container, the inside of which was exhausted, so as to close the through-hole, and sealing the container by arranging a cover member to cover the plate member and by bonding the arranged cover member and the outer surface of the container to each other via a sealant positioned between the cover member and the outer surface of the container. The sealing includes hardening the sealant after deforming the sealant by pressing the plate member, and the plate member has a terminal portion including a conductive material. Additional steps include providing an anode electrode in the airtight container, and performing the sealing in a state that the terminal portion is in contact with the anode electrode.

Owner:CANON KK

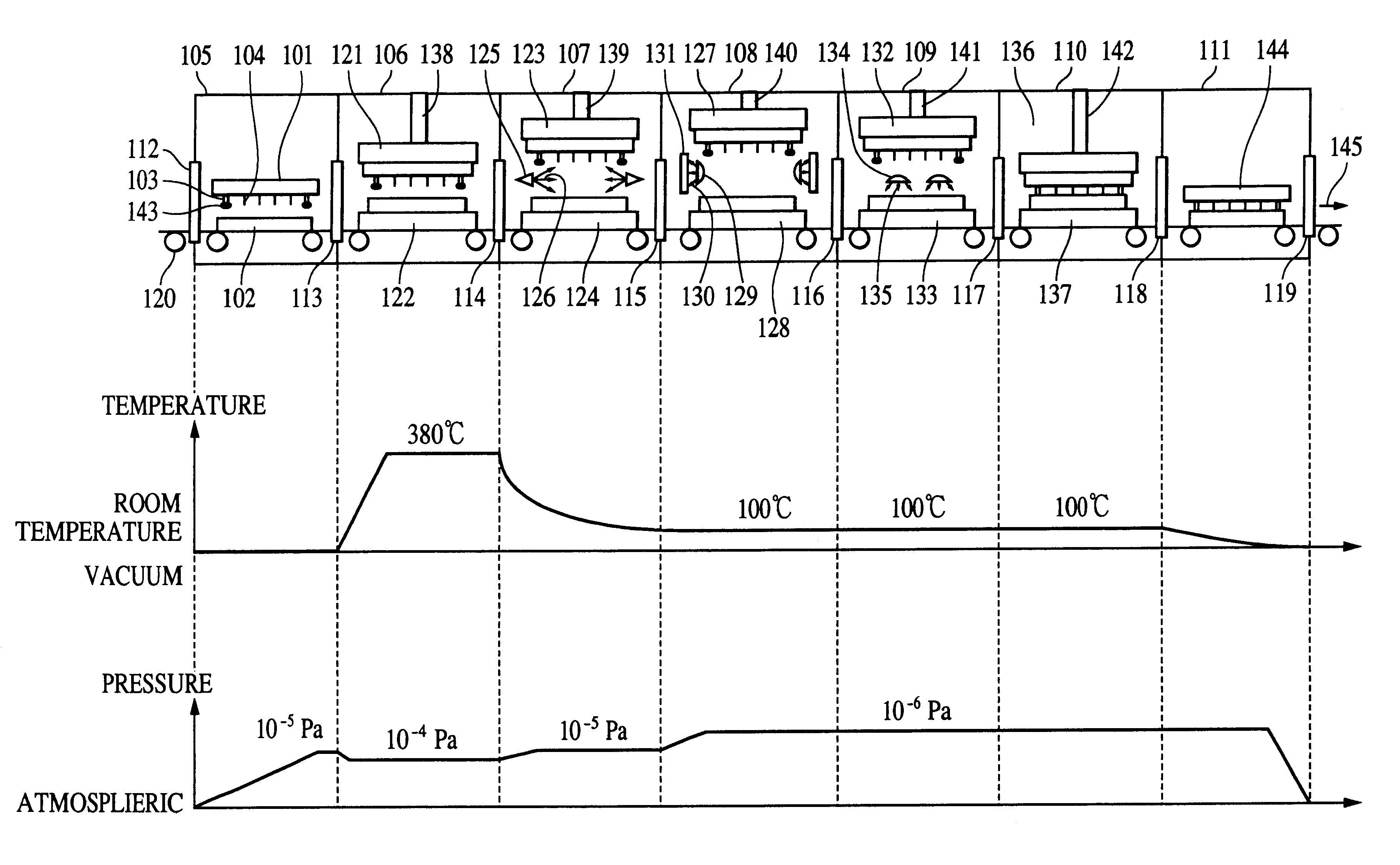

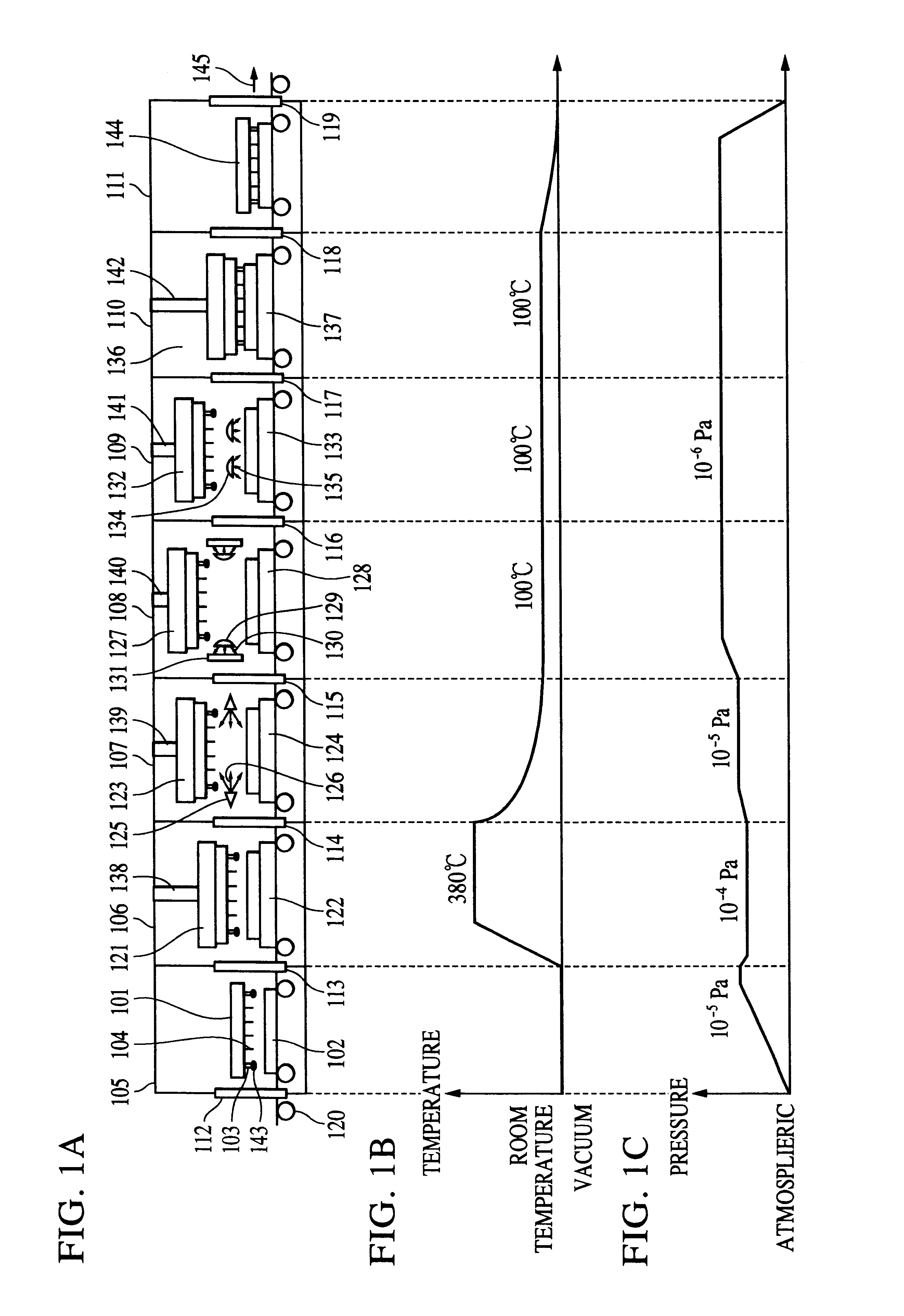

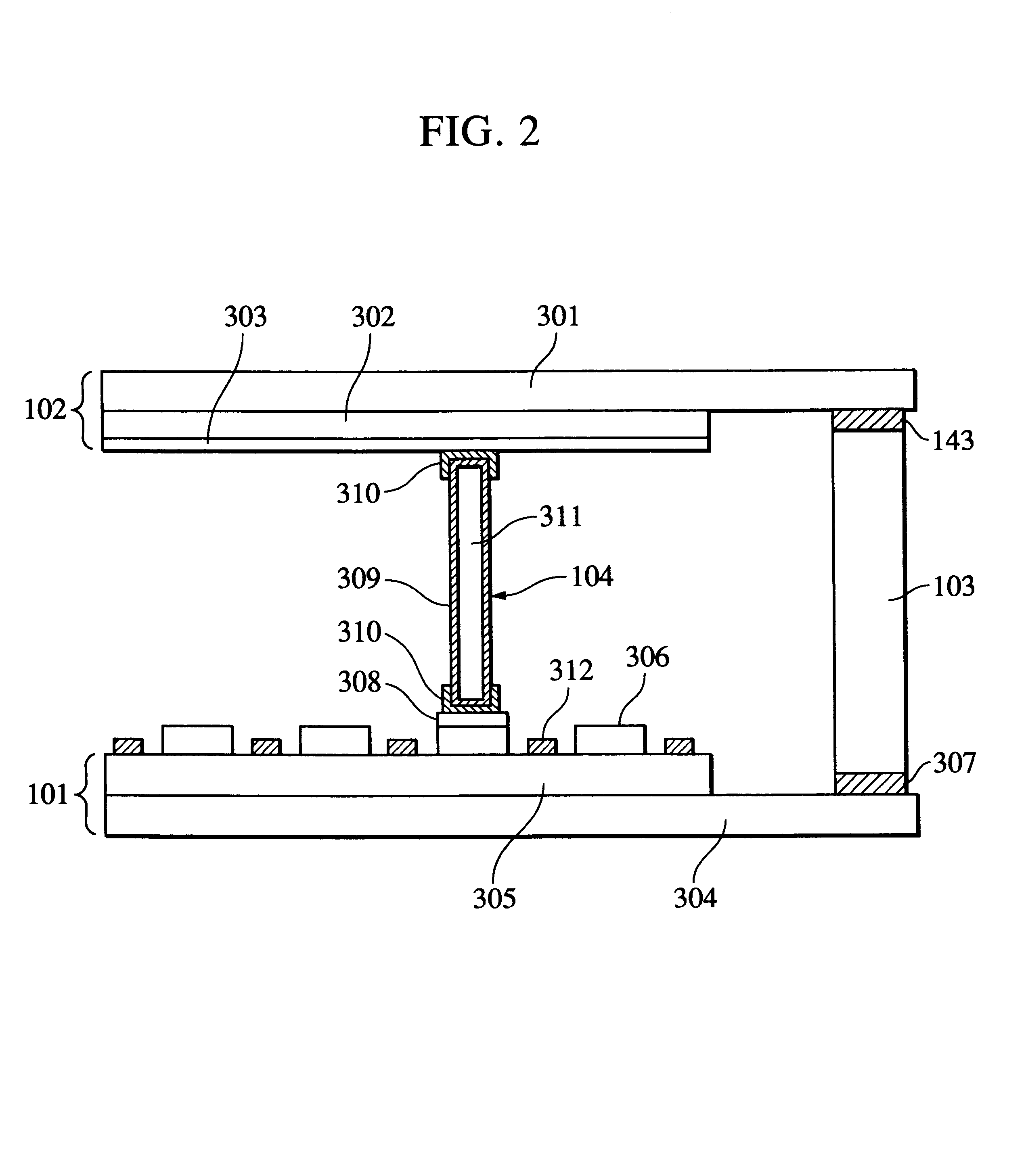

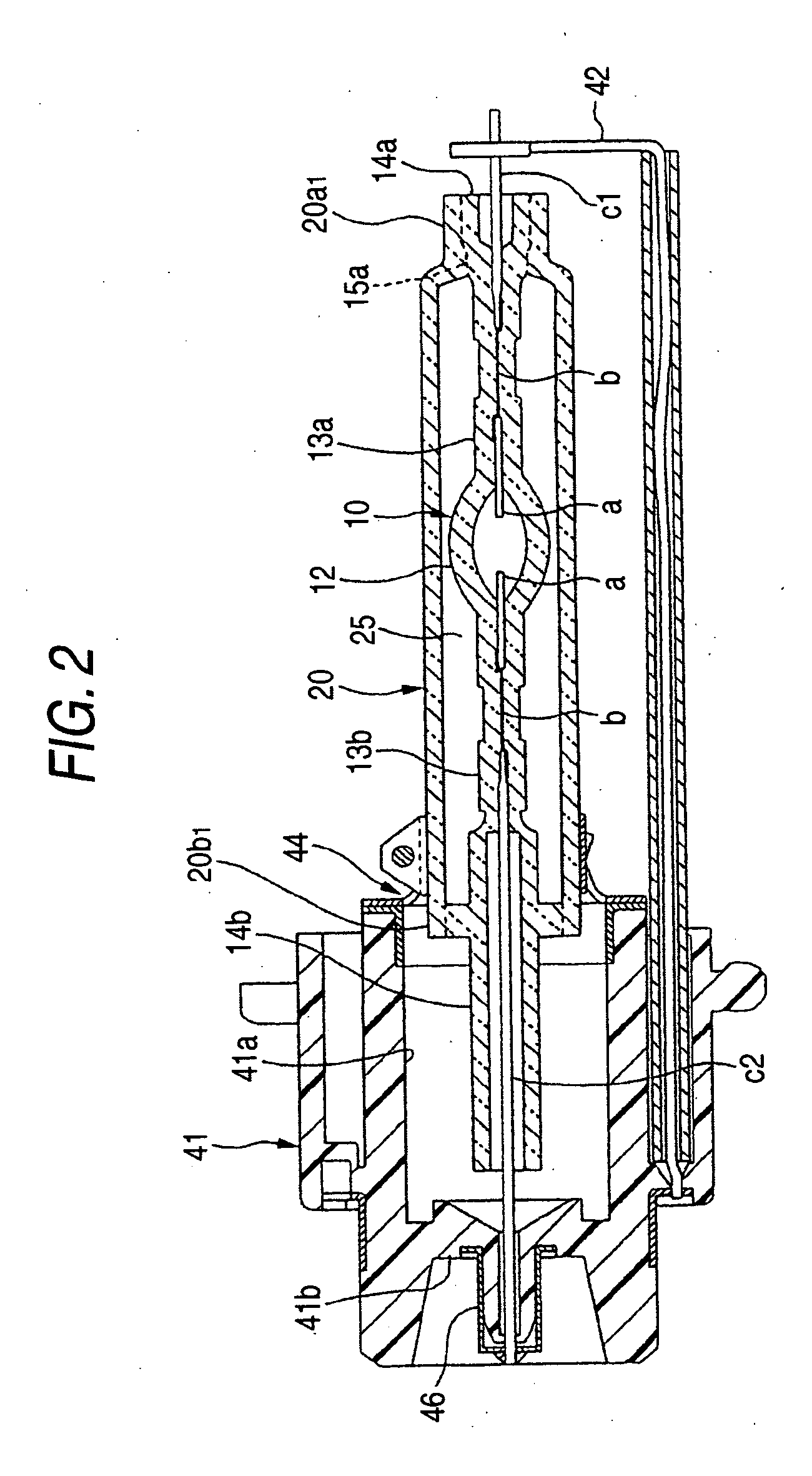

Method and apparatus for manufacturing image display device

InactiveUS6702636B2Glass furnace apparatusTube/lamp vessel degassingTemperature controlDisplay device

The present invention provides a method of manufacturing an image display device in which a panel member constituting a panel of an image display device is transferred to a plurality of processing chambers each having a temperature control unit, and subjected to a plurality of processing steps under temperature control. The temperature of the panel member in each of the processing chambers is set to be not more than the set temperature of the panel member in the previous processing chamber by the temperature control unit.

Owner:CANON KK

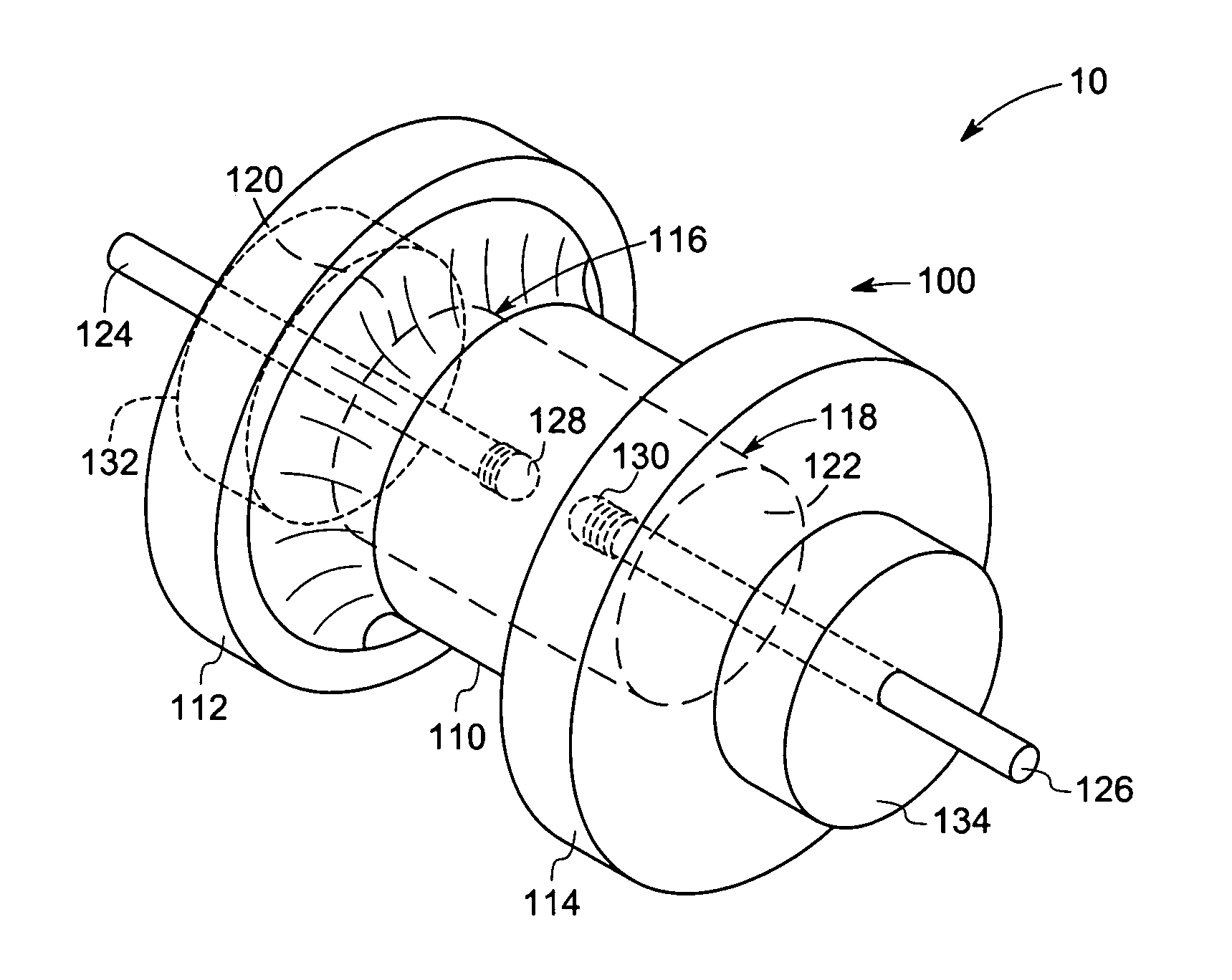

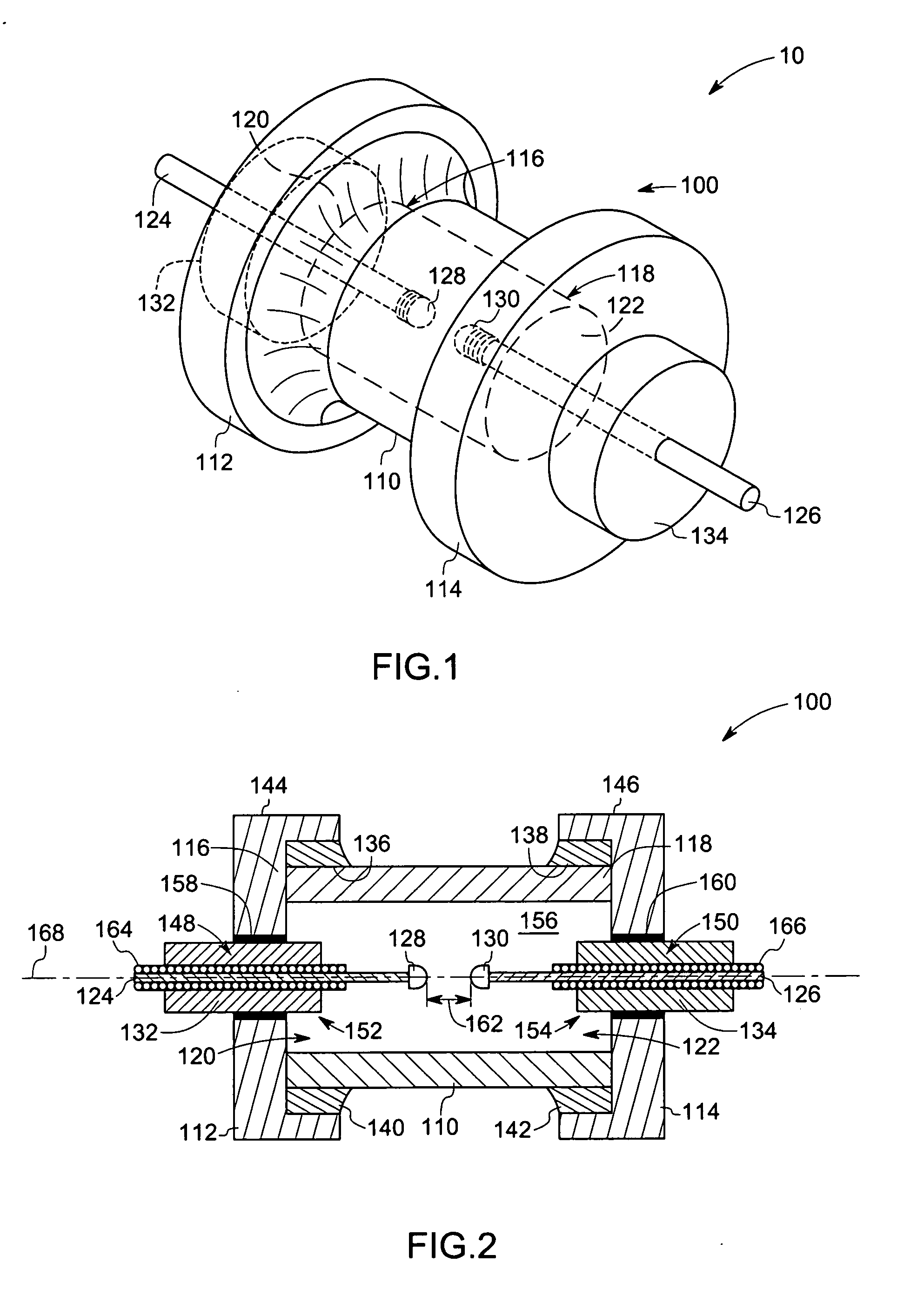

Ceramic lamp having molybdenum-rhenium end cap and systems and methods therewith

InactiveUS20070001610A1Improve performanceElectroluminescent light sourcesTube/lamp vessel fillingRheniumBiomedical engineering

A lamp comprising an arc envelope and a molybdenum-rhenium end structure coupled to the arc envelope.

Owner:GENERAL ELECTRIC CO

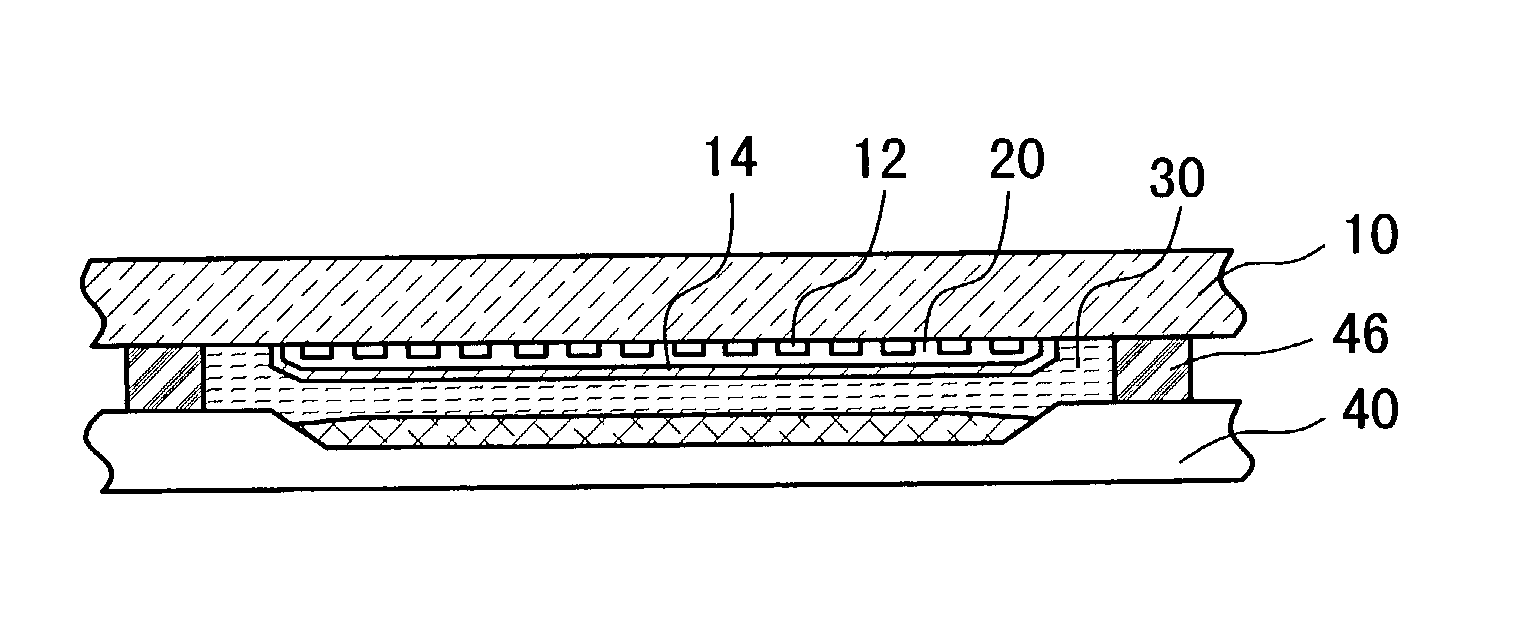

Organic light-emitting display device and method of manufacturing the same

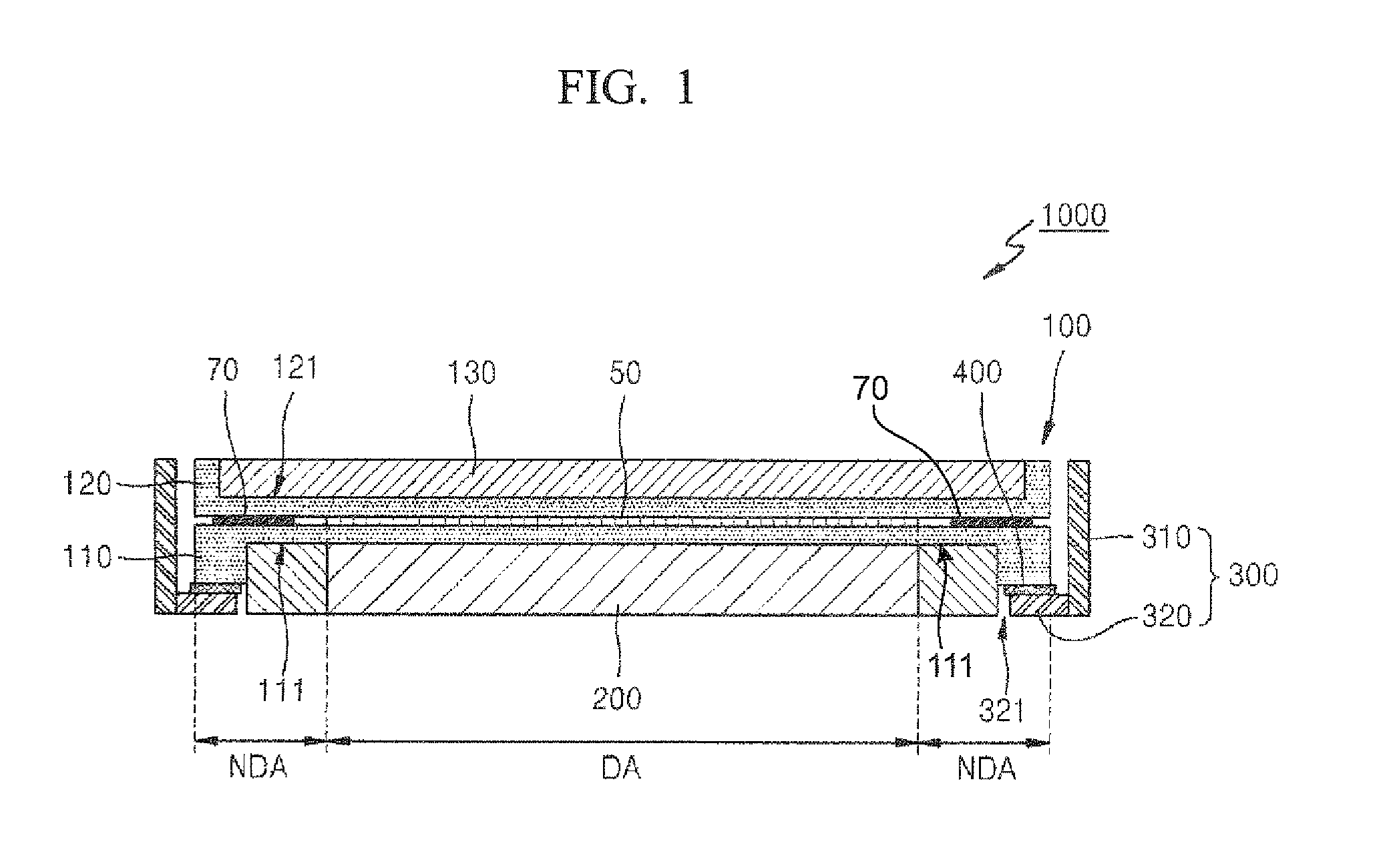

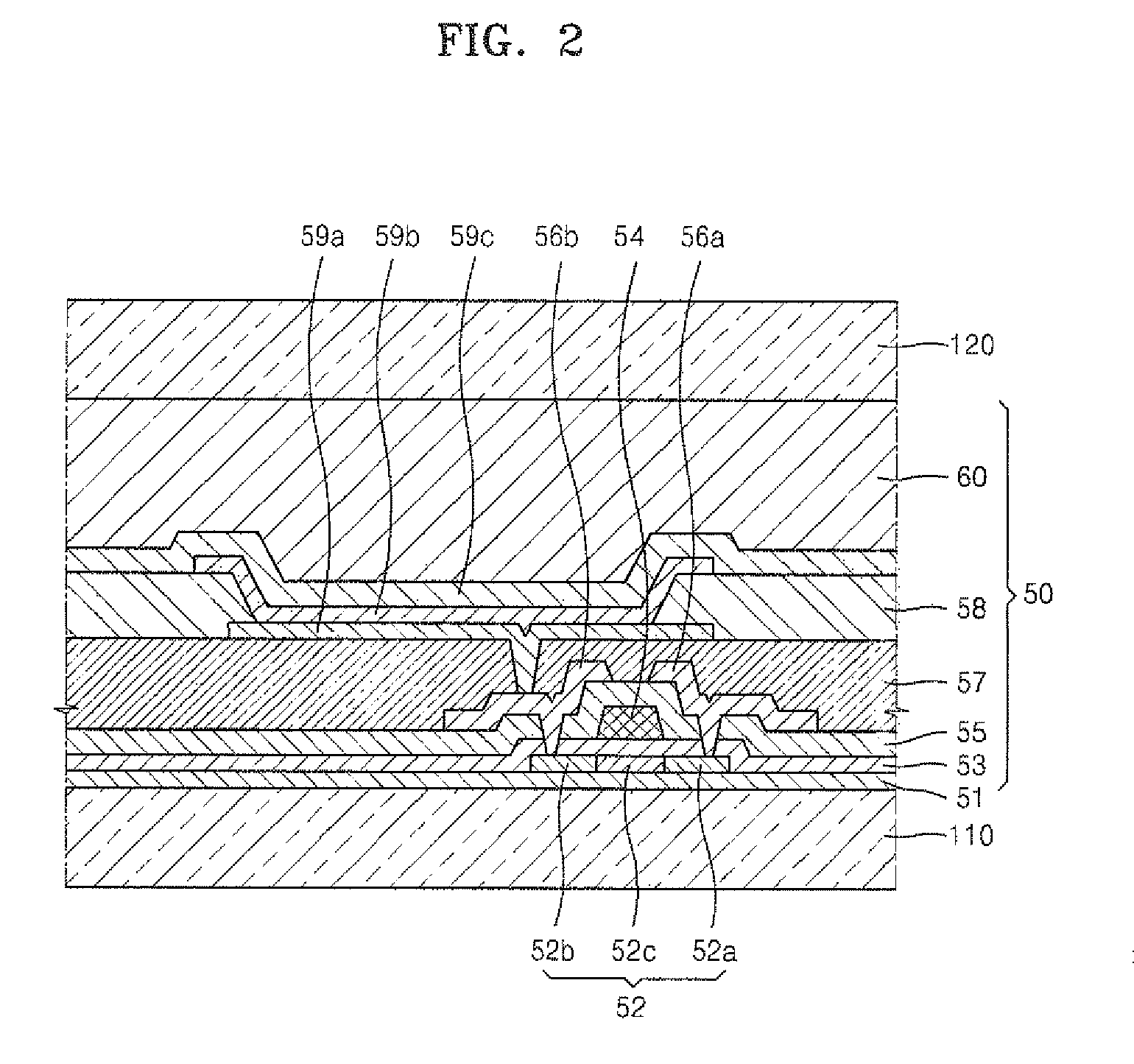

InactiveUS8466613B2High mechanical strengthDischarge tube luminescnet screensDigital data processing detailsDisplay deviceEngineering

In an organic light-emitting display device which is thin and has excellent mechanical strength and a method of manufacturing the organic light-emitting display device, the organic light-emitting display device comprises: a panel including a first substrate and a second substrate coupled to each other by a sealing resin interposed between an internal surface of the first substrate and an internal surface of the second substrate, wherein a first concave portion is formed in an outer surface of the first substrate, and a second concave portion is formed in an outer surface of the second substrate; and a buffer cushion disposed in the first concave portion, wherein the density of an edge portion of the buffer cushion is greater than the density of a center portion of the buffer cushion.

Owner:SAMSUNG DISPLAY CO LTD

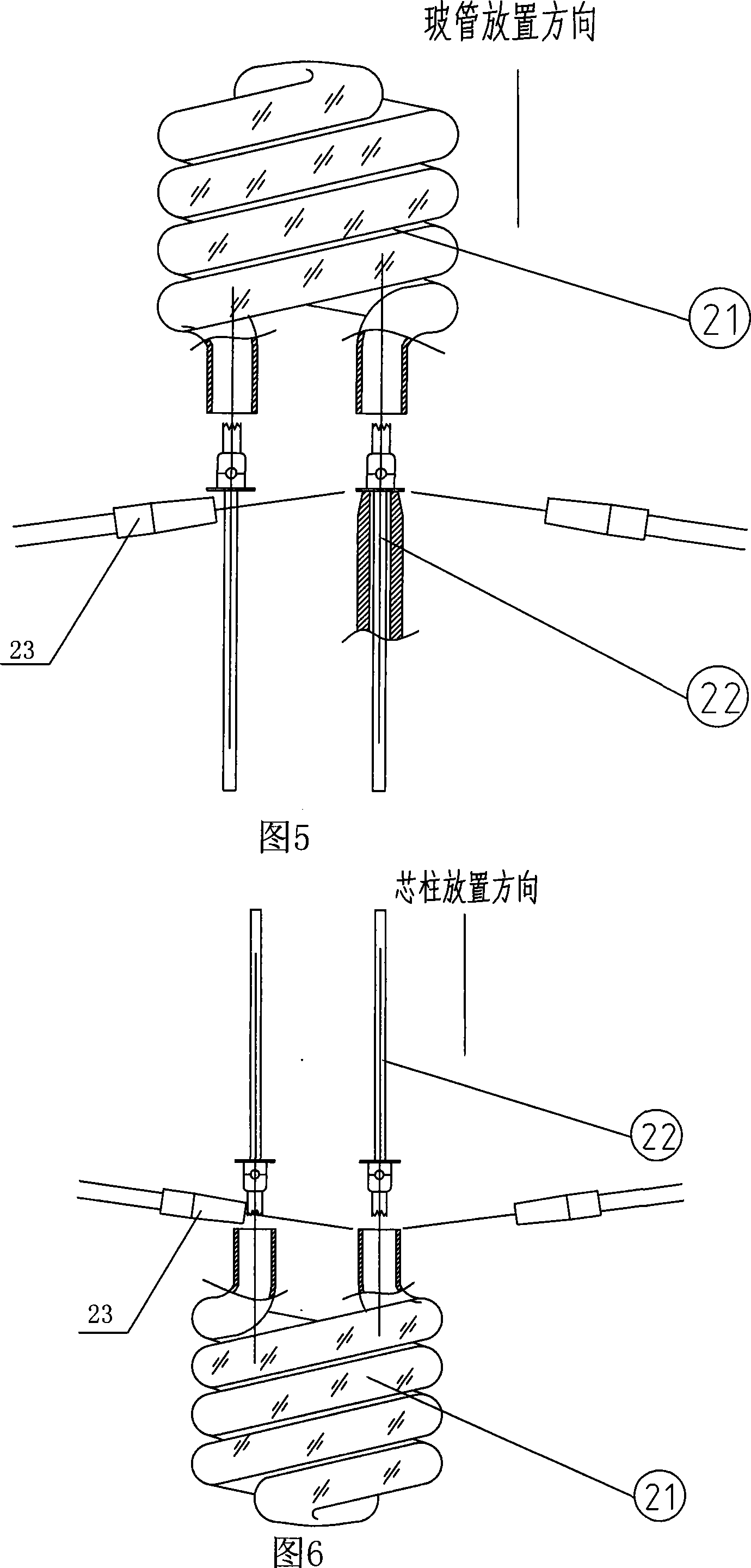

Automatic sealing device of spiral tubes

InactiveCN101645380AImprove seal qualityReduce labor intensityTube/lamp vessels closingEngineeringMechanical engineering

Owner:外商独资镇江金品机械有限公司

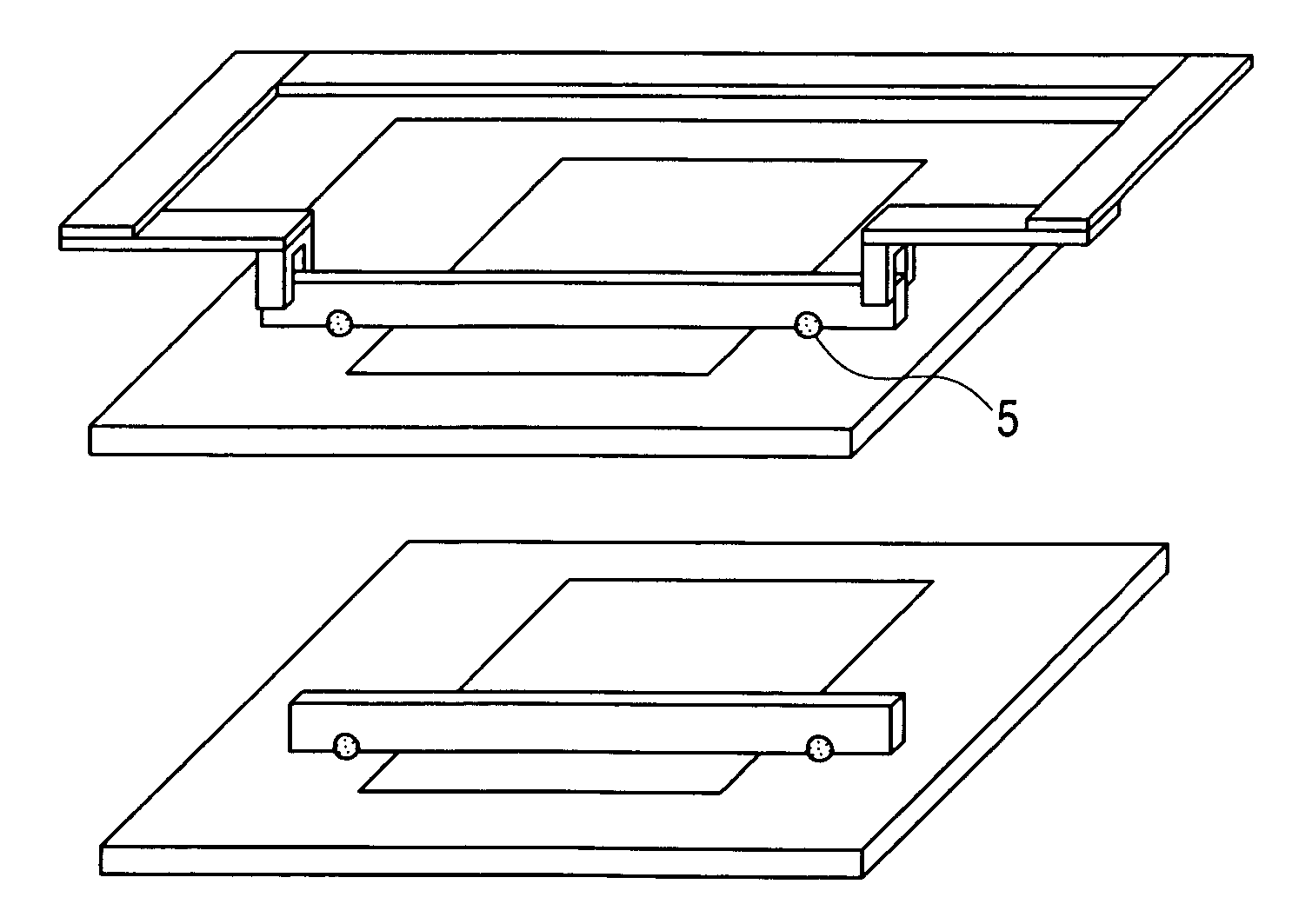

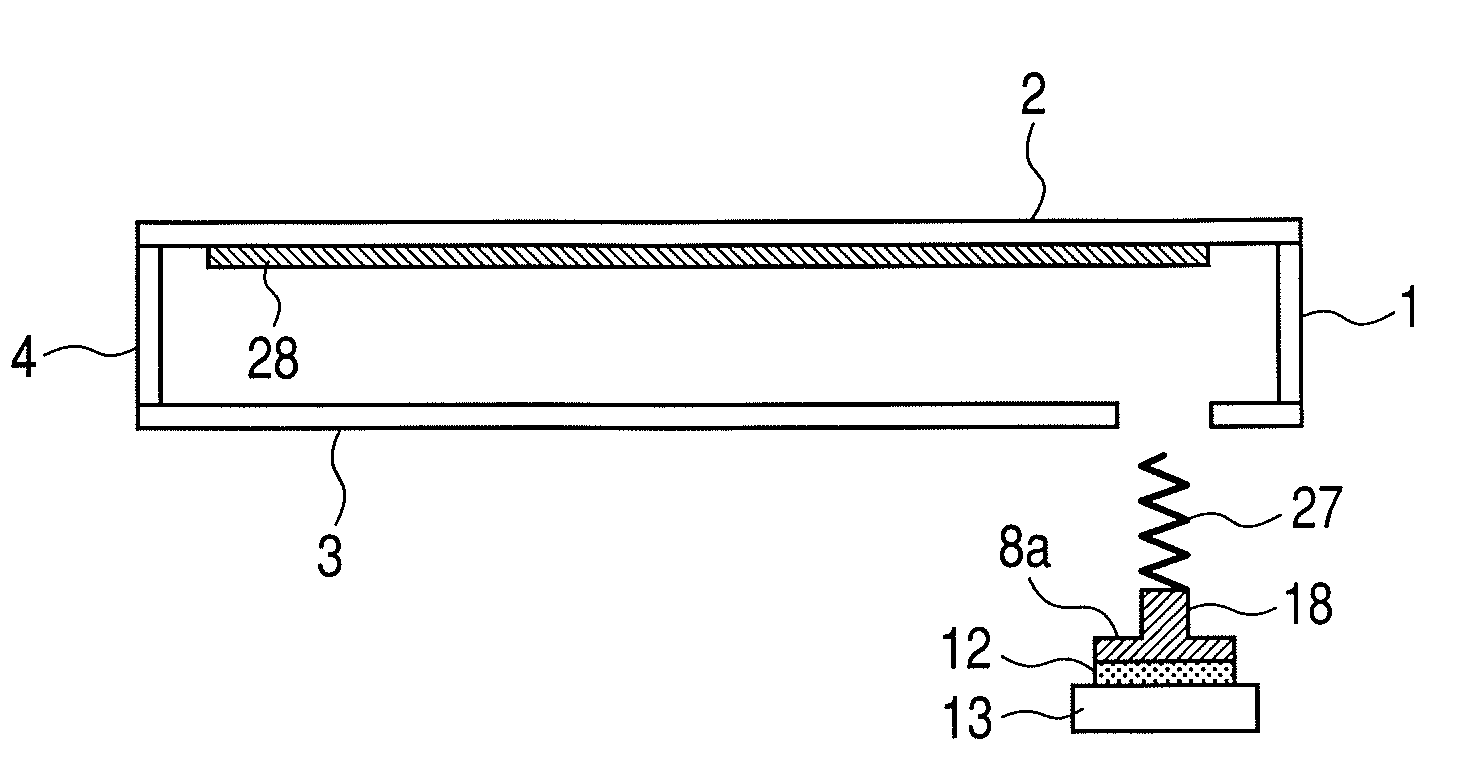

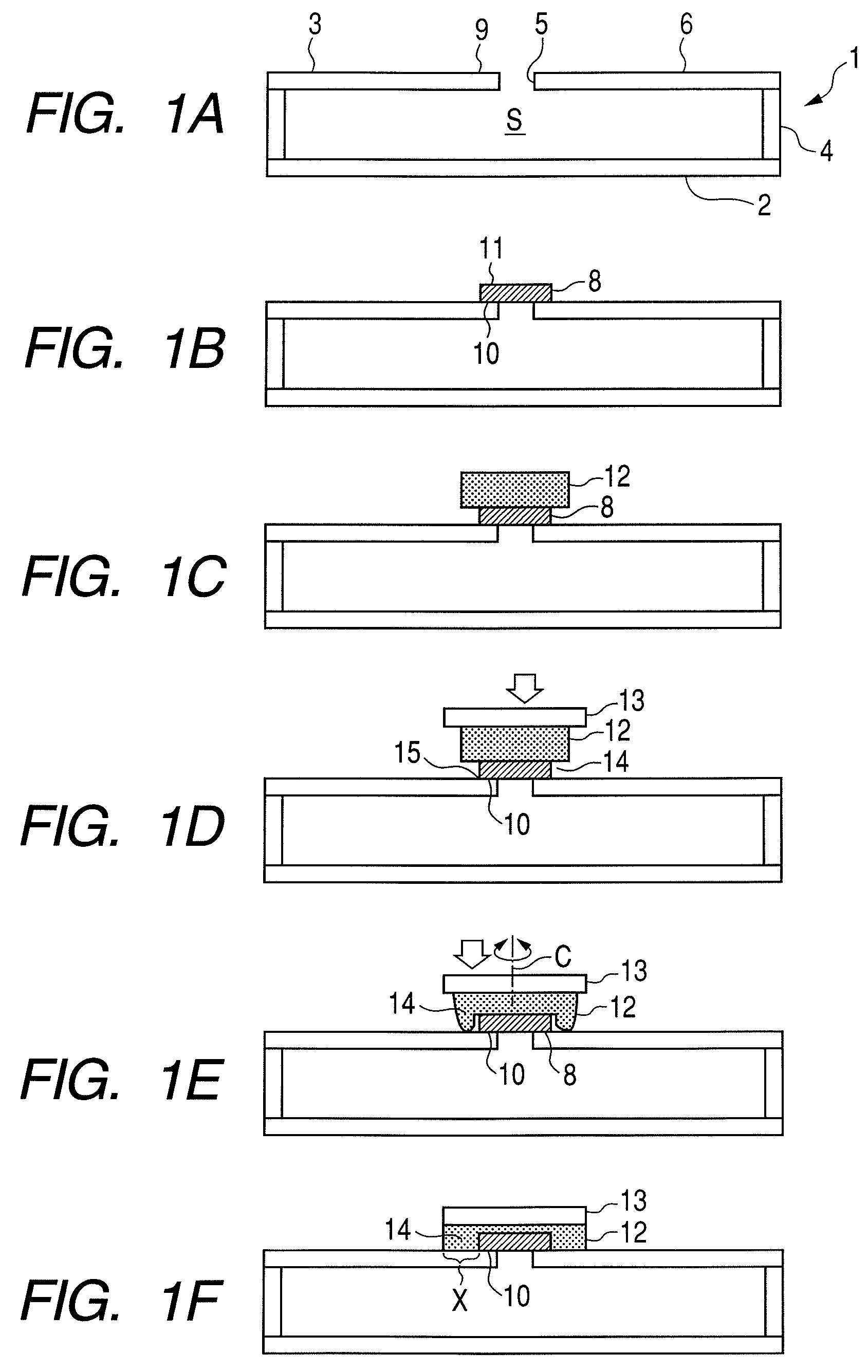

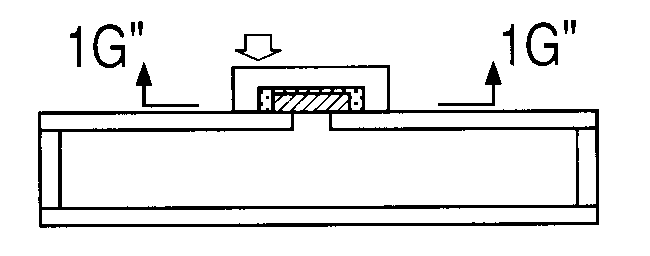

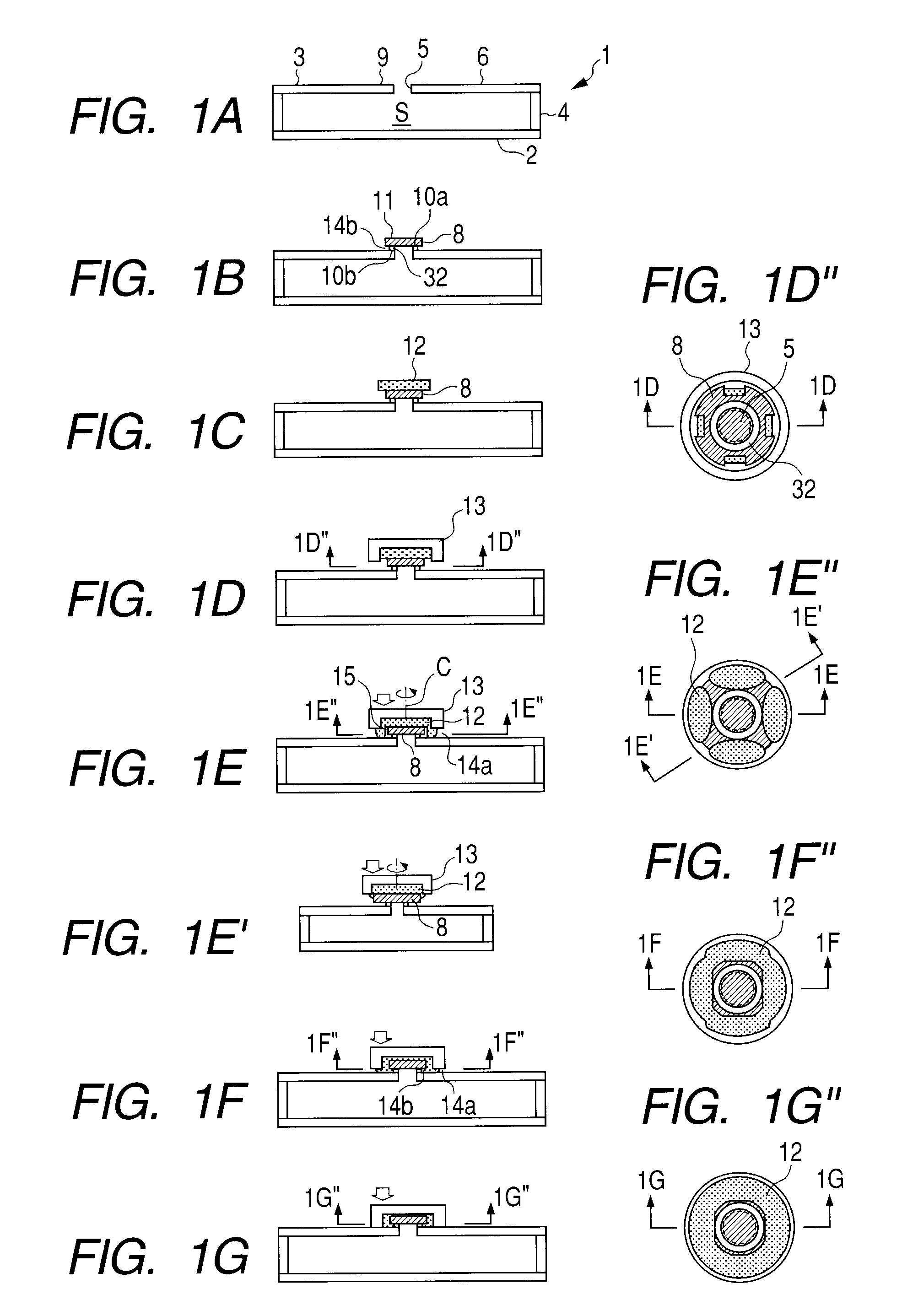

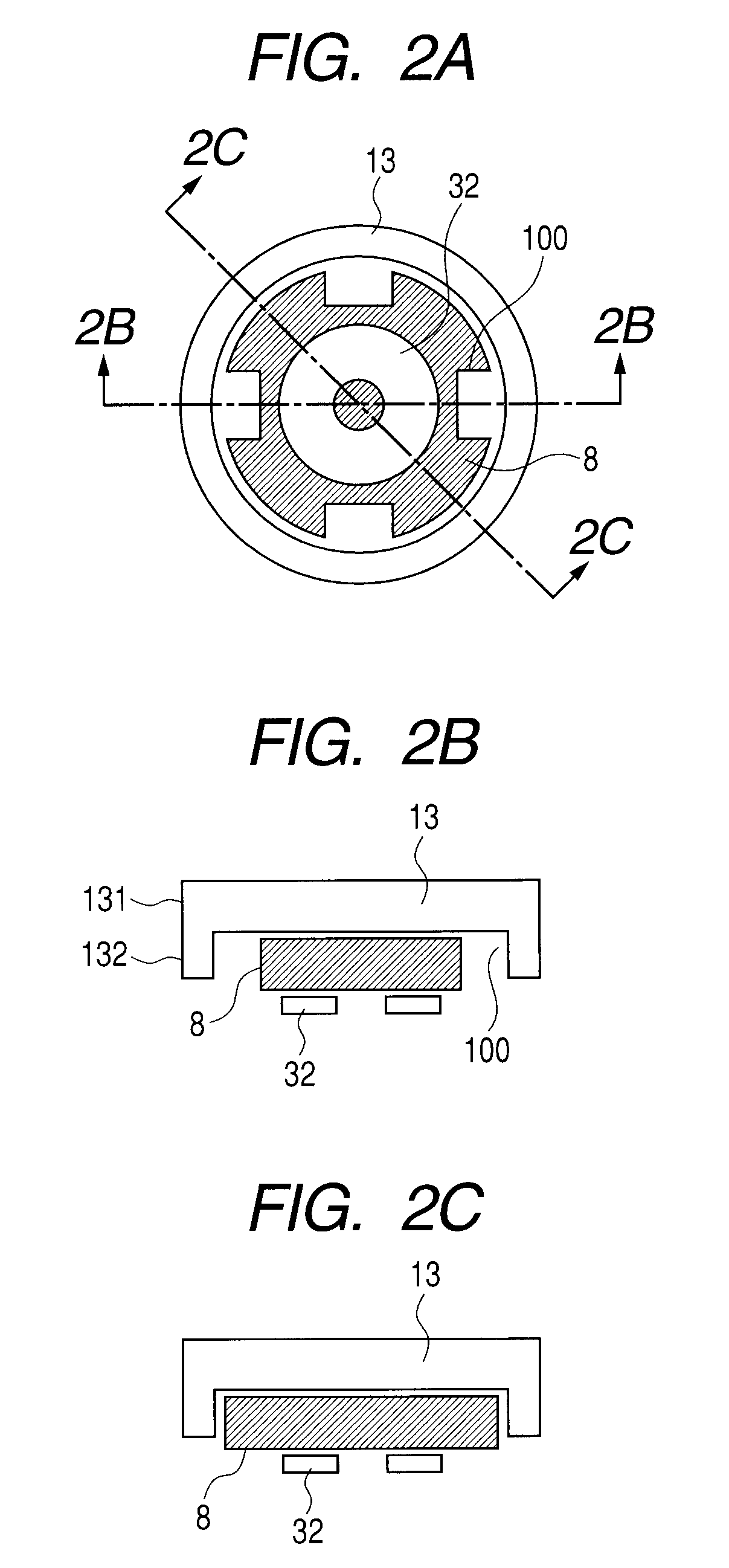

Manufacturing method of airtight container and image displaying apparatus

InactiveUS20100190409A1Sealing is reliablePreventing sealantCathode-ray/electron-beam tube vessels/containersTube vessels vacuum closureEngineeringSealant

In an airtight container manufacturing method including sealing a through-hole by a cover, it secures sealing performance and restrains a sealant from flowing into the through-hole. The method comprises: (a) exhausting the inside of a container through the through-hole provided on the container; (b) arranging a plate member having, at its periphery, grooves penetrating the plate member in its plate thickness direction on the outer surface of the container the inside of which has been exhausted, so as to close up the through-hole; and (c) arranging the cover so as to cover the plate member via the sealant and bonding the cover and the outer surface of the container via the sealant, wherein the sealing includes hardening the sealant after deforming the sealant as pressing the plate member by the cover so that the sealant is positioned between the cover and the outer surface of the container via the grooves.

Owner:CANON KK

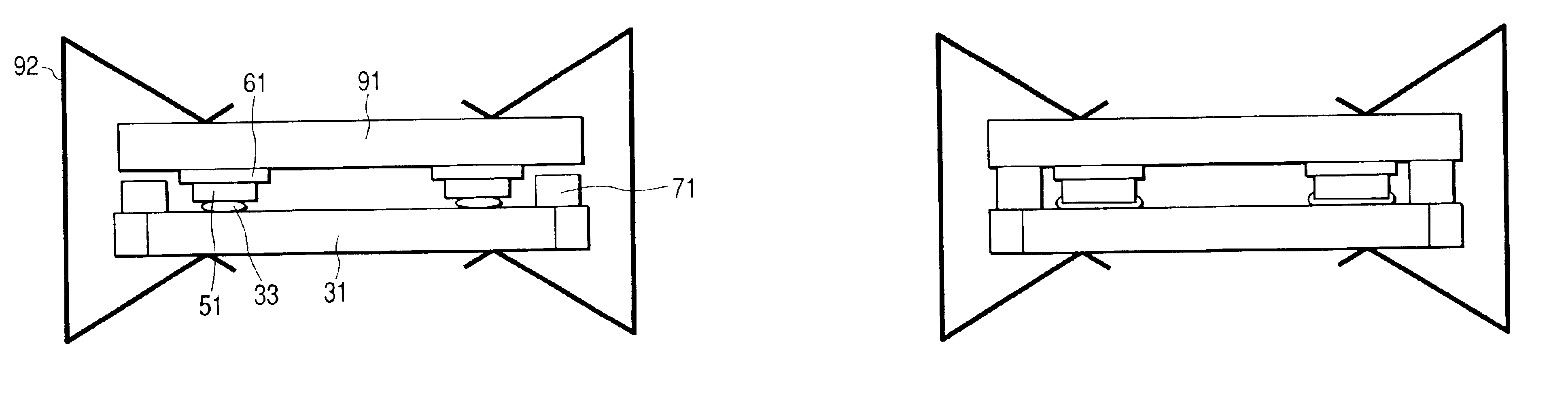

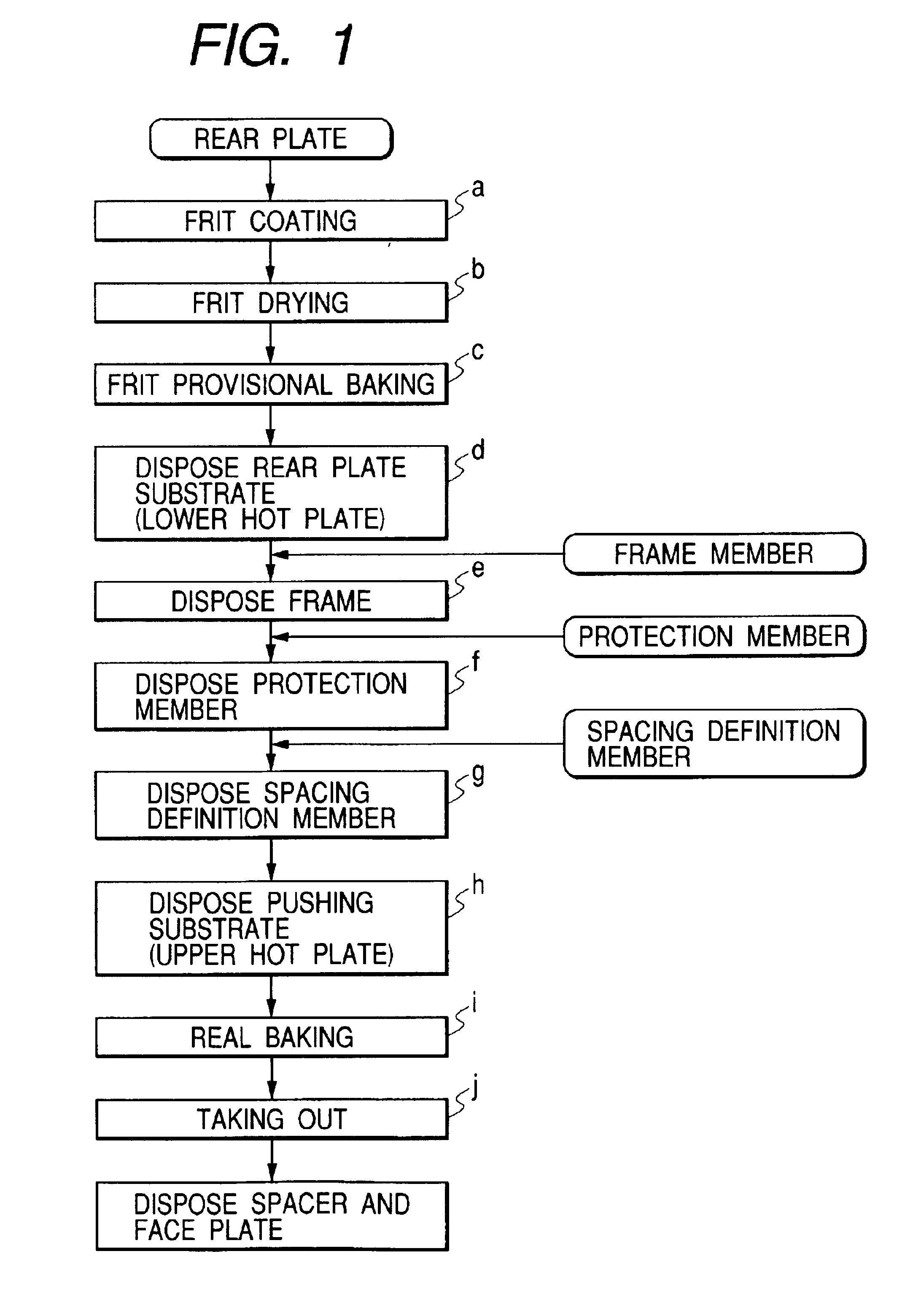

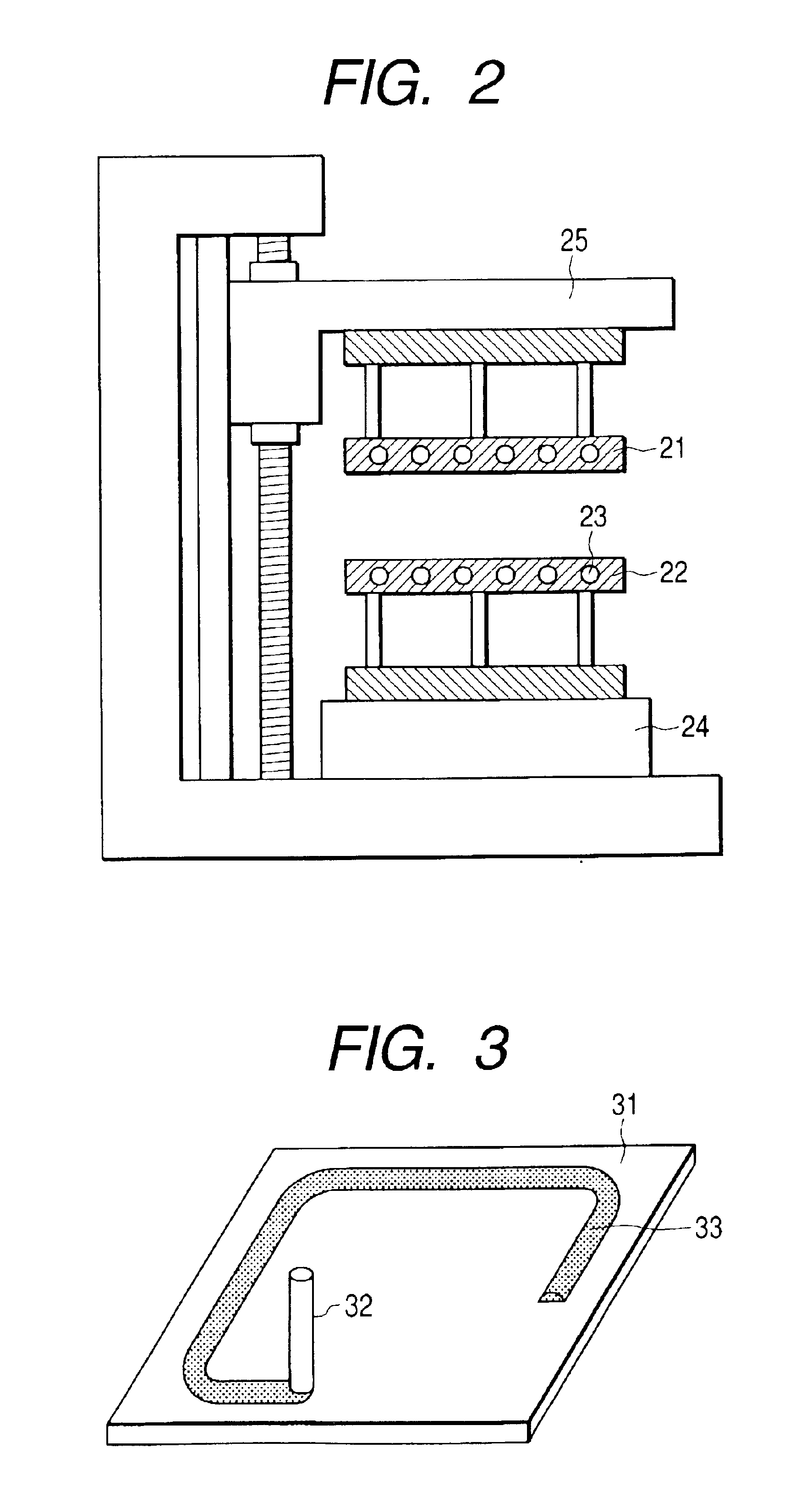

Method for fabricating vacuum container and method for fabricating image-forming apparatus using the vacuum container

InactiveUS7081029B2Prevent unnecessary activationConductance can be deterioratedDischarge tube luminescnet screensGas discharge vessels/containersFritEngineering

A method that makes uniform the frame height after joining a frame and a substrate constituting the vacuum container of an image-forming apparatus without damaging the substrate surface in the vacuum container. A frame member is joined with a rear plate by applying frit glass to the rear plate, disposing a frame member on the frit glass, disposing a spacing definition member to a portion of the rear plate nearby the frame member where the vacuum container is not formed, pressurizing the frame member, and then softening the frit glass and thereby joining the frame member with the rear plate.

Owner:CANON KK

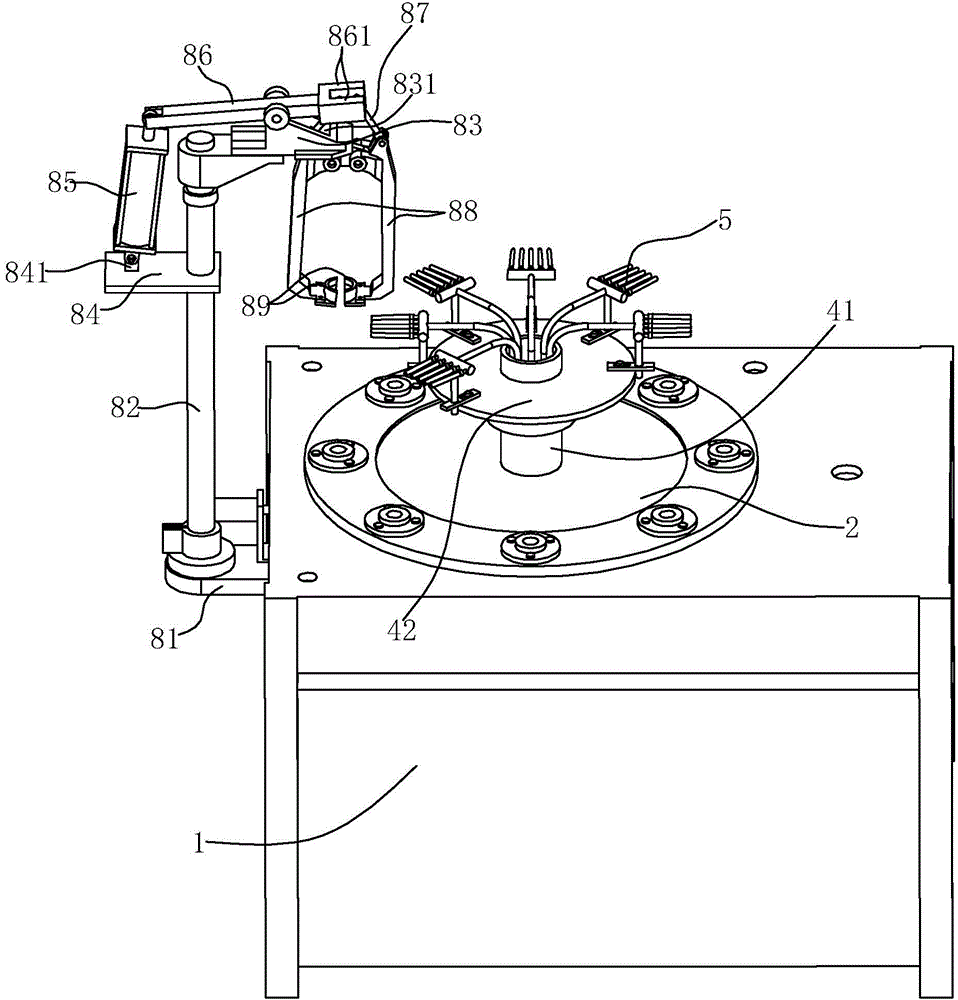

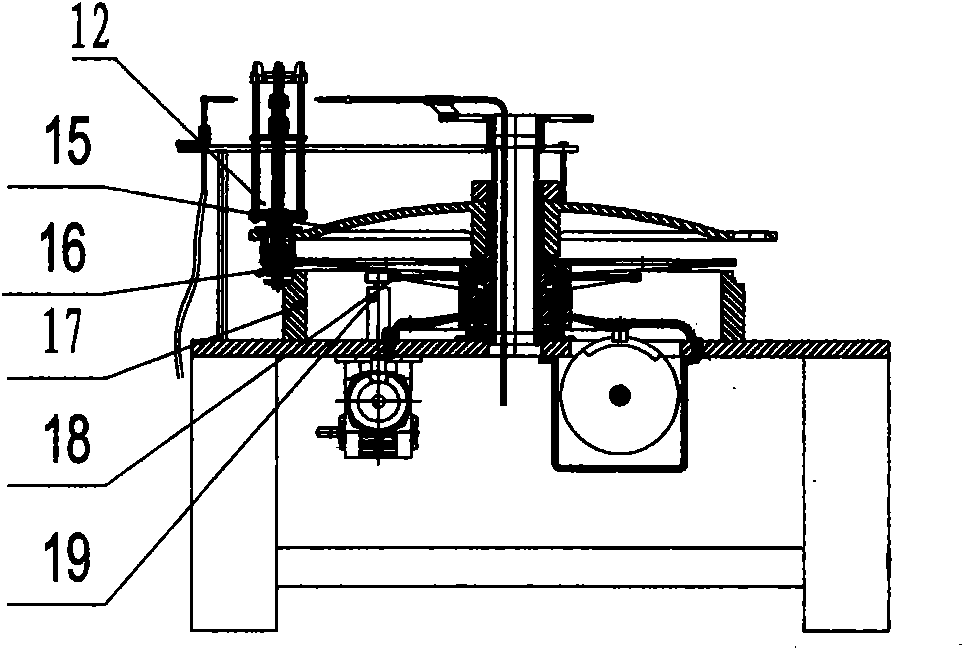

Bulb sealing machine

InactiveCN104576264ACompact and reasonable structureReduce volumeSealing tube apparatusSequential operation station machinesEngineeringMechanical engineering

The invention relates to a bulb sealing machine which comprises a machine body. An upper table board of the machine body is provided with a rotating plate capable of rotating. The rotating plate is provided with a plurality of bulb brackets in the circumferential direction. An installing table is arranged above the rotating plate and fixed to the machine body through a hole in the center of the rotating plate. A drive device for driving the rotating plate to rotate and driving the bulb brackets to rotate automatically is arranged in the machine body. The upper table board and the installing table are fixedly provided with a plurality of groups of welding guns arranged oppositely. The welding guns arranged oppositely in each group are distributed on the two sides of the bulb brackets in the radial direction of the rotating plate. A sealing device is fixedly arranged on the machine body. The bulb sealing machine is reasonable in structure and high in machining efficiency.

Owner:宁波吉胜海洋光电有限公司

Joined bodies, luminous containers and assemblies for high pressure discharge lamps

InactiveUS7187128B2Improve joint strengthAvoid crackingSolid cathode detailsTube/lamp vessels closingEngineeringHigh pressure

A joined body is provided, including a first member having a first joining face and sapphire exposed at the first joining face and a second member having a second joining face and sapphire or polycrystalline alumina exposed at the second joining face. The first member and second member are joined by providing a raw material for the joining material between the first and second members and heat treating the raw material at a temperature of 1730° C. or lower.

Owner:NGK INSULATORS LTD

Manufacturing method of airtight container and image displaying apparatus

InactiveUS20100190408A1Effective protectionSuppression problemCathode-ray/electron-beam tube vessels/containersPackaging under special atmospheric conditionsEngineeringSealant

In an airtight container manufacturing method including sealing a through-hole by a cover, it secures sealing performance and restrains a sealant from flowing into the through-hole. The method comprises: (a) exhausting the inside of a container through the through-hole provided on the container; (b) arranging a plate member having, at its periphery, grooves penetrating the plate member in its plate thickness direction on the outer surface of the container the inside of which has been exhausted, so as to close up the through-hole; and (c) arranging the cover so as to cover the plate member via the sealant and bonding the cover and the outer surface of the container via the sealant, wherein the sealing includes hardening the sealant after deforming the sealant as pressing the plate member by the cover so that the sealant is positioned between the cover and the outer surface of the container via the grooves.

Owner:CANON KK

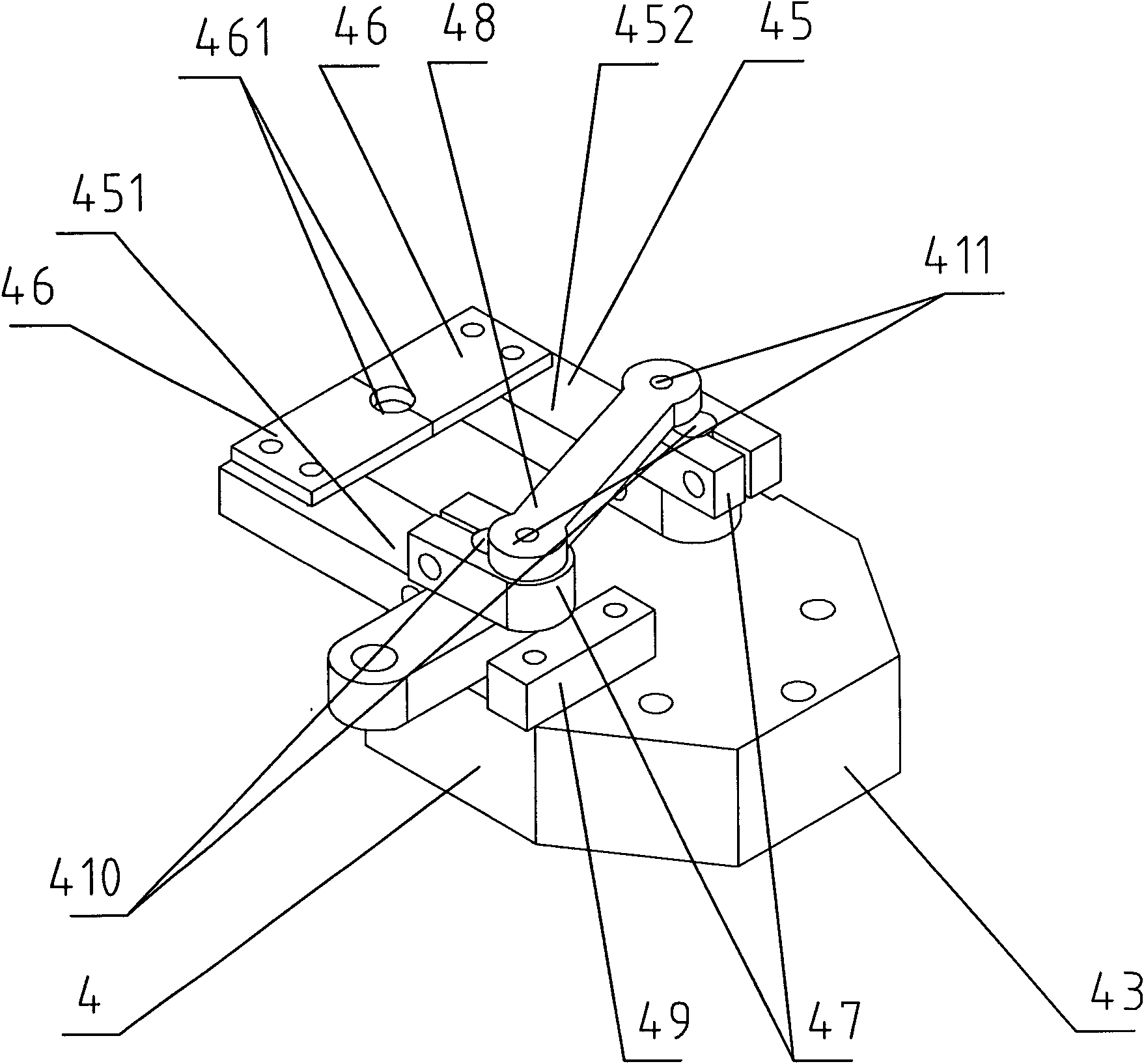

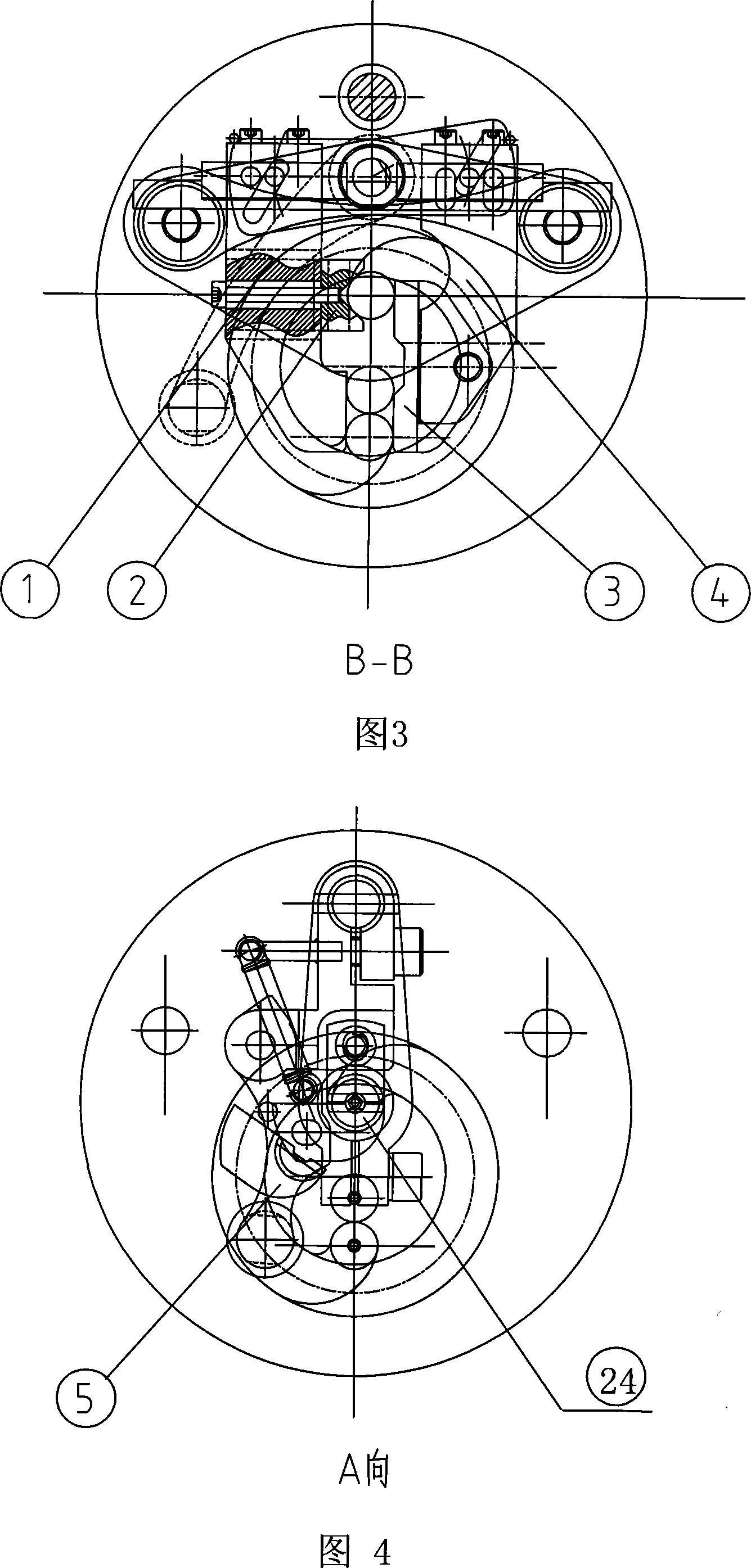

An upper laid sealing and fixture device for spiral lamp and the corresponding sealing techniques

The invention relates to a spiral lamp top-mounted sealing clamping device and the sealing process, and is characterized in that the invention adopts a movable clamp piece to be arranged on a right clamp piece, a left clamp piece and the right clamp piece are respectively arranged on a sliding track component; a plate-shaped slot cam is arranged on an arc-shaped support plate, a rotating arm is sheathed on a support shaft, the sliding track component is fixed on two vertical poles, the vertical poles are fixed on a rotary T-shaped shaft, a hafu clamp is arranged on the rotating arm, an ascending and descending shaft is linked with a main shaft, and the rotary T-shaped shaft is arranged in a rotary component. A spiral glass lamp tube of the invention is arranged below a sealing fire source, the lamp tube foot is upward; a lamp wire core pole is inserted from the upper part of the spiral glass lamp tube, the spiral glass lamp tube and the lamp wire core pole are fused by flame heating. The clamping of the spiral glass lamp tube is stable and reliable, which can reduce the high temperature heat amount at the tube foot to the maximum extent and fundamentally solve the defects of the traditional sealing mode and the phenomena of cold explosion of the glass tube and the gas leakage which are difficult to overcome.

Owner:周维耀

Image display device and method of manufacturing the same

InactiveCN1799116AImprove air tightnessImprove the display effectCathode-ray/electron-beam tube vessels/containersElectroluminescent light sourcesMetal coatingDisplay device

A vacuum envelope (10) of an image display comprises a front plate (11) and a back plate (12) arranged opposite to each other and a seal portion (40) by which the peripheral portion of the front plate and that of the back plate are sealed with each other. The seal portion comprises a frame body (13) lying along the peripheral portions of the front and back plates and a sealing material (32). The frame body has a core member (15) made of a metal and a metal coating (17) covering the surface of the core member.

Owner:KK TOSHIBA

Method and apparatus for welding shroud glass tube in arc tube for discharge lamp

InactiveUS20050255783A1Reliable shieldingCarry-out quicklyTube/lamp screens manufactureElectroluminescent light sourcesSecondary sideInert gas

A method of secondarily welding one end of a shroud glass tube covering an arc tube body having a discharge emitting portion, having the other end welded primarily to one of the arc tube body ends, to the other end side of the arc tube body, while discharging air from, and introducing an inactive gas into, the tube through the opening end of the glass tube to hold a negative pressure. Heating and melting from a side is carried out. The opening end of the glass tube is connected to a piping passage component for discharging air and introducing an inactive gas through a rotatable magnetic fluid seal unit. Secondary welding is carried out with the rotation of the glass tube around an axis. The glass tube rotated with respect to secondary side heater is uniformly heated, molten and softened circumferentially, and welded along the arc tube body outer periphery.

Owner:KOITO MFG CO LTD

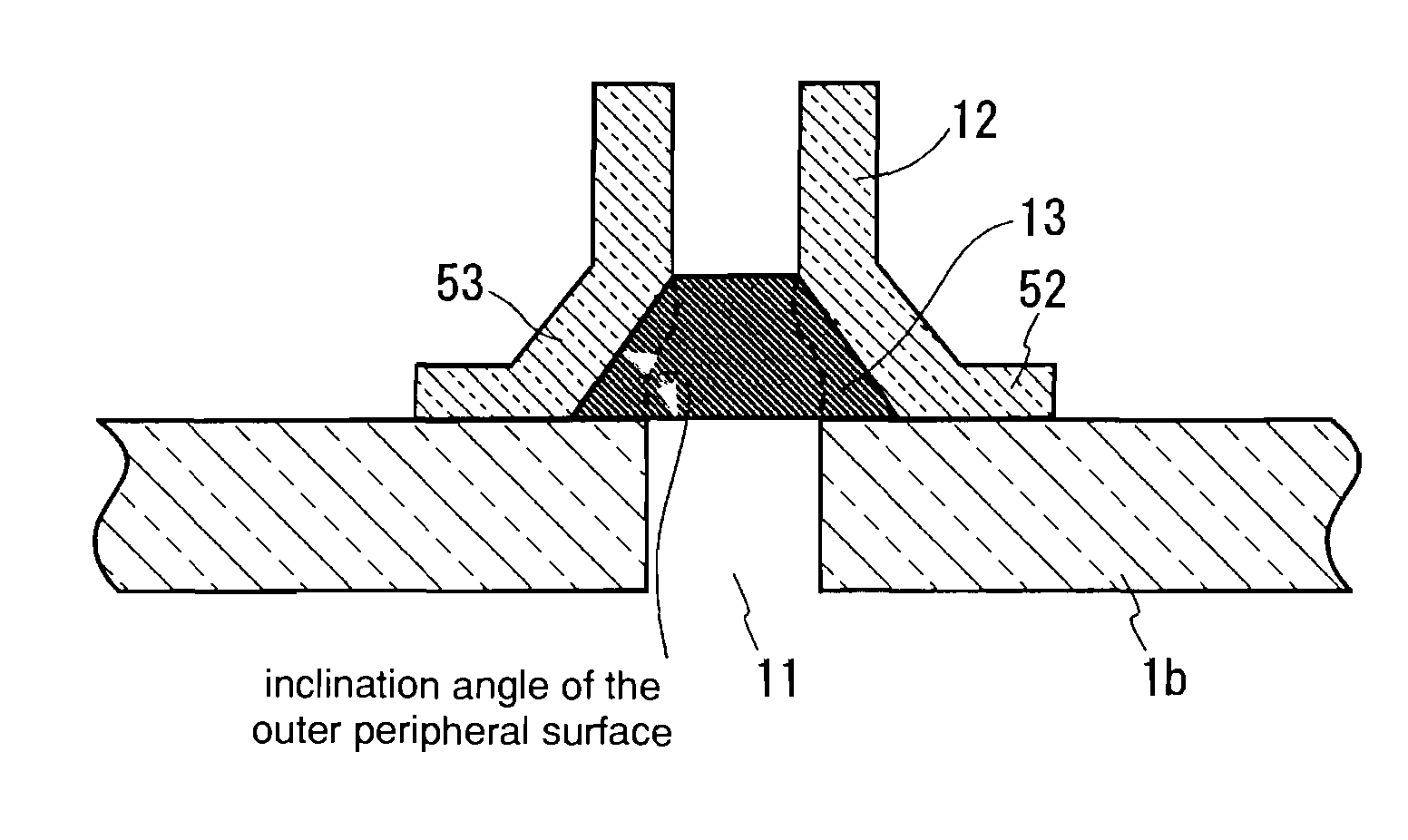

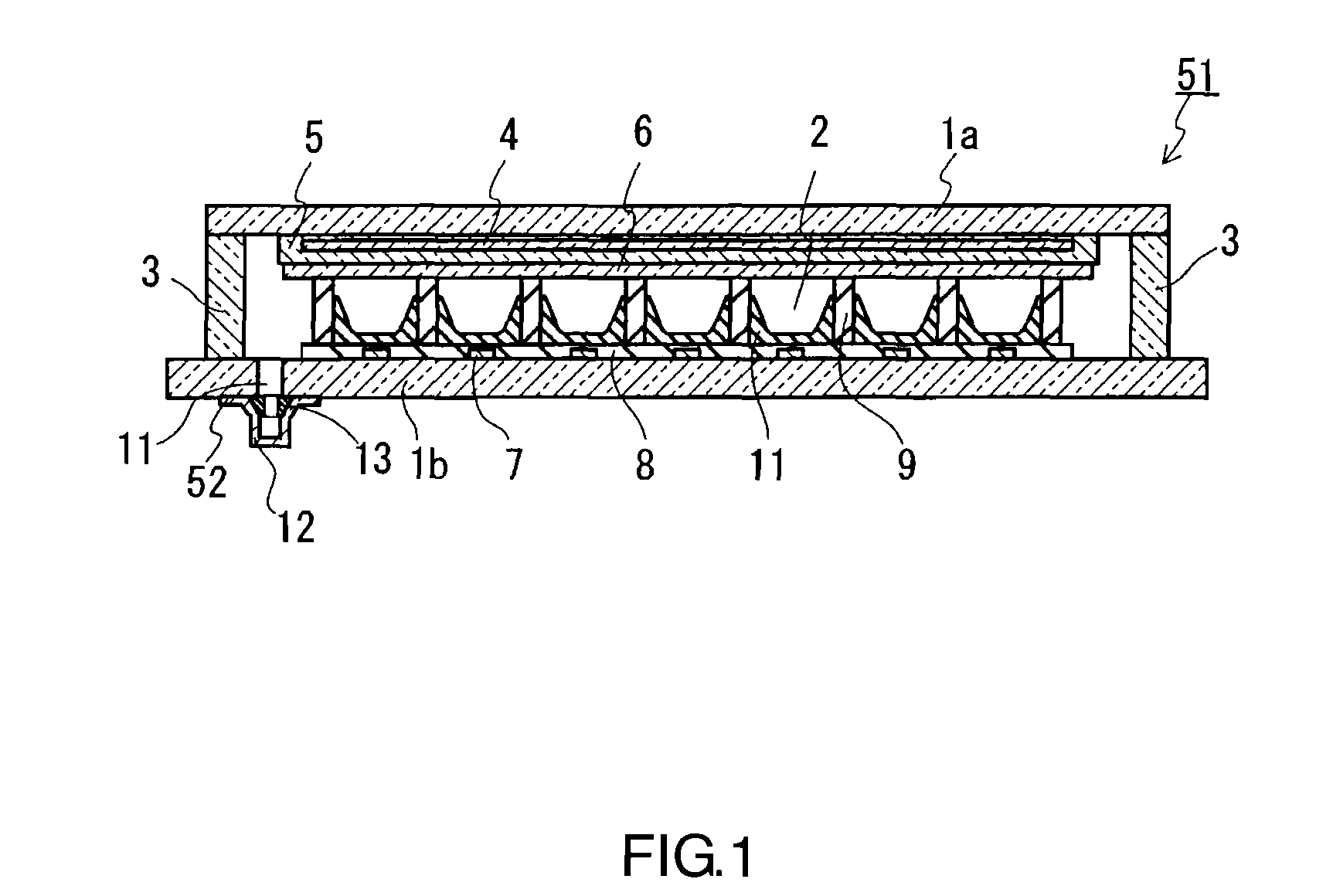

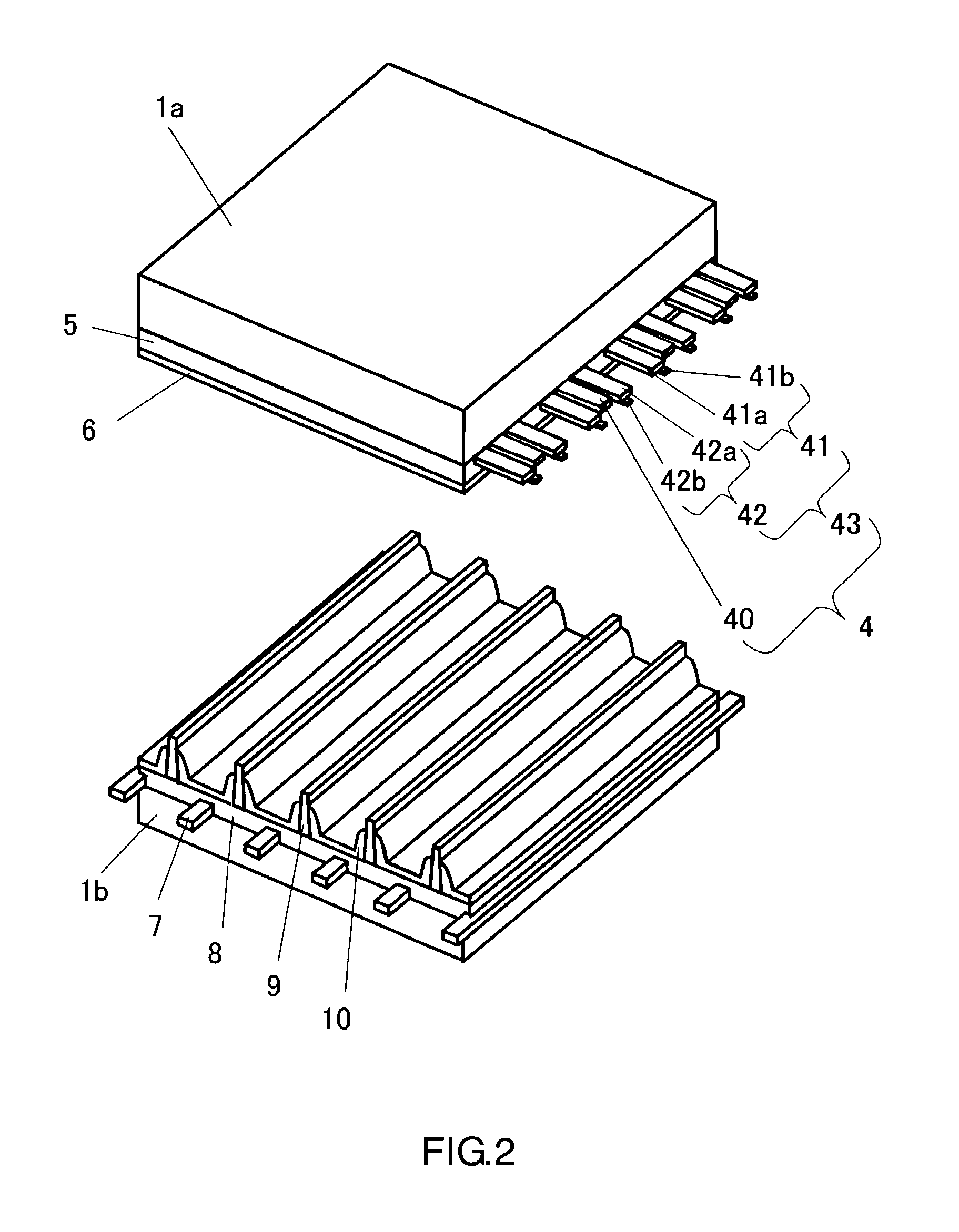

Display device, vent tube with glass ring, phosphate glass ring, and method of producing the same

InactiveUS20090260845A1Reduce airtightnessConvenient lifeCathode ray/electron stream lampsTube/lamp vessels exhaustionDisplay deviceEngineering

The present invention reduces the amount of lead used in a display device and improves its long-term moisture resistance. This display device includes: a panel (1b) provided with a hole (11) formed therein; a phosphate glass member (13); and a tube (12) mounted on the panel (1b) via the glass member (13) so as to cover the hole (11). The glass member (13) is bonded to at least a partial area of the inner wall surface of the tube (12) and to a partial area of the panel (1b), so that the entire periphery of the end face of the tube (12) located on the side of the hole (13) is in contact with the panel (1b).

Owner:PANASONIC CORP

Full-automatic electrodeless lamp sealing machine

InactiveCN101916701AImprove product qualityIncrease productivityTube/lamp vessels closingMaterial resourcesEngineering

The invention discloses a full-automatic electrodeless lamp sealing machine which comprises a machine frame, a main motor, an auxiliary motor, a reduction box, a manipulator, a mold clamping mechanism, a shaping mechanism, a blow exhaust pipeand a blowing plant. The invention is characterized in that a table board is arranged above the machine frame, the lower end of the table board is provided with the main motor, the auxiliary motor, the reduction box, a transposition cam belt pulley and a transposition cam; the main motor is connected with the transposition cam belt pulley; the auxiliary motor is connected with the reduction box; the reduction box is connected with the transposition cam; a track, a fire bracket, the blow exhaust pipe, the blowing plant, the mold clamping mechanism and the manipulator are arranged on the table board; the top of the track is provided with a station; the station is provided with a large aluminum disc, a large fluted disc and a conical fluted disc; and the lower end of the large fluted disc is provided with a small fluted disc. The sealing machine has the advantages of automatic feeding, automatic discharge, automatic shaping, automatic blowing, automatic mold clamping, stable product quality and high production efficiency, saves human and material resources, specially designs a machine integrating functions of electrodeless bulb shell sintering, mold clamping and sealing, and can be used for manufacturing bulb shells of various specifications.

Owner:江苏锐阳照明电器设备有限公司

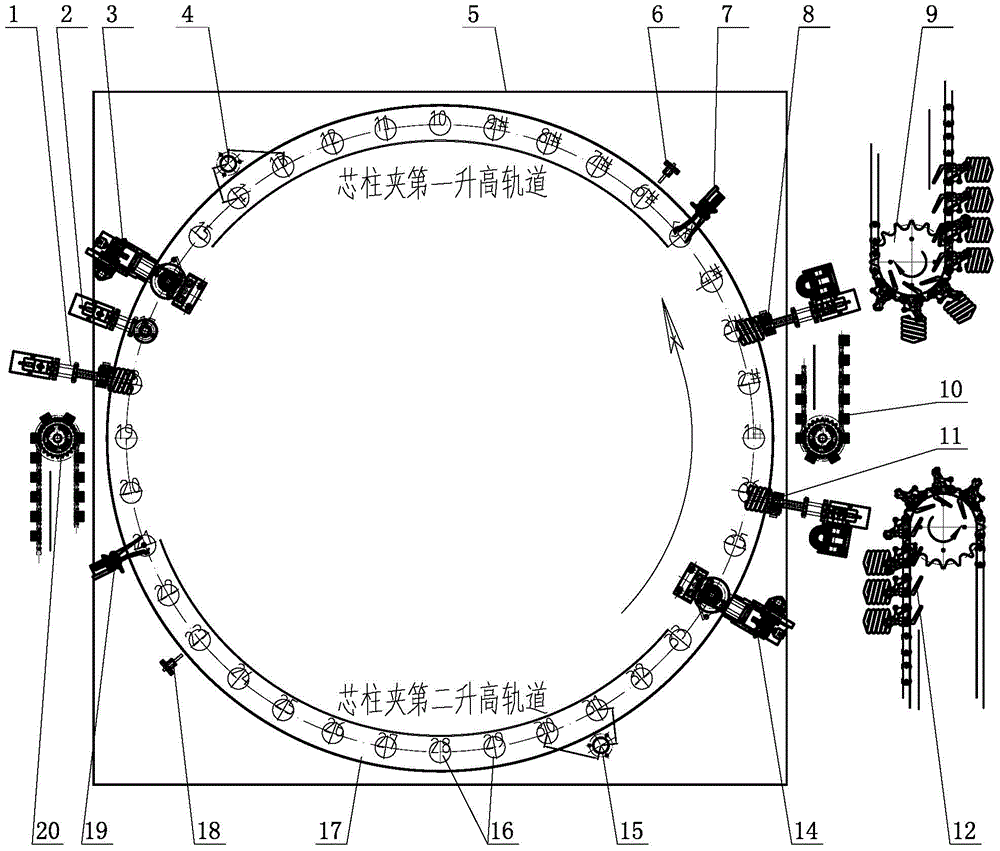

On-production-line filament-arranging glass core-cutting lamp tube sealing process and dedicated sealing machine

InactiveCN104103473AAvoid secondary clampingCold blast problem thoroughlyTube/lamp vessels closingEngineeringManufacturing line

The invention belongs to the technical field of energy-saving lamps, and discloses an on-production-line filament-arranging glass core-cutting lamp tube sealing process and a dedicated sealing machine. The process enables the processes of filament-arranging, glass core-cutting and the like to be integrated and finished on a sealing machine production line without twice tube pin clamping. The sealing machine comprises a machine frame. The machine frame is provided with a workbench. The workbench is provided with a station clamp for clamping a lamp tube and a glass core column. When the workbench is rotating, the station clamp on the bench passes a tube-feeding station, twice sealing stations, a filament-arranging and filament-separating station, a glass core-cutting station, pin-changing station and tube-taking off station and the like successively. According to the sealing machine, the filament-arranging station and the glass core-cutting station and the like are arranged between the tube-feeding station and the tube-taking off station based on the process conception. Therefore, the problem of tube pin cold explosion due to twice tube pin clamping after sealing is effectively solved.

Owner:JIANGSHAN YOUHE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com